OPERATIONAL MANUAL

MODEL: TYP-28A MAGNETIC DRILLING MACHINE

by BLUEROCK ® Tools

Volume

1.1

UNPACKING THE ITEM

Caution: This machine is packed together with items that may be sharp, oily and overly heavy objects.

Remove the machine from the packaging in a safe manner. Check to ensure all accessories are included with

the item while unpacking. If any parts are found to be missing, contact the retailer as soon as possible. Do

not throw away the packaging until the item is out of the guarantee period. Dispose of the packaging in an

environmentally responsible manner. Recycle if possible. Keep all plastic bags away from children due to

risk of suffocation.

WEEE - Waste Electrical & Electronic Equipment. Note this machine should be disposed of as electrical & electronic waste.

© THE NEWMAN TRADING COMPANY LLC DBA BLUEROCK® TOOLS 2016

1100 SW 16th St • Suite D

Renton, WA 98057

Phone 206.604.8363 • Fax 425.572.5167

www.bluerocktools.com

TYP- 28A MAG DRILL

Table&of&Contents&

SAFETY' 1!

PRE-OPERATIONAL SAFETY CHECKS! 1!

OPERATIONAL SAFETY CHECKS! 1!

SPECIFICATIONS' 4!

INCLUDED'ACCES SO R IE S' 4!

ADDITIONAL'AVAILABLE'ACCESSORIES' 5!

ADDITIONAL ACCESSORIES FOR THIS MACHINE CAN BE FOUND IN BLUEROCK ® TOOLS ONLINE SHOP AT

WWW.BLUEROCKTOOLS.COM OR FROM YOUR LOCAL RETAILER.! 5!

OPERATIONS' 6!

PURPOSE! 6!

OPERATIONAL PRINCIPLES! 6!

MACHINE COMPONENTS! 6!

TRANSPORTING THE MACHINE! 7!

RUNNING THE MACHINE! 7!

INSTALLING ANNULAR CUTTERS! 9!

TROUBLESHOOTING' 11!

GENERAL'MAINTENANCE' 12!

OCCASIONAL'MAINTENANCE' 12!

PARTS'LIST' 13!

BREAKDOWN'VIEW' 14!

TYP- 28A MAG DRILL

1

Safety

DO NOT USE THIS MACHINE UNLESS YOU HAVE READ THE

OPERATING INSTRUCTIONS!

Safety glasses must be worn at all

times in work areas.

Long and loose hair must be

contained.

Appropriate footwear must be worn.

Close fitting/protective clothing

must be worn.

Safety gloves should be worn at all

times and jewelry must not be worn.

Hearing protection should be

worn when using this machine.

Hard-hat must be worn while using

machine.

Dust mask must be worn while

using this machine.

Read operational manual prior to use.

PRE-OPERATIONAL SAFETY CHECKS

Ø Examine the power cord and plug for damage. This tool is supplied with a ground plug and

must always be used with the proper grounded circuit.

Ø Examine the body of the machine and inspect for damage or defects.

OPERATIONAL SAFETY CHECKS

Ø ONLY to be operated by qualified personal who have read instructions.

o NOTE: Failure to read and follow instructions could result in electrical shock, fire,

property damage and/or serious injury!

Ø DO ensure all non-essential people are clear of the immediate work area.

Ø DO keep body parts, clothing & power cords clear of turning/cutting pieces. Stay alert and

use common since when using this tool.

Chapter

1

TYP- 28A MAG DRILL

2

Ø DO allow machine to reach operating speed before starting a hole.

Ø DO unplug machine while changing or adjusting cutting bits so as not to accidentally turn

machine on.

Ø DO remove adjusting keys or hex wrenches prior to turning the machine on.

Ø DO use cutting paste (instead of cutting oil) when using this drill in an inverted position to

prevent oils from entering the electrical system and for ease of cutting.

Ø DO tie a loop in any extension cord connections to prevent cords coming apart and a loss of

power.

Ø DO guard against electric shock by preventing body contact with grounded surfaces such as

pipes, radiators, ranges, refrigerators, etc.

Ø DO be mindful that power tools can expose an operator to vibrations transmitted trough

contact with the machine. Prolonged exposure can lead to medical issues which should be

discussed with a medical professional.

Ø DO tie in a drip loop in the power cord to prevent cutting fluid from running into the power

receptacle.

Ø DO use a dust extraction system for cutting materials that create dust such as cast iron. The

operator should also wear a protective respiratory device.

Ø DO NOT make adjustments to machine while the machine is running.

Ø DO NOT switch off the machine when it is under load, except in an emergency.

