BlueBird Kaydee Kaddy User Manual

Operator &

Models:

Parts Manual

Hydraulic Lifts

MANUAL NO. 8277 REV. 01 (05/03/04)

KD1200

KD1500

Tip Tow II

Tip Tow 10

Tip Tow 3000

Kaydee Kaddy

2

INDEX

Specifications.........................................4

Illustrations.............................................5

Safety.....................................................6

Instructions.............................................7

Trouble shooting....................................8

Maintenance...........................................9

3 Ton Jack Model 4351 (Parts)..............10-11

5 Ton Jack Model 4451 (Parts)..............12-13

Assembly Instructions

for Knockdown Lift .................................14-15

Kaydee 1200 & 1500 (Parts) ................. 16-17

Tip-Tow II, Tip-Tow 3000,

Tip-Tow 10 (Parts)..................................18-19

Kaydee Kaddy Assembly & Storing .......20-21

Kaydee Kaddy (Parts)............................22-23

©2004 BlueBird International. All Right Reserved.

Beatrice, NE. Printed in the U.S.A.

3

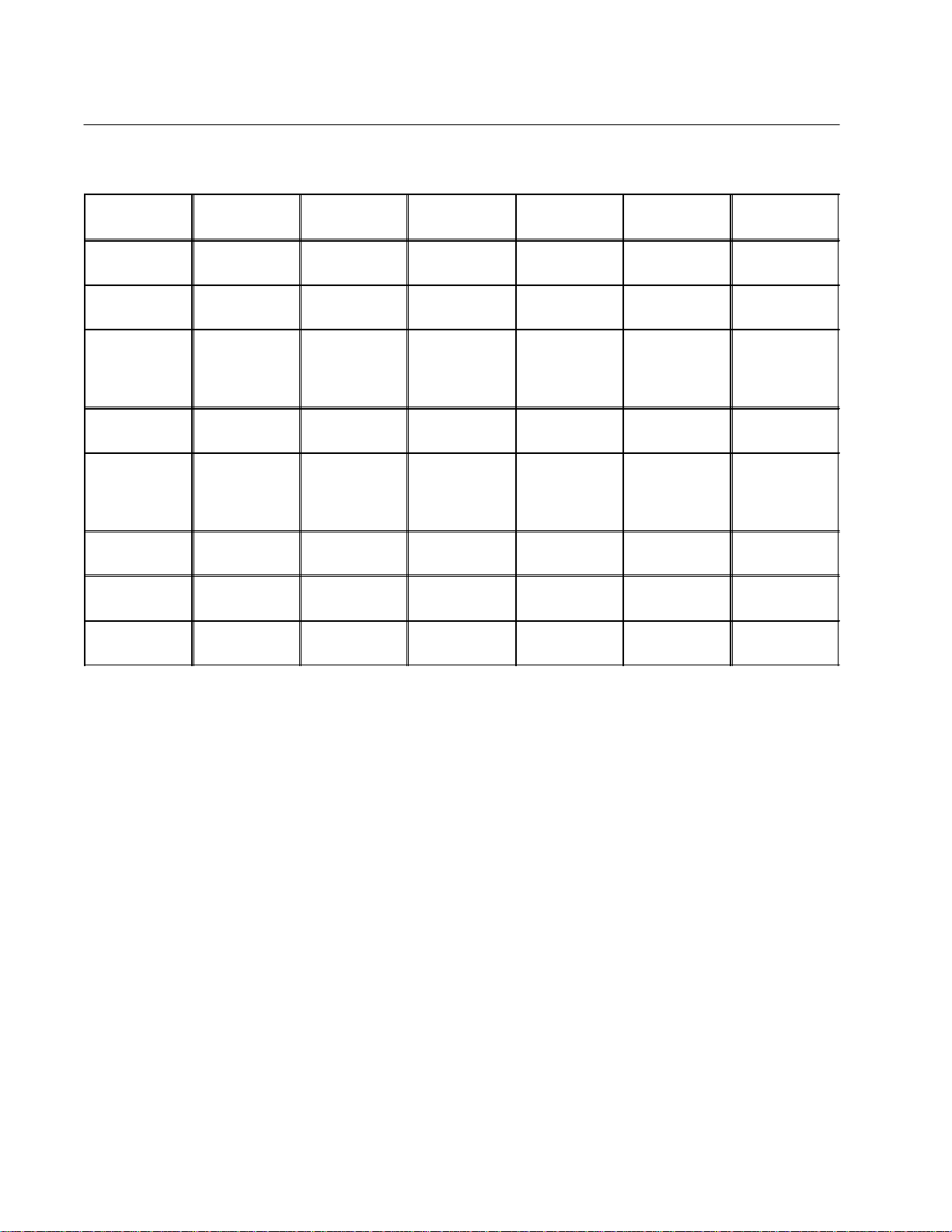

SPECIFICATIONS

Capacity

KD1200 1200 lbs. 250 lbs. 294 lbs. 40.5" 99.5" 74.5"

