Page 1

Page 2

Message from BMI Racing

The DB12R is a revolutionary step forward in 1/12th scale car design. Two years of research and

development has culminated in the kit you have before you. The goal of the DB12R project was to take the

best features of T-bar cars and Link cars and combine them to make a new type of rear suspension that will

set new standards for speed, versatility and ease of use. I call this new suspension system the BMI Flex Link.

What if you could have a t-plate car that was as stiff side to side as with a .075” t-plate but more flexible front to

rear than a .063” t-plate with 2 screws in the read pod?

What if you could have a link car that had insane steering with very little front wheel travel, transitions left to

right in chicanes like it was hard wired to your brain and was equally at home on carpet and asphalt?

Stop wondering, the DB12R delivers on all of the above.

The DB12R’s suspension allows racers to enjoy the rising side to side spring rate inherent in a T-bar rear

suspension system with the separation of the front to back versus side to side spring and damping effects as

seen in link cars. This allows serious racers to balance forward traction, side traction and steering

aggressiveness independently of each other with the ultimate goal in mind. This means FASTER LAP TIMES!

Please read through the instruction manual carefully. Even if you are an experienced R/C racer, there are

some details about the DB12R that are different. To get the most out of your kit you must have it assembled

correctly.

With Regards,

Items needed to assemble your DB12R

1. .050”, 1/16” and 3/32” Allen wrenches

2. A #2 Phillips Screwdriver

3. 3/16” and 11/32” nut drivers

4. A pair of needle nose pliers

5. A pair of slip join pliers

6. A hobby knife

7. A ruler or calipers

8. A file

9. A soldering iron

10. Diff Grease

11. Electric Motor Cleaner Spray

12. 35wt silicon shock oil (for center shock)

13. 5000wt silicon diff oil (for damper tubes)

Jason Breiner

BMI Racing

Items needed to operate your DB12R

1. Two channel surface Radio system

2. A mini servo*

3. One or more 4 cell battery packs

4. A battery charger

5. An electronic speed control

6. An electric motor

7. A 64 pitch pinion gear

8. A small servo saver.

9. 1/12thscale body

10. 1/12thscale tires

* The DB12R was designed for servos with

dimensions similar to the Futaba 9602 and 9650.

These will fit perfectly with a centered output shaft.

Other servos will fit but may require different servo

mounts and/or modifications to the lower chassis.

Page 3

Front suspension assembly

Step 1

Locate your lower front suspension arms and the

hard anodized alloy pivot balls. Note that the arms

are symmetrical. At this time you must pick which

one will become the left and right arms as this will

determine how you pop the pivot ball into the arms.

Pop the pivot balls into the arms with the shoulder

on the ball facing up. Do this by placing the ball on

a hard flat surface and placing the arm over the

ball. Carefully push the arm down over the pivot

ball. Be careful. It will take a lot of force.

Special Note:

The DB12R uses IRS hard anodized alloy pivot

balls and the new IRS lower suspension arms. If

the balls are tight in the lower arms carefully

squeeze them with pliers until the ball just begins to

move freely

Step 2

Locate your upper suspension arm rod ends. Note

that the top side of the rod end opening is smaller

than the bottom

With a hobby knife, carefully chamfer the top of

the rod ends opening. This creates clearance for

the king pin shims that will go here later. This will

ensure there is no binding in the suspension.

The inset picture shows a finished rod end.

Step 3

Locate the two remaining hard anodized alloy pivot

balls and snap them into the upper arm rod ends with

the shoulder on the ball facing down. As with the lower

arms, squeeze the rod ends if the balls do not move

freely.

Step 4

Locate the upper suspension arms, the upper arm

turnbuckles and assemble as shown above.

We prefer to thread the right hand thread portions

of the turnbuckles into the rod ends and the left

hand thread into the upper arms.

Note:

The arms have a bottom and a top. They have

small circular impressions on the bottoms.

Step 5

Locate the 10 degree reactive caster upper

suspension mounts, upper suspension hinge pin,

e-clip and nylon caster spacers.

Assemble as shown.

Make sure the upper suspension arms pivots

freely. If there is any binding at all, the car may

handle poorly. If the upper arms are tight, use the

back of a hobby knife to scrape the front and back

of the reactive caster blocks and the inside of the

upper suspension arms to make more clearance

for the caster spacers. Take your time here and

get it right!

