Page 1

TC60 | TC61 | TC62 | TC63-10 | TC63-30 | TC64-10

Touch probe TC Series – A3

Workpiece Measurement

Radio Transmission

shark360 Technology

Wear-free Measuring Mechanism

Single- & Mass Production

Axes Compensation

Operating instructions English

Type P03.6000-010 | P03.6100-020 |

P03.6200-010 | P03.6300-010 |

P03.6300-030 | P03.6400-010

All manuals and user guides at all-guides.com

all-guides.com

Page 2

All manuals and user guides at all-guides.com

Page 3

by Blum-Novotest 2012 3

TC60

TC61

TC62

TC63-10 /

TC76

TC63-30 /

TC76

TC64-10

X X X X X X

Workpiece Measurement

X

Tool Measurement

X X X X X X

Radio Transmission

X X X

shark360 Technology

X

X

Multidirectional

X X

Modular System

X X X X X X

Wear-free Measuring Mechanism

X X X X X X

Single & Mass Production

X X X X

Pulling Measurement

X X X X X X

Axes Compensation

X X

Contour Measurement

X

Tool Length Measurement

X

Tool Radius Measurement

X

Tool Breakage Detection

All manuals and user guides at all-guides.com

Page 4

4 by Blum-Novotest 2012

Content

1. Safety rules .......................................................................................... 5

2. System overview .................................................................................. 6

2.1 Description ..................................................................................................................... 6

2.2 Display elements ............................................................................................................ 6

2.3 Tool holder ..................................................................................................................... 8

2.4 Technical data .............................................................................................................. 10

2.5 Complete system .......................................................................................................... 14

3. Mounting and commissioning ............................................................ 15

3.1 Insert / change battery ................................................................................................. 15

3.2 Mounting of the tool holder ......................................................................................... 17

3.3 Mounting of the TC76-T ............................................................................................... 19

3.4 Mounting of the stylus ................................................................................................. 20

3.5 Cranked styli (TC63-30/TC64-10/TC76) ........................................................................ 22

3.6 Display of the basic adjustments .................................................................................. 23

3.7 Programming of the basic adjustments........................................................................ 25

3.8 System coding .............................................................................................................. 28

3.9 Probe pairing ................................................................................................................ 28

3.10 Switch-on probe (via radio receiver) .......................................................................... 28

4. Notes concerning measuring sequence ............................................... 29

5. Maintenance ..................................................................................... 29

5.1 Cleaning of the transparent ring .................................................................................. 29

5.2 Exchange of external bellows (TC60 / TC61 / TC63(TC76) / TC64 only) ....................... 30

6. Trouble shooting ................................................................................ 32

7. Order numbers .................................................................................. 34

8. Shipping instructions / storage ........................................................... 37

9. Radio approval................................................................................... 38

P03.6000-000.012S

306000012S_EN.docx

07.08.2012 version: V1B

Original operating instructions

Subject to technical change without any notice

All manuals and user guides at all-guides.com

Page 5

Safety rules

by Blum-Novotest 2012 5

Keys

CAUTION

Important advice for appliance protection

Advice to secondary literature

Additional advice

LED shines

LED flashes

Green Red Blue Orange Violet

Abbreviations:

BTH Blum Tool Holder

M

d

Tightening Torque

LF: Low Force

1. Safety rules

CAUTION

Important advice for appliance protection:

• Handle probe like a precision tool.

• Keep the probe clean.

• Mount the probe in assigned tool holders only.

• Battery: Please insert before operating!

• Protect the probe by using programmed maximum travel.

• Ensure that adequate safety regulations as well as safety interlockings

are kept.

• Damaged styli are not reusable.

GN

GN

GN

VT

OG

BU

RD

All manuals and user guides at all-guides.com

Page 6

System overview

6 by Blum-Novotest 2012

2. System overview

2.1 Description

Fig. 2.1

(1) Shaft for tool holder BTH

(2)

Centering screws

(3) Battery cover

(4)

Colour coding

(5)

Battery

(6a) Hall sensor MODE

(6b)

Hall sensor SET

(7)

LED Status 3 x 120° = 360°

(8) Measuring mechanism

(9)

Stylus

(10)

Pin hole

see chap.3.8

2.2 Display elements

Colour LED Status (7)

Standby

Stylus initial position

Stylus deflected

Stylus initial position - battery low

Stylus deflected - battery low

Battery low

Fig. 2.2

GN

GN

GN

GN

GN

BU

GN

BU

RD

RD

RD

RD

RD

BU

BU

RD

RD

All manuals and user guides at all-guides.com

all-guides.com

Page 7

System overview

by Blum-Novotest 2012 7

Fig. 2.3

* trigger point TC61: see data sheet

Ø28

Ø63

TC60

TC62 TC63-10

TC64-10

TC63-30

Z

X/Y

Z

X/Y

Z

X/Y

Z

X/Y

10

100

L

15°

24

L

Ø13

Ø28

Ø63

24

113

Ø40

14,1

62

L

6

5

Ø13

Ø40

Ø25

Ø25

14,1

53

TC76-T

TC63-10

TC76-T

T

C63-30

L

L

5

93

11° (TC62)

9°(TC62 T)

Z

X/Y

5

Ø13

Ø40

Ø25

14,1

L

68

15°

15°

15°

TC61

Z+

Z-

X

Ø28

Ø63

24

110

L

24,5

15°

0,4°*

0,80,8

63

All manuals and user guides at all-guides.com

Page 8

System overview

8 by Blum-Novotest 2012

2.3 Tool holder

Type L Order number L Order number

System BTH 50

(TC60/61/63-30)

System BTH 25

(TC62/63-10/64-10)

HSK-A 32 35 P03.8000-036.132A

HSK-A 40 57 P03.8000-035.140A 35 P03.8000-036.140A

HSK-A 50 63 P03.8000-035.150A 42 P03.8000-036.150A

HSK-A 63 50 P03.8000-035.163A 42 P03.8000-036.163A

HSK-A 80 55 P03.8000-035.180A

HSK-A 100 60 P03.8000-035.100A

HSK-E 25 32,5 P03.8000-036.125E

HSK-E 32 35 P03.8000-036.132E

HSK-E 40 57 P03.8000-035.140E 35 P03.8000-036.140E

HSK-E 50 63 P03.8000-035.150E 42 P03.8000-036.150E

HSK-E 63 50 P03.8000-035.163E 42 P03.8000-036.163E

SK 30 56 P03.8000-035.230 20 P03.8000-036.230

SK 40 46 P03.8000-035.240 24 P03.8000-036.240

SK 50 24 P03.8000-035.250

MAS-BT 30 46 P03.8000-035.330 24 P03.8000-036.330

MAS-BT 40 50 P03.8000-035.340 28 P03.8000-036.340

MAS-BT 50 40 P03.8000-035.350

Tab. 2.1

L

All manuals and user guides at all-guides.com

Page 9

System overview

by Blum-Novotest 2012 9

CAUTION

Coolant

Pls. use coolant pipe for tool holder HSK for machining centers with

internal coolant supply.

