Blue Angel Pumps SBS100 User Manual [en, es, fr]

Jet Pump Water Systems

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or

maintain the product described. Protect yourself and others by observing all safety information. Failure to

comply with instructions could result in personal injury and/or property damage! Retain instructions for future

reference.

© 2007 Blue Angel™ Pumps

Description

Shallow well jet pumps are single stage

domestic water pumps designed for

pumping portable water in applications

where the water is located less than 25

feet vertically from the pump. A pressure switch is a standard feature. The

shallow well pump can be mounted to

either a precharged, conventional type

or free standing pressure tank.

Unpacking

After unpacking the jet pump, carefully

inspect for any damage that may have

occurred during transit. Check for

loose, missing or damaged parts.

Safety Guidelines

This manual contains information that

is very important to know and understand. This information is provided for

SAFETY and to PREVENT EQUIPMENT

PROBLEMS. To help recognize this

information, observe the following

symbols.

Danger indicates

an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

Warning indicates

a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Caution indicates a

potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

Notice indicates

important information, that if not followed, may cause

damage to equipment.

General Safety

Information

1. Read the instruction manual included

with the product carefully. Be thor-

Operating Instructions and Parts Manual SBS50, SBS75, and SBS100

oughly familiar with the controls and

the proper use of the equipment.

2. Know the pump application, limitations and potential hazards.

Always install a

pressure relief valve

to match the system pressure rating and

the maximum flow rate.

Do not use to pump

flammable or explosive fluids such as gasoline, fuel oil,

kerosene, etc. Do not use in explosive

atmospheres. Pump should only be used

with liquids compatible with pump component materials. Failure to follow this

warning can result in personal injury

and/or property damage.

Disconnect power

and release all pressure from the system before attempting

to install, service, relocate or perform any

maintenance. Lock the power disconnect

in the open position. Tag the power disconnect to prevent unexpected application of power.

Install a screen

around the inlet

pipe to prevent entrapment of swimmers.

3. Drain all liquids from the system

before servicing.

4. Secure the discharge line before

starting the pump. An unsecured discharge line will whip and possibly

cause personal injury and/or property

damage.

5. Check hoses for weak or worn condi-

tion before each use. Make certain

all connections are secure.

6. Periodically inspect pump and system

components. Perform routine maintenance as required (See

Maintenance).

7. Personal Safety:

a. Wear safety glasses at all times

when working with pumps.

b. Keep work area clean, unclut-

tered and properly lighted replace all unused tools and

equipment.

c. Keep visitors at a safe distance

from work area.

340100-002 1/07

d. Make the workshop childproof

use padlocks, master switches

and remove starter keys.

8. Do not pump chemicals or corrosive

liquids. Pumping these liquids

shortens the life of the pumps seals

and moving parts and will void the

warranty.

9. When installing pump, cover the

well to prevent foreign matter

from falling into well and contaminating the water and damaging

internal mechanical pumping components.

10. Always test the water from the

well for purity before use. Check

with local health department for

test procedure.

11. Complete pump and piping system

MUST be protected against below

freezing temperature. Freezing

temperatures could cause severe

damage and void the warranty.

12. Do not run the pump dry or damage will occur and will void warranty.

Risk of electrical

shock. This pump is

designed for indoor installation only.

All wiring should be

performed by a

licensed or certified electrician.

13. For maximum safety, the unit

should be connected to a grounded

circuit equipped with a ground

fault interrupter device.

14. Before installing the pump, have

the electrical outlet checked by a

licensed or certified electrician to

make sure the outlet is properly

grounded.

15. Make sure the line voltage and frequency of electrical current supply

agrees with the motor wiring.

16. Do not attempt repairs to the electric

motor. All repairs to the motor must

be completed at a licensed or certified electrical motor repair shop.

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

For parts, product & service information

visit www.blueangelpumps.com

General Safety

Information (Continued)

Do not touch an

operating motor.

Modern motors are designed to operate at

high temperatures.

17. Avoid kinking electrical cord and

protect from sharp objects, hot surfaces, oil and chemicals. Replace or

repair damaged or worn cords

immediately.

Disconnect power

and release all pressure from the system before attempting

to install, service, relocate or perform any

maintenance. Lock the power disconnect

in the open position. Tag the power disconnect to prevent unexpected application of power.

18. Keep fingers and foreign objects

away from ventilation and other

openings. Do not insert any objects

into the motor.