Special Note:

The DB12R uses IRS upper hinge pins and does

not require setscrews in the upper suspension arm

mounts.

Page 4

Step 6

Attach the upper

suspension arm assembly

to the lower suspension

arms as shown with 4-40 x

½” screws.

Step 7

Locate the left and right steering spindles. Trim the

steering arms length to the line molded on the part as

shown.

Step 8

Locate the Ti front axles, four 4-40 alloy lock nuts,

and two alloy pivot balls.

Thread the Ti axles into the steering spindles.

Note that the threads on the axles that go into the

spindles are left hand. After the axles are fully

seated tighten an alloy 4-40 lock nut onto the

threaded stub coming out the back of the spindle.

Thread the alloy pivot balls into the holes on the

steering arms and secure them with alloy 4-40 lock

nuts. Remember these are alloy pivot balls so

make the nuts snug. They are strong enough to

last a few racing seasons; but if you crank them

down, you can snap them.

Step 9

Locate 2 steel 1/8” king pins,10 1/8” shims, 4 eclips and 2 .020” springs.

1. Snap an e-clip on to one end of the king pin.

2. Slide 3 shims onto the king pins against the

e-clip.

3. Pass this through the pivot ball in the upper

suspension arms rod end.

4. Place one more shim on the king pin.

5. Slide the steering spindle onto the king pin.

6. Slide the king pin through the pivot ball in the

lower suspension arm.

7. Slide the .020” spring and nylon retainer

onto the king pin and snap an e-clip on the

bottom of the king pin.

8. Repeat for the other side of the front

suspension.

Special notes:

Make sure the steering arms on the spindle

are pointing towards the rear of the car as

shown in the picture.

The axle is offset in the spindle. Make sure

the axle is closest to the lower suspension

arm. As shown in the picture to the left

It is important that the king pin slide freely in

all of the parts including the steering

spindle. When you thread the axle into the

spindle, it may swell the king pin bore and

make it tight on the spindle. You can try to

use a 1/8” drill to open it up but the best

solution is to use a 1/8” reamer.

You can order the reamer from:

www.mcmaster.com. The part number is

2995A61

Page 5

Step 10

Locate four 8-32 x 5/8” screws and 4 nylon lower suspension arm risers.

Pass a screw through the chassis and slide a nylon riser over the screw. Start threading the screw into the

lower suspension arm but do not tighten it. Pass another screw through the chassis and slide a nylon riser over

that screw. Start threading the screw into the other hole on the lower suspension arm. Tighten both screws.

Repeat on the other side.

Special Note:

In testing, we found we preferred to not use any suspension brace, strap or tube to connect the left and right

suspension assemblies. This was true on high traction carpet tracks to low bite asphalt tracks. You can add or

remove lower arm spacers to adjust ride height and to compensate for tire wear.

Rear suspension assembly

Step 11

Locate two flex plates*, 2 Nickel Teflon plated Alloy

pivot balls, 2 delrin pivot ball housings, 2 delrin

housing caps, 2 10-32 set screws* and 4 2-56

button head screws.

1.Place a pivot ball in a pivot ball housing with the

shoulder on the ball facing down.

2.Place a housing cap over the ball.

3.Place the flex plate over this assembly.

4.Pass the 2-56 screws through the pivot ball

housing from the bottom up so they thread into the

flex plate.

5.Thread 10-32 set screw into the large hole on the

flex plate above the housing cap. Just get the 10-32

started into the flex plate for now as we will adjust it

later.

The 10-32 set screw is there to adjust tension on the

pivot ball so it can move freely but have zero play.

*Black flex plates and 10-32 set screws were used

for photos. The production links are natural G10 in

color and the production screws are stainless steel.

