Page 1

Front Suspension Assembly

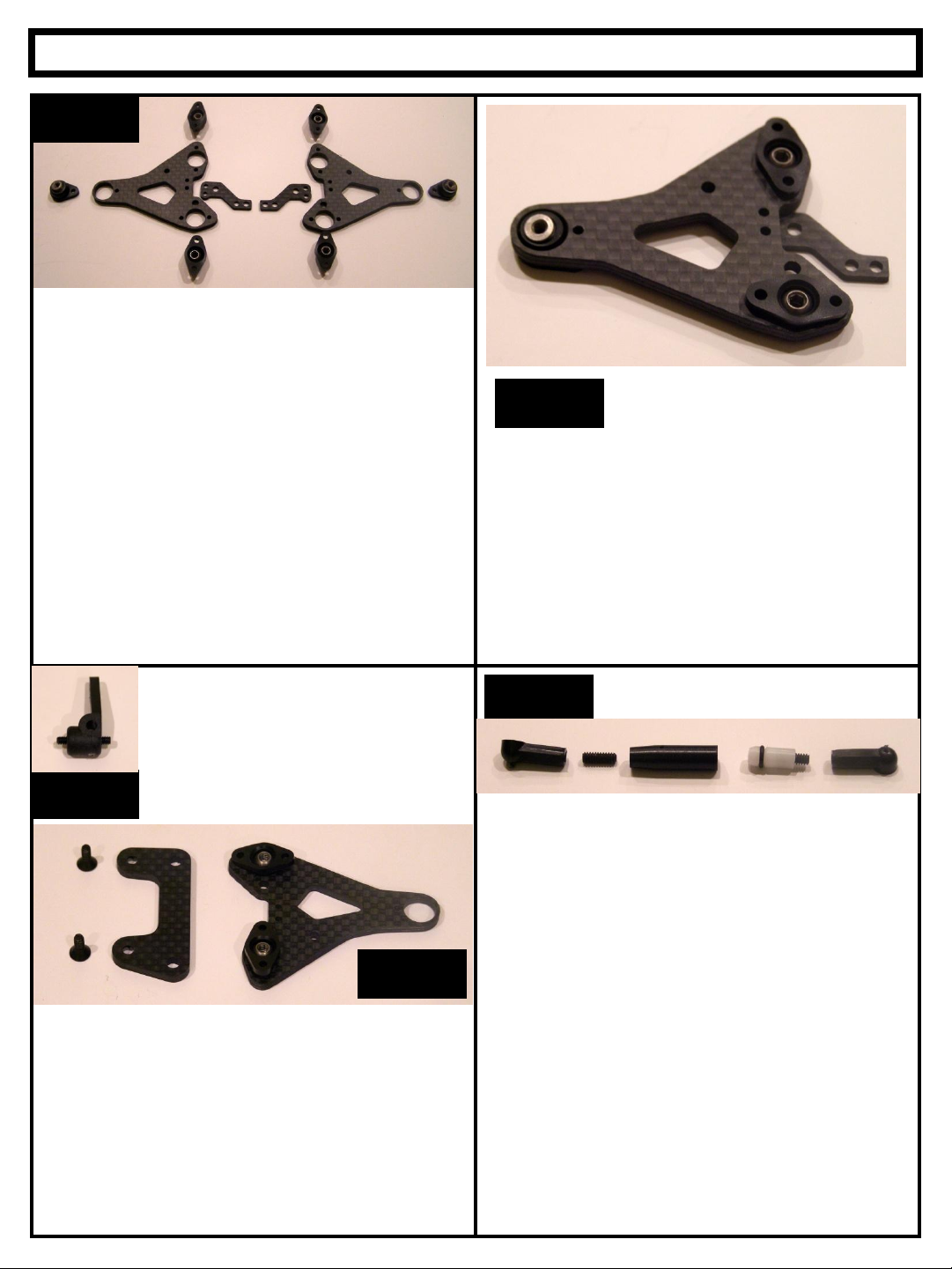

Step 1

Locate your lower front suspension arms, flex

plates,4 pivot ball housings with balls installed, and

14 2-56 x 3/16 button head screws. Note that the

arms are symmetrical. At this time you must pick

which one will become the left and right arms as

this will determine how you insert the housings into

the arms.