Type System BTH 25 / 50

HSK 25 P03.8000-035.125K

HSK 32 P03.8000-035.132K

HSK 40 P03.8000-035.140K

HSK 50 P03.8000-035.150K

HSK 63 P03.8000-035.163K

HSK 80 P03.8000-035.180K

HSK 100 P03.8000-035.100K

Tab. 2.2

All manuals and user guides at all-guides.com

Page 10

System overview

10 by Blum-Novotest 2012

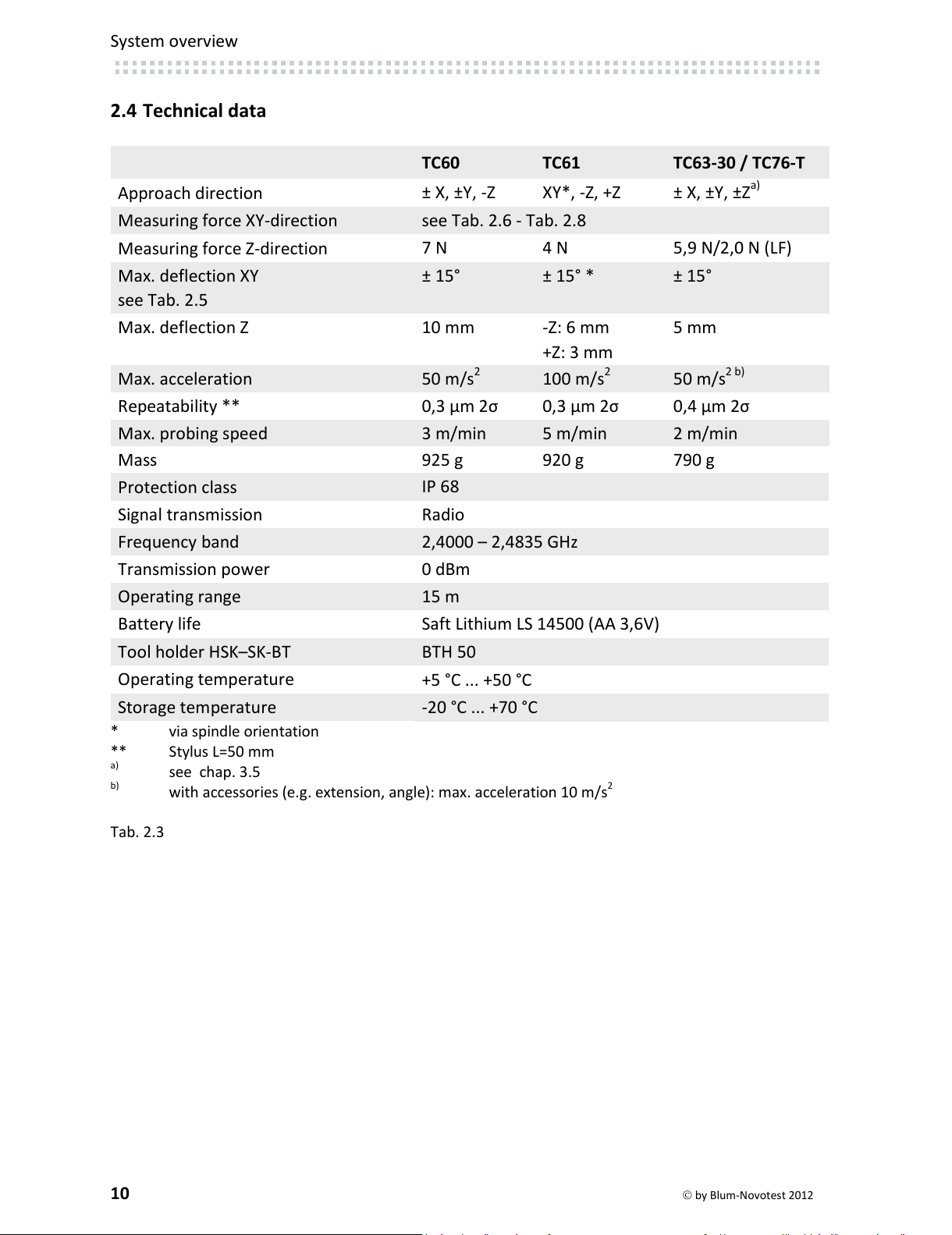

2.4 Technical data

TC60 TC61 TC63-30 / TC76-T

Approach direction

± X, ±Y, -Z XY*, -Z, +Z

± X, ±Y, ±Za)

Measuring force XY-direction

see Tab. 2.6 - Tab. 2.8

Measuring force Z-direction

7 N 4 N 5,9 N/2,0 N (LF)

Max. deflection XY

see Tab. 2.5

± 15° ± 15° * ± 15°

Max. deflection Z 10 mm -Z: 6 mm

+Z: 3 mm

5 mm

Max. acceleration

50 m/s2

100 m/s2

50 m/s

2 b)

Repeatability **

0,3 µm 2σ

0,3 µm 2σ

0,4 µm 2σ

Max. probing speed

3 m/min

5 m/min

2 m/min

Mass

925 g

920 g

790 g

Protection class

IP 68

Signal transmission

Radio

Frequency band 2,4000 – 2,4835 GHz

Transmission power

0 dBm

Operating range

15 m

Battery life

Saft Lithium LS 14500 (AA 3,6V)

Tool holder HSK–SK-BT

BTH 50

Operating temperature

+5 °C ... +50 °C

Storage temperature

-20 °C ... +70 °C

* via spindle orientation

** Stylus L=50 mm

a)

see chap. 3.5

b)

with accessories (e.g. extension, angle): max. acceleration 10 m/s

2

Tab. 2.3

All manuals and user guides at all-guides.com

Page 11

System overview

by Blum-Novotest 2012 11

TC62

TC63-10 /

TC76-T

TC64-10

Approach direction

± X, ±Y, -Z

± X, ±Y, ±Z

a)

± X, ±Y, ±Za)

Measuring force XY-

direction

see Tab. 2.6 - Tab. 2.8

Measuring force Z-

direction

5,7 N

1,6 N (LF)

10 N (TC62 T)

5,9 N

2,0 N (LF)

5,9 N

2,0 N (LF)

10,6 N (TC64-10 T)

Max. deflection XY

see Tab. 2.5

± 11°

± 9° (TC62 T)

± 15° ± 15°

Max. deflection Z 6 mm

3,5 mm (TC62 T)

5 mm 5 mm

Max. acceleration 50 m/s

2

200 m/s2 (TC62 T)

50 m/s

2 b)

50 m/s2

200 m/s2 (TC64-10 T)

Repeatability* 0,3 µm 2σ (Standard)

Z: 0,2 µm 2σ (LF)

XY: 0,3 µm 2σ (LF)

0,4 µm 2σ 0,4 µm 2σ

Max. probing speed 2 m/min 2 m/min 2 m/min

Mass 250 g

225 g

(TC63-10)

230 g

Protection class

IP 68

Signal transmission

Radio

Frequency band 2,4000 – 2,4835 GHz

Transmission power 0 dBm

Operating range

5 m

Battery life

Saft Lithium LS 14250 (½ AA 3,6V)

Tool holder HSK–SK-BT

BTH 25

Operating temperature

+5 °C ... +50 °C

Storage temperature

-20 °C ... +70 °C

* stylus L=30 mm

a)

see chap. 3.5

b)

with accessories (e.g. extension, angle): max. acceleration 10 m/s2

Tab. 2.4

All manuals and user guides at all-guides.com

all-guides.com

Page 12

System overview

12 by Blum-Novotest 2012

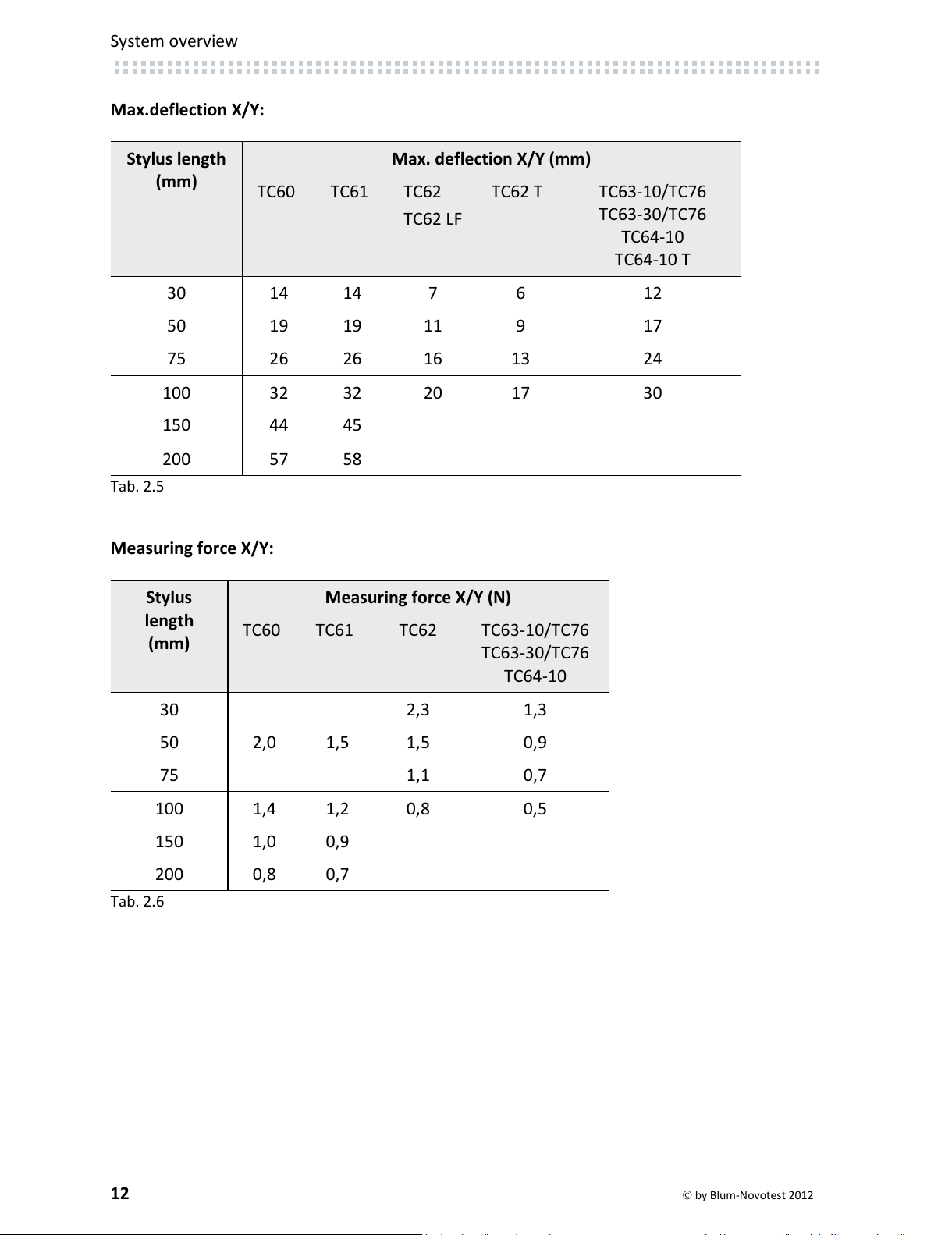

Max.deflection X/Y:

Stylus length

(mm)

Max. deflection X/Y (mm)

TC60 TC61 TC62

TC62 LF

TC62 T TC63-10/TC76

TC63-30/TC76

TC64-10

TC64-10 T

30 14 14 7 6 12

50 19 19 11 9 17

75 26 26 16 13 24

100 32 32 20 17 30

150 44 45

200 57 58

Tab. 2.5

Measuring force X/Y:

