Page 1

Concentration Meter

DynFAS MW

Hardware Manual

User's Guide

ID No. 54877BA2

Rev. No. 00 01.07.2009

Page 2

Page 3

Page 4

The units supplied should not be repaired by anyone other than BMA Schaltanlagen

Service engineers or technicians by BMA Schaltanlagen.

In case of operation trouble, please address to our central service department.

The complete user’s guide consists of two parts, namely the hardware and software instructions.

The hardware manual comprises:

¾ mechanical components

¾ installation

¾ electrical installation

¾ technical data

¾ electrical and mechanical drawings

The software manual comprises:

¾ operation of the control unit

¾ parameter description

¾ basic setting

¾ calibration

¾ error messages

The present part is the hardware instruction.

Subject to change without prior notice.

BMA Schaltanlagen GmbH

Am Alten Bahnhof 5 38122 Braunschweig

Germany

Tel. +49 531 804 261 ⋅ Fax +49 531 804 269

schaltanlagen@bma-de.com

www.bma-worldwide.com

DynFAS MW

Page 5

Table of Contents

Table of Contents

Page

Chapter 1. Safety Instructions 7

1.1 Identification and warning notices 7

1.2 General Instructions 8

1.3 General Safety Instructions 9

Chapter 2. General Information 11

2.1 Use and Function 11

2.2 Frequency approval 12

2.3 Intended Use 14

2.4 Definitions 15

Chapter 3. System Description 16

3.1 Principle of Measurement 16

3.2 Calculation of Measured Values 17

3.3 Temperature Compensation 18

3.4 Mechanical Components 19

3.4.1 Control Units 20

3.4.2 Flow Cell 23

3.4.3 Container Probe 24

3.4.4 High-Frequency Cable 28

3.5 Pipeline Measurement Configuration 30

3.6 Container Measurement Configuration 31

Chapter 4. Getting Started 32

4.1 Transport 32

4.2 Installation 32

4.2.1 Flow Cell Installation 32

4.2.2 Container Probe Installation 34

4.2.3 Installing the Control Unit 36

4.3 Connecting the Control Unit 37

4.3.1 Connecting the HF Cable 37

4.3.2 Pin Configuration of the Connector Strip 40

4.3.3 Digital Outputs, Relays 44

Chapter 5. Service Instructions 45

5.1 General Information 45

5.2 Wearing Parts 45

5.3 Instrument Cleaning 45

5.4 Battery 46

5.5 Fuse Replacement 46

Chapter 6. Technical Data 47

6.1 Control Unit 47

6.2 Technical Data Sensors 50

6.3 Technical Data HF-Cable 52

6.4 Format of Serial Data Output RS 232 and RS 485 53

DynFAS MW

5

Page 6

Table of Contents

Chapter 7. Certificates 55

7.1 EC Declaration of Conformity 55

7.2 Frequency Approval 57

Chapter 8. Technical Drawings 63

8.1 Dimensional Drawing of Control Unit Hous ing 63

8.1.1 Control Unit Standard CS-100 63

8.1.2 Control Unit High Dynamic CH-200 64

8.2 Electrical Wiring Diagram 65

8.3 Dimensional Drawings Flow Cells 66

8.3.1 Type FC-050-016 66

8.3.2 Type FC-065-040 67

8.3.3 Type FC-080-016 68

8.3.4 Type FC-100-016 69

8.3.5 Type FC-150-016 70

8.3.6 Type FC-020-150 71

8.3.7 Type FC-025-300 72

8.3.8 Type FC-030-150 73

8.3.9 Type FC-040-150 74

8.3.10 Type FC-060-150 75

8.4 Dimensional Drawings Probes 76

8.4.1 Type P-065-006 76

8.4.2 Type P-080-016 77

8.4.3 Type P-100-016 78

8.4.4 Type P-150-016 79

8.4.5 Type P-025-150 80

8.4.6 Type P-030-150 81

8.4.7 Installation Situation in Pipelines 82

8.5 Dimensional Drawings Flush Probes 83

8.5.1 Type PF-065-006 83

8.5.2 Type PF-080-016 84

8.5.3 Type PF-100-016 85

8.5.4 Type PF-150-016 86

8.5.5 Type PF-025-150 87

8.5.6 Installation Situation in Pipelines 88

8.6 Installation Sheets for DynFAS MW (Probe) 89

8.7 Installation Sheets for DynFAS MW (Flush Probe) 91

6

DynFAS MW

Page 7

Chapter 1 Safety Instructions

Chapter 1. Safety Instructions

1.1 Identification and warning notices

The term BMA Schaltanlagen in this User’s Manual stands for the

company BMA Schaltanlagen GmbH.

Please observe the warnings and safety instructions given in this

User’s Manual to rule out physical injury and property damage.

They are identified by the following symbols: DANGER, WARNING,

CAUTION or NOTICE.

Indicates an imminently dangerous condition. Failure to

follow the instructions will lead to death or serious injury.

Indicates a potentially dangerous condition. Failure to follow the

instructions may lead to death or serious injury.

Indicates a potentially dangerous condition. Failure to follow the

instructions may lead to slight injury or a medium-degree inju ry.

Indicates a situation which may cause property damage if the instructions are not followed.

IMPORTANT

Paragraphs with this symbol provide important information on the

product or how to work with the product.

DynFAS MW

Tip

Includes application tips and other useful information.

Further Symbols

Warning sign: no intervention, change nothing

7

Page 8

Chapter 1 Safety Instructions

Instruction: Disconnect from mains supply

Instruction: Wear safety shoes

1.2 General Instructions

The most important safety measures are summarised in this operation manual. It supplements the applicable regulations which

have to be studied by the personnel in charge.

Please keep in mind:

¾ the national safety and accident prevention regulations

¾ the national installation regulations (e.g. EN 60079)

¾ the generally accepted engineering rules

¾ the information on transportation, installation, operation, ser-

vice and maintenance

¾ the safety instructions and information in this User’s Manual

and the enclosed technical drawings and wiring diagrams

¾ the characteristic data, limit values and the information on the

operating and environmental conditions on the type labels an d

data sheets

¾ the signs on the devices

8

DynFAS MW

Page 9

Chapter 1 Safety Instructions

1.3 General Safety Instructions

IMPORTANT

The instrument housings are protected according to protection

type IP 65 and are suitable for outdoor application. The instrument has been tested by the manufacturer and is delivered in a

condition that allows safe and reliable operation.

The measuring systems have to be protected against direct sun

rays and rain during outdoor applications e. g. by a suitable protective cover.

IMPORTANT

Never change the installation and the parameter settings without

a full knowledge of these operating instruction s, as well as a full

knowledge of the behavior of the connected controller and the

possible influence on the operating process to be controlled.

Ambient conditions

The systems may be used only in technically good order and only

according to regulations!

Only authorized persons who have been trained, have the proper

qualification and have received the necessary instructions may

work with the systems! Installations and modifications on the systems which may affect the operational safety are not permitted!

IMPORTANT

All systems components require non corrosive ambient conditions

during transport, storage and starting up.

Electrical shock hazard:

Disconnect power to rule out any contact with live parts during

installation and when servicing.

Turn off power supply before opening the instrument. NEVER work

on open and live instruments.

DynFAS MW

9

Page 10

Chapter 1 Safety Instructions

Attention! Possible danger, damage to property! Concerns the system type CH-200-024 Control Unit High Dynamic 24 V DC (Id.-No.

54878-02):

When connecting the 24 V DC auxiliary power, the + and – Poles

should be connected correctly. There is no reverse voltage protection!

Qualified Persons

Spare fuses must match the rating specified by the device manufacturer. Short-circuiting or manipulation is not permitted.

IMPORTANT

The DynFAS MW and all ancillary units have to be connected to

mains via grounded connection.

IMPORTANT

The concentration measuring system DynFAS MW is to be serviced

and repaired solely by qualified persons.

Persons are qualified if they have acquired adequ ate knowledge in

the area concerned in the course of their professional education,

and if they are familiar with the pertinent national occupational

safety regulations, accident prevention regulations, directives and

acknowledged rules of technology. They must be capable of assessing the result of their work safely; moreover, they need to be

familiar with the contents of this User’s Manual.

10

IMPORTANT

If liquid gets inside the instrument, cut off the power supply. The

instrument has to be checked and cleaned by an authorized service center.

DynFAS MW

Page 11

Chapter 2 General Information

Chapter 2. General Information

2.1 Use and Function

The DynFAS MW has been designed as a concentration measuring

system and may only be used for this purpose. If it is used in any

manner, which is not described in this user’s manual, the protection of the device is impaired and all warranty claims are void.

BMA Schaltanlagen only guarantees that the devices comply with

the published specifications. The DynFAS MW may only be inst alled

in an undamaged, dry and clean condition. Alteration work and

modification of the system components are not permitted.

The DynFAS MW does not qualify as a “safety regulated measurements.

Conformance with

standards

Protection type

Misuse warning

The standards and regulations customary to the DynFAS MW are

listed in the system instructions in chapter 2.2 f requency approval

and in chapter 7.1 EC-conformity certificate.

The degree of protection of the DynFAS MW according to IEC

60529 is max. IP 65.

The following is contrary to the intended use and, therefore, has to

be prevented:

¾ Use under other conditions and prerequisites than those speci-

fied by the manufacturer in the technical documents, data

sheets, operating and installation instructions and in other specifications.

¾ Use after repair by persons who have not been authorized by

BMA Schaltanlagen.

¾ Use in a damaged or corroded state.

¾ Operation with open or inadequately closed cover.

¾ Operation with inadequately tightened adapters and screwed

cable glands.

¾ Operation without observing the safety precautions defined by

the manufacturer.

Authorized Persons

DynFAS MW

¾ Tampering with or bypassing existing saf et y in stallations.

Authorized persons are persons, who are foreseen for certain ac-

tivities as a consequence of statutory provisions, or who have been

approved by BMA Schaltanlagen for carrying out certain activities.

11

Page 12

Chapter 2 General Information

2.2 Frequency approval

The DynFAS MW complies with part 15 of the FCC1 Rules. These

devices fulfill the requirements regarding immunit y to interference

and emitted interference and are licensed for operation.

FCCApproval plates

12

1

FCC ... Federal Communications Commission

DynFAS MW

Page 13

Chapter 2 General Information

The DynFAS MW complies with the R&TTE regulations 1999/5/EG

and fulfill herein all requirements for this type of high-frequency

device. The devices bear the identification of conformity according

to the CE symbol, No. 0682 of the certification office. The certificate can be found in chapter 7.2 Frequency Approval.

The DynFAS MW is a system for concentration measurement using

microwave technology. The emitted microwaves have a very low

activity and are, therefore, not at all hazardous to human beings

or the environment. Also, the product is not affected at all by the

microwaves.

IMPORTANT

The DynFAS MW has been manufactured in compliance with the

safety requirements for microwave devices. If special legal provisions exist regarding the use of microwaves, it will be the responsibility of the user to adhere to them.

IMPORTANT

Any change in frequency or any other manipulation on the microwave device will result in a loss of the frequency approval and w ill

be prosecuted.

The microwave modules do not include any replaceable components and must not be opened.

DynFAS MW

13

Page 14

Chapter 2 General Information

2.3 Intended Use

The measuring system DynFAS MW can be used to determine the

concentration of nearly all materials which can be dissolved or suspended in water using microwave technology. The following sensor

and control unit versions are available:

1. The container probes have been designed for installation into

pipelines with a nominal width of ≥ 200 mm and in containers,

for example, crystallizers. The probe is installed such that both

measuring rods (transmitter and receiver) are immersed into

the product being measured.

2. The Flow Cell is a tubular probe, with microwave transmitter

and receiver being firmly welded onto the outside of t he pipe.

The inside of the pipe is Teflon-coated. The flow cell is installed into the existing pipeline system inline or into a bypass.

The control unit is available in two versions: The Standard Model

CS-100 and the high dynamic version CH-200. The control unit

CH-200 can only be used when sufficiently large microwave attenuation (min. 40 dB) is present. The Standard Model CS-100

should be used for lower microwave attenuation.

During operation, the concentration measuring device DynFAS MW

send out electromagnetic radiation in the frequency range between

2.4 GHz and 2.5 GHz (range restrictions depending on local regu-

lations in your country). The microwaves which emerge are not

dangerous to human beings and the environment (power emission

< 10 mW). The microwaves are emitted from the microwave window; the product is not changed by the microwaves.

To ensure proper function of the meter, please pay attention to the

following:

14

Tip

¾ The material being measured must not be electrically conduc-

tive, i.e. the ohmic resistance is infinite.

¾ The product must not contain any gas bubbles, or gas bubbles

have to be compressed with adequate pressure when carrying

out measurements in pipelines.

¾ The ion concentration, e.g. salt content, has to be nearly con-

stant.

¾ The total attenuation of microwave signals must be at least 40

dB for the control unit CH-200. For details, see Chapter 3.4.1

the control units

DynFAS MW

Page 15

Chapter 2 General Information

2.4 Definitions

Attenuation Weakening of microwave signals, microwave measurement

effect.

Container flush

probe

Factory setting All parameters have been set to standard values by the manu-

Flow cell Tubular probe for simple integration into the ex isting pipeline

HF cable High-frequency cable.

Microwaves Electromagnetic waves in a certain frequency range.

Phase Phase or phase shift. Microwave measurement effect.

Quad cable Combination of four HF cables of equal length in a corrugated

Softkeys Buttons associated with the software.

Container probe with flushing device.

facturer. In most cases this simplifies calibration of the device

significantly. Despite factory setting, calibration always has to

be performed.

system.

tube.

TC Temperature compensation.