KD1500 1500 lbs. 240 lbs. 279 lbs. 40.5" 91.5" 70.5"

1000 lbs. outter

Tip Tow II

Tip Tow 3000 3000 lbs. 365 lbs. 365 lbs. 52.5" 100" 75.75"

Tip Tow I0

Kaddy NA 66 lbs. 71 lbs. 20" 41.2" high 29"

3 Ton Jack NA 20 lbs. 23 lbs. NA NA NA

5 Ton Jack NA 24 lbs. 26 lbs. NA NA NA

hook

1500 lbs. inner

hook

1500 lbs. outter

hook

2000 lbs. inner

hook

Net Weight

(lbs)

307 lbs. 307 lbs. 52"

530 lbs. 530 lbs. 66" 10 feet 96"

Shipping

Weight (lbs)

Width

(inches)

Overall reach

(inches)

100.5" outter

hook

89.5 inner

hook

Length

(inches)

82.5"

4

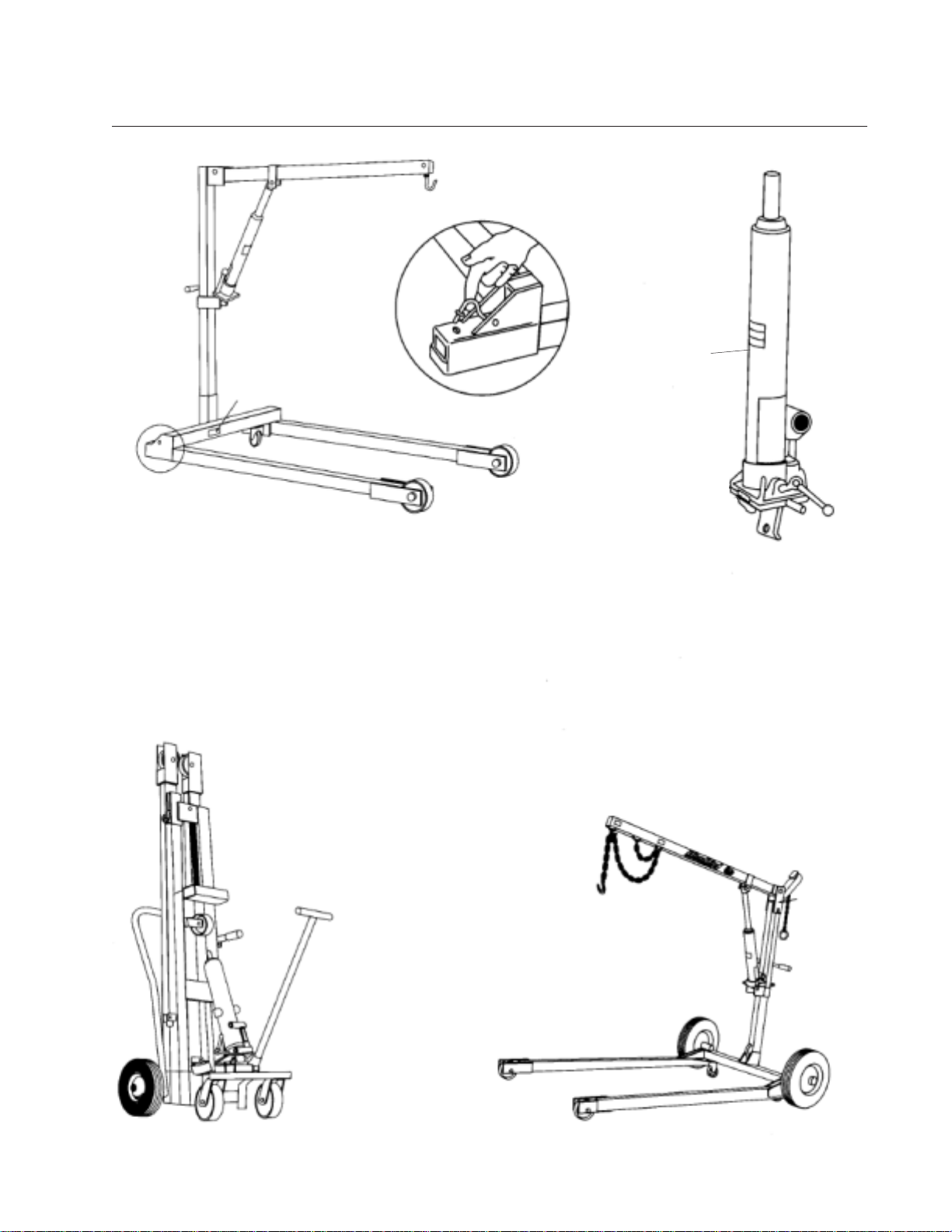

ILLUSTRATIONS

Serial Number

Knock-Down Lift

Leg Latch

Serial Number

Kaydee Kaddy

Hydraulic Jack

Towable Lifts

Serial Number

5

SAFETY

W ARNING

DO NOT forget to position leg latches

on cross-axle. Leg latches MUST be

in DOWN position and IN THE HOLE

at rear of leg. These leg latches prevent the legs from being withdrawn

when moving lift. (On Knock-Down

Lifts only).

NEVER use lift on anything other than

a firm level surface.

DO NOT use the jack handle to move

the lift when handle is in pump socket.

Doing so will break the pump plunger .

NEVER push the boom up by hand.

Read all maintenance and service instructions before attempting work.

ALWAYS use the jack to raise the

boom.

ALWAYS use the moving handle to

move the lift.

Make sure that the boom is fully lowered before adding oil to unit reservoir .

Use EXTREME CARE when carrying

load or unloading jack so release

valve is not damaged.

6

INSTRUCTIONS

TOWING:

1. Release jack to lower boom to the lowest point.

2. Place chain hook into hookup point at center

of base of the lift.

3. Take up slack in chain by placing lock chain