Stylus

length

(mm)

Measuring force X/Y (N)

TC60 TC61 TC62 TC63-10/TC76

TC63-30/TC76

TC64-10

30 2,3 1,3

50 2,0 1,5 1,5 0,9

75 1,1 0,7

100 1,4 1,2 0,8 0,5

150 1,0 0,9

200 0,8 0,7

Tab. 2.6

All manuals and user guides at all-guides.com

Page 13

System overview

by Blum-Novotest 2012 13

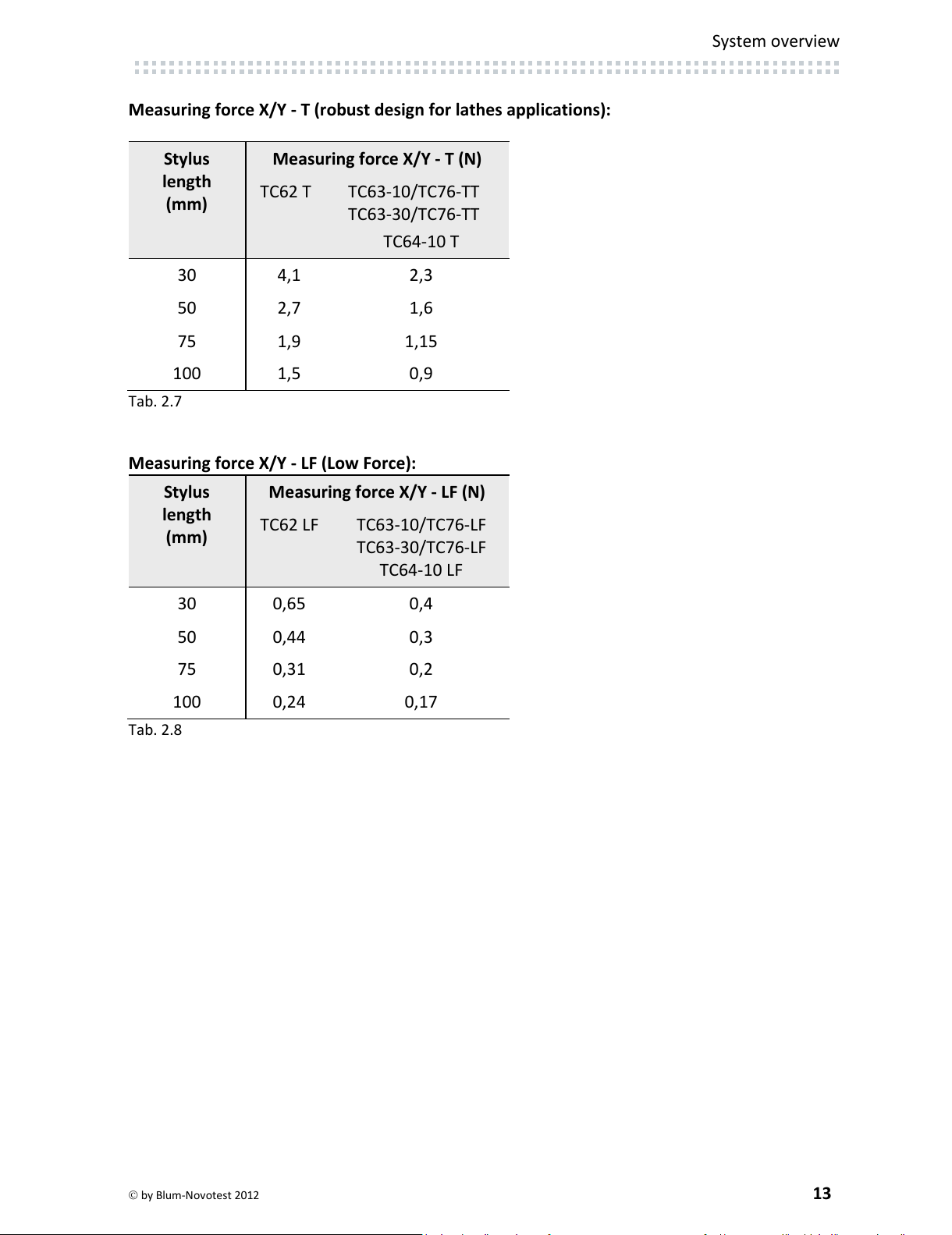

Measuring force X/Y - T (robust design for lathes applications):

Stylus

length

(mm)

Measuring force X/Y - T (N)

TC62 T TC63-10/TC76-TT

TC63-30/TC76-TT

TC64-10 T

30 4,1 2,3

50 2,7 1,6

75 1,9 1,15

100 1,5 0,9

Tab. 2.7

Measuring force X/Y - LF (Low Force):

Stylus

length

(mm)

Measuring force X/Y - LF (N)

TC62 LF TC63-10/TC76-LF

TC63-30/TC76-LF

TC64-10 LF

30 0,65 0,4

50 0,44 0,3

75 0,31 0,2

100 0,24 0,17

Tab. 2.8

All manuals and user guides at all-guides.com

Page 14

System overview

14 by Blum-Novotest 2012

2.5 Complete system

Fig. 2.4

RC66:

⇒ switch ON/OFF via radio signal

⇒ signal transmission for TC series

Installation instructions RC66 (P03.6600-000.011)

Installation instructions IF59-A2 (P03.5900-000.011)

RC66

TC60/61/62/ 63

IF59 - A2

TC63 / TC64

Z-Nano RC

Z-Nano

Aux

All manuals and user guides at all-guides.com

Page 15

Mounting and commissioning

by Blum-Novotest 2012 15

3. Mounting and commissioning

3.1 Insert / change battery

Recommended battery type

TC60/TC61/TC63-30 TC62/TC63-10/TC64-10

Type Saft Lithium LS14500 (AA 3,6V) Saft Lithium LS14250 (½ AA 3,6V)

mAh 2600 1200

Contin.

operation

approx. 150 h approx. 78 h

5% Use approx. 270 days approx. 60 days

Standby approx. 1000 days approx. 700 days

Order number 980702010 980702004

Further recommendations:

TC60/TC61/TC63-30 mAh

TC62/TC63-10/TC64-10 mAh

Xeno XL-060F 2400

Tadiran TL-4902 1200

Vitzrocell SB-AA11 2500 XENO XL-050F 1200

Tadiran SL-360 2400 OmniCel ER-14250 1200

Vitzrocell SB-AA02 1200

Dispose batteries acc. to legal requirements.

CAUTION

Destruction of the measuring system

Be careful to correct position of gasket.

Keep battery space absolutely clean and dry.

Grease gasket surface of the cover slightly before insert.

