BlueBird H742G User Manual

Operators & Parts

Manual

MANUAL NO. 107999 REV. 04 (07/21/05)

MODELS:

B124 H424G

B130 B530A

B130A H530A

B142 H530AG

B424 B742

H424 H742

B530B H742G

Lawn Aerators

Section 1 · Operator’s Guide Page

Specifications................................................................................................. 3

Features and Controls ................................................................................. 4-6

General Information ........................................................................................ 7

Safety Procedures.......................................................................................... 7

Safety and Instruction Decals ........................................................................ 8

Decal Placement............................................................................................ 9

Assembly Instructions.................................................................................. 10

Section 2 · Operating Instructions Page

Aeration Tips ................................................................................................ 11

Before Y ou Start ........................................................................................... 1 1

Aerating........................................................................................................ 11

Throttle Adjustment (Model 742 Honda engine only)..................................... 11

Rear Wheel Adjustment................................................................................ 12

Turning and Maneuvering .............................................................................. 13

Operating on Hills......................................................................................... 13

Section 3 · Maintenance and Service Instructions Page

Transporting the Husqvarna Aerator .............................................................. 14

Cleaning and Washing ................................................................................. 15

Two Minute W arning ..................................................................................... 15

Storage......................................................................................................... 15

Preventative Maintenance Schedule

Inspection Schedule ......................................................................... 15

Lubrication Schedule ........................................................................ 15

Tine Wear ........................................................................................ 16

Service

Engine Service & Maintenance.................................................... 16

Drive Train

Engine Removal and Replacement ................................................... 16

Drive Belt Replacement and Adjustment........................................... 16

Clutch Cable Removal and Replacement .......................................... 17

Throttle Cable Replacement (Model 742 Honda Engine Only) .......... 17

Chain Removal and Replacement..................................................... 17

Adjusting Chain Tension ................................................................... 18

Handle

Inspection ........................................................................................ 18

Adjustment....................................................................................... 18

Wheels

Drive Wheel Shaft Removal and Replacement.................................. 18

Rear Wheel Removal and Replacement ........................................... 19

Tine andTine Shaft

Tine Replacement ............................................................................ 19

Tine Shaft Bearing Removal and Replacement ................................. 19

Free Wheeling Tine Assembly Removal and Replacement ............... 20

Unit Assembly and Part s Diagrams

Model 424 ................................................................................... 21-25

Model 530A................................................................................. 26-33

Model 742 ................................................................................... 34-39

Section 4 · General Product Information Page

Warranty ...................................................................................................... 41

WARNING: Engine exhaust, some of it’s constituents, and certain vehicle components

contain or emit chemicals known to the State of California to cause cancer and birth defects

or other reproductive harm.

Operator’s Guide

SPECIFICATIONS

A) POWER UNIT 424 530A 742

Engine 3.5HP Briggs I/C 3.5HP Briggs I/C 3.5HP Briggs l/C

(2.6kw) (2.6kw) (2.6kw)

4HP Honda (3kw) 4HP Honda (3kw) 4HP Honda (3kw)

Clutch Belt tensioner Belt tensioner Belt tensioner

Primary drive One V-belt (A-44”) One V-belt (A-44”) One V-belt (A-44”)

Secondary drive Permalube Chain Permalube Chain Permalube Chain

Gear reduction 6:1 6:1 6:1

B) WHEELS

Bearings FRONT – ¾” (1.9 cm) FRONT – ¾” (1.9 cm) FRONT – ¾” (1.9 cm)

sealed sealed sealed

ball bearings with ball bearings with ball bearings with

stamping kit stamping kit stamping kit

REAR - ¾” (1.9 cm) REAR - ¾” (1.9 cm) REAR - ¾” (1.9 cm)

roller bearing roller bearing roller bearing

Rear tires 8” x 2” (20 x 5cm) 8” x 2” (20 x 5cm) 8” x 2” (20 x 5cm)

solid rubber solid rubber solid rubber

Front tire 10” x 6” (25 x 15cm) 10” x 6” (25 x 15cm) 10” x 6” (25 x 15cm)

semi-pneu. semi-pneu. semi-pneu.

C) AERA TION

Tines ¾” - (1.9 cm) ¾” - (1.9 cm) ¾” (1.9 cm)

open spoon tine. open spoon tine. open spoon tine.

24 per unit 30 per unit 42 per unit

Aeration width 17.5” (44.5 cm) 19” (48.3 cm) 25.5” (64.8 cm)

Hole pattern 4.4” x 6.5" 3.8” x 6.5” 3.6” x 6.5”

(11.2 x 16.5cm) (9.7 x 16.5cm) (9 x 16.5cm)

Core depth Up to 3” (7.6 cm) Up to 3” (7.6 cm) Up to 3” (7.6 cm)

Holes per sq ft 6.7 7.7 8.1

Working speed 250 ft/min (4.57 km/h) 250 ft/min (4.57 km/h) 290 ft/min (5.3 km/h)

Productivity Up to 23,000 sq ft/hr Up to 25,000 sq ft/hr Up to 40,000 sq ft/hr

(2137 m2/h) (2323 m2/h) (3716 m2/h)

D) WEIGHTS

Net weight 265 Ibs (120 kg) 288 Ibs (131 kg) 420 Ibs (191 kg)

Shipping weight 209 lbs (132 kg) 355 Ibs (161 kg) 487 Ibs (221 kg)

Removable weights 2 x 36 Ibs (16.3 kg) 2 x 36 Ibs (16.3 kg) 2 x 36 Ibs (16.3 kg)

E) DIMENSIONS

Height 28" (71.1 cm) 37” (94cm) 28” (71 1cm)

w/handle folded w/ handle folded less handle

Height overall 49.5" (126 cm) 51.5 (130.8cm) 52” (132cm)

Length 40" (101.6 cm) 39.5 (100.3cm) 33”(83.8cm)

w/handle folded w/ handle folded less handle

Length overall 48" (122 cm) 57.5 (146.1cm) 54” (137cm)

Width 26.5" (67.3 cm) 29.75” (75.6cm) 38” (96.5cm),31”

(78.74cm) w/o wls.

