AT6020

Commercial Fertilizer Injection Applicator

TM

Assembly

and Operators

Manual

Manual Number

0606020

Rev. 2-19-18 $20.00 Net.

Thurston Manufacturing Company • 1708 H Ave • Box 218 • Thurston, Nebraska, 68062-0218

Phone: 402-385-3041 • E-mail: box218@thurstonmfgco.com

Design specications and features as described are subject to change without notice. BLU-JET is a registered trademark of Thurston Manufacturing Company, Thurston NE.

/BLU-JET

@BLU-JET01

/SIronWorks

@SIronWorks

Table of Contents

AT6020

Manual Number:

0606020

Rev. 2-19-18

Introduction------------------------------------------------------------------------------------------------------- 1

Deliver--------------------------------------------------------------------------------------------------------------- 4

To The Owner----------------------------------------------------------------------------------------------------- 5

Warranty------------------------------------------------------------------------------------------------------------ 6

Safety--------------------------------------------------------------------------------------------------------------- 7

Operating Instructions---------------------------------------------------------------------------------------- 11

Anhydrous Ammonia Operating Instructions--------------------------------------------------------- 19

Coupler Operation---------------------------------------------------------------------------------------------- 22

Parts----------------------------------------------------------------------------------------------------------------- 23

Emergency Fresh Water Tank--------------------------------------------------------------------------------- 23

Operational Guide For Various Residue Situations BLU-JET StripTill Implement--------------- 24

Center Section Bundle 66000103 Parts List--------------------------------------------------------------- 35

Primary Wing Right-hand Bundle 66000103--------------------------------------------------------------- 40

Primary Wing Left-hand Bundle 66000103----------------------------------------------------------------- 42

Center Section Bundle 66000103 Exploded Views------------------------------------------------------- 44

Center Section Bundle 66000103 Depth Control Parts-------------------------------------------------- 48

Secondary Wing Right-hand With Hydraulic Gauge Wheel Bundle 66000107-------------------- 50

Secondary Wing Left-hand With Hydraulic Gauge Wheel Bundle 66000107---------------------- 52

Dual Wheel Lift Bundle 66000105---------------------------------------------------------------------------- 54

Pin Adjust Gauge Wheel Bundle 55000100---------------------------------------------------------------- 56

48’ and 60’ Complete Toolbar Drawings--------------------------------------------------------------------- 57

Hydraulics 60’------------------------------------------------------------------------------------------------------ 58

Hydraulics 48’------------------------------------------------------------------------------------------------------ 63

Third Wing Bundle 66000108 Left Side--------------------------------------------------------------------- 70

Third Wing Bundle 66000108 Right Side------------------------------------------------------------------- 72

Stagger Brackets Offset 6 x 6 Mounting-------------------------------------------------------------------- 74

Stagger Bracket 40 x 48 Double, (AAM2125)------------------------------------------------------------- 75

Offset Stagger Bracket (AAM2136)-------------------------------------------------------------------------- 76

Super 1200 Flex Coulter and Shank------------------------------------------------------------------------- 77

Nurse Tank Hitch Assembly PKG00234--------------------------------------------------------------------- 78

Nurse Tank Hitch Assembly, Low Mounting PKG00247------------------------------------------------- 79

Auto-Lok Nurse Tank Hitch (AAM2831)-------------------------------------------------------------------- 80

Blades---------------------------------------------------------------------------------------------------------------- 82

SealPro ll and SealPro SKF------------------------------------------------------------------------------------ 83

Hitches--------------------------------------------------------------------------------------------------------------- 90

Jack------------------------------------------------------------------------------------------------------------------ 91

Shanks-------------------------------------------------------------------------------------------------------------- 92

Row Clamps------------------------------------------------------------------------------------------------------- 93

Manual Holder----------------------------------------------------------------------------------------------------- 96

Impellicone Mounting Hardware------------------------------------------------------------------------------ 97

SuperShooter------------------------------------------------------------------------------------------------------ 98

SuperShooter III Add-on Parts (66000136) Single Assembly------------------------------------------ 100

SuperShooter III Add-on Parts (66000137) Dual Assembly------------------------------------------- 102

GDI With Pump Distribution (Rear Mount) (Bundle 20200119)---------------------------------------- 104

Heat Exchanger (CCP2755)----------------------------------------------------------------------------------- 107

GDI WithTwin Pump Distribution (Rear Mount)(Bundle 20200121)---------------------------------- 112

Meter Assembly Impellicone Manifolds--------------------------------------------------------------------- 121

MaxPac AR700 Parts and Assembly------------------------------------------------------------------------ 131

MaxPac Basket Mount Arm------------------------------------------------------------------------------------ 132

Coulter Extension Kit (9-7/8”)----------------------------------------------------------------------------------- 133

MaxPac Assembly------------------------------------------------------------------------------------------------- 134

Torsion Arm Basket Parts---------------------------------------------------------------------------------------- 136

Torsion Arm Assembly-------------------------------------------------------------------------------------------- 137

Torsion Arm Mounting Bracket Rigid Fertilizer Row------------------------------------------------------ 138

Basket Mount Flat With Hardware---------------------------------------------------------------------------- 139

Decals---------------------------------------------------------------------------------------------------------------- 140

StripTill Residue Manager Parts------------------------------------------------------------------------------- 141

Coulter Shank Extensions Brackets-------------------------------------------------------------------------- 142

StripTill Residue Manager Assembly------------------------------------------------------------------------- 143

Light Kit/Slow Moving Vehicle--------------------------------------------------------------------------------- 149

Light Kit/Slow Moving Vehicle 20” Row Spacing---------------------------------------------------------- 151

GDI Lift Kit---------------------------------------------------------------------------------------------------------- 153

Hub and Spindle Assembly------------------------------------------------------------------------------------- 154

Hydraulic Repair Kit---------------------------------------------------------------------------------------------- 160

Tie-rod Cylinder Disassembly-Assembly Procedure----------------------------------------------------- 161

Torque Specications-------------------------------------------------------------------------------------------- 162

Specications------------------------------------------------------------------------------------------------------ 163

Assembly................................................................................................................................ 165

Main Frame and Primary Wings------------------------------------------------------------------------------ 165

Secondary Wings------------------------------------------------------------------------------------------------- 166

Dual Wheel Lift----------------------------------------------------------------------------------------------------- 168

Primary Wing Gauge Wheels----------------------------------------------------------------------------------- 171

Center Section Wheel Lift Linkage--------------------------------------------------------------------------- 175

Tongue Mounting------------------------------------------------------------------------------------------------- 177

Tongue Linkage--------------------------------------------------------------------------------------------------- 178

Bolt-on Cylinder Lug--------------------------------------------------------------------------------------------- 181

Primary Wing Cable Release---------------------------------------------------------------------------------- 182

Hitch and Safety Chain------------------------------------------------------------------------------------------ 183

Jack------------------------------------------------------------------------------------------------------------------ 184

Hose Holder and Hose Tender-------------------------------------------------------------------------------- 185

Turnbuckle Wrench----------------------------------------------------------------------------------------------- 186

Hitch Storage------------------------------------------------------------------------------------------------------ 187

Manual Holder----------------------------------------------------------------------------------------------------- 188

Stagger Brackets-------------------------------------------------------------------------------------------------- 189

Primary Wing Linkage------------------------------------------------------------------------------------------- 190

Secondary Wing Linkage--------------------------------------------------------------------------------------- 191

Third Wing Linkage----------------------------------------------------------------------------------------------- 193

Secondary Wing Latch Standard Wing---------------------------------------------------------------------- 194

Hose Holder Placement 60’------------------------------------------------------------------------------------- 195

Hydraulics 60’ Assembly------------------------------------------------------------------------------------------ 196

Depth Control Parts and Assembly---------------------------------------------------------------------------- 201

Hydraulic Hoses 60’ Assembly--------------------------------------------------------------------------------- 210

Hose Holder Placement 48’------------------------------------------------------------------------------------- 218

Hydraulics 48’ Assembly----------------------------------------------------------------------------------------- 220

Hydraulics Hoses 48’ Assembly------------------------------------------------------------------------------- 222

Nurse Tank Hitch Single PKG00234------------------------------------------------------------------------- 234

Nurse Tank Hitch Single Low Mounting PKG00247------------------------------------------------------ 236

SuperShooter III Add-on Parts (66000136) Single Assembly------------------------------------------ 238

SuperShooter III Add-on Parts (66000137) Dual Assembly------------------------------------------ 242

Swing Adjust Gauge Wheel------------------------------------------------------------------------------------ 246

Coulter--------------------------------------------------------------------------------------------------------------- 247

Shank---------------------------------------------------------------------------------------------------------------- 249

Spring Cushion---------------------------------------------------------------------------------------------------- 251

Light Kit & Slow Moving Vehicle------------------------------------------------------------------------------ 253

Light Kit & Slow Moving Vehicle 20” Row Spacing------------------------------------------------------- 258

Safety Tank--------------------------------------------------------------------------------------------------------- 261

Depth Collars------------------------------------------------------------------------------------------------------ 262

Decals--------------------------------------------------------------------------------------------------------------- 263

Hydraulic System Charging------------------------------------------------------------------------------------ 265

Folding Tool Bar--------------------------------------------------------------------------------------------------- 266

Row Spacing Layout------------------------------------------------------------------------------------------- 267

1

AT6020

Introduction

Welcome to Thurston Manufacturing Company. Our goal is to provide

quality products and services to our customers. The company’s BLU-JET

products have a reputation for quality, excellence in design and proven

durability. Energetic, resourceful and continuous improvement goals in

Environmental, Safety, Quality, Production and Engineering keep our

rm at the cutting edge of technology.

We hope your BLU-JET equipment will give you years of service.

Read this manual carefully. It will instruct you on how to operate and

service your machine safely and correctly. Failure to do so could result

in personal injury and/or equipment damage.

SAFETY INFORMATION

Indicates an imminently hazardous situation that, if

not avoided, will result in death or serious injury.

The sign will have the color combination of red and

white.

Indicates a potentially hazardous situation that, if

not avoided, could result in death or serious injury.

The sign will have the color combination of orange

and black.

Indicates a potentially hazardous situation that, if

not avoided, may result in minor or moderate injury.

The sign will have the color combination of yellow

and black.

NOTE: Indicates a special point of information.

Carefully read and follow all safety signs. Reinstall safety signs that

are damaged or missing.

DANGER

WARNING

CAUTION

Right-hand and left-hand sides of the implement are determined by

facing in the direction the implement will travel when going forward.

2

AT6020

Introduction

General Information:

The BLU-JET AT6020 Commercial Class Fertilizer Injection Applicator

achieves a new performance dimension for high acre, high rate applications.

The BLU-JET AT6020 can easily be congured for a number of operations

including Pre-Plant, Side-Dress, and StripTill applications with anhydrous,

liquid, dry, or dual placement fertilizer injection.