Page 6

Step 12

Step 13

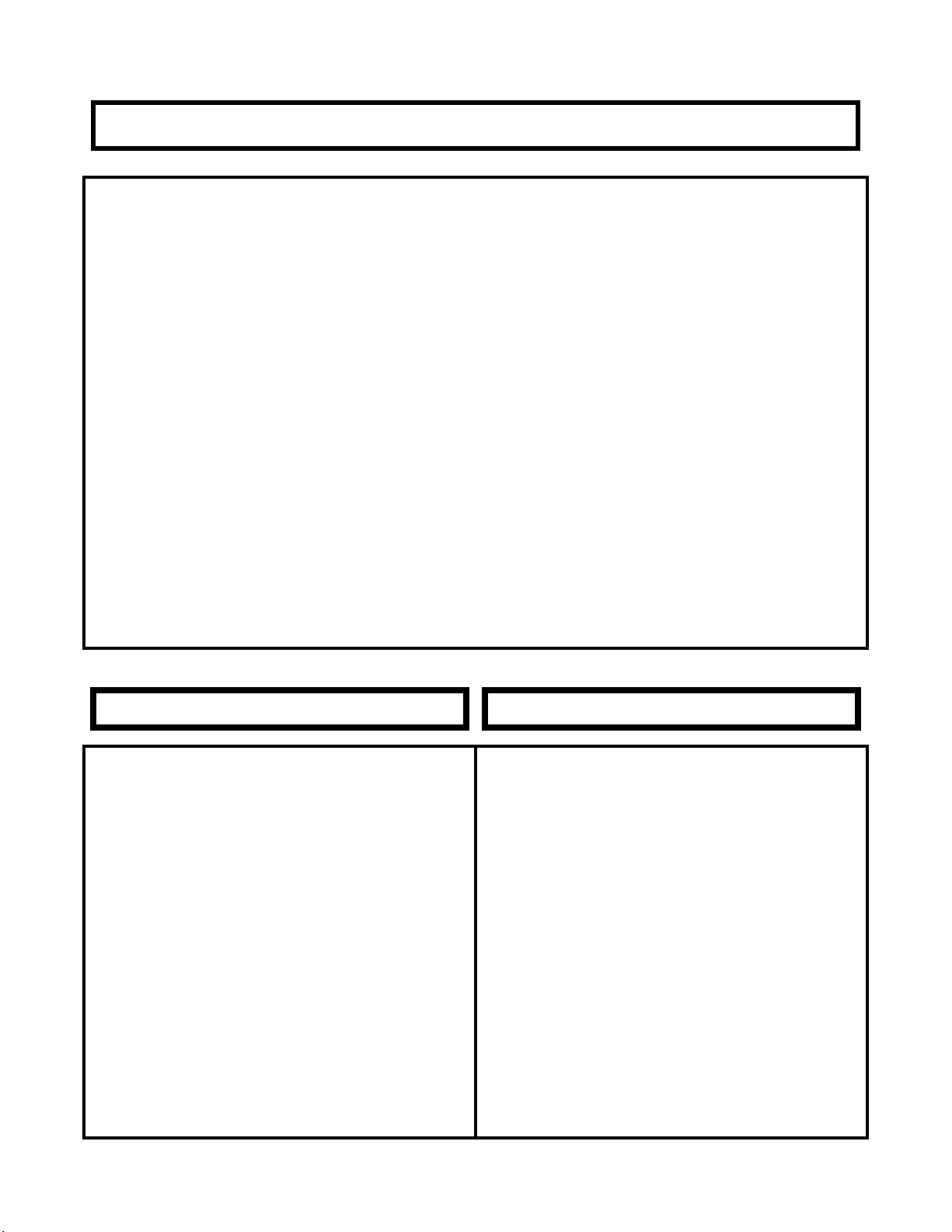

Take a minute to prepare all your carbon components

for assembly. With a file or sand paper knock off any

sharp edges along the perimeter or the carbon parts.

The cell slots in the chassis are designed to fit the

cells properly if you just knock off the sharp edges. If

you bevel the cell slots the batteries will hang below

the bottom of the chassis.

Special note:

Carbon fiber dust is really bad for you. Always

wear a mask and eye protection when sanding or

filing carbon fiber.

Step 14

Locate the delrin center pivot assembly one 4-40 x ¼”

and two 4-40 x 3/8” flat head screws.

Attach the center pivot assembly to the rear most hole

in the center of the lower chassis plate with the ¼”

screw. The shoulder on the pivot ball and the two

bosses on the center pivot assembly should face

down towards the chassis. The pivot ball has a 3/32”

hex in the top so you can use a wrench to tighten it

firmly.

Attach the rear lower pod plate to the center pivot

assembly with two 4-40 x 3/8” flat head screws.

