Page 1

Operating Instructions and Parts Manual SBS50 Boost

Please read and save these instructions. Read carefully before attempting to assemble, install, operate

or maintain the product described. Protect yourself and others by observing all safety information.

Failure to comply with instructions could result in personal injury and/or property damage! Retain

The Professional’s Line

instructions for future reference.

Pressure Booster System

Description

The booster is designed to increase

General Safety

Information

water pressure from municipal sources

or private water systems. The unit is

equipped with a 1/2 HP, 120 volt singlephase motor. Use only to pump clear

water. The system includes the pump,

control box, pressure sensing switch,

bladder tank, and fl ow sensing switch.

Do not attempt to

use product at 240

volt. Only 120 volt is allowed.

Unpacking

After unpacking the pressure booster system, carefully inspect for any damage that

may have occurred during transit. Check

for loose, missing or damaged parts.

Safety Guidelines

This manual contains information that is

very important to know and understand.

This information is provided for SAFETY

and to PREVENT EQUIPMENT PROBLEMS.

To help recognize this information,

observe the following symbols.

Danger indicates an

imminently hazardous

situation which, if not avoided, will result

in death or serious injury.

Warning indicates a

potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

Caution indicates a

potentially hazardous

situation which, if not avoided, may

result in minor or moderate injury.

Notice indicates

important

information, that if not followed, may

cause damage to equipment.

CALIFORNIA PROPOSITION 65

This product or its

contain chemicals known to the State

of California to cause cancer and birth

defects or other reproductive harm. Wash

hands after handling.

GENERAL SAFETY

1. Read the instruction manual included

with the product carefully. Be

thoroughly familiar with the controls

and the proper use of the equipment.

2. Know the pump application,

limitations and potential hazards.

Always install a

to match the system pressure rating and

the maximum fl ow rate.

Do not use to pump

explosive fl uids such as gasoline,

fuel oil, kerosene, etc. Do not use in

explosive atmospheres. Pump should

only be used with liquids compatible

with pump component materials. Failure

to follow this warning can result in

personal injury and/or property damage.

Disconnect power

pressure from the system before

attempting to install, service, relocate

or perform any maintenance. Lock the

power disconnect in the open position.

Tag the power disconnect to prevent

unexpected application of power.

3. Drain all liquids from the system

before servicing.

4. Secure the discharge line before

starting the pump. An unsecured

discharge line will whip and possibly

cause personal injury and/or

power cord may

pressure relief valve

fl ammable or

and release all

Figure 1

property damage.

5. Periodically inspect pump and

system components. Perform routine

maintenance as required (See

Maintenance).

6. PERSONAL SAFETY:

a. Wear safety glasses at all times

when working with pumps.

b. Keep work area clean,

uncluttered and properly lighted.

Replace all unused tools and

equipment.

c. Keep visitors at a safe distance

from work area.

d. Make the workshop childproof

use padlocks, master switches

and remove starter keys.

7. Do not pump chemicals or corrosive

liquids. Pumping these liquids

shortens the life of the pumps seals

and moving parts and will void the

warranty.

8. Complete pump and piping system

MUST be protected against below

freezing temperature. Freezing

temperatures could cause severe

damage and void the warranty.

9. Do not run the pump dry or damage

will occur and will void warranty.

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or fi le it for safekeeping.

© 2010 Blue Angel™ Pumps For parts, product & service information

visit www.blueangelpumps.com

341602-002 7/10

Page 2

Operating Instructions and Parts Manual SBS50 Boost

General Safety

Information

(Continued)

Risk of electrical

shock. This pump is

designed for indoor installation only.

All wiring should

be performed by a

licensed or certifi ed electrician.

10. For safety, the unit must be

connected to a grounded circuit

equipped with a ground fault

interrupter device.

11. Before installing the pump, have the

electrical outlet checked by a licensed

or certifi ed electrician to make sure

the outlet is properly grounded.

12. Make sure the line voltage and

frequency of electrical current supply

agrees with the motor wiring.

Do not attempt to

use product at 240

volt. Only 120 volt is allowed.

13. Do not attempt repairs to the electric

motor. All repairs to the motor

must be completed at a licensed or

certifi ed electrical motor repair shop.

Do not touch an

operating motor.

Modern motors are designed to operate

at high temperatures.

14. Avoid kinking electrical cord and protect

from sharp objects, hot surfaces, oil and

chemicals. Replace or repair damaged or

worn cords immediately.

Disconnect power and release all

pressure from the system before

attempting to install, service, relocate

or perform any maintenance. Lock the

power disconnect in the open position.

Tag the power disconnect to prevent

unexpected application of power.

15. Keep fi ngers and foreign objects away

from ventilation and other openings. Do

not insert any objects into the motor.

Risk of electric shock!

Never connect the

green (or green and yellow wire) to a

live terminal!

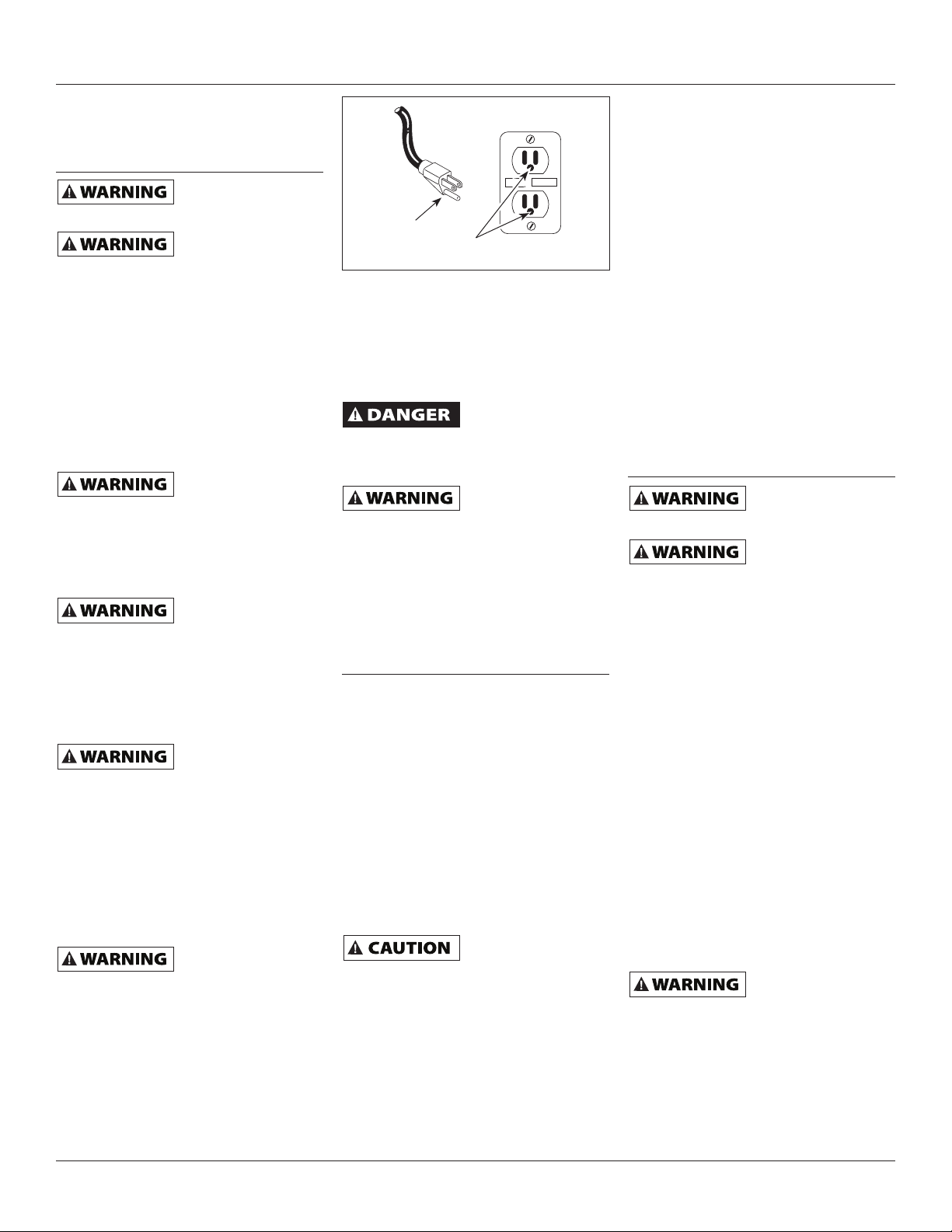

16. To reduce the risk of electrical shock,

the pump should be plugged directly

into a properly installed and grounded

3-prong grounding type receptacle, as

shown in Figure 2. The green (or green

and yellow) conductor in the cord is

the grounding wire. The motor must

be securely and adequately grounded

for protection against shock.

www.blueangelpumps.com

RESET

TEST

Grounded

Pin

Figure 2

Grounded Outlet

17. Where a 2-prong is encountered,

replace the plug with a properly

grounded 3-prong receptacle in

accordance with the National Electrical

Code, local codes and ordinances.

To ensure a proper ground, the

grounding means must be tested by a

licensed or certifi ed electrician.

Do not handle pump

wet hands, when standing on a wet or

damp surface or when standing in water.

Fatal electrical shock could occur.

Pump motor is

automatic resetting thermal protector

and may restart unexpectedly. Protector

tripping is an indication of motor

overloading because of operating pump

at low heads (low discharge restriction),

excessively high or low voltage,

inadequate wiring, incorrect motor

connections or defective motor or pump.

or pump motor with

equipped with an

Installation

LOCATION

Select a location as close to the water supply

as possible. Be sure to comply with any state

or local codes regarding the placement

of the pump. The equipment must be

protected from the elements. A basement

or heated pump house is a good location.

Make sure the pump has proper ventilation.

The temperature surrounding the pump

is not to exceed 100°F (40°C) or nuisance

tripping of the motor overload may occur.

PIPING

Piping may be copper, steel, rigid PVC

plastic or fl exible polyethylene plastic.

Flexible pipe is not

recommended on

suction pipe (inlet pipe). Flow sensor is

designed for 1” NPT connection.

The pipe must be clean and free of rust or

scale. Apply Tefl on

to the 1” male NPT pipe threads and install

the switch into the piping system. Thread the

fl ow switch onto the male pipe thread until

hand-tight. Tighten pipe 1 additional turn. If

improper seal results, continue turning pipe

into unit 1/4 turn increments. Do Not Exceed

1 Additional Turn All connections must be air

tight to insure normal operation.

®

thread tape or sealant

Slope all inlet piping upwards towards

the pump to prevent trapping air.