All manuals and user guides at all-guides.com

Page 16

Mounting and commissioning

16 by Blum-Novotest 2012

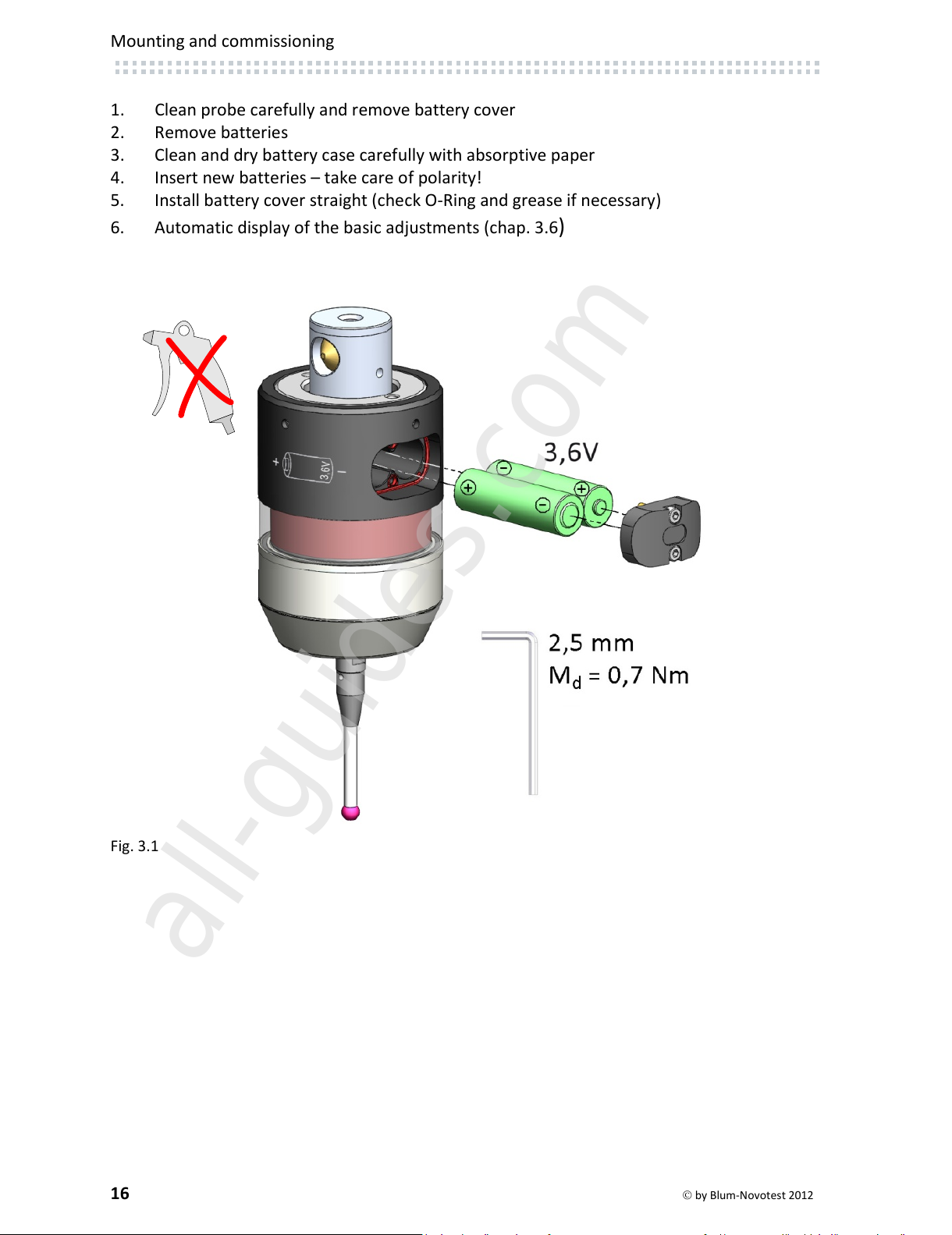

1. Clean probe carefully and remove battery cover

2. Remove batteries

3. Clean and dry battery case carefully with absorptive paper

4. Insert new batteries – take care of polarity!

5. Install battery cover straight (check O-Ring and grease if necessary)

6. Automatic display of the basic adjustments (chap. 3.6

)

Fig. 3.1

All manuals and user guides at all-guides.com

all-guides.com

Page 17

Mounting and commissioning

by Blum-Novotest 2012 17

3.2 Mounting of the tool holder

CAUTION

Destruction of the measuring system

The probe is not allowed to be twisted for mounting of the tool holder.

Holding screw (A) must be aligned with the centering screws.

If the measuring system is in the working area we recommend visual contact to the

receiver.

1. Insert probe into tool holder (System BTH 50 resp. BTH 25)

2. Tighten screw (A) slightly only

3. Mount stylus (see chap. 3.4)

Adjustment of the run-out at TC61 with optical presetter!

4. Insert probe into spindle (TC60 / TC62 / TC63 / TC64 only)

5. Turn probe by 360°

6. Observe display of run-out – stylus is not allowed to be deflected.

7. Adjust concentricity (4 internal hexagon screws 2 mm)

e.g. X-direction (fig. 3.4):

Release centering screws (1) and (3) slightly only.

Alignment by reciprocal release and tightening of centering screws (2) and (4).

Y-direction (fig. 3.5):

Release centering screws (2) and (4) slightly only.

Alignment by reciprocal release and tightening of centering screws (1) and (3).

Run-Out TC60 / TC62 / TC63 / TC64: < 10 µm

Run-Out TC61: < 100 µm

8. Tighten holding screw (A)

Concentricity adjustment is fixed now.

9. Check concentricity.

10. Carry out calibration cycle

All manuals and user guides at all-guides.com

Page 18

Mounting and commissioning

18 by Blum-Novotest 2012

Fig. 3.2

All manuals and user guides at all-guides.com

Page 19

Mounting and commissioning

by Blum-Novotest 2012 19

3.3 Mounting of the TC76-T

TC63-10/TC63-30:

M

d

= 10 Nm

Fig. 3.3

(C) hook wrench (scope of delivery)

Mounting of the extension / angle: see referring data sheet

All manuals and user guides at all-guides.com

Page 20

Mounting and commissioning

20 by Blum-Novotest 2012

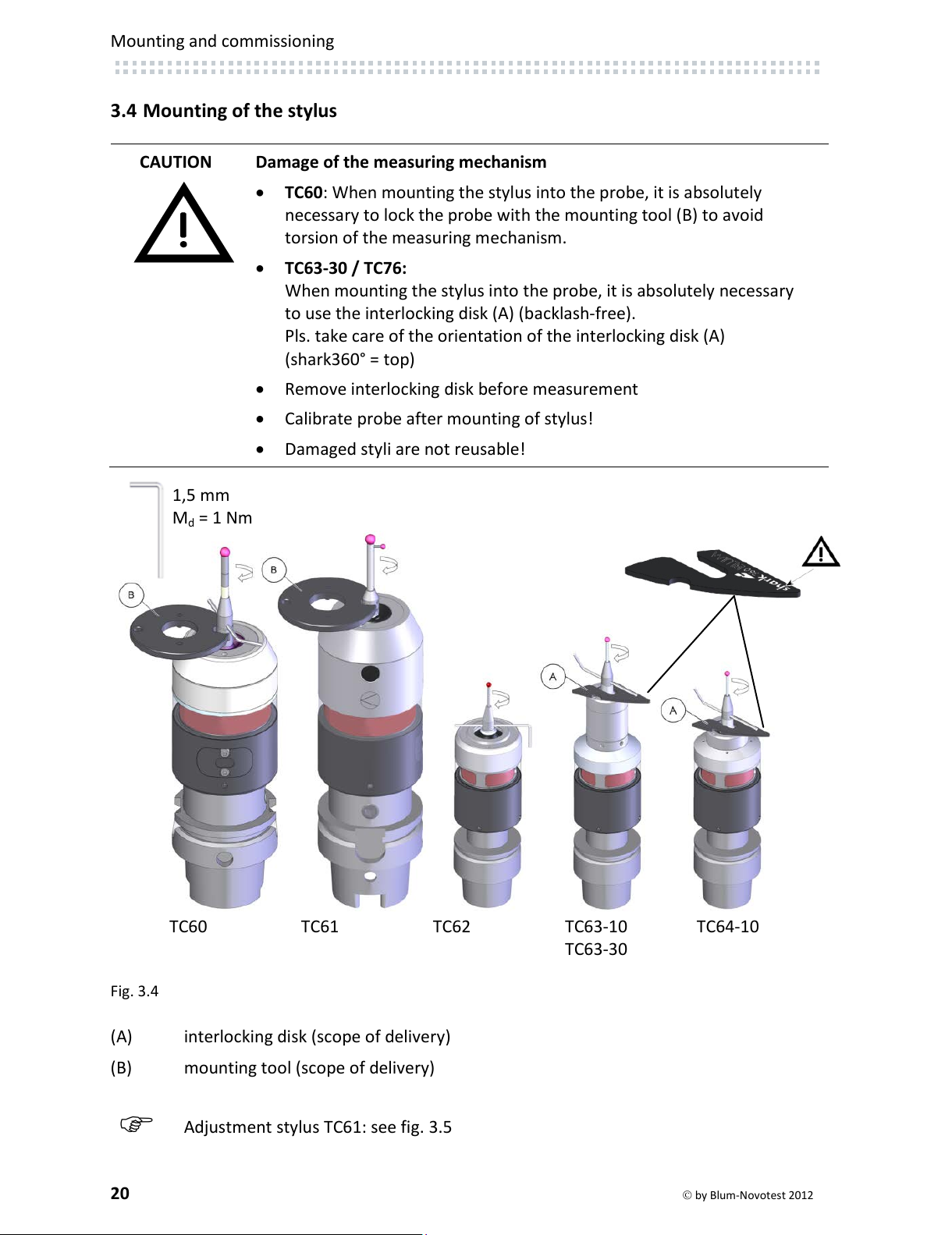

3.4 Mounting of the stylus

CAUTION

Damage of the measuring mechanism

• TC60: When mounting the stylus into the probe, it is absolutely

necessary to lock the probe with the mounting tool (B) to avoid

torsion of the measuring mechanism.

• TC63-30 / TC76:

When mounting the stylus into the probe, it is absolutely necessary

to use the interlocking disk (A) (backlash-free).

Pls. take care of the orientation of the interlocking disk (A)

(shark360° = top)

• Remove interlocking disk before measurement

• Calibrate probe after mounting of stylus!

• Damaged styli are not reusable!

TC60

TC61

TC62

TC63-10

TC63-30

TC64-10

Fig. 3.4

(A) interlocking disk (scope of delivery)

(B) mounting tool (scope of delivery)

Adjustment stylus TC61: see fig. 3.5

1,5 mm

Md = 1 Nm

All manuals and user guides at all-guides.com

Page 21

Mounting and commissioning

by Blum-Novotest 2012 21

Adjustment stylus TC61:

Fig. 3.5

DIN913 M3 x 3 (4x)

Md ~ 0,5 Nm

All manuals and user guides at all-guides.com

all-guides.com

Page 22

Mounting and commissioning

22 by Blum-Novotest 2012

3.5 Cranked styli (TC63-30/TC64-10/TC76)

CAUTION

Damage of the measuring mechanism

Pay attention to area of operation and max. overtravel

Fig. 3.6

Z+measurement: area of operation: C measurement: area of operation:

area of operation

Z+ measurement: max. overtravel:

S

overtravel

Fig. 3.7

X

y

Z

Z+

C

R

P

0

10

20

30

40

50

20 30 40 50 60 70 80 90 100

P [mm]

R

[mm]

0

10

20

30

40

50

16,5 50

R

[mm]

P [mm]

0,0

1,0

2,0

3,0

4,0

5,0

6,0

7,0

15 20 25 30 35 40 45 50 55 60 65 70

[mm]

P [mm]

R22

R30

R40

S

All manuals and user guides at all-guides.com

Page 23

Mounting and commissioning

by Blum-Novotest 2012 23

3.6 Display of the basic adjustments

The probe can be set up for different applications.