The AT6020 was designed to be used in combination with BLU-JET’s

Super 1200 Coulter, MaxPac 700 AutoReset shank mounting, residue managers,

SealPro disc sealers, torsion arm rming baskets and BLU-JET’s complete

line of shank mountings.

Warranty is provided for customers who operate and maintain their equi pme nt

as described in this manual. Warranty registration is accomplished by

the dealer completing and forwarding the WARRANTY REGISTRATION FORM

to Thurston Manufacturing Company. It is in your best interest to ensure that

this has been done.

For your convenience we have four easy ways to register your warranty.

• Call our toll free number and ask for warranty registration.

1-800-658-3127

• Register on-line at: www.BLU-JET.com

• Complete and mail this Product Registration form to:

Attn: Thurston Manufacturing Company

Product Registration

PO Box 218

Thurston, NE. 68062

• Email a copy to: warranty@thurstonmfgco.com

Thurston Manufacturing Company Warranty does not cover the following:

1) Cleaning, transporting, mailing and service call charges.

2) Depreciation or damage caused by normal wear, accidents,

improper protection or improper use.

The Serial Number

is located from the

rear of the tool bar

on the right-hand

side behind the

Tractor side

Record your implement model and serial number in the space provided below.

Your dealer needs this information to give you prompt, efcient service when

you order parts.

MODEL NO.__________________________

SERIAL NO.__________________________

DATE PURCHASED___________________

tongue pull plate.

3

AT6020

Dealer Checklist

To The Dealer:

Inspect the implement thoroughly after assembly to be certain it is

functioning properly before delivering it to the customer. The following

checklist is a reminder of points to cover. Check off each item as it is

found satisfactory or after proper adjustment is made.

PRE-DELIVERY CHECKLIST

1. All hardware properly tightened

2. Lubrication of grease ttings

3. All decals properly located and readable

4. Other adjustments for machine level height, etc.

5. Overall condition (touch up any scratches, clean and

polish)

6. Operator’s manual

DATE SET UP_______________________________

SIGNATURE________________________________

DELIVERY

Review the operator’s manual with the customer. Explain

the following:

1. Safe operation and service

2. Correct machine installation and operation

3. Daily and periodic lubrication and maintenance

4 Daily and periodic inspections

5. Trouble shooting

6. Storing machine

7. Thurston Manufacturing Company parts and service

8. Have the customer write the machine model and serial

number in space provided in manual introduction.

9. Give customer the operator’s manual and encourage

the customer to read the manual carefully.

10. Completion and mailing of warranty registration

form.

DATE DELIVERED__________________________

SIGNATURE_______________________________

MODEL NO.________________________________

SERIAL NO.________________________________

4

AT6020

To The Owner

Thank you for your recent purchase of a new BLU-JET

implement. The primary objective of Thurston Manufacturing

Company is to build and provide you with a quality product.

However, in the event that a problem does occur, it is imperative

that your warranty registration is on le in order to accurately

respond to your specic service circumstances.

For your convenience we have four easy ways to register

your warranty:

For your convenience we have four easy ways to register your warranty.

• Call our toll free number and ask for warranty registration.

1-800-658-3127

• Register on-line at: www.BLU-JET.com

• Complete and mail this Product Registration form to:

Attn: Thurston Manufacturing Company

Product Registration

PO Box 218

Thurston, NE. 68062

• Email a copy to: warranty@thurstonmfgco.com

This manual has been prepared to assist you in the assembly

of your new machine and contains information pertaining to

safety, operations and all of its parts. Our personnel in sales

and service are always available to assist you when questions

arise concerning the assembly or operations of your tool bar.

When ordering parts, please refer to part numbers and

descriptions as listed throughout this book. All parts and

whole goods will be shipped FOB Thurston, Nebraska. Or

FOB your regional distributor. Always check merchandise

immediately upon receipt for damage or shortage. Note any

discrepancy on carrier’s bill of lading and notify Sender within

10 days. Returned goods will be subject to a 15% restocking

charge. Thurston Manufacturing Company reserves the right

to make improvements and modications on equipment

without obligation to change previously built equipment. All

prices are subject to change without notice.

5

AT6020

Limited Warranty

Thurston Manufacturing Company warrants each new BLU-JET machine

primary framework to be free from defects in material and workmanship for a period

of ve (5) years, normal wear of wearing parts excepted. Thurston Manufacturing

Company further warrants each new BLU-JET product to be free from defects in

material and workmanship, normal wear of wearing parts excepted, for a period

of one (1) year. All accessories purchased and resold by Thurston Manufacturing

Company will be warranted according to their respective manufacturer. Tires on

BLU-JET equipment are warranted through their respective tire manufacturers and

their network of dealers in your local area.

Warranty begins from date of delivery to the original purchaser and applies

to all new BLU-JET products that have not been altered and are being used for the

intended purpose. Negligence, abuse or modication of equipment manufactured

by or purchased and resold by Thurston Manufacturing Company will void this

warranty.

The obligation of Thurston Manufacturing Company to honor this warranty

is limited to the repair or replacement of defective merchandise, to the original

purchaser, subject to inspection of equipment in question by an authorized Thurston

Manufacturing Company sales or service technician. In the USA, freight of warranty

replacement parts including main frame centers and wings will be prepaid for a

period of one (1) Year by Thurston Manufacturing Company. Shipments of repaired

or replaced parts including main frame centers and wings after one year will be paid

by the customer.

Return of defective goods must be made within thirty (30) days of failure to

Thurston Manufacturing Company, Thurston, Nebraska USA or to the nearest

authorized BLU-JET Distributor or Rep Sales and service outlet.

Thurston Manufacturing Company will not be held responsible for any repair

charges made by customers without prior written consent and prior equipment

inspection by an authorized Thurston Manufacturing Company sales or service

technician.

This warranty shall not be interpreted to render liability for injury or damages

of any kind, direct, consequential or contingent to person or property. This warranty

does not extend to loss of crops, economic and/or commercial loss, loss because

of delay in crop production or any expense incurred for labor, supplies, substitute

machinery, rental or for any other reason. This warranty is subject to any existing

condition of supply, which may directly affect Thurston Manufacturing Company’s

ability to obtain materials of manufacture and delivery of replacement parts.

Thurston Manufacturing Company reserves the right to make improvements

in design and changes in specications at any time without incurring any obligation

to owners of units previously sold.

No one is authorized to alter, modify or enlarge this warranty nor its exclusions,

limitations and reservations. Thurston Manufacturing Company makes no

representations or warranties, expressed or implied (including implied warranties

of merchantability and tness), except for those set forth in Thurston Manufacturing

Company’s current applicable published warranty policies and procedures.

Layton W. Jensen, President 022398\mgmt

6

AT6020

Safety

RECOGNIZE SAFETY INFORMATION

• This is the safety-alert symbol. When you see his symbol

on your machine or in this manual, be alert to the

potential for personal injury. Follow recommended

precautions and safe operating practices.

FOLLOW SAFETY INSTRUCTIONS

• Carefully read all safety messages in this manual and

on your machine safety signs. Keep safety signs in good

condition. Replace missing or damaged safety signs.

• Learn how to operate the machine and how to use

controls properly.

• Do not let anyone operate without instruction.

• Keep your machine in proper working condition.

• Unauthorized modication to the machine may

impair the function and/or safety and affect machine life.

PROTECT CHILDREN AND BYSTANDERS

• Before you back, LOOK CAREFULLY behind for

children.

• Clear area of children, pets and bystanders.

HIGHWAY AND TRANSPORT OPERATIONS

Adopt safe driving practices:

• Keep the brake pedals latched together at all times.

NEVER USE INDEPENDENT BRAKING WITH MACHINE

IN TOW AS LOSS OF CONTROL AND/OR UPSET OF

UNIT CAN RESULT.

• Always drive at a safe speed relative to local

conditions and ensure that your speed is low enough

for a emergency stop to be safe and secure. Keep

speed to a minimum.

• Reduce speed prior to turns to avoid the risk of

overturning.

• Avoid sudden uphill turns on steep slopes.

• Always keep the tractor or towing vehicle in

gear to provide engine braking when going downhill.

Do not coast.

• Do not drink and drive.

• Comply with state and local laws governing highway

safety and movement of farm machinery on public roads.

• Use approved accessory lighting and necessary

warning devices to protect operators of other vehicles

on the highway during daylight and nighttime transport.

• The use of ashing amber lights is acceptable in most

localities. However, some localities prohibit their use.

Local laws should be checked for all highway lighting

and marking requirements.

• When driving the tractor and equipment on the road

or highway under (20 mph max.) (32 kmph max.) at night or

during the day, use ashing amber warning lights

and a slow moving vehicle (SMV) identication emblem.

7

AT6020

Safety

HIGHWAY AND TRANSPORT OPERATIONS

• Plan your route to avoid heavy trafc.

• Be a safe and courteous driver. Always yield to oncoming

trafc in all situations, including narrow bridges,

intersection, etc.

• Be observant of bridge loading ratings. Do not cross

bridges rated lower than the gross weight at which you

are operating.

• Always operate equipment in a position to provide

maximum visibility at all times. Makes allowances for

increased length and weight of the equipment when

making turns, stopping the unit, etc.

TRANSPORT SAFETY

• A safety chain will help control drawn equipment

should it accidentally separate from the drawbar.

• Attach the chain to the tractor drawbar support or

other anchor location. Provide only enough slack in

the chain to permit turning.

• Use hydraulic cylinder transport lockup during road

transportation.

• Maximum road speed is 20 m.p.h.

AVOID HIGH PRESSURE FLUIDS

• Escaping uid under pressure can penetrate the skin

causing serious injury.

• Avoid the hazard by relieving pressure before

disconnecting hydraulic or other lines. Tighten

all connections before applying pressure.

• Search for leaks with a piece of cardboard.

• Protect hands and body from high pressure uids.

• If an accident occurs, see a doctor immediately.

DISPOSE OF FLUIDS PROPERLY

• Improperly disposing of uids can harm the

environment and ecology. Before draining any

uids, contact your local environmental agency

for the proper waste disposal methods.

• Use proper container when draining uids. Do

not use food or beverage containers that may

mislead someone into drinking from them.

• DO NOT pour oil into the ground, down a drain, or

into a stream, pond, or lake. Observe relevant

environmental protection regulations when disposing

of oil and other harmful waste.

8

AT6020

Safety

Observe Safety Signs

AP 2234-7-98

AP 2483-8-98

AP 2914

AP 222 8-90

AP 2469-7-98

9

AT6020

Safety Decals

AP2972

AP2227

AP2974

AP2973

AP2975

10

AT6020

Operating Instructions

Hitch

NOTE:

Implement

hitch weights

are designed

to match

tractor size

ranges.

Check the

following

chart to

conrm your

particular

implement

specication.