Shipping carton 28" x 29" x 43" 41” x 34” x 30” 41” x 34” x 30”

(71 x 74 x 109 cm) (104 x 86 x 76cm) (104 x 86 x 76cm)

3

Operator’s Guide

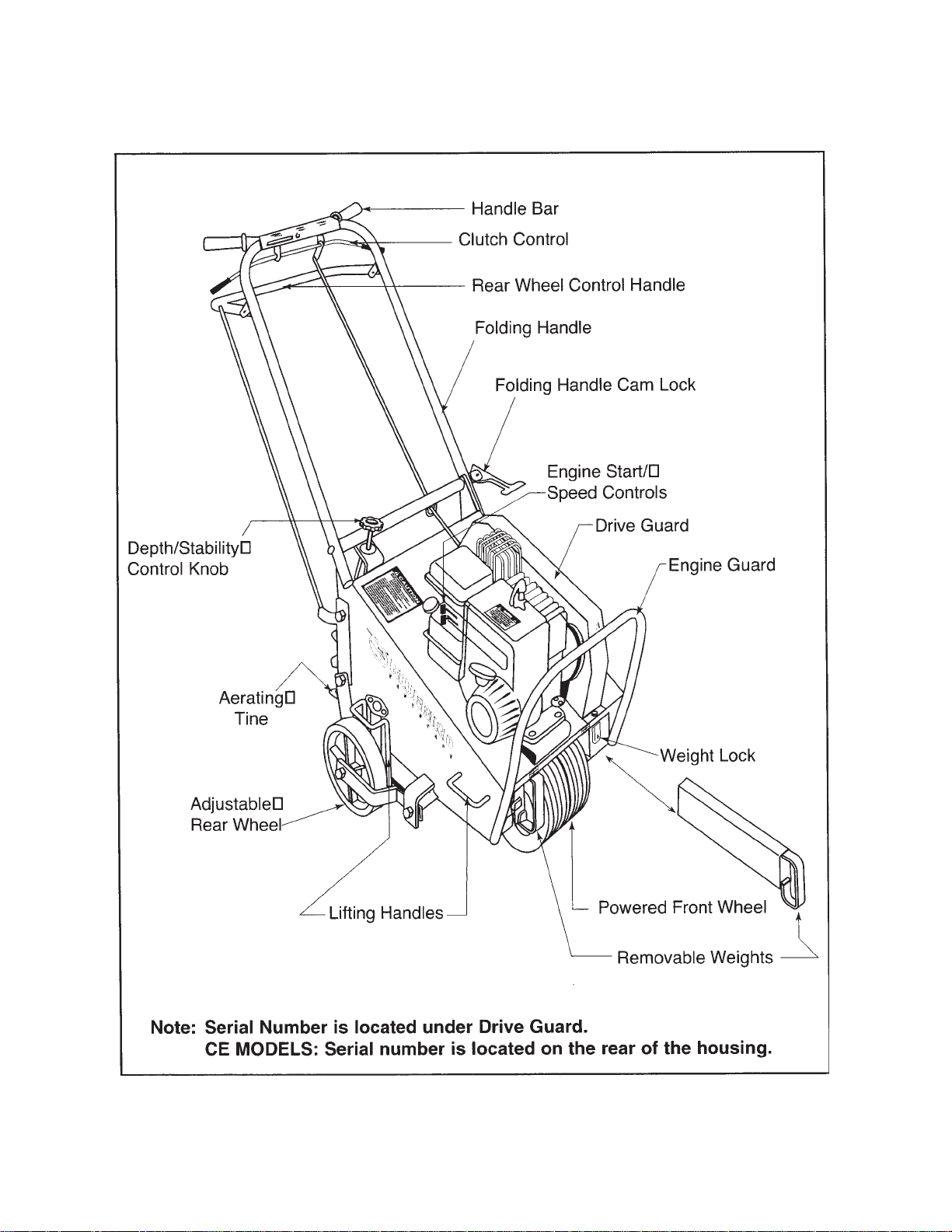

MODEL 424 - FEATURES AND CONTROLS

Figure 1

4

Operator’s Guide

MODEL 530A - FEATURES AND CONTROLS

Clutch Control

Rear Wheel

Control Handle

Engine

Guard

Removable

Weight

Note: Serial number is located on the rear of the housing.

