1

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

Service Manual

Electric Fryers

E43 / E43E and E44 / E44E

2

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

ALL INSTALLATION AND SERVICE REPAIR WORK MUST BE CARRIED OUT BY

QUALIFIED PERSONS ONLY.

WARNING:

MAKING ALTERATIONS MAY VOID WARRANTIES AND APPROVALS.

IMPORTANT:

3

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

This manual is designed to take a more in depth look at the E43 and E44 electric fryers for the purpose of

making the units more understandable to service people.

There are settings explained in this manual that should never require to be adjusted, but for completeness

and those special cases where these settings are required to change, this manual gives a full explanation

as to how, and what effects will result.

Section Page Number

1. Specifications ............................................................................................1

2. Installation ................................................................................................5

3. Operation................................................................................................... 9

3.1 Description of Controls

4. Cleaning and Maintenan c e ......................................................................13

5. Trouble-shooting Guide........................................................................... 15

5.1 Trouble-shooting Chart

5.2 Fault Diagnosis

6. Service Procedures ..................................................................................21

6.1 Access

6.2 Replacement

6.3 Adjustment / Calibration

7. Accessories .............................................................................................. 29

8. Replacement Parts ................................................................................. 30

8.1 E43

8.2 E43E

8.3 E44

8.4 E44E

9. Wiring Diagrams...................................................................................... 41

10. Service Contacts ......................................................................................44

Contents

4

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

1

1

Specifications

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

LEGEND

- Electrical connection entry point

Dimensions shown in millimetres.

External dimensions: E43 / E43E

1

Specifications

2

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

External dimensions: E44 / E44E

LEGEND

- Electrical connection entry point

Dimensions shown in millimetres.

3

1

Specifications

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

Electrical supply

E43 E44

Oil capacity

27l

21.6kg

12l (per tank)

10kg (per tank)

Useable internal

dimensions of tank

(width x length)

365mm x 380mm 175mm x 380mm

Useable depth of oil 95mm 95mm

Tank capacity

Model

Power Supply

Total Power

Input

Amps

Voltage Type Frequency

L1 L2 L3

E43

400-415 Vac 3 P+N+E 50 / 60 Hz 17 kW 23.6 23.6 23.6

E43E

400-415 Vac 3 P+N+E 50 / 60 Hz 17 kW 23.6 23.6 23.6

E44

400-415 Vac 3 P+N+E 50 / 60 Hz 17 kW 23.6 23.6 23.6

E44E

400-415 Vac 3 P+N+E 50 / 60 Hz 17 kW 23.6 23.6 23.6

2

Installation

4

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

Installation Requirements

NOTE: It is most important that this appliance is installed correctly and that operation is correct before

use. Installation shall comply with local electrical and health and safety requirements.

Blue Seal Deep Fryers are designed to provide years of satisfactory service, and correct installation is

essential to achieve the best performance, efficiency and trouble-free operation.

This appliance must be installed in accordance with National installation codes and in addition, in

accordance with relevant National / Local codes covering electrical, fire safety and health and safety.

Australia / New Zealand AS/NZS3000 - Wiring Rules.

United Kingdom: BS 7671 - Requirements for Electrical Installations.

Installations must be carried out by authorised persons only. Failure to install equipment to relevant codes and manufacturers specifications in this section will void warranty.

Unpacking

• Remove all packaging and transit protection from the appliance including all protective plastic

coating from the door outer panel and exterior stainless steel panels.

• Check equipment and parts for damage. Report any damage immediately to the carrier and

distributor.

• Report any deficiencies to the distributor who supplied the appliance.

• Check that the available electrical supply is correct to that shown on the rating plate l ocated on t he inside

of the access door.

• Check that the following parts have been supplied with the appliance:

E43 / E43E E44 / E44E

Baskets 2 2

Sediment Trays 1 2

Lid 1 1

Adjustable Legs 4 4

Drain Stick 1 1

Drain Extension 1 2

Location

1. Any appliance requires adequate clearance and ventilation for optimum and trouble-free o peration. The

minimum installation clearances shown below are to be adhered to.

2. Position the Deep Fryer in its approximate working position.

3. The legs must always be fitted. Ensure that the legs are securely attached.

Clearances

NOTE:

• Only non-combustible materials can be used in close proximity to this appliance.

• In order to facilitate easy operation, drainage and servicing of the appliance, a minimum

of 600mm clearance should be maintained at the front of the appliance.

Assembly

This model is delivered completely assembled. Ensure that the legs are securely attached.

NOTE:

• This appliance is fitted with adjustable feet to enable the appliance to be positioned

securely and level. This should be carried out on completion of t he electrical conn ection. Refer t o

the “Electrical Connection” section below.

Combustible Surface Non Combustible Surface

Left/Right hand side 50 mm 0 mm

Rear 25 mm 0 mm

2

Installation

5

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

Electrical Connection

NOTE: ALL ELECTRICAL CONNECTIONS MUST ONLY BE CARRIED OUT BY A QUALIFIED

PERSON.