IMPORTANT: Pump is built to handle

clear water only; it is not designed to

handle water containing sand, silt or

other abrasives.

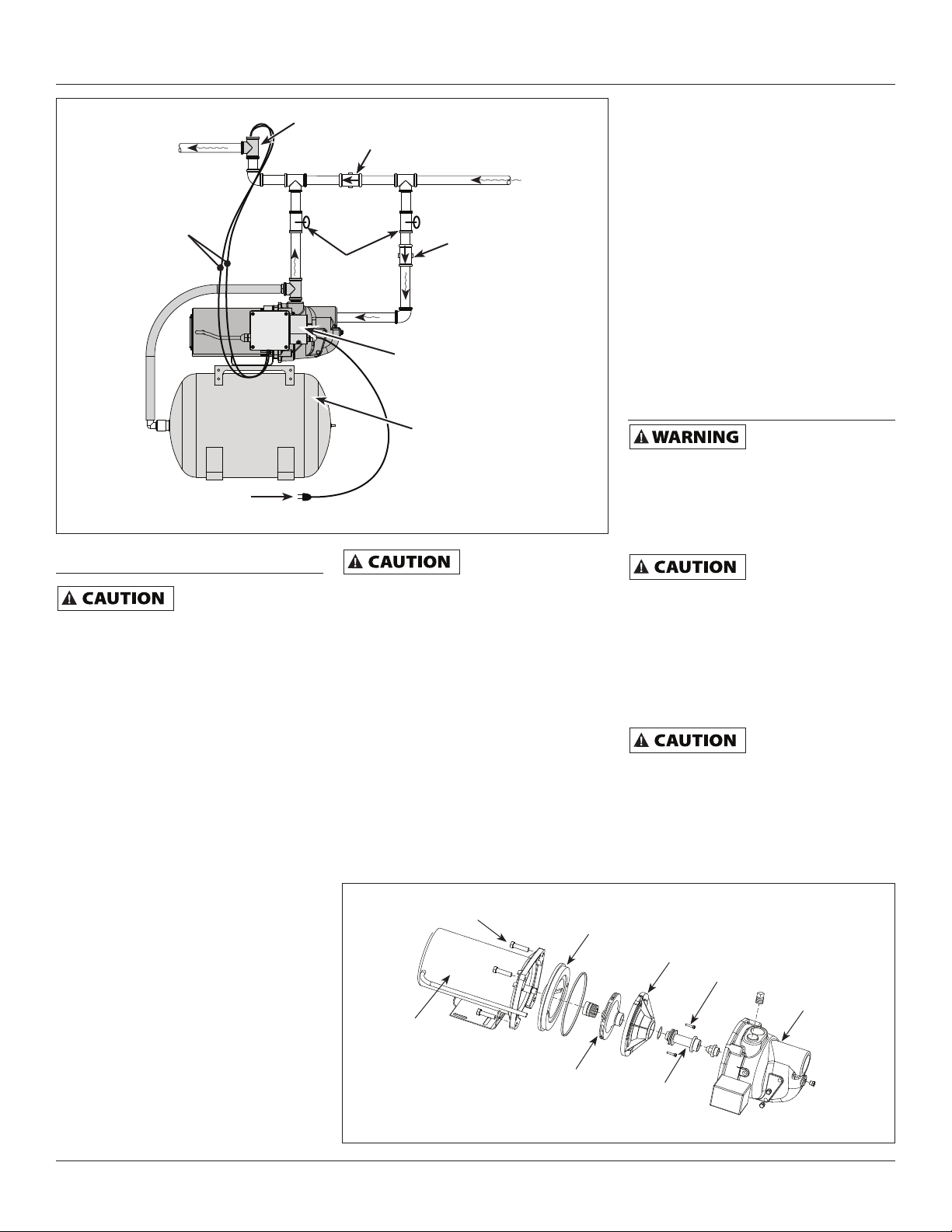

1. Refer to Figure 3

for typical

installations.

2. Bolt pressure booster system to a

secure foundation.

3. Locate the pump so that there will

always be a positive supply of water

to the pump (See Figure 3).

4. For service convenience, the installer

is recommended to add gate valves

and unions as needed to provide for

easier maintenance.

5. Pressure gauges on the inlet and

outlet, provided by the installer, are

recommended to show if suffi cient

water is being supplied to the pump

and to show service pressure.

Electrical

Risk of electrical

shock. This pump is

designed for indoor installation only.

Disconnect power

and release all pressure from the system

before attempting to install, service,

relocate or perform any maintenance.

IMPORTANT: Do not use an extension

cord or splice wires. Joints should be

made in an approved junction box. If the

above information is confusing, consult

a licensed electrician.

Your unit is supplied with a pressure

switch, fl ow sensor and a control box.

The only wire connection needed is to

plug the two red wires from the control

box into the two red wires on the fl ow

sensor (See Figure 3).

MOTOR PROTECTION

This motor has built in thermal protection.

The overload protects the motor against

burnout from overload of low voltage,

high voltage and other causes. The device

is automatic and resets itself once the

temperature has dropped to a safe point.

Frequent tripping of the device indicates

trouble in the motor or power lines and

immediate attention is needed.

Never examine,

or touch the motor before disconnecting the main electrical supply switch.

The thermal device may have opened the

electrical circuit. The pump motor should

be equipped with a correctly fused disconnect switch to provide protection. Consult

local or United States National Electrical

Codes for proper fuse protection.

make wiring changes

2

Page 3

Operating Instructions and Parts Manual SBS50 Boost

Flow

Switch

To Service

Flow Switch

Connections

120 VAC Plug

Figure 3 - Typical installation

Operation

Unit must be full of

fl uid before

operating. Do not run dry or against a

closed discharge. Do not pump dirty water

or abrasive liquids. To do so will cause the

pump failure and will void the warranty.

VALVES

The inlet and outlet isolation valves

should be in the full open position.

PRIMING

NOTE: Before starting the pump it

is absolutely necessary that both

the pump and the inlet pipe be

completely fi lled with water.

PRESSURE BOOST INSTALLATIONS

Priming is automatic when pump is

connected to a pressure source such as a

hydrant or city main. (See Figure 3).

1. Open valves or nozzle on inlet and

discharge side of pump.

2. Open a faucet nearest the booster

unit. Plug pump into outlet. When

the water fl ow from the faucet

reaches one gallon per minute, or

greater, the pump will automatically

start. Keep the faucet open for

approximately 30 seconds to relieve

trapped air in the line. When the

faucet is closed, the pump will

continue to run until pressure

reaches 60 psi.

NOTE: Orient Flow Switch as indicated

Check Valve

Municipal

Water

Check Valve

Isolation

Valves

Pressure

Switch

Tank

NOTE: “T”’s, Elbows,

and Isolation Valves

are not included

The pressure switch

is factory set at 50

psi and must not be changed.

3. If you installed a pressure gauge at

the pump inlet, a reading of 2 psi

minimum should show whenever the

pump is in operation. This reading

ensures that there is an ample supply

of water into the pump inlet housing.

4. The controller, fl ow sensor and

pressure switch continuously

monitor water pressure and fl ow.

The system automatically turns the

unit off if pressure reaches 50 to

53 psi. The control package also

protects the unit from dry run by

shutting down if water usage drops

below 1 gallon per minute.

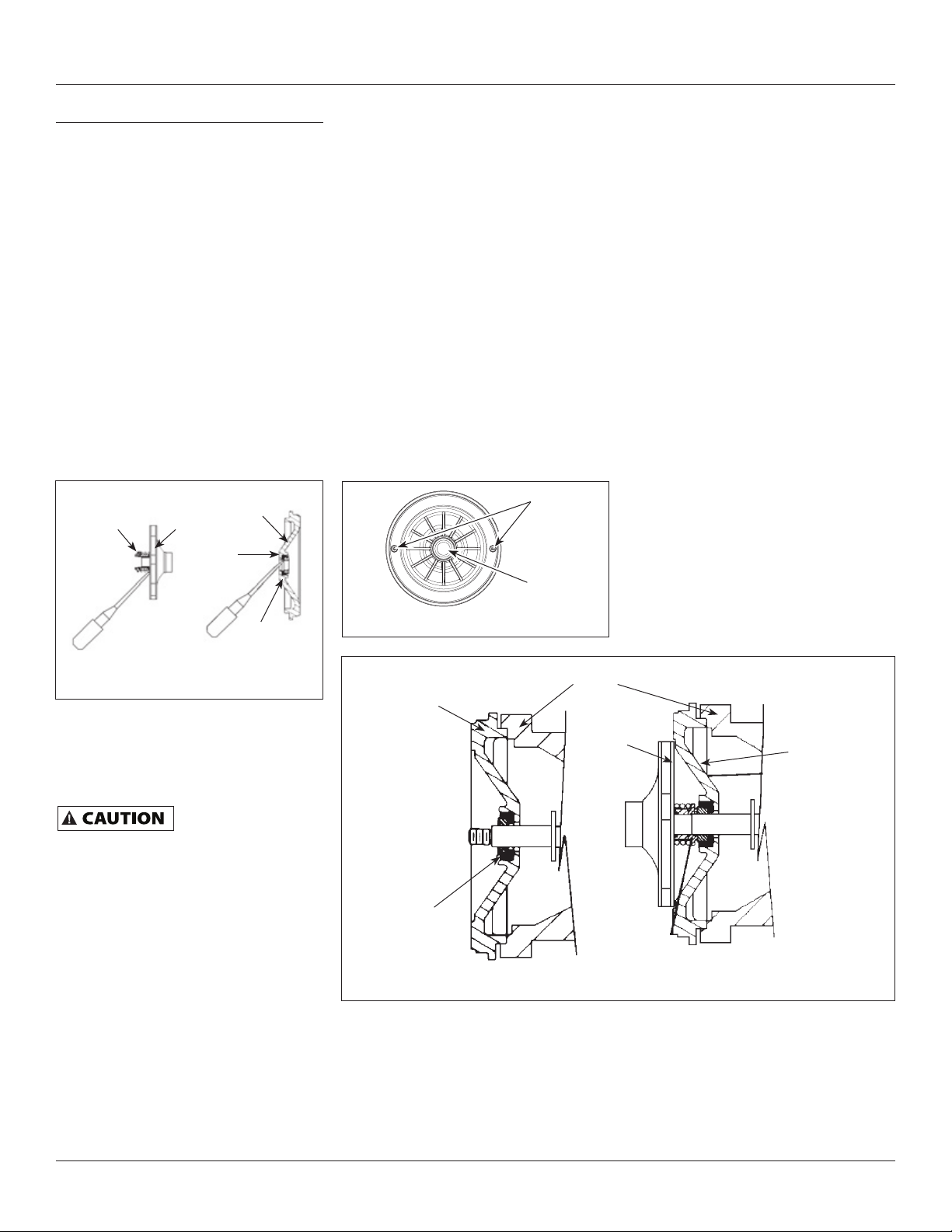

Cap Screws

Motor

Impeller

Figure 4

MOTOR/PUMP ROTATION

1. The motor rotates in a counter

clockwise rotation when facing the

pump end and cannot be reversed.