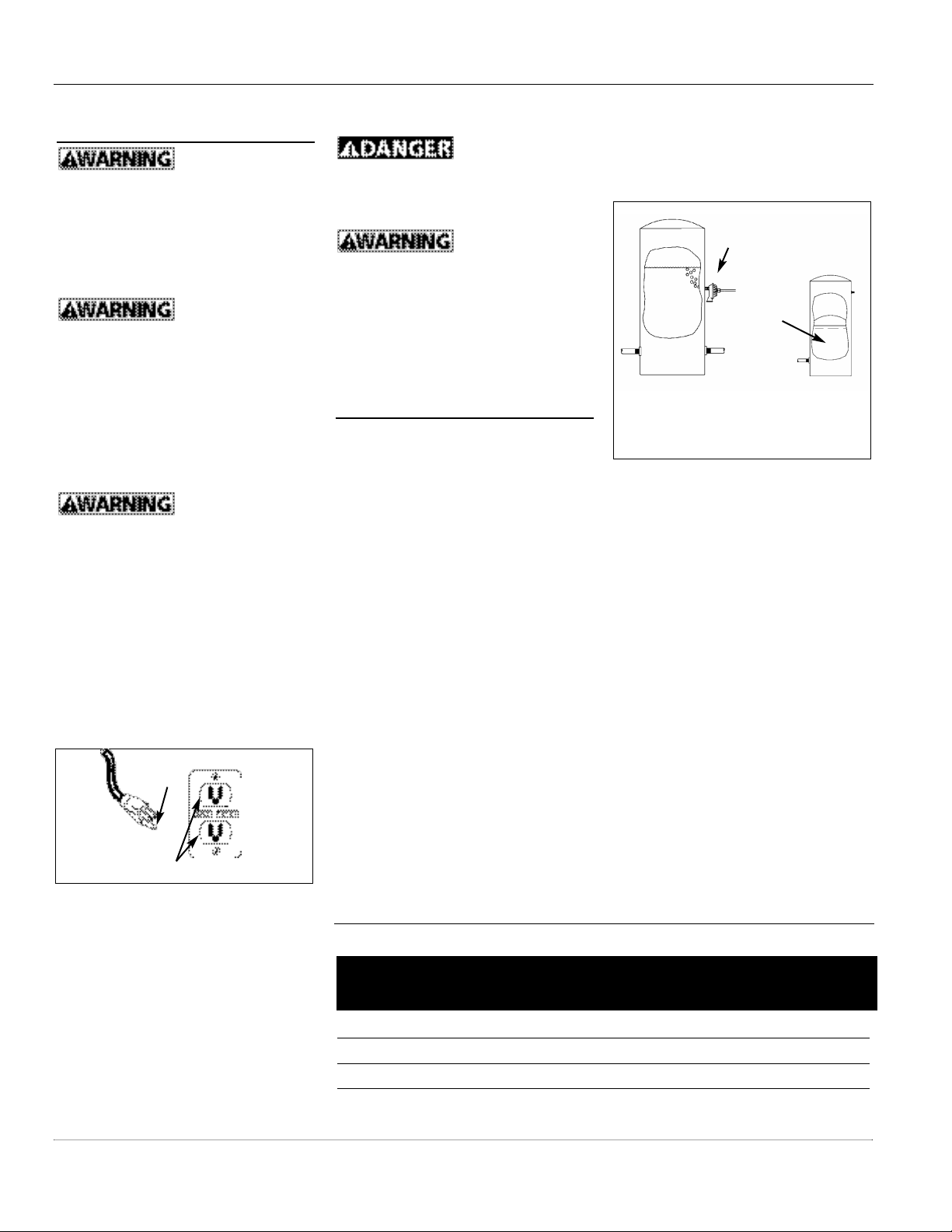

Risk of electric

shock! Never connect the green (or green and yellow wire)

to a live terminal!

19. To reduce the risk of electrical

shock, the pump should be plugged

directly into a properly installed and

grounded 3-prong grounding type

receptacle, as shown in Figure 1.

The green (or green and yellow)

conductor in the cord is the grounding wire. The motor must be

securely and adequately grounded

for protection against shock.

20. Where a 2-prong is encountered,

replace the plug with a properly

grounded 3-prong receptacle in

accordance with the National

Electrical Code, local codes and ordinances. To ensure a proper ground,

the grounding means must be tested by a licensed or certified electrician.

21. Use only 3-wire extension cords that

have a 3-prong, grounding type

plug, and 3-pole receptacles that

accept the equipment plug.

22. Use wire of adequate size to minimize voltage drop at the motor.

Do not handle

pump or pump

motor with wet hands, when standing

on a wet or damp surface or when

standing in water. Fatal electrical

shock could occur.

Pump motor is

equipped with an

automatic resetting thermal protector and

may restart unexpectedly. Protector tripping is an indication of motor overloading

because of operating pump at low heads

(low discharge restriction), excessively

high or low voltage, inadequate wiring,

incorrect motor connections or defective

motor or pump.

Pre-Installation

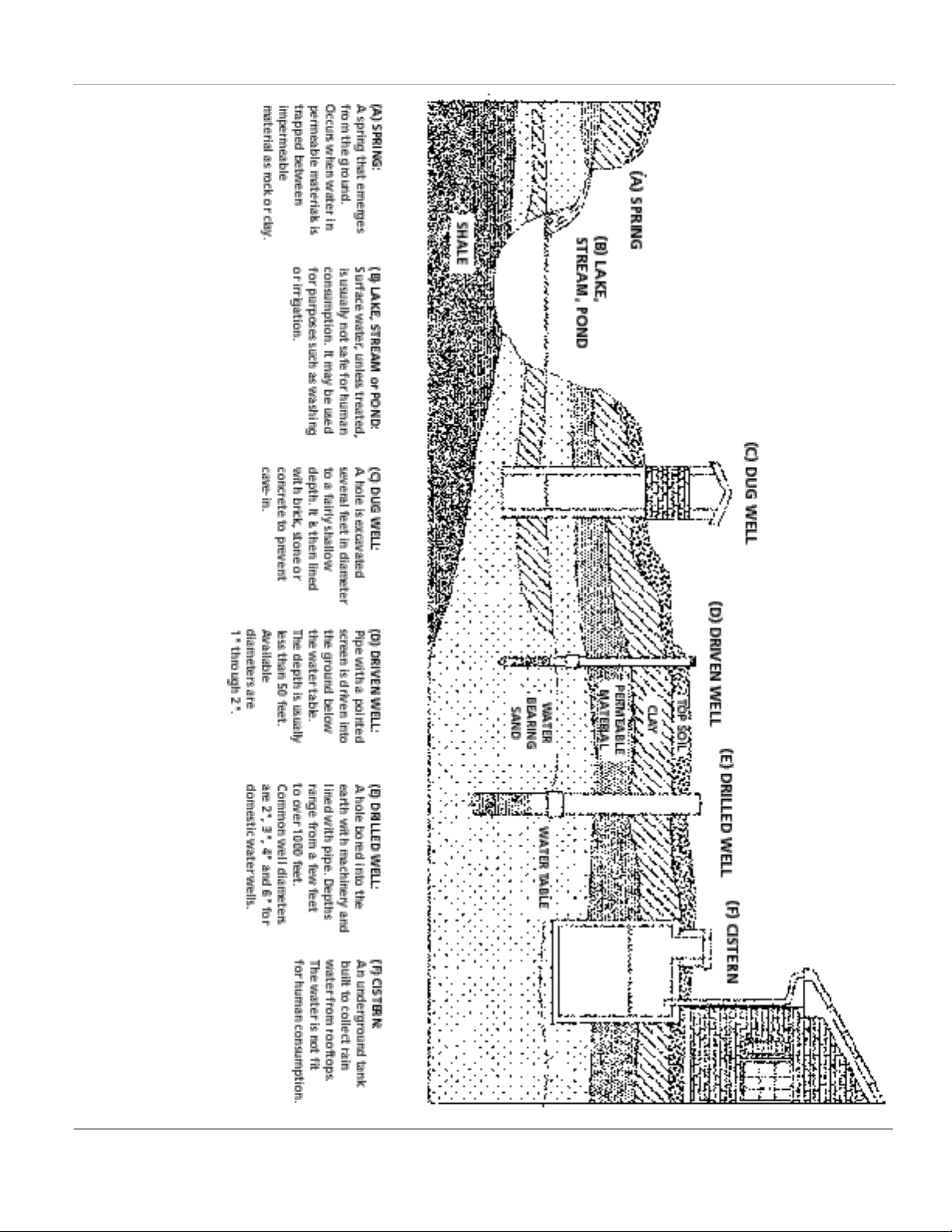

WATER SUPPLIES

The water supplies illustrated in Figure

12 are possible sources for water.