DynFAS MW

15

Page 16

Chapter 3 System Description

r

r

Chapter 3. System Description

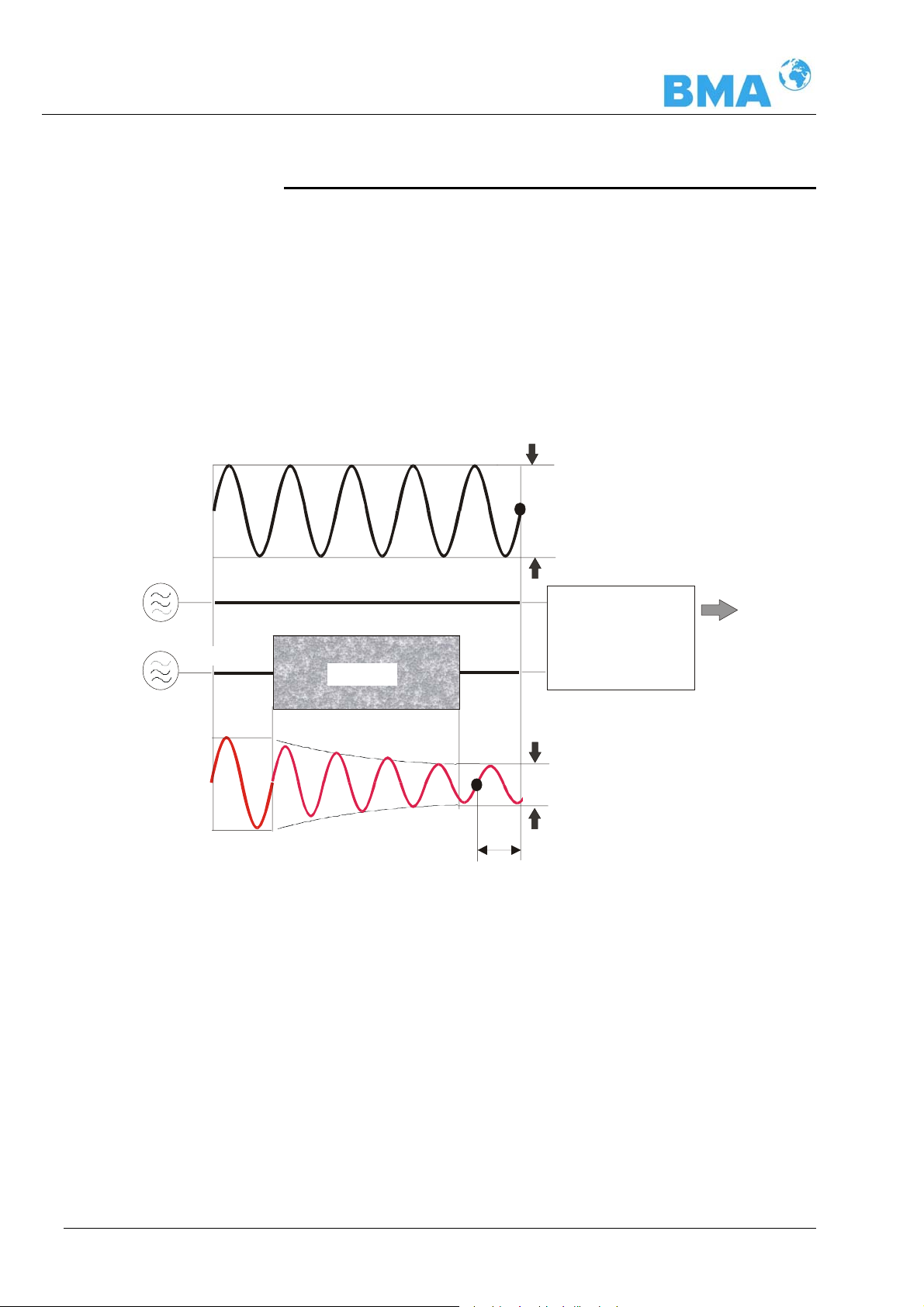

3.1 Principle of Measurement

The microwaves that spread between the rods pass through the

product being measured; their propagation speed is slowed down

(= phase shift) and their intensity is damped (= attenuation).

Figure 3-1 illustrates the principle of measurement: the propagation speed of microwaves passing through the product being

measured is slowed down (phase shift) and their intensity (attenuation) is reduced, relative to a reference signal.

HF- sources

Figure 3-1:

Schematic diagram:

Change of microwave

by product

Transmitte

Reference signal

Reference path

Phase comparison

--> Phase

Product

Receive

Amplitude comp

--> Attenuation

Measured value:

Concentration %TS

Measurement signal

Phase shift

Prerequisite is that the product being measured shows some

dielectric properties. In general, water is a very distinct dielectric fluid. The water or dry mass concentration, respectively, can

therefore be determined by measuring the phase shift and/or

attenuation.

The concentration to be detected in the product is therefore dependent in good approximation linear on phase shift and attenuation. For this reason we can measure the concentration or

the Brix content of the product using a linear calibration (see

chapter 3.2 Calculation of Measured Values ).

16

DynFAS MW

Page 17

Chapter 3 System Description

+ϕ⋅

3.2 Calculation of Measured Values

The microwave measuring phase and attenuation are calibrated

after an automatic plausibility analysis.

During calibration, the phase and/or the attenuation or a concentration value (or density value) are assigned by sampling. The

calibration is full automatic and the sample taking is supported by

the control unit.

Which of the parameters, either phase, attenuation or both are

used for the calibration depends on the size and interference of the

measuring effect. For example, the attenuat ion is significantly

more sensitive to electrolytic conductivity (salt content).

In many cases, the mere phase measurement is recommended

and is calculated in good approximation by a linear calibration as

follows:

=

Con concentration

A, C coefficients of respective calibration function

ϕ phase

The DynFAS MW allows you to calibrate, display and output two

concentrations Con1 and Con2. You have to enter the calibration

coefficients separately for concentration 1 and 2. For more information please refer to the Software Manual.

CACon

DynFAS MW

17

Page 18

Chapter 3 System Description

θΔ⋅

+

θΔ⋅

+

3.3 Temperature Compensation

Temperature compensation (TC) is necessary if the product temperature varies. In general, we recommend connecting a temperature compensation, i.e. a temperature signal (0/4...20 mA or

Pt 100) to the control unit and, if necessary, to enable the compensation in the control unit. The control unit is designed such that

the required TC’s can be calculated automatically. The variat ion in

temperature where temperature compensation becomes absolutely

essential is dependent on the product and on the water content. In

first approximation, ± 2°C should be set as fluctuation limit.

Tip

TC has to be carried out whenever you are working with.

The TC corrects the phase and attenuation before the measured

value calculation (calibration), in most applications according to

the following formulae (linear compensation, additive).

ϕ=ϕ

=

C

meascomp

CDD

ϕ

Dmeascomp

Where

= measured phase

ϕ

meas

ϕ

= compensated phase

comp

= measured attenuation

D

meas

= compensated attenuation

D

meas

= temperature coefficient

C

ϕ

= temperature coefficient

C

D

Δθ = measured temperature (T

) – reference temp. (T

meas

Ref

)

Depending on the selected function (additive, multiplicative, lin ear,

quadratic), the required temperature coefficients appear on the

Calibration menu. Temperature coefficients that are not used are

set to zero.

If you select two-range calibration (split concentration), separate

TC’s have to be entered for both concentration ranges. The coefficients are entered in the course of calibration.

TC can be carried out via Pt 100 or via current input. This has to

be defined on the Calibration menu. The Pt 100 temperature range

is between –50°C and +200°C.

How to work with the temperature compensation is described in

detail in the Software Manual.

18

DynFAS MW

Page 19

Chapter 3 System Description

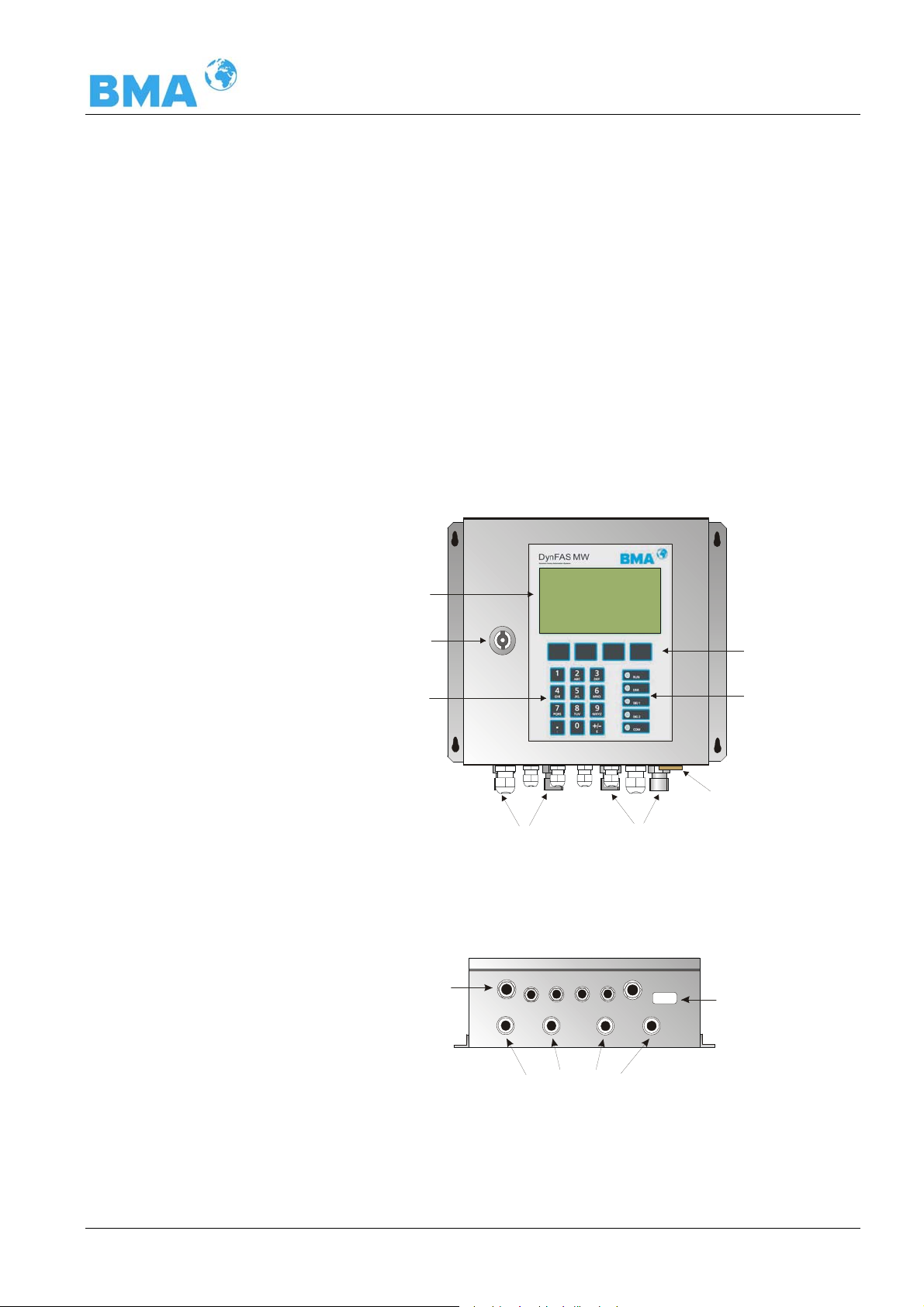

Figure 3-2:

Control Unit Standard

CS-100

3.4 Mechanical Components

The measurement system consists of a control unit, a probe and a

set of special high frequency cables (in short HF-cable). The control unit is available in two versions: the standard model CS-100

and the high dynamic version CH-200, see Figure 3-2 and 3-3.

DynFAS MW

Figure 3-3:

Control Unit

High Dynamic

CH-200

19

Page 20

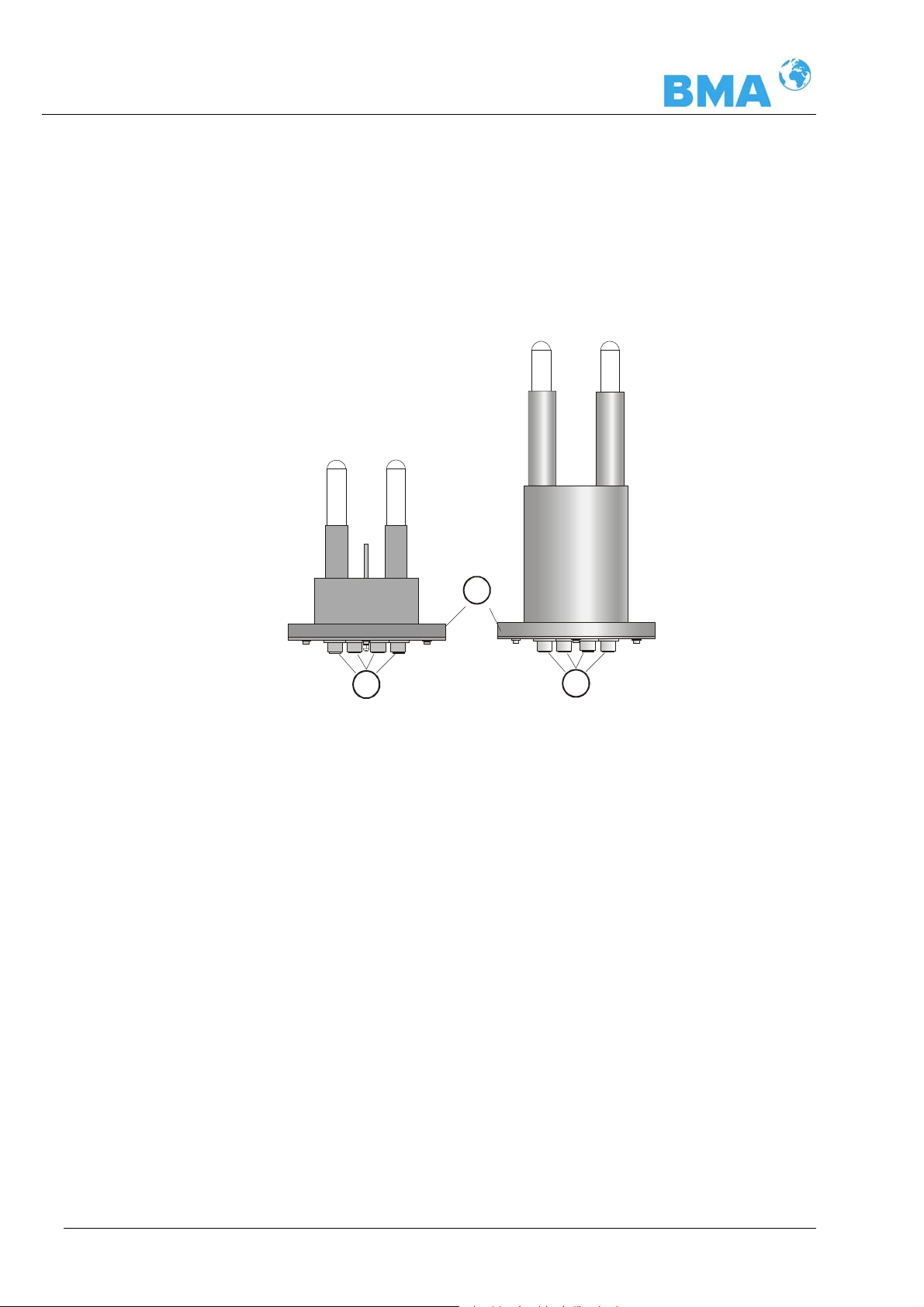

Chapter 3 System Description

The probes are available in different versions, as pipeline and container probe with and without flushing device (see Figure 3-4, 3-5

and 3-6).