START-UP PROCEDURE

Once the preceding instructions have

been completed, the unit is ready for

normal operation.

1. During the fi rst few hours of

operation, inspect the pump, piping

and any auxiliary equipment used in

connection with the unit for leaks,

excessive vibration or unusual noises.

2. The booster unit will turn on and

off automatically, based on water

usage.

Maintenance

Disconnect power

and release all

pressure from the system before

attempting to install, service, relocate

or perform any maintenance. Lock the

power disconnect in the open position.

Tag the power disconnect to prevent

unexpected application of power.

Protect the pump

from freezing during

winter conditions.

DRAINING THE PUMP

Drain openings are provided on all

models. To drain the pump:

1. Remove drain plug and prime plug

to vent the system.

REMOVING OLD SHAFT SEAL

Turn disconnect switch

to “off” position.

1. Open a faucet nearest the tank and

allow all water to drain from the

tank.

2. Remove the four cap screws holding

the pump housing (volute) to the

motor (Figure 4).

Seal Plate

Diffuser

Cap Screws

Pump

Housing

(Volute)

Venturi

www.blueangelpumps.com

3

Page 4

Operating Instructions and Parts Manual

SBS50 Boost

Operation (Continued)

3. Separate the pump housing (volute)

from the motor to expose the

diffuser and the seal plate.

4. Remove the two cap screws and

diffuser from the seal plate to

expose the impeller.

5. Remove the small end cap on the

end of the motor opposite the

impeller.

6. With a large screwdriver or

adjustable wrench, keep the shaft

from rotating and remove the

impeller by hand (standard right

hand thread). Be sure to hold onto

the seal plate when removing the

impeller from the shaft.

7. Remove the seal plate.

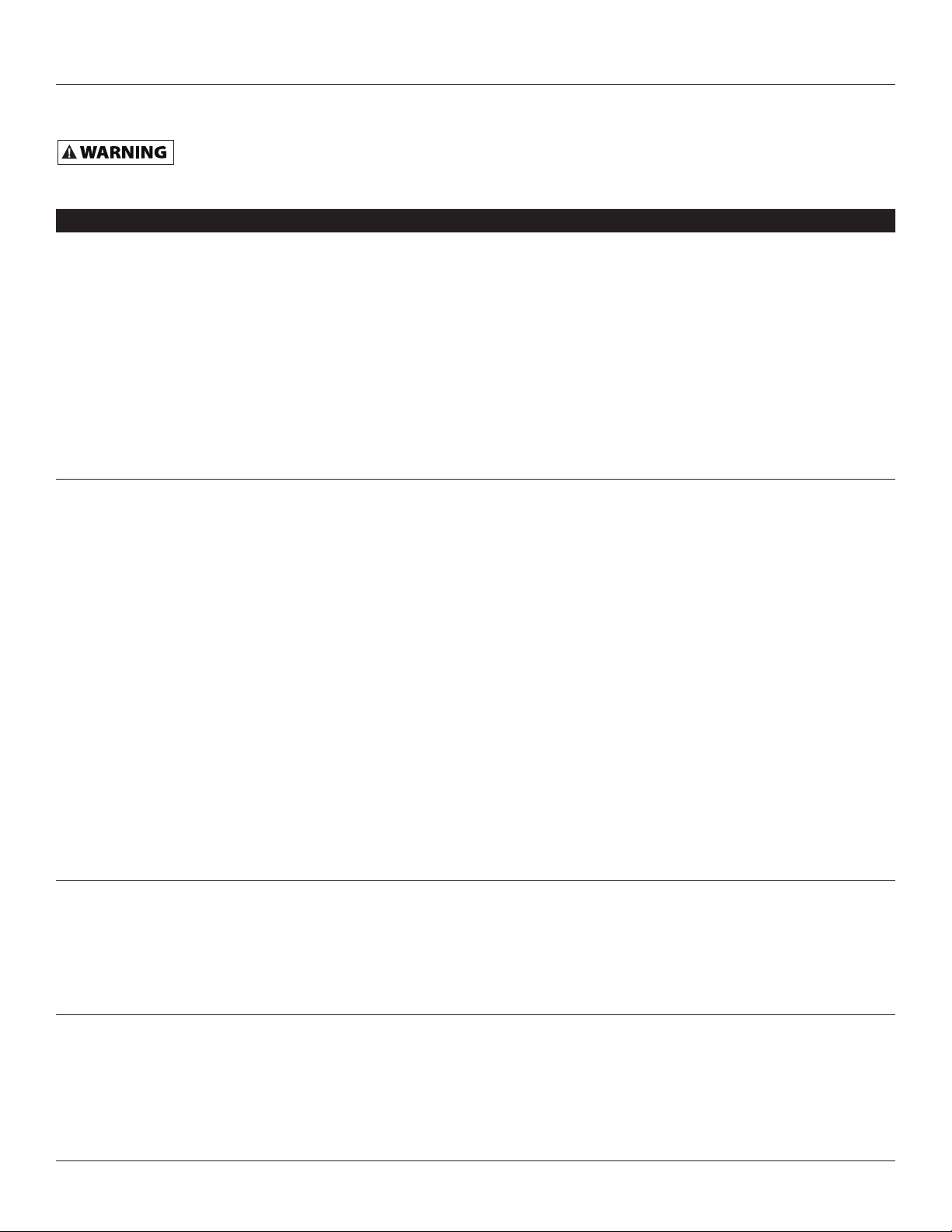

8. Pry the rotating shaft seal member

from the impeller (Figure 5).

Rotating

Shaft Seal

Member

Figure 5 - Removing Shaft Seal and

Ceramic Seat

Impeller

9. Push or pry the ceramic seat free

from the seal plate (Figure 5).

10. Remove loose particles from

impeller hub and seal plate.

Seal

Plate

Rubber

Seat Ring

Ceramic

Seat

1. Wet the inside of the seal cavity

on seal plate and the rubber cup

enclosing the new ceramic seat with

cooking oil. Be careful not to scratch

the ceramic surface of the seal seat

and push seat enclosed in rubber

into seal cavity on seal plate. Use a

cardboard washer to protect polished

surface when pushing against ceramic

seat with any object. Be sure to

remove cardboard washer.

2. Carefully slip seal plate over shaft.

Do not disturb seal position in

seal plate. The seal plate must be

orientated during assembly so the

two screw holes are on a horizontal

line across the motor shaft and the

(4) locating pins on the back of the

seal plate line up with the tabs on

the motor housing (Figure 6). This

placement should be done to ensure

proper draining and priming.

Screw

Holes

Motor

Shaft

Figure 6 - Seal Plate Replacement

Motor

Seal Plate

3. Place rotating shaft seal member in

position on impeller and press into

place. Take care not to press against

polished seal surface.

4. Position impeller on shaft and

tighten securely (Figure 7).

5. Secure diffuser to seal plate using the

two cap screws. Be sure the screws

are orientated on a horizontal line as

described in Step 2.

6. Carefully position pump housing

(volute) gasket over the diffuser

onto the seal plate. In all shallow

well applications care must be taken

that the o-ring is clean and properly

positioned on the venturi. Cleaning

and positioning makes a good seal

inside the diffuser when assembled.

7. Assemble the pump housing (volute)

to the motor using the four cap

screws. Be sure the pump housing

(volute) gasket is positioned

correctly and tighten the screws

securely.

NOTE: Shaft must rotate freely and

motor end cap should be secured before

operation.

Impeller

Seal Plate

INSTALLING NEW SHAFT SEAL

Before handling shaft

seal parts wipe hands

clean. Dirt or grease can damage the seal.

www.blueangelpumps.com

Seal Seat

Figure 7 - Motor Shaft

4

Seal Facing Must Be

Clean for Proper Seal

Page 5

Operating Instructions and Parts Manual

SBS50 Boost

Troubleshooting Chart

ELECTRICAL PRECAUTIONS - Before servicing a pump, always shut off the main power breaker and then unplug

the pump. Make sure you are not standing in water and are wearing insulated protective sole shoes. Under

fl ooded conditions, contact your local electric company or qualifi ed licensed electrician for disconnecting electrical service prior

to pump removal.

Symptom Possible Cause(s) Corrective Action

Pump won’t start or run

at full speed

Pump operates, but

delivers little or no water

Excessive noise while

pumping

Pump leaks 1. Worn mechanical seal (leaks at shaft) 1. Replace shaft (rotary) seal

1. Blown fuse or open circuit breaker 1. Replace fuse or close circuit breaker. See wire

chart for proper breaker/fuse size

2. AC power is OFF 2. Turn power on

3. Incorrect voltage 3. Low voltage

a. Voltage must be within ± 10% of motor rated

voltage. Check incoming voltage. Contact

power company

b. Motor voltage is set for 120V AC. System is

not designed for 240V service.

4. Defective motor 4. Replace motor

5. Pump internal components clogged/

worn/ damaged

1. Valves plumbed into system restricting

fl ow

2. In-line fi lter restricting fl ow 2. Check all in-line fi lters to be sure they are not

3. Low line voltage 3. See low line voltage corrective action (above)

4. Inadequate water supply to booster

pump

5. Undersized piping 5. Replace undersized piping

6. Leak on inlet side of system 6. Make sure connections are tight. Repair leaks as

7. Worn or defective pump parts or pump 7. Replace worn parts or entire plugged impeller.

8. Suction lift to great 8. Pump should be operated under fl ooded suction

9. Pump not primed 9. Prime pump. Make certain inlet pipe connections

1. Pump not secured to fi rm foundation 1. Secure properly

2. Piping not supported 2. Make adjustments

3. Restricted inlet line 3. Clean, correct, or eliminate restrictions

4. Cavitation (pumping marbles) 4. Increase inlet pipe size

5. Worn motor bearings 5. Replace motor

2. Damaged o-ring seals 2. Replace square ring rubber gasket

5. Replace worn parts or entire pump. Clean parts if

required

1. a. Check valves on pump inlet and discharge sides

of system. Be certain they are opened completely to allow fl ow to and from the pump.

b. Bleed trapped air in pump. (Normally due to

closed valve in discharge plumbing).

plugged or restricted

4. Check pressure on inlet side of booster to be sure

positive pressure is maintained to the booster

pump at all times

needed

Clean parts if required

only. See Corrective Action 4 above.

are tight and pump and pipe are full of water

www.blueangelpumps.com

5

Page 6

Operating Instructions and Parts Manual

SBS50 Boost

For Replacement Parts, call 1-888-636-6628

Please provide following information: Address parts correspondence to:

- Model number Blue Angel Pumps

- Serial number (if any) 101 Production Drive

- Part description and number as shown in parts list Harrison, OH 45030 U.S.A.