These water supplies can be divided

into two categories:

SURFACE WATER

Water from a lake, stream, pond and

cistern. This water is usually not fit for

human consumption, but may be suitable for washing, irrigation or other

household uses.

GROUND WATER

Water found in the water bearing stra-

tum at various levels beneath the earth.

Of all the fresh water found on earth

only 3 percent is found on the surface

and 97 percent is underground.

TANKS - CONVENTIONAL STORAGE

The function of the tank is to store a

quantity of water under pressure.

When full, the tank contains approximately 2/3 water and 1/3 compressed

air. The compressed air forces the

water out of the tank when a faucet is

opened. An air volume control auto-

2

Operating Instructions and Parts Manual

matically replaces air lost or absorbed

into the water. The usable water, or

drawdown capacity, of the tank is

approximately 1/6 of the tanks total

volume when operated on a “20-40”

pressure setting (Figure 2).

TANKS - PRECHARGED STORAGE

A precharged storage tank has a flexible bladder or diaphragm that acts as a

barrier between the compressed air

and water. This barrier prevents the air

from being absorbed into the water

and allows the water to be acted on by

compressed air at initially higher than

atmospheric pressures (precharged).

More usable water is provided than

with a conventional type tank.

Precharged tanks are specified in terms

of a conventional tank. For example, a

20 gallon precharged tank will have

the same usable water or drawdown

capacity as a 40 gallon conventional

tank, but the tank is smaller in size

(Figure 2).

PRESSURE SWITCH

The pressure switch provides for automatic operation. The pump starts

when pressure drops to a cut-in setting.

The pump stops when pressure reaches

a cut-out setting.

SBS50, SBS75, and SBS100

Air Volume

Control

Type Required

Well X Precharged No

PCA Precharged No

12P & 30P Horizontal Conventional Yes

FX Horizontal Precharged No

CHART 1 - JET PUMP/TANK ASSEMBLIES

Air Volume

Control

Bladder

Conventional

Tank

Precharged

Tank

Figure 2 - Conventional & Precharged

Storage Tanks

Grounded

Pin

Grounded Outlet

Figure 1

www.blueangelpumps.com

3

Pre-Installation

(Continued)

PACKAGE SYSTEMS

There are four jet pump/tank assemblies sold as packages (Chart 1).

WELLS

A new well should be pumped clear of

sand before installing the pump. Sand

will damage the pumping parts and

seal. The drawdown level of the well

should not exceed the maximum rated

depth for the pump. The capacity of

the pump will be reduced and a loss of

prime may occur.

Installation

LOCATION

Select a location as close to the water

supply as possible. Be sure to comply

with any state or local codes regarding

the placement of the pump. The

equipment must be protected from the

elements. A basement or heated pump

house is a good location. Make sure

the pump has proper ventilation. The

temperature surrounding the pump is

not to exceed 100° F (40°C) or nuisance

tripping of the motor overload may

occur.

PIPING

Piping may be copper, steel, rigid PVC

plastic or flexible polyethylene plastic.

Flexible pipe is not

recommended on

suction pipe (inlet pipe).

The pipe must be clean and free of rust

or scale. Use a pipe joint compound on

the male threads of the metal pipe.

Teflon®tape should be used with plastic threads. All connections must be air

tight to insure normal operation.

Slope all inlet piping upwards towards

the pump to prevent trapping air.

Unions or hose couplings can be

installed near pump to facilitate

removal for servicing or storage. A

rubber hose installed between the

water system and the house piping will

reduce the noise transmitted to the

house.

PIPE SIZES

Long horizontal pipe runs and an

abundance of fittings and couplers

decrease water pressure due to friction

loss. See Chart 2 to determine the

proper pipe size.