into the rear grab hook on boom.

4. Pump the jack up until chain is tight.

The above instructions will:

• Prevent the boom from “jackknifing” when be-

ing towed. Other wise the jack can become

inoperative because of air being pulled under

the plunger (ram).

• Position the boom correctly so that the cou-

pler is horizontal to the ground and at the proper

height for towing.

STORAGE:

1. Clean unit.

2. Cover all scratches with touch up paint.

3, Grease all wheels so they turn freely.

4. Store jack indoors.

3 & 5 TON JACKS:

These jacks are manufactured exclusively for the

use on BlueBird hydraulic lifts. The finest available,

it incorporates two unique features: An internal

safety bypass valve and a slow release valve.

The bypass valve is set at the factory and SHOULD

NOT BE TAMPERED WITH. This valve becomes

operative as the load reaches the capacity of the

lift. It then bypasses the hydraulic fluid from the

pump into the reservoir so that no greater pressure may be exerted on the ram, regardless of the

load being lifted. This averts possible damage to

the jack or the lift itself.

The specially engineered slow release valve is

designed to provide the operator with complete

control when lowering the load. This restricts the

return flow of hydraulic fluid so the load will never

drop suddenly or too fast. To aid in the prevention

of accidental removal or the possibility of over tightening of the release valve, a STOP has been

welded to the jack mounting plate. Never remove

the stop, if it should become damaged or broken

off, replace immediately.

LIFT MAINTENANCE:

1. Grease wheels and casters periodically to insure free movement.

2. For jack maintenance, see jack maintenance

section.