Abb. 3-4 left:

Probe

Abb. 3-5 right:

Probe with Flushing

Figure 3-6:

nominal width 50 mm

Flow Cell

3.4.1 Control Units

The control units consist of evaluation analyser with microwave

unit. The microwaves are generated, received and analyzed by the

microwave unit. Signal processing and communication take place

in the evaluation computer. For simple operation, the measuring

system includes a display, 4 softkeys and an alphanumeric keypad.

Different functions are assigned to the softkeys on the display.

20

DynFAS MW

Page 21

Chapter 3 System Description

High Dynamic Version

CH-200

Differences between Control Unit Standard CS-100 and

Control Unit High Dynamic CH-200

The Control Unit High Dynamic CH-200, has an additional HF amplifier module in comparison to the standard model, whereby the

wall housing is larger (dimensions see chapter 6.2 Technical Data

control unit). Otherwise, the control units only differ in their applications.

Higher product attenuations are allowed for the high dynamic version of DynFAS MW. Therefore larger measuring paths can be irradiated, for example measuring cells of larger nominal width can be

used. The application of both control units is predetermined by the

product attenuation. Up to an attenuation of 50 dB, CS-100 is used

and beyond, CH-200. The CH-200 generally requires an attenuation of 40 dB. If this is lower, the software indicates an err or message.

An RS232 interface is included on the underside of the instrument.

Figure 3-7:

Front view of

CS-100

LCD display

Lock

Numerical

keypad

Cable feed-through

M 20 and M 16

HF connections for

signal cable reference cable

and cable feed-through

M-TxM-Rx R-Tx

R-Rx

Softkey buttons

LED’s

RS232 connection

RS232

9-pole Sub-D-connector

Figure 3-8:

Control Unit -

bottom view

DynFAS MW

High-frequency connections

21

Page 22

Chapter 3 System Description

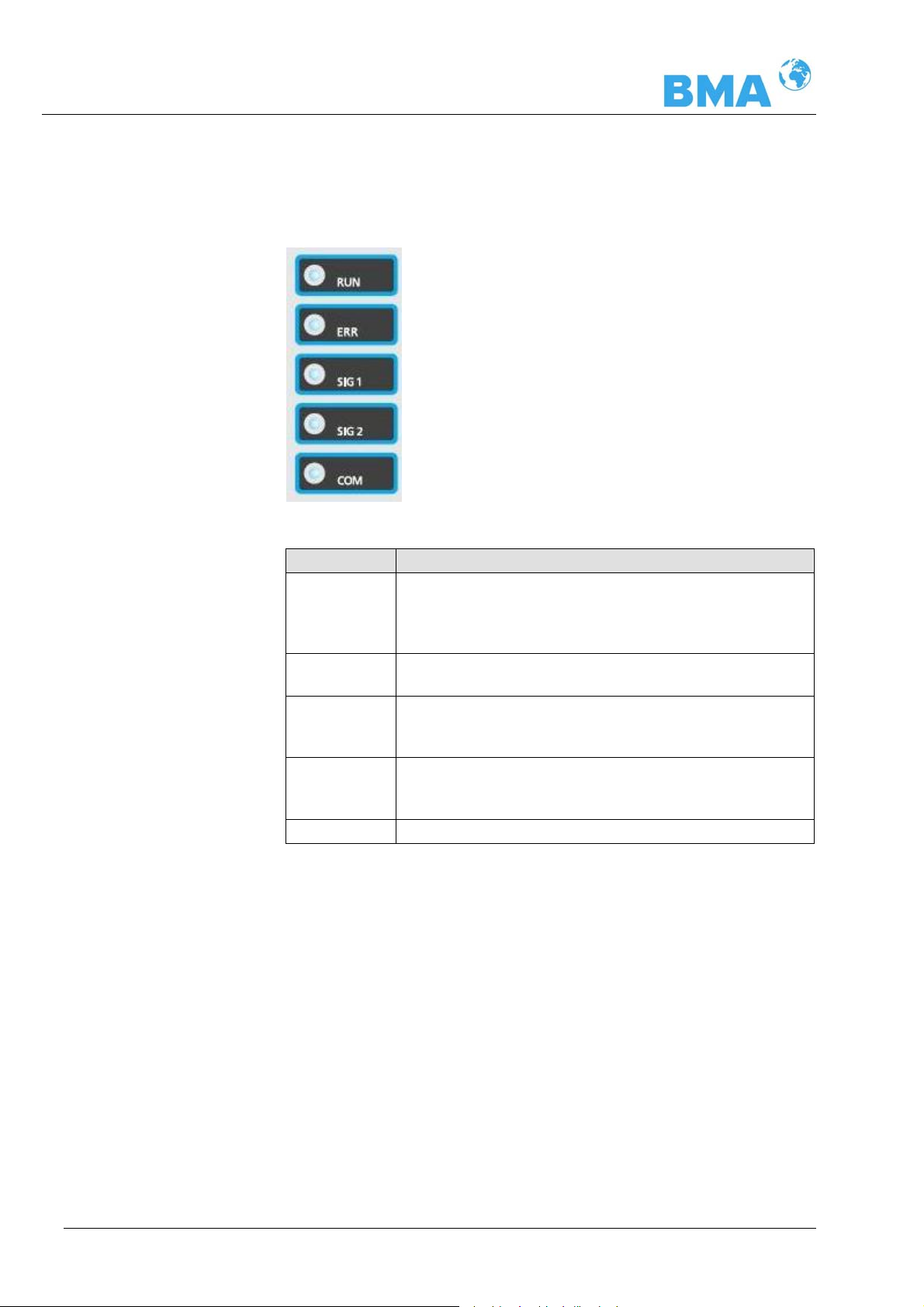

LED’s on the Front Panel

Five LED’s on the instrument front panel indicate the instrument

status.

Figure 3-9:

LED’s on the front panel

of the Control Unit

LED Function

RUN Instrument in measurement mode

Display is flashing when concentration average

value is put on hold, e.g. if an error has occurred,

if the measurement has been paused or stopped

ERR Error

Goes out after reset or if fault has been repaired

SIG 1 Display depending on the selected function of relay

1, possible functions: error, no product, limit value

min., limit value max., measurement stopped

SIG 2 Display depending on the selected function of relay

2, possible functions: error, no product, limit value

min., limit value max., measurement stopped.

COM Communication active, e.g. via RS 232

Terminal Block

The electrical connections of the DynFAS MW are located on a connector strip in the wall housing. The terminal block is accessible

from the front after you have opened the cover. There, you also

find the power cut-off switch and the fuses. The high-frequency

connections are located on the outside of the housing. All other

elements, especially the live elements (on the motherboard) are

provided with a protection cap.

22

DynFAS MW

Page 23

Chapter 3 System Description

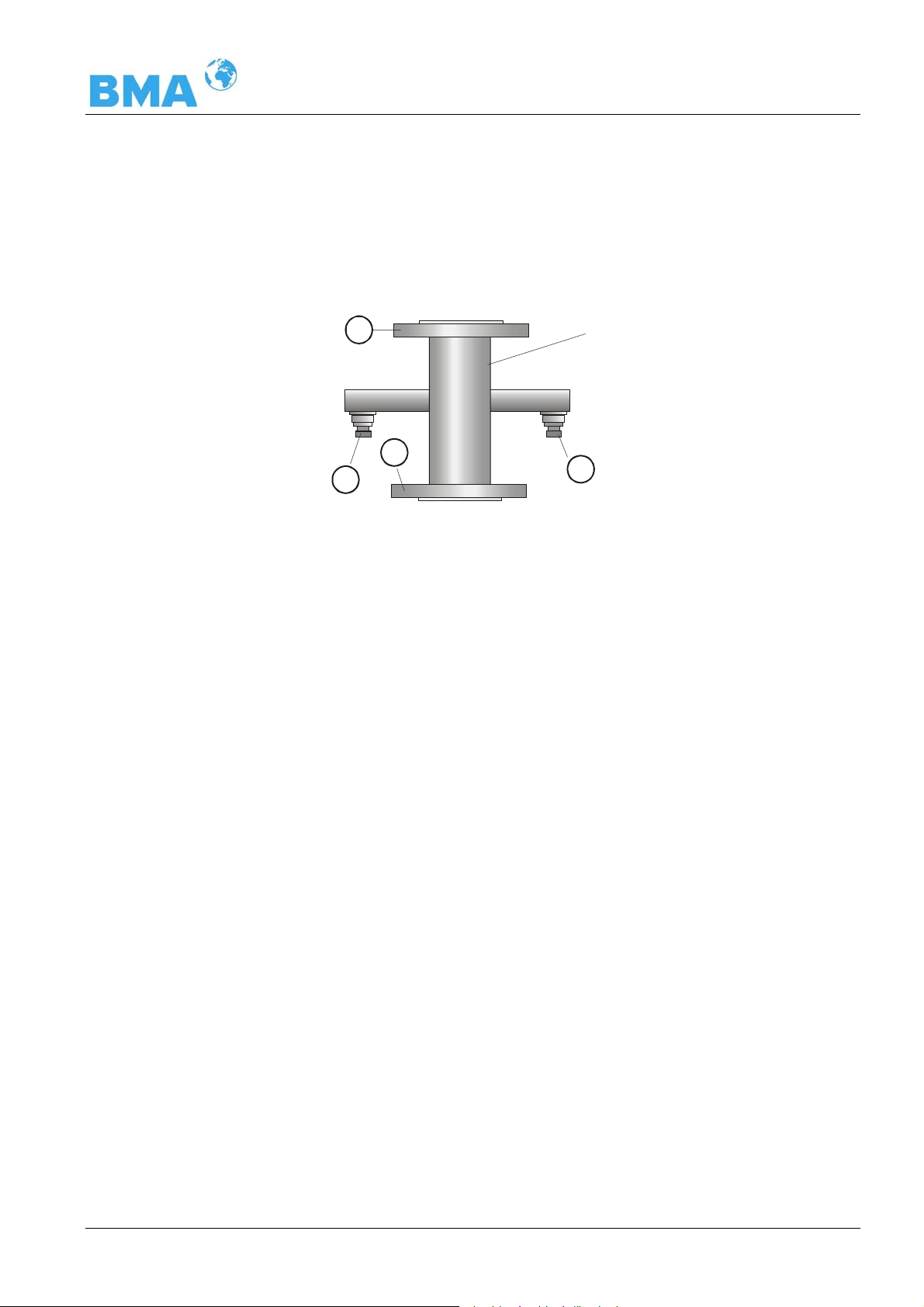

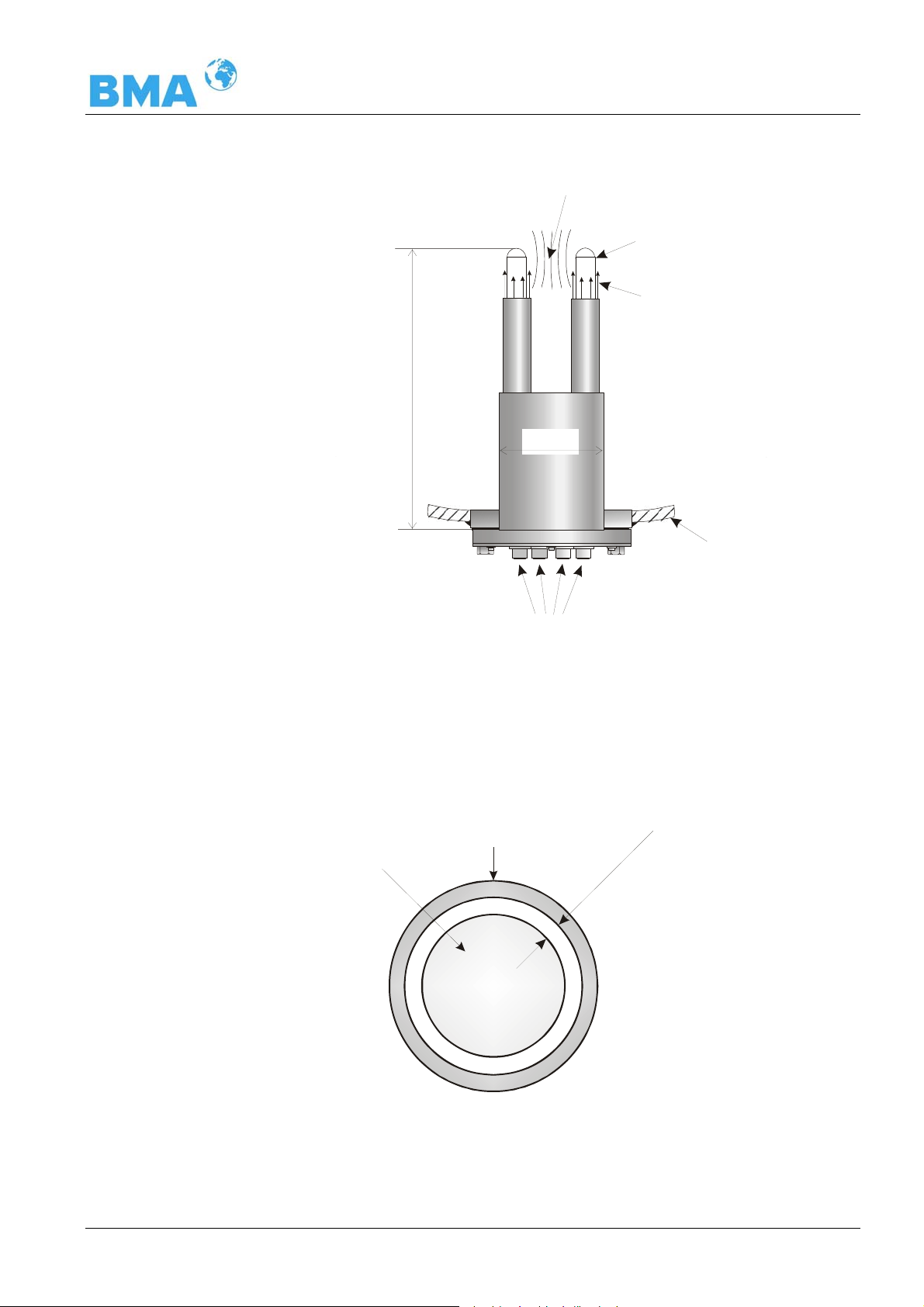

3.4.2 Flow Cell

The flow cells are available with nominal widths from 50 to 150

mm (see Figure 3-10) and different flanges. For technical data

please refer to chapter 6.2.