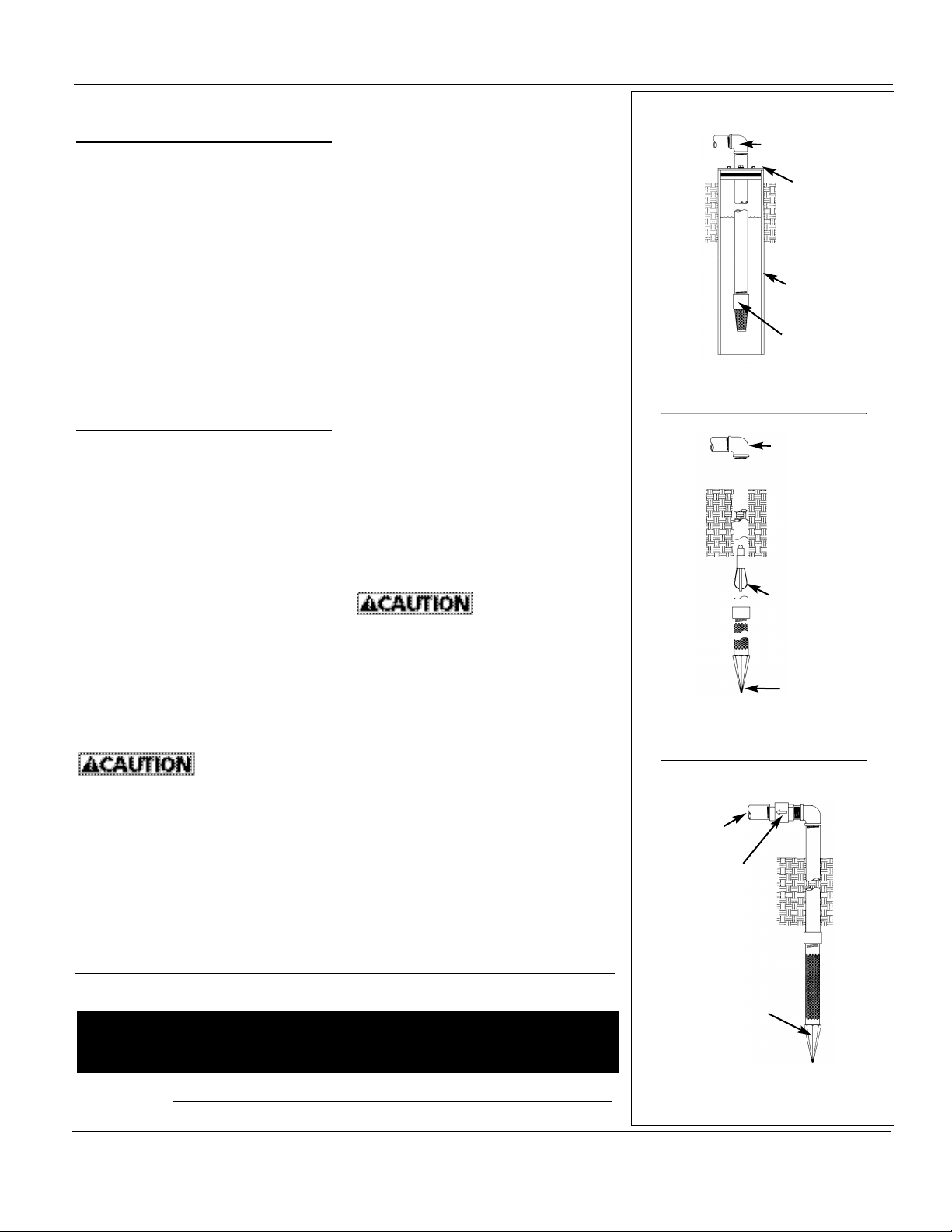

SHALLOW WELL INSTALLATION

A shallow well pump can be used when

the pump is located within 25 feet vertically of the water level. Shallow well

pumps have only one pipe between the

pump and the water supply (Figure 3).

DRILLED WELL (FIGURE 12)

1. Install a foot valve on the first section

of pipe (Figure 3, Illustration A).

2. Lower the pipe into the well.

3. Add pipe until the foot valve is 5

feet below the lowest anticipated

water level.

The foot valve

should be at least

18” from the bottom of the well or

sand or sediment could be drawn into

the system.

4. After proper depth is reached,

install a well seal or pitless adapter

to support pipe and prevent surface

water and other contaminants from

entering well.

5. Slope the horizontal pipe upward

toward the pump to eliminate trapping air. Sloping the pipe will also

aid in priming the pump.

DRIVEN WELL (FIGURE 12)

1. Drive the point several feet below

the water table.

NOTE: A packer type foot valve can be

installed in the well (Figure 3, Illustration B). This type of foot valve allows

Operating Instructions and Parts Manual

SBS50, SBS75, and SBS100

CHART 2 - PIPE SIZING

Illustration B

Illustration C

Packer

Type

Foot

Valve

Drive

Point

To Pump

Incline

Check

Valve

Drive

Point

To Pump

Figure 3

To Pump

Illustration A

Well

Seal

Well

Casing

Foot

Valve

Horizontal Distance

Pump Pump (Feet)

Model Opening 0-25 26-100 100-300

Shallow Well Inlet 11/4” 11/2” 2”

Outlet 3/4” 1” 11/4”

www.blueangelpumps.com

2. Connect the copper tube from the

air volume control to the uppermost

1/8” NPT opening on the side of

pump. Be sure the connections are

tight. Leaking can cause the pump

not to prime.

3. Install a valve and an isolator hose

between the tank and the house

plumbing to aid in pump removal

for servicing and for reducing the

noise transmitted to the house

thrugh the piping.

4. Provide a hose bib (faucet) at the

lowest point in the system to drain

the system for service or storage.

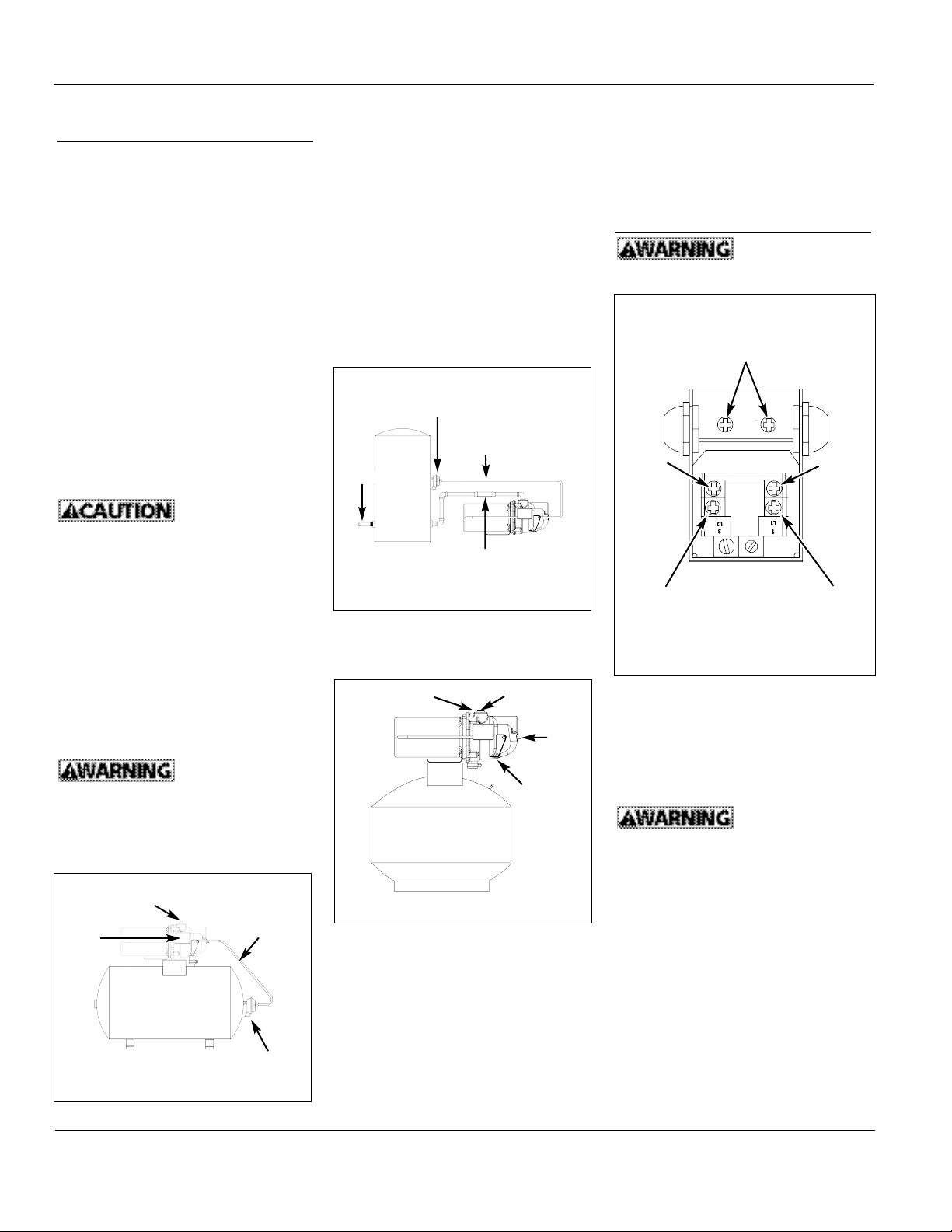

SHALLOW WELL PUMP WITH

PRECHARGED STORAGE TANK

(FIGURE 6)

1. Shut off the power to the pump.

2. Open the faucet nearest the tank

and allow all water to drain from

the tank.