After insert of the batteries, the display of the basic adjustments is started. The magnetic pin

is not necessary.

1. Remove batteries

2. Wait for 30 sec.

3. Insert batteries again (pls. observe pole position), put on cover of battery box.

The LED Status starts flashing. The basic adjustments are displayed. (display phase)

4. After the display is finished, the probe goes into standby mode.

(7) LED Status

Fig. 3.8

If the LED Status (7) is flashing red or shining red, pls. check the batteries.

See chapt. 6, Trouble shooting.

All manuals and user guides at all-guides.com

Page 24

Mounting and commissioning

24 by Blum-Novotest 2012

MODE SET

Transmission mode

Normal*

(3x MODE – SET)

Robust

Fast

Switch-on time

Fast

(3x MODE – SET)

Normal*

Slow

Probe type

Standard*

EcoMode

TWIN A

TWIN B

Battery capacity

O.K.

(3x MODE – SET)

low

Standby

* Standard

RD

GN

BU

BU

RD

OG

GN

GN

RD

GN

BU

OG

BU

RD

GN

RD

All manuals and user guides at all-guides.com

Page 25

Mounting and commissioning

by Blum-Novotest 2012 25

3.7 Programming of the basic adjustments

In this mode the basic adjustments can be adjusted. The magnetic pin is required for

programming.

The position of the elements on the transparent ring may differ, see chapter 2.1.

CAUTION

Risk of collision

If adjustments on the probe have been changed, the probe must be

paired again.

Probe pairing: see installation instructions IF59-A2 (P03.5900-000.011)

1. Remove batteries

2. Wait for 30 sec.

3. Insert batteries again (pls. observe pole position), put on cover of battery box.

The LED Status starts flashing. The basic adjustments are displayed. (display phase)

4. Change into programming mode during the display phase:

Hold magnetic pin on label „MODE“ until the LED Status is changing from green to violet.

5. Change adjustments (SET)

Hold magnetic pin on label „SET“

6. Menu change (MODE)

Hold magnetic pin on label „MODE“

The LED Status (7) is shortly flashing violet to confirm the menu change

7. After the last menu the basic adjustments are repeated (3x MODE-SET). During the display

phase it can be changed again into the programming mode.

(7) LED Status

All manuals and user guides at all-guides.com

Page 26

Mounting and commissioning

26 by Blum-Novotest 2012

MODE SET

Transmission

mode

Normal

• standard adjustment

Robust

• ambient conditions with

radio interferences

• high chip pollution

Fast

• fast measuring speeds

• interference-free ambient

conditions

Switch-on

time

Fast

• fast switch-on time

• setting decreases battery

life

Normal

• normal switch-on time

• standard setting

Slow

• low switch-on time

• setting increases battery life

• not suitable for switch

on/off impulse controlled

Probe type

Standard

•

ready for activation1)

• setting decreases battery

life

EcoMode

• ready for activation

2)

• setting increases battery life

TWIN A

• setting for double spindle

machines:

set first probe to TWIN A

set second probe to TWIN B

TWIN B

Automatic display of the basic adjustments

Standby

BU

RD

OG

GN

GN

RD

GN

BU

OG

BU

RD

GN

RD

All manuals and user guides at all-guides.com

all-guides.com

Page 27

Mounting and commissioning

by Blum-Novotest 2012 27

1)

In standby mode the probe is ready for re-activation at any time.

2)

If the probe is outside of the receiving range of the radio receiver the probe changes into

Eco mode. If the probe is inside of the receiving range of the radio receiver it is ready for

re-activation at any time.

Not valid resp. reserved combinations are not stored.

Please check adjustments after programming (chap.3.6) and list them in the system

certificate.

Please adapt color code on the probe (see chap.3.8)

All manuals and user guides at all-guides.com

Page 28

Mounting and commissioning

28 by Blum-Novotest 2012

3.8 System coding

In case several radio probes are used in the machine, they can be marked.

Please always use the transparent label to protect!

Fig. 3.9

3.9 Probe pairing

Installation instructions IF59-A2 (P03.5900-000.011)

3.10 Switch-on probe (via radio receiver)

Switch-on probe e.g. via M-functions

Installation instructions RC66 (P03.6600-000.011)

Installation instructions IF59-A2 (P03.5900-000.011)

All manuals and user guides at all-guides.com

Page 29

Notes concerning measuring sequence

by Blum-Novotest 2012 29

4. Notes concerning measuring sequence

Start measuring block only when interference-free radio transmission with

radio receiver is guaranteed (signal level Error = High)

Installation instructions radio receiver RC66

(P03.6600-000.011)

Installation instructions Interface IF59

(P03.5900-000.011)

5. Maintenance

• The probe needs minimum maintenance only

• Keep the glass ring clean

• Check bellows for damages

5.1 Cleaning of the transparent ring

Please do always use mild detergents (e.g. neutral soap solution or diluted

washing-up liquid) for cleaning of the transparent ring. Please do always

use a soft, clean cloth to clean.

CAUTION

Damage of the transparent ring

Please, do not use any detergents containing acetone, alcohol, cleaning

benzine or solvent! They can damage the transparent ring.

Please, do not use any detergents containing abrasive substances (e.g.

scouring powder or cleansing milk. They can damage the transparent ring!

All manuals and user guides at all-guides.com

Page 30

Maintenance

30 by Blum-Novotest 2012

5.2 Exchange of external bellows (TC60 / TC61 / TC63(TC76) / TC64 only)

CAUTION

Pollution of measuring mechanism

It is not allowed to exchange the internal bellows!

In case that it should be damaged, please send probe for repair.

Pls. take care that the internal bellows is not removed from its position.

The measuring mechanism is not allowed to be twisted!

TC62 / TC62-LF / TC76-LF (Low Force) / TC64-10 LF (Low Force):

The bellows is allowed to be exchanged by Blum-Novotest only!

1. Clean probe and remove stylus if necessary (chap.3.4), while using the interlocking disk

(A) resp. mounting tool (B).

2. Remove front ring (16) with mounting tool (B).

3. Remove external bellows carefully (13), without twisting the measuring mechanism (10).

4. Grease new bellows (13) at the contact surface to the groove slightly

(grease: ISOFLEX TOPAS NB 52 or STABURAGS NBU30).

5. Install new bellows (13), without twisting the measuring mechanism.

The bellows must click to the groove (10a) on the measuring system (10).

Please take care of plane supporting surface of the bellows.