Tractor to

tool bar

connection

1. The tractor must be equipped

with a drawbar and a draw bar safety chain clevis. For

rigid frame tractors equipped

with swinging drawbar, the

drawbar must be located in a

xed position in the center of

the tractor. Refer to your

tractor operators manual for

drawbar adjustment and

drawbar operating instructions.

Engine

Category

2. Before connecting the tool bar to the tractor drawbar, raise the

tractor three point hitch (if equipped) to prevent interference

between the implement and the tractor.

Connect the tool bar to tractor drawbar ONLY. DO NOT connect

the tool bar to any other part of the tractor. Connect the tool bar

clevis to the tractor drawbar with hitch pin. Install the safety

chain through the tractor drawbar support bracket.

I

II

III

IV

HP Range

20

40

80

100

47

133

227

400

Generic Photo

Drawbar

Vertical Load Pounds

731

1,236

2,248

4,777

1,405

3,597

5,957

10,341

Safety

hitch pin

Safety

chain

3. Always use a safety hitch pin of the correct diameter. Make sure

that the hitch pin is locked in place with a safety type lock pin or

other locking device.

4. Always use a safety chain between the toolbar and the tractor.

Install the chain to the tractor drawbar support bracket. Support

the center of the chain with a clevis installed to the tractor

drawbar.

WARNING: In case the tractor hitch pin is lost during transport-

WARNING

ing. The safety chain must be attached between the implement

and tractor to prevent separated implement from running freely

and causing damage or injury.

WARNING: Do not move articulated tractor steering wheel

WARNING

until everyone is clear of the equipment. Moving the steering

wheel can swing or move attached equipment which could

cause serious personal injury.

WARNING: Tractor drawbar must be in a xed position before

WARNING

transporting implement. Implement will sway or slam against

tractor resulting in equipment damage or injury to personnel.

11

AT6020

Operating Instructions

Remote

hydraulic

NOTE:

Always

connect the

hoses so

the toolbar

raises when

the tractor

remote control lever is

moved rearward and

lowers when

the lever

is moved

forward.

Remote

hydraulic

5. Connect the toolbar hydraulic

hoses to the tractor remote

couplers. The 1/2” hoses

supply oil to the toolbar lift

cylinders. The 3/8” hoses

supply oil to the wing fold

cylinders.

6. It may be necessary to tie

the hydraulic hoses up to

keep them away from the

hitch area. A tarp strap

around the hoses and

between the two point arms

works well.

WARNING

WARNING: Hydraulic uid escaping under pressure can have

enough force to penetrate the skin. Hydraulic uid may also

infect a minor cut or opening in the skin. If injured by escaping

uid, see doctor at once. Serious infection or reaction can result

if medical treatment is not given immediately. Make sure all

connections are tight and that hoses and lines are in good

condition before applying pressure to the system. Relieve all

pressure before disconnecting the lines or performing other work

on the hydraulic systems.

Attaching

electrical

harness

Jack stand

7. Attach 7 pin electrical

harness before road

transport.

8. Lower the jack and pull

ring on drop leg jack

plunger and raise the sand

pad off the ground. Secure

plunger in holes.

I

MPORTANT: Always lower the

jack stand to the ground before

disconnecting the tool bar from the

tractor.

Ring

12

AT6020

Operating Instructions

Leveling

Machine

9. Before leveling the machine

the tire pressure should be

checked.

Inate center section lugged

tractor tires to 56 P.S.I. Maximum

Truck tires 95 P.S.I. Maximum

Before beginning operation of

this machine the main frame

must be level.

Place tool bar on level surface.

Use the turnbuckle wrench to

loosen the lower turnbuckle

jam nut. Adjust turnbuckle with

wrench until the main frame is

level front to back. After making

the necessary adjustment,

lock turnbuckle with jam nut.

Jam Nut

Main Frame

CAUTION

CAUTION: To prevent serious accident or injury

do not remove wing latch cable release mechanism. Wing fall may result during road transport.

10. Unlatch primary wing latch

with the cable release located

on the front of the tool bar

before unfolding tool bar.

NOTE: Cable must be free. Do not place

hydraulic hoses, EVA hoses or ties around

the cable.

13

AT6020

Operating Instructions

Leveling

adjustable

gauge

wheels

NOTE:

Adjust until

tool bar is

level

across the

entire bar

NOTE:

Coulter will

require

nal

working

depth

adjustment

in the eld.

11. Check tire pressure before

adjusting.

Loosen the two 1” x 4” Hex bolts

at the top of the adjust linkage.

Loosen 1” hex nut on inside of

threaded rod. Turn 1” hex nut

on outside clockwise to lower

wing and counter clockwise to

raise wing. Secure both nuts on

threaded rod against cylinder

lug adjust. Tighten

1” x 4” hex cap screws after

wheel adjustment.

Tighten one inch

hex nuts after

wheel adjustment.

Cylinder lug adjust

One Inch hex nut

14

Pin adjust

gauge

wheel

Depth

collars

12. Adjust pin adjust gauge wheel

to level position with the

hydraulic gauge wheel.

13. Install equal lengths of cylinder

depth collars to the right and left

hand center section wheel lift

cylinders.

NOTE: Unequal depth collar installation

may result in wheel lift linkage damage.

AT6020

Operating Instructions

LOCKED POSTION

DEPTH ADJUSTMENT

1. One complete revolution equals 1/2” of

depth increase.

LOCKING DEPTH ADJUSTMENT

LINKAGE

1. Rotate depth control adjuster latch

over handle and lock in place with

(27) (BP3376) 1/4” x 2” wire retaining

pin.

15

AT6020

Operating Instructions

Nurse tank

hitch

NOTE:

Periodically

check Latch

mechanism to

ensure proper

latching in the

extended

position.

Secondary

wing latch

14. Nurse tank hitch can be

retracted and moved from

side to side for easy hookup.

Hitch will automatically lock

in the extended position.

WARNING

Pinch point

To prevent Injury

Keep hands clear

when extending or

retracting the swing

slide insert

15. Mechanism must swing

freely in order to operate

properly. Installed position

must be squared with frame

to allow maximum freedom

of movement. Keep soil and

debris from area to allow

maximum movement.

16

Latch in open position

before wing is folded

Cylinder rod

maintenance

NOTE: After seasonal storage,

check wing latch for freedom of

movement.

16. All exposed cylinder rods

should be greased before

seasonal storage to prevent

rusting.

Remove depth collars and

lubricate exposed cylinder

rods.

AT6020

Operating Instructions

Lug Nut

Torque

Lubrication

Zerks

Zerk

17. Lug nut Torque

1. Check every hour rst four

hours.

2. Check every four hours to

rst twenty hours.

3. Check once every fty hours

thereafter.

17. Lubrication

• Grease all zerks daily

• Grease coulters daily

Lift Wheel Pivot Zerk

(Torque 150-180 ft. lbs.)

Zerk

Wing Linkage

Zerk

Wing Hinges

Zerk

Under

Hitch

Zerks On Wing Gauge

Wheel Pivot

(Torque 100 ft./lbs.)

Zerk

Wing Linkage

17

AT6020

Lubrication

Operating Instructions

Zerks On Wing Gauge

Wheel Pivot

(Torque 100 ft./lbs.)

Zerks On Linkage

And Hinge

Coulter

pivot shaft

lubrication

Coulter

hub

lubrication

Emergency

water tank

operation

and

maintenance

18. Grease all coulter arm pivots.

19. The plug on the coulter hub

can be removed. A zerk can

be installed. Hub and spindle

assembly should be greased

twice seasonally.

20. emergency water tank/toolbox.

Change water daily to provide

fresh clean water to ush

exposed skin or eyes.

Drain water daily in cold

temperatures to prevent

freezing and bursting tank.

18

AT6020

Anhydrous Ammonia Operating Instructions

Attend Anhydrous Ammonia Safety Training Class Provided By Your

Dealer Before Operating this equipment .

Operator protection

Because of the hazards associated

with handling Anhydrous Ammonia,

operators must use proper protective

equipment. Minimum equipment includes

tight-tting chemical-proof goggles,

long cuff rubber gloves, heavy-duty

long sleeved shirt. In case of exposure,

have a minimum of 5 gal`s of ushing

water available at all times.

Checking System

With personal protective equipment in

place, visually inspect the tool bar and system components for integrity, includes

hoses that may be subject to inadvertent contact with structural surfaces resulting in

premature exterior hose deterioration.

Tank Connection

Body Guard

NOTE: A light application

of oil maybe applied to the

break away coupler mating.

Hooking Up Nurse Tank

With personal protective equipment in place, hitch the nurse tank to the tool bar using

a keyed hitch pin. Afx wagon tongue safety chains securely to Nurse tank chain loops

provided.

Break Away

Carefully hand tighten the nurse tank supply hose connection. Position hose to allow

unobstructed movement in case of Nurse Tank break away. Do not allow supply hose

to contact surfaces that may cause abrasion or wear including sharp corners, soil or

roads.

With personal protective equipment in place, conrm the functional operation of the

break away coupler on a daily basis. First bleed pressure off of tank supply hose and

1-1/4” quick coupler using the bleed valves provided.

Sharply pull on the tank supply hose. The coupler mechanism should release under

these forces. Visually inspect coupler for corrosion, foreign elements and proper

seating of mating poppets.

DO NOT transport equipment from eld to eld with tank and supply line valves open.

When immediately ready for eld application, beginning at the tank, and with personal

protective equipment in place, slowly open all supply line valves.

WARNING

WARNING: Position your body away from the bleed

valve exit hole to avoid contact with Anhydrous

Ammonia when bleed valve is opened. Contact with

skin will cause severe chemical burns.

WARNING: Avoid breathing ammonia vapors. Clear

WARNING

all personnel from the area before opening system.

Inhalation of vapors will irritate or damage respiratory

tract and lungs, resulting in injury or death.

Bleed

Valve

19

AT6020

Anhydrous Ammonia Operating Instructions

Disconnection Of Nurse Tank

1. With personal protective equipment in place, and beginning at the tank, fully

shut off the supply hose valves. If the supply hose is a tank wagon component

(as opposed to a tool bar component) an additional hand operated globe valve

shut off located between the quick coupler and the Heat Exchanger feed line

will signicantly speed up the tank wagon change process.

2. Clear all personnel from area except for the operator. While considering the

direction of the wind to avoid ammonia vapor drift toward the operator or any

other personnel, beginning at the tank, slowly open supply line bleed valves to

release pressure from the hose.

3. Physically grasp, lift and lightly shake the supply hose mid section to insure

total evacuation of ammonia. Once again, be wary of the wind direction.

4. Place the supply hose in a transport storage position, preventing it from

becoming entangled or in contact with sharp edges or abrasive

surfaces.

5. Always park and unhook the nurse tank on a smooth and level surface.

Block the wheels to prevent tank wagon runaway. High winds or uneven

terrain can cause unblocked tank wagons to move out of control.