3. Measure the tank precharge at the

valve stem using a tire pressure

gauge.

4. If necessary, precharge with an air

pump to 28 - 30 psi on 1/2, 3/4 and 1

HP pumps.

4

5. Slope the horizontal pipes upward

toward the pump to prevent trapping air. If the horizontal distance

exceeds 25 feet, see Chart 2 for the

recommended pipe size.

Electrical

Risk of electrical

shock. This pump is

designed for indoor installation only.

Select the proper size wire and fuse

(Chart 3). Time delay fuses are recommended over standard fuses for motor

circuit protection. All pump motors

have built-in automatic overload protection that will prevent damage to the

motor due to overheating.

Do not connect to

electric power supply until unit is permanently grounded.

Connect ground wire to approved ground

then connect terminal provided.

A metal underground water pipe or

well casing at least 10 feet long makes

the best ground electrode. If plastic

pipe or insulated fittings are used, run

a wire directly to the metal well casing

or use a ground electrode furnished by

the power company.

There is only one proper ground terminal on the unit. The terminal(s) is

located under the pressure switch

cover, is painted green and is identified

as GRD. The ground connection must

be made at this terminal (Figure 7a or

Installation

(Continued)

the well to be filled with water when

priming and makes the inlet pipe much

easier to test for leaks. Follow the

manufacturer’s instructions when

installing the packer type foot valve.

As an alternative, an in-line check valve

can be used with a driven well (Figure

3, Illustration C). The pipe between the

check valve and the water level will

always be under a vacuum.

Leaking joints or couplings will allow

air to leak into the pipe and cause

abnormal pump operation. Make sure

to use pipe joint compound on all male

pipe threads.

DUG WELL, CISTERN, LAKE AND SPRING

INSTALLATION (FIGURE 12)

1. Install a foot valve on inlet pipe and

lower into water.

The foot valve

should be at least

18” from the bottom of the well or

sand or sediment could be drawn into

the system.

NOTE: When a lake is used as a water

supply, make sure the inlet pipe is deep

enough to be submerged at all times.

Slope the horizontal piping upward

toward the pump to prevent trapping

air. The pipe must be removed during

winter months or protected against

freezing.

Protect the pipe from damage from

swimmers and boats.

Install a screen

around the inlet

pipe to prevent the entrapment of swimmers.

SHALLOW WELL PUMP WITH CONVENTIONAL STORAGE TANK

(FIGURES 4 & 5)

1. Install air volume control on tank.

Operating Instructions and Parts Manual

SBS50, SBS75, and SBS100

Figure 7 - Electrical Connections

Figure 4 - Horizontal Tank

Air

Volume

Control

Tubing

Pressure

Switch

Prime

Plug

Air

Volume

Control

Figure 5 - Vertical Tank

Air

Volume

Control

Outlet

Air Volume

Control

Tubing

Hose

Coupling

Figure 6 - Precharged Storage Tank

28-30 psi

3/4 HP & 1 HP

Motor

www.blueangelpumps.com

Motor

Motor

Line

Line

Ground

Outlet

Priming

Plug

Nozzle

Clean

Out

Drain

Fitting

5

Electrical (Continued)

7b). The ground conductor must not

be smaller than the circuit conductors

supplying the motor.

Disconnect power

and release all pres-

sure from the system before attempting

to install, service, relocate or perform any

maintenance.

Operation

PRIMING THE SHALLOW WELL PUMP

To prevent damage

to the pump, do not

start motor until pump has been filled

with water.

1. Remove prime plug (Figure 4 or 5).

2. Fill pump and piping completely full

of water.

3. Replace the prime plug.

4. Open a faucet to vent the system.

5. Start the motor. Water will pump in

a few minutes. If pump fails to

prime in 5 minutes, stop motor and

refill pump with water. Priming

time is proportional to the amount

of air in inlet pipe.

6. Let the system operate for several

minutes to flush all pipes.

7. Close faucet and allow pump to

build pressure in tank. When the

pressure reaches the cut-out setting,

the motor will stop.

The system is now in operation and will

automatically cycle on demand.

Maintenance

Disconnect power

and release all pressure from the system before attempting

to install, service, relocate or perform any

maintenance. Lock the power disconnect

in the open position. Tag the power disconnect to prevent unexpected application of power.

Protect the pump

from freezing during winter conditions.

DRAINING THE PUMP

Drain openings are provided on all

models. To drain the pump:

1. Remove drain plug and prime plug

to vent the system.

2. Drain all piping to a point below

the freeze line.

DRAINING THE TANK

Conventional tanks can be drained by

opening an outlet at the lowest point

in the system. Remove plug or the air

volume control to vent the tank.

Precharged tanks force virtually all the

water from the tank when system pressure is released. No draining is necessary.

RESTARTING PUMP

If the pump has been serviced, drained

or has not been used for some time, be

sure there is water in the pump housing (volute) and the piping to the well.

There must be water in the pump housing (volute) at all times when the pump

is running to avoid internal damage of

seal members (Priming the Shallow

Well).

WATERLOGGED TANKS:

CONVENTIONAL

When a tank system has an inadequate

ratio of air and water, the pump will

start and stop often and eradically.

1. Disconnect the power to the pump.

2. Open the lowest faucet in the system to release all pressurized water

in the system.

3. Prime the pump (Priming the

Shallow Well).

4. Reconnect the power to the pump.

NOTE: As the pump refills the tank with

water, the air volume control supplies

the tank with the correct air to water

ratio for the system to operate. If the air

volume control is good, the pump will

Operating Instructions and Parts Manual

SBS50, SBS75, and SBS100

shut off at the desired cut-off and will be

adjusted correctly.

