F-2000

MODEL RT

INSTRUCTION MANUAL

R

Blue-White

Industries, Ltd.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

F-2000

Page 2

TABLE OF CONTENTS

Section Heading Page

1.0 Features 3

2.0 Applications 3

3.0 Specifications 3

3.1 Physical 3

3.2 Dimensional Drawing 4

3.3 Temperature vs. Pressure Graph 4

4.0 Flow ranges 5

5.0 Mounting Options 6

6.0 Electrical Wiring Connections 8

6.1 Enclosure Knock-Out Instructions 8

6.2 Optional Circuit Board Installation 8

6.3 Model RT Circuit Board Wiring 9

6.4 Model FHXX and FCXX Sensor Wiring 10

7.0 Operation 11

7.1 Theory of operation 11

7.2 Model RT Operation 11

7.2.1 Model RT Applications 11

7.2.2 Model RT Features 12

7.2.3 How to Determine Calibration Constants 12

7.2.4 Programming the Model RT 15

7.2.5 Calibration Constants 16

7.3 Programming flow chart 18

8.0 Maintenance 19

8.1 Troubleshooting 19

F-2000 parts list 20

. . . F-2000 exploded view 21

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 3

1.0 FEATURES

!

Battery powered rate and total

!

Weather resistant enclosure (NEMA 4X)

F-2000

!

Extended battery life mode

(screen blanks after 30 seconds)

!

Easy to read, eight digit LCD display

!

Installs quickly on existing pipe

!

Factory programmed

!

Field programmable front panel push buttons

!

No pressure drop

2.0 APPLICATIONS

Model RT

!

Measure and display the rate of flow

!

Measure and display the total flow

Model AO

!

Measure and display the rate of flow

!

Measure and display the total flow

!

Control external devices with 4-20mA

control signal

!

Control external devices with 0-10VDC

control signal

!

Corrosion resistant PVDF sensor

!

Corrosion resistant ABS enclosure

!

High accuracy

!

Extended flow range

!

Front panel security lockout

!

Minimal maintenance required

Model PC

!

Measure and display the rate of flow

!

Measure and display the total flow

!

Maintain a flow rate range alarm

!

Trigger a high flow rate alarm

!

Trigger a low flow rate alarm

!

Manually controlled batch processing

!

Timed auto-reset batch processing

!

Proportional flow chemical pump process

control

3.0 SPECIFICATIONS

3.1 Physical

Maximum Working Pressure ...... ............300 psig (20.7 bar)

Maximum fluid temperature........ ............200 F (93 C) - saddle and sensor only

200 F (93 C) - polypropylene and PVDF inline units

140 F (60 C) - molded PVC tee units

140 F (60 C) - when mounted on PVC pipe

Ambient temperature range........ ............32 F (0 C) to 110 F (43 C)

Enclosure ......... ............ ............ ............NEMA 4X (acceptable for outdoor use)

NOTE: Protect the LCD display from direct sunlight.

Sensor Accuracy ........... ............ ............±1% of full scale reading

Repeatability..... ............ ............ ............±1% of full scale reading

Power requirements ...... ............ ............15 VDC Nominal (12 - 24 VDC Absolute - DO NOT EXCEED 24.0 VDC)

Model RT units only....... ............Four standard AA alkaline batteries or 12-24VDC Plug in transformer

(Battery life expectancy 1 year minimum)

All units ............ ............ ............12-24VDC (plug-in transformer supplied)

Model AO analog output board... ............Linear, Non-isolated, powered loop. 250 ohm max for 4-20 ma / 500

Model PC Process control board ............Relay SPDT, NO/NC

Maximum switching load 8 amps @ 115 VAC, 220 VAC, 230 VAC

Maximum fluid debris size .......... ............0.020” diameter

o o

o o

o o

o o

o o o o

ohms minimum for 0-10 VDC

7 amps @ 30 VDC (resistive load)

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

F-2000

Page 4

3.2 Dimensional Drawing

4.00 in.

(101.6 mm)

BLUE-WHITE INDUSTRIES

4.00 in.

(101.6 mm)

8888.8888

MA BATCH # RATE TOTAL SETPOINT

ENTER

Flow Monitoring System

3.3 Temperature vs. Pressure

Temperature

200°F (93.3°C)

190°F (87.8°C)

180°F (82.2°C)

170°F (76.7°C)

160°F (71.1°C)

150°F (65.6°C)

140°F (60°C)

130°F (54.4°C)

120°F (48.9°C)

110°F (43.3°C)

100°F (37.8°C)

90°F (32.2°C)

80°F (26.7°C)

70°F (21.1°C)

Note: Pressure and temperature limits are inversely proportional.

0 (0) 60 (4.1) 120 (8.3) 180 (12.4) 240 (16.5)

PSIg (BAR)

When mounted on Polypropylene and PVDF inline units

When mounted on Molded PVC Tee or PVC pipe units

F-2000

CLEAR

SETPOINT

3.25 in.

(82.55 mm)

®

CLEAR

TOTAL

Fig. 1

300 (20.7)

Fig. 2

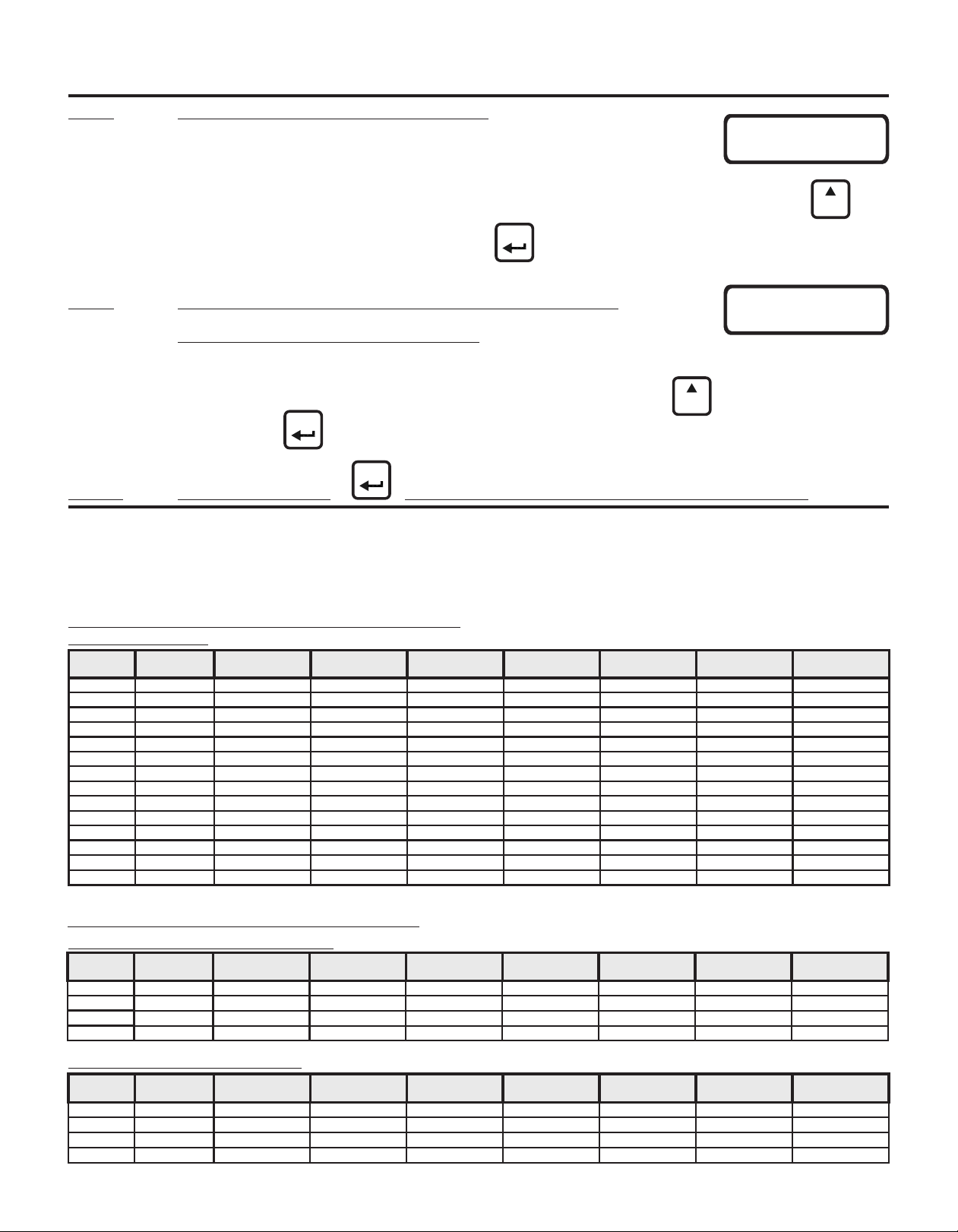

4.0 FLOW RANGES

Note: Due to increased wear on the paddle and axle, continuous operation at the upper 25% of the

flow range is not recommended

METRIC PIPES

SADDLES - Standard Flow [Min - Max]