Each fryer should be connected to an adequately protected power supply and isolation switch mo unted adjacent

to, but not behind the fryer. This switch must be clearly marked and readily accessible in case of fire.

The fryer is equipped with 32A fusing on L1, L2 and L3 supplies. Ensure that fuses are fitted (Type F1(NS) gG).

1. Check that the electricity supply is corr ect as shown on the Rating Plate attached to the inside of the ac cess door.

2. The supply terminal connections are located at the lower front of the fryer.

3. Open the door and remove the service panel (6 screws) located behind the drain valve(s) to allow

connection access for the electrical supply.

4. Bring the supply cable up through the grommet at the back of the fryer, and through the compression

type gland provided on the rear of the main electrical switchgear panel.

5. Connect the mains supply to L1, L2 and L3 fuse carrier connections for 3 phases.

6. Connect neutral and earth conductors to neutral stud and earth stud respectively.

7. For all connections ensure that conductors are secure and appropriately terminated.

8. Tighten the cable gland to secure against tension on the cable.

NOTE:

• This appliance must be grounded / earthed.

• Fixed wiring installations must incorporate an all-pole disconnection switch.

Commissioning

1. Before leaving the new installation;

a. Check the following functions in accordance with the operating instructions specified in the “Operation”

section of the User manual.

• Check the current draw and loading for the equipment. Refer specification section for

correct electrical requirements.

• Check that all the connections are correct and that all cover panels have been re-fitted.

• Check that the unit functions in accordance with the operating instructions.

• Ensure that the tank drain extension and this instruction manual are left with the

appliance.

• Ensure that all the relevant details and contacts have been added to the front of the User

manual.

b. The thermostat operation check should be carried out by filling the fryer with oil/shortenin g to the

appropriate oil 'FILL LEVEL' mark at the rear of the tank and setting the thermostat to 180°C. Light

the pilot burners and turn on the elements in accordance with “Operation Instruct ions” found in the

User manual.

c. The calibration of the thermostat should be checked once the oil is up to temperature. If a

discrepancy is found, the thermostat calibration should be referred to the supplier.

d. Ensure that the operator has been instructed in the areas of correct operation and shutdown

procedure for the appliance.

2. The User manual must be kept by the owner for future reference, and a record of Date of

Purchase, Date of Installation and Serial Number of Unit recorded and kept with the manual. (These

details can be found on the Rating Plate fitted to the inside of the access door and in the “Specifications”

section of this manual.

NOTE:

• If for some reason it is not possible to get the unit to operate correctly, turn off the

electrical power supply and contact a qualified service person. The supplier of this unit

will be able to recommend a suitable person.

• Make sure that the electrical supply is turned off before any service or maintenance work

is carried out.

3

Operation

6

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

Electronic controls - E43E and E44E

3.1 Description of controls

Manual controls - E43 and E44

Temperature Control Knob

Temperature Graduations

60°C to 200°C.

Power ‘ON’ Indicator. (When

main power switch is ‘ON’).

Heating ‘ON’ Indicator. (When

thermostat is turned to a

selected temperature.

Operating the reset switch

resets the element.

(Press to operate).

Turns power ‘ON’ and ‘OFF’ to

the unit. (White LED Indicator

illuminates (Green) when

switched ‘ON’).

Neon Indicator

(White)

Neon Indicator

(Orange)

Temperature

Cut-Out Reset

Switches

Located Behind Main Access Door

Electronic Controller

See description of Electronic

Controller overleaf.

Operating the reset switches

resets the elements.

(One switch for each element.

Press to operate).

Turns power ‘ON’ and ‘OFF’ to

the unit. (Green LED Indicator

illuminates when switched

‘ON’).

Temperature

Cut-out Reset

Switches

Located Behind Main Access Door

Mains Isolation

Switch

Mains Isolation

Switch

4

Cleaning / Maintenance

7

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

General

To achieve the best results cleaning must be regular and thorough and all controls and mechanical

parts checked and adjusted periodically by a competent serviceman. If any small faults occur, have

them attended to promptly. Don't wait until they cause complete breakdown. It is recommended

that a service check is conducted every six months.

Clean the fryer regularly. A clean fryer looks better, will last longer and will perform better. A build

up of grease on the surface will hinder the transfer of heat from the cooking surface to the food.

This will result in loss of cooking efficiency.

NOTE:

• DO NOT use abrasive detergents, sharp scrapers, strong solvents or caustic detergents as they could corrode or damage the fryer.

• Ensure that any detergent or cleaning material have been completely removed after

each cleaning.

To keep your fryer clean and operating at peak efficiency, follow the procedures below:-

Draining and Cleaning

Opening the Drain Valve

a. Lift the locking slide on valve handle to release valve.

b. While holding the locking slide in the withdrawn position, rotate the handle anticlockwise to open

the valve.

c. When the valve is closed, the locking slide will drop down over the locking valve to prevent

accidental opening of the valve.