16

1

2

3

4

6

5

7

9

17

8

10

18

12

13

11

14

15

Ref.

No. Description

Part

Numbers Qty.

1 Motor 32059-001 1

2 Screw 16636-002

3 Seal plate 17145-001 1

4 • Square ring rubber gasket 17150-001 1

5 • Shaft seal assembly 56393 1

6 Impeller 23285-002 1

7 Diffuser 17148-001 1

8 Screw 67007-001

9 • O-ring 15557 1

10 Venturi 17151-002 1

11 Nozzle 15672 1

12 Pipe plug 3/4” 15921 1

13 Volute 56869-001 1

14 Pipe plug 1/4” NPT 16314-002 1

15 Pipe plug 1/8” NPT 15766-002 1

16 Base 23029-001 1

17 Pressure switch 30010-001 1

18 Flow switch 30048-001 1

• Repair kit (Includes #4, 5 and 9) 56874-001 1

www.blueangelpumps.com

6

Page 7

Operating Instructions and Parts Manual SBS50 Boost

Notes

www.blueangelpumps.com

7

Page 8

Operating Instructions and Parts Manual

SBS50 Boost

Limited Warranty

For two (2) years from the date of purchase, Blue Angel will repair or replace, at its option, for the original purchaser any part

or parts of its Sump Pumps or Water Pumps (“Product”) found upon examination by Blue Angel to be defective in materials or

workmanship. Please call Blue Angel (1-888-636-6628) for instructions or see your dealer. Be prepared to provide the model

number and serial number when exercising this warranty. All transportation charges on Products or parts submitted for repair

or replacement must be paid by purchaser.

This Limited Warranty does not cover Products which have been damaged as a result of accident, abuse, misuse, neglect,

improper installation, improper maintenance, or failure to operate in accordance with Blue Angel’s written instructions.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO TWO YEARS FROM THE DATE OF PURCHASE. THIS IS THE

EXCLUSIVE REMEDY AND ANY LIABILITY FOR ANY AND ALL INDIRECT OR CONSEQUENTIAL DAMAGES OR EXPENSES

WHATSOEVER IS EXCLUDED.

Some states do not allow limitations on how long an implied warranty lasts, or do not allow the exclusions or limitations of

incidental or consequential damages, so the above limitations might not apply to you. This limited warranty gives you specific

legal rights, and you may also have other legal rights which vary from state to state.

In no event, whether as a result of breach of contract warranty, tort (including negligence) or otherwise, shall Blue Angel or

its suppliers be liable for any special, consequential, incidental or penal damages including, but not limited to loss of profit or

revenues, loss of use of the products or any associated equipment, damage to associated equipment, cost of capital, cost of

substitute products, facilities, services or replacement power, downtime costs, or claims of buyer’s customers for such damages.

You MUST retain your purchase receipt along with this form. In the event you need to exercise a warranty claim, you MUST

send a copy of the purchase receipt along with the material or correspondence. Please call Blue Angel (1-888-636-6628) for

return authorization and instructions.

DO NOT MAIL THIS FORM TO Blue Angel. Use this form only to maintain your records.

MODEL NO. _______________________ SERIAL NO. _______________________ INSTALLATION DATE _______________________

ATTACH YOUR RECEIPT HERE

www.blueangelpumps.com

8

Page 9

Instructions d’Utilisation et Manuel de Pièces SBS50 Boost

S’il vous plaît lire et conserver ces instructions. Lire attentivement avant de monter, installer, utiliser

ou de procéder à l’entretien du produit décrit. Se protéger ainsi que les autres en observant toutes

les instructions de sécurité, sinon, il y a risque de blessure et/ou dégâts matériels! Conserver ces

The Professional’s Line

instructions comme référence.

Système de surpresseur

Description

Le surpresseur est conçu pour augmenter

la pression d’eau du réseau d’alimentation

d’eau de sources municipales ou

privées. L’appareil est doté d’un moteur

monophasé de 1/2 HP et 120 volts. Utiliser

seulement pour pomper de l’eau claire.

Le système inclut la pompe, la boîte de

contrôle, l’interrupteur de manomètre,

le réservoir à parois souples et un

interrupteur de détection d’écoulement.

Ne pas essayer

d’utiliser le produit à

240 volts. Seulement 120 volts est permis.

Déballage

Dès que l’appareil est déballé, l’inspecter

attentivement pour tout signe de

dommages en transit. S’assurer de

resserrer tous les raccords, boulons, etc.

avant de le mettre en service.

Directives de Sécurité

Ce manuel contient de l’information

très importante qui est fournie pour

la SÉCURITÉ et pour ÉVITER LES

PROBLÈMES D’ÉQUIPEMENT. Rechercher

les symboles suivants pour cette

information.

Danger indique une

situation hasardeuse

imminente qui RÉSULTERA en perte de

vie ou blessures graves.

Avertissement in

dique une situation

hasardeuse potentielle qui PEUT résulter

en perte de vie ou blessures graves.

i Attention indique

une situation

hasardeuse potentielle qui PEUT résulter

en blessures..

Avis indique de

l’information

importante pour éviter le dommage de

l’équipement.

Généralités sur la

Sécurité

PROPOSITION 65 DE CALIFORNIE

Ce produit ou son

cordon peuvent

contenir des produits chimiques

qui, de l’avis de l’État de Californie,

causent le cancer et des anomalies

congénitales ou autres problèmes de

reproduction. Lavez-vous les mains après

la manipulation.

GÉNÉRALITÉS SUR LA SÉCURITÉ

1. Lire attentivement ces instructions

et directives. Manque de suivre ces

instructions peut résulter en blessures

graves et/ou en dégâts matériels.

2. Connaissez l’application de la pompe,

ses limites et tous les risques.

Toujours installer

une soupape de

sûreté correspondante à la classifi cation

de pression du système et au taux de

débit maximum.

Ne pas pomper

les liquides

infl ammables ou explosifs tels que

l’essence, l’huile à chauffage, le kérosène,

etc. Ne pas utiliser dans un atmosphère

explosif. Utiliser la pompe seulement avec

les liquides compatibles avec les matériaux

de fabrication de la pompe. Manque de

suivre cet avertissement peut résulter en

blessures graves et/ou en dégâts matériels.

Mettre hors

circuit et dissiper

toute la pression du système avant

d’essayer de monter, de déplacer ou

de procéder au service ou à l’entretien.

Verouiller le sectionneur de puissance

dans la position ouverte. Étiquetter le

sectionneur de puissance afi n d’éviter

l’alimentation inattendue.

3. Purger tous les liquides du système

avant de procéder au service.

4. Fixer la ligne de décharge avant le

démarrage de la pompe. Une ligne

Figure 1

qui n’est pas bien fixée pourrait

fouetter et causer des blessures

personnelles et/ou le dégât matériel.

5. Inspecter la pompe et les pièces

détachées du système périodiquement.

Procéder à l’entretien ordinaire au

besoin (Voir la section Entretien).

6. SÉCURITÉ PERSONNELLE:

a. Toujours porter des lunettes de

sécurité pendant l’utilisation d’une

pompe.

b. Garder l’endroit de travail pro-pre,

pas encombré et bien éclairé. Ranger

tous les outils et l’équipement dont

on ne se sert pas.

c. Garder les visiteurs à distance

respectueuse de l’endroit de travail.

d. Protéger l’atelier des enfants

en utilisant des cadenas et des

interrupteurs principals. Enlever les

clés de démarrage.

7. Ne pas pomper de produits chimiques

ni de liquides corrosives. Le pompage

de ces liquides peut raccourcir la durée

des joints et des pièces mobiles de la

pompe et niera la garantie.

8. Le système complet de pompe et de

tuyaux DOIT être protégé contre les

températures inférieures à zéro. Les

témpératures congélantes peuvent

causer le dommage sérieux et nieront

la garantie.

© 2010 Blue Angel™ Pumps

MÉMENTO: Gardez votre preuve datée d’achat à fi n de la garantie!

Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

341602-002 7/10

Page 10

Instructions d’Utilisation et Manuel de Pièces SBS50 Boost

Généralités sur la

Sécurité

9. Ne pas faire fonctionner la pompe

au sec, ceci l’endommagera.

Risque de choc

pompe est conçue seulement pour une

utilisation à l’intérieur.

Toute installation

effectuée par un électricien certifi é ou

diplômé.

10. Pour la sécurité maximum, le modèle

devrait être branché à un circuit

de terre équipé d’un appareil qui

protège contre le dérangement dû à

une mise accidentelle à la terre.

11. Faire instpecter la prise de courant par

un électricien diplômé ou certifié afin

d’assurer que la prise soit mise à la terre

correctement avant d’installer la pompe.

12. S’assurer que la tension de ligne et

que la fréquence de la source de

courant électrique soient compatibles

avec l’installation de fils du moteur.

Ne pas essayer

240 volts. Seulement 120 volts est permis.

13. Ne pas essayer de réparer le moteur

électrique. Toutes réparations du

moteur électrique doivent être

complétées à un atelier de réparations

de moteur certifié.

Ne jamais toucher

marche. Les moteurs modernes sont

conçus pour le fonctionnement aux

températures élevées.

14. Éviter le tortillement du cordon

d’alimentation et protéger le cordon

d’alimentation contre les objets

pointus, les surfaces chaudes, l’huile

et les produits chimiques. Remplacer

ou réparer les cordons endommagés

ou usés immédiatement.

Mettre hors tension

toute la pression du système avant

d’essayer d’installer, de réparer, de

déplacer ou de procéder à l’entretien.

Verrouiller le sectionneur de courant

en position ouverte. Étiqueter le

sectionneur de courant pour éviter toute

mise sous tension imprévue.

15. Garder les doigts et les objets à l’écart

des ouvertures telles que celles de

ventilation. Ne jamais introduire des

objets dans le moteur.

Risque de secousse

brancher le fi l vert (ou vert et jaune) à

une borne sous tension!