Pipe Size

50 MM - PN 10 & PN 16

63 MM - PN 10 & PN 16

90 MM - PN 10 & PN 16

110 MM - PN 10 & PN 16

160 MM - PN 10 & PN 16

200 MM - PN 10 & PN 16

160 MM - PN 10

200 MM - PN 10

Find Quality Products Online at: sales@GlobalTestSupply.com

LPM 1

110 - 1100

230 - 2300

350 - 3500

720 - 7200

1150 - 11500

1700 - 17000

2700 - 27000

LPH 1

4200 - 4200070.0 - 700.0

6600 - 66000

13800 - 138000

21000 - 210000

43000 - 430000

70000 - 700000

100000 - 1000000

170000 - 1700000

M3H 1

4.20 - 42.00

6.60 - 66.00

13.8 - 138.0

21.0 - 210.0

43.0 - 430.0

70.0 - 700.0

100 - 1000

170 - 1700

www.GlobalTestSupply.com

Page 5

IPS PIPES

MOLDED INLINE BODIES - min - max operating flow range

Pipe Size

3/8”

3/8”

1/2”

1/2”

3/4”

3/4”

1”

1”

1-1/2”

1-1/2”

1-1/2”

2”

2”

2”

2”

RANGE#

1

2

1

2

1

2

1

2

1

2

3

1

2

3

4

MACHINED INLINE BODIES - min - max operating flow range

Pipe Size

3/8”

3/8”

1/2”

1/2”

3/4”

3/4”

1”

1”

1-1/2” 15.0 - 150.0 900 - 9000 21500 - 215000

1-1/2”

1-1/2”

1-1/2” 2.00 - 20.00 120 - 1200 2800 - 28000

1-1/2” 1.00 - 10.00 60.0 - 600.0 1440 - 14400

2” 1800 - 1800030.0 - 300.0 43000 - 430000

2” 15.0 - 150.0 900 - 9000 21500 - 215000

2”

2”

2”

2” 2.00 - 20.00 120 - 1200 2800 - 28000

RANGE#

1

2

1

2

1

2

1

2

1

2

3

4

5

1

2

3

4

5

6

GPM

2.00 - 20.00

.500 - 5.000

3.00 - 30.00

.800 - 8.000

5.00 - 50.00

2.00 - 20.00

10.0 - 100.0

4.00 - 40.00

6.00 - 60.00

10.0 - 100.0

20.0 - 200.0

GPM

2.00 - 20.00

.500 - 5.000

4.00 - 40.00

.800 - 8.000

6.00 - 60.00

2.00 - 20.00

10.0 - 100.0

10.0 - 100.0

6.00 - 60.00

4.00 - 40.00

GPH

48.0 - 480.0.800 - 8.000

20.0 - 200.0.400 - 4.000

120 - 1200

30.00 - 300.0

180 - 1800

48.0 - 480.0

300 - 3000

120 - 1200

240 - 24004.00 - 40.00

360 - 36006.00 - 60.00

600 - 6000

240 - 2400

360 - 3600

1200 - 12000

GPH

48.0 - 480.0.800 - 8.000

20.0 - 200.0.400 - 4.000

120 - 1200

30.00 - 300.0

240 - 2400

48.0 - 480.0

360 - 3600

120 - 1200

600 - 6000 14400 - 144000

360 - 36006.00 - 60.00

240 - 2400

1100 - 11000

2800 - 28000

4320 - 43200

1100 - 11000

7200 - 72000

2800 - 28000

5700 - 57000

8600 - 86000

14400 - 144000

5700 - 57000

8600 - 86000

14400 -144000600 - 6000

28800 - 288000

1100 - 11000

2800 - 28000

5700 - 57000

1100 - 11000

8600 - 86000

2800 - 28000

8600 - 86000

14400 -144000600 - 6000

8600 - 86000360 - 3600

5700 - 57000

GPD

550 - 5500

700 - 7000

GPD

550 - 5500

700 - 7000

F-2000

LPM

7.00 - 70.00

2.00 - 20.00

11.0 - 110.0

3.00 - 30.00

20.0 - 200.0

7.00 - 70.00

40.0 - 400.0

15.0 - 150.0

25.0 - 250.0

40.0 - 400.0

70.0 - 700.0

LPM

7.00 - 70.00

2.00 - 20.00

15.0 - 150.0

3.00 - 30.00

25.0 - 250.0

7.00 - 70.00

60.0 - 600.0 3600 - 36000 3.60 - 36.00

40.0 - 400.0

7.00 - 70.00 420 - 4200 0.420 - 4.200

4.00 - 40.00 240 - 2400 0.240 - 2.400

60.0 - 600.0 3600 - 36000 3.60 - 36.00

40.0 - 400.0

25.0 - 250.0

15.0 - 150.0

7.00 - 70.00 420 - 4200 0.420 - 4.200

LPH

180 - 18003.00 - 30.00

60.0 - 600.01.00 - 10.00

420 - 4200

120 - 1200

660 - 6600

180 - 1800

1200 - 12000

420 - 4200

900 - 900015.0 - 150.0

1500 - 1500025.0 - 250.0

2400 - 24000

900 - 9000

1500 - 15000

2400 - 24000

4200 - 42000

LPH

180 - 18003.00 - 30.00

60.0 - 600.01.00 - 10.00

420 - 4200

120 - 1200

900 - 9000

180 - 1800

1500 - 15000

420 - 4200

2400 - 24000

1500 - 1500025.0 - 250.0

6000 - 60000100 - 1000 6.00 - 60.00

2400 - 24000

1500 - 15000

900 - 9000

M3H

0.180 - 1.800

0.060 - 0.600

0.420 - 4.200

0.120 - 1.200

0.660 - 6.600

0.180 - 1.800

1.20 - 12.00

0.420 - 4.200

0.900 - 9.000

1.50 - 15.00

2.40 - 24.00

0.900 - 9.000

1.50 - 15.00

2.40 - 24.00

4.20 - 42.00

M3H

0.180 - 1.800

0.060 - 0.600

0.420 - 4.200

0.120 - 1.200

0.900 - 9.000

0.180 - 1.800

1.50 - 15.00

0.420 - 4.200

2.40 - 24.00

1.50 - 15.00

2.40 - 24.00

1.50 - 15.00

0.900 - 9.000

SADDLES - Standard Flow [Min - Max]

Pipe Size

1-1/2” IPS

2.0” IPS

3.0” IPS

4.0” IPS

6.0” IPS

8.0” IPS

10.0” IPS

12.0” IPS

GPM = Gallons Per Minute LPM = Litters Per Minute OZM = Ounces Per Minute GPH = Gallons Per Hour

LPH = Litters Per Hour M3H = Cubic Meters per Hour GPD = Gallons Per Day LPD = Litters Per Day

Find Quality Products Online at: sales@GlobalTestSupply.com

GPM 1

15.0 - 150.0

30.0 - 300.0

60.0 - 600.0

100 - 1000

250 - 2500

400 - 4000

600 - 6000

800 - 8000

GPH 1

900 - 9000

1800 - 18000

3600 - 36000

6000 - 60000

15000 - 150000

24000 - 240000

36000 - 360000

48000 - 480000

GPD 1

21500 - 215000

43000 - 430000

86500 - 865000

144000 - 1440000

360000 - 3600000

575000 - 5750000

865000 - 8650000

1150000 - 11500000

LPM 1

60.0 - 600.0

100 - 1000

250 - 2500

400 - 4000

900 - 9000

1500 - 15000

2200 - 22000

3000 - 30000

www.GlobalTestSupply.com

LPH 1

3600 - 36000

6000 - 60000

15000 - 150000

24000 - 240000

54000 - 540000

90000 - 900000

132000 - 1320000

180000 - 1800000

M3H 1

3.60 - 36.00

6.00 - 60.00

15.0 - 150.0

24.0 - 240.0

54.0 - 540.0

90.0 - 900.0

132 - 1320

180 - 1800

F-2000

5.0 Mounting Options

Rotating Display

Page 6

Step 1: Remove Two Screws

Angle Mount on Horizontal Pipe

Step 2: Rotate 90°

Recommended

Vertical

Step 3: Re-attach Screws

Fig. 6

45° Acceptable45° Acceptable

Panel Mount

PANEL

F-2000

HEX NUTS

BRACKET

STUDS

Fig. 8

WASHERS

CAP PLUG

3.622 ±

(92.0 ±

.032

.000

.80

.00

Fig. 7

in.

mm)

Fig. 9

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 7

Optional Pipe and Wall Mount Adapter Kit

F-2000

Screw

Wall Mount

Pipe Mount

®

BLUE-WHITE INDUSTRIES

F-2000

ENTER

CLEAR

CLEAR

SETPOINT

TOTAL

Flow Monitoring System

Display

Module

Fig. 10

Display

Module

Wire to

Sensor

Clamp

Mounting

Base

Cap

Plug

Mounting

Base

Wall

Wall

Screw

Pipe

®

BLUE-WHITE INDUSTRIES

F-2000

ENTER

CLEAR

CLEAR

SETPOINT

TOTAL

Flow Monitoring System

Ordering Information

Kit Number

71000-301

71000-302

71000-303

71000-304

71000-305

71000-306

71000-307

Fig. 11

Sensor

Decription

Wall Mount Kit

Pipe Mount Kit for 1-1/2” pipe

Pipe Mount Kit for 2” pipe

Pipe Mount Kit for 3” pipe

Pipe Mount Kit for 4” pipe

Pipe Mount Kit for 6” pipe

Pipe Mount Kit for 8” pipe

Wire to

Cap

Screw

Plug

71000-414 Pipe Mount Kit for 10” pipe

71000-415 Pipe Mount Kit for 12” pipe

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

F-2000

6.0 F-2000 Electrical Wiring Connections

6.1 Enclosure knock-out Instructions

Option A: Conduit Connection

1. Remove the red cap plug.

2. Install your pipe fitting (1/2 - 14 NPT male

end).