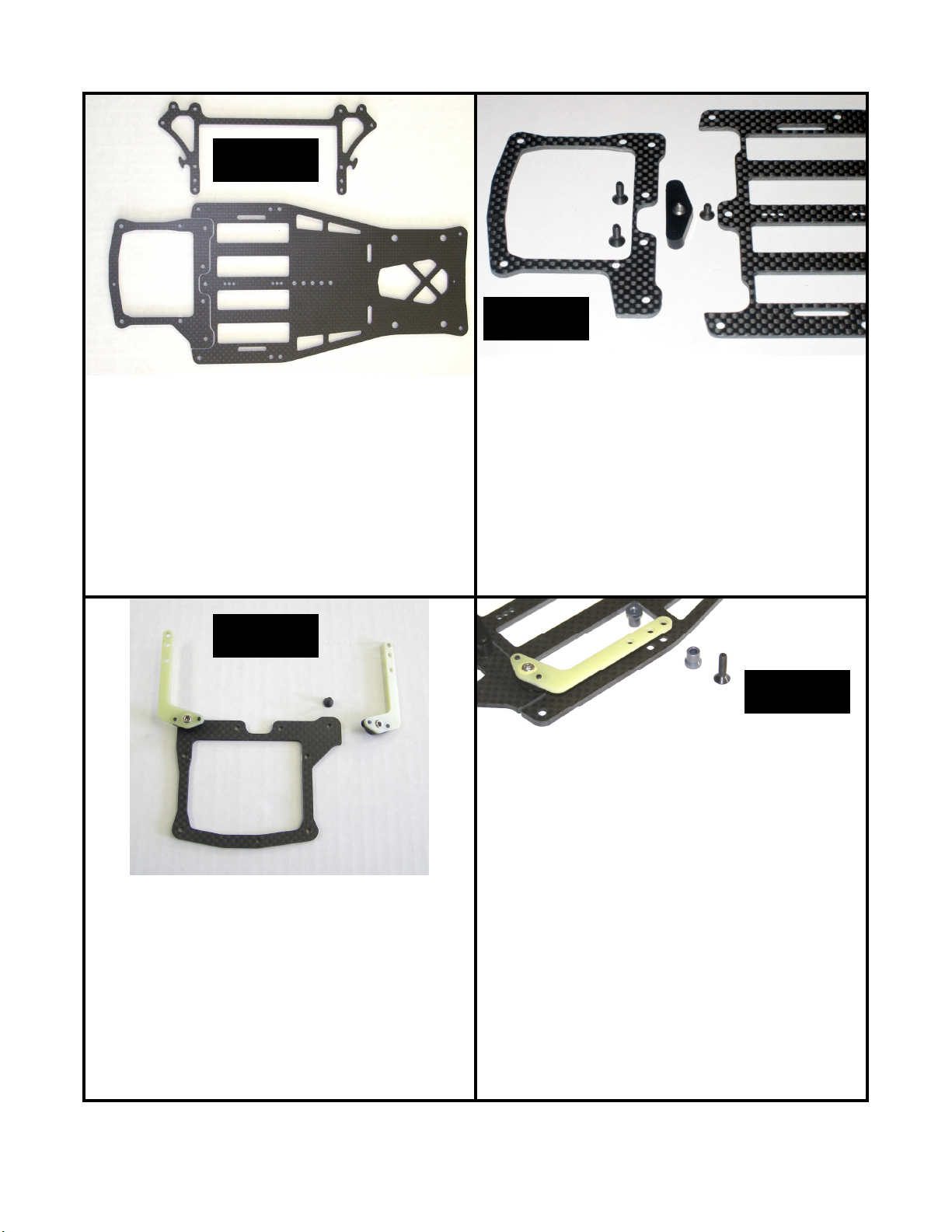

Step 15

Locate 2 gray anodized non-threaded spacers, 2

gray anodized threaded spacers and 2 4-40 x ½” flat

head screws.

1.Pass a 4-40 x ½” flat head screw through the hole

in the chassis corresponding to the front hole on the

flex plate.

Attach the two flex plate assemblies to the real lower

pod plate with 4-40 x 1-4: flat head screws.