16. Pour réduire le risque de secousse

(Suite)

électrique. Cette

de fi ls doit être

d’utiliser le produit à

un moteur en

et ensuite dissiper

électrique! Ne jamais

Broche

de terre

Figure 2

électrique, la pompe devrait être

branchée directement dans une

prise de courant à 3 broches mise

à la terre et installée correctement

telle qu’indiquée sur la Figure 1. Le

fil conducteur vert (ou vert et jaune)

dans le cordon est le fil de terre. Le

moteur doit être mis à la terre avec

sûreté afin de protéger contre les

secousses électriques.

17. S’il y a une prise à 2 broches, remplacer

la prise avec une prise de courant à

3 broches mise à la terre correctement

conformément aux Code Électrique

National (National Electrical Code) et

aux codes et règlements locaux. Assurer

une mise à la terre correcte requiert

l’inspection par un électricien certifié

ou diplômé.

Ne pas manipuler

moteur de pompe avec les mains trempes,

si debout sur une surface trempe ou

humide ou debout dans l’eau. Ceci peut

résulter en secousse électrique mortelle.

Le moteur de la pompe

protecteur thermique à réenclenchement

automatique et peut se mettre en marche

sans avis. Le déclenchement du protecteur

indique le surcharge du moteur causé

par l’opération de la pompe avec une

restriction de décharge basse, tension

très élevée ou basse, installation de fi ls

incorrecte, branchements de moteur

incorrects ou moteur/pompe défectueux.

Montage

SITUATION

Choisir un site aussi près de l’alimentation

d’eau que possible. S’assurer de se conformer

à tous les codes d’état ou locaux portant sur

le placement de la pompe. L’équipement

doit être protégé des éléments. Un sous-sol

ou une station de pompage chauffée est

un bon endroit. S’assurer que la pompe est

bien ventilée. La température ambiante de

la pompe ne doit pas dépasser 40 °C (100 °F)

sinon il pourrait y avoir un déclenchement

intempestif de surcharge de moteur.

TUYAUTERIE

Les tuyaux peuvent être de cuivre,

d’acier, de plastique de PVC rigide ou de

plastique de polyéthylène fl exible.

TEST

Prise de courant

mise à la terre

la pompe ni le

est équipé d’un

RESET

Un tuyau fl exible

n’est pas recommandé

sur le tuyau d’aspiration (tuyau d’entrée).

Le détecteur d’écoulement est conçu pour

une connexion de 2,54 cm (1 po) NPT.

La tuyauterie doit être propre et libre de

rouille ou de tartre. Appliquer du ruban

de téfl on® ou du mastic aux fi lets du tuyau

de 2,54 cm (1 po) mâle NPT et installez

l’interrupteur dans le système de tuyauterie.

Enfi ler l’interrupteur de débit sur le fi let du

tuyau mâle jusqu’à ce qu’il soit bien serré à

la main. Resserrer le tuyau 1 d’un autre tour.

Si le joint n’est pas approprié, continuer

à tourner le tuyau en incréments de 1/4 de

tour. Ne pas dépasser 1 autre tour Toutes

les connexions doivent être étanches pour

assurer un fonctionnement normal.

Incliner tous les tuyaux d’entrée vers

le haut et vers la pompe pour éviter

d’emprisonner l’air.

IMPORTANT: La pompe est fabriquée

pour traiter l’eau propre seulement, elle

n’est pas conçue pour l’eau contenant

du sable, de la vase ou autres abrasifs.

1. Voir la fi gure 3 pour les installations

typiques.

2. Boulonner le système de surpresseur

à une base sécure.

3. Placer la pompe pour qu’il y ait

toujours une alimentation positive

d’eau à la pompe (voir la fi gure 3).

4. Pour la commodité du service, il est

recommandé à l’installateur d’ajouter

des vannes d’obturateur et des raccords

au besoin pour faciliter l’entretien.

5. On recommande des manomètres

d’entrée et de sortie, fournis par

l’installateur pour montrer s’il y a

assez d’eau fournie à la pompe et

pour montrer la pression de service.

Électricité

Risque de choc

électrique Cette

pompe est conçue seulement pour une

utilisation à l’intérieur.

Mettre hors tension

et ensuite dissiper

toute la pression du système avant

d’essayer d’installer, de réparer, de

déplacer ou de procéder à l’entretien.

IMPORTANT: Ne pas utiliser de rallonges

ni de fi ls épissurés. Les joints devraient

se faire dans une boîte de connexion

approuvée. Si l’information précédente

prête à confusion, consulter un

électricien agréé.

L’appareil est fourni avec un pressostat,

un détecteur d’écoulement et une

boîte de contrôle. La seule connexion

de fi l nécessaire est de brancher les

deux fi ls rouges de la boîte de contrôle

dans les deux fi ls rouges du détecteur

d’écoulement (voir la fi gure 3).

10 Fr

Page 11

Instructions d’Utilisation et Manuel de Pièces SBS50 Boost

Interrupteur

de débit

Vers le service

Connexions

d’interrupteur

de débit

Fiche de 120 V c.a.

Figure 3 - Installation typique

PROTECTION DU MOTEUR

Ce moteur a une protection thermique

intégrée. La surcharge protège le moteur

contre le grillage suite à une surcharge

de basse tension, haute tension et autres

causes. L’appareil est automatique et

se réinitialise après que la température

atteint un point sécuritaire. Des

déclenchements fréquents de l’appareil

indiquent un problème du moteur ou des

lignes de courant et il faut une attention

immédiate.

Ne jamais examiner,

changer les câbles ou

toucher le moteur avant de mettre le tout

hors tension à l’interrupteur principal.

L’appareil thermique pourrait avoir ouvert

le circuit électrique. Le moteur de pompe

doit être doté d’un sectionneur à fusibles

appropriés pour fournir la protection.

Consulter les codes d’électricité locaux ou

le United States National Electrical Code

pour la protection appropriée à fusibles.

Clapet de non-retour

Vannes

d’isolement

AMORÇAGE

REMARQUE : Avant de mettre la pompe

en marche, il faut absolument que la

pompe et le tuyau d’entrée soient

entièrement remplis d’eau.

INSTALLATIONS DES SURPRESSEURS

L’amorçage est automatique lorsque la

pompe est branchée à une source de

pression comme une bouche d’incendie ou

une conduite publique. (Voir la fi gure 3).

1. Ouvrir les vannes ou la buse du

côté de décharge et d’entrée de la

pompe.

2. Ouvrir un robinet le plus proche du

surpresseur. Brancher la pompe dans

une prise. Lorsque le débit d’eau du

robinet atteint quatre litres ou un

gallon à la minute ou plus, la pompe

démarrera automatiquement.

Fonctionnement

L’appareil doit

être plein de fl uide

avant de mettre en marche. Ne pas faire

fonctionner à sec ou contre une décharge

fermée. Ne pas pomper d’eau sale ou de

liquides abrasifs. Ceci mènerait à la défaillance

de la pompe et annulera la garantie.

VANNES

Les vannes d’isolement d’entrée et

de sortie devraient être en position

complètement ouverte.

Figure 4 - Joint d’Arbre

REMARQUE : Orienter

l’interrupteur de débit

comme indiqué

Eau

municipale

Soupape de

retenue

Manostat

Réservoir

REMARQUE : Les « T »,

les coudes et les vannes

d’isolement ne sont pas inclus

Vis d’Assemblage

Moteur

Turbine

Garder le robinet ouvert pendant

environ 30 secondes pour dégager

l’air emprisonné dans la conduite.

Lorsque le robinet est fermé, la

pompe continuera à fonctionner

jusqu’à ce que la pression atteigne

414 kPa (60 lb/po²).

Le pressostat est

réglé en usine à 345

kPa (50 lb/po²) et ne doit pas être modifi é.

3. Si l’on installe un manomètre à

l’entrée de la pompe, un relevé

d’au moins 14 kPa (2 lb/po²) devrait

apparaître lorsque la pompe est en

marche. Ce relevé assure qu’il y a

suffi samment d’eau dans le boîtier

d’entrée de la pompe.

4. Le contrôleur, le détecteur

d’écoulement et le pressostat

surveillent continuellement la

pression et le débit d’eau. Le système

éteint automatiquement l’appareil

si la pression atteint 345 à 365 kPa

(50 à 53 lb/po²). La trousse de

contrôle protège aussi l’appareil

de tout fonctionnement à sec en

s’arrêtant si l’usage d’eau tombe sous

quatre litres ou 1 gallon à la minute.

ROTATION DE POMPE/MOTEUR

1. Le moteur tourne dans une rotation

antihoraire lorsqu’il est face à

l’extrémité de la pompe et ne peut

pas être inversé.

PROCÉDURE DE DÉMARRAGE

Après avoir terminé les instructions

précédentes, l’appareil est prêt pour une

utilisation normale.

1. Durant les premières heures de

fonctionnement, inspecter la

pompe, la tuyauterie et tout autre

équipement auxiliaire utilisé avec

l’appareil pour tout signe de fuites,

vibrations excessives ou bruits

inhabituels.

2. Le surpresseur se mettra en marche

et s’éteindra automatiquement selon

l’usage d’eau.

Plaque

d’Etanchéité

Diffuseur

Vis d’Assemblage

Carter de

Pompe

(Volute)

Venturi

11 Fr

Page 12

Instructions d’Utilisation et Manuel de Pièces SBS50 Boost

Entretien

Mettre hors

tension et ensuite

dissiper toute la pression du système

avant d’essayer d’installer, de réparer,

de déplacer ou de procéder à l’entretien.

Verrouiller le sectionneur de courant

en position ouverte. Étiqueter le

sectionneur de courant pour éviter

toute mise sous tension imprévue.

Protéger la pompe du

gel pendant l’hiver.

DRAINER LA POMPE

Des ouvertures de drainage sont fournies

sur tous les modèles. Pour drainer la pompe:

1. Retirer le bouchon de vidange et

le bouchon de remplissage pour

ventiler le système.

RETIRER LE VIEUX JOINT

D’ÉTANCHÉITÉ DE L’ARBRE

Mettre le sectionneur

à la position « off »

(arrêt).

1. Ouvrir un robinet près du réservoir et

laisser toute l’eau sortir du réservoir.

2. Retirer les quatre vis d’assemblage

retenant le boîtier de la pompe

9. Pousser ou sortir et dégager le siège

de céramique de la plaque de joint

(fi gure 5).

10. Retirer les particules meubles du moyeu

d’impulseur et de la plaque de joint.

INSTALLER LE NOUVEAU JOINT

D’ÉTANCHÉITÉ DE L’ARBRE.

Avant de manipuler

de l’arbre, il faudrait se laver les mains.