WARNING:

DO NOT

USE FLAMMIBLE SOLVENTS AND CLEANING AIDS ON OR IN CLOSE PROXIMITY TO THE FRYER

WHILST THE FRYER IS STILL HOT.

C

AUTION

:

Always turn off the electrical supply before cleaning the appliance.

This appliance is not water proof.

Do not use water jet spray to clean interior or exterior of this appliance.

C

AUTION

:

Never drain the fryer with power or elements switched ‘ON’.

Always switch ‘OFF' the fryer before draining or re-filling the tank.

WARNING:

DO NOT ATTEMPT TO MOVE THE FRYER WHILST THE FRYER IS FULL OF OIL.

BEFORE ATTEMPTING TO MOVE THE FRYER, ENSURE THAT ALL THE OIL HAS BEEN

DRAINED FROM THE TANK. REFER TO THE INFORMATION BELOW ON HOW TO DRAIN THE

OIL FROM THE FRYER.

4

Cleaning / Maintenance

8

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

Daily Cleaning

1. At the end of each day or at the end of each shift, if the frying schedule is heavy, the frying medium

should be drained and filtered into a receptacle.

2. Always filter the fryer when the cool zone under the elements is hot and liquid. A cold fryer heated

up won't drain, because the frying medium in this zone will remain hard if using solid fat/oils.

3. Screw on the drain extension pipe and position a suitable container and filter under the drain.

4. Do not empty the total contents into one large container, as this will be dangerous and may be

difficult when lifted up, to pour the hot oil back into the tank.

5. Lift the element assembly up out of the tank.

6. Open the drain valve slowly to minimise splashing, and take care not to overfill the container.

7. If necessary, use a drain stick to stir up any solid medium into the top medium to melt it.

8. Slip a muslin or other suitable bag over the drain valve. Crumbs will be caught in the bag but frying

medium will strain freely through bag the bag into the receptacle.

9. When the tank has been drained, use a ladle or small pan with a handle as a ladle and dip into the

hot frying medium from the receptacle and pour vigorously around sides and bottom of the tank to

wash out crumbs and particles adhering to them.

10. Continue to dip and pour until all crumbs are washed down and into the filter bag.

11. Open the drain valve fully and check for any particles or crumb residue lodged in the valve. Clean

out with a stiff nylon brush. Do not use a wire brush or metal rods as these damage the seating in

the valve and will eventually lead to valve leakage. If the obstruction in the valve cannot be

removed with a brush, use a wooden probe to dislodge the obstruction.

12. Wipe all exterior panels with a cloth dampened with detergent and rinse off any residue with clean

warm water.

13. Once the daily cleaning operation is completed, close the valve and pour the frying medium back

into the tank and continue the days work.

14. Straining takes less time than frying one load of potatoes and will pay dividends in food quality and

saving of frying medium.

Locking Slide

Fig 5

Fig 4

Locking Slide

C

AUTION

:

HOT OIL WILL BURN - DO NOT RUSH THIS JOB.

4

Cleaning / Maintenance

9

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

Weekly Cleaning

NOTE: If the fryer usage is very high, we recommend that the weekly cleaning procedure is carried

out on a more frequent basis.

1. Proceed as for “Daily Cleaning” to drain and filter the tank. Do not refill the tank with frying medium

until it has been cleaned as shown below.

2. Fill the fryer with cold water to the normal fill level and add a high quality commercial cleaner that

has been specifically formulated for fryers.

All purpose cleaners are not recommended

.

NOTE: Never use a caustic or lye solution, as this will leave a fat destroying film on the tank.

3. Ensure that the elements are lowered into the tank. Switch ‘ON’ the power and heat the water to

approximately 80-90°C.

4. Clean the fryer baskets at the same time by simply immersing them in the cleaning solution. Allow

the fryer to soak for 5-10 minutes or as directed on the cleaner instru ctions. Remove th e baskets

and switch ‘OFF’ the fryer.

5. Scrub the baskets and fryer tank lightly, but vigorously with a stiff nylon bristle brush to remove any

remaining deposits. DO NOT use a wire brush, as this will scratch the sides of the tank.

6. Empty the fryer and rinse thoroughly with water. Use a 1 part vinegar to 15 parts water solution to

rinse the tank and neutralise any cleaner residue. Use a weaker solution of up to 1 part

vinegar to 25 parts water if this proves unsuitable for the cleaner being used.

7. Rinse the tank thoroughly with water, drain and dry.

8. Refill the tank with new filtered frying medium to the correct level as shown in the Operation

section - ‘Filling the Tank(s)’.

Stainless Steel Surfaces

a. With the tank(s) drained, cleaned and dried as shown above, clean the exterior surfaces of the

fryer with hot water, a mild detergent solution and a soft cloth. Note that the control knobs are a

push fit onto the thermostats and can be removed to allow cleaning of the front control panel.

b. Dry all components thoroughly with a dry cloth and polish with a soft dry cloth.

c. To remove any discolouration, use an approved stainless steel cleaner or stainless steel wool.