Figure 3-10:

Flow Cell

B

Pipeline with

nominal width

50 ... 150 mm

B

A

A: High-frequency connections

B: Process connection, flanges of different sizes

The flow cell consists of a sturdy stainless steel body. The microwave transmitter and receiver are firmly welded to the outside of

the pipe. The entire product pipe is PTFE-coated and fulfills the

special requirements for use in foodstuffs.

There are not objects extending into the pipe (such as measuring

sensors). The flow cell can be installed in the pipeline via flange.

A

DynFAS MW

The flow cell has two HF connections to feed in and output microwave signals. Input and output can be allocated as needed (M-Tx,

M-Rx). The microwave signals transmit the product over the entire

pipeline cross-section.

23

Page 24

Chapter 3 System Description

A

3.4.3 Container Probe

Two different container probe versions are available – either with

or without flushing device (see Figure 3-11). For technical data

please refer to chapter 6.2 Technical Data.

Probe

with flushing device

Probe

without flushing device

Figure 3-11:

Container probes

B

A

A: High-frequency connections

B: Process connection, flanges of different sizes

The container probe has been specially designed for concentration

measurements in containers. Both measuring rods are immersed

into the product. Microwaves are emitted from one end of the rod

and received by the other end of the rod; they are emitted only

towards the opposite end of the rod. This direction characteristic of

the probe minimizes the interfering influence of metal parts in the

vicinity of the probe and allows installation if only little space is

available. For example, the concentration of sugar strike can be

measured continuously to find the suitable inoculation time.

The plastic rods meet the special requirements for application in

foodstuffs.

24

DynFAS MW

Page 25

Chapter 3 System Description

Two different probe types are available:

¾ The standard type is the container probe without flushing de-

vice

¾ The probe with flushing is employed in processes where incrus-

tations are likely to occur, for example, due to increased depositions. The flushing device prevents any deposition on the microwave exit windows. Long travel times are supported by continuous crystal processes (i.e. VKT).

The flow direction of the product being measured should be vertical, as shown in Figure 3-12. This ensures that the product between the measuring rods is representative, provided it is mixed

thoroughly.

Product

Microwave

measur in g f ield

Plastic rods

~ 190 mm

100 mm

Pt100

Container wall

Figure 3-12:

Probe

HF conne ct ions

Pt 100 Only the probe without flushing is provided with a Pt 100 and is

connected to the control unit via 4-wire cable. The wiring diagram

for the Pt 100 is described in chapter 4.3.2 Pin Configuration of the

Connector Strip. To reduce the danger of incrustation in the immediate vicinity of the measuring rods, the probe with flushing is not

provided with a Pt 100.

DynFAS MW

25

Page 26

Chapter 3 System Description

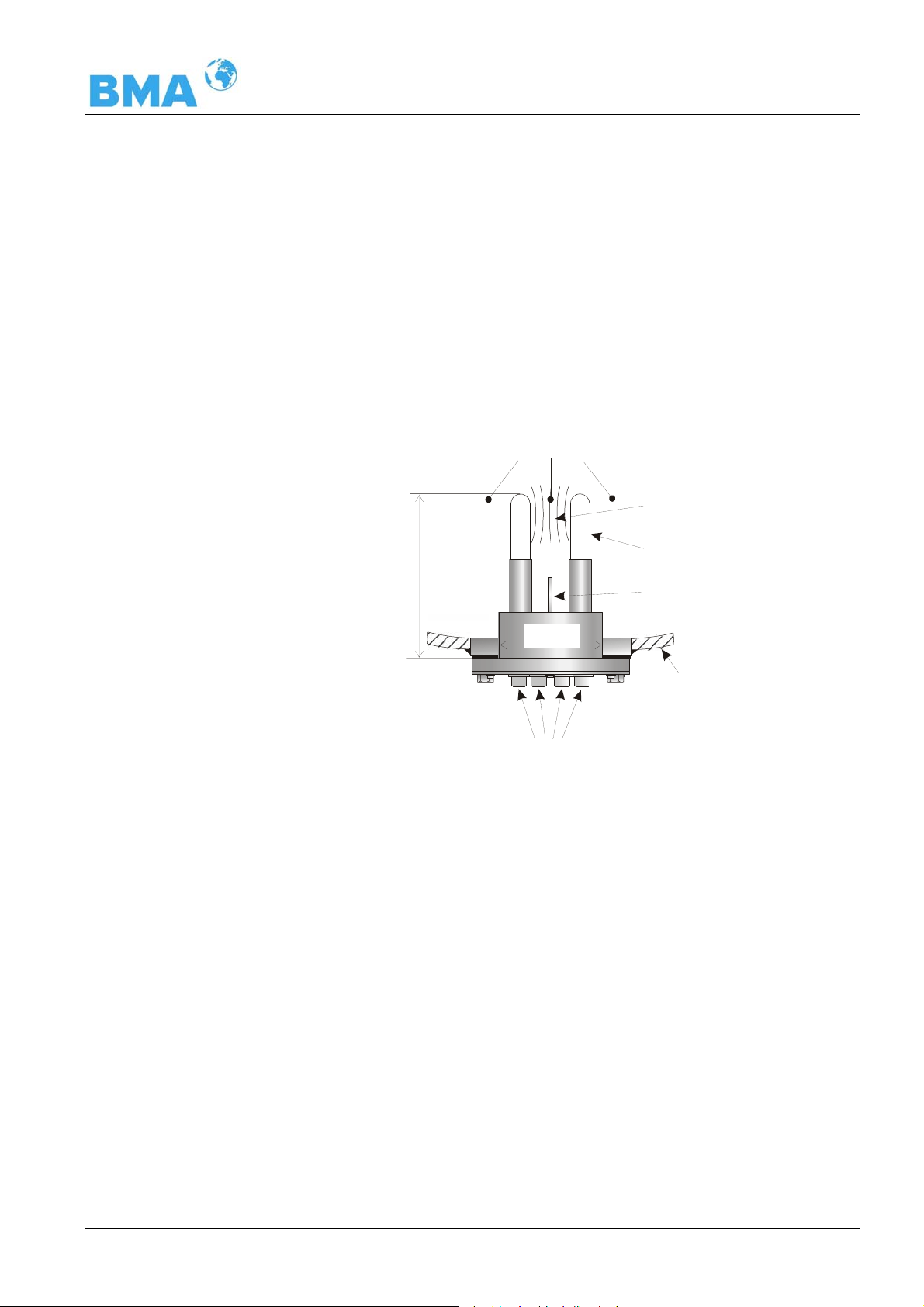

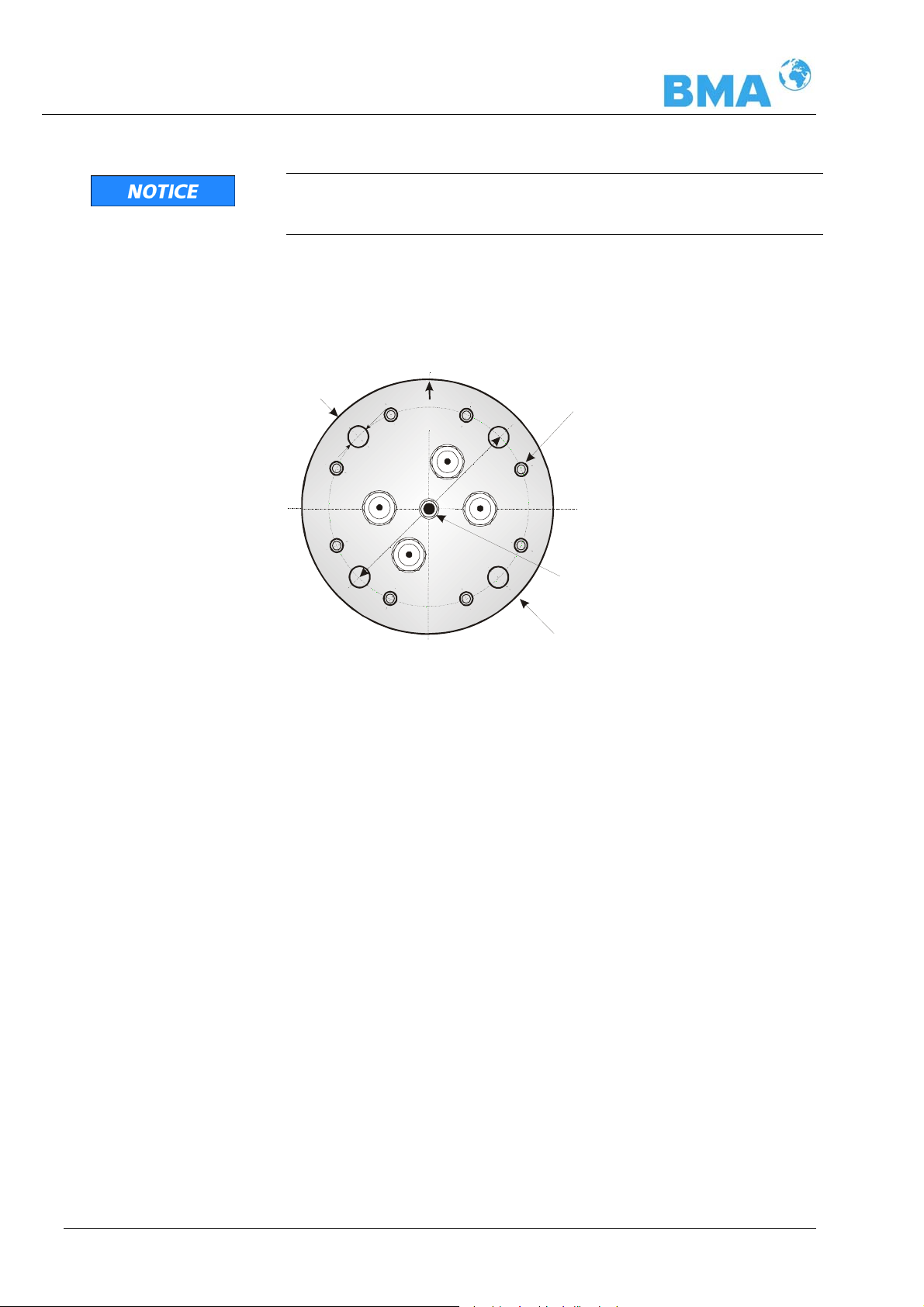

Warning, possible property damages!

Do not open the cover screws on the front of the container probes,

see Figure 3-13.

Probe flange

e.g. Probe DN65 / PN6

Figure 3-13:

The front of the probe

Flow

4

1

Strömung

ø

R-Tx

M-Rx

ø

1

30

R-Rx

M-Tx

do not remove!

PT100

ø

16

0

Probe with Flushing

The probe with flushing device has been designed for processes

where depositions, for example, due to incrustations are likely to

occur on the probe.

26

The flush probe has two flushing channels which keep the plastic

rod free from incrustations; this ensures that the microwaves

come into direct contact with the product being measured. All

parts coming into contact with the product meet the specific requirements for application in foodstuffs. Figure 3-14 shows the

probe design.

DynFAS MW

Page 27

Chapter 3 System Description

Microwave

measuring field

Plastic rods

Rinsing medium

~ 320 mm

100 mm

Container wall

Figure 3-14:

Probe with Flushing

Figure 3-15:

Rod head

with flushing pipe

4 x HF connections

2 x 3/8’’ Flushing connections, internal thread

The flushing slit width is the same for both probe rods and shown

in Figure 3-15.

Flushing pipe

Plastic rods

F

lush

ng slit

i

.5

m

m

~ 1

DynFAS MW

27

Page 28

Chapter 3 System Description

3.4.4 High-Frequency Cable

High-frequency cables (HF cable) are used to transmit microwaves

between probe and evaluation electronics.

HF cables change their conductivity (for microwaves) relative to

the temperature. Therefore, variations in the ambient temperature

would create measurement errors. This error is compensated for

by enabling the cable compensation. Influences of the ambient

temperature on the signal cable are compensated for by means of

the reference cable. The reference cable has the same length as

the signal cable; during operation, it should be exposed to the

same ambient temperature. Therefore, we recommend installing

both cable types together in a corrugated tube; this also simplifies

installation.

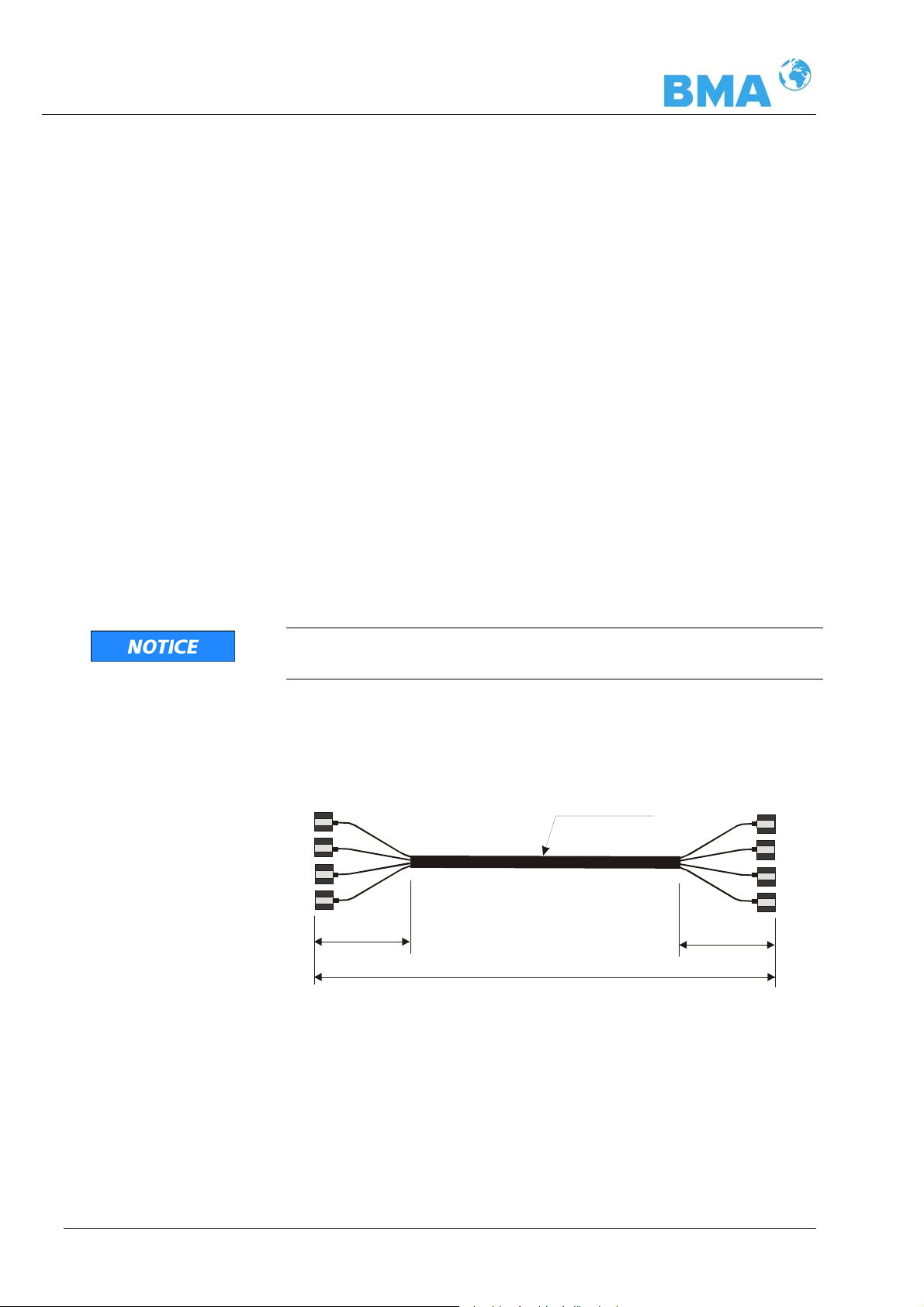

The HF cable quad (see Figure 3-16) consists of four individual HF

cables of the same length, which each end with one HF plug connector (N-type). Available cable lengths: 2, 4, 6 and 10 m.