Ø DO NOT remove or modify grounding plug. Only to be used on a properly grounded circuit.

Ø DO NOT leave the machine running when not in use.

Ø DO NOT hold the work piece by hand or using body. Always mechanically clamp or secure

work piece.

Ø DO NOT allow coolant oil to enter the machine’s ventilation system.

Ø DO NOT operate machine outside of machine specifications.

Ø DO NOT touch moving parts while the machine is running as death or dismemberment could

occur.

Ø DO NOT allow children or untrained personal to operate machine.

Ø DO NOT use this machine in the rain or a wet environment. If using outdoors, make sure the

adhering surface is clean and dry.

Ø DO NOT operate in the presence of explosive materials as power tools create sparks which

may ignite dust or fumes.

Ø DO NOT drill into an area that may contain a live electrical wire/circuit.

Ø DO NOT operate this machine on the same work surface where welding is being performed.

This could result in severe damage to the machine or personal injury to the user.

Ø DO NOT use this machine without the safety chain or safety strap.

TYP- 28A MAG DRILL

3

Ø DO NOT operate this machine on a lower voltage as it may result in the electromagnet being

at a reduced power level and the machine could become unstable while cutting. This could

also limit the motor life.

o NOTE: Use of long small gauge power extension cords can result in decreased

voltage. As local voltages can vary, it may be a good idea to test the voltage at the

end of the extension cord to ensure proper voltage requirements are met. You might

also consult an electrician to make sure the length of cord matches up with the proper

wire gauge for this size motor. Make sure to use outdoor cords when operating

outdoors.

TYP- 28A MAG DRILL

4

Specifications

ELECTRICAL DATA

Voltage

120V, 60Hz

Current

7.9 Amps

Motor Size

950W

Power Connection

US Standard 3 Prong Type B Plug

MECHANICAL DATA

Cutter Range

Annular Cutter: 7/16” Min to 1.5” Max (12mm - 35mm)

Cutting Depth

2” Max Depth

Cutting Speed

640 RPM One Speed Gearbox

Tool Holder

Direct Arbor with ¾” Weldon Shank

Magnetic Adhesion

2600 Lbs (13000N)

PHYSICAL DATA

Shipping Weight

30 Lbs

Machine Size

10” x 6” x 10”

Included Accessories

DESCRIPTION

QTY

Instruction Manual

1

Coolant/Oil Bottle

1

Feed Handles (with two end caps)

1

Safety Chain

1

Plastic Case (for protection during shipping)

1

Hex Wrench

2

Chapter

2

TYP- 28A MAG DRILL

5

Note

UPON RECEIPT, CHECK CAREFULLY TO ENSURE THAT THE

MACHINE IS IN GOOD CONDITION AND HAS ALL

ACCESSORIES LISTED ABOVE.

Additional Available Accessories

Additional accessories for this machine can be found in BLUEROCK ® Tools

online shop at www.bluerocktools.com or from your local retailer.

DESCRIPTION

13 Pc 2” Depth HSS Annular Cutter Set with Centering Pin

6 Pc 2” Depth HSS Annular Cutter Set with Centering Pin

6 Pc 1” Depth HSS Annular Cutter Set with Centering Pin

TYP- 28A MAG DRILL

6

Operations

Note

THOROUGHLY READ THROUGH THE ENTIRE MANUAL BEFORE

OPERATING THIS MACHINE!

PURPOSE

Ø The purpose of the TYP-28A is to drill through steel using annular cutters or ¾”

Weldon shank type drill bits.

Ø These drills are designed to magnetically adhere to a ferrous surface using their

electromagnetic base. Generally these drills are designed and used to drill through

mild steel. This magnetic base will not work without a power connection.

o NOTE: The entire magnetic base must cover the work area to have full

magnetic adhesion. Using only a portion of the magnet is dangerous! Make

sure the base fits completely on the surface.

Ø These machines can be used vertically, horizontally or overhead (inverted) provided

strong enough magnetic adhesion and an acceptable work environment. NOTE: For

safety, the safety chain should always be used incase of an accidental power failure

or other loss of magnetic adhesion.

OPERATIONAL PRINCIPLES

Ø The main drilling shaft rotates in the forward direction. The main drilling motor

connects to the tool holder to make contact with a surface and slowly bore a hole.

Using the feed handles on the side of the drill, the user can raise or lower the drilling

motor.

MACHINE COMPONENTS

Ø The main components of the TYP-28A are the tool holder, gearbox, motor, frame and

magnetic base. The tool holder is driven by the gearbox and the motor.

o These components must be not be removed except by a qualified technician.

Power must be disconnected prior to any service.