Always rub in the direction of the grain.

Periodic Maintenance

NOTE: All maintenance operations should only be carried out by a qualified service person.

To achieve the best results cleaning must be regular and thorough and all controls and mechanical parts

should be checked and adjusted periodically by a qualified service person. If any small faults occur, have

them attended to promptly. Don't wait until they cause a complete breakdown. It is recommended that

the appliance is serviced every 6 months.

WARNING:

DO NOT ATTEMPT TO MOVE THE FRYER WHILST THE FRYER IS FULL OF OIL.

BEFORE ATTEMPTING TO MOVE THE FRYER, ENSURE THAT ALL THE OIL HAS BEEN

DRAINED FROM THE TANK. REFER TO THE INFORMATION ON THE PREVIOUS PAGES ON

HOW TO DRAIN THE OI L FROM THE FRYER.

5

Trouble-shooting

10

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

ALL INSTALLATION AND SERVICE REPAIR WORK MUST BE CARRIED OUT BY

QUALIFIED PERSONS ONLY.

WARNING:

Fault Possible Cause Remedy

5.1 Trouble shooting chart

5

Trouble-shooting

11

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

5.2 Fault Diagnosis

5.2.1

A

a

6

Service Procedures

12

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

ALL INSTALLATION AND SERVICE REPAIR WORK MUST BE CARRIED OUT BY

QUALIFIED PERSONS ONLY.

ENSURE ELECTRICAL SUPPLY IS SWITCHED OFF BEFORE SERVICING

WARNING:

Section Page Number

6.1 Access ......................................................................................................22

6.1.1 ..........................................................................................................................

6.2 Replacement ............................................................................................22

6.2.1 ................................................................................................................

6.3 Adjustment / Cali bration.........................................................................28

6.3.1 ..........................................................................................................................

6

Service Procedures

13

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

6.1.1 Control panel

6.1 Access

7

Accessories

14

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

8

Exploded Parts Diagrams

15

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

8.1 E43 Single Tank Fryer

Item Part Number Description

1 227511 FRYER SIDE PANEL RH

2 227512 FRYER SIDE PANEL LH

3 228792 SPLASHBACK E43/44

4 227441 BASKET HANGER 370mm

5 228761 LID 450 FRYER

6 227762 HOB FRONT WA BSEAL

7 230422 FRYER DOOR ASSEMBLY (NO BADGE)

227449 DOOR HANDLE

228846 DOOR OUTER

227453 DOOR INNER

227466 FRYER CATCH RECEIVER

228132 TUBE CLIP

228308 HINGE PIVOT WA

8 227960 BADGE BLUESEAL

9 228300 HINGE PLATE

228301 HINGE BUSH

8.1.1 E43 Main Assembly

8

Exploded Parts Diagrams

16

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

8.1.2 E43 Main Assembly

Item Part No Description

10 014612 ELEMENT 5666W 240V

11 018019 FRYER BASKET -STANDARD

12 229419 SEDIMENT TRAY WA E43

229404 TIE WIRE

13 228247 SEDIMENT TRAY HANDLE E43

14 227856 MAGNETIC CATCH 02-10-201-10

15 018358 BALL VALVE

16 227852 LEG PLATE

17 227850 LEG 150mm (FLUSH STUD)