La saleté ou la graisse peut endommager

le joint.

1. Mouiller l’intérieur de la cavité du joint

sur la plaque et le godet de caoutchouc

enfermant le nouveau siège de

céramique avec de l’huile de cuisson.

Attention de ne pas égratigner la

surface de céramique du siège du joint

et pousser le siège enfermé dans le

caoutchouc dans la capacité du joint sur

la plaque du joint. Utiliser une rondelle

de carton pour protéger la surface

polie en poussant contre le siège de

céramique avec tout objet. S’assurer de

retirer la rondelle de carton.

2. Glisser avec soin la plaque de joint sur

l’arbre. Ne pas déplacer la position du

joint dans la plaque de joint. La plaque

de joint doit être orientée durant

(volute) au moteur (fi gure 4).

3. Séparer le boîtier de la pompe (volute)

du moteur pour exposer le diffuseur et

la plaque de joint.

4. Retirer les deux vis d’assemblage et le

diffuseur de la plaque de joint pour

exposer l’impulseur.

5. Retirer les petit bouchon d’extrémité à

l’extrémité du moteur du côté opposé

de l’impulseur.

6. Avec un large tournevis ou une clé

Figure 6 - Replacement de Plaque

d’Etanchéité

ajustable, empêcher l’arbre de tourner

et retirer l’impulseur à la main (fi let

standard de main droite). S’assurer

de tenir la plaque de joint en retirant

l’impulseur de l’arbre.

7. Retirer la plaque de joint.

8. Sortir la section du joint de l’arbre

rotatif de l’impulseur (fi gure 5).

Plaque

d’Étanchéité

les pièces du joint

Trous de

Vis

Arbre de

Moteur

l’assemblage pour que les deux trous de

vis soient à l’horizontale à travers l’arbre

du moteur et les (4) goupilles de montage

à l’arrière de la plaque de joint s’alignent

avec les languettes du boîtier du moteur

(fi gure 6). Ceci devrait se faire pour

assurer un bon drainage et amorçage.

3. Placer en place la section du joint

de l’arbre rotatif en position sur

l’impulseur et enfoncer en place.

Attention de ne pas presser contre la

surface polie du joint.

4. Placer l’impulseur sur l’arbre et bien

resserrer (fi gure 7).

5. Fixer le diffuseur à la plaque de joint

avec les deux vis d’assemblage. S’assurer

que les vis sont orientées à l’horizontale

selon la description de l’étape 2.

6. Placer avec soin le joint d’étanchéité

du boîtier de la pompe (volute) sur le

diffuseur sur la plaque de joint. Pour

toutes les applications de puits peu

profonds, il faut s’assurer que le joint

torique est propre et bien placé sur

le venturi. Nettoyer et positionner

permet d’obtenir une bonne

étanchéité à l’intérieur du diffuseur

assemblé.

7. Assembler le boîtier de la pompe

(volute) au moteur avec les quatre vis

d’assemblage. S’assurer que le joint

d’étanchéité du boîtier de la pompe

(volute) est placé correctement et

bien resserrer les vis.

REMARQUE : L’arbre doit tourner

librement et le chapeau d’extrémité

du moteur doit être bien fi xé avant

l’opération.

Moteur

Turbine

Plaque

d’Étanchéité

Piéce de

Joint d’Arbre

Rotative

Figure 5 - Enlever le Joint d’Arbre

et le Siège Céramique

Plaque

d’Etanchéité

Turbine

Bague de

Siége en

Caoutchouc

Siége

Céramique

Siège de

Joint

La Face du Joint Doit

être Propre pour un

Joint Étanche

Figure 7 - Arbre du Moteur

12 Fr

Page 13

Instructions d’Utilisation et Manuel de Pièces SBS50 Boost

Guide de Dépannage

PRÉCAUTIONS ÉLECTRIQUES - Avant tout entretien ou réparation de pompe, toujours couper le courant au

disjoncteur, puis débrancher la pompe. S’assurer de ne pas être debout dans l’eau et de porter des chaussures à

semelles de protection isolées. Sous des conditions d’inondation, contacter la société locale d’électricité ou un électricien agréé qualifi é

pour couper le service électrique avant le retrait de la pompe.

Symptôme Cause(s) Possible(s) Mesure Corrective

La pompe ne démarre pas

ou ne fonctionne pas à

pleine vitesse

La pompe fonctionne,

mais donne peu ou

aucune eau

Bruit excessif en pompant 1. Pompe non fi xée à une base ferme 1. Fixer correctement

La pompe fuit 1. Garniture mécanique usée (fuite à l’arbre) 1. Remplacer le joint de l’arbre (rotatit)

1. Fusible grillé ou disjoncteur déclenché 1. Remplacer le fusible ou fermer le disjoncteur

2. Courant c.a. coupé 2. Mettre sous tension

3. Mauvaise tension 3. Basse tension

4. Moteur défectueux 4. Remplacer le moteur

5. Composants internes de la pompe

bloqués/usés/endommagés

1. Vannes aplombées dans le système

réduisant la circulation

2. Filtre en ligne réduit la circulation 2. Vérifi er tous les fi ltres en ligne pour s’assurer

3. Basse tension de ligne 3. Voir la mesure corrective de basse tension de

4. Approvisionnement d’eau insuffi sant

pour surpression de pompe

5. Tuyauterie sous dimensionnée 5. Replacer la tuyauterie sousdimensionnée

6. Fuite côté entrée du système 6. S’assurer que les connexions sont serrées. Réparer

7. Pompe ou pièces de pompe défectueuses

ou usées

8. Soulèvement d’aspiration trop élevé 8. La pompe devrait fonctionner seulement sous

9. Pompe ne s’amorce pas 9. Amorcer la pompe. S’assurer que les connexions

2. Tuyauterie non supportée 2. Ajuster

3. Conduite d’entrée entravée 3. Nettoyer, corriger ou éliminer les restrictions

4. Cavitation (pompage vibre) 4. Augmenter la taille de la conduite d’aspiration

5. Roulements de moteur usés 5. Remplacer le moteur

2. Joint torique endommagé 2. Remplacer le joint d’étanchéité de caoutchouc

Consulter le tableau des fi ls pour la bonne taille

de fusible/disjoncteur

a. La tension doit être dans ± 10 % de tension du

moteur Vérifi er la tension en entrée. Contacter

les services publics d’électricité

b. La tension du moteur est réglée à 120 V c.a.

Le système n’est pas conçu pour un

service de 240 V.

5. Remplacer les pièces usées ou toute la pompe.

Nettoyer les pièces, au besoin

1. a. Ouvrir les vannes des côtés de décharge et

d’entrée de la pompe du système. S’assurer

qu’elles sont entièrement ouvertes pour laisser

la circulation aller-retour de la pompe.

b. Purger l’air enfermé dans la pompe. (normale-

ment à cause d’une vanne fermée dans la

plomberie de décharge).

qu’ils ne sont pas bloqués ou entravés.

ligne (plus haut)

4. Vérifi er la pression du côté d’entrée du surpresseur pour s’assurer que la pression positive est

maintenue au surpresseur en tout temps.

les fuites au besoin

7. Remplacer les pièces usées ou tout l’impulseur

bloqué. Nettoyer les pièces, au besoin

l’aspiration inondée. Voir la mesure corrective

4 plus haut.

de la tuyauterie d’entrée sont resserrées et que

la pompe et la tuyauterie sont pleines d’eau.

de l’anneau carré

13 Fr

Page 14

Instructions d’Utilisation et Manuel de Pièces SBS50 Boost

Pour Pièces de Rechange ou assistance technique,

appeler 1-888-636-6628

S’il vous plaît fournir l’information suivante:

Adresser toute correspondance à:

- Numéro du modèle

Blue Angel Pumps

- Code Estampé

101 Production Drive

- Description et numéro de la pièce

Harrison, OH 45030 U.S.A.

16

1

2

3

4

6

5

7

9

17

8

10

18

12

13

11

14

15

No. de

Ref. Description

1

2

3

4•

5•

6

7

8

9•

10

11

12

13

14

15

16

Moteur

Vis

Plaque de joints

Joint de caoutchouc à anneau carré

Assemblage de boîte d’étanchéité

Rotor

Diffuseur

Vis

Joint torique

Venturi

Buse

Bouchon d’amorçage 3/4 po

Volute

Bouchon d’amorçage 1/4 po NPT

Bouchon d’amorçage 1/8 po NPT

Base

Numbéro de

Pièces Qté.

32059-001 1

16636-002

17145-001 1

17150-001 1

56393 1

23285-002 1

17148-001 1

67007-001

15557 1

17151-002 1

15672 1

15921 1

56869-001 1

16314-002 1

15766-002 1

23029-001 1

17 Pressostat 30010-001 1

18 Interrupteur de débit 30048-001 1

•

Nécessaire de réparation (Indut #4, 5 and 9) 56874-001 1

14 Fr

Page 15

Instructions d’Utilisation et Manuel de Pièces SBS50 Boost

Notes

15 Fr

Page 16

Instructions d’Utilisation et Manuel de Pièces SBS50 Boost

Garantie Limitée

Pour deux (2) ans à compter de la date d’achat, Blue Angel™ Pumps (« Blue angel ») réparera ou remplacera, à son choix,

pour l’acheteur original, toute pièce(s) de sa Pompe de puisard ou Pompe à eau (le « Produit ») qui, après une inspection par

Blue angel, s’est révélée défectueuse en matière ou en fabrication. S’il vous plaît appeler Blue angel (1-888-636-6628) pour

des instructions ou contacter votre marchand. S’assurer d’avoir, à votre disposition, le numéro du modèle afin d’effectuer

cette garantie. Les frais de transportation des Produits ou pièces soumis pour la réparation ou le remplacement sont la

responsabilité de l’acheteur.

Cette Garantie Limitée ne couvre pas les Produits qui se sont fait endommagés en résultat d’un accident, utilisation abusive,

mauvais usage, négligence, l’installation incorrecte, entretien incorrect, ou manque d’utilisation conformément aux

instructions écrit de Blue angel.

IL N’Y A AUCUNE AUTRE GARANTIE EXPRESSE. LES GARANTIES IMPLICITES, Y COMPRIS CELLES DE

COMMERCIALISATION OU CONVENABLE À UN USAGE PARTICULIER, SONT LIMITÉES À DEUX (2) ANS, À COMPTER DE

LA DATE D’ACHAT. CECI EST LA REMÈDE EXCLUSIVE ET N’IMPORTE QUELLE RESPONSABILITÉ POUR N’IMPORTE QUEL

ET TOUT DOMMAGES INDIRECTS OU DÉPENSES QUOI QUE SE SOIT EST EXCLUS.