Temporarily remove the 10-32 set screws in the flex

plates in order to access the 3/32” hex in the top of

the pivot ball so you can tighten it down firmly.

Replace the 10-32 set screw and adjust it so there is

no play between the pivot ball and the pivot ball

housing on the flex plate. However, the flex plate

must still move freely. If you lift the front of the flex

plate, it should fall under its own weight when you let

it go.

2.Pass a gray non-threaded spacer over the screw.

3.Slide the forward hole on the flex plate over the

screw and the spacer.

4.Thread the gray threaded spacer onto the screw

and hold it with needle nose pliers as you tighten

the screw.

5.Repeat to assemble the other side

Note: Use forward mounting holes in flex plate and

chassis as a starting point

Page 7

Step 16

Locate the two alloy rear pod plates, the alloy rear

pod plate spacer tube 2 4-40 x 3/8” flat head screws

and 4 4-40 x ¼” flat head screws.

Attach the alloy pod plates to the lower carbon pod

plate with the 4 4-40 x ¼” screws.

Step 18

Locate and install the two long gray anodized threaded

spacers as shown with 4-40 x ¼” flat head screws

Step 18

Attach the alloy rear pod plate spacer tube to the

allow rear pods with the 2 4-40 x 3/8” screws.

Step 19

Locate the damper tube parts bag, the rear pod top

plate and 4 4-40 x ¼” flat head screws..

1.Thread a 4-40 x ½” set screw into each of the 4

ball cups from the damper parts bag.

2.Thread a ball cup/set screw assembly into the

ends of each of the damper tube pistons and

damper tubes.

Locate and install the two carbon damper

tube/body mount wings as shown with 4-40 x ¼”

button head screws.

3. Apply 5000wt silicon diff oil to the pistons and

insert them into the damper tubes.

4. Attach the alloy pivot balls to the bottom of the

pod top plate and the tops pf the side wings as

shown above. Secure them with alloy lock

nuts

5. Attach the carbon pod top plate to the alloy

rear pod plates

6. Snap the ball cups of the assembled damper

tubes onto the pivot balls on the pod top plate

and wings.

Note:

If you feel play between your ball cups and

ball studs, you can place a single layer of

plastic bag material between your ball cup and

ball stud then snap them together. This will

cut and insert a disc of plastic into your ball

cup reducing or eliminating the play. If you

still feel play, repeat the process. We find you

usually need one to two layers to get the

proper feel, no play but totally free movement.

Page 8

Step 20

1. Install the molded shock mount-antenna mount

with 2 4-40 x 3/8” flat head screws

2. Assemble the IRS Nickel-Teflon Pro Shock as per

the included instructions with 35wt silicon shock oil.

3. Place the one long black alloy ball stud in the

antenna mount and a standard ball stud in the rear

pod top plate as shown. Secure the top pod plate

ball stud with an alloy lock nut.

4. Install the included gold shock spring onto the

shock and snap the shock in place.

Trim the ball cup on the shock that attaches to the

antenna mount to .472” (12mm) in length. Thread this

short ball cup on so the over all shock length is 2.6”

(66mm). This length will give you the standard setting

of 1.5mm of rear pod droop. If you thread on the ball

cup until it stops, you will have zero pod droop.

Step 21

Locate the rear axle parts bag. There are a couple of steps

that can make your diff last longer that should be done at

this time.

Use the right alloy diff hub as a holder and sand both sides

of each diff ring on 600 grit sand paper using electric

motor cleaner spray as a lubricant. Sand until you see an

even scoring pattern across the face of each diff ring.

Clean them with motor spray and set them aside.

The diff balls may have a protective oil coating on them.

Place them on a clean paper towel and carefully clean

them with motor spray. When dry drop them into your cup

of diff grease and stir them to coat them with diff grease.

Diff Assembly:

Step 21 Continued

1. Put a small dab of diff grease on the axle flange

so the diff will stick to it. Place a diff ring on the

flange so its flat keys onto the flat on the diff

flange.

2. Place a flanged 3/8 x ¼” bearing in the center

of the spur gear. Slide the spur gear and

bearing unit on to the axle until it stops against

the diff ring.

3. With a small flat screw driver remove the diff

balls from the diff grease and snap them into

the outer row of holes in the spur gear.