Page 8

Option A: 1 / 2-14 MPT

Red Cap Plug

(for pipe fitting)

Option B: Liquid-Tight Connections

Internal View

1. Remove knock-out(s) using a screwdriver.

2. Trim edge(s) with a knife and remove sharp

edges.

3. Install the provided liquid-tight connector(s).

Option B: 3/4 DIA.

Knock-out

(large liquid-tight connector)

Option B: 1/2 DIA.

Knock-out

(small liquid-tight connector)

Notes:

For the large liquid-tight connector (3/4” knock-out), the acceptable cable diameter is between .200 - .394 in (5.1 -

10.0 mm).

For the small liquid-tight connector (1/2” knock-out), the acceptable cable diameter is between .118 - .255 in (3.0 -

6.5 mm).

6.2 Optional Circuit Board Installation

CAUTION: DISCONNECT POWER

SOURCE BEFORE SERVICING.

F-2000-PC

1. Carefully align optional board’s Pin

Header with the Pin Header socket

located on the main circuit board.

F-2000

2. Press firmly into place.

Enclosure

Cover

3. Secure the board with the two screws

provided.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

(OPTIONAL BOARD)

N.C.

N.O.

C

F-2000-RT

(MAIN BOARD)

F-2000-AO

(OPTIONAL

BOARD)

Page 9

6.3 Model RT Circuit Board Wiring

CAUTION: DISCONNECT POWER SOURCE BEFORE SERVICING.

Jumper Configuration

F-2000

Jumpers

J1 Installed

J1 Left Open

J2 Installed

J2 Left Open

J3 Installed and J4 Left Open

J3 Left Open and J4 Installed

Terminal Configuration

Terminal Function

Supply power

input

AC coil sensor

input

6

5

2

3

1

Hall Effect

sensor input

2

3

1

Micro-Flo

sensor input

2

3

Open connector

pulse output

(from sensor)

7

4

Function

Battery Input (4 - 1.5 VDC, AA Cells)

Plug-In Transformer (115 VAC / 15 VDC, 220 VAC / 15 VDC, 230 VAC / 15 VDC)

Front Panel Programming is Disabled

Front Panel Programming is Enabled (factory default)

Hall Effect Sensor and Micro-Flow Sensor Input

AC Coil Sensor Input

Positive (+) power input (red wire from battery pack, or black with stripe wire from 15 VDC plug-in transformer)

Ground (-) power input (black wire from battery pack or 15 VDC plug-in transformer)

Ground (-) input (black wire from coil sensor body)

Pulse input (yellow or red wire from coil sensor body)

Positive (+) input (red wire from hall effect sensor)

Ground (-) input (black wire from hall effect sensor)

Pulse input (bare wire from hall effect sensor)

Positive (+) input (red wire from hall effect sensor)

Ground (-) input (black wire from Micro-Flo sensor or negative (-) output from Micro-Flo display circuit board)

Pulse input (bare wire from Micro-Flo sensor or positive (+) output from Micro-flo display circuit board)

NPN positive (+) signal output

NPN negative (-) signal output

(Max voltage: 30VDC, Max load: 15mA, 2k ohm pull-up recommended.)

F-2000 RT Board

F-2000 PC Board

Mounting Screw

Bushings

SIP Socket for

F-2000 PC Board

BAT = ON

J1

J2

J3

J4

Backup Battery

Connector

SIP Socket for

F-2000 AO Board

F-2000 AO Board

Mounting Screw

Bushings

Jumper Positions

Jumper Not

Installed (open)

Jumper

Installed

7 6 5 4 3 2 1

P H M

Jumpers

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Terminal Blocks

F-2000

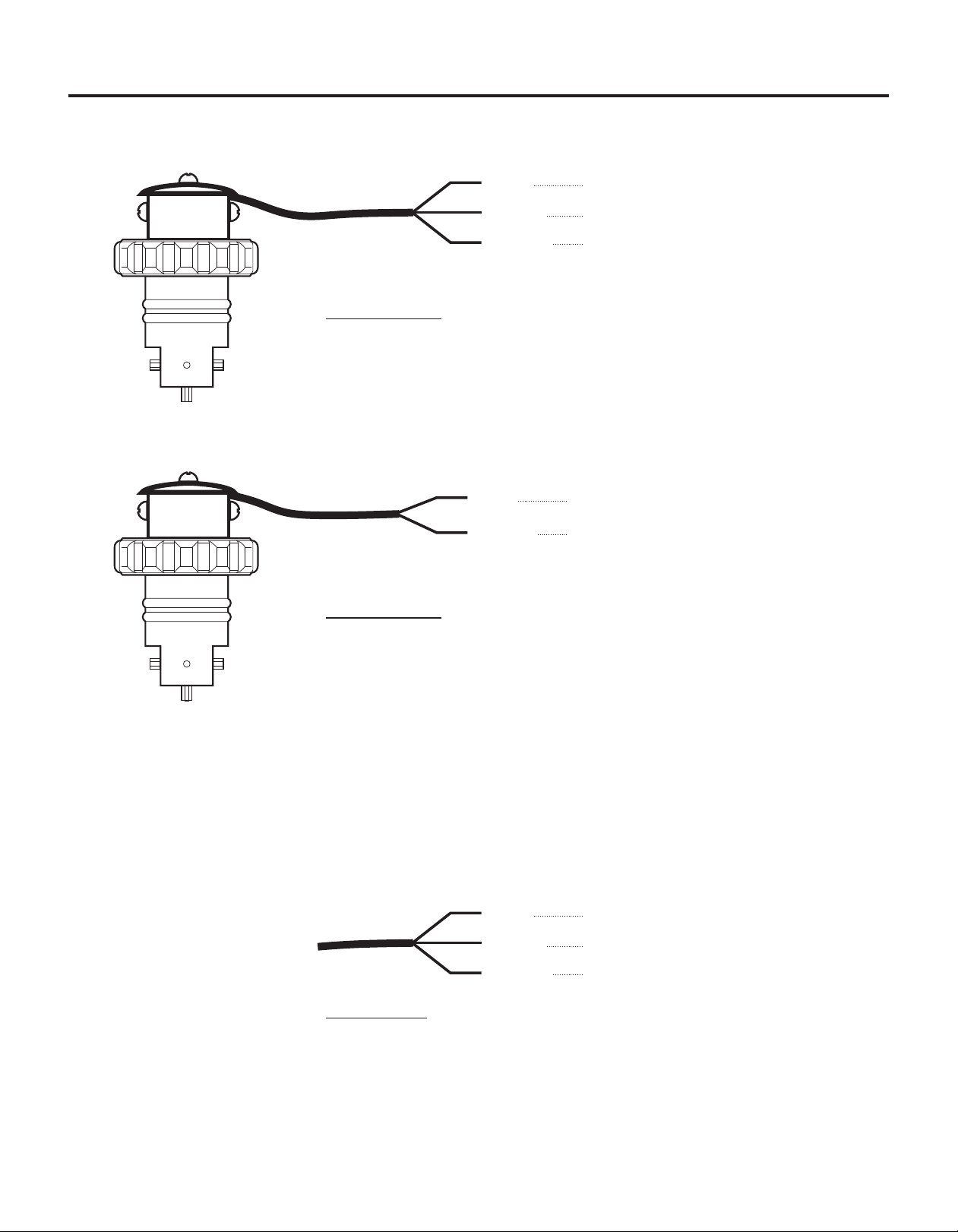

6.4 Model FHXX and FCXX Sensor wiring

Page 10

RED

BARE

BLACK

Input Supply Voltage (+ 6 to 24 Vdc)

Signal Output (square wave)

Ground (-)

Model FHXX

Note: Output type - current sinking type hall effect sensor (13.5mA max).

Pull-up resistor is recommended. 5k ohm across red & bare wires.

Approximately 10 to 350 Hz operating range.

RED

BLACK

Signal Output (Sine wave)

Ground (-)

Model FCXX

Note: Output type - AC sine wave. 100 mV peak to peak.

0.06 to 3.00 volts AC / 10uA to 500uA AC.

Approximately 10 to 350 Hz operating range.

RED

BARE

BLACK

Input Supply Voltage (+ 6 to 24 Vdc)

Signal Output (square wave)

Ground (-)

Model FVS

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 11

F-2000

7.0 HOW TO OPERATE THE F-2000

7.1 Theory of Operation

The MODEL RT is the base unit of the F-2000 flow monitoring system. Fluid flowing through the pipe causes the

paddlewheel to spin. Pulses generated by the spinning paddlewheel are counted and multiplied by scaling factors. The

resulting flow rate amounts and total flow amounts are displayed on the LCD readout. Pressing the enter button located

on the front panel toggles the display between flow rate and total flow or allows entry into the programming mode.