6. Disconnect tank wagon tongue safety chains, hitch pin key and hitch pin.

CAUTION

CAUTION: Fifth wheel style running gear front axles may inadvertently

rotate in uneven soil conditions when the hitch pin is pulled causing the

tongue to come into contact and potentially injuring the operator.

WARNING

WARNING: Before maintenance is preformed on any part of the NH3

system, be sure the total system is bled off and all liquid is drained. Liquid

ammonia can remain trapped in system cavities, even when the system

has been opened to atmospheric pressure. Always assume that ammonia

remains in the system components and hoses at all times. Always wear

tight-tting chemical-proof goggles, long cuff rubber gloves, heavy-duty

long sleeved shirt and exercise extreme caution.

20

AT6020

Safety Decals

AP2972

AP2227

AP2974

AP2973

AP2975

21

AT6020

Coupler Operations

NOTE:

Read

coupler

operation

decal

(AP2974)

for safety

instructions.

Coupler release handle

Female coupler

Male coupler neck

Body Guard III

Feed-line to tank

Coupler bleed valve

Male coupler half

Check valve plunger

Connecting

DANGER

DANGER:

Always wear

protective

gear.

1. Stand on the upwind side. Close all

feed-line valves and inspect all

components for proper condition.

2. Relieve pressure in nurse tank

hose between male coupler (F) and

rst shutoff valve towards nurse tank

by carefully opening coupler bleed

valve (E). The Squibb Flo-Max coupler

is designed to re-couple safely with

pressure on the female coupler half

(B). CAUTION: Leave coupler bleed

valve (E) open for now.

A

B

C

D

Flow

Downstream

E

F

G

22

DANGER:

DANGER

Avoid

breathing

ammonia

vapors.

DANGER

DANGER:

Hazardous

chemical

under

pressure.

Disconnect

3. While holding and pointing the

hose and male coupler (F) downwind

and away from your person, depress

check valve plunger (G) with gloved

nger to ensure proper operation.

Wipe foreign debris from coupler neck

(C) with clean cloth.

4. Make certain BodyGuard III

is installed fully with slot oriented

around check valve plunger (G) to

protect against ammonia spray-back

during coupling.

5. Insert male coupler neck (C) into

female coupler half (B) as far as possible.

Then, while applying insertion

pressure, pull downward on coupler

release handle (A) to complete the

coupling process. Release handle (A)

after engagement of coupler neck (C).

6. Lightly pull on male coupler (F) to

ensure proper engagement.

7. Close bleed valve (E) and others if

open. Open tank and hose valves just

prior to applying ammonia.

TM

(D)

1. After closing all valves, bleed

pressure from male coupler half

(F) by opening coupler bleed valve

(E). Leave bleed valve (E) open.

2. Then, pull down on coupler

release handle (A) and remove

male coupler half (F).

AT6020

NOTE:

Mount

Safety Tank

after

machine

has been

folded to

avoid

hitting and

collapsing

tank

Emergency Fresh Water Tank Location and Assembly

Location of Nine-gallon safety water

tank/toolbox.

Change water daily to provide fresh

clean water to ush exposed skin

or eyes. Drain water daily in cold

temperatures to prevent freezing

and bursting tank.

In case of exposure to anhydrous

ammonia, open faucet or pull top

end of hose loose to ush exposed

part of body. Remove contaminated

clothes as soon as possible. Seek

medical attention.

NOTE:

Safety Tank

placement

will depend

on row

spacing

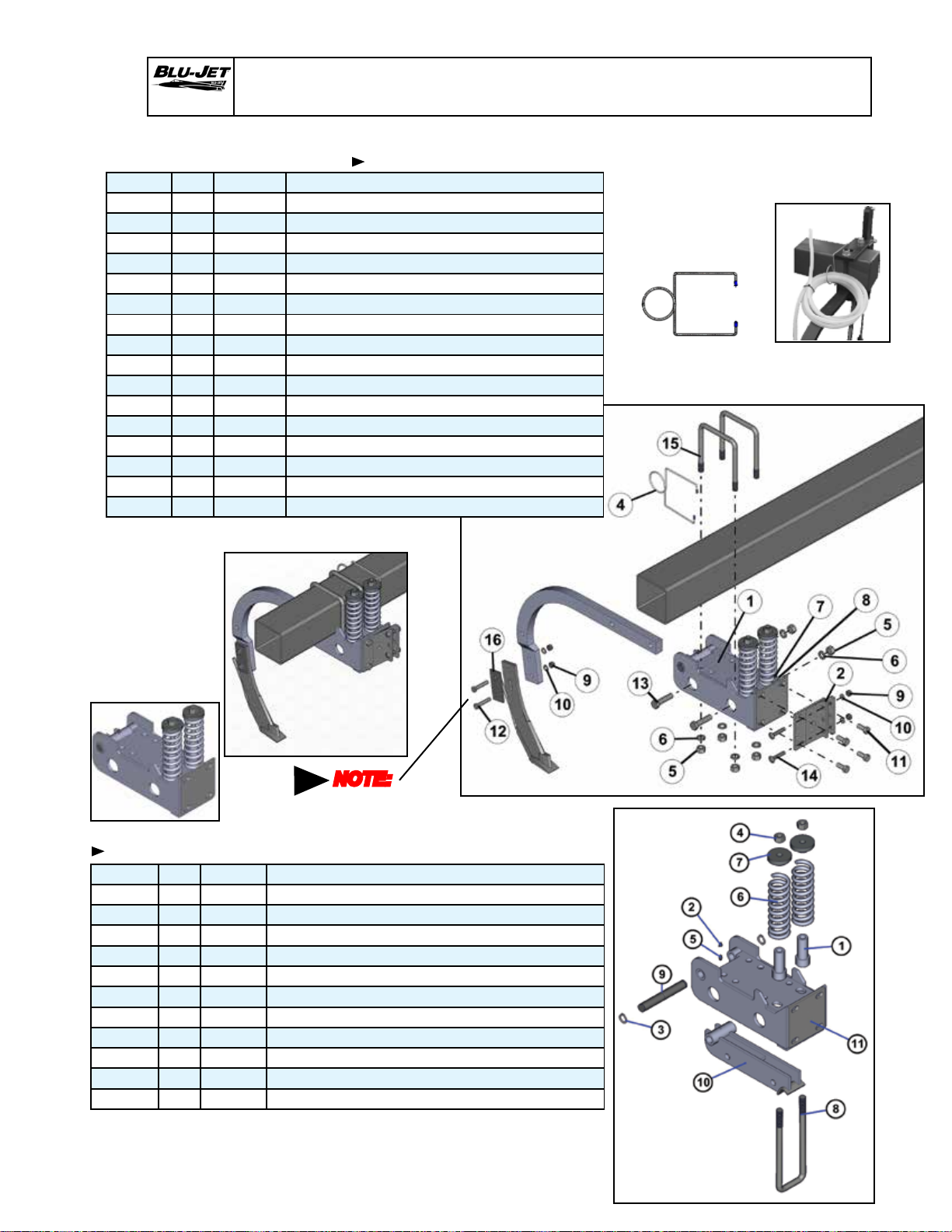

BOM ID Qty Item No Description

1 1 PKG00040 PACKAGE, 9 GALLON SAFETY TANK

2 1 AP2137 SAFETY TANK, 9 GALLON

2A 1 AP2137 TANK TANK

2B 1 AP2137 LID TOOLBOX LID

2C 1 CP2577 HOSE BARB, 3/4”MP X 3/4” HOSE BARB, POLY

2D 1 CP2471 ELBOW, 90 DEGREE, 3/4”MP X 3/4” HOSE BARB, POLY

2E 1 AP2329 SPIGOT

2F 1 AP2137 HOSE 3/4” CLEAR HOSE - CP2069 - 24” LENGTH

2G 1 AP2272 2” FILL CAP

3 2 AM2136 BRACKET, TANK MOUNTING, 9 GALLON

4 6 BP3159 WASHER, FLAT, 5/16”, PLATED

5 6 BP3158 WASHER, LOCK, 5/16”, PLATED

6 6 BP3108 HEX CAP SCREW, 5/16”-18 X 1”, GRADE 5, PLATED

7 4 BP3002 WASHER, LOCK, 3/8”, PLATED

8 4 BP3001 NUT, HEX, 3/8”-16, GRADE 2, PLATED

9 2 BP3351 U-BOLT, 3/8”-16 X 6”W X 7”L

10 1 AP2215 DECAL, BLU-JET, 3” X 8”

23

AT6020

Operational Guide For Various Residue Situations

BLU-JET StripTill Implement

Beans

(Soy or

Pinto)

NOTE:

Left-hand

and

right-hand

as viewed

from the rear

Coulter Blades

• 3”-4” Deep (make sure hub is not running in the ground)

• If blades are new or being used for the rst time in a season,

or if residue is hair pinning, sharpening each blade will assist

in cutting during the rst few acres of operation. After the

rst few acres, blades will self-sharpen

Residue Managers – Light pressure setting (particularly in light soils)

Shank depth – Minimum 4” deep from ground level (optimum depth

for fertilizer placement is 6”-8”)

Sealer Blade Position – Front holes on the sealer arm

Sealer Blade Pitch – Determined by soil type and season in soybean

residue

Sealer Blade Down Pressure – Determined by soil type and season

in this residue

Basket Pressure – Determined by soil type and season in this residue

Right-hand

Front holes

24

Light Pressure

Setting

Front holes

Residue Managers

Left-hand

Front holes

Sealers

Torsion

Basket

AT6020

Operational Guide For Various Residue Situations

BLU-JET StripTill Implement

Corn

Grain under

250 bushel

(in one year

corn/bean

rotation or

corn/corn/

bean rotation

if not Strip-

Tilling beans)

For best results follow these operating recommendations:

• Leaving standing stalks in the eld when harvesting (about

knee high) is preferable to shredding the residue

• Row units on the machine should be operated between last

year’s corn rows (split last year’s rows)

Coulter Blades

• 3”-4” Deep (make sure hub is not running in the ground)

• If blades are new or being used for the rst time in a season,

or if residue is hair pinning, sharpening each blade will assist

in cutting during the rst few acres of operation. After the rst

few acres, blades will self-sharpen

Residue Managers – Heavy pressure setting

Shank depth – Minimum 4” deep from ground level (optimum

depth for fertilizer placement is 6”-8”)

Sealer Blade Position – Rear holes on the sealer arm

Sealer Blade Pitch – Blades should be even in pitch and backs of

the blades should be at least 8” apart

Sealer Blade Down Pressure – Determined by soil type and season

in this residue

Basket Pressure – Determined by soil type and season in this residue

NOTE:

Left-hand

and

right-hand

as viewed

from the rear

Heavy Pressure

Setting

Rear holes

Residue Managers

Left-hand

Rear holes

Down Pressure Kit

Sealers

Adjust Sealers

8” apart

Right-hand

Rear holes

Torsion

Basket

25

AT6020

Operational Guide For Various Residue Situations

BLU-JET StripTill Implement

Corn

Grain over

250 bushel

(in one year

corn/bean

rotation)

For best results follow these operating recommendations:

• Leave standing stalks do not shred the residue in the eld when

harvesting (about knee high)

• Row units on the machine should be operated between last

year’s corn rows (split last year’s rows)

Coulter Blades

• 3”-4” Deep (make sure hub is not running in the ground)

• If blades are new or being used for the rst time in a season,

or if residue is hair pinning, sharpening each blade will assist

in cutting during the rst few acres of operation. After the rst

few acres, blades will self-sharpen

Residue Managers – Heavy pressure setting

Shank depth – Minimum 4” deep from ground level (optimum

depth for fertilizer placement is 6”-8”)

Sealer Blade Position – Offset (left blade in rear holes and right

blade in front holes)

Sealer Blade Pitch –

• Left blade should be set at nearly maximum pitch

• Right blade should be set at about half pitch when compared to

the left blade

Sealer Blade Down Pressure – Down Pressure Kits are recommended

for this residue situation

Basket Pressure – Running a basket is recommended for this residue

situation. Consult: Setting the Implement for eld

operation: pages

26

NOTE:

Left-hand

and

right-hand

as viewed

from the rear

Heavy Pressure

Setting

Residue Managers

Left-hand

Rear holes

Maximum

Pitch

Down Pressure Kit

Right-hand

Front holes

Half Pitch

Sealers

Torsion

Basket

AT6020

Operational Guide For Various Residue Situations

BLU-JET StripTill Implement

Corn

Grain under

250 bushel

(in 2+ years

corn rotation)

For best results follow these operating recommendations:

• Leave standing stalks do not shred the residue in the eld when

harvesting (about knee high)

• Row units on the machine should be operated 7.5” to one side

of last year’s corn row (RTK guidance recommended)

Coulter Blades

• 3”-4” Deep (make sure hub is not running in the ground)

• If blades are new or being used for the rst time in a season,

or if residue is hair pinning, sharpening each blade will assist

in cutting during the rst few acres of operation. After the rst

few acres, blades will self-sharpen

Residue Managers – Heavy pressure setting

Shank depth – Minimum 4” deep from ground level (optimum

depth for fertilizer placement is 6”-8”)

Sealer Blade Position – Rear holes on the sealer arm

Sealer Blade Pitch – Blades should be even in pitch and backs of

the blades should be at least 10” apart

Sealer Blade Down Pressure – Down Pressure Kits are recommended

for this residue situation

Basket Pressure – Determined by soil type and season in this residue

NOTE:

Left-hand

and

right-hand

as viewed

from the rear

Heavy Pressure

Setting

Residue Managers

Left-hand

Rear holes

Even Pitch

Down Pressure Kit

Sealers

Adjust Sealers

10” apart

Right-hand

Rear holes

Even Pitch

Torsion

Basket

27

AT6020

Operational Guide For Various Residue Situations

BLU-JET StripTill Implement

Corn

Grain over

250 bushel

(in 2+ years

corn rotation)

For best results follow these operating recommendations:

• Leave standing stalks do not shred the residue in the eld when

harvesting (about knee high)

• Row units on the machine should be operated 7.5” to one side

of last year’s corn row (RTK guidance recommended)

Coulter Blades

• 3”-4” Deep (make sure hub is not running in the ground)

• If blades are new or being used for the rst time in a season,

or if residue is hair pinning, sharpening each blade will assist

in cutting during the rst few acres of operation. After the rst

few acres, blades will self-sharpen

Residue Managers – Heavy pressure setting

Shank depth – Minimum 4” deep from ground level (optimum

depth for fertilizer placement is 6”-8”)

Sealer Blade Position – Offset (left blade in rear holes and right

blade in front holes)

Sealer Blade Pitch –

• Left blade should be set at nearly maximum pitch

• Right blade should be set at about half pitch when compared to

the left blade

Sealer Blade Down Pressure – Down Pressure Kits are recommended

for this residue situation

Basket Pressure – Running a basket is recommended for this residue

situation.

28

NOTE:

Left-hand

and

right-hand

as viewed

from the rear

Heavy Pressure

Setting

Residue Managers

Left-hand

Rear holes

Maximum

Pitch

Down Pressure Kit

Right-hand

Front holes

Half Pitch

Sealers

Torsion

Basket

AT6020

Operational Guide For Various Residue Situations

BLU-JET StripTill Implement

Corn

Silage

NOTE:

Left-hand

and

right-hand

as viewed

from the rear

For best results follow these operating recommendations:

• Row units on the machine should be operated at least 7.5” off of

any corn row where root ball masses remain mostly intact

Coulter Blades

• 3”-4” Deep (make sure hub is not running in the ground)

• If blades are new or being used for the rst time in a season,

or if residue is hair pinning, sharpening each blade will assist

in cutting during the rst few acres of operation. After the rst

few acres, blades will self-sharpen

Residue Managers – Light pressure setting (particularly in light soils)

Shank depth – Minimum 4” deep from ground level (optimum

depth for fertilizer placement is 6”-8”)

Sealer Blade Position – Front holes on the sealer arm

Sealer Blade Pitch – Determined by soil type and season in this residue

Sealer Blade Down Pressure – Determined by soil type and season in

this residue

Basket Pressure – Determined by soil type and season in this residue

Right-hand

Front holes

Light Pressure

Setting

Front holes

Residue Managers

Left-hand

Front holes

Sealers

Torsion

Basket

29

AT6020

Operational Guide For Various Residue Situations

BLU-JET StripTill Implement

Cover

Crop

Live or

Residue

NOTE:

Left-hand

and

right-hand

as viewed

from the rear

Coulter Blades

• 3”-4” Deep (make sure hub is not running in the ground)

• If blades are new or being used for the rst time in a season,

or if residue is hair pinning, sharpening each blade will assist

in cutting during the rst few acres of operation. After the rst

few acres, blades will self-sharpen

Residue Managers – Heavy pressure setting

Shank depth – Minimum 4” deep from ground level (optimum

depth for fertilizer placement is 6”-8”)

Sealer Blade Position – Rear holes on the sealer arm

Sealer Blade Pitch – Blades should be even in pitch and backs of the

blades should be at least 8” apart

Sealer Blade Down Pressure – Down Pressure Kit recommended in

this residue situation

Basket Pressure – Determined by soil type and season in this residue

Down Pressure Kit

Right-hand

Rear holes

30

Heavy Pressure

Setting

Rear holes

Residue Managers

Left-hand

Rear holes

Sealers

Adjust Sealers

8” apart

Torsion

Basket

AT6020

Operational Guide For Various Residue Situations

BLU-JET StripTill Implement

Sugar

Beets

NOTE:

Left-hand

and

right-hand

as viewed

from the rear

Coulter Blades

• 3”-4” Deep (make sure hub is not running in the ground)

• If blades are new or being used for the rst time in a season,

or if residue is hair pinning, sharpening each blade will assist

in cutting during the rst few acres of operation. After the rst

few acres, blades will self-sharpen

Residue Managers – Light pressure setting (particularly in light soils)

Shank depth – Minimum 4” deep from ground level (optimum

depth for fertilizer placement is 6”-8”)

Sealer Blade Position – Front holes on the sealer arm

Sealer Blade Pitch – Determined by soil type and season in this residue

Sealer Blade Down Pressure – Determined by soil type and season in

this residue

Basket Pressure – Determined by soil type and season in this residue

Right-hand

Front holes

Light Pressure

Setting

Front holes

Residue Managers

Left-hand

Front holes

Sealers

Torsion

Basket

31

AT6020

Operational Guide For Various Residue Situations

BLU-JET StripTill Implement

Wheat &

Other

Small

Grain

NOTE:

Left-hand

and

right-hand

as viewed

from the rear

Coulter Blades

• 3”-4” Deep (make sure hub is not running in the ground)

• If blades are new or being used for the rst time in a season,

or if residue is hair pinning, sharpening each blade will assist

in cutting during the rst few acres of operation. After the rst

few acres, blades will self-sharpen

Residue Managers – Heavy pressure setting

Shank depth – Minimum 4” deep from ground level (optimum

depth for fertilizer placement is 6”-8”)

Sealer Blade Position – Rear holes on the sealer arm

Sealer Blade Pitch – Blades should be even in pitch and backs of the

blades should be at least 8” apart

Sealer Blade Down Pressure – Down Pressure Kit recommended in

this residue situation

Basket Pressure – Determined by soil type and season in this residue

Down Pressure Kit

Right-hand

Rear holes

32

Heavy Pressure

Setting

Rear holes

Residue Managers

Left-hand

Rear holes

Sealers

Adjust Sealers

8” apart

Torsion

Basket

Setting the Implement for eld operation:

AT6020

1. Run the implement in the eld for approximately 100 feet (making sure the tractor reaches the

speed at which you wish to operate the machine). Stop while leaving the shanks in the ground.

2. Check for your desired shank depth on a middle row and on each wing. Shank depth should

be at least 4” from ground level (6”-8” is optimum fertilizer placement depth for corn in most areas).

Adjust the mainframe and wing wheels accordingly and repeat steps 1&2 until desired depth

across the machine is achieved.

3. Ensure the frame is level from front to back when the shanks are in the ground at the depth you

have chosen.

4. Walk to the back of the machine

a. Check for uniformity on the strips from row to row. Below: are items to look for.

i. Fall Operation (In areas with a good freeze-thaw over the winter):

1. Top of the berm should be at a minimum height of 4” from ground level

(expect it to mellow 2”-3” over the winter)

2. Berm should be 8”-10” wide

3. There should be little to no residue within the strip (if using Residue Managers)

4. The top of the berm should be slightly attened and most dirt clods

should be no larger than your st (if using baskets on a light setting).

ii. Fall Operation (In areas with little to no freeze-thaw over the winter):

1. Top of the berm should be at a height of 2”-3” from ground level (expect

it to mellow 1”-2” with winter moisture)

2. Berm should be 8”-10” wide

3. There should be little to no residue within the strip (if using Residue Managers)

4. The top of the berm should be moderately at and most dirt clods should

be no larger than a golf ball (if using baskets on a medium setting)

iii. Spring Operation (all areas)

1. Top of the berm should be at a height of 1”-2” from ground level

2. The berm should be 8”-10” wide

3. There should be little to no residue within the strip (if using Residue Managers)

4. The top of the berm should be at and soil should have a nished look,

ready for planting.

b. If you see uniformity in the strips across each row, and they are as described above

based on the season and climate in which you are running, you are ready to proceed with

normal operation.

5. If you do not see uniformity in the strips from row to row, pick one of the strips that looks like

the description above and use it as an example row. Set the components on the other rows

similar to your example row. Below are some of the component settings to check.

a. Coulters

i. Look across the tops of the coulter shanks to see if they are set at equal depth.