Depth/Stability

Control Knob

Handle

Stop s

Powered

Front Wheel

Drive Guard

Folding Handle

Locking Cam

Removable

Weight

Adjustable

Rear Wheel

Figure 2

5

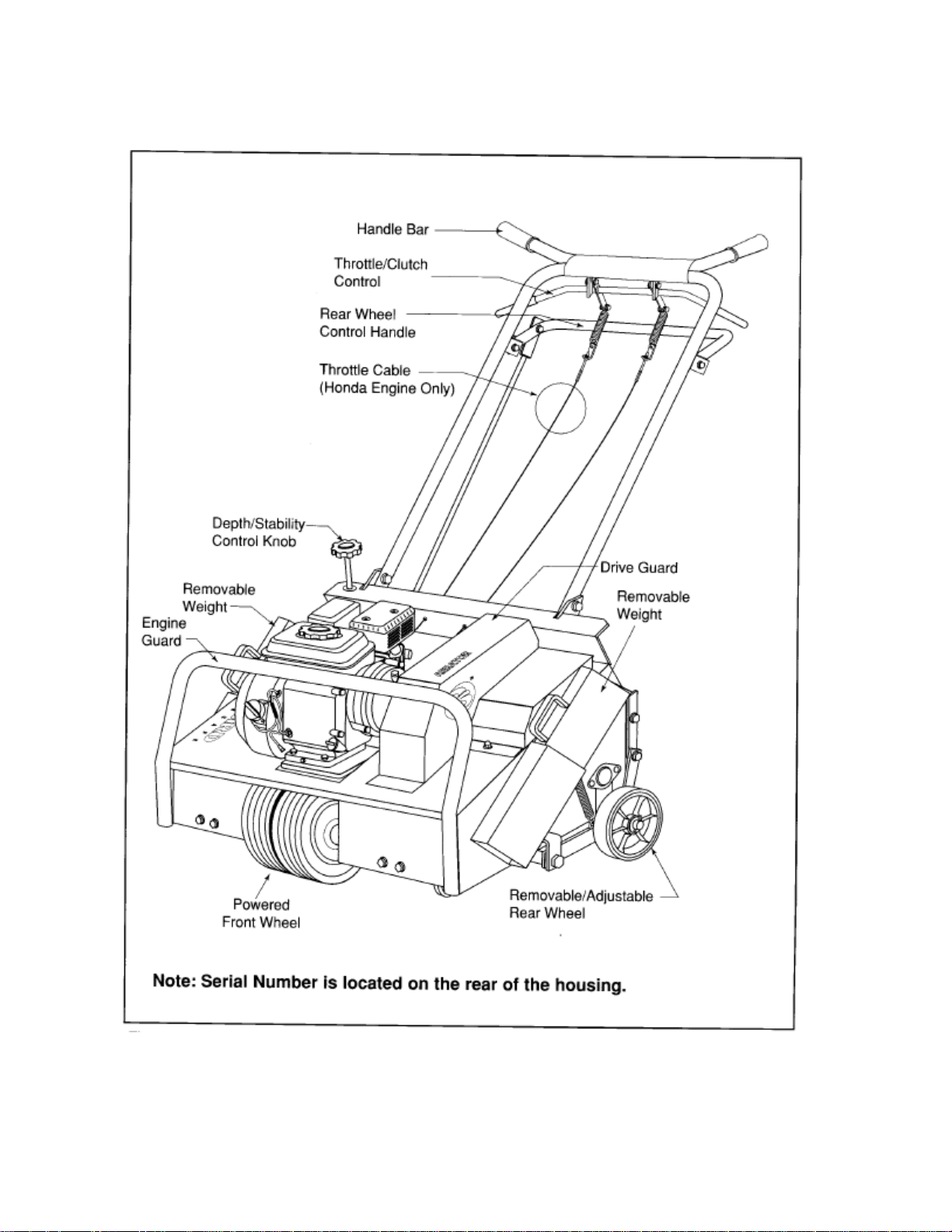

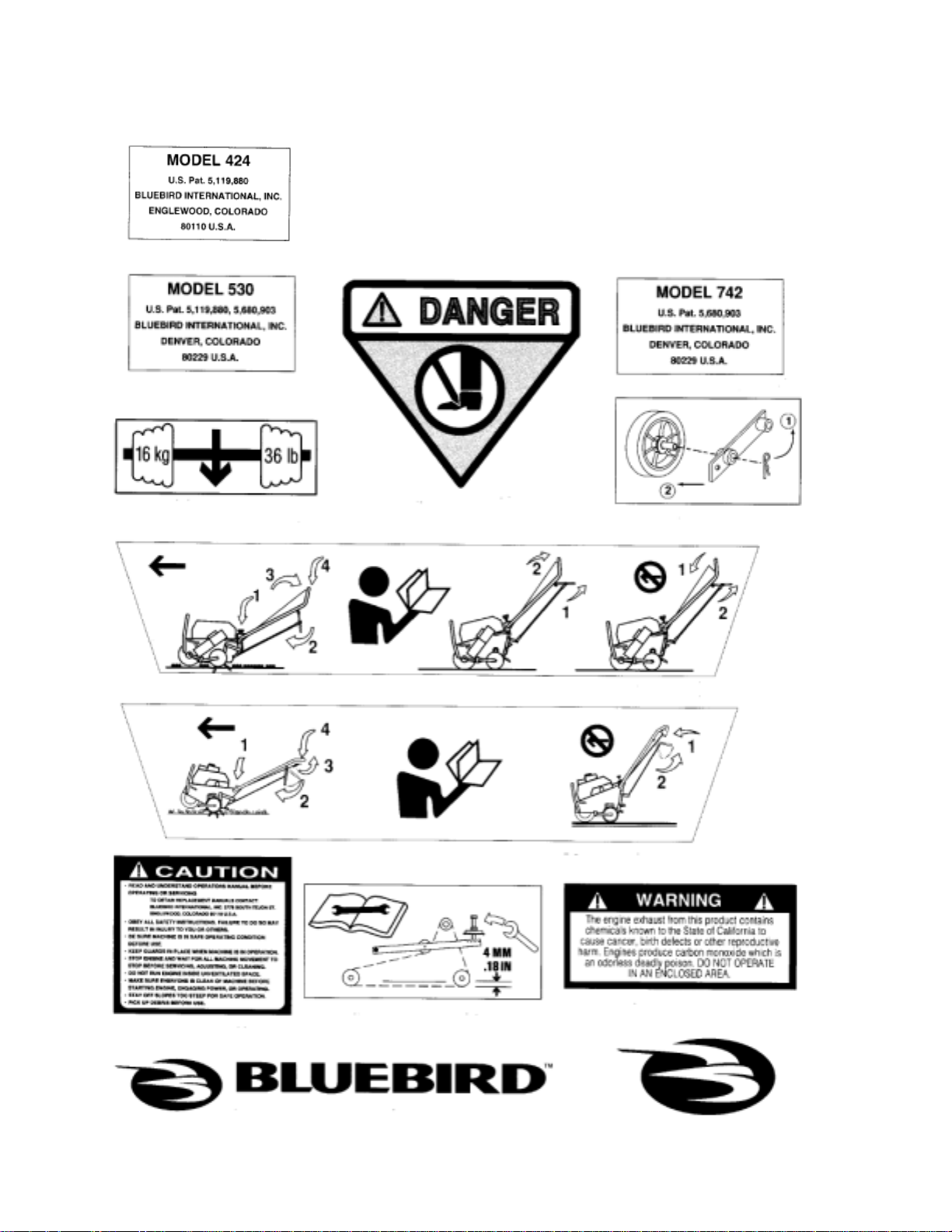

Operator’s Guide

MODEL 742 - FEATURES AND CONTROLS

Figure 3

6

Operator’s Guide

GENERAL INFORMATION

This manual will assist you in the safe operation

and proper maintenance of your Husqvarna

equipment. Read it thoroughly before attempting

to operate the machine. Call your dealer or

Husqvarna if additional information is required.

The following safety symbols are used

throughout the manual to alert you to information

about unsafe actions or situations:

DANGER indicates immediate hazards that

may result in severe injury or death.

WARNING indicates unsafe actions or

situations that may cause severe injury, death

and/or major equipment or property damage.

CAUTION indicates unsafe actions or

situations that may cause injury, and/or minor

equipment or property damage.

This equipment should not be modified without

the manufacturer’s prior written authorization.

Doing so may not only affect the equipment’s

performance and durability , but also create

safety hazards for the operator and the

surroundings. Warranty will be void if changes

are made to the equipment without the

manufacturer’s prior written authorization.

SAFETY PROCEDURES

DO:

• Read all maintenance and service instructions

before attempting work.

• Read engine manufacturer’s operating and

maintenance instructions.

• Remove spark plug wire before commencing

service.

• Inspect lawn to be aerated and remove rocks,

wire, string and other objects that might present