Pressing the clear total button while the total flow value is displayed will return the total to zero (must be activated in the

programming mode - not the factory default setting). A small icon will light at the bottom of the LCD indicating the mode

being displayed.

The MODEL PC includes all of the features of the MODEL RT as well as a relay which can be used to switch external

electrical equipment when user programmed setpoints are reached. The relay must be assigned to respond to either the

rate value for rate alarm applications (rate mode), or to the total value for batching or proportional feed applications (batch

mode). Only one may made be used at any one time. When assigned to the batch mode, the display can be toggled to

show four different values, the rate of flow, total flow, current batch number or current batch total, by pressing the enter

button located on the front panel. A small icon will light at the bottom of the LCD display indicating the mode being

displayed. The model PC is described in a separate instruction manual.

The MODEL AO includes all of the features of the MODEL RT as well as a 4-20mA or 0-10VDC output signal which is

proportional to the flow rate value. This mode is always active although the output value can not be displayed on the LCD.

A small icon will light indicating the mode is active. The model AO is described in a separate instruction manual.

The MODEL AP includes the features of all three F-2000 models, the RT, PC, and AO.

7.2 How To Operate The MODEL RT

7.2.1 What Was The MODEL RT Designed To Do?

!

Display the rate of flow up to eight digits.

!

Display the total amount of flow up to eight digits.

!

Output an open collector signal (NPN) that is proportional to the flow rate.Operates by batteries or plug-in AC

transformer.

!

Greater than 1 year battery life.

!

Front panel user programmable.

!

Front panel programming can be disabled for security.

!

Front panel total reset can be disabled for security.

!

Programmable battery saving mode. (Screen blanks after 30seconds)

!

Programmable decimal point locations for both rate and total modes.

!

Display can be mounted on the sensor or panel mounted (1/4 DIN). See figure 6 and 8.

!

Display can be rotated on sensor. See figure 6.

!

Display can be mounted on a pipe or wall with optional mounting bracket kit. See figure 8 - 11.

!

Display can be panel mounted up to 250 ft. from sensor when used with AC coil sensor.

!

Display can be panel mounted up to 1 mile from sensor when used with Hall Effect sensor.

!

Optional circuitry, AO (analog output) and PC (process control) boards, can be field installed at a later time.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

F-2000

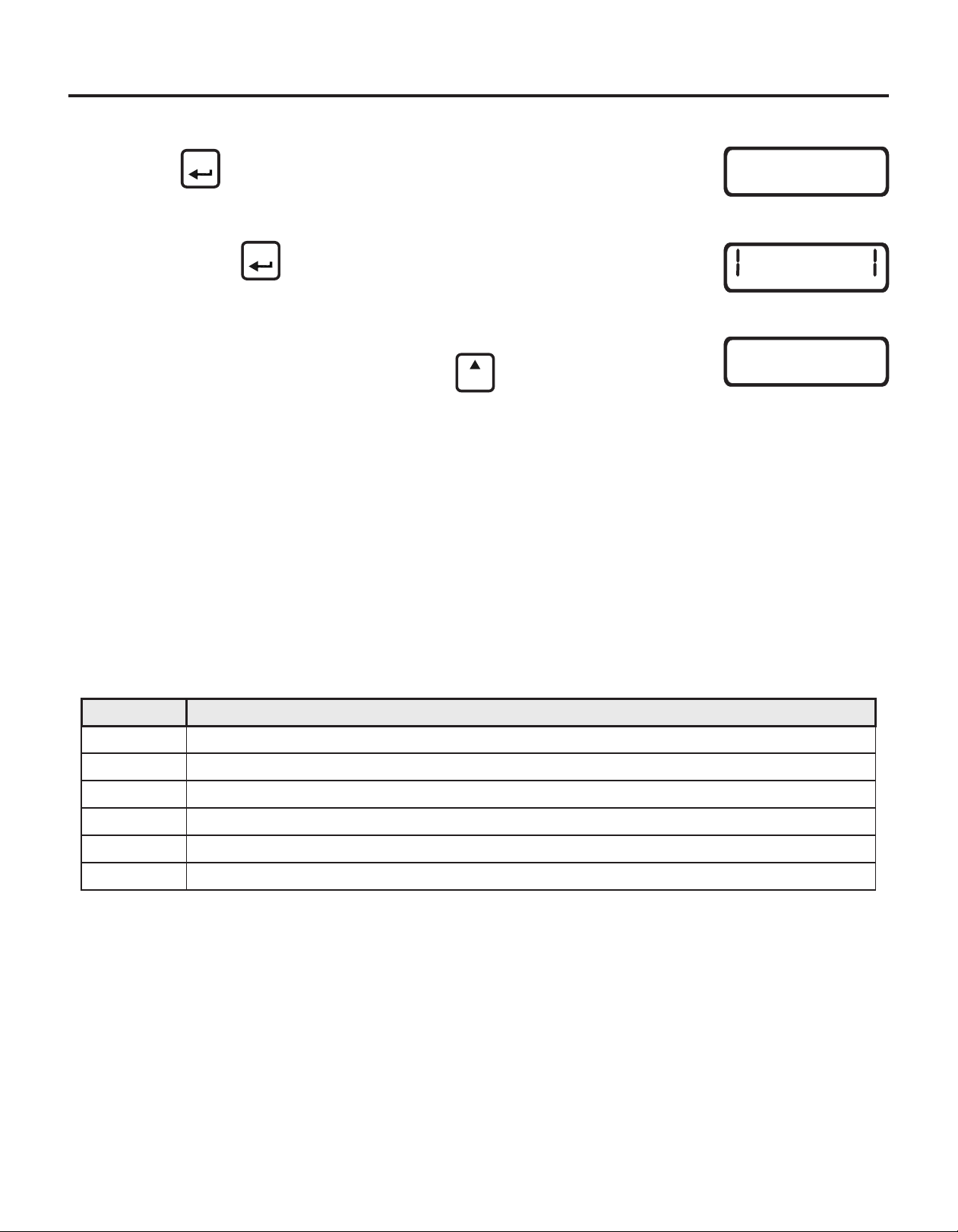

7.2.2 What Features Are Available On The MODEL RT?

Page 12

!

Press to toggle between RATE and TOTAL display modes. The icon will

light to indicate the active mode.

!

Press and hold for at least 1.25 seconds to enter the programming mode.

Allow twenty seconds to pass so the display will switch back to the readout

mode. See section 7.1.

!

While the TOTAL mode is displayed, press to reset the total amount to

zero. (Must be enabled in the program mode - see page 24, step 6.)

ENTER

ENTER

CLEAR

TOTAL

RATE TOTAL

00000

RATE

TOTAL

0

0

7.2.3 How Do I Determine My Calibration Numbers?

When ordered as a complete system, the F-2000 MODEL RT is factory programmed to the flow range you specified when

you placed your order. See section 4.0 for various flow ranges.

Note: The F-2000 model AO and PC functions will always require field programming. All F-2000 models will require field

programming when components are purchased separately. See section 7.2 and 7.3.

The following screens are used to input the calibration constants and to turn on or off the various features of the MODEL

RT. The MODEL RT has six different input screens. They are listed in the table below.

Screen No. Programming Functions

RATE 1

RATE 2

RATE 3

TOTAL 1

TOTAL 2

TOTAL 3

Before programming the unit, the following calibration constants must be determined. Remember, when

purchased as a complete system, the model RT is pre-programmed at the factory. No further programming is

necessary.

Toggle Battery Saving mode - on / off (factory default: off)

Toggle front panel Clear Total button - on (enabled) / off (disabled) -- (factory default: off)

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 13

Step 1 Where would you like your displayed flow rate decimal point located?

F-2000

Desired Location = D (Decimal Rate Factor) Note: Four decimal places maximum.

XXXXX = 1

XXXX.X = 10

XXX.XX = 100

XX.XXX = 1000

X.XXXX = 10000 Enter your D here.

Step 2 What time factor would you like to use in your measurement?

Example: Per Minute = 60 seconds

Per Hour = 3600 seconds

Per Day = 86400 seconds

Fill in the amount of seconds you desire here.

Step 3 To determine your flow rate K-Factor, the following information is needed.

a. What size pipe you are going to install this meter on? inch pipe

b. What schedule pipe are you using? Sch 40 or Sch 80 or Inline

c. What is your flow range? Low Flow or Standard Flow (refer to pages 16 & 17)

r

r

d. Using the data you specified above, locate your K-Factor from the correct table. Pages 16 & 17.

e. What is your K-Factor?

f. If you are going to be using gallons as your unit of measure, you can go directly to Step 4.

g. To convert K-Factor to other units of measure, use the following formulas:

Ounces = K-factor ÷ 128

Liters = K-factor ÷ 3.785

Cubic Meters = K-factor ÷ 0.003785

Example: To convert 2” schedule 80 gallons K-factor to

liters, you will use the following formula:

Note: Locate your K-factor off the table on pages 16 & 17..