1. Blades should be running 3”-4” in the ground

2. Be sure the coulter is not set so deep that the hub is running in the ground

ii. If the implement has been used before, check the coulter blades to make sure they

have similar wear.

b. Residue Managers

BLU-JET StripTill Implement

33

Setting the Implement for eld operation:

AT6020

i. There is a heavy and light spring pressure setting. Be sure that all Residue Managers

are set on the same pressure setting.

ii. Lift up on the Residue Managers to gauge pressure if settings are the same, but

you suspect the spring pressure is different.

iii. See recommended setting for your residue type and climate above

c. Sealer Blade Hanger Position

i. Check to make sure all sealer blade hanger brackets are mounted on the sealer

arms in the same positions (all front, all back, or all offset)

ii. Check to make sure all sealer blade hanger brackets are mounted on the same

width position (either all narrow or all wide)

iii. See recommended setting for your residue type and climate above

d. Sealer Blade Angle

i. Check to see that the blades on each row are set at a similar angle

ii. Check to see that the backs of the blades on each row are set approximately the

same distance apart.

iii. See recommended settings for your residue type and climate above

e. Baskets

i. Check to see that all baskets are running on the same pressure setting.

ii. Ensure that all baskets freely spin and some are not signicantly more restricted

compared to others.

iii. See recommended setting for your residue type and climate above

f. Knives

i. Lift the implement out of the ground and ensure knives are identical in make and

model

ii. If the implement has been used before, check to make sure wear characteristics

on the knives are similar.

BLU-JET StripTill Implement

6. If you have checked all settings and still do not see uniformity across the rows, or you have tried

different settings and cannot achieve a strip like those described above, call 800.658.3127 for

additional assistance.

34

AT6020

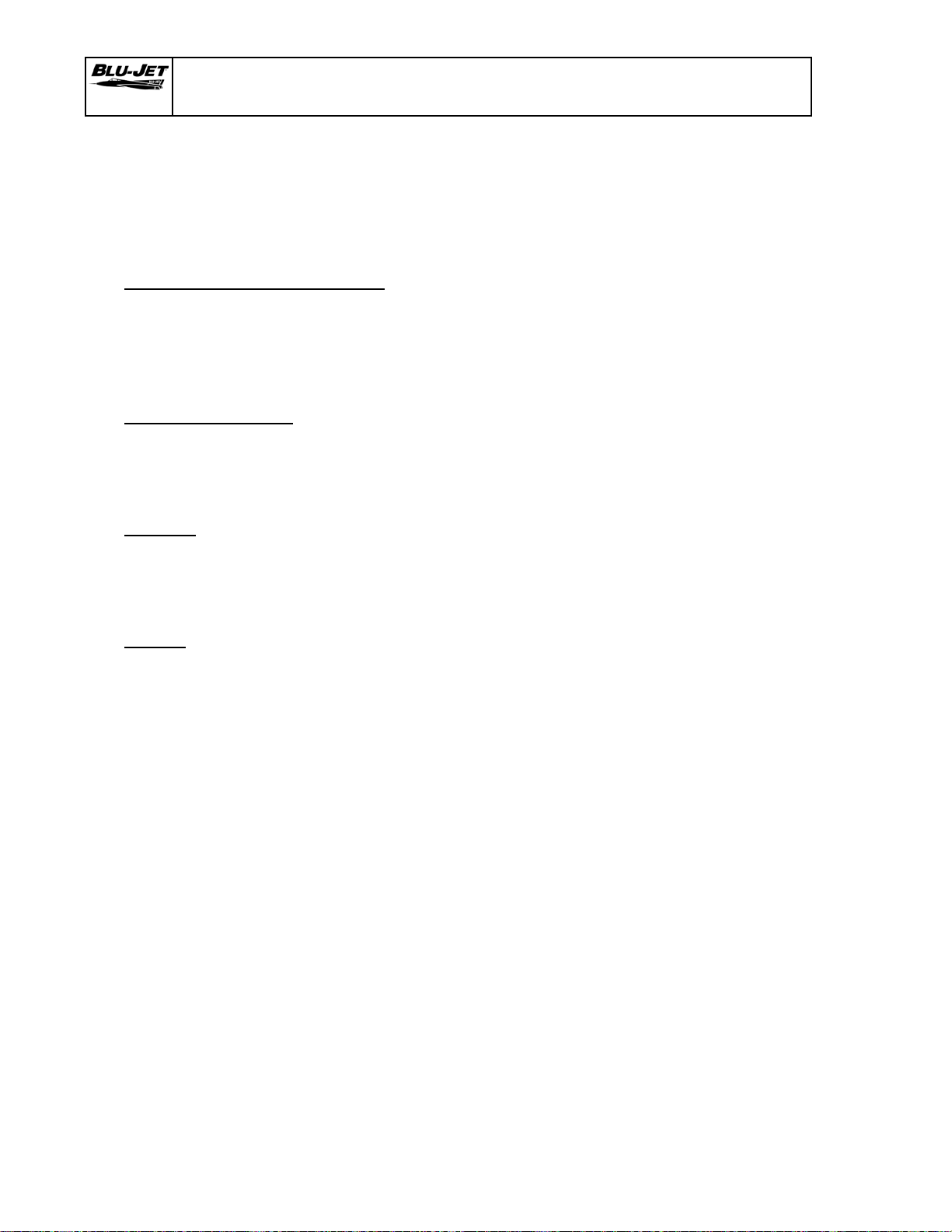

BOM ID Qty Item No Description

1 1 66000103 AT6020 MAIN FRAME & PRIMARY WINGS

2 1 AAM2140 PERFECT HITCH ASSEMBLY, CAT IV/V, W/MTG HARDWARE

2A 1 AP3127 PERFECT HITCH ASSEMBLY, CAT IV-V

2B 3 BP3020 WASHER, LOCK, 1, PLATED

2C 3 BP3275 NUT, HEX, 1”-8, GRADE 8, PLATED

2D 3 BP3448 HEX CAP SCREW, 1’-8 X 8”, GRADE 8, PLATED

3 2 AAM2437 HOSE RETAINER ASSEMBLY, CLOSED LOOP, 4X6 TUBE

3A 2 AM4015 HOSE RETAINER, CLOSED LOOP, 6” & 7” MOUNTING

3B 4 BP3001 NUT, HEX, 3/8”-16, GRADE 2, PLATED

3C 4 BP3002 WASHER, LOCK, 3/8”, PLATED

3D 2 BP3045 U-BOLT, 3/8”-16 X 6”W X 5”L, PLATED

4 11 AAM2438 HOSE RETAINER ASSEMBLY, CLOSED LOOP, 6X6 TUBE

4A 11 AM4015 HOSE RETAINER, CLOSED LOOP, 6” & 7” MOUNTING

4B 22 BP3001 NUT, HEX, 3/8”-16, GRADE 2, PLATED

4C 22 BP3002 WASHER, LOCK, 3/8”, PLATED

4D 11 BP3351 U-BOLT, 3/8”-16 X 6W X 7L, PLATED

5 1 AAM2639 MANUAL HOLDERW/ 6X4 MOUNTING

5A 1 AM7640 BRACKET, MOUNTING, MANUAL HOLDER

5B 1 AP4254 MANUAL HOLDER, BLACK

5C 3 BP3001 NUT, HEX, 3/8”-16, GRADE 2, PLATED

5D 3 BP3002 WASHER, LOCK, 3/8”, PLATED

5E 1 BP3006 HEX CAP SCREW, 3/8”-16 X 1”, GRADE 5, PLATED

5F 1 BP3045 U-BOLT, 3/8”-16 X 6”W X 5”L, PLATED

6 1 AAM2928 STOP ARM, W/ PLUNGER, DEPTH CONTROL

6A 1 AM4627 PLUNGER, DEPTH GAUGE

6B 1 AM6265 ARM, STOP, DEPTH CONTROL

6C 1 AP2193 SPRING, 1.4” OD X 3” OAL, LHC 177P 02M

6D 1 BP3162 PIN, ROLL, 3/8” X 2”, PLATED

7 1 AAM2929 ADJUSTMENT LINKAGE, AT6020 DEPTH CONTROL

7A 1 AM6267 LINKAGE BODY, AT6020 DEPTH CONTROL ADJUSTMENT

7B 1 AM6268 ROD END, 3/4” BALL JOINT, 3/4”-16LH X 5”

7C 1 AM6269 ROD END, 3/4” BALL JOINT, 3/4”-16RH X 5”

7D 1 AP2584 DECAL, DEPTH CONTROL

8 1 AAM4768 ASSEMBLY, TURNBUCKLE

9 1 AM2144 HITCH, CLEVIS

10 1 AM2145 BRACKET, HITCH STORAGE, 6” MOUNTING

11 1 AM2197 BRACKET, WRENCH STORAGE

12 1 AM2518 JACK, 9TWDL

13 1 AM2526 CRANK W/ GRIP, 90 LONG

14 3 AM4015 HOSE RETAINER, CLOSED LOOP, 6” & 7” MOUNTING

15 2 AM4415 HOSE RETAINER, OPEN LOOP

16 2 AM4442 HOSE RETAINER, CLOSED LOOP

17 1 AM4511 BRACKET, TURNBUCKLE SUPPORT MOUNTING

18 1 AM4512 TURNBUCKLE SUPPORT

19 2 AM4517 WING LOCK

20 2 AM4524 ROCKER, AT6020

20A 4 BP3072 GREASE ZERK, 1/4”-28

20B 2 BP3560 TENSION BUSHING, 1-1/2” X 1-1/4” X 1” OAL

21 2 AM4528 BRACKET, HOSE HOLDER W/ PRESSURE GAUGE MOUNT

22 2 AM4529 SAFETY LAUNCH TRIP, PRIMARY WING, AT 5000

23 1 AM4563 CYLINDER LUG, BOLT-ON 5” CYLINDER

Center Section Area of Bundle 66000103

35

36

AT6020

24 2 AM4564 CYLINDER LUG, SCREW ADJUST

24A 2 BP3516 TENSION BUSHING, 1-1/4” X 1” X 1” OAL

25 2 AM4566 WING LATCH PIVOT, SECONDARY WING

26 2 AM4567 SPACER PIPE, 6-1/4” OAL

27 4 AM4568 SECONDARY WING LOCK PLATE

28 1 AM4759 TURNBUCKLE WRENCH, 3-1/16”