hazard before starting.

• Indentify and mark all ground objects to be

avoided, such as sprinkler heads, stakes, water

valves, clothes line anchors, etc.

• Use machine for lawn aeration only .

• Keep unsupervised children away from the

equipment.

• Adopt safe lif ting and moving techniques when

loading/unloading and moving the equipment.

• Make sure all decals are in place.

DO NOT:

• Do not run engine while servicing.

• Do not use on any surface other than grass.

• Do not operate on slopes exceeding 35%

grade.

• Do not place hands or feet near moving or

rotating parts.

• Do not lift Model 424 alone.

• Do not lift Model 530A.

• Do not lift Model 742

• Do not run engine in an unventilated space.

• Do not run engine while servicing. Remove

spark plug wire before commencing service.

• Do not smoke or allow open flames or sparks

near unit, and always stop the engine when

refueling

• Do not remove guards when operating.

• Do not modify this equipment.

• Do not use this equipment for purposes other

than lawn aeration.

7

SAFETY AND INSTRUCTION DECALS

The following decals are found on Model 424,530 and 742 aerators. If any are missing or not

legible, replace them before operating aerator.

8343 Decal kit, Model 424

7630 Decal kit, Model 530A

7404 Decal kit, Model 742

A - Model 424 only (1 EA)

B - Model 530A only (1 EA)

D - Models 424, 530A & 742 (2

EA)

F - Models 424, 530A & 742 (1

EA)

G1 - Model 530A (1 EA)

C - Model 742 only (1 EA)

E - Model 742 only (2 EA)

H - Models 424, 530A & 742 (1 EA)

K - Models 530A & 742 (1 EA)

424 (2 EA)

G2 - Model 424 & 742 (1 EA)

I - Models 424, 530A & 742 (1 EA)

8

J - Models 424, 530A & 742 (1 EA)