Chapter

3

TYP- 28A MAG DRILL

7

TRANSPORTING THE MACHINE

Ø When transporting the machine, always use the carrying handle.

Ø Ensure the drilling head is at the lowest position.

Ø DO NOT transport the machine with cutters or bits in the tool holder.

Ø If the coolant bottle is connected, ensure the valve is in the “off” position or the

coolant has been drained.

Ø If transporting inside a vehicle, it is recommended to transport it on its side so as to

avoid the item falling over.

Ø If possible, transport in a case.

Ø DO NOT carry the machine by the cord.

Ø DO NOT allow the cord or plug to drag along the floor when transporting.

RUNNING THE MACHINE

Ø Do all pre-operational and operational safety checks from Chapter 1.

Ø Consider your security and stability as well as the orientation of the machine in the

work area.

o Consider the work surface material, condition, strength, density and rigidity.

These factors directly affect the tools magnetic adhesion. Magnetic adhesion

diminishes with thinner material and rough surface. Full magnetic spec’d

adhesion is considered on 1” material. When using on material 3/8” or less,

the drill should be mechanically clamped to the work-piece.

Ø After placing the machine in work area, connect the safety chain.

o The safety chain should attach to the machine (preferably through the

carrying handle) as well as attached to the work area in such a manner that

prevents the machine from detaching or falling from the work area in the

event of magnetic deactivation or lost adhesion.

Ø Ensure the feed handle is securely attached to the feed spindle.

1) Gearbox

2) Feed Handle

3) ¾” Weldon Shank Tool Holder

4) Machine Carrying Handle

5) Drill Motor

6) Brush Holder

7) Motor Off Switch

8) Motor On Switch

9) Magnetic Base

TYP- 28A MAG DRILL

8

Ø Ensure the work surface and bottom of magnet are free of debris, oil, etc.

Ø Select and set up oiling method or cutting pastes.

o If drilling overhead or horizontal use cutting paste liberally applied to the

cutting bit.

Ø If using the machine horizontally with the oil bottle, connect bottle to the side of the

machine using the two set screws located on the drill frame.

o Connect the oil bottle tube into the side of the tool holder by firmly pressing

in the hose.

§ To remove the hose later, press in the plastic piece around the hose

towards the tool holder while simultaneously pulling the plastic hose

away from the tool holder.

o Make sure the oil bottle valve is in the off position.

§ This is generally at a 90 degree angle from the valve hose.

o Fill the oil bottle with cutting fluid.

Ø Select appropriate size annular cutter or Weldon type twist drill bit.

o The ¾” Weldon shank uses two Allen head bolts. The annular cutters will go

in the shank and be secured on the two flat sides by the two Allen head

screws. See next section below for more specifics on using annular cutters.

Ø Plug the machine into power source.

o Form a loose knot in the power cord close to the plug connection to prevent

cutting fluid from running down the cord and into the power receptacle.

Ø Engage the magnet by pressing the magnet on/off switch on the back of the machine.

o Check that the machine is firmly attached to the work area.

Ø Turn feed handle raising the cutter until the bit is above the work surface.

Ø Open the oil bottle valve to allow oil to come out to the work surface.

o You may have to gently squeeze or shake the bottle to get the oil to start

flowing.

Ø Turn the machine on.

o Start the machine by pressing the green “on” switch. Stop the machine by

pressing the red “off” switch.

Ø Very slowly engage the cutting bit with the material surface by lightly engaging the

hand crank down towards the material.

Ø After about 1/16” of cutting has been achieved in the work surface, slightly more

force can be applied. This will be the normal amount of force the rest of the hole.

TYP- 28A MAG DRILL

9

o NOTE: Do not force the hole. Let the machine do most of the work.

Excessive physical effort should be avoided as it can cause damage to the

machine or the user.

o If the unit jams in a hole, stop the drill immediately to prevent injury.

Disconnect the drill from the power supply and loosen the cutter by turning

drill spindle counterclockwise. Never attempt to free cutter by starting motor!

Ø Make sure to keep the cutting material adequately lubricated.

Ø Ease up on feed pressure as the cutter starts breaking through the backside of the

material.

o Be mindful that the metal cutting slug can eject at a rapid rate, so be sure all

is clear on the output side of this slug to prevent injury to persons or

property.

Ø Finish drilling the hole.

Ø Turn the motor off and disconnect power once the drill is safely back up in the non-

drilling position.

o Remove metal chips wrapped around cutter and tool holder. Use a leather

glove or pliers as these metal pieces can be sharp.

Ø Disconnect safety chain and move the drill to a new drilling location.