Certaines Provinces n’autorisent pas de limitations de durée pour les garanties implicites, ni l’exclusion ni la limitation des

dommages fortuits ou indirects. Les limitations précédentes peuvent donc ne pas s’appliquer. Cette garantie limitée donne, à

l’acheteur, des droits légales précis, et vous pouvez avoir autres droits légales qui sont variable d’une Province ou d’un État à

l’autre.

En aucun cas, soit par suite d’un rupture de contrat de garantie, acte dommageable (y compris la négligence) ou autrement,

ni Blue angel ou ses fournisseurs seront responsables pour aucune dommage spéciale, incidentel ou pénal, y compris, mais

pas limité à la perte de profits ou recettes, la perte d’usage des produits ou n’importe quel équipement associé, dommage à

l’équipement associé, coût de capital, coût de produits remplaçants, aménagements, services ou abilité de remplaçement, coût

de temps que le produit n’est pas en service, ou la réclamation des clients de l’acheteur pour ces dommages.

Vous DEVEZ garder votre facture d’achat avec ce bulletin. Il est NÉCESSAIRE d’envoyer une COPIE de la recette d’achat avec

le matériel ou correspondance afin d’effectuer une réclamation de la garantie. S’il vous plaît appeler Blue angel (1-888-636-

6628) pour l’autorisation et instructions concernant le renvoi.

NE PAS ENVOYER, PAR LA POSTE, CE BULLETIN À BLUE ANGEL. Utiliser ce bulletin seulement pour vos archives.

Nº DU MODÈLE________________________ Nº DE SÉRIE______________________ DATE D’INSTALLATION________________________

FIXER VOTRE FACTURE ICI

16 Fr

Page 17

Manuel de Instrucciones y Lista de Piezas SBS50 Boost

Sírvase leer y conservar estas instrucciones. Léalas con cuidado antes de intentar armar, instalar,

operar o efectuar mantenimiento al producto descrito. Protéjase a sí mismo y a los demás observando

la información de seguridad. El no cumplir con estas instrucciones podría provocar lesiones personales

The Professional’s Line

y/o daños materiales. Conserve estas instrucciones para futura referencia.

Sistema de aumento de la presión

Descripción

La bomba reforzadora está diseñada para

aumentar la presión del agua de fuentes

municipales o sistemas de agua privados.

La unidad está equipada con un motor

monofásico de 1/2 HP y 120 voltios. Use

la bomba únicamente para bombear

agua limpia. El sistema incluye la bomba,

la caja de control, el interruptor con

sensibilidad de presión, el depósito

fl exible y el interruptor sensor del fl ujo.

No intente usar

el producto a 240

voltios. Permite únicamente 120 voltios.

Desempacar

Al desempacar este producto, reviselo con

cuidado para cerciorarse de que este en

perfecto estado. Igualmente, cerciorese

de apretar todos los pernos, tuercas y

conexiones antes de usarlo.

Medidas de Seguridad

Este manual contiene información que es

muy importante conocer y comprender.

Esta información se proporciona con

fi nes de SEGURIDAD y para EVITAR

PROBLEMAS CON EL EQUIPO. Para

ayudarlo a reconocer esta información,

observe los siguientes símbolos:

Peligro indica una

situación de riesgo

inminente, la cual, si no se evita,

provocará la muerte o graves lesiones.

Advertencia indica

una situación

potencialmente riesgosa, la cual, si no se evita,

podría provocar la muerte o graves lesiones.

Precaución indica una

situación potencialmente

riesgosa, la cual, si no se evita, puede provocar

lesiones menores o moderadas.

Aviso indica

información

importante, la cual, si no se cumple, puede

ocasionar daño al equipo.

Généralités sur la

Sécurité

PROPOSICIÓN 65 DE CALIFORNIA

Este producto, o su

cordón eléctrico,

puede contener productos químicos

conocidos por el estado de California

como causantes de cáncer y defectos de

nacimiento u otros daños reproductivos.

Lave sus manos después de usar.

INFORMACIONES GENERALES DE

SEGURIDAD

1. Lea con atención el manual de

instrucciones incluido con este

producto. Familiarícese bien con

los controles y el uso adecuado del

equipo.

2. Conozca las aplicaciones, las

limitaciones y los posibles peligros

de la bomba.

Instale siempre una

válvula de alivio

de la presión para que la presión del

sistema y el fl ujo máximo correspondan

con los que debe tener el sistema.

No use la bomba

para líquidos

infl amables ni explosivos como gasolina,

aceite, querosén, etc. No la use en

ambientes explosivos. La bomba sólo se

debe usar con líquidos que sean compatibles

con los materiales de que están hechas

las piezas de la bomba. El no cumplir con

estas advertencias puede provovar lesiones

personales y/o daños materiales.

Desconecte la

corriente eléctrica

y libere toda la presión del sistema

antes de intentar instalar, darle servicio,

mantenimiento o cambiarlo de lugar.

Trabe el desconector de corriente en

la posicion de abierto, y rotúlelo para

evitar una aplicación inesperada de

corriente.

3. Antes de darle servicio, drene todos

los líquidos del sistema.

Figure 1

4. Mantenga sujeta la tubería de descarga

antes de hacer funcionar la bomba. Una

tubería de descarga que no esté sujeta

golpeará y es posible que cause lesiones

personales y/o daños materiales.

5. Inspeccione periódicamente la bomba

y los componentes del sistema. Lleve a

cabo el mantenimiento de rutina según

sea necesario (Vea Mantenimiento).

6. SEGURIDAD PERSONAL:

a. Use anteojos de seguridad todo el

tiempo que trabaje con la bomba.

b. Mantenga la zona de trabajo

despejada, limpia y con la

iluminación adecuada, guarde

todas las herramientas y el equipo

que no se hayan usado.

c. Mantenga a los visitantes a una

distancia segura de la zona de trabajo.

d. Haga que el taller sea a “prueba de

ninos,” use candados, interruptores

maestros y retire las llaves de arranque.

7. No bombee químicos ni líquidos

corrosivos. El bombear ese tipo de

líquidos acorta la vida de los sellos

de las bombas y las piezas móviles e

invalidará la garantía.

8. El sistema completo de la bomba y la

tubería DEBE estar protegido contra

temperaturas por debajo del punto

de congelamiento. Las temperaturas

de congelamiento pueden causar

daños serios e invaldiar la garantía.

RECORDATORIO: ¡Guarde su comprobante de compra con fecha para fi nes de la garantía!

© 2010 Blue Angel™ Pumps

Adjúntela a este manual o archívela en lugar seguro.

341602-002 7/10

Page 18

Manuel de Instrucciones y Lista de Piezas SBS50 Boost

Informaciones Generales

de Seguridad

9. No haga funcionar la bomba en seco,

si lo hace, se puede dañar.

Existe riesgo de

Está bomba está diseñada únicamente para

ser instalada en interiores.

Esta bomba

ser instalada exclusivamente en interiores.

La instalación no en interiores aumenta

signifi cativamente el riesgo de heridas o

muerte por choque eléctrico.

10. Para máxima seguridad, la unidad

se debe conectar a un circuito con

conexión a tierra que tenga un

dispositivo de interrupción para

cuando falle la conexión a tierra.

11. Antes de instalar la bomba, haga

que un electricista certificado o con

licencia verifique el tomacorriente

para comprobar que tenga una

conexión a tierra adecuada.

12. Asegúrese de que las conexiones

eléctricas del motor sean adecuadas

para el voltaje y la frecuencia de la

linea de suministro eléctrico.

No intente usar

voltios. Permite únicamente 120 voltios.

13. No intente reparar el motor eléctrico.

Todas las reparaciones del motor

deben hacerse en un taller certificado

o con licenia para reparar motores

eléctricos.

No toque un motor

Los motores modernos están diseñados

para trabajar a altas temperaturas.

14. Evite doblar el cordón de electricidad

y protéjalo de objetos cortantes,

superficies calientes, aceite y químicos.

Reemplace o repare los cordones

dañados o gastados de inmediato.

Desconecte la energía

presión del sistema antes de intentar

instalar, realizar un servicio, reubicar o

realizar cualquier tipo de mantenimiento.

Trabe la desconexión de la energía en

la posición abierta. Etiquete la conexión

de la energía para evitar la aplicación

de energía inesperada.

15. Mantenga los dedos y los objetos

extraños alejados de la ventilación

y otras aberturas. No inserte ningún

objeto en el motor.

Existe riesgo de un

Nunca conecte el alambre verde (o el verde y

amarillo) a un terminal con corriente.

16. Para reducir el riesgo de choque eléctrico,

la bomba se debe enchufar directamente

( Continuación)

un choque eléctrico.

está diseñada para

el producto a 240

en funcionamiento.

y libere toda la

choque eléctrico!

Terminal para

conexión a

tierra

Figura 2

en un tomacorriente para tres patillas

debidamente instalado y conectado a

tierra, como se muestra en la Figura 1.

El conductor verde (o verde y amarillo)

del cordón es el alambre a tierra. Para la

protección contra el choque eléctrico, el

motor debe estar conectado a tierra en

forma segura y adecuada.

17. Cuando se encuentre un tomacorriente

para dos patillas se debe reemplazar con

uno para tres patillas de acuerdo con

el Código Nacional de Electricidad de

EUA y los códigos y ordenanzas locales.

Para estar seguro de que la conexión a

tierra sea adecuada, la debe probar un

electricista certificado o con licenia.

No mani pule la

con las manos mojadas, ni cuando esté

parado en superfi cies húmedas, mojadas

o en el agua. Puede ocurrir un choque

eléctrico fatal.

El motor de la

con un protector automático termal de

recalibración por lo que puede volver a

funcionar en forma inesperada. Cuando

el protedctor hace la desconexión, esto

es una indicación de que el motor está

sobrecargado porque la bomba está

funcionando a niveles bajos (restricción de

descarga baja), el voltaje es excesivamente

bajo o alto, el cableado es inadecuado, las

conexiones del motor no son las correctas

o el motor o la bomba tiene defectos.

Instalación

LUBICACIÓN

Elija un lugar tan cerca del agua como

sea posible. Asegúrese de cumplir con los

códigos estatales o locales referentes a la

ubicación de la bomba. El equipo debe ser

protegido de las inclemencias climáticas.

Un sótano o una cubierta para bomba de

calor es una buena ubicación. Asegúrese

de que la bomba tenga una ventilación

adecuada. La temperatura que rodea la

bomba no debe exceder los 100 ºF (40 ºC)

o el motor podría sobrecargarse causando

interrupciones molestas.

