Page 1

Marine Electrical Prod

ucts

Dual Battery Main Distribution Panel

One Selector Battery Switch

PN 8687/8691

Features

• Power distribution, switching, and circuit protection combined in one panel

• Confi gurable to suit specifi c needs of individual boat owners

• Familiar Selector Battery Switch: m-Series (8687) or e-Series (8691)

• Two 15A thermal circuit breakers provide 24-hour circuit protection

• Each circuit contains circuit labels and LED indicator lights that provide circuit

status

• Blank slots to accommodate additional circuit breakers or switches

Panel Specifi cations

Material: 0.125” 5052-H32 Aluminum Alloy

Primary Finish: Chemical Treatment per Mil Spec C-5541C

Final Panel Finish: Graphite color 2 part textured Polyurethane

Maximum Voltage Rating: 24V DC

House Amperage Rating: 100A Max (on installed circuit)

Switch Amperage Ratings: Continuous: 8687-300A, 8691-350A

Intermittent (5 min.): 8687-500A, 8691-600A

Cranking (100 sec.): 8687-700A, 8691-900A

Inrush (2.5 sec.): 8687,1500A, 8691-1750A

Inches Millimeters

Dimensions: 8687 4.50 x 7.50 114.3 x 190.50

8691 5.25 x 8.00 133.35 x 203.20

Mounting Centers: 8687 3.67 x 6.67 93.22 x 169.42

8691 4.42 x 7.17 112.27 x 182.12

Battery Switch Terminal Studs: 3/8”-16 (accepts M10 terminal)

Torque: 140 in-lbs.

Blue Sea Systems Inc. Phone (360) 738-8230

425 Sequoia Drive Fax (360) 734-4195

Bellingham, WA 98226 USA E-mail conductor@bluesea.com

www.bluesea.com

Document 6344 Rev.B

WARNING

@ If the installer is not knowledgeable about electrical systems, consult an

electrical professional.

@ If either the panel front or back is to be exposed to water it must be

protected with a waterproof shield.

@ The panels must not be installed in explosive environments such as

gasoline engine rooms or battery compartments because the circuit

breakers are not ignition protected.

@ The main positive connection must be disconnected at the battery post

to avoid the possibility of a short circuit during the installation of this

distribution panel.

Guarantee

If at any time you are not satisfi ed with this product, you may return it

for a refund or replacement.

Useful Reference Books

Calder, Nigel, 2005: Boatowner’s Mechanical and Electrical Manual,

3rd edition, Blue Ridge Summit, PA: TAB Books, Inc.

Wing, Charlie, 1993: Boatowner’s Illustrated Handbook of Wiring,

Blue Ridge Summit, PA: TAB Books, Inc.

Applicable Standards

• American Boat and Yacht Council (ABYC) Standards and Recommended

Practices for Small Craft sections: E-1, E-3, E-11.

• United States Coast Guard 33 CFR Sub Part 1, Electrical Systems.

• National Fire Protection Agency (NFPA) 302

Related Products Available from Blue Sea Systems

Toggle World Circuit Breakers, e.g., 7200

Small Case Rockers, e.g., 7300, 7408 (fl at), 7433 (slot reset)

Large Case Rockers, e.g., 7450

CLB with Adapter, e.g., 7050/4111

Push Button Switches with Adapter, e.g., 8200

Toggle Switches with Adapter, e.g., 8204

Installation

1. Disconnect all DC power

To eliminate the possibility of a short circuit while installing the panel,

disconnect the main positive cable from all batteries.

2. Select mounting location and cut opening

Select a mounting location that is protected from water on the panel

front and back and is not in an area where fl ammable vapors from

propane, gas or lead acid batteries accumulate. Using the panel

template provided, make a cut out in the mounting surface where

the panel is to be mounted. Do not fasten the panel to the

mounting surface.

3. Install LED negative feed wire

Use a 16 AWG wire to connect the LED negative feed (Yellow) wires

to a DC negative bus.