INSTALLING ANNULAR CUTTERS

Ø WARNING: Annular cutters are extremely sharp and should only be handled with a

thick glove so as not to cut the user during installation or removal.

Ø Check that the cutters are sharp and not damaged.

o Annular cutters that are dull or damaged should not be used.

Ø Make certain the machine is unplugged from power.

Ø Raise the tool holder to ensure ample room to install the cutter.

Ø Insert the annular cutter into the ¾” adapter.

Ø Align the two “flat” sides of the annular cutter with the flat sides of the adapter.

o CAUTION: Make certain the hex screw is seated into the flat side and not

simply on the round side of the cutter shank.

Ø Tighten one of the hex screws while slowly rotating the cutter forward and

backwards.

o Continue to tighten the screw until fully tightened.

Ø Tighten the 2nd hex screw.

Ø The annular cutter is ready to use.

TYP- 28A MAG DRILL

10

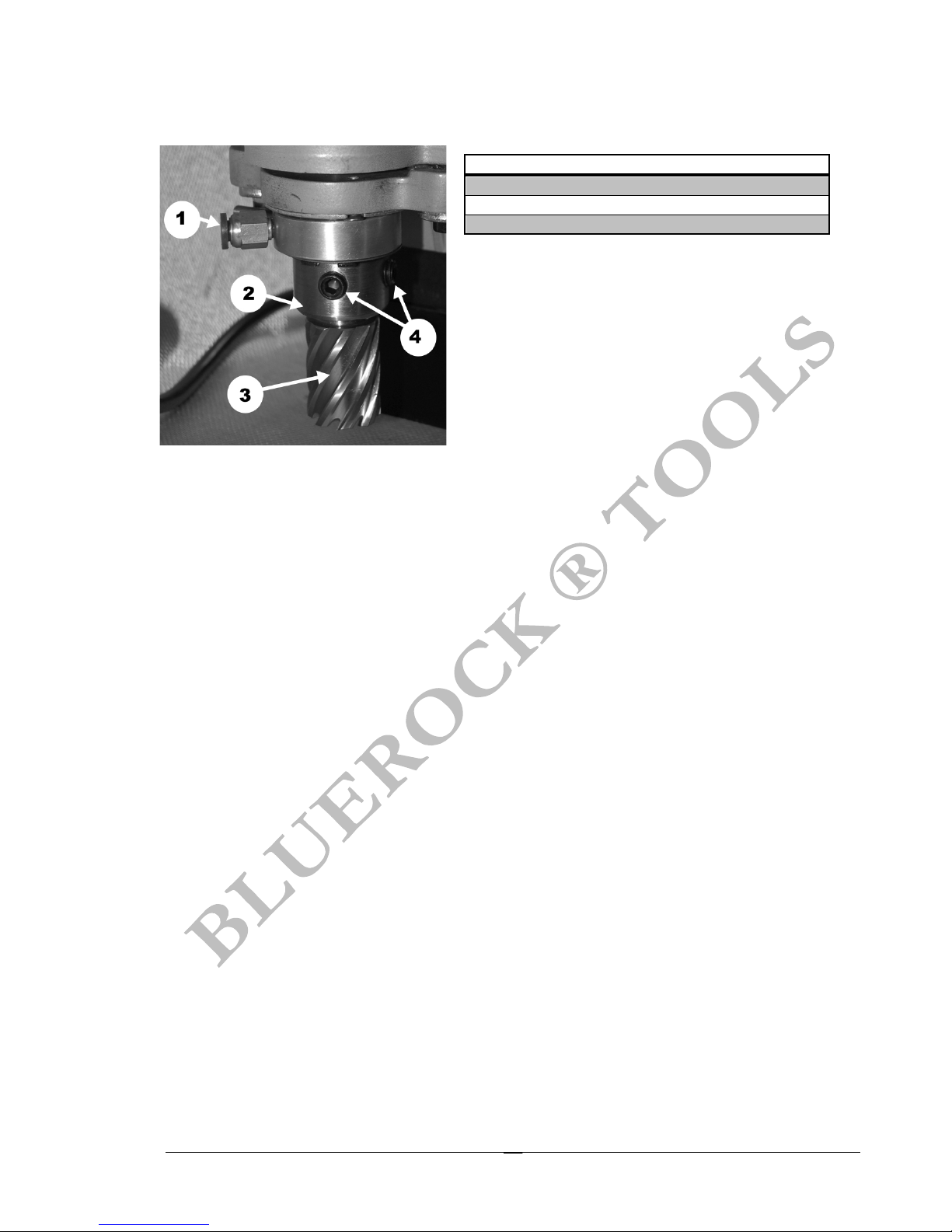

1) Oil Bottle Input

2) ¾” Weldon Shank Tool Holder

3) Annular Cutter (not included)

4) ¾” Adapter Hex Set Screws (2 total)

TYP- 28A MAG DRILL

11

Troubleshooting

Note

SERVICING SHOULD ONLY BE DONE BY A QUALIFIED TECHNICIAN.