58.82 (K-factor)

3.785

= 15.54

Your new liters K-factor is 15.54

Write your new K-Factor number here.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

F-2000

Page 14

Step 4 Calculate your Rate Scale Factor (S ) using the following formula.

D from Step 1, Seconds from Step 2, K-Factor from Step 3.

r

r

Example:

D x Seconds

S =

r

r

K-Factor

D = 10

r

Seconds = 3600

S =

10 x 3600

r

K-Factor = 63.52

S =

r

S =

r

Write your S (Rate Scale Factor) number here.

Step 5 Where would you like your displayed accumulated Total Decimal (D ) point located?

Desired Location = D (Total Decimal Factor) Note: Four decimal places maximum.

r

t

t

XXXXX = 1

XXXX.X = 10

XXX.XX = 100

XX.XXX = 1000

X.XXXX = 10000 Enter your D here.

t

63.52

36000

63.52

566.751

Step 6 Determine your Total K-factor.

Your Total K-factor and Flow Rate K-factor are the same if the same units (i.e., Gallons, liters, etc.) Are

displayed for both. However, you can use a different unit of measure for your total display. Follow the

instructions in step 3-g to convert to a different Total K-factor unit.

Write your Total K-factor here.

Step 7 Calculate your Total Scale Factor (S ) using the following formula.

D

S =

t

t

K

t

Example:

D

S =

t

K

S =

t

S =

Note: The Total Scale Factor may be

carried out to four decimal places.

t

58.82

t

1

00.0170

Write your Total Scale Factor (S ) here.

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

t

Page 15

F-2000

7.2.4 How Do I Program The MODEL RT?

Note: While in the programming mode, if no buttons are pressed within twenty seconds, the programming mode is

automatically exited without saving the input of the last screen. See page 18 for programming menu flow chart.

Step 1 Entering the Rate Scale Factor.

!

Press and hold down for at least 1.25 seconds.

!

Enter the Rate Scale Factor (Sr from Step 4, page 14).

!

Press to select the digit to be modified or the decimal point. Note: The selected digit will blink to notify you

it is selected.

!

Press to modify the selected digit or the decimal point. Repeat the process until all digits have been

modified.

!

When finished, press . This will move you to the RATE 2 screen.

Step 2 The Rate Decimal Point Location screen.

!

Press once to see the decimal point appear. Press repeatedly until the

decimal point is located in the desired location. Then press to move you to RATE 3.

!

This value should match Page 13, Step 1, desired decimal location. Ex. 0000.0

CLEAR

SETPOINT

CLEAR

TOTAL

CLEAR

TOTAL

ENTER

ENTER

ENTER

CLEAR

TOTAL

000000

RATE

2

RATE

00000

Step 3 The Battery Save Mode On / Off screen. Factory default = OFF

!

Press to toggle the ON and OFF settings. Press once you’ve selected

your setting.

Step 4 The Total Scale Factor screen is selected.

!

Enter the Total Scale Factor (S from Step 7, page 14).

!

Press to select the digit to be modified or the decimal point. Note: The selected digit will blink to notify you

it is selected.

!

Press to modify the selected digit or the decimal point. Repeat until all digits have been Entered.

!

When finished, press . This will move you to the TOTAL 2 screen.

CLEAR

TOTAL

CLEAR

SETPOINT

CLEAR

TOTAL

t

ENTER

ENTER

3

RATE

000000

TOTAL

OFF

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

F-2000

Step 5 The Total Decimal Point screen is selected.

!

The Total 2 screen is where you enter your Decimal Point Factor for your totalizer.

Use the information you calculated on D , on Page 14, Step 5. Move the decimal point by pressing the until

the decimal point is in the desired location. Then press . Ex. 00000

t

ENTER

Page 16

000000

2

TOTAL

CLEAR

TOTAL

Step 6 The Front Panel Clear Total Button Enable / Disable screen is

selected. Factory default = OFF (disabled)

!

The Total 3 screen gives you the option to turn on or off the clear total button function. It was designed to prevent

the user from making the mistake of clearing the totalizer screen. By pressing the you can scroll through the

ENTER

CLEAR

TOTAL

3

TOTAL

Off

on and off mode. Press once you have made your selection.

ENTER

Step 7 Press and hold down for at least 1.25 seconds to exit the programming mode.

7.2.6 Calibration Constants

Note: The values in the following tables are based on laboratory testing of nominal pipe dimensions. The F-2000 sensor is factory calibrated to ±1%

of full scale linearity. Your actual accuracy will vary based on your pipe I.D. And other installation factors.

METRIC PIPE PN10 & PN16 (Meets DIN 8062)

Saddle Mount Models (Pipe Insertion connection)

Standard Flow Range - LPM (liters per minute)

Pipe Size

(MM)

50

50

63

63

90

90

110

110

160

160

200

PN

Rating

10

16

10

16

10

16

10

16

10

16

10

16200 170.2 1150 - 11500 1.008 59.5501 00000 00.9925 00000

10250 226.2 1700 - 17000 0.565 106.232 00000 01.7705 00000

10315 285.0 2700 - 27000 0.353 170.003 00000 02.8334 00000

Pipe I.D. (MM)

45.2

42.6

57.0

53.6

81.4

76.6

99.4

93.6

144.6

136.2

180.8

Flow Range

(LPM)

70.0 - 700.0

70.0 - 700.0

110 - 1100

110 - 1100

230 - 2300

230 - 2300

350 - 3500

350 - 3500

720 - 7200

720 - 7200

1150 - 11500

K-Factor

(Pulse/L)

16.561

20.719

10.522

11.830

5.294

5.944

2.942

3.107

1.386

1.574

0.927

RATE 1 RATE 2

Rate Scale

Factor (Sr)

36.2297

28.9588

05.7023

05.0720

11.3335

10.0944

20.3969

19.3133

43.2782

38.1081

64.7077

Rate Display

Decimal Point

0000.0

0000.0

00000

00000

00000

00000

00000

00000

00000

00000

00000

TOTAL 1 TOTAL 2

Total Scale

Factor (St)

00.0604

00.0483

00.0950

00.0845

00.1889

00.1682

00.3399

00.3219

00.7213

00.6351

01.0785

Total Display

00000

00000

00000

00000

00000

00000

00000

00000

00000

00000

00000

I.P.S. PIPE (Meets ASTM-D-1785)

Molded Inline Bodies (Male NPT connection)

3/8” - 1” pipe sizes - Standard Range #1 - GPM (gallons per minute)

Pipe Size

(in.)

3/8

1 /2

3/4

1.0

Pipe Sch.

Inline

Inline

Inline

Inline

Body I.D. (In.)

0.375

0.500

0.660

0.840

Flow Range

(GAL/Min)

.800 - 8.000

2.00 - 20.00

3.00 - 30.00

5.00 - 50.00

K-Factor

(Pulse/GAL)

1456.31

1034.48

612.25

338.60

3/8” - 1” pipe sizes - Low Range #2 - GPM (gallons per minute)

Pipe Size

(in.)

3/8

1/2

3/4

1.0

Pipe Sch.

Inline

Inline

Inline

Inline

Body I.D. (In.)

0.218

0.250

0.375

0.500

Find Quality Products Online at: sales@GlobalTestSupply.com

Flow Range

(GAL/Min)

.400 - 4.000

.500 - 5.000

.800 - 8.000

2.00 - 20.00

K-Factor

(Pulse/GAL)

2926.83

2419.35

1518.99

1034.48

www.GlobalTestSupply.com

RATE 1 RATE 2 TOTAL 1 TOTAL 2

Rate Scale

Factor (Sr)

41.2000

05.8000

09.8000

17.7200

RATE 1

Rate Scale

Factor (Sr)

20.5000

24.8000

39.5000

05.8000

Rate Display

Decimal Point

00.000

000.00

000.00

000.00

Total Scale

Factor (St)

00.0069

00.0097

00.0163

00.0295

Total Display

Decimal Point

0000.0

0000.0

0000.0

0000.0

RATE 2 TOTAL 1 TOTAL 2

Rate Display

Decimal Point

00.000

00.000

00.000

000.00

Total Scale

Factor (St)

00.0034

00.0041

00.0066

00.0097

Total Display

Decimal Point

0000.0

0000.0

0000.0

0000.0

Page 17

Molded Inline Bodies (Male NPT connection) - continued

1-1/2” - 2” pipe sizes - GPM (gallons per minute)

Pipe Size

(in.)

1-1/2

1-1/2

1-1/2

2

2

2

2 4 20.0 - 200.0 67.416 8.9000 0000.0 00.1483 0000.0

Pipe Sch.

Inline

Inline

Inline

Inline

Inline

Inline

Inline

Flow Range #

1

2

3

1

2

3

Flow Range

(GAL/Min)

4.00 - 40.00

6.00 - 60.00

10.0 - 100.0

4.00 - 40.00

6.00 - 60.00

10.0 - 100.0

K-Factor

(Pulse/GAL)

466.20

192.93

156.94

468.75

196.40

162.16

Machined Inline Bodies (Female NPT connection)

Standard Flow Range #1 - GPM (gallons per minute)

Pipe Size

(in.)