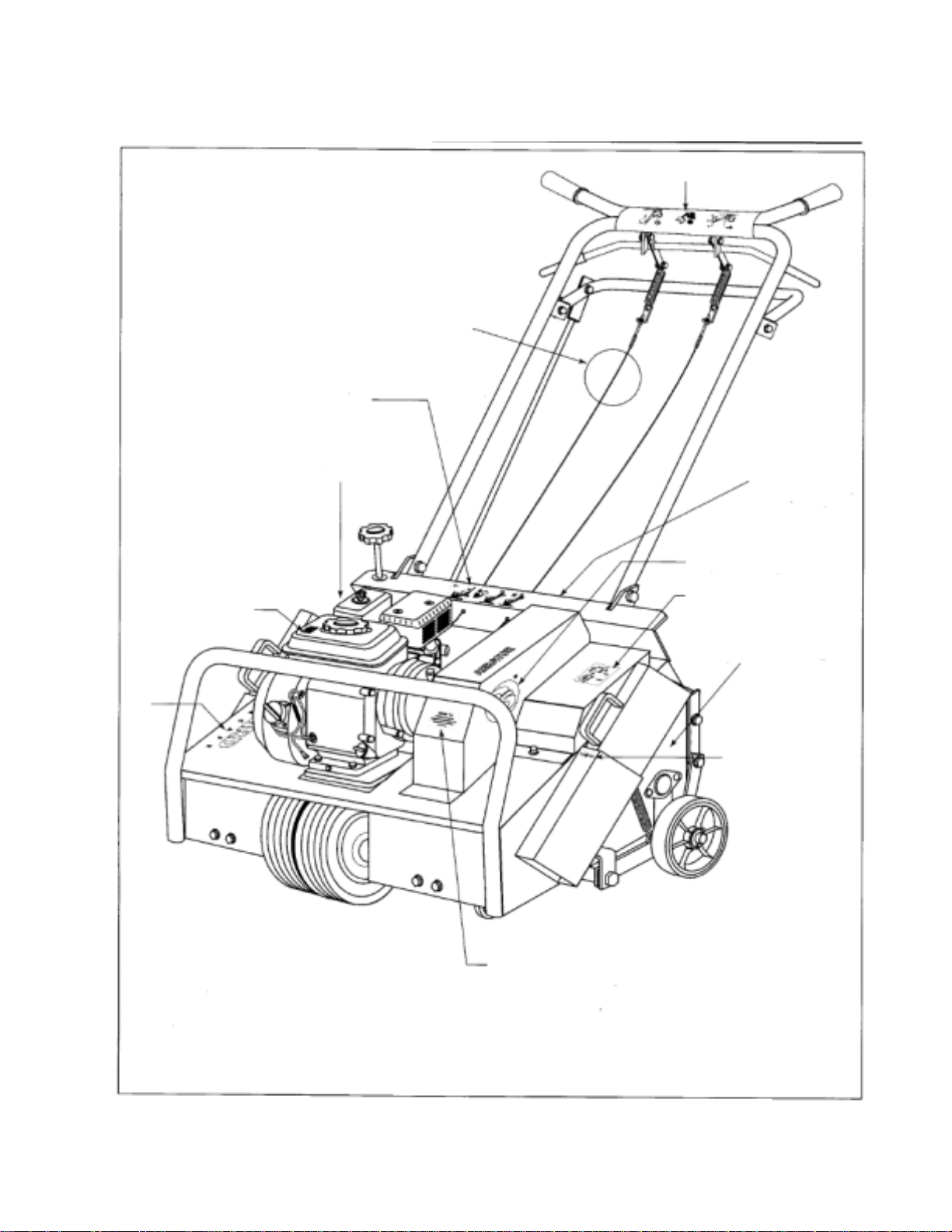

DECAL PLACEMENT - MODELS 424, 530A AND 742

Throttle Cable

(Model 742 with

Honda only)

G1

G2

H (on deck

behind

engine)

K (for Models 424 & 742

logo only)

I

J

K

F (on back

of housing

over tine

rotor)

E (for Model 742)

D

A (for Model 424)

B (for Model 530A)

C (for Model 742)

Figure 3

9

Operator’s Guide

ASSEMBLY INSTRUCTIONS

Model 424

1. Remove wooden blocks. Note: Watch for nails

and wood splinters. Wear eye protection.

2. Carefully cut open side of carton.

3. Lawn Aerator 424 is shipped with handle

folded. Rear wheel control handle strapped

together with the clutch control. First cut

straps, then unfold handle. Lock handle in

position using the cam lock lever.

Model 530A

1. Wear eye protection. Remove wooden blocks.

NOTE: Watch for nails and wood splinters.

2. Carefully cut open side of carton.

3. Lawn Aerator is shipped with handle folded.

Lock handle in position using the cam lock

lever.