When connecting the Flow Cell, the reference cable is shortcircuited to the probe side by means of N-connectors (see Figure

3-17).

Figure 3-16:

HF-cable quad

Never bend HF cables! The bending radius should not be less than

100 mm. After installation, fix cables with cable binders.

4 x N-connector

4 x N-

0.35 m

ø

18.5 mm

Corrugated tube

Lengths 2, 4, 6 and 10 m

4 x N-connector

0.35 m

28

DynFAS MW

Page 29

Chapter 3 System Description

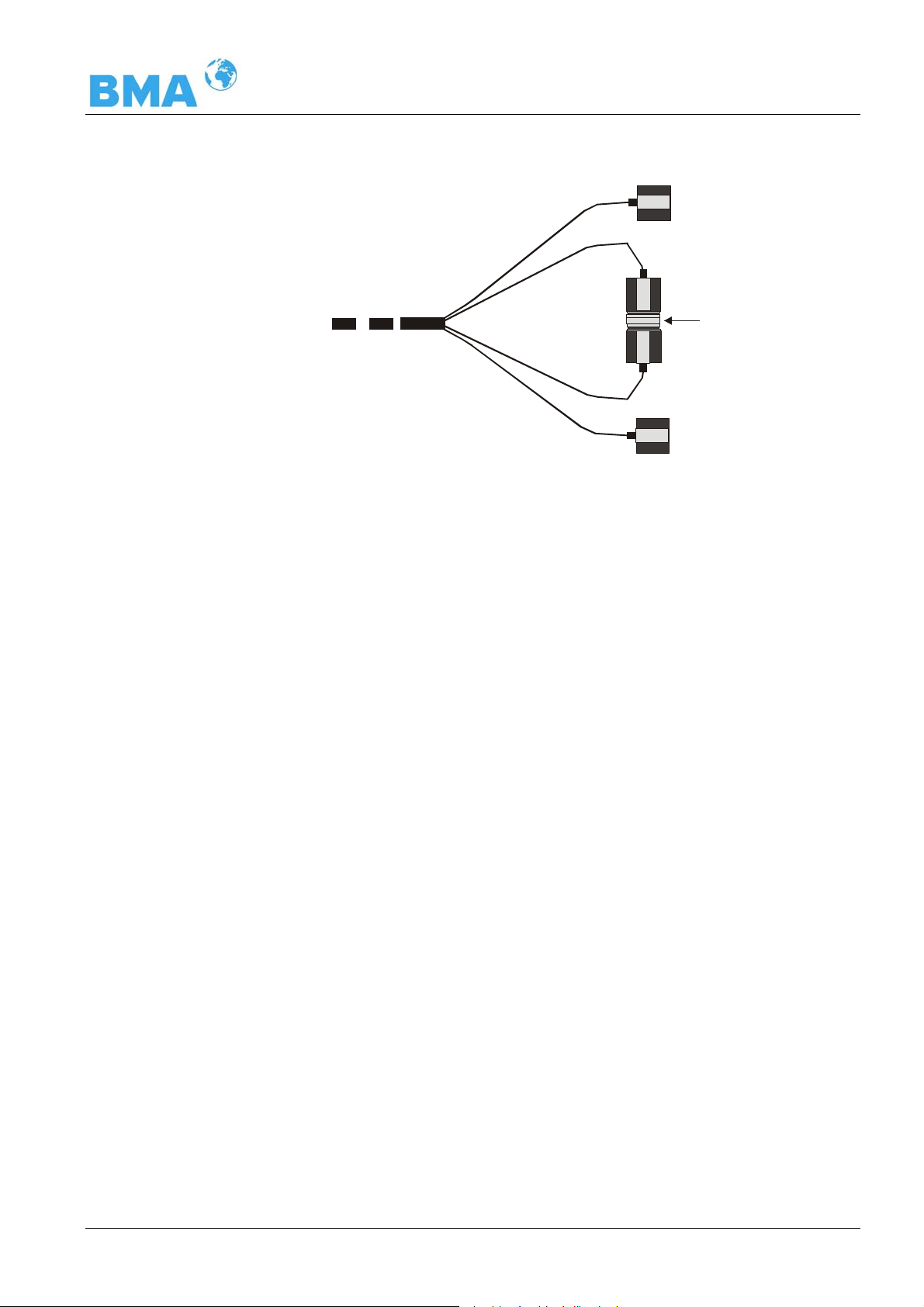

Figure 3-17:

HF-cable quad, at the

side of the probe

Sensor side

x

R

-

M

x

R

-

R

N-connector

CC-100

R

-

T

x

M

-

T

x

Figure 3-17: The ends of the reference cable R-Rx and R-Tx are

short-circuited with an N-connector.

For further technical data see chapter 6.3 Technical Data HFCable.

DynFAS MW

29

Page 30

Chapter 3 System Description

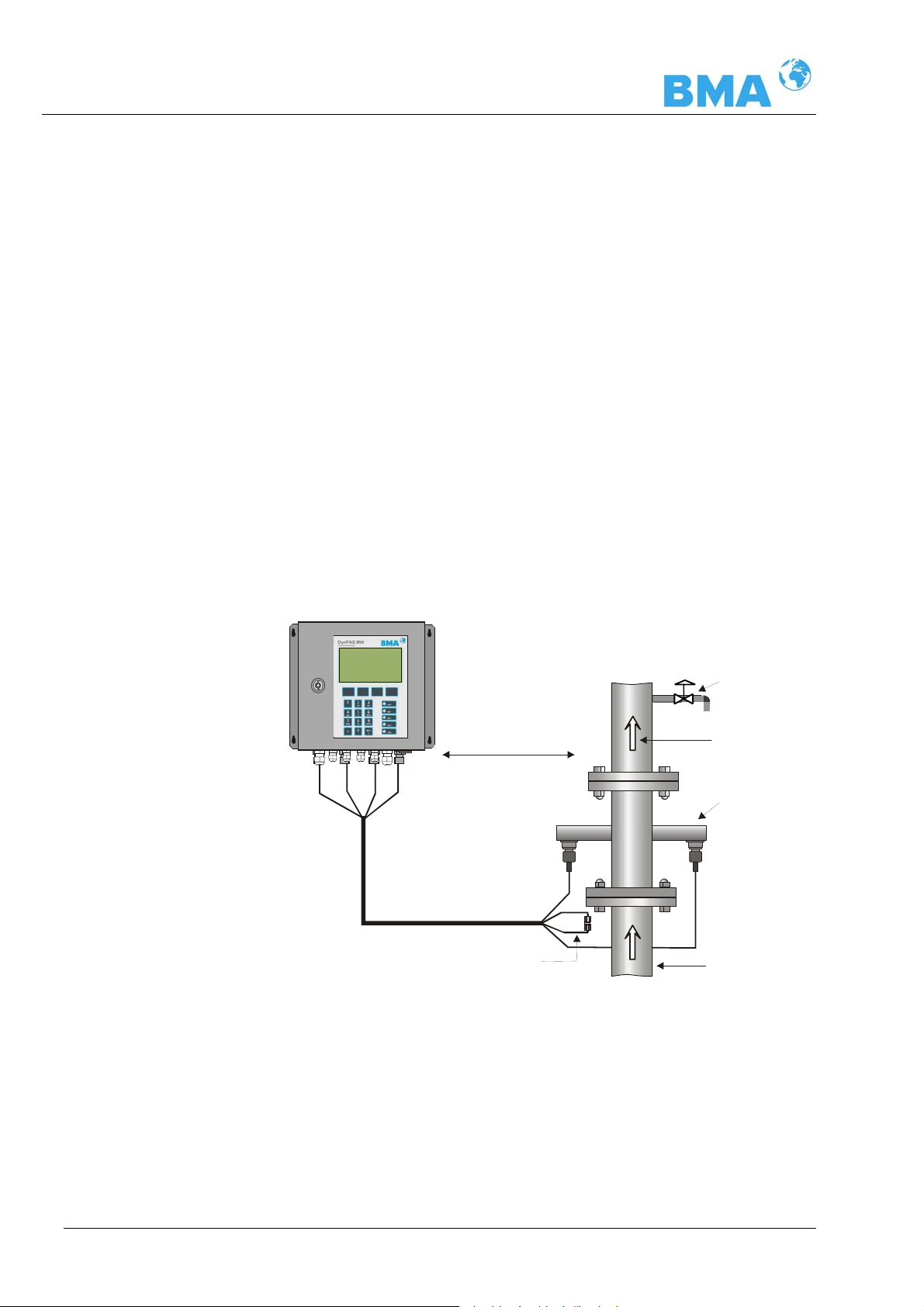

3.5 Pipeline Measurement Configuration

The control unit is installed in the immediate vicinity of the container probe to keep the HF-cable between control unit and probe

fairly short. The shorter the cable connection, the better the stability of the measurement. The standard length is 4 m and the maximum length of the HF-cables is 10 m.

The flow cell is installed into the exist ing pipeline system inline or

into a bypass. The orientation of the flow cell may either be vertical or horizontal. To rule out sedimentary depositions, vertical installation in a riser is preferred (see Figure 3-18).

The flow cell should be installed fairly close to the sampling location to ensure representative sampling for calibration.

For possibly required product temperature compensation, a representative temperature signal (current signal or Pt 100) has to be

connected to the control unit.

Figure 3-18:

Typical measurement

configuration

on a pipeline

Control Unit

Sampling

Distance:

typical 4 m

HF-cable quad

Reference line

with N-connector

CC-100

Product flow

Orientation:

HF-connections

facing down

Pipeline inline

or in bypass

30

DynFAS MW

Page 31

Chapter 3 System Description

3.6 Container Measurement Configuration

The control unit is installed in the immediate vicinity of the probe

to keep the HF-cable between control unit and probe fairly short.

The shorter the cable connection, the better the stability of the

measurement. The standard length is 2 or 4 m and the maximum

length of the HF-cables is 10 m.

The control unit should be installed fairly close to the sampling

location to ensure representative sampling for calibration. A representative temperature signal (current signal or Pt 100) should be

connected to the control unit for possibly required product temperature compensation.

Our example below shows the measurement configuration on a

discontinuous evaporation crystallizer. The probe is fixed to the

container wall such that both measuring rods are immersed into

the product.

Figure 3-19:

Typical system

configuration on a

evaporation

crystallizer

Distance typical 4 m

(no radiation heat)

a

a > 60 mm

Container wall

PT-100

HF quad cable

Product

HF connections

Microwave

measuring field

Pt100

DynFAS MW

31

Page 32

Chapter 4 Getting Started

Chapter 4. Getting Started

4.1 Transport

IMPORTANT

Risk of damage!

System parts may get damaged during transportation!

Transport probe and control unit in their original packaging. Protect parts against shocks. Especially the plastic rods of the container probes have to be protected against mechanical impact!

After unpacking, make sure all parts listed on the packing list have

been delivered and show no sign of damage; if necessary, clean

these parts.

If you detect any damage, please notify the forwarder and the

manufacturer immediately.

The weight of the system components can amount to more than

25 kg depending on the model. You should wear safety shoes.

4.2 Installation

4.2.1 Flow Cell Installation

For installation of the flow cell please keep in mind:

¾ The flow cell is installed into the pipelin e system. Keep in mind

that material sampling should be possible for calibration directly behind the flow cell.

¾ The flow cell should be installed in a vertical riser, if possible. It

has to be ensured that no material depositions occur on the pipe walls and no bubbles are present in the product. For horizontal installation, please observe the correct orientation of the

HF-connections (see Figure 4-2).

32

¾ There should be a straight pipe section of at least 200 mm and

equal nominal width before and after the flow cell to ensure a

fairly homogeneous flow profile and to rule out possibly occurring microwave reflections in the pipeline.

DynFAS MW

Page 33

Chapter 4 Getting Started

¾ No gas bubbles should be present in the product. If gas bub-

bles cannot be ruled out, a pressure of at least 4 bar is required in the pipeline to minimize the influence of gas bubbles.

Please observe the max. permissible working pressure (see

chapter 6.2 Technical Data Sensors)

¾ The high-frequency cable should preferably be connected to

the flow cell from below to prevent inflowing water from getting

to the connecting sockets.

¾ The HF cable should not come into contact with the warm pipe-

lines.

Figure 4-1:

Installation in a

vertical riser

HF-connections

min. 200 mm

Flow cell

Orientation:

facing down

M-Rx

( M-Tx )

Wrong arrangement !

Sampling

Product flow

Flange

200 ... 250 Nm

HF-connections

max. 2 Nm

M-Tx

( M-Rx )

Pipeline inline

or in bypass

Correct arrangeme nt !

Figure 4-2:

Horizontal installation:

orientation of

HF-connections

DynFAS MW

33

Page 34

Chapter 4 Getting Started

4.2.2 Container Probe Installation

For installation, please keep in mind:

¾ Select the installation site such that good mixing and a homo-

geneous product are ensured and no bubbles are present in the

probe. A tap should be provided in the direct vicinity to allow

representative sampling.