6. Install front ring (mounting tool (B)).

7. Mount stylus while using the interlocking disk (A) resp. mounting tool (B).

8. Carry out calibration cycle

All manuals and user guides at all-guides.com

Page 31

Maintenance

by Blum-Novotest 2012 31

Fig. 5.1 TC60

Fig. 5.2 TC61

Fig. 5.3 TC63-30 / TC76

(10) Measuring mechanism (14) Centering ring

(10a) Groove (15) Internal bellows

(13) External bellows (16) Front ring

All manuals and user guides at all-guides.com

all-guides.com

Page 32

Trouble shooting

32 by Blum-Novotest 2012

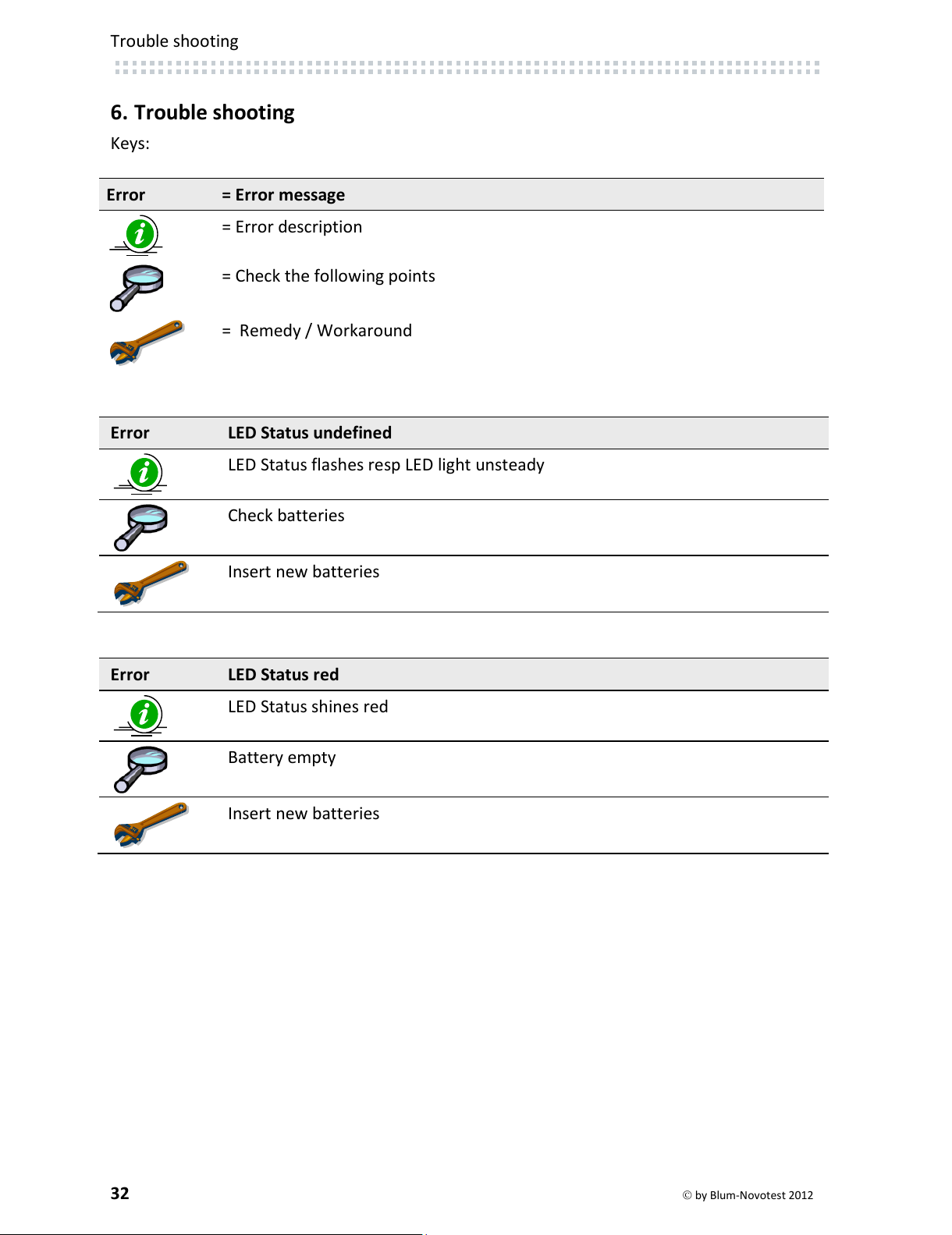

6. Trouble shooting

Keys:

Error LED Status undefined

LED Status flashes resp LED light unsteady

Check batteries

Insert new batteries

Error LED Status red

LED Status shines red

Battery empty

Insert new batteries

Error

= Error message

= Error description

= Check the following points

= Remedy / Workaround

All manuals and user guides at all-guides.com

Page 33

Trouble shooting

by Blum-Novotest 2012 33

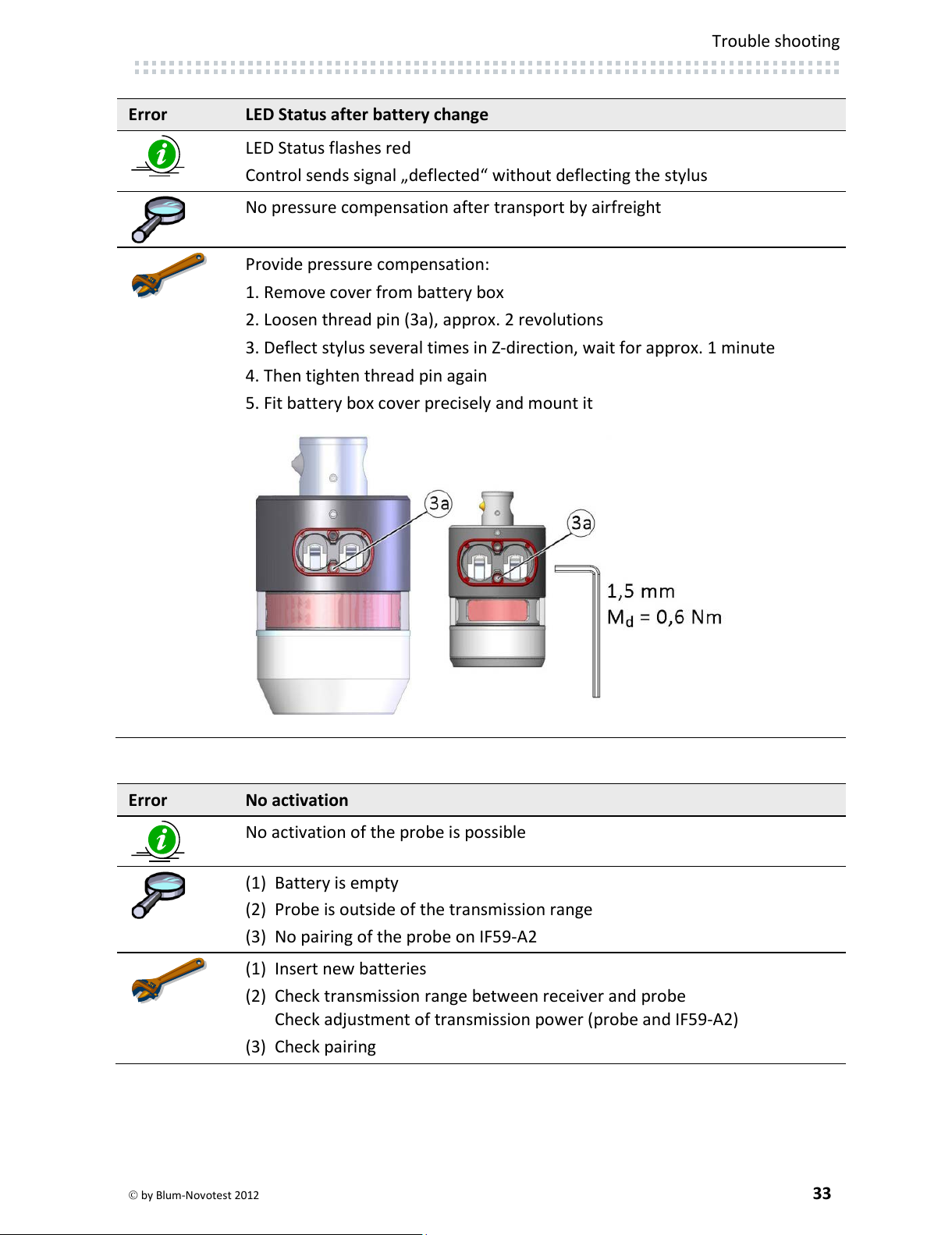

Error LED Status after battery change

LED Status flashes red

Control sends signal „deflected“ without deflecting the stylus

No pressure compensation after transport by airfreight

Provide pressure compensation:

1. Remove cover from battery box

2. Loosen thread pin (3a), approx. 2 revolutions

3. Deflect stylus several times in Z-direction, wait for approx. 1 minute

4. Then tighten thread pin again

5. Fit battery box cover precisely and mount it

Error No activation

No activation of the probe is possible

(1) Battery is empty

(2) Probe is outside of the transmission range

(3) No pairing of the probe on IF59-A2

(1) Insert new batteries

(2) Check transmission range between receiver and probe

Check adjustment of transmission power (probe and IF59-A2)