18 229674 REAR ROLLER ASSY

19 229671 LEG RING PLATE THREADED

8

Exploded Parts Diagrams

17

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

8.1.3 E43 Element Tilt Assembly

Item Part No Description

20 014814 EYE BOLT M10 x 200 CW M10 NUT

21 014858 ELEMENT SPRING

22 229589 CAPILLARY PLATE ELECTRIC

23 229587 PIVOT CLAMP SINGLE

24 014812 SPRING PIVOT ROD

25 229596 PIVOT ROD

26 228564 MICROSWITCH LINK ARM

27 227975 ELEMENT PIVOT BUSH

28 228539 ELEMENT SWITCH CRANK

29 228544 CRANK MTG BRACKET

30 228563 MICROSWITCH ACTUATOR ARM

8

Exploded Parts Diagrams

18

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

8.1.4 E43 Electrical Assembly

Item Part No Description

31 011982 THERMOSTAT 60°- 200°C

32 229355 SELECTOR SWITCH KIT

33 228571 INDEX MARK MOULDING

34 229410 CONTROL PANEL WA E43

35 228922 NEON - WHITE

36 227963 NEON - ORANGE-4122000478

37 227389 KNOB BLUE SEAL 6mm 60-200 deg

38 015966 CONTACTOR 100C09VA10

39 024018 OVERTEMP THERMOSTAT 238°C

40 021965 LABEL - RESET

41 013977 MICROSWITCH INSULATOR

42 024802 DOOR MICROSWITCH E32/G32

43 228375 ACTUATOR ON/OFF RED/YELLOW

44 228374 LOAD SWITCH ON/OFF 32A 3 POLE

45 229582 NEUTRAL TERMINAL

8

Exploded Parts Diagrams

19

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

8.2 E43E Single Tank Fryer

8.2.1 E43E Main Assembly

Item Part No Description

1 227511 FRYER SIDE PANEL RH

2 227512 FRYER SIDE PANEL LH

3 228792 SPLASHBACK E43/44

4 227441 BASKET HANGER 370mm

5 228761 LID 450 FRYER

6 227762 HOB FRONT WA BSEAL

7 229530 CONTROL PANEL WA E43E GT45E

8 228707 FAST DIGITAL CONTROLLER KIT

230101 OVERLAY DIGITAL 3 BASKET BSEAL

9 230422 FRYER DOOR ASSEMBLY (NO BADGE)

227449 DOOR HANDLE

228846 DOOR OUTER

227453 DOOR INNER

227466 FRYER CATCH RECEIVER

228132 TUBE CLIP

228308 HINGE PIVOT WA

10 227960 BADGE BLUESEAL

11 228300 HINGE PLATE

228301 HINGE BUSH

8

Exploded Parts Diagrams

20

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

8.2.2 E43E Main Assembly

Item Part No Description

12 017717 PROBE ELECTRONIC

13 014612 ELEMENT 5666W 240V

14 018019 FRYER BASKET -STANDARD

15 229419 SEDIMENT TRAY WA E43

229404 TIE WIRE

16 228247 SEDIMENT TRAY HANDLE E43

17 227856 MAGNETIC CATCH 02-10-201-10

18 018358 BALL VALVE

19 227852 LEG PLATE

20 227850 LEG 150mm (FLUSH STUD)

21 229674 REAR ROLLER ASSY

22 229671 LEG RING PLATE THREADED

8

Exploded Parts Diagrams

21

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

8.2.3 E43E Element Tilt Assembly

Item Part No Description

23 014814 EYE BOLT M10 x 200 CW M10 NUT

24 014858 ELEMENT SPRING

25 229589 CAPILLARY PLATE ELECTRIC

26 2295 87 PIVOT CLAMP SINGLE

27 0148 12 SPRING PIVOT ROD

28 229596 PIVOT ROD

29 2285 64 MICROSWITCH LINK ARM

30 2279 75 ELEMENT PIVOT BUSH

31 2285 39 ELEMENT SWITCH CRANK

32 2285 44 CRANK MTG BRACKET

33 2285 63 MICROSWITCH ACTUATOR ARM

8

Exploded Parts Diagrams

22

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

8.2.4 E43E Electrical Assembly

Item Part No Description

34 015966 CONTACTOR 100C09VA10

35 024018 OVERTEMP THERMOSTAT 238°C

36 021965 LABEL - RESET

37 013977 MICROSWITCH INSULATOR

38 024802 DOOR MICROSWITCH E32/G32

39 228660 TRANSFORMER WORKED

40 025948 TERMINAL BLOCK - 6 WAY

41 229033 FUSEHOLDER 6.3x32mm

020109 GLASS FUSE 2AMP 250V 1¼ x ¼

42 228375 ACTUATOR ON/OFF RED/YELLOW

43 228374 LOAD SWITCH ON/OFF 32A 3 POLE

44 229582 NEUTRAL TERMINAL

45 020532 RELAY BASE

020256 RESET RELAY 24V AC

8

Exploded Parts Diagrams

23

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

8.3 E44 Twin Tank Fryer

8.3.1 E44 Main Assembly

Item Part No Description

1 227511 FRYER SIDE PANEL RH

2 227512 FRYER SIDE PANEL LH

3 228792 SPLASHBACK E43/44

4 227441 BASKET HANGER 370mm

5 228761 LID 450 FRYER

6 227762 HOB FRONT WA BSEAL

7 230422 FRYER DOOR ASSEMBLY (NO BADGE)

227449 DOOR HANDLE

228846 DOOR OUTER

227453 DOOR INNER

227466 FRYER CATCH RECEIVER

228132 TUBE CLIP

228308 HINGE PIVOT WA

8 227960 BADGE BLUESEAL

9 228300 HINGE PLATE

228301 HINGE BUSH

8

Exploded Parts Diagrams

24

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

8.3.2 E44 Main Assembly

Item Part No Description

10 015299 ELEMENT 2833W 240V

11 018019 FRYER BASKET -STANDARD

12 228240 SEDIMENT TRAY WA E44

229420 TIE WIRE SHORT

13 228245 SEDIMENT TRAY HANDLE E44

14 227856 MAGNETIC CATCH 02-10-201-10

15 019390 BALL VALVE

16 227852 LEG PLATE

17 227850 LEG 150mm (FLUSH STUD)