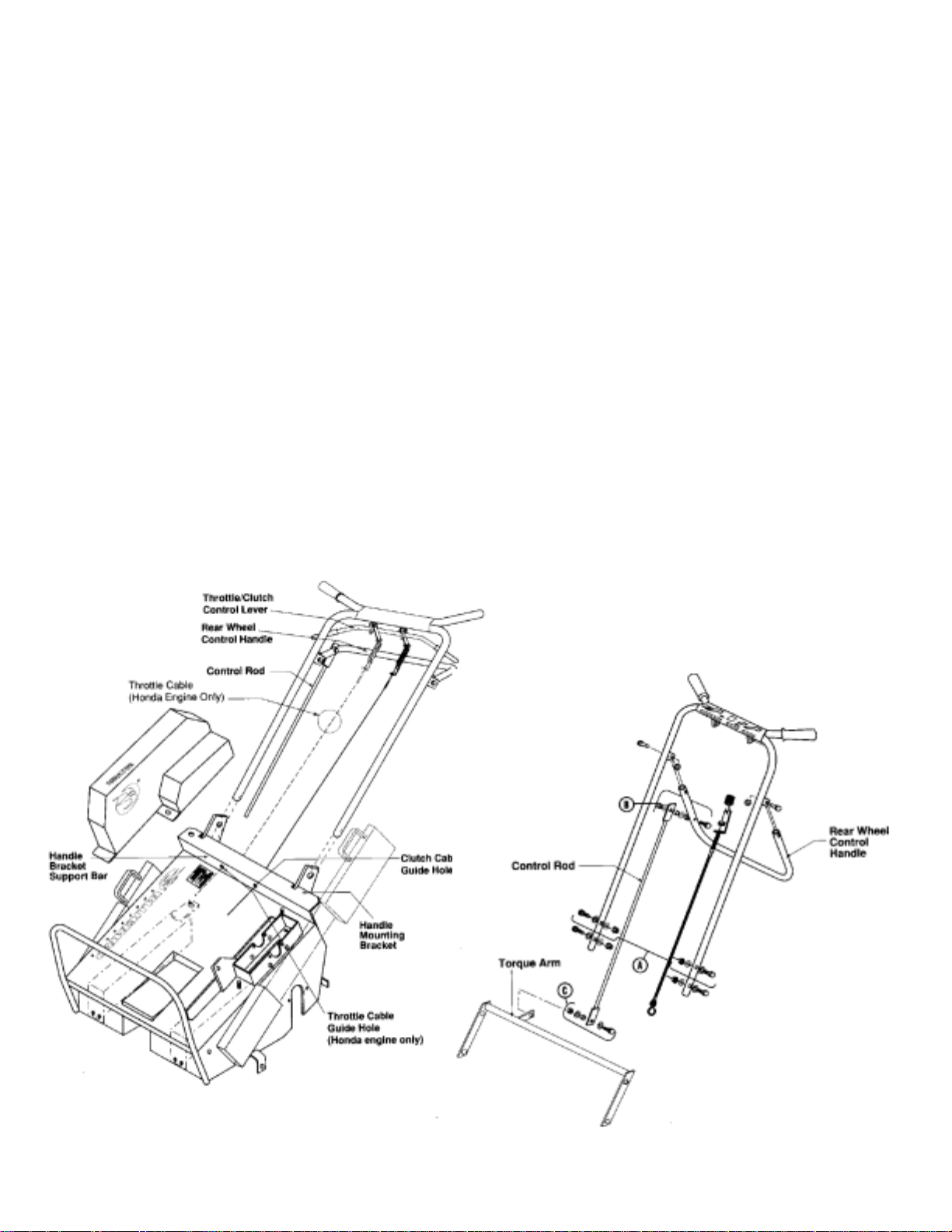

Model 742

1. Wear eye protection. Remove wooden blocks.

NOTE: Watch for nails and wood splinters.

2. Carefully cut open side of carton.

3. Lawn Aerator is shipped with the handle

detached. Mount the handle using 2 each ½”

wrenches.

(A) Slide handle onto handle mounting

brackets (see Figure 4).

(B) Insert and tighten fasteners, which

are located on handle mounting

brackets (see Figure 5-A). For further

detail on assembly, see parts section.

4. Connect top of control rod to rear wheel

control handle with fasteners located on rear

wheel control handle (see Figure 5-B) For

further detail on assembly, see parts manual.

5. Connect bottom of control rod to

of lever on the torque arm using the fastener

assembly (see Figure 5-C).

6. Run the clutch cable through the guide hole in

the handle bracket support bar located at rear

of the deck (see Figure 4).

7. Att ach end of cable to the “S” hook located on

the belt idler pulley .

8. (Honda Engines Only) Connect the throttle

cable by attaching the throttle spring to the

throttle/clutch control lever. (see Figure 4)

OUTER side

Figures 4

Figures 5

10

AERATION TIPS

Operating Instructions

Should I water before aerating?

Best aerating condition is a soft and moist

ground. If you are unsure of the ground

conditions, as in soil with high clay content, a

simple test will determine whether it is

necessary to water before aerating. Using a

garden hand spade or a large screw driver , you

should be able to drive the tool in the ground 2 to

3 inches with little effort. If you are unable to do

so, then watering the lawn a day before aerating

is necessary.

When should I use the removalole weights?

Soil conditions will dictate whether extra

machine weight is needed for effective coring

action. The weights are provided to give you

added control, and greater tine penetration.

BEFORE YOU START

1. Make sure that engine oil is at engine

manufacturer’s recommended level (refer to

engine manual). Be sure gear reduction oil is

at engine manufacturer’s recommended level.

Make sure the machine is level when filling

with oil.

2. With the folding handle in its operating

position, lock the handle cam lock (Models

424 & 530A only).

3. Rear wheel control handle must be pulled up

so rear wheels are all the way down.

4 Insert weights if needed.

5. Be sure handle is properly mounted.

6. Test clutch handle to insure clutch releases

freely.

7. The engine top speed is preset by the engine

manufacturer. Consult the engine

manufacturer’s manual for directions to

adjust the governor and carburetor if speed is

not within correct range.

8. 742 Honda Engines Only: The throttle cable

has been installed by the factory , however

throttle spring needs to be connected to

throttle/clutch control lever (see Figure 4).

AERATING

1. Start engine and adjust throttle setting to

provide a comfortable walking speed and

maintain control of the equipment at all times.

2. Adjust depth control knob (see Figure 1 or 2)

to desired depth. Coring depth decreases by

turning the knob clockwise.

NOTE: by raising the rear wheels all the way

up (to obtain maximum coring depth) you will

reduce the unit’s stability but increase length

of core.

3. Push down the rear wheel control handle to

lower aerating tines into the ground (rear

wheels will rise).

4. Push down on handle bar for better tine

penetration and maneuverability (front wheel

will rise).

5. Engage clutch control.

6. Adjust engine throttle setting, if needed, for

comfortable speed.

7. To stop, release clutch control.

CAUTION!

Be sure clutch cable is routed properly.

CAUTION!

NEVER cross hard objects or surfaces

(sidewalks, driveways, stepping stones,

etc.) with tines down.