4. Place a flanged 3/8 x ¼” bearing into the inside

face of the right side diff hub. Put a small dab of

diff grease on the hub flange so the diff will

stick to it. Place a diff ring on the flange so its

flat keys onto the flat on the hub flange. Slide

this unit on to axle.

5. Slide a flanged 3/8 x ¼” bearing over the axle

into the outside face of the right side diff hub.

Slide the stepped thrust cone onto the axles so

the smaller diameter part is against the right

hub bearing.

6. Thread the black nylon lock nut onto the

threaded stud on the axles until it makes

contact with the thrust cone.

7. Tighten the black lock nut gradually with an

11/32” nut driver until you notice you cannot slip

the spur gear when holding the axle and right

hub in a fixed position.

Six 4-40 x ¼” cap head screws are supplied to mount

your rear wheels.

Notes:

Keep you fingers clean with motor spray. Diff

assembly is like surgery. You do not want dirt

or oil where it does not belong.

The grease on the diff balls when you pluck them out

of the cup of diff grease is all you need.

Smearing diff grease on the rings will make

your diff get dirty faster and make a mess.

The ultimate goal in building a diff is one which is

extremely free and glass smooth but requires a

lot of force to slip the spur gear.

Page 9

Step 22

Step 23

Insert the IRS precision ride height adjuster cams into

the rear alloy pod plates. Insert a 3/8” x ¼” flanged

bearing into each ride height adjuster and insert the

axle as shown. Note that the left clamping hub has

the shallow center boss out towards the wheel. This

is necessary to have symmetrical wheel spacing.

Install your favorite wheels and measure the width of

the car. Shim as necessary to obtain a centered axle

and a 172mm rear track width.

Special Note:

The DB12R is designed to work with IRS precision

ride height adjuster cams. We find too much size

variation in other cams and cannot guarantee they will

fit properly.

Step 24

Angled Mounting

Install a 4-40 x ½” set screw into each flex plate.

Special note:

While these long set screws were initially designed

to be tweak screws in testing we found the nature

of the rear suspension system never lets the car

get tweaked.

Now, the set screws in the flex plates function as

roll stiffeners. If you want less roll in the rear of

you car, you can run them down so they just touch

the top of the lower chassis.

Under most conditions we run them so they are not

touching, or we do not install them at all.

You have two servo mounting options with the

DB12R, Angled or Flat. The new BMI Servo

Mounts have holes to allow either mounting option.

The Reactive Caster front suspension used on the

DB12R is designed to function best with angled

servo mounting. The hardware supplied with this

kit is what you need for angled mounting.

Flat Mounting

If you wish to mount your servo flat, you will need

two long off set ball studs to replace the standard

offset ball studs on your steering spindles. These

ball studs will correct the steering geometry and

eliminate the bump steer present if you did not use

them.

The servo is mounted to the servo mounts with two

4-40 x ¼” button head screws.

Page 10

Step 25

The Servo mounts are attached to the lower chassis

with two 4-40 x ¼” flat head screws.

At this time drill out the center holes on your servo

saver (not supplied) for two Nickel Teflon ball studs.

Secure them with two 3/16 alloy lock nuts.

You have two sets of servo mounting holes in the

chassis. They let you achieve proper linkage

geometry whether you run your ball studs in front of

the servo saver as shown or behind them. This is a

valuable tuning option as the servo’s weight has a big

effect on chassis weight distribution.

Step 26

Locate two titanium turnbuckles and four black ball

cups. Assemble them as shown and adjust them to

an over all length of 2.375” (60.5mm). This is a

starting point. You will need to reset their length after

setting your camber in order to achieve the desired

amount of front toe.

Note:

You can use the same plastic bag trick mentioned in

Step 19 to remove play in your steering linkage.

Remember you want to remove play but still have

totally free movement in the links. Any friction at all is

unacceptable and will make you car not center

properly after steering inputs

Step 27

Install your body posts with two 4-40 x 3/8” flat head

screws in the front and two 4-40 x ¼” button head

screws in the rear..

Step 28

Install the battery locater with 2 2-56 flat head

screws.

You can secure your batteries with the supplied

battery o-ring or strapping tape. Both methods

work well.

Congratulations, your done!

Go to the starting setup sheet, adjust your car to

the base setup and hit the track!

Loading...

Loading...