¾ The probe has to be flange-mounted on the container such that

the product being measured flows between both measuring

rods. That means the fork (both measuring rods) has to be installed at an angle of 90° to the material flow.

¾ The distance between the measuring rod tips and any metal-

ized walls (heating elements, stirrer, container wall) should be

at least 60 mm.

¾ The following installation hole sizes in the fitting flange

are required for installation of the probe:

Flange

DN 65 / PN 6

others

¾ For further installation dimensions please refer to chapter 8

(see installation sheets).

¾ Use the respective flat gasket (standard accessory) to compen-

sate for minor surface tolerances in the fitting flange.

Minimum installation hole size ∅ (mm)

100 ± 0.2

102 ± 0.5

Installation on Process Containers

Figure 3-19 shows the position of the container probe on the container. This position is also valid for the container flus h probe.

The assembly sheet in chapter 8 includes all the inf ormation required for installation.

Installation in Pipelines

The container probes can be installed in pipelines with a nominal

width ≥ 200 mm using an adapter flange. Please observe the position and orientation of the container probe (see the technical

drawings in chapters 8.4.7 and 8.5.6 Installation Situation in Pipelines).

34

DynFAS MW

Page 35

Chapter 4 Getting Started

Connection of the flushing pipes

The container probe with flushing device consists of two flushing

devices with a 3/8 inch inner thread (DIN ISO 228-1). The flushing

connections are subsequently sealed to this thread. A sealing to

the probe cover is not permitted, for example with silicone.

Flush Parameters (only for container flush probe)

The degree of deposition or incrustation is essential for the flush

parameters, i.e. flush frequency and duration. The flush parameters have to be adapted to the product and the process.

The following independent flushing parameters for products and

processes have to be observed:

Flush solution water, condensation

Temperature of

flush solution

Pressure

Fittings 2 x 3/8 inch female screw thread

Supply pipe

Independent flushing parameters product and process, typical

starting rates:

Interval every 2 hours

Duration 12 seconds

Temperature of

flush solution

For measurements on the C-product the flushing intervals can be

considerably reduced, e.g. every 6 hours for 30 seconds.

Maximum 120 °C

≥ 3 bar, max. 8 bar

(DIN ISO 228-1)

≥ 1/2 inch

average product temperature, mostly 65 ±5°C

Amount of water

DynFAS MW

The following is generally valid: the flushing devices can be

flushed simultaneously or in shifts. The flushing parameters are

valid for every flushing device.

Tip

The required flush duration has to take into account a possible

inertness of the system, e.g. valve openings. The flush supply

pipes have to be insulated well against heat to prevent that the

flush solution is initially colder.

The amount of water per flushing connector is approx. 0.8 l/sec at

a flushing pressure of 5 bars.

35

Page 36

Chapter 4 Getting Started

4.2.3 Installing the Control Unit

For installation of the control unit, please keep in mind:

¾ Install the control unit in the vicinity of the microwave probe,

keeping in mind the length of the HF cable. HF cables are

available in a length of 2, 4, 6 and 10 m; the standard cable

length are 2 or 4 m.

¾ Protect the instrument against vibrations.

¾ For instrument installation you should foresee a cutoff device to

allow easy and quick disconnection of the device from the

power supply.

¾ When installing the control unit on a crystallizer, use a distance

rail to minimize thermal radiation and heat conduction. See

Figure 4-3.

¾ When the control unit is set-up outdoors, it has to be protected

from direct sunshine and rain for example by means of an adequately large protective roof.

Figure 4-3:

View from above:

Installation of

control unit

on a crystallizer

Insulation container wall

Spacer

Control Unit

36

DynFAS MW

Page 37

Chapter 4 Getting Started

4.3 Connecting the Control Unit

4.3.1 Connecting the HF Cable

For the connection of the sensor with the control unit, you will

need a HF cable quad. Additionally, the flow cell requires an Nconnector.

Prerequisite for a proper measurement is the correct installation of

cables! Please keep in mind:

IMPORTANT

Make sure the cables do not get into contact with hot pipes over

the entire length (corrugated tube and single cable section after

splitting), e.g. direct contact with the device wall (not insulated).

This alone guarantees that all single cables are subject to the same ambient conditions and that the compensation of the cable

drift works properly.

Never bend HF cables! The bending radius should not be less than

100 mm. After installation, fix the cables with cable binders to

prevent the cable from slipping!

Connecting the Flow Cell

The HF-cable quad and the HF-connections on the control unit are

labeled. Connect the flow cell to the control unit as shown in Figure

4-4 and make sure that you only connect cables with equal labeling. The two connections on the flow cell are not labeled, the allocation of the cable connectors M-Tx and M-Rx is arbitrary. The cable plugs R-Tx and R-Mx are connector to the N-connector (shortcircuited).

DynFAS MW

37

Page 38

Chapter 4 Getting Started

Control Unit,

underside

Figure 4-4:

Connection of flow cell

version 1

M-Rx

M-Rx

Bending radius

min. 100 mm

M-Tx

M-Tx

R-Tx

R-Rx

R-Rx

R-Tx

HF-cable quad

(stand ard 4 m)

Flow cell

Reference line

with N-connector

Flange

200 ... 250 Nm

HF-connections

max. 2 Nm

M-Rx

( M-Tx )

R-Rx

R-Tx

M-Tx

( M-Rx )

Connecting the Container Probes

The HF cables and the HF connections on the control unit and on

the probe are labeled. Connect the flow cell to the control unit as

shown in Figure 4-5, and make sure that you only connect cables

with equal labeling.

Figure 4-5:

Connection of the

container probe to

the control unit

Microwave

measuring field

Control Unit, underside

M-Rx

M-Rx

M-Tx

R-Tx

ø100

R-Rx

M-Rx

PT-100

HF quad cable

M-Tx

M-Tx

R-Tx

R-Rx

R-Rx

R-Tx

38

DynFAS MW

Page 39

Chapter 4 Getting Started

IMPORTANT

When tightening the 21 mm screw nut, make sure that the connector is not twisted on the cable. If the connector is twisted relative to the cable, the shielding may get damaged and this could

result in mismatching and bad sealing.

Hand tighten all screwed connections of the HF cable (2 Nm = 0.2

kg/m)! Before tightening, carefully screw on the cable by hand.

Caution! Threaded joint jams easily.

Occasionally you should check if the screwed connection is still

properly tightened. If the installation is ex posed to vibrations, the

screwed connection may come loose and this may result in inaccurate measurements or corrosion of the connections.

As long as the cables are not connected, the coaxial sockets have

to be covered immediately with plastic caps and the cable connectors have to be protected by suitable provisions against moisture

and dirt.

DynFAS MW

39

Page 40

Chapter 4 Getting Started

4.3.2 Pin Configuration of the Connector Strip

Electrical shock hazard:

Disconnect power to rule out any contact with live parts during

installation and when servicing.

Turn off power supply before opening the instrument. NEVER work

on open and live instruments.

Temperature Signal Connection

A Pt 100 or a temperature current signal has to be connected to

current input 1 or 2 if temperature fluctuations occur in the product and if a temperature dependence of the phase or attenuation

measurement is likely to occur. The temperature sensor has to

measure the material temperature in the vicinity of the microwave

probe.

When taking the container probe into operation, connect the 4wire

cable of the Pt 100 to the connector strip of the control unit as

follows:

Figure 4-6:

Pt 100 connection

container probe

Contr o l Unit

Connector strip

(23)

(11)

( ) Terminal no.

blue

blue

white

white

PT-100 sensor

in the container

probe

40

DynFAS MW

Page 41

Chapter 4 Getting Started

Other Connections

¾ Connect all desired input and output signals to the terminal

strip as shown below. Use the M feed-through to maintain the

degree of protection.

¾ Check if the voltage indicated on the type plate matches your

local supply voltage.

¾ Connect the line cable to the terminals 3(L1), 2(N) and 1(PE).

¾ Check if the test switch (mains interru ption) is in position „on“

(see Figure 5-1).

¾ Close the instrument housing and turn on the power supply.

Attention! Possible danger, damage to property! Concerns the system type CH-200-024 Control Unit High Dynamic 24 V DC (Id.-No.

54878-02):

When connecting the 24 V DC auxiliary power, the + and – Poles

should be connected correctly. There is no reverse voltage protection!

The line cross-section for the power supply must be at least

1.0 mm

2

.

On the connector strip of the control unit you find the following

connections:

or / bzw.

DynFAS MW

Figure 4-7:

DynFAS MW

wiring diagram

- +

41

Page 42

Chapter 4 Getting Started

Power supply: Terminals 3 (L1, +), 2 (N, -) and 1 (PE, )

For CS-100, depending on instrument version, see type label on

the outer wall of the housing.

1.) 90 V - 265 V AC, 45 - 65 Hz

2.) 24 V DC: 18 … 36 V

24 V AC: -20%, +5%, 40 … 440 Hz

For CH-200, depending on instrument version, see type label on

the outer wall of the housing.

1.) 90 V - 265 V AC, 45 - 65 Hz

2.) 24 V DC: 18 … 36 V, no reverse voltage protection

Current input no. 1 (terminals 20+ and 8-), insulated

Input as 0/4 - 20 mA signal. e.g. for temperature compensation or

reference signal recording.

Current input no. 2 (terminals 22+ and 10-), not insulated

Input as 0/4 - 20 mA signal. e.g. for temperature compensation or

reference signal recording.

Current output no. 1 (terminals 27+ and 15-), insulated

Output as 4 - 20 mA signal. Output options: concentrations (1/2),

current inputs signals (1 / 2) and Pt 100 signal

Current output no. 2 (terminals 19+ and 7-), insulated

Output as 0/4 - 20 mA signal. Output options: concentrations

1 and 2, current input signals 1 and 2 and Pt 100 signal

Pt 100 (terminals 23+ and 11-)

Connection for temperature measurement.

Digital input 1: DI1 (terminals 24+ and 12-)

Configuration options:

¾ no function

¾ measurement: start (closed) and stop (open)

Digital input 2: DI2 (terminals 25+ and 13-)

Configuration options:

42

¾ no function

¾ average value: hold (closed) and continue averaging (open)

¾ product selection: product 1 (open) and product 2 (closed)

DynFAS MW

Page 43

Chapter 4 Getting Started

Digital input 3: DI3 (terminals 26+ and 14-)

Configuration options:

¾ no function

¾ start sampling, open: no action, closed: unique measurement

starts

¾ product selection

Relay 1: (terminals 4, 5 and 6)

Changeover contacts (SPDT), insulated, configuration option:

¾ no function

¾ error message

¾ stop measurement

¾ limit value min. and max.

¾ no product

Relay 2: (terminals 16, 17 and 18)

Changeover contacts (SPDT), insulated, configuration option:

¾ no function

¾ error message

¾ stop measurement

¾ limit value min. and max.

¾ no product

RS485 interface (terminals 21 (RS1) and 9 (RS2))

Serial data interface for output of live data (all measuring data for

every sweep, measuring cycle) the setup protocol and data log.

Data format: 38400 baud, 8 data bits, 1 stop bit, no parity, no

handshake.

RS232 interface (on instrument bottom)

9-pole SubD-connector. Serial data interface for output of live data

(all measuring data for every sweep, measuring cycle) the setup

protocol and data log.

Data format: 38400 baud (Data transfer rate ), 8 data bits, 1 stop

bit, no parity, no handshake.

DynFAS MW

43

Page 44

Chapter 4 Getting Started

5 6

4.3.3 Digital Outputs, Relays

The status of the measurement is output via two relays:

¾ Error

¾ Alarm (alarm min. and max.)

¾ No product

Under menu item Plausibility, you may enter a min. attenuation

for pause detection (e.g. for process pause, no product present); if this value is not reached, „no product“ is sign aled via a

relay and the current output drops to 0 or 4 mA.

A typical application is pause detection between t he discontinu-

ous evaporation crystal processes.

¾ Measurement stopped

The respective switching status is also signaled via LED’s on the

front panel (LED’s: signal 1 and 2).

Relay no. Error, alarm, no product,

measurement stopped,

currentless status

4

Normal

4

1

com

5

6

com

2

16

17

18

com

16

17

18

com

The relays with changeover contacts can either be operated as

make contact, terminals 4 & 5 (open at error, alarm ...) or as

break contact, terminals 5 & 6 (closed at error, alarm ...).

44

DynFAS MW

Page 45

Chapter 5 Service Instructions

Chapter 5. Service Instructions

5.1 General Information

The control unit has no wearing parts or components requirin g any

special maintenance.

A malfunction of the measuring system is not always due to a defect in the instrument. Often the error is caused by incorrect operation, wrong installation, or irregularities in the product being

measured.

If a malfunction occurs, anyway, the measuring system helps you

to identify and eliminate errors by displaying error messages on

the LCD, indicating operator errors and defects of the electronics.

Usually, faulty modules of the control unit cannot be repaired but

have to be replaced. The microwave module is fixed with screws to

a shielding cover and must not be opened.

5.2 Wearing Parts

The control unit consists of no wearing parts and components that

need special attention.

The plastic rods of the Probes and the PTFE lining of the Flow Cell

can eventually experience abrasion depending on the material being measured. A lower to middle abrasion influences inconsiderably

the measurement or is compensated by calibration. Therefore, you

should check the wearing parts approximately every 2 years.

The plastic rods of the Probe and the lining of the Flow Cell can be

exchanged if abrasion is heavy. During excessive wear, the plastic

rods of the Probe and the lining of the Flow Cells can be exchanged. These Probes and the Flow cells have to be sent back to

the company. An on-site exchange is not possible.

5.3 Instrument Cleaning

Clean all system components using a moistened cloth. Do not use

any chemical cleaning agent. Parts coming into contact with the

product (during regular operation) can be cleaned with hot water,

taking into account the temperature limits (see chapter 6.2

Technical Data Sensors).

DynFAS MW

45

Page 46

Chapter 5 Service Instructions

5.4 Battery

If the measuring system DynFAS MW is without power supply

(power failure or disconnected from mains), the system clock is

supplied with power by the Lithium battery on the CPU. The instrument works correctly even with empty battery, only measured

data which are output via one of the serial interfaces may become

useless as a result of the faulty date and time information.

The service life of the battery, even under continuous load, is at

least 8 years. To replace the battery, you have to disconnect the

instrument from mains.

Battery type: 3 Volt Lithium cell (round cell battery), type CR2032.

5.5 Fuse Replacement

The mains fuse of the DynFAS MW is located in the wall housing.