Step 2

There are 2 types of pivots. 4 of them use 2 screws

to mount and 2 use 1 screw to mount. The 1 hole

mount pivots go on the steering block end of the

arm. Insert into arms as shown and install screws.

The flex plates mount to the underside of the arm

as do the outer pivots. The other 4 pivots mount

from the top of the arm.

Special Note: Do not over tighten the 2-56 screws.

Over tightening may pinch the pivot ball.

Install a 4-40 x 5/8 set screw through

the steering spindle so that the same

amount is protruding from each end of

the spindle

Step 3

Step 4

Mount arms to sub plates using 2 4-40x1/4 inch

screws. They screw into the pivot balls. Note the

direction of the sub plate. This is with the

countersinks in the plate facing down.

This is how everything mounts to the arms. Please

check the direction of the pivots to insure proper

mounting. Once mounted, install 1 4-40x5/16

setscrew into each flex plate using the inward

hole(stiff position). Also install 1 4-40x5/15

setscrew into each arm. This will be used as a

droop screw. It is the hole located middle of the

arm by the rear pivot.

Step 5

Cut ball cups for damper tube to .400-.425 long.

After they are cut to size using a sharp exacto

knife, screw a 4-40 x 5/16 setscrew into each one.

Screw them in until they bottom out but do no over

tighten. Now screw 1 into the piston and one into

the body until they bottom out but again, do not

over tighten. Coat the piston with 15,000 weight

differential oil or #4 shurlube and then slowly install

piston into body. I like to spin the tube as it is

installed.