WATERLOGGED TANKS:

PRECHARGED

If a precharged tank becomes waterlogged, the bladder is normally leaking

or broken.

1. Test the tank by depressing the air

valve. The air valve will expel water if

the bladder is broken.

2. Replace the tank.

NOTE: Once a bladder is leaking or broken, the bladder cannot be repaired. The

tank must be replaced.

LUBRICATION

The bearings used in the pumps are lifetime lubricated at the factory and require

no additional lubrication.

PRECHARGED TANK

Some air is lost through the bladder in

any tank. To prevent tank failure, check

the tank precharge on a yearly basis.

1. Open a faucet nearest the tank and

allow all water to drain from the

tank.

2. Measure the tank precharge at the

valve stem using a tire gauge.

3. If necessary, adjust the precharge

with an air pump 28 - 30 psi on 1/2,

3/4 and 1 HP pumps.

REMOVING OLD SHAFT SEAL

Turn disconnect

switch to “off” posi-

tion.

1. Open a faucet nearest the tank and

allow all water to drain from the

tank.

Distance In Feet

From Meter To Motor

Dual 0 51 101 201

Element To To To To

Fuse 50 100 200 300

HP Volt 250V Wire Size

115 15 14 14 12 10

230 10 14 14 14 14

115 15 14 14 10 8

230 10 14 14 14 14

115 20 12 12 10 8

230 10 14 14 14 14

CHART 3 - RECOMMENDED FUSE & WIRING DATA - 60 HZ MOTORS

1/2

3/4

1

www.blueangelpumps.com

Maintenance

(Continued)

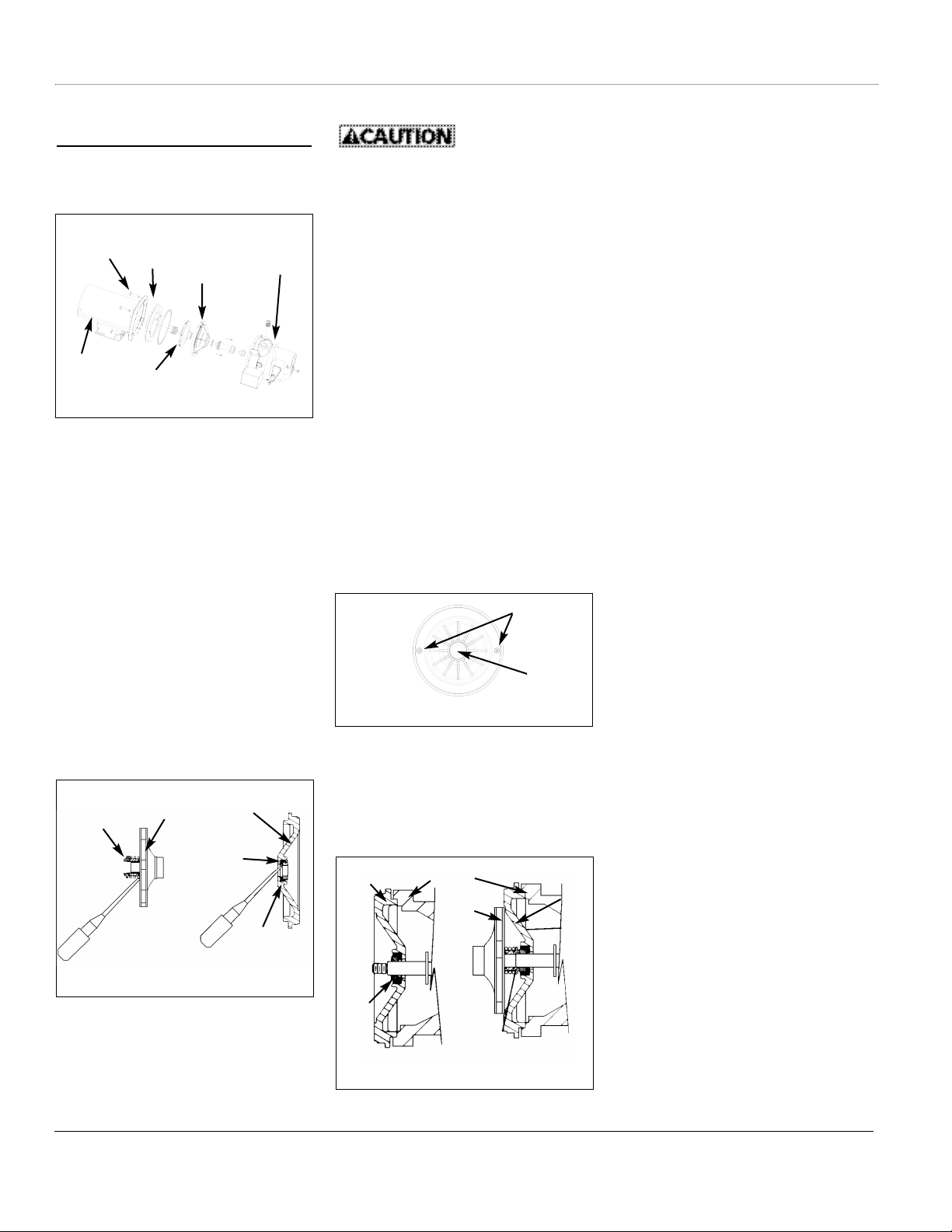

2. Remove the four cap screws holding

the pump housing (volute) to the

motor (Figure 8).

3. Separate the pump housing

(volute) from the motor to expose

the diffuser and the seal plate.

4. Remove the two cap screws and diffuser from the seal plate to expose

the impeller.

5. Remove the small end cap on the

end of the motor opposite the

impeller.

6. With a large screwdriver or

adjustable wrench, keep the shaft

from rotating and remove the

impeller by hand (standard right

hand thread). Be sure to hold onto

the seal plate when removing the

impeller from the shaft.

7. Remove the seal plate.

8. Pry the rotating shaft seal member

from the impeller (Figure 9).

9. Push or pry the ceramic seat free

from the seal plate (Figure 9).

10. Remove loose particles from

impeller hub and seal plate.

5. Secure diffuser to seal plate using the

two cap screws. Be sure the screws

are orientated on a horizontal line as

described in Step 2.

6. Carefully position pump housing

(volute) gasket over the diffuser onto

the seal plate. In all shallow well

applications care must be taken that

the o-ring is clean and properly positioned on the venturi. Cleaning and

positioning makes a good seal inside

the diffuser when assembled.