18 229674 REAR ROLLER ASSY

19 229671 LEG RING PLATE THREADED

8

Exploded Parts Diagrams

25

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

8.3.3 E44 Element Tilt Assembly

Item Part No Description

20 014814 EYE BOLT M10 x 200 CW M10 NUT

21 014858 ELEMENT SPRING

22 229589 CAPILLARY PLATE ELECTRIC

23 229588 PIVOT CLAMP DOUBLE

24 014812 SPRING PIVOT ROD

25 229596 PIVOT ROD

26 228564 MICROSWITCH LINK ARM

27 227975 ELEMENT PIVOT BUSH

28 228539 ELEMENT SWITCH CRANK

29 228544 CRANK MTG BRACKET

30 228563 MICROSWITCH ACTUATOR ARM

8

Exploded Parts Diagrams

26

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

8.3.4 E44 Electrical Assembly

Item Part No Description

31 011982 THERMOSTAT 60°- 200°C

32 229355 SELECTOR SWITCH KIT

33 228571 INDEX MARK MOULDING

34 229411 CONTROL PANEL WA E44

35 228922 NEON - WHITE

36 227963 NEON - ORANGE-4122000478

37 227389 KNOB BLUE SEAL 6mm 60-200 deg

38 015966 CONTACTOR 100C09VA10

39 024018 OVERTEMP THERMOSTAT 238°C

40 013977 MICROSWITCH INSULATOR

41 024802 DOOR MICROSWITCH E32/G32

42 021965 LABEL - RESET

43 228375 ACTUATOR ON/OFF RED/YELLOW

44 228374 LOAD SWITCH ON/OFF 32A 3 POLE

45 229582 NEUTRAL TERMINAL

8

Exploded Parts Diagrams

27

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

8.4.1 E44E Main Assembly

Item Part No Description

1 227511 FRYER SIDE PANEL RH

2 227512 FRYER SIDE PANEL LH

3 228792 SPLASHBACK E43/44

4 227441 BASKET HANGER 370mm

5 228761 LID 450 FRYER

6 227762 HOB FRONT WA BSEAL

7 229533 CONTROL PANEL WA

8 228707 FAST DIGITAL CONTROLLER KIT

230101 OVERLAY DIGITAL 3 BASKET BSEAL

9 230422 FRYER DOOR ASSEMBLY (NO BADGE)

227449 DOOR HANDLE

228846 DOOR OUTER

227453 DOOR INNER

227466 FRYER CATCH RECEIVER

228132 TUBE CLIP

228308 HINGE PIVOT WA

10 227960 BADGE BLUESEAL

11 228300 HINGE PLATE

228301 HINGE BUSH

8.4 E44E Twin Tank Fryer

8

Exploded Parts Diagrams

28

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

Item Part No Description

12 017717 PROBE ELECTRONIC

13 015299 ELEMENT 2833W 240V

14 018019 FRYER BASKET -STANDARD

15 228240 SEDIMENT TRAY WA E44

229420 TIE WIRE SHORT

16 228245 SEDIMENT TRAY HANDLE E44

17 227856 MAGNETIC CATCH 02-10-201-10

18 019390 BALL VALVE

19 227852 LEG PLATE

20 227850 LEG 150mm (FLUSH STUD)