(3) Check pairing

All manuals and user guides at all-guides.com

Page 34

Order numbers

34 by Blum-Novotest 2012

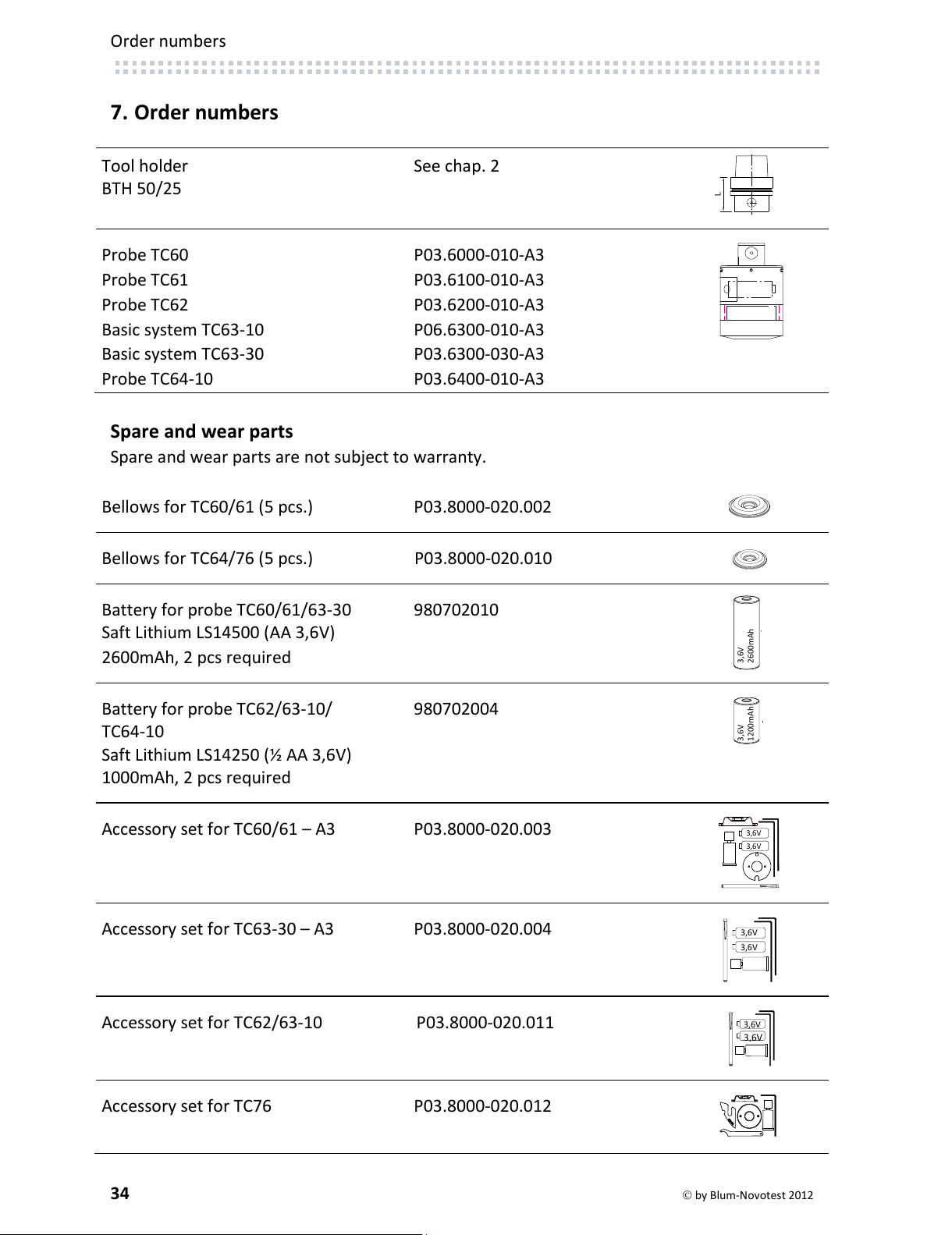

7. Order numbers

Tool holder

BTH 50/25

See chap. 2

Probe TC60

Probe TC61

Probe TC62

Basic system TC63-10

Basic system TC63-30

Probe TC64-10

P03.6000-010-A3

P03.6100-010-A3

P03.6200-010-A3

P06.6300-010-A3

P03.6300-030-A3

P03.6400-010-A3

Spare and wear parts

Spare and wear parts are not subject to warranty.

Bellows for TC60/61 (5 pcs.) P03.8000-020.002

Bellows for TC64/76 (5 pcs.) P03.8000-020.010

Battery for probe TC60/61/63-30

Saft Lithium LS14500 (AA 3,6V)

2600mAh, 2 pcs required

980702010

Battery for probe TC62/63-10/

TC64-10

Saft Lithium LS14250 (½ AA 3,6V)