7. Assemble the pump housing (volute)

to the motor using the four cap

screws. Be sure the pump housing

(volute) gasket is positioned correctly

and tighten the screws securely.

NOTE: Shaft must rotate freely and

motor end cap should be secured

before operation.

6

SBS50, SBS75, and SBS100

Operating Instructions and Parts Manual

INSTALLING NEW SHAFT SEAL

Before handling

shaft seal parts

wipe hands clean. Dirt or grease can

damage the seal.

1. Wet the inside of the seal cavity on

seal plate and the rubber cup

enclosing the new ceramic seat with

cooking oil. Be careful not to

scratch the ceramic surface of the

seal seat and push seat enclosed in

rubber into seal cavity on seal plate.

Use a cardboard washer to protect

polished surface when pushing

against ceramic seat with any

object. Be sure to remove cardboard washer.

2. Carefully slip seal plate over shaft.

Do not disturb seal position in seal

plate. The seal plate must be orientated during assembly so the two

screw holes are on a horizontal line

across the motor shaft and the (4)

locating pins on the back of the seal

plate line up with the tabs on the

motor housing (Figure 10). This placement should be done to ensure proper draining and priming.

3. Place rotating shaft seal member in

position on impeller and press into

place. Take care not to press against

polished seal surface.

4. Position impeller on shaft and tighten

securely (Figure 11).

Seal

Plate

Seal

Seat

Figure 11 - Motor Shaft

Figure 10 - Seal Plate Replacement

Screw Holes

Motor

Shaft

Motor

Impeller

Seal

Plate

Seal Facing Must

Be Clean For

Proper Seal

Figure 9 - Removing Shaft Seal &

Ceramic Seat

Seal

Plate

Ceramic

Seat

Rotating

Shaft Seal

Member

Rubber

Seat Ring

Impeller

Cap

Screws

Figure 8 - Shaft Seal

Seal

Plate

Diffuser

Pump

Housing

(Volute)

Impeller

Motor

www.blueangelpumps.com

7

SBS50, SBS75, and SBS100

Operating Instructions and Parts Manual

Water Supplies

Figure 12 - Water Supplies

www.blueangelpumps.com

Operating Instructions and Parts Manual

SBS50, SBS75, and SBS100

8

Symptom Possible Cause(s) Corrective Action

Troubleshooting Chart

Pump will not run

Motor hums but will not run

Overload trips

Pump runs but delivers little or

no water

Pump starts and stops too

of ten

1. Power off

2. Blown fuse or tripped breaker

3. Faulty pressure switch

4. Pressure switch tubing obstructed

5. Motor overload tripped

1. Low line voltage

2. Wiring too small

3. Damage or misalignment causing rotating

parts to bind

1. Incorrect line voltage

2. Damage or misalignment causing rotating

parts to bind

3. High surrounding temperature

4. Rapid cycling

1. Water level below pump intake

2. Control valve open too far (deep well)

3. Discharge not vented while priming

4. Leaking in piping on well side of pump

5. Well screen or inlet strainer clogged

6. Clogged nozzle (deep well)

7. Air volume control diaphragm ruptured

8. Foot valve may be clogged or stuck closed

9. Pump not fully primed

10. Control valve completely closed (deep well)

11. Water level below maximum lift

spec i fi ca tion

12. Undersized piping

13. Gaseous well

14. Distorted venturi

15. Incorrect jet for application

16. Undersized pump

17. Pump cavitates, sounds like pumping gravel

1. Water logged tank (conventional tank)

2. Air volume control tubing kinked or clogged

3. Air volume control tubing connected to

wrong opening on pump

4. Incorrect tank precharged (precharged tank)

5. Ruptured diaphragm/bladder (precharged

tank)

6. Leak in house piping

7. Foot valve or check valve stuck open

8. Motor overload tripping

9. Improperly adjusted pressure switch

1. Turn power on or call power com pa ny

2. Replace fuse or reset circuit break er

3. Replace switch

4. Clean or replace copper tubing

5. Let cool. Overload will au to mat i cal ly

re set

1. Rewire. See Chart 3*

2. Rewire. See Chart 3*

3. Replace or take to service shop for

re pair

1. Rewire. See Chart 3*

2. Take to motor repair shop or locate

and repair mechanical binding

3. Provide a shaded, well-ventilated area

for pump

4. Pump starts and stops too often sec tion

1. Lower suction pipe further into well

2. Repeat priming procedure

3. Open faucet, repeat priming pro ce dure

4. Repair piping as needed

5. Clean or replace as necessary

6. Pull jet and clear obstruction

7. Repair or replace air volume control

8. Clean or replace as needed

9. Continue priming, paus ing ev ery 5

min utes to cool pump body. Refill

pump as need ed

10. Adjust control valve per deep well

prim ing procedure

11. Select applicable pump and/or jet

as sem bly

12. Replace as needed

13. Install baffle on pump intake to pre vent gas from entering system

14. Inspect and replace

15. Purchase a jet matched to your sys tem

when replacing another brand pump

16. Increase horsepower of pump

17. Increase suction plumbing diameter or

decrease pipe friction

1. Replace tank or air volume control

2. Clean or replace as needed

3. Move to correct pump opening

4. Add or release air as needed

5. Replace tank

6. Locate and repair leak

7. Remove and replace

8. See overload trips section

9. Readjust or replace switch

* All rewiring and motor repair must be done by licensed or certified professionals

www.blueangelpumps.com

9

SBS50, SBS75, and SBS100

Operating Instructions and Parts Manual

For Replacement Parts, call 1-888-636-6628

Please provide following information:

- Model number

- Serial number (if any)

- Part description and number as shown in parts list

Address parts correspondence to:

Blue Angel

101 Production Drive

Harrison, OH 45030 U.S.A.