21 229674 REAR ROLLER ASSY

22 229671 LEG RING PLATE THREADED

8.4.2 E44E Main Assembly

8

Exploded Parts Diagrams

29

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

8.4.3 E44E Element Tilt Assembly

Item Part No Description

23 014814 EYE BOLT M10 x 200 CW M10 NUT

24 014858 ELEMENT SPRING

25 229589 CAPILLARY PLATE ELECTRIC

26 229588 PIVOT CLAMP DOUBLE

27 014812 SPRING PIVOT ROD

28 229596 PIVOT ROD

29 228564 MICROSWITCH LINK ARM

30 227975 ELEMENT PIVOT BUSH

31 228539 ELEMENT SWITCH CRANK

32 228544 CRANK MTG BRACKET

33 228563 MICROSWITCH ACTUATOR ARM

8

Exploded Parts Diagrams

30

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

8.4.4 E44E Electrical Assembly

Item Part No Description

34 015966 CONTACTOR 100C09VA10

35 021965 LABEL - RESET

36 024018 OVERTEMP THERMOSTAT 238°C

37 013977 MICROSWITCH INSULATOR

38 024802 DOOR MICROSWITCH E32/G32

39 228660 TRANSFORMER WORKED

40 025948 TERMINAL BLOCK - 6 WAY

41 229033 FUSEHOLDER 6.3x32mm

020109 GLASS FUSE 2AMP 250V 1¼ x ¼

42 228375 ACTUATOR ON/OFF RED/YELLOW

43 228374 LOAD SWITCH ON/OFF 32A 3 POLE

44 229582 NEUTRAL TERMINAL

45 020532 RELAY BASE

020256 RESET RELAY 24V AC

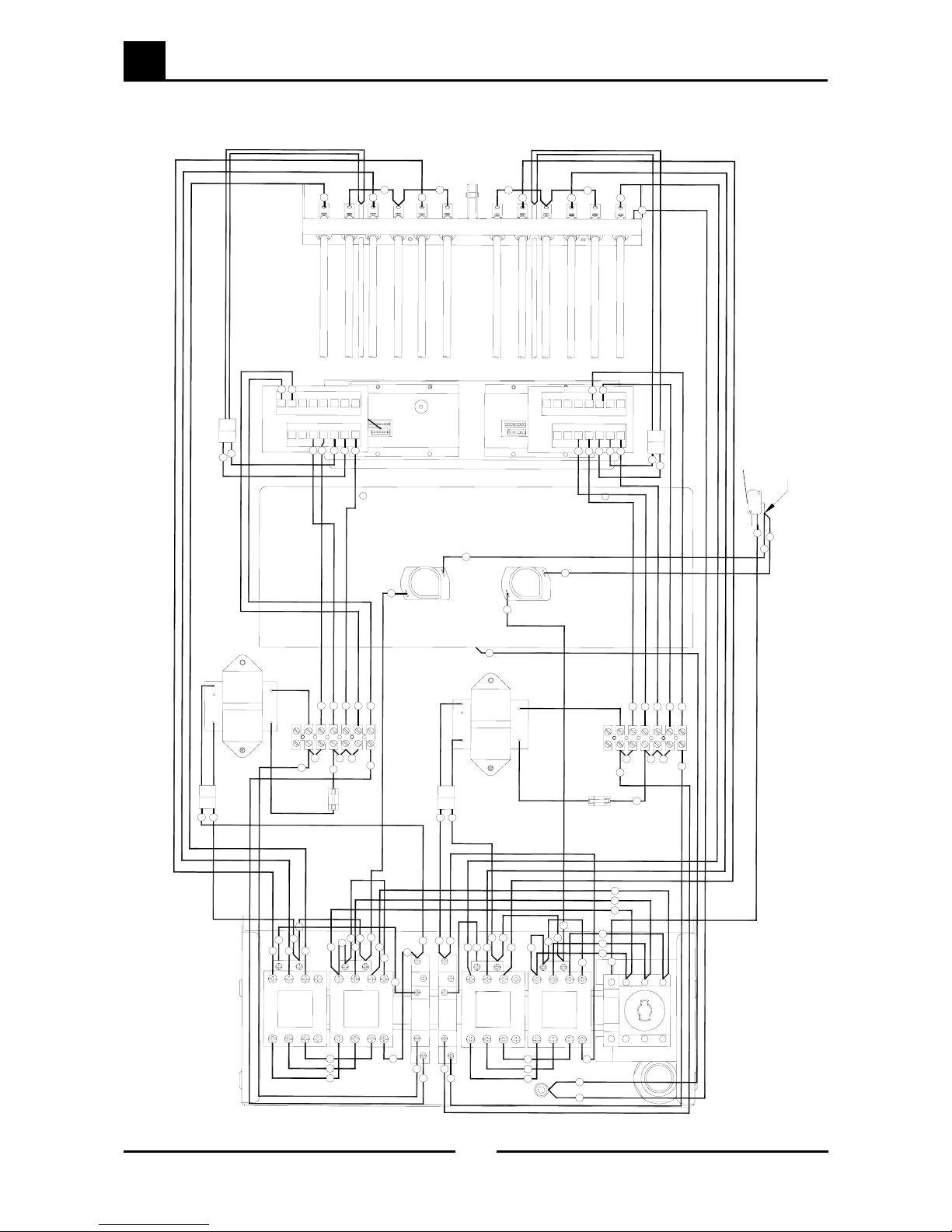

9

Wiring Diagrams

31

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

9.1 E43 - Single Tank Fryer

MICROSWITCH

GEAR TRAY

OVERTEMP PANEL

ELEMENTS

THERMOSTAT PANEL

SELECTOR

SWITCH

THERMOSTAT

POWER

HEAT

OVERTEMP

L1 L2 L3N

EARTH

1 11

222

3

3

3

3

3

3

4

5

6

7

10

13

11

10

12

6

14

15

15

16

17

18

17

18

16

20

21

12

14

8

8

9

9

19

21

20

19

7

9

Wiring Diagrams

32

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

9.2 E43E - Single Tank Fryer

CONTROL PANEL

BROWN

BROWN

BROWN

BROWN

MICROSWITCH

GEAR TRAY

OVERTEMP PANEL

ELEMENTS

OVERTEMP

L1 L2 L3

N

111

222

3

3

3

3

3

3

4

5

6

21

21

22

23

24

23

24

22

27

11

Com

N/O

26

7

7

8

8

9

1912131415

16

11

11

18

10

10

20

20

2513251912

14

15

16 17

17

25 25

26

27

9

Wiring Diagrams

33

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

9.3 E44 - Twin Tank Fryer

MICROSWITCH

GEAR TRAY

THERMOSTAT PANEL

CONTROL PANEL

THERMOSTAT

OVERTEMP

L1 L2 L3

N

EARTH

111

222

3

3

3

7

9

10

27

26

26

25

23

29

24

23

25

35

36

7

7

3

3

3

8

8

4

4

666

15

7

5

7

31

22

16

17

30

31

SELECTOR

SWITCH

POWER

HEAT

20

33

21

20

22

16

SELECTOR

SWITCH

POWER

HEAT

13

28

14

13

15

9

555

27

10

29

30

32

5

7

5

17

ELEMENTS

34

24

QC DOUBLE CONECTOR

P/N 013107

19

19

12

12

18

18

11

11

34

35

36

32

9

Wiring Diagrams

34

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

9.4 E44E - Twin Tank Fryer

T

O

P

B

O

T

T

O

M