Replace the fuses only if the instrument is disconnected from

mains. Be sure that the new fuses match the rating specified.

Use only fuses with correct rating:

For CS-100:

Instrument version with 90 ... 265 V AC: 2.0 A slow-blow

Instrument version with 24 V AC/DC: 2.0 A slow-blow

For CH-200:

Instrument version with 90 ... 265 V AC: 2.0 A slow-blow

Instrument version with 24 V DC: 6.3 A slow-blow

Spare fuses must match the rating specified by the device manufacturer. Short-circuiting or manipulation is not permitted.

Netzteil

Test switch Motherboard

I

0

Fuses

Line connecto r

Protective cover

EEprom

(can be pulled off)

Feed-through for

Figure 5-1:

Look inside the

instrument CS-100

46

line connector

Terminal strip

(can be pulled off)

Battery

DynFAS MW

Page 47

Chapter 6 Technical Data

Chapter 6. Technical Data

General Specifications

Method Microwave transmission measurement

Working frequency 2.4 – 2.5 GHz (ISM band), depending on local

regulations

Transmission power CS-100: < 0.1 mW (< -10 dBm)

CH-200: < 10 mW (< 10 dBm)

All coaxial line power

Applications Concentration measurement in containers and

pipes

6.1 Control Unit

Control unit

Housing

Protection type IP 65

Weight CS-100: approx. 6.5 kg

Operating

temperature

Storage

temperature

Achievable

accuracy

Display Dot matrix LC display, 114 mm x 64 mm, 240 x

Keyboard Freely accessible foil keypad, light-stable and

Power supply For CS-100 depending on instrument version:

Wall housing made of stainless steel, material

1.4571 (~316+Ti), see dimensional drawing in

chapter 8.

CS-100: HxWxD: 300 x 323 x 140 mm

CH-200: HxWxD: 400 x 338 x 170 mm

CH-200: approx. 8.0 kg

-20 ... +60°C ( 253 ...333 K ),

Humidity 0 – 90% relatively, no condensation

-20 ... +80°C ( 253 ...353 K ),

Humidity 0 – 90% relatively, no condensation

≤ 0.2 weight % (standard deviation) depending on

product and sensor

128 pixels, with back-lighting, automatic contrast

setting

weatherproof: alphanumeric keyboard and four

softkeys (software-assigned buttons)

1.) 90 ... 265 V AC, 45 ... 65 Hz or

2.) 24 V DC: 18 ... 36 V

24 V AC: -20%, +5%, 40 ... 440 Hz

For CH-200 depending on instrument version:

1.) 90 ... 265 V AC, 45 ... 65 Hz or

2.) 24 V DC: 18 ... 36 V, no reverse voltage protection

DynFAS MW

47

Page 48

Chapter 6 Technical Data

Power

consumption

Fuses For CS-100:

Battery type 3 V Lithium button cell, type CR2032

Measured value e.g. concentration, dry content

For CS-100:

max. 30 VA (AC/DC), depending on configuration

For CH-200:

max. (48/60) VA (AC/DC), depending on configu-

ration

2 x 2.0 A / slow-blow

For CH-200:

2 x 2.0 A / slow-blow for 90 … 265 V AC or

2 x 6.3 A / slow-blow for 24 V DC

Inputs and Outputs

Cable

cross-section

Cable

feed-through

Sensor connection

min. 1.0 mm² (mains supply)

2 x M20x1.5 for cable 5...14 mm (depending on

application)

4 x M16x1.5 for cable 5 ...8 mm

(depending on application)

Inputs and outputs for signal and

reference channel, 50 Ω N-socket

HF-cable

Current input 2 x current input 0/4 ...20 mA, ohmic resistance

Current output

Pt 100

connection

Cable lengths: 2, 4, 6 and 10 m; 50 Ω;

both sides with 4 N connectors

50 Ω, 1x insulated, 1x instrument ground

e.g. for temperature compensation

Current output 1: 4...20 mA, ohmic resistance

max. 800 Ω , insulated

current output 2: 0/4...20 mA, ohmic resistance

max. 800 Ω , insulated

e.g. for measured value or temperature output

Measuring range: -50 ... +200°C (223 ... 473 K);

measurement tolerance: < 0.4°C

48

DynFAS MW

Page 49

Chapter 6 Technical Data

Digital input 3 x digital inputs (DI1..3), for floating connectors

Configuration options:

DI1: none, measurement start/stop

DI2: none, measurement hold, product selection

DI3: none, sampling, product selection

Function description:

1. Measurement (Start/Stop)

open: measurement stopped

closed:

running

2. Hold measurement

open:

closed:

values and current output are held

3. Product selection

open:

closed:

with two DI’s: DI2 open & DI3 open

closed & DI3 open: P2, DI2 open & DI3 closed:

P3, DI2 closed &DI3 closed:

4. Start sampling

open:

closed: single measurement starts

measurement started or measurement

measurement running

measurement stopped, i.e. average

product 1 (P1)

P2;

no actions

: P1, DI2

P4

Relay outputs 2 x relays, insulated

Configuration options:

- Collective failure message

- Stop measurement

- Limit value (alarm min. and max.)

- No product

Load capacity:

AC: max. 400VA

DC: max. 90W

AC / DC: max. 250V, max. 2A, non-inductive

≥ 150V: voltage must be grounded

The cable and insulation that are to be connected

to these cables must correspond to a mains connection.

Restrictions for 24 V AC/DC mains supply, if the

ground conductor is not connected to terminal 1

(PE):

AC: max. 50 V

DC: max. 70 V

Serial interfaces

RS 232 on the underside of the instrument,

RS 485 through terminal block

Data type: 38400 baud, no handshake,

8 data bits, 1 stop bit, no parity

DynFAS MW

49

Page 50

Chapter 6 Technical Data

6.2 Technical Data Sensors

Flow Cells

Application Microwave flow cell with various nominal widths and

flanges for measurement on pipelines

Material Stainless steel, PTFE lining

Process coupling

Process pressure Up to 20 bar (relative), depending on nominal width

Flange according to DIN EN 1092 Type 05 and ASA

and flange type, see table below

Temperature range

Connections

Versions Nominal pipe widths from 50 ... 150 mm

Dimensions See dimensional drawings in chapter 8

Product temperature: +10 ... +130°C (283 … 403 K)

Ambient temperature: -20 ... +60°C (253 … 333 K)

Storage temperature: +10 ... +80°C (283 … 353 K)

2 x HF connections: N-socket, 50 Ω

for HF-cable with max. 10 m length

Overview Flow Cells

Designation ID-No. Nominal

width

Flange Pressure

[bar]

[mm]

FC-050-016 54943 50 DN 50 / PN 16 16

FC-065-040 54944 65 DN 65 / PN 40 20

FC-080-016 54945 80 DN 80 / PN 16 16

FC-100-016 54946 100 DN 100 / PN 16 16

FC-150-016 54941 150 DN 150 / PN 16 16

FC-020-150 54947 50 ASA 2’’ / 150 PSI 16

FC-025-300 54948 65 ASA 2.5’’ / 300 PSI 20

FC-030-150 54949 80 ASA 3’’ / 150 PSI 16

FC-040-150 54950 100 ASA 4” / 150 PSI 16

FC-060-150 54951 150 ASA 6’’ / 150 PSI 16

50

DynFAS MW

Page 51

Chapter 6 Technical Data

Probes

Application Probes with and without flushing

device for concentration measurement in

process containers and pipelines with nominal width

≥ 200 mm.

Material Plastic rod, stainless steel

PT100 connection cable: Silicon / Teflon

Process coupling Flange according to DIN EN 1092 Type 05 DN65 / PN6,

DN 80, 100, 150 / PN16;

ASA flange 2.5’’, 3’’ / 150 PSI

Process pressure Up to 16 bar (relative), depending on model

Temperature range Product temperature: +10 ... +120°C (283 … 393 K)

Ambient temperature: -20 ... +60°C (253 … 333 K)

Storage temperature: +10 ... +80°C (283 … 353 K)

Connections

Dimensions See dimensional drawings in chapter 8

4 x HF connections: N-socket, 50 Ω

for HF-cable with max. 10 m length

Accessory sealing washer

Material Klingersil C-4400

Thickness 3 mm

Overview Probes

Designation ID-No. Flange Pressure

[bar]

P-065-006 54939-01 DN 65 / PN 6 6

P-080-016 54939-02 DN 80 / PN 16 16

P-100-016 54939-03 DN 100 / PN 16 16

P-150-016 54939-04 DN 150 / PN 16 16

P-025-150 54939-05 ASA 2.5’’ / 150 PSI 16

P-030-150 54939-09 ASA 3’’ / 150 PSI 16

DynFAS MW

PF-065-006 54940-01 DN 65 / PN 6 6

PF-080-016 54940-02 DN 80 / PN 16 16

PF-100-016 54940-03 DN 100 / PN 16 16

PF-150-016 54940-04 DN 150 / PN 16 16

PF-025-150 54940-05 ASA 2.5’’ / 150 PSI 16

51

Page 52

Chapter 6 Technical Data

6.3 Technical Data HF-Cable

HF-Cable Quad

Material Corrugated tube: Polyamide (PA6)

Cable sheath: Polyethylene (PE)

Protection type IP 66

Temperature Operating temperature: -30 ... +70°C (243 … 343 K)

Installation temperature: -20 ... +70°C (253… 343 K)

Summary HF-Cable Quad, Cable lengths

Length [m] Id No.

2.0 54856

4.0 54857

6.0 54858

10.0 54859

52

DynFAS MW

Page 53

Chapter 6 Technical Data

6.4 Format of Serial Data Output RS 232 and RS 485

Header

Date·Time→Flags→Status→Product→Att→Phi→R2→Tint→IN1→IN2→Pt 100→C→Cm→C2→C2m¶

Following lines

01.01.2005·00:00:00→0000→0→1→0.43→5.30→0.07→0.0→0.0→0.0→0.0→75.36→75.00→0.00→0.00¶

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Column no. Description Format

1 Date and time DD.MM.YY·HH:MM:SS

2 Flags (for test purposes) 4 digits, HEX

3 Status: Information on quality of last

measurement

4 Product number X (1 to 4)

5 Attenuation [dB] X.XX

6 Phase [°/GHz] X.XX

7 Statistical spread of phase regression X.XX

8 Instrument temperature [temperature unit] X.X

9 Current input 1 [unit of current input] X.X

10 Current input 2 [unit of current input] X.X

11 Pt 100 temperature [temperature unit] X.X

[…] by selection of unit g/cm

12 Concentration 1 live X.XX [X.XXXX]

13 Concentration 1 averaged X.XX [X.XXXX]

14 Concentration 2 live X.XX [X.XXXX]

15 Concentration 2 averaged X.XX [X.XXXX]

0 : measurement OK

< 0 : error

3

Special characters

“→” Tabulation “¶” Carriage return + Line feed “·” Blank character

DynFAS MW

53

Page 54

Page 55

Chapter 7 Certificates

7.1 EC Declaration of Conformity

Chapter 7. Certificates

DynFAS MW

55

Page 56

Chapter 7 Certificates

56

DynFAS MW

Page 57

Chapter 7 Certificates

7.2 Frequency Approval

DynFAS MW

57

Page 58

Chapter 7 Certificates

58

DynFAS MW

Page 59

Chapter 7 Certificates

DynFAS MW

59

Page 60

Chapter 7 Certificates

60

DynFAS MW

Page 61

Chapter 7 Certificates

DynFAS MW

61

Page 62

Chapter 7 Certificates

62

DynFAS MW

Page 63

Chapter 8 Technical Drawings

Chapter 8. Technical Drawings

8.1 Dimensional Drawing of Control Unit Housing

8.1.1 Control Unit Standard CS-100

DynFAS MW

63

Page 64

Chapter 8 Technical Drawings

8.1.2 Control Unit High Dynamic CH-200

64

DynFAS MW

Page 65

Chapter 8 Technical Drawings

8.2 Electrical Wiring Diagram

Line in for CS-100:

1. / 2. depending on instrument version

1.

AC 90-265V, 45-65 Hz

2.

DC 24 V (18-36 V) or

AC 24 V -20% / +5%, 40-440 Hz

________________________________

Line in for CH-200:

1. / 2. depending on instrument version

1.

AC 90-265V, 45-65 Hz

2.