3/8

1/2

3/4

1.0

1-1/2

2.0

Pipe Sch.

Inline

Inline

Inline

Inline

Inline

Inline

Body I.D. (In.)

0.375

0.500

0.750

1.000

1.500

1.900

Low Flow Range #2 - GPM (gallons per minute)

Pipe Size

(in.)

3/8

1/2

3/4

1.0

1-1/2

2.0

Pipe Sch.

Inline

Inline

Inline

Inline

Inline

Inline

Body I.D. (In.)

0.218

0.250

0.375

0.500

1.250

1.500

Low Flow Ranges #3, 4, 5, 6 - GPM (gallons per minute)

Pipe Size

(in.)

1-1/2

1-1/2

1-1/2

2.0

2.0

2.0

2.0

Pipe Sch.

Inline

Inline

Inline

Inline

Inline

Inline

Inline

Flow Range #

3

4

5

3

4

5

6 2.00 - 20.00 950.87 6.3100 000.00 00.0105 0000.0

Flow Range

(GAL/Min)

.800 - 8.000

2.00 - 20.00

4.00 - 40.00

6.00 - 60.00

15.0 - 150.0

30.0 - 300.0

Flow Range

(GAL/Min)

.400 - 4.000

.500 - 5.000

.800 - 8.000

2.00 - 20.00

10.0 - 100.0

15.0 - 150.0

Flow Range

(GAL/Min)

6.00 - 60.00

2.00 - 20.00

1.00 - 10.00

10.0 - 100.0

6.00 - 60.00

4.00 - 40.00

K-Factor

(Pulse/GAL)

1469.87

985.22

471.70

204.08

86.120

48.884

K-Factor

(Pulse/GAL)

3468.21

2631.58

1469.87

985.22

155.00

89.020

K-Factor

(Pulse/GAL)

217.39

1076.60

1283.88

162.47

224.67

493.83

Saddle Models (Pipe insertion connection)

Standard Flow Range - GPM (gallons per minute)

Pipe Size

(in.)

1.5

1.5

2.0

2.0

2.5

2.5

3.0

3.0

4.0

4.0

6.0

6.0

8.0

8.0

10.0

10.0

12.0

12.0

Pipe Sch. Pipe I.D. (In.)

40

80

40

80

40

80

40

80

40

80

40

80

40

80

40

80

40

80

1.610

1.500

2.067

1.939

2.469

2.323

3.068

2.900

4.026

3.826

6.065

5.761

7.981

7.625

10.020

9.564

11.938

11.376

Flow Range

(GAL/Min)

15.0 - 150.0

15.0 - 150.0

30.0 - 300.0

30.0 - 300.0

40.0 - 400.0

40.0 - 400.0

60.0 - 600.0

60.0 - 600.0

100 - 1000

100 - 1000

250 - 2500

250 - 2500

400 - 4000

400 - 4000

600 - 6000

600 - 6000

800 - 8000

800 - 8000

K-Factor

(Pulse/GAL)

86.580

102.04

50.850

58.820

34.8635

39.200

21.820

24.000

11.8577

12.7659

5.3507

5.5738

2.985

2.940

1.594

1.845

1.116

1.296

RATE 1 RATE 2 TOTAL 1 TOTAL 2

Rate Scale

Factor (Sr)

12.8700

31.0994

3.8231

12.8000

30.5499

3.7000

Rate Display

Decimal Point

000.00

000.00

0000.0

000.00

000.00

0000.0

Total Scale

Factor (St)

00.0215

00.0518

00.0637

00.0213

00.0509

00.0617

RATE 1 RATE 2 TOTAL 1 TOTAL 2

Rate Scale

Factor (Sr)

40.8200

06.0900

12.7200

29.4000

6.9670

12.2740

Rate Display

Decimal Point

00.000

000.00

000.00

000.00

0000.0

0000.0

Total Scale

Factor (St)

00.0068

00.0102

00.0212

00.0490

00.0116

00.0205

RATE 1 RATE 2 TOTAL 1 TOTAL 2

Rate Scale

Factor (Sr)

17.3000

22.8000

40.8200

06.0900

3.8710

6.7401

RATE 1 RATE 2

Rate Scale

Factor (Sr)

27.6002

5.5731

4.6733

3.6930

26.7058

12.1500

Rate Display

Decimal Point

00.000

00.000

00.000

000.00

0000.0

0000.0

Rate Display

Decimal Point

000.00

000.00

000.00

0000.0

000.00

000.00

Total Scale

Factor (St)

00.0029

00.0038

00.0068

00.0102

00.0065

00.0112

TOTAL 1 TOTAL 2

Total Scale

Factor (St)

00.0460

00.0093

00.0078

00.0062

00.0445

00.0203

RATE 1 RATE 2 TOTAL 1 TOTAL 2

Rate Scale

Factor (Sr)

06.9300

05.8800

11.7994

10.2006

17.2010

15.3061

27.4977

25.0000

05.0600

04.7000

11.2135

10.7647

20.1000

20.4082

37.6412

32.5203

53.7634

46.2963

Rate Display

Decimal Point

0000.0

0000.0

0000.0

0000.0

0000.0

0000.0

0000.0

0000.0

00000

00000

00000

00000

00000

00000

00000

00000

00000

00000

Total Scale

Factor (St)

00.0116

00.0098

00.0197

00.0170

00.0287

00.0255

00.0458

00.0417

00.0843

00.0783

00.1869

00.1794

00.3350

00.3401

00.6274

00.5420

00.8961

00.7716

F-2000

Total Display

Decimal Point

0000.0

0000.0

0000.0

0000.0

0000.0

0000.0

Total Display

Decimal Point

0000.0

0000.0

0000.0

0000.0

00000

00000

Total Display

Decimal Point

0000.0

0000.0

0000.0

0000.0

00000

00000

Total Display

Decimal Point

0000.0

0000.0

0000.0

00000

0000.0

0000.0

Total Display

Decimal Point

00000

00000

00000

00000

00000

00000

00000

00000

00000

00000

00000

00000

00000

00000

00000

00000

00000

00000

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

F-2000

7.3 Programming Menu Flow Chart

Page 18

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

SCREEN

000000

RATE

00000

2

RATE

3

RATE

O00000

TOTAL

00000

2

TOTAL

3

TOTAL

MODEL PC UNITS ONLY

sETPOINT

CLEAR

TOTAL

RATE sETPOINT

OFF

OFF

OFF

DESCRIPTION

MODIFYING

RATE 1 - Rate Scale Factor

RATE 2 - Rate Decimal Factor

RATE 3 - Battery Save Mode On / Off

TOTAL 1 - Total Scale Factor

TOTAL 2 - Total Decimal Factor

TOTAL 3 - Clear Total Enable On / Off

SETPOINT MODE ASSIGN - on rate / on batch / off

Setpoint ON - Assigned to RATE

CLEAR

SETPOINT

CLEAR

TOTAL

CLEAR

TOTAL

CLEAR

SETPOINT

CLEAR

TOTAL

CLEAR

TOTAL

Or

Or

CLEAR

TOTAL

CLEAR

TOTAL

ENTER

ENTER

ENTER

ENTER

ENTER

CLEAR

TOTAL

BATCH SETPOINT

ENTER

ENTER

ENTER

MODEL AO UNITS ONLY

00000

RATE SETPOINT

00000

2

RATE SETPOINT

00000

3

RATE SETPOINT

00000

4

RATE SETPOINT

5

RATE SETPOINT

BATCH SETPOINT

2 OFF

BATCH SETPOINT

3

BATCH SETPOINT

000

00000

00000

Setpoint Rate 1 - High Alarm Trigger

Setpoint Rate 2 - High Alarm Release

Setpoint Rate 3 - Low Alarm Trigger

Setpoint Rate 4 - Low Alarm Release

Setpoint Rate 5 - Alarm Delay Timer

Setpoint ON - Assigned to BATCH

Setpoint Batch 1 - Batch Amount

Setpoint Batch 2 - Auto Reset On / Off

Setpoint Batch 3 - External Equip. Timer

CLEAR

SETPOINT

CLEAR

SETPOINT

CLEAR

SETPOINT

CLEAR

SETPOINT

CLEAR

SETPOINT

CLEAR

SETPOINT

CLEAR

SETPOINT

CLEAR

SETPOINT

Or

Or

Or

Or

Or

Or

Or

Or

CLEAR

TOTAL

CLEAR

TOTAL

CLEAR

TOTAL

CLEAR

TOTAL

CLEAR

TOTAL

CLEAR

TOTAL

CLEAR

TOTAL

CLEAR

TOTAL

ENTER

ENTER

Find Quality Products Online at: sales@GlobalTestSupply.com

00000

MA

00000

2

MA

www.GlobalTestSupply.com

MA-1 - Low Analog Out Value

MA-2 - High Analog Out Value

CLEAR

SETPOINT

CLEAR

SETPOINT

Or

Or

CLEAR

TOTAL

CLEAR

TOTAL

Page 19

8.0 MAINTENANCE

The F-2000 requires very little maintenance, however, some conditions will cause increased wear or

possible damage to the unit.