11

Operating Instructions

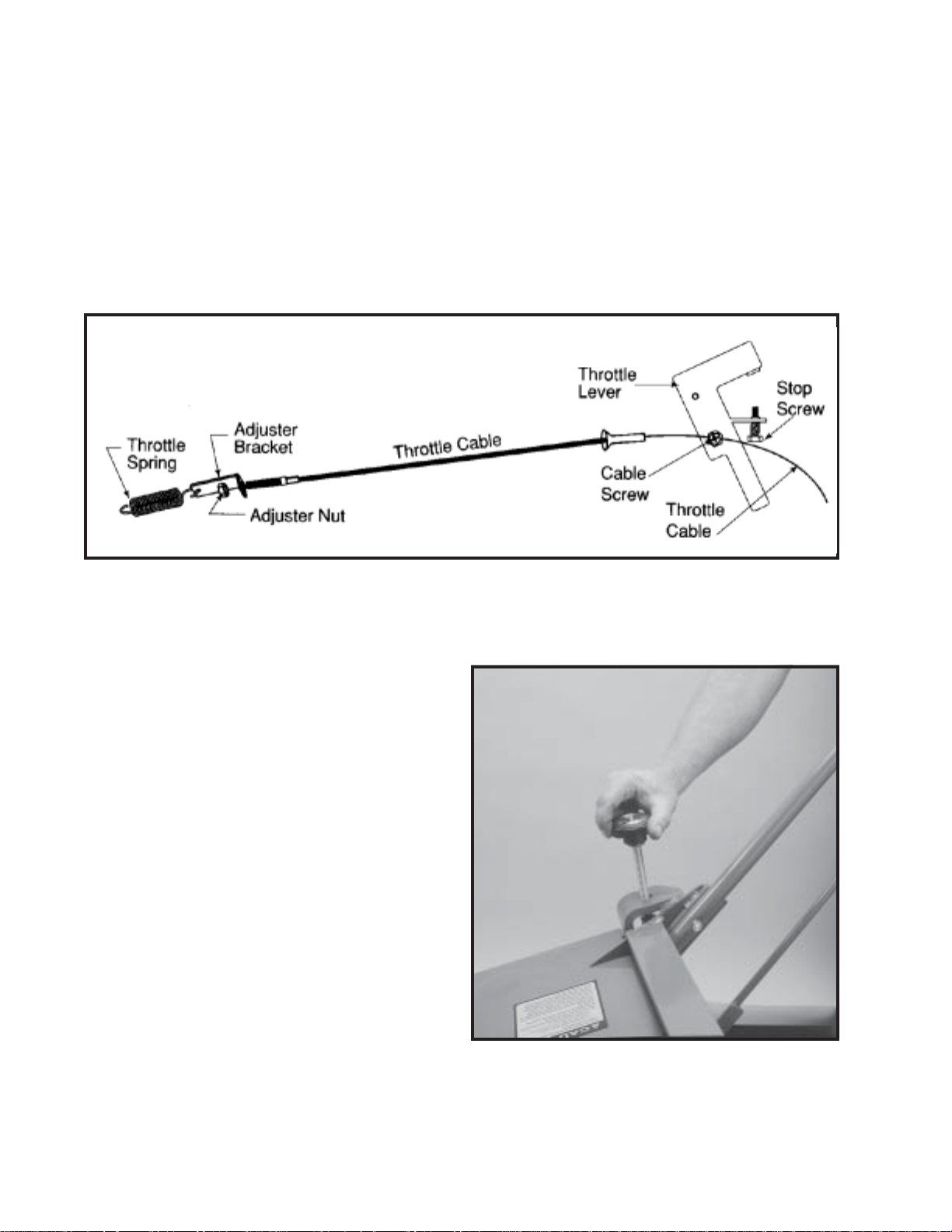

THROTTLE CABLE ADJUSTMENT. Model 742 (Honda Engine Only)

1. Start engine and allow it to reach operating

temperature.

2. Adjust the throttle cable at the adjuster

bracket by turning the adjuster nut. Tightening

will increase engine speed, loosening will

reduce engine speed.

NOTE: A properly adjusted throttle will slightly

increase engine speed as the clutch engages.

• If the clutch engages too soon, the engine

will stall.

• If the engine speed is too high, the gradual

controlled start is lost.

Figure 6

REAR WHEEL ADJUSTMENT

The rear wheel depth/stability control knob (see

Figure 7) allows adjustment for better stability

and maneuverability by turning knob clockwise.

Adjusting for depth by turning knob counter

clockwise determines the length of the cores

pulled in the following ways:

(A) The rear wheels can be adjusted to the

level you desire so you can control the

penetrationof the tines to within a

fraction of an inch. The length of the

cores pulled can be

controlled accordingly .

(B) With the rear wheels adjusted to the full

up position, you will obtain maximum

tine penetration. Pushing down on the

machine’s handle bars will put most of

the weight of the machine on the tines.

In this configuration you will pull the

longest cores. (Front wheel will rise).

Figure 7

12

Operating Instructions

NOTE: Adjusting for greater st ability will shorten

the length of the cores you pull. You will gain

greater side-to-side stability (see below

“Operating on Hills.” Adjustment s for greater

stability will also improve maneuverability during

aeration.)

TURNING AND MANEUVERING THE AERATOR

Gradual maneuvering while aerating can be

accomplished by simply guiding the machine.

We recommend that you adjust your engine’s

speed control to allow for a comfortable walking

speed. This will also help you maintain complete

control while working in tight spaces. Adjusting

for more stability (with the rear wheels lowered,

reducing tine penetration) will make turning

easier.

When reversing direction or making sharp turns

two methods of turning can be used. Select the

safest and most comfortable method for the

conditions you face:

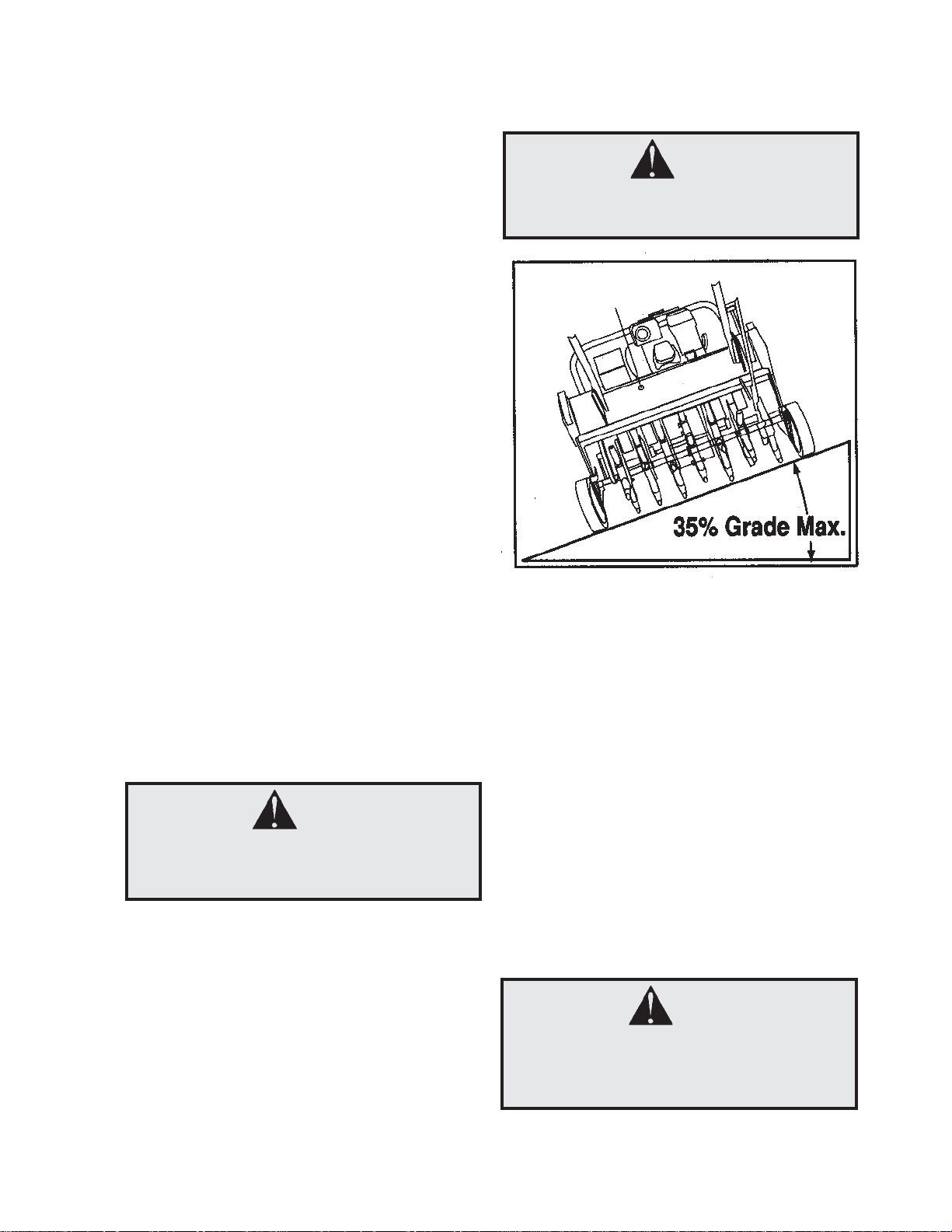

OPERATING ON HILLS

WARNING!

DO NOT operate on hills exceeding 35%

grade.

Figure 8

(A) Release clutch control handle, pull up rear

wheel control handle, then pivot machine on

rear wheels to turn.

(B) Release clutch control handle, lift handle bar

and pivot machine on front wheel.

WARNING!

This method is NOT recommended when

operating on hills. (See next section.)

This unit is not designed to be used on steep

slopes. Be aware that when operating on hills

the

tilt of the aerator will cause the machine’s center

of gravity to shift to the downhill side of the

machine. Under these circumstances you may

experience:

(A) The need to exert a greater effort to

steer and maintain the balance of the

machine.

(B) Uneven tine penetration, when

operating across a hill. Due to the shifted

center of gravity

the downhill tines will penetrate to the

maximum depth, while uphill tines may

not.

WARNING!

In extreme situations (very steep hills)

the machine may be so unbalanced, that

it may present the danger of rolling over.

13

Operating Instructions

When operating on hills you should

consider the following:

(A) Operate the machine up and down the

hills rather than across them.

(B) Use the rear wheel depth/stability control

knob to set the rear wheels for extra

stability. This can be a great benefit

when you do choose to run the aerator

across a hill. An added benefit of using

the rear wheel depth control when

aerating across a hill is that you will

improve the consistency of the cores

pulled from the uphill tines when

compared to those pulled by the

downhill tines.

(C) Removing the downhill weight reduces

roll-over risk and maintains consistent

core plug length. (See Figure 9)

(D) Remove remaining weight from downhill

side to uphill side after each pass when

operating across hills.

WARNING!

NEVER disengage tines from ground

when travelling up or down hill. ONLY

disengage on flat surface.

TRANSPORTING THE BLUEBIRD

AERATOR

MODEL 424

The BlueBird 424 Aerator has three convenient

features to assist you in transporting the unit in

your pick-up truck, van and even in some car

trunks. Those features are: removable weights,

a folding handle and convenient lifting handles on

the sides of the machine. The features are

provided for your optional use and can be of

great benefit when required.

Removable Weights

• Unlatch weight locks.

• Grab weight handles and pull the weights

from the machine.

Note: Weight 36 lb/16 kg each.

Folding Handle

• Release handle cam lock.

• Fold handle forward over the engine until it

is resting on the engine guard.

Lifting Handles

Lifting handles are located on both sides of the

aerator, to allow two people to lif t the unit.

CAUTION!

Avoid back or muscle injury! Use safe

lifting techniques, DO NOT exceed your

physical limitatons. DO NOT attempt to lift

ALONE. Weight 193 lb/88 kg w/o weights.

Figure 9

MODELS 530A AND 742

The removable weights are for side hill stability

and tine penetration as applicable.

CAUTION!

DO NOT lift aerators.

With the weights in place, these models are

designed for easy loading and unloading on

ramps and trailers. The treaded front wheel

provides increased control during transport. Use

engine power to load unit.

14

Loading...

Loading...