7

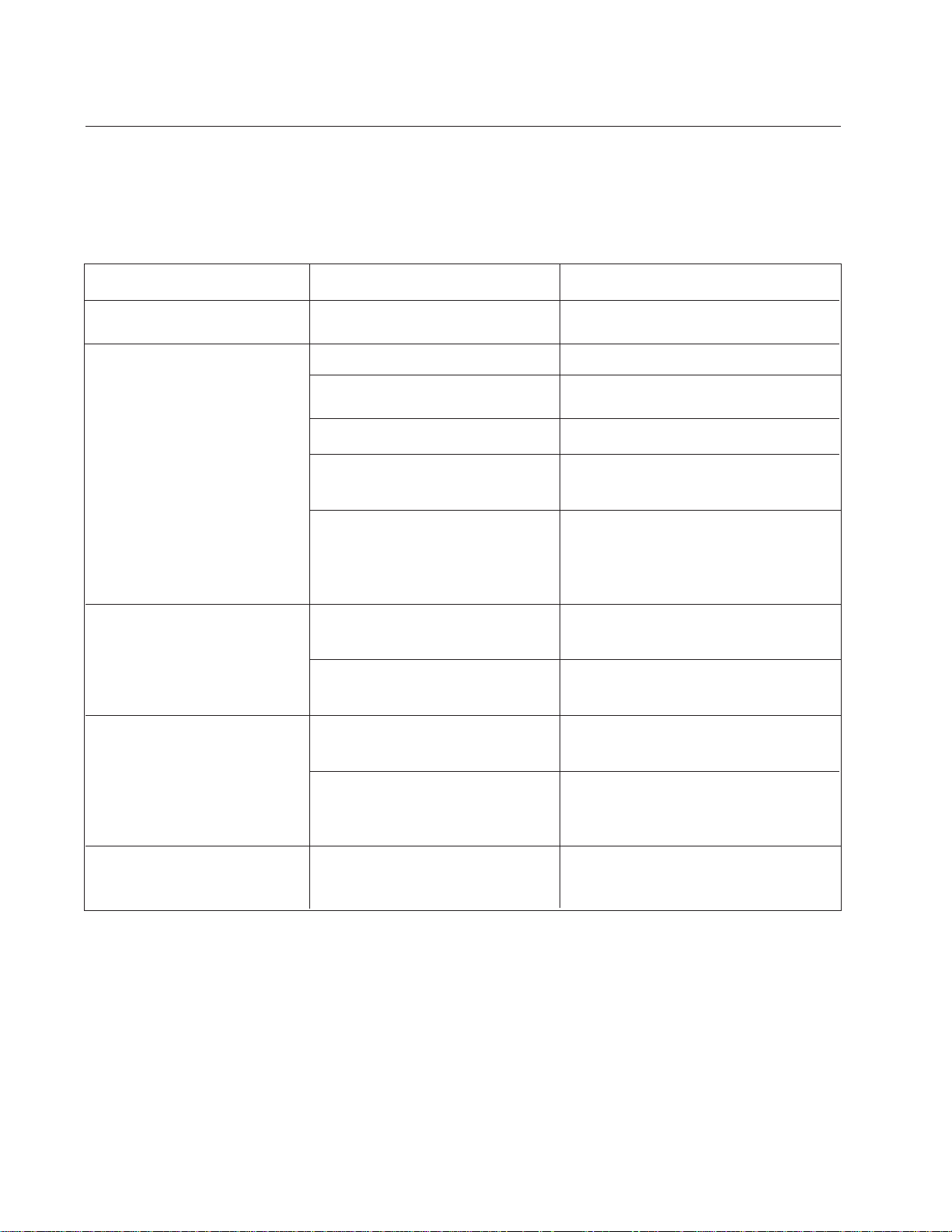

TROUBLE SHOOTING

The unique design of the BlueBird hydraulic jacks eliminates nearly all the problems normally associated with hydraulic jacks. There are very few areas that will render your jack inoperative. Here are the

most common and their remedies: (refer to parts list for part identification).

Symptom Cause Remedy

Spongy action when lifting load Air under ram Bleed air from jack.

Will not pump up Air lock Bleed air from jack.

Oil level is too low or too high Check oil level adjust oil to proper level.

Large ball check not reseating Reseat large ball.

Release valve ball missing or Inspect for damaged or missing ball re-

damaged place if necessary (part # 4333).

Pump plunger cup (part # 4346) Inspect cups and replace as necessary .

or Ram plunger cup (part # 4326

for 3 Ton or 4426 for 5 Ton)

damaged or worn

Load descends slowly , jack Large ball check not seating Reseat large ball

handle raises during this (part # 6048)

process

Foreign matter interfering with Drain and flush jack,

large ball check Inspect and reseat large ball

Load descends slowly , jack Release valve (part # 4334) not Close release valve, inspect for

handle DOES NOT rise during closed completely or damaged damage and replace as necessary .

this process

Ram plunger cup (part # 4326 for Inspect ram plunger cup replace as

3 T on or 4426 for 5 Ton) worn or necessary .

damaged

Oil leaks Generally caused by loose Inspect and tighten as needed.

components

Remember: If you need assistance with your jack a BlueBird representative is just a phone

call away .

8

Loading...

Loading...