4. Electrical Connections

Battery cable terminals must be attached under battery switch stud

nut and lock washer. The electrical connection illustration is general

in nature and is not meant to be a guide for the wiring of any specifi c

vessel. There is a wide range of wiring confi gurations possible.

Consult your marine electrical professional for the wiring system

applicable to your boat.

Make appropriate adjustments to the wiring diagram to suit your

specifi c installation and equipment. Fusing may be appropriate

in several of the lines depending on the proximity of components,

conductor sheathing, and the conductivity of the surrounding structure.

Consult the Wire Sizing Chart to determine the appropriate wire sizes.

5. Apply Labels and Mount Panel

Apply a label to each of the circuits from the label sheet provided. Use

the panel mounting screws supplied with the panel to secure the panel

to the mounting surface. Additional labels are available from

Blue Sea Systems.

Caution

Caution: ABYC Interrupt

In certain circumstances, main DC circuit breakers may have to break

very high amperages. The ability of a circuit breaker to safely break high

amperage is its Ampere Interrupt Capacity (AIC) rating. AIC is a function

of a battery’s Cold Cranking Amperes (AIC) capacity. According to ABYC

E-11 standards, circuit breakers shall have a DC voltage rating of not less

than the nominal system voltage, be capable of an interrupting capacity

according to the values in the table below, and remain operable after the

fault. For example, a boat with a group 24 or 27 battery may have as much

as 650 CCA. The DC main circuit breaker for this circuit must have an AIC

rating of 1500 Amperes.

DC voltage rating CCA of all

connected

batteries

12 Volt and 24 Volt 650 or less 1500 750

651-1100 3000 750

over 1100 5000 2500

32 Volts 1250 or less 3000 1500

over 1250 5000 2500

Blue Sea Systems Battery Management Panels contain thermal (push

button reset) circuit breakers rated at 15A. These circuit breakers are

suitable for 24-hour circuits connected directly to 12V or 24V battery banks

with CCA capacities less than 660A.

Installation of this panel in systems with battery banks of 660A or higher

should include an additional fuse or circuit breaker of appropriate interrupt

capacity in the line between the battery bank and the pushbutton circuit

breakers to comply with ABYC E-11 and NFPA 302.

Ampere Interrupt Capacity (AIC)

Main Circuit

Breaker (Amperes)

Branch Circuit

Breaker(Amperes)