1000mAh, 2 pcs required

980702004

Accessory set for TC60/61 – A3 P03.8000-020.003

Accessory set for TC63-30 – A3 P03.8000-020.004

Accessory set for TC62/63-10 P03.8000-020.011

Accessory set for TC76 P03.8000-020.012

3,6V

2600mAh

3,6V

1200mAh

3,6V

3,6V

3,6V

3,6V

3,6V

3,6V

All manuals and user guides at all-guides.com

Page 35

Order numbers

by Blum-Novotest 2012 35

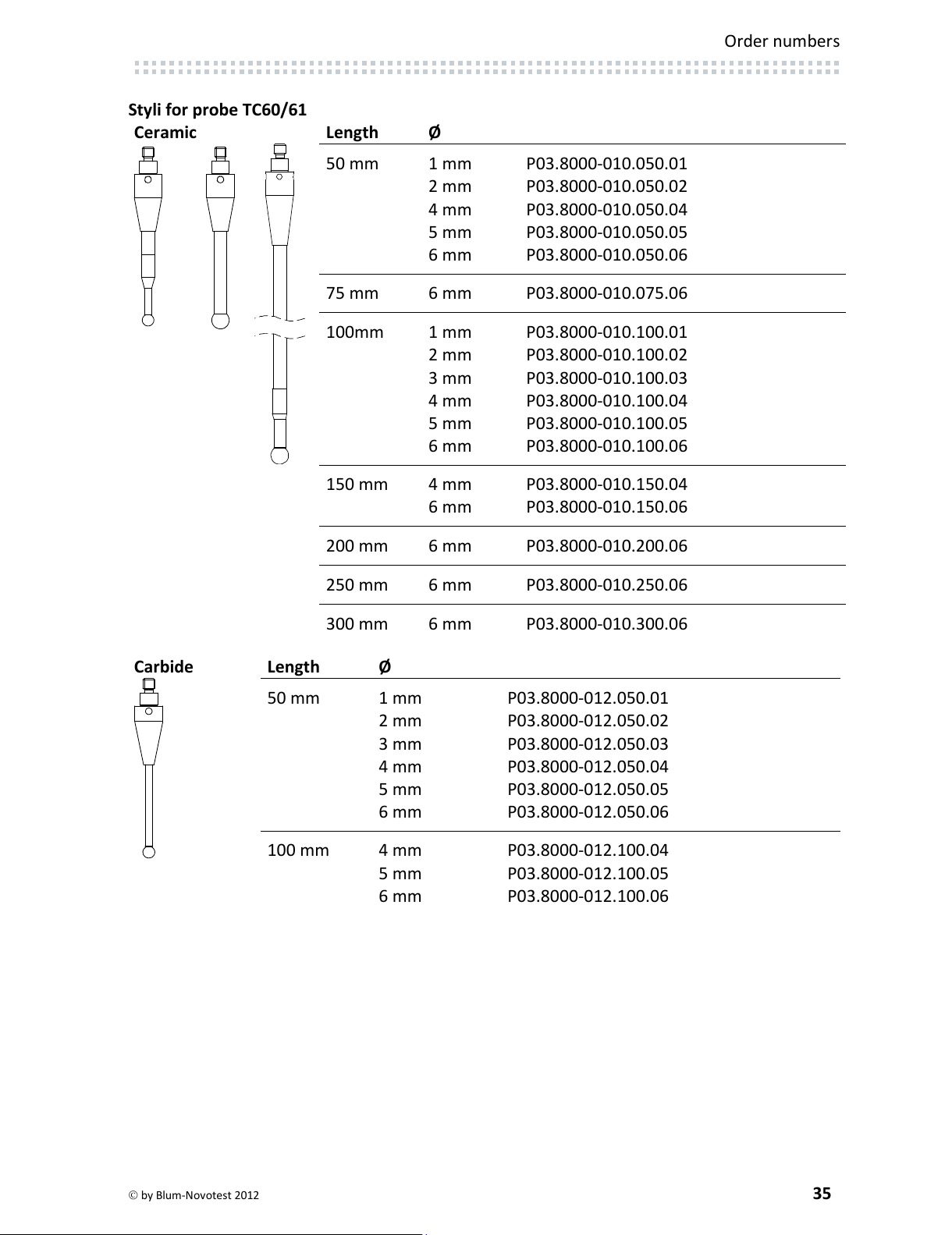

Styli for probe TC60/61

Ceramic

Length

Ø

50 mm

1 mm

2 mm

4 mm

5 mm

6 mm

P03.8000-010.050.01

P03.8000-010.050.02

P03.8000-010.050.04

P03.8000-010.050.05

P03.8000-010.050.06

75 mm

6 mm

P03.8000-010.075.06

100mm

1 mm

2 mm

3 mm

4 mm

5 mm

6 mm

P03.8000-010.100.01

P03.8000-010.100.02

P03.8000-010.100.03

P03.8000-010.100.04

P03.8000-010.100.05

P03.8000-010.100.06

150 mm

4 mm

6 mm

P03.8000-010.150.04

P03.8000-010.150.06

200 mm

6 mm

P03.8000-010.200.06

250 mm

6 mm

P03.8000-010.250.06

300 mm

6 mm

P03.8000-010.300.06

Carbide

Length

Ø

50 mm

1 mm

2 mm

3 mm

4 mm

5 mm

6 mm

P03.8000-012.050.01

P03.8000-012.050.02

P03.8000-012.050.03

P03.8000-012.050.04

P03.8000-012.050.05

P03.8000-012.050.06

100 mm

4 mm

5 mm

6 mm

P03.8000-012.100.04

P03.8000-012.100.05

P03.8000-012.100.06

All manuals and user guides at all-guides.com

Page 36

Order numbers

36 by Blum-Novotest 2012

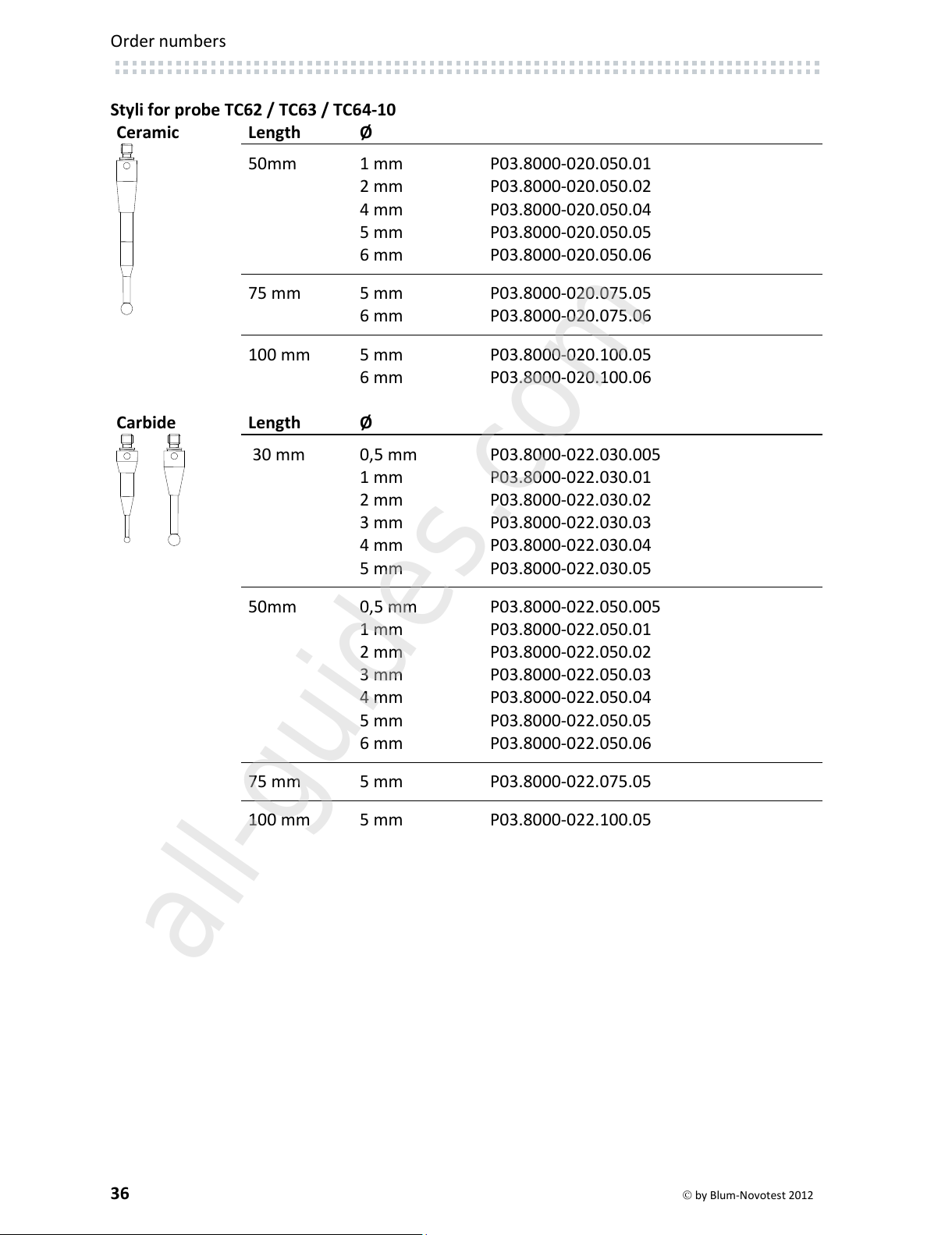

Styli for probe TC62 / TC63 / TC64-10

Ceramic

Length

Ø

50mm

1 mm

2 mm

4 mm

5 mm

6 mm

P03.8000-020.050.01

P03.8000-020.050.02

P03.8000-020.050.04

P03.8000-020.050.05

P03.8000-020.050.06

75 mm

5 mm

6 mm

P03.8000-020.075.05

P03.8000-020.075.06

100 mm

5 mm

6 mm

P03.8000-020.100.05

P03.8000-020.100.06

Carbide

Length

Ø

30 mm

0,5 mm

1 mm

2 mm

3 mm

4 mm

5 mm

P03.8000-022.030.005

P03.8000-022.030.01

P03.8000-022.030.02

P03.8000-022.030.03

P03.8000-022.030.04

P03.8000-022.030.05

50mm

0,5 mm

1 mm

2 mm

3 mm

4 mm

5 mm

6 mm

P03.8000-022.050.005

P03.8000-022.050.01

P03.8000-022.050.02

P03.8000-022.050.03

P03.8000-022.050.04

P03.8000-022.050.05

P03.8000-022.050.06

75 mm

5 mm

P03.8000-022.075.05

100 mm

5 mm

P03.8000-022.100.05

All manuals and user guides at all-guides.com

all-guides.com

Page 37

Shipping instructions / storage

by Blum-Novotest 2012 37

Styli for probe TC63/64

Adapter

P03.8000-025.300

Length

□

Stylus

27 mm

30 mm

36 mm

47 mm

52 mm

62 mm

77 mm

Q6

Q6

Q6

Q6

Q6

Q6

Q6

P03.8000-025.342

P03.8000-025.341

P03.8000-025.343

P03.8000-025.340

P03.8000-025.345

P03.8000-025.344

P03.8000-025.346

8. Shipping instructions / storage

• If the probe should be stored for a longer period, please remove the

battery from the battery box.

• If you return the probe for repair, please enclose a detailed error

description and the probe certificate.

• The probe is to be returned in the original packing only.

• The packing is not allowed to deflect the probe, neither in X/Y- nor in Z-

direction.

• Tool holder and battery are to be removed before packing.

• The probe should be packed shock and pollution protected.

Adapter

Tasteinsatz/stylus

Ø2

All manuals and user guides at all-guides.com

Page 38

Radio approval

38 by Blum-Novotest 2012

9. Radio approval

Area: Radio Approval: Regulations:

Europa: 0681 EN 300 328 V1.4.1, EN 301 489-17 V1.2.1,

EN 60950-1:2001

Japan: R 202WW10568411

“This device has been granted a designation number by Ministry of Internal

Affairs and Communications under „Ordinance concerning Technical

Regulations Conformity Certification etc. of Specified Radio Equipment

(特定無線設備の技術基準適合証明等に関する規則)“ Article 2-1-19.

USA: FCC ID: ZCQTCA FCC Part 15

This device complies with part 15 of the FCC Rules. Operation is subject to the

following two conditions: (1) This device may not cause harmful interference,

and (2) this device must accept any interference received, including

interference that may cause undesired operation.

The antenna(s) used for this transmitter must not be co-located or operating

in conjunction with any other antenna or transmitter.

Canada: IC:9570A-TCA

Operation is subject to the following two conditions: (1) this device may not

cause interference, and (2) this device must accept any interference, including

interference that may cause undesired operation of the device. This device

and its antenna(s) must not be co-located or operating in conjunction with any

other antenna or transmitter.

This equipment complies with IC Canada RF radiation exposure limits set forth

for an uncontrolled environment as per RSS-102 Issue 4.

The device is complying with standard IEEE 802.15.4a.

All manuals and user guides at all-guides.com

Page 39

by Blum-Novotest 2012 39

EC Declaration of Incorporation

acc. to the EC Machine Regulations 2006/42/EC in the edition from 17 May.2006

We hereby confirm that the subsequently following components are defined for the installation into

other machines and that they are in accordance with the following safety requirements of the EC

regulations.

Commissioning is not allowed until it is ascertained that the machines, in which the components are

installed, are in accordance with the EC regulations 2006/42/EC.

The relevant technical information is compiled acc. to annex VII part B and, where appropriate, we will

send the information concerning the components to the different countries. The industrial property

rights of Blum-Novotest GmbH will remain unaffected.

Component name: P03.6000 / P03.6100/ P03.6200

P06.6300 / P06.6400 / P06.7600 /

Probe for workpiece measurement

Safety requirements

2006/42/EG, Annex I 1.5.1

Applied standards:

EC-Regulations: 2004/108/EG

2006/95/EG

1999/5/EG

Applied harmonized standards: EN61000-6

EN60204-1

EN ISO 12100

EN 300 328

EN 301 489-17

EN 60950-1:2001

Applied national standards: DIN VDE 0100

DIN VDE 0113

Authorised presentative for technical information: Blum-Novotest GmbH

Kaufstr. 14

88287 Gruenkraut, Germany

All manuals and user guides at all-guides.com

Page 40

40 by Blum-Novotest 2012

Service order

Please fill out completely this repair order and attach it to the system. This will save you and

us costs due to time-consuming inquiries and ensures a quick repair.

Blum-Novotest GmbH

Kaufstr. 14, 88287 Gruenkraut - Germany

Tel. +49 751 6008-0, Fax. +49 751 6008-156

Company:

Department:

Contact:

Address:

Phone:

Fax:

Email:

Probe Type, Serial No.:

Machine Type, Manufacturer:

Description of Defect:

All manuals and user guides at all-guides.com

Page 41

All manuals and user guides at all-guides.com

all-guides.com

Page 42

All manuals and user guides at all-guides.com

Page 43

All manuals and user guides at all-guides.com

Page 44

Blum-Novotest GmbH

Kaufstr. 14

88287 Gruenkraut, Germany

Tel.:+49 751 6008-0

Fax:+49 751 6008-156

www.blum-novotest.com

Sales: vk@blum-novotest.com

Service: snc@blum-novotest.com

Hotline:

Vertrieb/sales: Tel.:+49 751 6008-200

Service LaserControl : Tel.:+49 751 6008-202

Service Messtaster/probes: Tel.:+49 751 6008-203

Blum-Novotest GmbH Prüftechnik KK Blum Laser Measuring Technology

Willich, Deutschland Nagoya, Japan

Tel. +49 2154 921970 Tel. +81 568 74-5311

Blum-Novotest Srl Blum-Novotest

Como, Italy Shanghai, China

Tel. +39 031 283 955 Tel. +86 21 52080480

Blum-Novotest Ltd. Blum Production Metrology Co., Ltd.

Birmingham, England Taichung, Taiwan

Tel. +44 1543 257111 Tel. +886 4 2358 3900

Blum Laser Measuring Technology Inc. Blum Production Metrology Pte. Ltd.

Cincinnati, USA Singapore, Singapore

Tel. +1 859 3446789 Tel. +65 62720998

Blum-Novotest Sarl Blum-Novotest Ltd.

Bordeaux, France Seoul, Republic of Korea

Tel. +33 55702 0135 Tel. +82 2 2026-1300

Blum-Novotest s.r.o. Blum-Novotest Measuring & Testing Technology Pvt Ltd

Kroměříž, Czech Republic Bangalore, India

Tel. +420 573 330373 +91 80 23185468

Support

All manuals and user guides at all-guides.com

Loading...

Loading...