DON’T FORGET TO UNPLUG POWER TO UNIT PRIOR TO SERVICE!

PROBLEM

SOLUTION

Motor does not turn on.

1) Check external power source (extension cord, breaker, etc).

2) Loose internal wire. Check and secure if necessary.

3) Motor brushes defective. Replace if necessary.

4) Check to ensure the motor on/off switch is operable. Replace if

necessary.

Excessive sparking

when motor is running.

1) This may indicate the presence of debris in the motor or worn out

carbon brushes. Check the brushes for unusual wear and replace

if necessary. Clean out the internal motor armature if necessary.

2) Armature has a rough edge. Inspect and replace if necessary.

Magnetic does not hold

to work area.

1) Work surface thickness is too small. A minimum of 3/8” (10mm)

continuous ferrous steel must be used for magnetic adhesion.

CAUTION: These drills do not work on sheet metal!

2) Entire magnet base is not on the work surface.

3) Voltage is low at the machine. Check voltage.

4) There is debris or excess material between the work area and the

magnetic base. Clean work area surface.

Hole is not cutting.

1) Cutter is dull. Sharpen or replace.

2) Work area material is not appropriate for cutter type. High carbon

type steels require special cutting bits (tungsten carbide tip, etc).

Chapter

4

TYP- 28A MAG DRILL

12

General Maintenance

Ø Inspect electrical cords and electrical connections.

Ø Keep machine clean and free of debris.

Ø Periodically check and lubricate the drilling spindle as necessary using molybdenum grease.

Ø Check for misalignment, binding and breakage of all moving parts. If damaged, repair tool

before use.

Ø Keep cutting tools sharp and clean. Sharp cutters are less likely to bind and are easier to

control.

Occasional Maintenance

Ø Have the power tool serviced by a qualified service technician using identical replacement

parts.

o Change motor brushes:

1) Disconnect drill from power.

2) Unscrew left and side brush holder caps.

3) Take out old brushes.

4) Replace with exact same size new brushes.

5) Screw in brush holder caps tightly.

Chapter

5

TYP- 28A MAG DRILL

13

Parts List

Chapter

6

1.

Catch spring

27.

Catch spring

53.

Axle cap

79.

Oil bottle

2.

Spring stop

28.

Gear stop

54.

Handle

80.

3.

Spring

29.

M5x6 screw

55.

Flexible cable

81.

4.

Catch spring

30.

Gear

56.

Cable protector

82.

5.

Oil hold

31.

Bearing

57.

Cable hold

83.

6.

Catch spring

32.

Gera box cap

58.

Magnetic switch

84.

7.

M8x10 screw

33.

M6x30 screw

59.

M4x12 screw

85.

8.

Spindle

34.

Bearing

60.

Plate

86.

9.

Bearing

35.

M6x12

61.

Electric bridge

87.

10.

Catch spring

36.

Motor

62.

Induction

88.

11.

M5x6 screw

37.

Bearing

63.

Capacity

89.

12.

M6x12 screw

38.

Winder stop

64.

M6x12 screw

90.

13.

Bearing stop

39.

M5x65 screw

65.

Motor switch

91.

14.

Bearing hold

40.

Field core

66.

Switch holder

92.

15.

Catch spring

41.

Motor hold

67.

M6x25 screw

93.

16.

Catch spring

42.

M5x45 screw

68.

Cable connect

94.

17.

Bearing

43.

Motor hold cap

69.

Slide key

95.

18.

Rack

44.

Brush holder

70.

Slide key hold

96.

19.

Internal spindle

45.

Brush

71.

Spring

97.

20.

6x10 key

46.

Brush hold cap

72.

Machine hold

98.

21.

Gear

47.

Bearing

73.

M10x20 screw

99.

22.

Bearing

48.

Axle

74.

6x10 key

100.

23.

Gear box

49.

3x10 key

75.

Plate

101.

24.

Gear

50.

Gear

76.

Magnetic base

102.

25.

3x10 key

51.

Gear cap

77.

5mm wrench

103.

26.

Bearing

52.

M4x12 screw

78.

Safety strain

104.

TYP- 28A MAG DRILL

14

Breakdown View

Loading...

Loading...