TUBERÍA

La tubería puede ser de cobre, acero, plástico

PVC rígido o plástico polietileno fl exible.

RESET

TEST

Tomacorriente

conectado a tierra

bomba ni su motor

bomba está equipado

No se recomienda

una tubería fl exible

para la tubería de succión (tubería de

entrada). El sensor de fl ujo está diseñado

para una conexión NPT de 1 pulg.

La tubería debe estar limpia y sin óxido ni

sarro. Aplique cinta para roscas de Tefl on

®

o sellante a las roscas de la conexión NPT

macho de 1 pulg. e instale el interruptor

en el sistema de tuberías. Enrosque el

interruptor de fl ujo en la rosca de la

tubería macho hasta que quede apretado

manualmente. Ajuste la tubería una

vuelta más. Si el sellado no es adecuado,

continúe girando la tubería en la unidad

en incrementos de 1/4 de vuelta. No exceda

1 vuelta adicional. Todas las conexiones

deben ser herméticas para asegurar un

funcionamiento normal.

Coloque todas las tuberías de entrada con

pendiente hacia arriba hacia la bomba para

evitar que quede aire atrapado.

IMPORTANTE: la bomba está construida

para funcionar únicamente con agua

limpia; no está diseñada para funcionar

con agua que contenga arena, cieno u

otros abrasivos.

1. Consulte la Figura 3 para ver la

instalación típica.

2. Asegure con pernos el sistema de

aumento de la presión a una base

segura.

3. Ubique la bomba de forma que

siempre haya un suministro positivo

de agua a la bomba (consulte la

Figura 3).

4. Para practicidad del servicio, se

recomienda al instalador agregar

válvulas de compuerta y uniones

según sea necesario para proporcionar

un mantenimiento más fácil.

5. Se recomienda la instalación de

manómetros en la entrada y la salida,

proporcionados por el instalador, para

mostrar si se suministra sufi ciente

agua a la bomba y para mostrar la

presión del servicio.

Eléctricas

Riesgo de choque

está diseñada únicamente para la

instalación en interiores.

Desconecte la

toda la presión del sistema antes de

intentar instalar, realizar un servicio,

reubicar o realizar cualquier tipo de

mantenimiento.

IMPORTANTE: no use un cable de

extensión ni cables empalmados. Las

juntas deben hacerse en una caja de

empalmes aprobada. Si la información

anterior es confusa, consulte a un

electricista licenciado.

Su unidad se entrega con un interruptor

eléctrico. Esta bomba

energía y libere

18 Sp

Page 19

Manuel de Instrucciones y Lista de Piezas SBS50 Boost

Interruptor

Para realizar

servicio

Conexiones

de interruptor

de fl ujo

Enchufe 120 V CA

Figura 3 - Instalación típica

Eléctricas

( Continuación)

de fl ujo

Válvula de

aislamiento

de presión, un sensor de fl ujo y una caja

de control. La única conexión de cable que

se necesita es para enchufar los dos cables

rojos de la caja de control a los dos cables

rojos del sensor de fl ujo (ver Figura 3).

PROTECCIÓN DEL MOTOR

Este motor tiene protección térmica

incorporada. La sobrecarga protege

el motor de quemarse por sobrecarga

de bajo voltaje, alto voltaje y otras

causas. El dispositivo es automático y

se reinicia una vez que la temperatura

haya bajado a un punto seguro. La

interrupción frecuente del dispositivo

indica problemas en el motor o en las

líneas de energía y debe atenderse

inmediatamente.

Nunca examine,

el cableado ni toque el motor antes de

desconectar el interruptor de suministro

eléctrico principal. El dispositivo

térmico puede haber abierto el circuito

eléctrico. El motor de la bomba debe

estar equipado con un interruptor de

desconexión con fusibles correctamente

colocados para proporcionar protección.

Consulte el código eléctrico nacional de

los Estados Unidos o el código local para

una protección por fusibles adecuada.

haga cambios en

NOTA: oriente el interruptor de

fl ujo como se indica

Valvula de chequeo

Presostato

contra una salida cerrada. No bombee agua

sucia ni líquidos abrasivos. Hacerlo hará

que la bomba falle e invalidará la garantía.

VÁLVULAS

Las válvulas de aislamiento de entrada

y salida deben estar en la posición

totalmente abierta.

CEBADO

NOTA: antes de iniciar la bomba es

absolutamente necesario que tanto la

bomba como la tubería de entrada

estén completamente llenas de agua.

INSTALACIONES PARA EL AUMENTO

DE LA PRESIÓN

El cebado es automático cuando la

bomba está conectada a una fuente de

presión como un hidrante o una toma

de agua industrial. (Vea la Figura 3).

1. Abra las válvulas o la boquilla en

los lados de la entrada y salida de la

bomba.

Motor

Agua del

servicio

público

Valvula de chequeo

Tanque

NOTA: las conexiones en

“T”, los codos y las válvulas

no están incluidas.

Tornillos de Casquetes

2. Abra el grifo que se encuentre más

cerca de la unidad de aumento de

la presión. Enchufe la bomba en la

salida. Cuando el fl ujo de agua del

grifo llega a un galón por minuto,

o más, la bomba se encienda

automáticamente. Mantenga el

grifo abierto aproximadamente

durante 30 segundos para liberar

el agua de la línea. Cuando se

cierre el grifo, la bomba continuará

funcionando hasta que la presión

llegue a 60 psi.

El interruptor

de presión está

confi gurado de fábrica a 50 psi y no debe

ser cambiado.

3. Si instaló un manómetro en la

entrada de la bomba, debe haber una

lectura de un mínimo de 2 psi siempre

que la bomba esté funcionando. Esta

lectura asegura que existe un amplio

suministro de agua en la entrada de

la caja de la bomba.

4. El controlador, el sensor de fl ujo y

el interruptor de presión controlan

continuamente la presión y el fl ujo

de agua. El sistema automáticamente

apaga la unidad si la presión llega

de 50 a 53 psi. El paquete de control

también protege la unidad del

funcionamiento en seco apagándose

si el uso de agua baja a menos de

1 galón por minuto.

ROTACIÓN DEL MOTOR/LA BOMBA

1. El motor gira hacia la derecha

cuando está de frente al extremo

de la bomba y no puede invertirse.

PROCEDIMIENTO DE ENCENDIDO

Una vez completadas las instrucciones

anteriores, la unidad está lista para el

funcionamiento normal.

1. Durante las primeras horas de

funcionamiento, inspecciones la

bomba, la tubería y cualquier otro

equipo auxiliar usado en conexión

con la unidad para verifi car que

la unidad no presenta pérdidas,

vibración excesiva o ruidos inusuales.

2. La unidad de aumento de la

presión se encenderá y se apagará

automáticamente, según el uso

del agua.

Placa de Sellado

Difusor

Tornillos de Casquetes

Cubierta

en Espiral

(Voluta)

Funcionamiento

La unidad debe estar

llena de líquido antes

de funcionar. No haga funcionar en seco o

Impulsor

Venturi

Figura 4 - Bomba Convertible para Pozos

19 Sp

Page 20

Manuel de Instrucciones y Lista de Piezas SBS50 Boost

Maintenimiento

Desconecte la

energía y libere toda

la presión del sistema antes de intentar

instalar, realizar un servicio, reubicar o

realizar cualquier tipo de mantenimiento.

Trabe la desconexión de la energía en

la posición abierta. Etiquete la conexión

de la energía para evitar la aplicación

de energía inesperada.

Proteja la bomba

del congelamiento

durante las condiciones invernales.

9. Empuje o saque el asiento cerámico

de la placa de sellado (Figura 5).

10. Quite las partículas sueltas del cubo

del impulsor y la placa de sellado.

INSTALACIÓN DE UN NUEVO

SELLO DEL EJE

Antes de manipular

eje límpiese las manos. La tierra o la grasa

pueden dañar el sello.

1. Moje la parte interna de la cavidad

del sello en la placa de sellado y

la copa de goma que protege el

DRENAJE DE LA BOMBA

Todos los modelos cuentan con

aberturas para el drenaje. Para drenar

la bomba:

1. Quite el tapón del drenaje y el tapón

de cebado para ventilar el sistema.

CÓMO QUITAR UN SELLO DE EJE VIEJO

Coloque el interruptor

de desconexión en la

posición “off” (apagado).

1. Abra el grifo que se encuentre más

cerca del tanque y permita que toda

el agua drene del tanque.

2. Quite los cuatro tornillos de la tapa

que sostienen la caja de la bomba

(espiral) al motor (Figura 4).

3. Separe la caja de la bomba (espiral)

del motor para dejar expuesto el

difusor y la placa de sellado.

4. Quite los dos tornillos de la tapa y el

difusor de la placa de sellado para

exponer el impulsor.

5. Quite la pequeña tapa que se

encuentra en el extremo del motor

Figura 6 - Reemplazo de la Placa Sellado

nuevo asiento cerámico con aceite

de cocina. Tenga cuidado de no

rayar la superfi cie de cerámica del

asiento del sello y empuje el asiento

cubierto en gamo en la cavidad del

sello en la placa de sellado. Use una

arandela de cartón para proteger

la superfi cie pulida cuando empuje

contra un asiento de cerámica con

cualquier objeto. Asegúrese de

quitar la arandela de cartón.

2. Deslice con cuidado la placa de

sellado sobre el eje. No cambie

la posición del sello en la placa de

sellado. La placa de sellado debe

orientarse durante el armado de

del lado opuesto del impulsor.

6. Con un destornillador grande o

una llave ajustable, evite que el

eje rote y quite el impulsor con la

mano (rosca estándar a la derecha

manual). Asegúrese de sostener la

placa de sellado cuando quite el

Seal Plate

impulsor del eje.

7. Retire la placa de sellado.

8. Quite del impulsor la pieza rotatoria

del sello (Figura 5).

Pieza

Rotatoria

de Sellado

del Eje

Impulsor

Anillo de

Caucho de

Asentamiento

Place de

Sellado

las piezas del sello del

Orifi cios

para los

Tornillos

Eje del

Motor

Motor

Impeller

forma que los dos orifi cios para

tornillos estén en línea horizontal

a través del eje del motor y los (4)

pasadores de ubicación de la parte

posterior de la placa de sellado se

alineen con las lengüetas de la caja

del motor (Figura 6). Esta colocación

debe realizarse para asegurar un

drenado y un cebado correctos.

3. Coloque la parte de sellado del eje

giratorio en posición en el impulsor

y presione para colocarla en su lugar.