!

Periodically remove the sensor assembly from the pipe fitting and inspect the meter for signs of wear

and obstructions. Clean the paddle of any foreign objects. Replace the paddle and axle if worn.

!

Although the meter is capable of operating at the high end of the flow range, continuous use at very

high flow rates (upper 25% of the calibrated flow range), is not recommended. The paddle and axle life

is related to the rate of flow and the fluid being measured. Corrosive fluids moving at high flow rates

will cause increased wear requiring frequent inspection and maintenance. Ceramic, titanium or nickel

axles are available for extreme corrosive environments.

!

Although the F-1000 is designed to withstand outdoor conditions, a cool, dry location where the unit can

be easily serviced is recommended. The life of the LCD display will be severely reduced when

installed in direct sunlight. Do not install the meter so that the LCD is in direct sunlight.

!

O-rings should be inspected periodically. Immediately replace the o-rings at any sign of wear, swelling,

cracking or discoloration.

!

Battery operated models. Replace the four AA batteries every 12 months. The program memory will

not erase when replacing the batteries. The unit will function normally for approximately 2 minutes

while replacing the batteries. To replace the batteries, open the front panel of the enclosure by

removing the four Phillips screws. After replacing the batteries, be sure the foam insert is in place

before closing the front panel.

!

Test the electronics by removing the sensor assembly from the pipe fitting and spinning the paddle by

hand. If a reading does not appear in the display window, replace the batteries. If a reading still does

F-2000

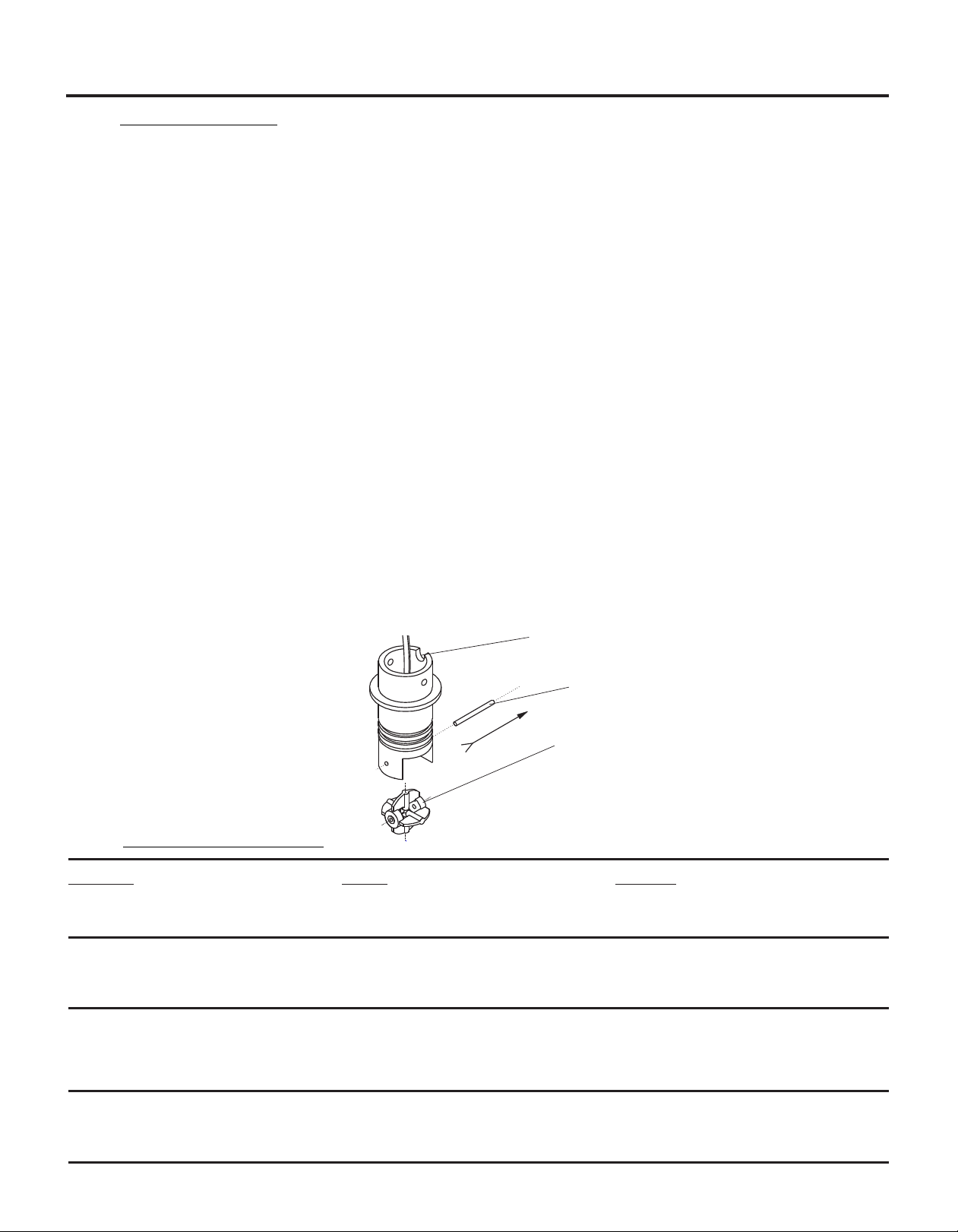

Step 1: Locate notch on the sensor

PADDLE REMOVAL

Fig. 12

Arrow

Direction

Step 2: Push shaft out in the direction shown.

Step 3: Replace the paddle, then press shaft

back into place in the opposite

8.1 TROUBLESHOOTING

Situation Cause Solution

Leaking Improper installation Pipe Fitting Manual pages 6 thru 10

Worn or damaged o-rings Pipe Fitting Manual pages 6 thru 10

Flow rate reading is inaccurate Improper installation Pipe Fitting Manual page 6

Improper velocity profile Pipe Fitting Manual page 4

Flow rate is out of range Model RT Manual page 4

No display Dead batteries Model RT Manual page 19

Blocked paddle Pipe Fitting Manual page 7

Damaged electronics Model RT Manual page 19

Battery save mode is ON Model RT Manual page 18

Display shows zero flow Improper alignment / installation Pipe Fitting Manual page 7