28A 1 AP2413 GRIP, JACK HANDLE

29 1 AM5158 TONGUE, CAT IV, EXTENDED, WEIGHTED

30 1 AM6163 WHEEL LEG, LH, W/ 2-3/4” SPINDLE LOOP

30A 1 BP3213 GREASE ZERK

30B 1 BP3516 TENSION BUSHING, 1-1/4” X 1” X 1” OAL

30C 2 BP3538 TENSION BUSHING, 2” X 1-3/4” X 1-1/2” OAL

31 1 AM6164 WHEEL LEG, RH, W/ 2-3/4” SPINDLE LOOP

31A 1 BP3213 GREASE ZERK

31B 1 BP3516 TENSION BUSHING, 1-1/4” X 1” X 1” OAL

31C 2 BP3538 TENSION BUSHING, 2” X 1-3/4” X 1-1/2” OAL

32 1 AM6172 FRAME, MAIN, AT6020

32A 1 BP3516 TENSION BUSHING, 1-1/4” X 1” X 1” OAL

33 4 AM6179 LINKAGE, CYLINDER LUG SUPPORT

34 1 AM6182 LINKAGE, TONGUE CYLINDER ARM

34A 4 BP3072 GREASE ZERK, 1/4”-28

34B 1 BP3516 TENSION BUSHING, 1-1/4” X 1” X 1” OAL

35 1 AM6183 LINKAGE, TONGUE CYLINDER

36 1 AM6187 WING, PRIMARY, LH, AT6010

36A 2 BP3072 GREASE ZERK, 1/4”-28

37 1 AM6188 WING, PRIMARY, RH, AT6010

37A 2 BP3072 GREASE ZERK, 1/4”-28

38 2 AM6202 CYLINDER LUG, BOLT-ON W/ NOTCH

38A 2 BP3516 TENSION BUSHING, 1-1/4” X 1” X 1” OAL

39 1 AM6263 BRACKET, PIVOT, DEPTH CONTROL

40 1 AM6264 ARM, VALVE, DEPTH CONTROL

41 1 AM6266 LINKAGE, STOP, DEPTH CONTROL

42 1 AM6270 BRACKET, ADJUSTER, DEPTH CONTROL

43 1 AM6271 LATCH, DEPTH CONTROL ADJUSTER

44 4 AP2215 DECAL, BLU-JET, 3 X 8

45 1 AP2222 DECAL, STAND CLEAR OF TONGUE, TONGUE LIGHT

46 1 AP2231 DECAL, FEMA, 2-1/2” X 1-1/2”

47 4 AP2234 DECAL, DANGER STAND CLEAR FALLING WING

48 1 AP2469 DECAL, SAFETY CHAIN

49 1 AP2483 DECAL, DANGER, FALLING FROM EQUIPMENT

50 2 AP2558 DECAL, AT6020 COMMERCIAL CLASS APPLICATOR

51 12 AP2711 SNAP RING, 1-1/4” EXTERNAL, HEAVY DUTY

52 2 AP2871 HOSE RETAINER

53 1 AP2914 DECAL, WARNING, HIGH-PRESSURE FLUID

54 1 AP4391 TRANSPORT CHAIN, 60,000#, 5/8’’

55 1 BM3453 SPACER

56 2 BM3465 PIN, 1-1/4” X 7-3/4: OAL, W/ 13/32 HOLE, PLATED

57 4 BM3485 PIN, 1-3/4” X 12-1/8” OAL, W/ 21/32” HOLE, PLATED

58 1 BM3487 PIN, 1” X 7-3/4” OAL, W/ 13/32” HOLE, PLATED

59 2 BM3497 PIN, 1-3/4” X 14-3/4” OAL

60 2 BM3544 PIN, 1-1/4” X 9” USEABLE

61 2 BM3547 PIN, 1-1/4” X 5-3/4” USEABLE

62 2 BM3555 HEX BOLT, 1”-8 X 7-5/16”, FULL THREAD WELDED HEAD

Center Section Area of Bundle 66000103

Center Section Area of Bundle 66000103

AT6020

63 2 BM3565 PIN, 2” X 10-1/4” OAL, W/ 21/32” HOLE, PLATED

64 2 BM3610 PIN, 1-3/4” X 6-1/8” USEABLE W/ANTI-ROTATION HEAD

65 2 BM3664 PIN, 1-3/4” X 16-9/16” OAL, W/ 21/32” HOLE

66 12 BP3001 NUT, HEX, 3/8”-16, GRADE 2, PLATED

67 12 BP3002 WASHER, LOCK, 3/8”, PLATED

68 9 BP3003 NUT, HEX LOCK, 3/8”-16, GRADE 2, PLATED

69 6 BP3005 HEX CAP SCREW, 3/8”-16 X 1-1/2”, GRADE 5, PLATED

70 2 BP3006 HEX CAP SCREW, 3/8”-16 X 1”, GRADE 5, PLATED

71 2 BP3015 WASHER, FLAT, 3/8”, PLATED

72 14 BP3019 NUT, HEX, 1”-8, GRADE 2, PLATED

73 6 BP3020 WASHER, LOCK, 1, PLATED

74 2 BP3027 NUT, HEX LOCK, 3/4”-10, GRADE 2, PLATED

75 8 BP3034 NUT, HEX, 3/4”-10, GRADE 2, PLATED

76 8 BP3035 WASHER, LOCK, 3/4”, PLATED

77 16 BP3038 NUT, HEX, 5/8”-11, GRADE 2

78 16 BP3039 WASHER, LOCK, 5/8”, PLATED

79 4 BP3042 NUT, HEX, 1/2”-13, GRADE 2, PLATED

80 4 BP3043 WASHER, LOCK, 1/2”, PLATED

81 2 BP3045 U-BOLT, 3/8”-16 X 6”W X 5”L, PLATED

82 6 BP3072 GREASE ZERK, 1/4”-28

83 3 BP3096 HEX CAP SCREW, 3/8”-16 X 2-1/2”, GRADE 5, PLATED

84 2 BP3099 U-BOLT, 5/8”-11 X 6” X 6”, PLATED

85 2 BP3111 HEX CAP SCREW, 5/16”-18 S 2-1/2”, GRADE 5, PLATED

86 3 BP3115 HEX CAP SCREW, 3/8”-16 X 2”, GRADE 5, PLATED

87 4 BP3118 HEX CAP SCREW, 3/8”-16 X 5, GRADE 5, PLATED

88 6 BP3135 HEX CAP SCREW, 5/8”-11 X 3-1/2”, GRADE 5, PLATED

89 4 BP3136 HEX CAP SCREW, 5/8”-11 X 4, GRADE 5, PLATED

90 1 BP3139 HEX CAP SCREW, 3/4”-10 X 2”, GRADE 5, PLATED

91 1 BP3145 HEX CAP SCREW, 3/4-10 X 4-1/2”, GRADE 5, ZP

92 2 BP3157 NUT, HEX, 5/16”-18, GRADE 2, PLATED

93 2 BP3158 WASHER, LOCK, 5/16, PLATED

94 2 BP3179 HEX CAP SCREW, 1/2”-13 X 8, GRADE 5, PLATED

95 4 BP3200 HEX CAP SCREW, 1”-8 X 3-1/2”, GRADE 5, PLATED

96 8 BP3205 MACHINERY BUSHING, 2-1/2” OD X 1-3/4” ID, 10GA, PLATED

97 2 BP3215 MACHINERY BUSHING, 1-1/2” OD X 1” ID, 14GA, PLATED

98 2 BP3244 NUT, HEX LOCK, 1/2”-13, PLATED

99 12 BP3249 MACHINERY BUSHING, 1-7/8” OD X 1-1/4” ID, 14GA, PLATED

100 2 BP3255 WASHER, FLAT, 3/4, PLATED STRUCTURAL 10GA

101 6 BP3291 HEX CAP SCREW, 1”-8 X 4”, GRADE 5, PLATED

102 2 BP3330 U-BOLT, 1/2”-13 X 6”W X 5-1/8”L

103 4 BP3347 U-BOLT, 5/8”-11 X 4” X 5-5/8”, PLATED

104 4 BP3350 U-BOLT, 3/4”-10 X 6”W X 7-11/16”L, PLATED

105 2 BP3354 U-BOLT, 5/8”-11 X 4” X 7-3/4”, PLATED

106 10 BP3375 NUT, HEX LOCK, 5/8”-11, NYLOCK

107 1 BP3376 PIN, WIRE RETAINING, 1/4” X 2”, PLATED

108 1 BP3500 PIN, HAIR CLIP, 3/16”

109 2 BP3504 PIN, HAIRCLIP, 1/8”

110 2 BP3519 PIN, ROLL, 3/8” X 2-1/2”, PLAIN

111 2 AP4880 PIN, CLEVIS, 3/4” X 3”, ZP

112 1 CP2660 NUT, HEX LOCK, 3/8”-16, NYLOCK

113 1 DP4484 REPHASING CYLINDER, 3-1/2” X 12”, PMS-AM-2564

114 1 EM3735 BUSHING

37

AT6020

Center Section Area of Bundle 66000103

38

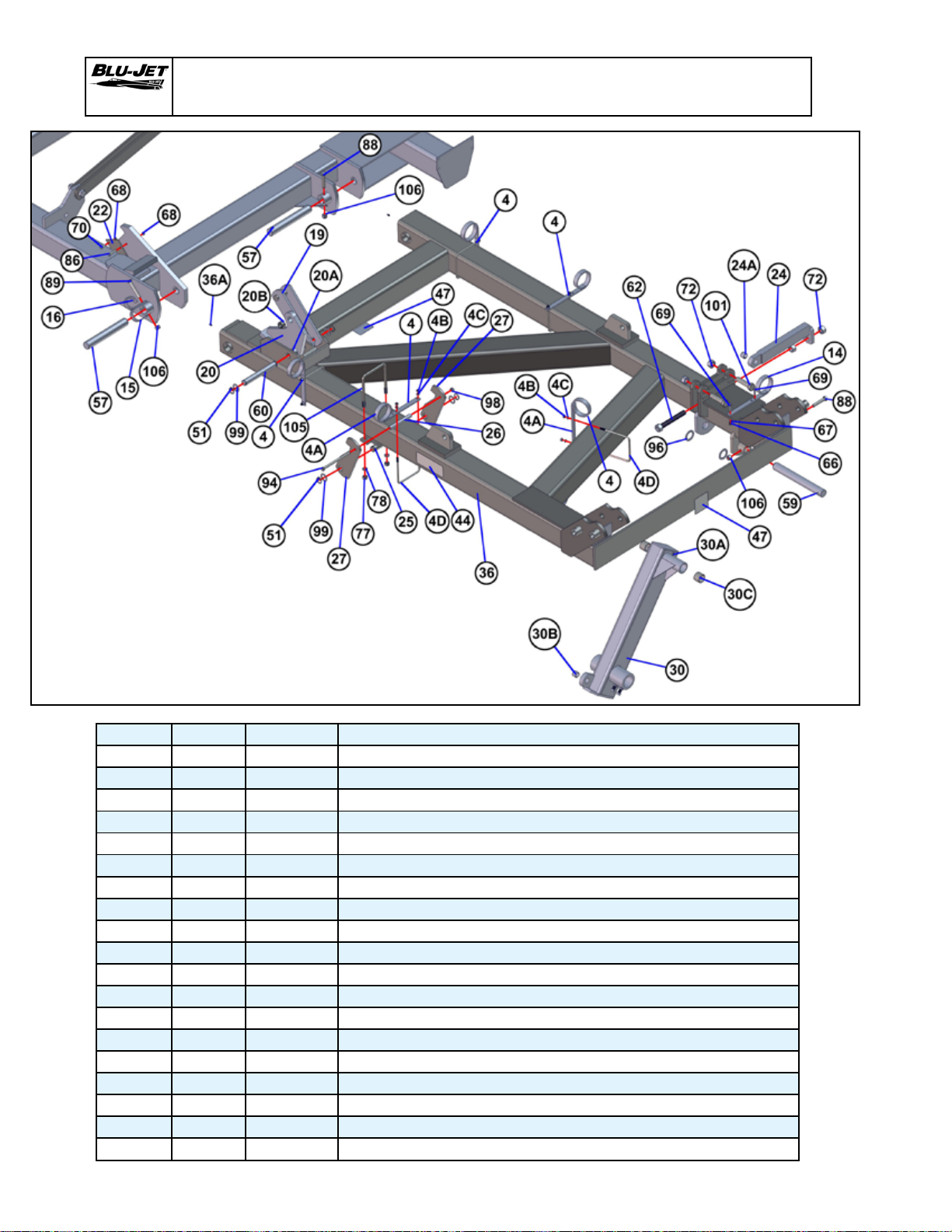

NOTE:

AAM4768,

turnbuckle

assembly:

Double nut

to hitch

weldment

Center Section Area of Bundle 66000103

AT6020

BOM ID Qty Item No Description

2 1 AAM2140 PERFECT HITCH ASSEMBLY, CAT IV/V, W/MTG HARDWARE

2A 1 AP3127 PERFECT HITCH ASSEMBLY, CAT IV-V

2B 3 BP3020 WASHER, LOCK, 1, PLATED

2C 3 BP3275 NUT, HEX, 1”-8, GRADE 8, PLATED

2D 3 BP3448 HEX CAP SCREW, 1’-8 X 8”, GRADE 8, PLATED

3 2 AAM2437 HOSE RETAINER ASSEMBLY, CLOSED LOOP, 4X6 TUBE

3A 2 AM4015 HOSE RETAINER, CLOSED LOOP, 6” & 7” MOUNTING

3B 4 BP3001 NUT, HEX, 3/8”-16, GRADE 2, PLATED

3C 4 BP3002 WASHER, LOCK, 3/8”, PLATED

3D 2 BP3045 U-BOLT, 3/8”-16 X 6”W X 5”L, PLATED

7 1 AAM2929 ADJUSTMENT LINKAGE, AT6020 DEPTH CONTROL

8 1 AAM4768 ASSEMBLY, TURNBUCKLE

12 1 AM2518 JACK, 9TWDL

13 1 AM2526 CRANK W/ GRIP, 90 LONG

21 2 AM4528 BRACKET, HOSE HOLDER W/ PRESSURE GAUGE MOUNT

42 1 AM6270 BRACKET, ADJUSTER, DEPTH CONTROL

43 1 AM6271 LATCH, DEPTH CONTROL ADJUSTER

45 1 AP2222 DECAL, STAND CLEAR OF TONGUE, TONGUE LIGHT

46 1 AP2231 DECAL, FEMA, 2-1/2” X 1-1/2”

48 1 AP2469 DECAL, SAFETY CHAIN

49 1 AP2483 DECAL, DANGER, FALLING FROM EQUIPMENT

50 2 AP2558 DECAL, AT6020 COMMERCIAL CLASS APPLICATOR

52 2 AP2871 HOSE RETAINER

53 1 AP2914 DECAL, WARNING, HIGH-PRESSURE FLUID

54 1 AP4391 TRANSPORT CHAIN, 60,000#, 5/8’’

64 2 BM3610 PIN, 1-3/4” X 6-1/8” USEABLE W/ANTI-ROTATION HEAD

66 12 BP3001 NUT, HEX, 3/8”-16, GRADE 2, PLATED

67 12 BP3002 WASHER, LOCK, 3/8”, PLATED

68 9 BP3003 NUT, HEX LOCK, 3/8”-16, GRADE 2, PLATED

71 2 BP3015 WASHER, FLAT, 3/8”, PLATED

77 16 BP3038 NUT, HEX, 5/8”-11, GRADE 2

78 16 BP3039 WASHER, LOCK, 5/8”, PLATED

79 4 BP3042 NUT, HEX, 1/2”-13, GRADE 2, PLATED

80 4 BP3043 WASHER, LOCK, 1/2”, PLATED

83 3 BP3096 HEX CAP SCREW, 3/8”-16 X 2-1/2”, GRADE 5, PLATED

84 2 BP3099 U-BOLT, 5/8”-11 X 6” X 6”, PLATED

87 4 BP3118 HEX CAP SCREW, 3/8”-16 X 5, GRADE 5, PLATED

100 2 BP3255 WASHER, FLAT, 3/4, PLATED STRUCTURAL 10GA

102 2 BP3330 U-BOLT, 1/2”-13 X 6”W X 5-1/8”L

107 1 BP3376 PIN, WIRE RETAINING, 1/4” X 2”, PLATED

109 2 BP3504 PIN, HAIRCLIP, 1/8”

110 2 BP3519 PIN, ROLL, 3/8” X 2-1/2”, PLAIN

111 2 AP4880 PIN, CLEVIS, 3/4” X 3”, ZP

39

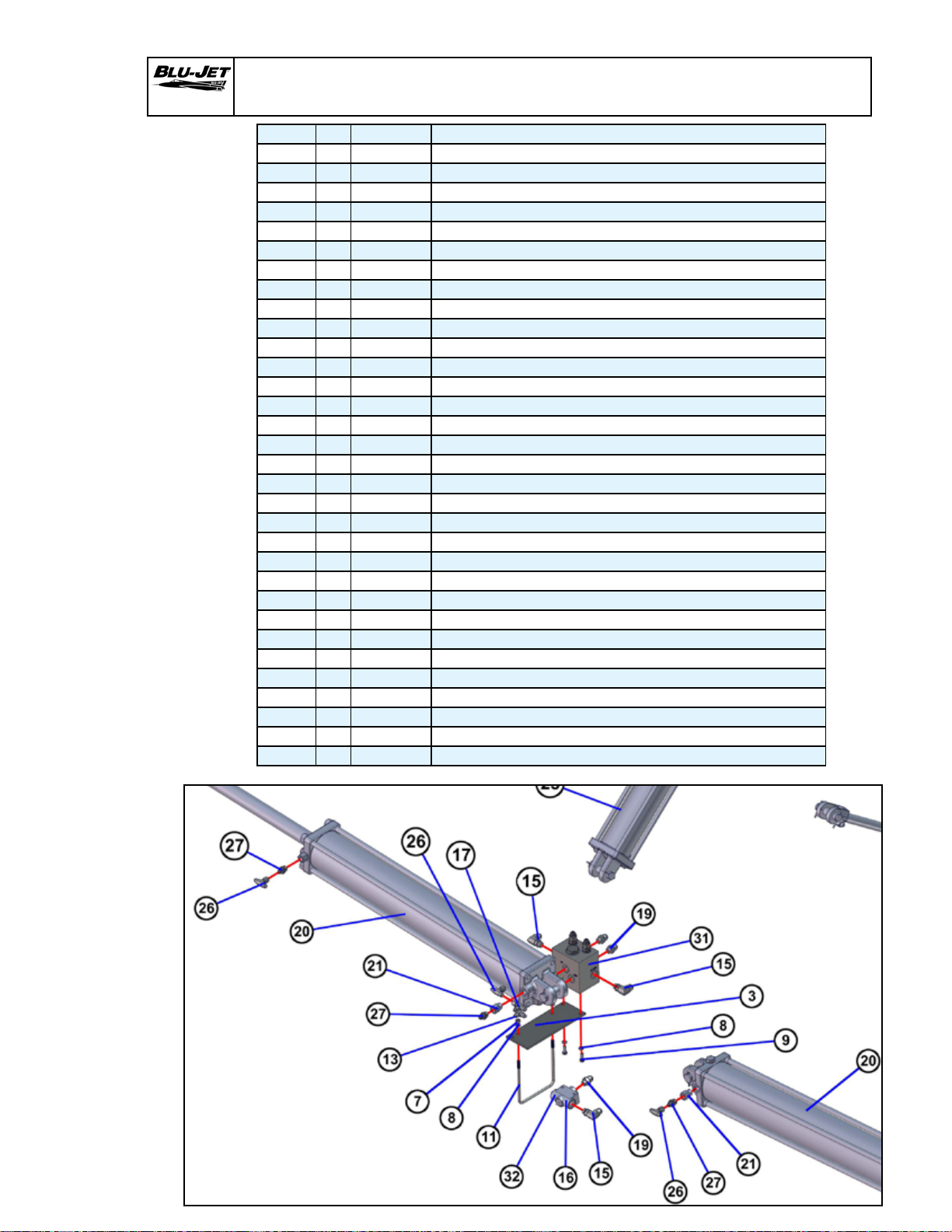

AT6020

Center Section Area of Bundle 66000103

40

BOM ID Qty Item No Description

5 1 AAM2639 MANUAL HOLDERW/ 6X4 MOUNTING

6 1 AAM2928 STOP ARM, W/ PLUNGER, DEPTH CONTROL

7 1 AAM2929 ADJUSTMENT LINKAGE, AT6020 DEPTH CONTROL

8 1 AAM4768 ASSEMBLY, TURNBUCKLE

9 1 AM2144 HITCH, CLEVIS

10 1 AM2145 BRACKET, HITCH STORAGE, 6” MOUNTING

11 1 AM2197 BRACKET, WRENCH STORAGE

14 3 AM4015 HOSE RETAINER, CLOSED LOOP, 6” & 7” MOUNTING

15 2 AM4415 HOSE RETAINER, OPEN LOOP

17 1 AM4511 BRACKET, TURNBUCKLE SUPPORT MOUNTING

18 1 AM4512 TURNBUCKLE SUPPORT

19 2 AM4517 WING LOCK

23 1 AM4563 CYLINDER LUG, BOLT-ON 5” CYLINDER

28 1 AM4759 TURNBUCKLE WRENCH, 3-1/16”

29 1 AM5158 TONGUE, CAT IV, EXTENDED, WEIGHTED

32 1 AM6172 FRAME, MAIN, AT6020

AT6020

Center Section Area of Bundle 66000103

34 1 AM6182 LINKAGE, TONGUE CYLINDER ARM

34A 4 BP3072 GREASE ZERK, 1/4”-28

34B 1 BP3516 TENSION BUSHING, 1-1/4” X 1” X 1” OAL