Page 2

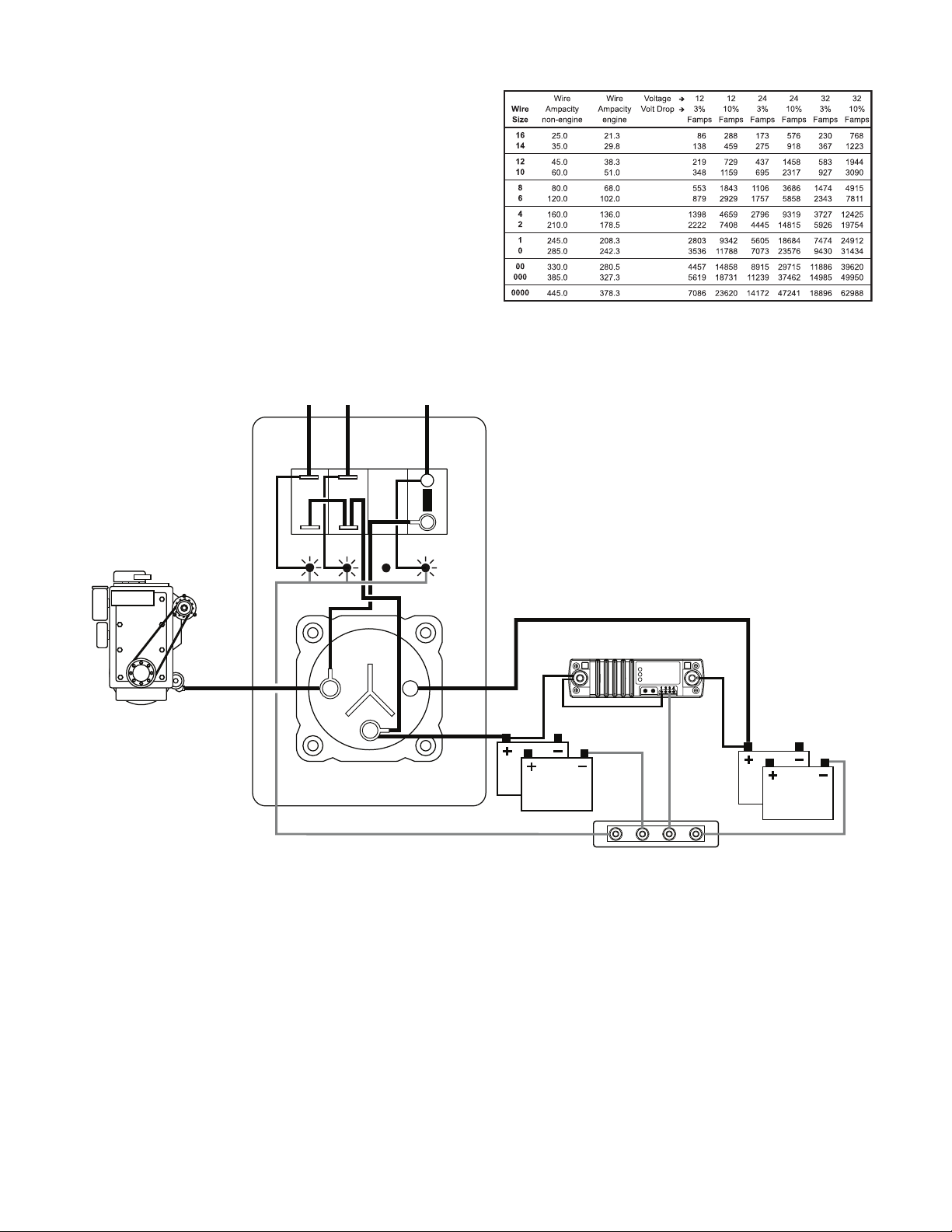

Wire Sizing Chart

B A

1. Calculate the maximum sustained amperage of the circuit. Measure the

length of the circuit from the power source to the load and back.

2. Calculate Famps (Feet x amps). Multiplycircuit lenght by max. current.

3. Base the wire on either the 3% or 10% voltage drop. In general, items

which affect the safe operation of the boat and its passengers (running

lights, bilge blowers, electronics) use 3%; all other loads use 10%.

4. Are the circuit runs in an engine space or non engine space?

5. Starting in the Famps column with the right voltage and voltage drop,

run down the list until arriving at a value which is greater than the

calculated Famps. Move left to the Ampacity column to verify that the

total amperage of the circuit does not exceed the maximum allowable

amperage of the wire size for that row. If it does, move down until the

wire ampacity exceeds the circuit amperage. Finally, move left to the

wire size column to select the wire size.

Example

A 12 volt system at 10% drop with a 40’ circuit x 45 amps = 1800 Famps.

A wire size of 8 is required.

OUTPUT TO

ENGINE

ALTERNATOR

OR STARTER

TO 24 HOUR

CIRCUITS

COMMON

TO DC HOUSE

DISTRIBUTION

PANEL OR HIGH

AMP DC LOAD

2

Note: For wire with 105°C insulation rating and AWG wire sizes.

100A

LEDLEDLEDLED

CL-SERIES 7600

BATTERYLINK

Chart courtesy of the West Advisor

TM

ACR

1

HOUSE

Wiring Diagram

Dual Battery Main Distribution Panel

PN 8687 Shown

ENGINE

DC NEGATIVE

DISTRIBUTION BUS

Loading...

Loading...