M

I

C

R

O

S

W

I

T

C

H

G

E

A

R

T

R

A

Y

T

H

E

R

M

O

S

T

A

T

P

A

N

E

L

O

V

E

R

T

E

M

P

L

1

L

2

L

3

N

E

A

R

T

H

1

1

1

2

2

2

3

3

3

7

9

2

3

2

4

2

4

2

5

2

7

4

5

2

6

2

7

2

5

5

1

7

7

3

3

3

8

8

4

4

6

6

6

1

5

5

5

5

4

3

4

4

2

2

2

8

4

2

4

3

5

5

5

4

5

4

4

7

7

7

E

L

E

M

E

N

T

S

5

0

2

6

3

0

1

1

2

9

2

9

1

0

1

0

5

0

5

1

1

1

1

2

4

1

3

4

3

5

3

6

3

7

3

8

3

3

3

3

4

0

3

9

2

2

1

5

1

6

1

7

1

8

1

9

1

4

1

4

2

1

1

3

2

0

3

1

P

R

O

B

E

P

R

O

B

E

B

R

O

W

N

B

R

O

W

N

3

2

F

U

S

E

Q

C

D

O

U

B

L

E

C

O

N

E

C

T

O

R

P

/

N

0

1

3

1

0

7

B

R

O

W

N

B

R

O

W

N

3

8

3

7

3

5

4

1

4

8

4

9

3

6

1

5

2

2

4

6

4

7

1

6

1

8

1

7

4

7

4

6

1

2

2

3

1

9

2

0

3

1

4

2

3

8

3

9

4

9

4

8

F

U

S

E

2

2

3

0

10

Service Contacts

35

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

Australia

VICTORIA - MOFFAT PTY

HEAD OFFICE AND MAIN WAREHOUSE

740 Springvale Road Tel (03) 9518 3888

Mulgrave VIC 3170 Fax (03) 9518 3838

Spare Parts Department Free Call 1800 337 963

Fax (03) 9518 3895

NEW SOUTH WALES - MOFFAT PTY

Unit 3/142 James Ruse Drive Tel (02) 8833 4111

Rosehill NSW 2142

Spare Parts Free Call 1800 337 963

Fax (03) 9518 3895

QUEENSLAND - MOFFAT PTY

30 Prosperity Place Tel (07) 3630 8600

Geebung QLD 4034

Spare Parts Free Call 1800 337 963

Fax (03) 9518 3895

WESTERN AUSTRALIA - MOFFAT PTY

67 Howe St Tel (08) 9202 6820

Osbourne Park, WA 6017 Fax (08) 9202 6836

Spare Parts Free Call 1800 337 963

Fax (03) 9518 3895

NATIONAL COVERAGE FOR 24 HOUR SERVICE OR MAINTENANCE DIAL

FREE CALL 1800 622 216 (AUSTRALIA ONLY)

Canada

SERVE CANADA

22 Ashwarren Rd Tel 416-631-0601

Downview Fax 416-631-0315

Ontario M3J1Z5

New Zealand

CHRISTCHURCH - MOFFAT LTD

16 Osborne St Tel (03) 389 1007

PO Box 10-001 Fax (03) 389 1276

Christchurch

Spare Parts Free Call 0800 MOFFAT

(0800 66 33 28)

Fax (03) 381 3616

AUCKLAND - MOFFAT LTD

4 Waipuna Road Tel (09) 574 3150

Mt Wellington Fax (09) 574 3159

Auckland

Spare Parts Free Call 0800 MOFFAT

(0800 66 33 28)

10

Service Contacts

36

Blue Seal Evolution Series E43 / E44 Electric Fryers

Revision 1/

© Moffat Ltd, January 2007

United Kingdom

BLUESEAL LTD

Units 67

Gravely Industrial Park Tel 0121 327 5575

Gravely Park, Erdington Fax 0121 327 9711

Birmingham B24 8TQ

England

United States of America

MOFFAT INC.

3765 Champion Blvd

Winston-Salem Tel 1800 551 8795

NC27115 Fax 336 661 9546

NATIONAL COVERAGE FOR SERVICE OR MAINTENANCE DIAL

FREE CALL 1800 551 8795 (USA ONLY)

Loading...

Loading...