Page 2

Step 6

Install 2 black ball

studs into lower

arms and secure

with supplied

aluminum lock

nuts. Then attach

arm assemblies to

chassis and snap

the damper tube

onto the ball studs

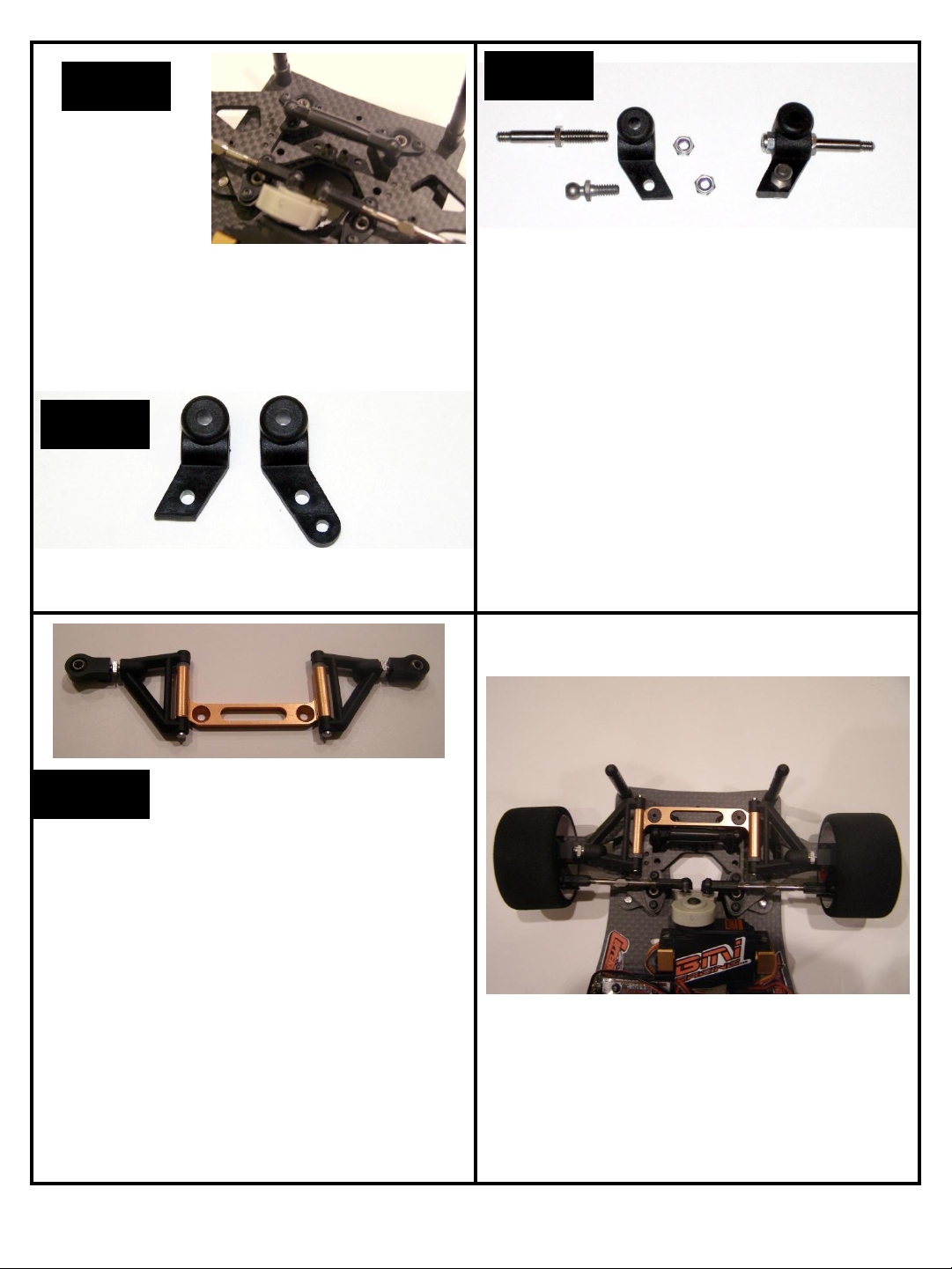

Step 7

Locate the left and right steering spindles. Trim the

steering arms length to the line molded on the part as

shown.

Step 8

Locate the titanium front axles, four 4-40 alloy lock

nuts, and two alloy pivot balls.

Thread the titanium axles into the steering

spindles. Note that the threads on the axles that

go into the spindles are left hand. After the axles

are fully seated tighten an alloy 4-40 lock nut onto

the threaded stub coming out the back of the

spindle.

Thread the alloy pivot balls into the holes on the

steering arms and secure them with alloy 4-40 lock

nuts. Remember these are alloy pivot balls so

make the nuts snug. They are strong enough to

last a few racing seasons; but if you crank them

down, you can snap them.

Step 9

Locate 2 steel 1/8” king pins,10 1/8” shims, 4 eclips and 2 .020” springs.

Assemble upper arms as shown. Make sure that

the turnbuckle threads into the arm and eyelet very

straight. If it is not straight, this will mess up your

caster settings so be very careful. In testing on

carpet, we liked running 2 shims to the rear of the

block which will give you 6 degrees of caster.

Page 3

Step 10

Put the 2 enclosed gray standoffs on top of the inner front pivot balls as shown. Lay the upper hinge pin block

on top of them and attach using 2 4-40 x ½ inch flathead screws. Then install steering blocks by threading the

upper and lower pivot balls onto the set screw running through the steering blocks. The picture in the top right

side shows the way it should look when completed.

CONGRATULATIONS!! YOU ARE DONE!!

Go out and race. Check out the setup tips below

Suspension Adjustment

To set your ride height, back the droop screws

out so they do not touch the sub plates. Then

use the set screws in the flex plates to adjust

your ride height. Tightening the set screws in

the flex plates will raise your ride height and

loosening them will lower it. Once you adjust

your ride height, then you want to tighten your

droop screws just enough so that you have your

desired amount of up travel. Do not use the

droop screws to adjust your ride height as this

will preload your flex plates and you will lose all

of your droop.

Once you have your ride height set and your

droop roughly set, You will now want to fine tune

and accurately set your droop. I normally run .51mm of up travel for droop. When your car is

race ready and at ride height, slide the tip of

your exacto blade under the center of the front

of the car. Slowly lift the front of the car with

your exacto blade. What you want is for the

wheels to leave the ground at the exact same

time. You can adjust the droop screws until this

happens. Once complete, recheck your ride

height and up travel.

Set Up For Carpet:

1.5mm flex plates with set screw in stiff position

#4 shurlube in damper tube

3.25mm ride height

.75mm up travel for droop

1 degree camber

6 degrees caster(2 shims to back)

Angled servo and set for no bumpsteer

Loading...

Loading...