Worn paddle and / or axle Model RT Manual page 19

Damaged electronics Model RT Manual page 19

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

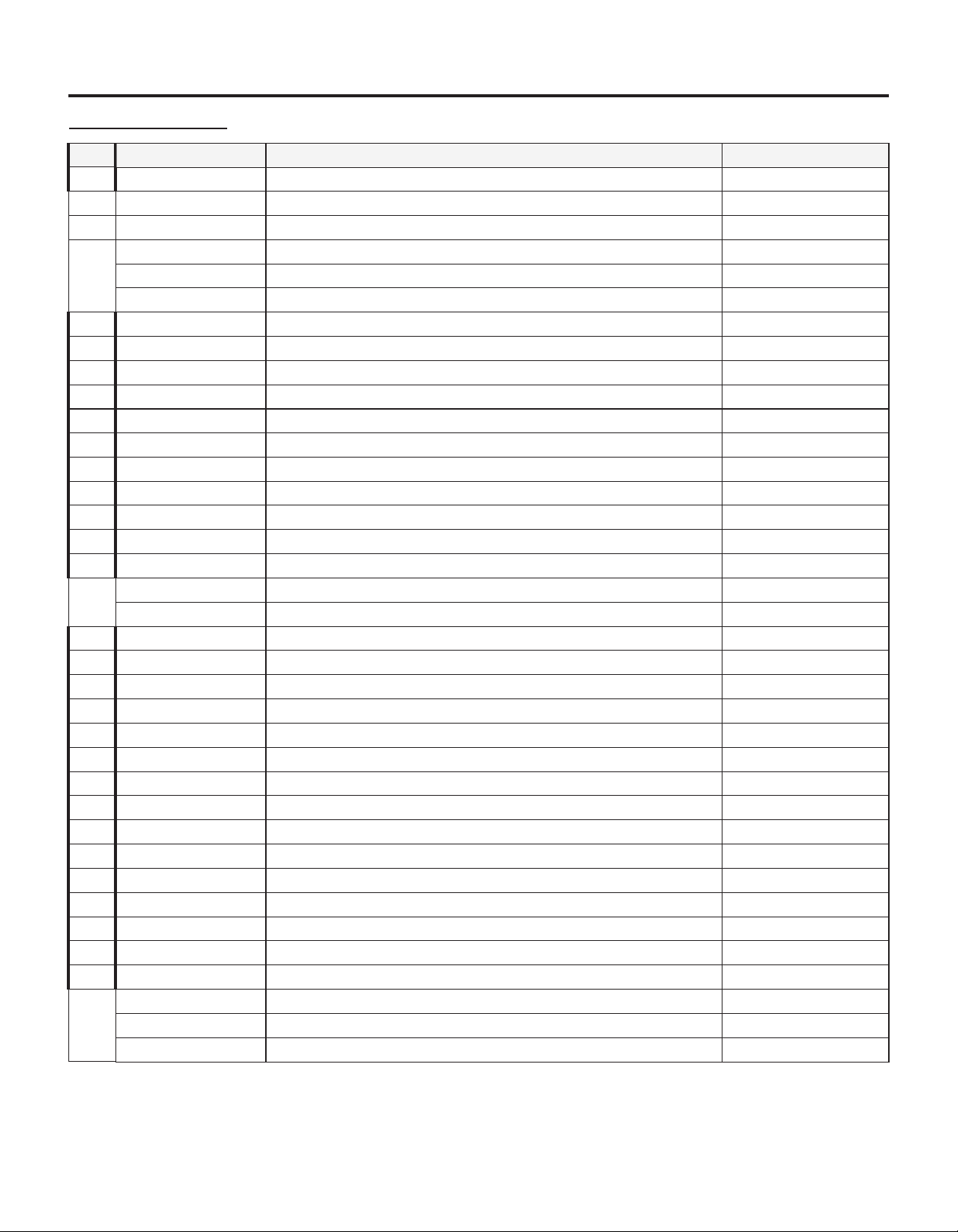

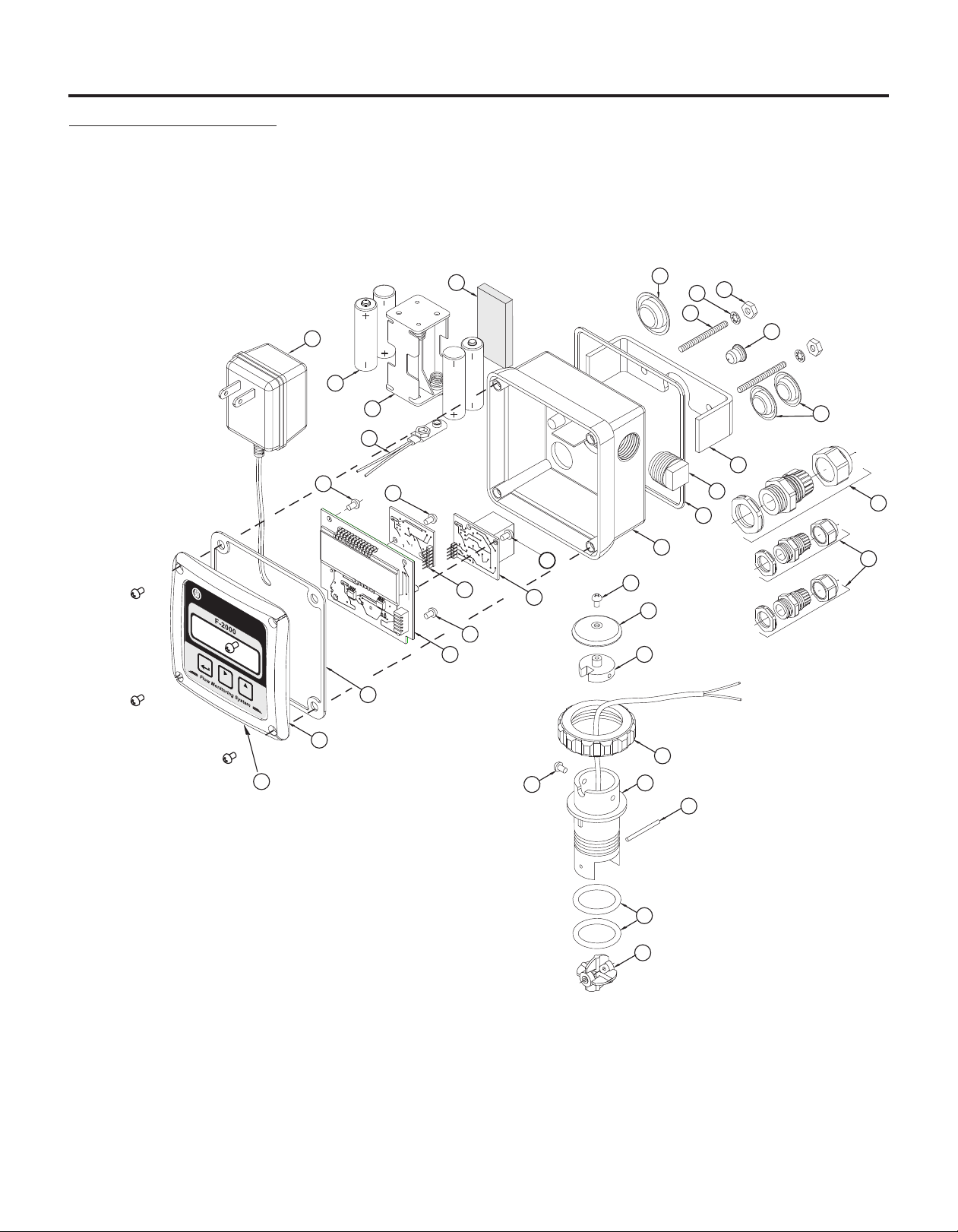

Item Part Number Description Quantity

F-2000

F-2000 Parts List

Item Part Number Description Quantity

1 70000-783 Paddle assembly Kynar 1

2 90003-021 O-ring 022 Viton E60 2

3 90007-589 Axle PVDF 1

4 71000-238 Sensor body AC coil 1’ cable 1

71000-289 Sensor body AC coil 25’ cable 1

70000-290 Sensor body Hall effect 25’ cable 1

5 90011-080 Screw #6-32 x .37 PH pan B 18/8 5

6 91001-280 Union nut 1

7 76000-628 Retainer sensor cap 1

8 90006-550 Cap sensor body SS 1

9 90012-208 Switch overlay F-2000 1

10 71000-356 Cover F-2000 w/ Switch overlay 1

11 90006-592 Gasket F-2000 housing neoprene 1

12 90010-227 Circuit board F-2000 RT 1

13 71000-311 Kit Circuitry model F-2000 AO (AO Board 90010-229) 1

14 71000-316 Kit Circuitry model F-2000 PC(PC Board 90010-228) 1

15 90011-155 Screw #6-32 x .31 PH pan SS 4

16 76001-149 Enclosure F-2000 sensor mount 1

76001-150 Enclosure F-2000 panel mount 1

17 90006-593 Gasket F-2000 1/4 DIN panel mount 1

18 90008-331 Cap plug P-48 1/2 NPT red F-2000 1

19 71000-294 Kit F-2000 1/4 DIN panel mount 1

20 70000-500 Connector liquid-tight 1/2 in. 2

21 70000-589 Connector liquid-tight 3/4 in. 1

22 90008-332 Plug 1/2 in. 2

23 90008-340 Cap plug VTP-25 red 1

24 90011-038 Stud screw #10-32 1.62 long 2

25 90011-092 Star washer #10-32 2

26 90011-026 Hex nut #10-32 2

27 90008-333 Plug 7/8 in. 1

28 90013-222 Foam pad 1/4 in. thick 1

29 90008-254 Battery clip 1

30 90010-233 Battery holder F-2000 4x AA 1

31 90008-330 Battery alkaline AA 4

32 90008-336 Power supply 115VAC/15VDC 1

90008-337 Power supply 220VAC/15VDC Europe 1

71000-310 Power supply 230VAC/15VDC 1

Page 20

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Page 21

F-2000 Exploded View

F-2000

BLUE-WHITE

®

INDUSTRIES

F-2

0

00

ENTER

CLEAR

Flow Monitoring System

SETPOINT

CLEAR

T

OT

28

27

26

25

24

32

SIZE AA BATTERY

23

31

30

SIZE AA BATTERY

22

29

19

5

15

18

21

17

8888.8888

15

13

14

16

20

5

8

15

12

AL

11

7

10

6

9

5

4

3

2

1

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Warranty

!

Blue-White flowmeters are warranted to be free from defects in material and workmanship for 12 months from date of

factory shipment. Warranty coverage is limited to repair or replacement of the defective flowmeter only.

!

This warranty does not cover damage to the flowmeter that results from misuse or alterations, nor damage that occurs

as a result of: meter misalignment, improper installation, over tightening, use of non-recommended chemicals, use of

non-recommended pipe dopes or adhesives, excessive heat or pressure or allowing the meter to support the weight of

related piping.

!

Flowmeters are repaired at the factory only. Call or write the factory to receive a RA (return authorization) number.

Carefully pack the flowmeter to be returned, including a brief description of the problem, chemical used, and a description of the application. Note: Write the RA number on the outside of the shipping carton.

!

Prepay all shipping costs. The factory does not accept C.O.D. Shipments. Damage that occurs during shipping is the

responsibility of the sender.

Users of electrical and electronic equipment (EEE) with the WEEE marking per Annex IV of

the WEEE Directive must not dispose of end of life EEE as unsorted municipal waste, but

use the collection framework available to them for the return, recycle, recovery of WEEE

and minimize any potential effects of EEE on the environment and human health due to the

presence of hazardous substances. The WEEE marking applies only to countries within the

European Union (EU) and Norway. Appliances are labeled in accordance with European

Directive 2002/96/EC.

P.N. 80000-355 Rev 6/25/2014

Find Quality Products Online at: sales@GlobalTestSupply.com

Contact your local waste recovery agency for a Designated Collection Facility in your area.

www.GlobalTestSupply.com

Loading...

Loading...