DC 24 V (18-36 V), no reverse voltage

protection

DynFAS MW

65

Page 66

Chapter 8 Technical Drawings

8.3 Dimensional Drawings Flow Cells

8.3.1 Type FC-050-016

66

DynFAS MW

Page 67

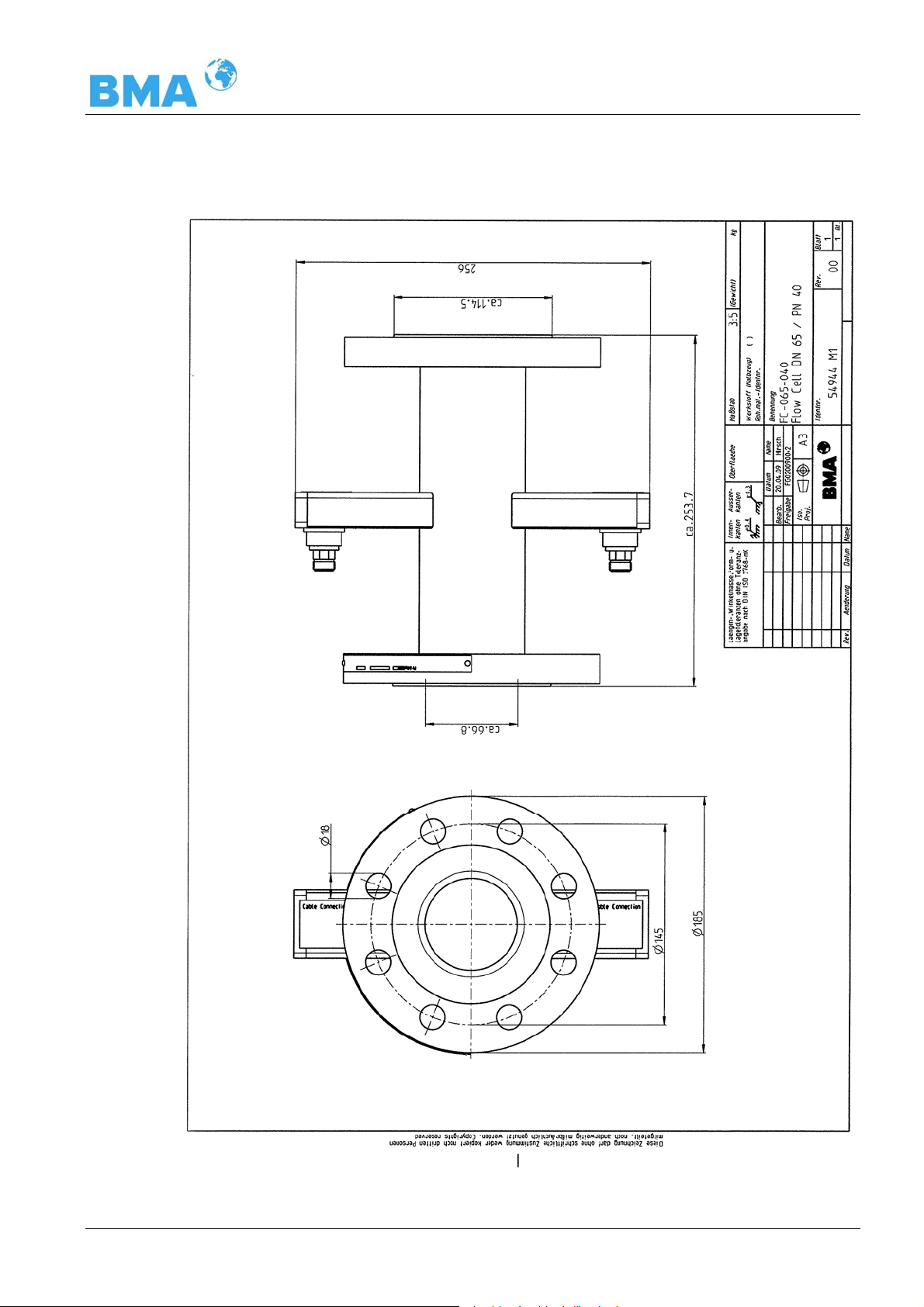

Chapter 8 Technical Drawings

8.3.2 Type FC-065-040

DynFAS MW

67

Page 68

Chapter 8 Technical Drawings

8.3.3 Type FC-080-016

68

DynFAS MW

Page 69

Chapter 8 Technical Drawings

8.3.4 Type FC-100-016

DynFAS MW

69

Page 70

Chapter 8 Technical Drawings

8.3.5 Type FC-150-016

70

DynFAS MW

Page 71

Chapter 8 Technical Drawings

8.3.6 Type FC-020-150

DynFAS MW

71

Page 72

Chapter 8 Technical Drawings

8.3.7 Type FC-025-300

72

DynFAS MW

Page 73

Chapter 8 Technical Drawings

8.3.8 Type FC-030-150

DynFAS MW

73

Page 74

Chapter 8 Technical Drawings

8.3.9 Type FC-040-150

74

DynFAS MW

Page 75

Chapter 8 Technical Drawings

8.3.10 Type FC-060-150

DynFAS MW

75

Page 76

Chapter 8 Technical Drawings

8.4 Dimensional Drawings Probes

8.4.1 Type P-065-006

76

DynFAS MW

Page 77

Chapter 8 Technical Drawings

8.4.2 Type P-080-016

DynFAS MW

77

Page 78

Chapter 8 Technical Drawings

8.4.3 Type P-100-016

78

DynFAS MW

Page 79

Chapter 8 Technical Drawings

8.4.4 Type P-150-016

DynFAS MW

79

Page 80

Chapter 8 Technical Drawings

8.4.5 Type P-025-150

80

DynFAS MW

Page 81

Chapter 8 Technical Drawings

8.4.6 Type P-030-150

ll

DynFAS MW

81

Page 82

Chapter 8 Technical Drawings

8.4.7 Installation Situation in Pipelines

82

DynFAS MW

Page 83

Chapter 8 Technical Drawings

8.5 Dimensional Drawings Flush Probes

8.5.1 Type PF-065-006

DynFAS MW

83

Page 84

Chapter 8 Technical Drawings

8.5.2 Type PF-080-016

84

DynFAS MW

Page 85

Chapter 8 Technical Drawings

8.5.3 Type PF-100-016

DynFAS MW

85

Page 86

Chapter 8 Technical Drawings

8.5.4 Type PF-150-016

86

DynFAS MW

Page 87

Chapter 8 Technical Drawings

8.5.5 Type PF-025-150

DynFAS MW

87

Page 88

Chapter 8 Technical Drawings

8.5.6 Installation Situation in Pipelines

88

DynFAS MW

Page 89

Chapter 8 Technical Drawings

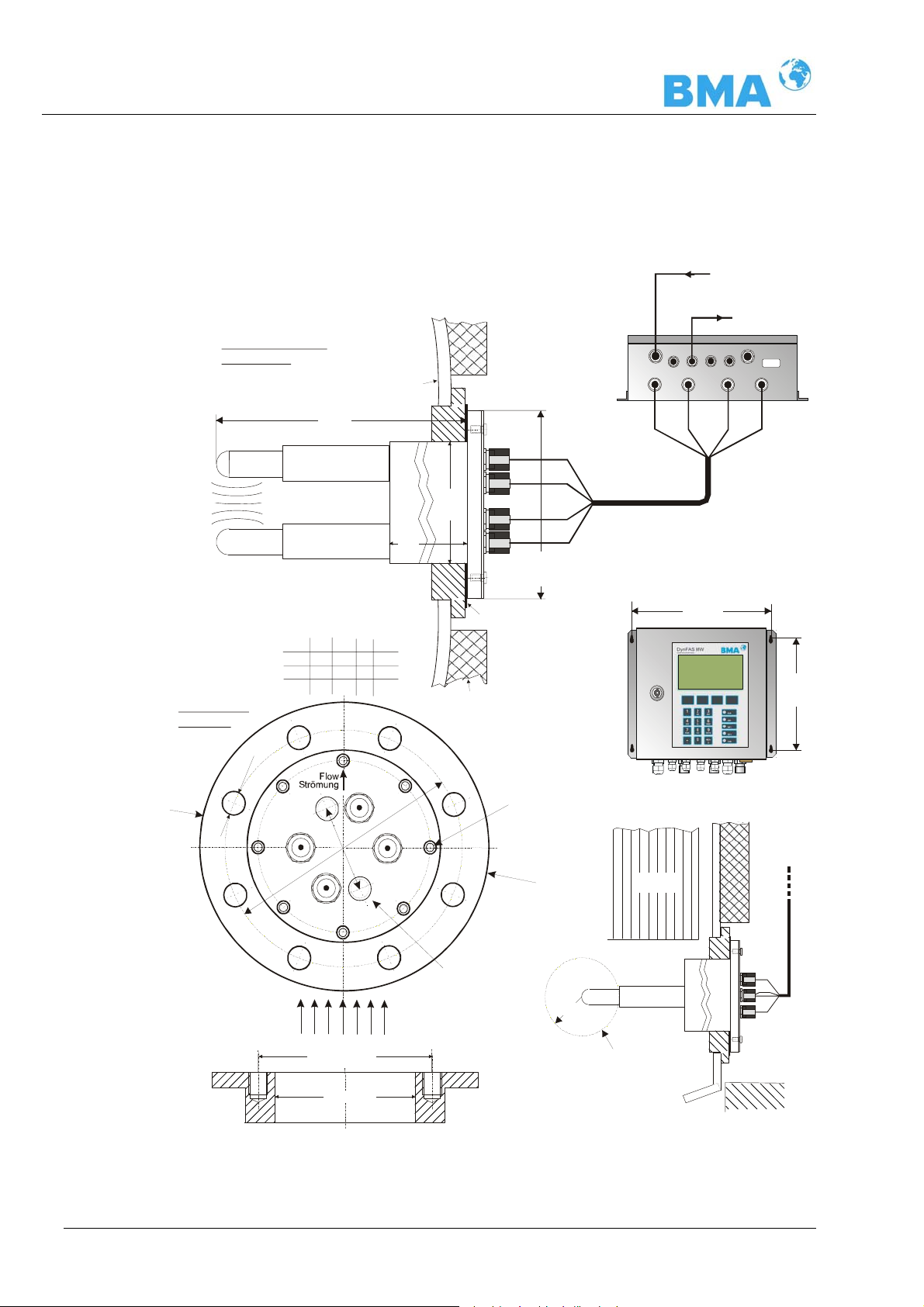

8.6 Installation Sheets for DynFAS MW (Probe)

DynF AS MW with Probe

- Installa t ion In Cryst a llizer -

top view into the

crystallizer

evaluation unit

botten side

M-Rx

M-Tx

90 - 265 V AC

or 24 V AC/DC

(24 V DC)

output

0/4 - 20 mA

R-Tx

R-Rx

microwave

measuring field

probe flange DN65 / PN6

14

installation

position

ø

M-Rx

ø

1

30

R-Rx

190

PT100

container wall

Flow

Strömung

R-Tx

M-Tx

60

100

ø

insulation

ø

1

M-Tx

R-Tx

R-Rx

M-Rx

sealing

do not remove!

PT100

6

0

M-Rx

PT100

HF cable quad

M-Tx

R-Rx

R-Tx

Control Unit

160

ø

(...) for CH-200

heating

300

(318)

220

(320)

DynFAS MW

fitting flange

ø

130 / 4 x M12

±

ø

100

current stream

0.2

0

6

area without

metalic

installations

89

Page 90

Chapter 8 Technical Drawings

DynFAS MW with Probe

- Installa tion In C rystallizer -

top view into the

crystallizer

microwave

measuring field

probe flange DN80, 100, 15 0 / PN16

installation

position

DN

80

100

150

container wall

190

PT100

ABC

160

200

18 M16

180 220

18 M16

240

28522M20

60

S

100

ø

sealing

insulation

evaluation unit

botten side

M-Tx

R-Tx

R-Rx

M-Rx

B

ø

M-Rx

M-Rx

PT100

HF cable quad

Control Unit

(...) for CH-200

M-Tx

M-Tx

300

(318)

90 - 265 V AC

or 24 V AC/DC

(24 V DC)

output

0/4 - 20 mA

R-Tx

R-Rx

R-Rx

R-Tx

220

(320)

C

ø

fitting flange

M-Rx

A

ø

R-Rx

ø

R-Tx

A / 8 x S

±

ø

102

M-Tx

current stream

0,5

do not remove!

ø

B

PT100

0

6

area without

metalic

installations

heating

90

DynFAS MW

Page 91

Chapter 8 Technical Drawings

8.7 Installation Sheets for DynFAS MW (Flush Probe)

DynFAS MW with Pro be with Flus hi ng

- Installation In Crystallizer -

top view into the

crystallizer

evaluation unit

botten side

M-Rx

M-Tx

90 - 265 V AC

or 24 V AC/DC

(24 V DC)

output

0/4 - 20 mA

R-Tx

R-Rx

microwave

measuring field

320

container wall

160

M-Tx

R-Tx

100

ø

sealing

R-Rx

M-Rx

160

ø

HF cable quad

M-Tx

M-Rx

Control Unit

(...) for CH-200

300

(318)

R-Rx

R-Tx

probe flange DN65 / PN6

insulation

220

(320)

installation

position

ø

M-Rx

ø

R-Tx

M-Tx

5

5

0

3

1

R-Rx

Flow

14

Strömung

current stream

fitting flange

ø

130 / 4 x M12

±

0,2

ø

100

do not remove!

flushing connection:

intern a l th r e a d

2 x G3/8’’

(DIN ISO 228-1 )

ø

160

heating

60

area without

metalic

installations

DynFAS MW

91

Page 92

Chapter 8 Technical Drawings

DynFAS MW with Probe with Flushing

- Installation In Crystallizer -

top view into the

crystallizer

microwave

measuring field

container wall

320

100

160

ø

evaluation uni t

M-Tx

R-Tx

R-Rx

M-Rx

B

ø

probe fl ange DN80, 100, 150 / PN16

DN

installation

position

100

150

80

ABC

160

180 220

240

285 22 M20

200

S

18 M16

18 M16

sealing

insulation

botten side

HF cable quad

M-Rx

M-Tx

M-Tx

M-Rx

Control Unit

(...) for CH-200

300

(318)

90 - 265 V AC

or 24 V AC/DC

(24 V DC)

output

0/4 - 20 mA

R-Tx

R-Rx

R-Rx

R-Tx

220

(320)

C

ø

fitting flange

ø

M-Rx

A

R-Rx

ø

A / 8 x S

ø

102

R-Tx

5

5

±

0,5

M-Tx

current stream

do not remove!

ø

B

flushing connection:

inte rn a l th read

2 x G3/8’’

(DIN ISO 228-1)

heating

60

area without

metalic

installations

92

DynFAS MW

Page 93

Index

A

accuracy · 47

adapter flange · 34

Index

foodstuffs · 24

Frequency Approval · 13, 57

Fuse Replacement · 46

G

B

Battery · 46

bending radius · 28

C

Calculation of Measured Values · 17

CE symbol · 13

Certificates · 55

Components · 19

Connecting the Container Probes · 38

Connecting the Flow Cell · 37

Container Probe · 24

Container Probe Installation · 34

Control unit Housing · 63

Control Units · 20

cooling crystallizers · 18

D

Data format RS232 · 53

Data format RS485 · 53

Data transfer rate · 43

Digital Outputs · 44

Dimensional Drawings Flow Cells · 66

Dimensional Drawings Flush Probes · 83

Dimensional Drawings Probes · 76

distance rail · 36

gas bubbles · 14, 33

H

High-Frequency Cable · 2 8

I

Installation in Pipelines · 34

Installation Sheets · 89

Installation Situation in Pipelines · 82, 88

Instrument Cleaning · 45

L

LED’s · 22

M

Measurement Configuration · 30, 31

Microwaves · 15

O

Overview Flow Cells · 50

Overview Probes · 51

P

E

EC Declaration of Conformity · 55

Electrical Wiring Diagram · 65

F

Factory setting · 15

fitting flange · 34

Flow Cell · 23

Flow Cell Installation · 32

Flush Parameters · 35

flush probe · 26

DynFAS MW

Principle of Measurement · 16

Pt 100 connection · 40

R

Reference temperature · 18

Relays · 44

riser · 32

RS232 interface · 43

93

Page 94

Index

S

safety instructions · 7

salt content · 14

Softkeys · 15

symbols · 7

T

Technical Data · 47

Technical Data HF-Cable · 52

Technical Data Sensors · 50

Technical Drawings · 63

Temperature Compensation · 18

Transmission power · 47

Transport · 32

W

Wearing Parts · 45

94

DynFAS MW

Page 95

Notes

DynFAS MW

95

Page 96

Notes

96

DynFAS MW

Page 97