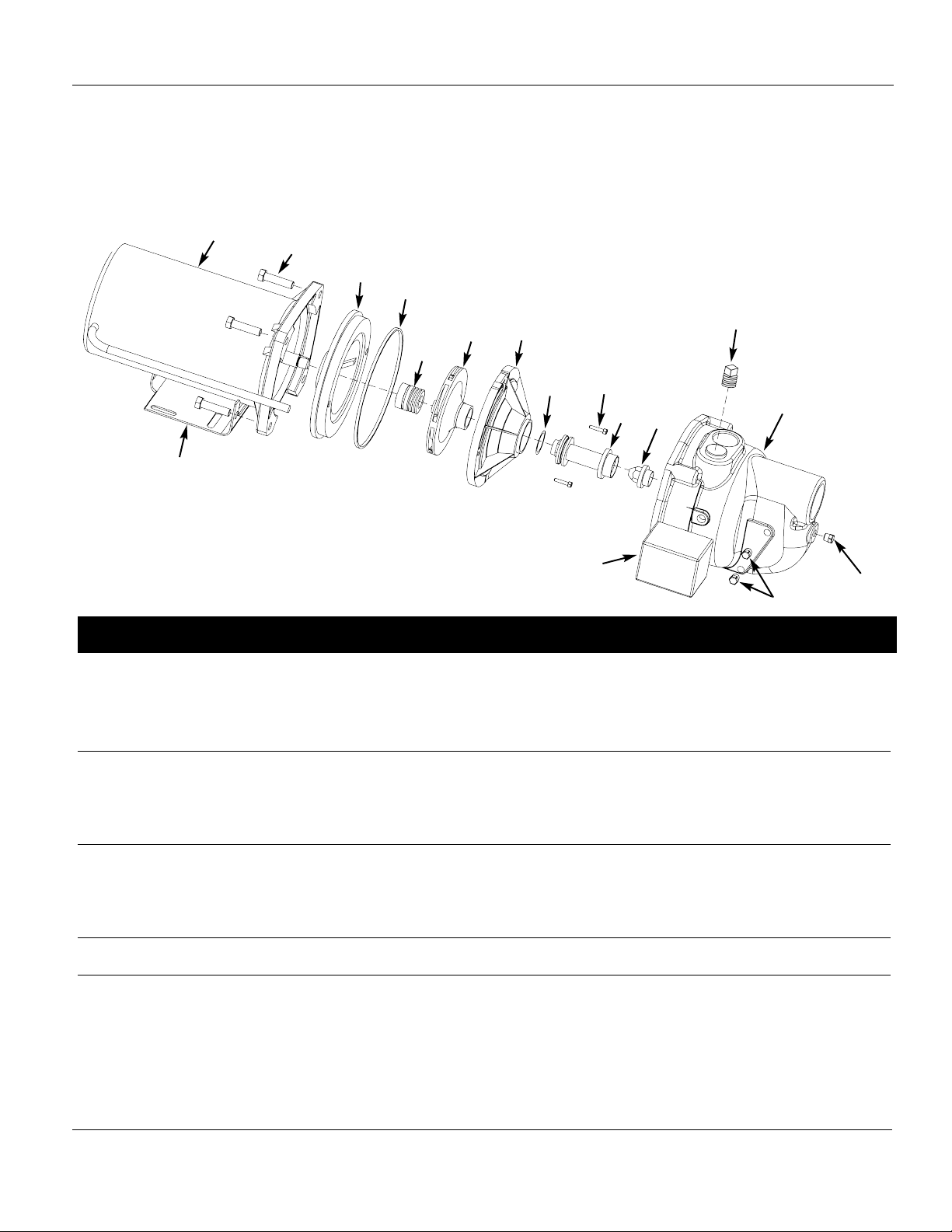

1 Motor 32059-001 34142-002 34142-001 1

2 Screw 16636-002 16636-002 16636-002 4

3 Seal plate 17145-001 17145-001 17145-001 1

4 • Square ring rubber gasket 17150-001 17150-001 17150-001 1

5 • Shaft seal assembly 56393 56393 56393 1

6 Impeller 23285-002 23285-001 23285-001 1

7 Diffuser 17148-001 17148-001 17148-001 1

8 Screw 67007-001 67007-001 67007-001 2

9 • O-ring 15557 15557 15557 1

10 Venturi 17151-002 17151-003 17151-004 1

11 Nozzle 15672 15672 15672 1

12 Pipe plug 3/4” 15921 15921 15921 1

13 Volute 56869-001 56869-001 56869-001 1

14 Pipe plug 1/4” NPT 16314-002 16314-002 16314-002 1

15 Pipe plug 1/8” NPT 15766-002 15766-002 15766-002 1

16 Base 23029-001 23029-001 23029-001 1

17 Pressure switch 30010-001 30010-001 30010-001 1

• Repair kit (Includes #4, 5 and 9) 56874-001 56874-001 56874-001 1

Ref. Part Numbers for Models

No. Description SWS50-1/2 HP SWS75-3/4 HP SWS100-1 HP Qty.

17

1

2

3

4

5

6

7

8

11

12

10

13

14

16

9

15

www.blueangelpumps.com

Operating Instructions and Parts Manual

SBS50, SBS75, and SBS100

10

Limited Warranty

For three years from the date of purchase, Blue Angel will repair or re place, at its option, for the original purchaser any part

or parts of its Pond Kit, Sump Pumps or Water Pumps (“Product”) found upon examination by Blue Angel to be defective in

materials or work man ship. Please call Blue Angel (888-636-6628) for instructions or see your dealer. Be pre pared to provide

the model and serial number when exercising this warranty. All trans por ta tion charges on Products or parts submitted for

repair or replacement must be paid by purchaser.

This Limited Warranty does not cover Products which have been damaged as a result of accident, abuse, misuse, neglect,

improper installation, improper main te nance, or failure to operate in accordance with Blue Angel’s written instructions.

THERE IS NO OTHER EXPRESS WARRANTY. IM PLIED WARRANTIES, IN CLUD ING THOSE OF MER CHANT ABIL I TY AND

FITNESS FOR A PARTICULAR PUR POSE, ARE LIMITED TO THREE YEARS FROM THE DATE OF PUR CHASE. THIS IS THE

EXCLUSIVE REM E DY AND ANY LIABILITY FOR ANY AND ALL IN DI RECT OR CON SE QUEN TIAL DAM AG ES OR EX PENS ES WHATSOEVER IS EXCLUDED.

Some states do not allow limitations on how long an implied warranty lasts, or do not allow the exclusions or limitations of

incidental or consequential damages, so the above lim i ta tions might not apply to you. This limited war ran ty gives you specific legal rights, and you may also have other legal rights which vary from state to state.

In no event, whether as a result of breach of contract warranty, tort (in clud ing negligence) or otherwise, shall Blue Angel or

its suppliers be liable for any special, consequential, incidental or penal damages including, but not limited to loss of profit

or revenues, loss of use of the products or any associated equipment, damage to associated equip ment, cost of capital, cost

of substitute products, facilities, services or replacement power, downtime costs, or claims of buyer’s cus tom ers for such damages.

You MUST retain your purchase receipt along with this form. In the event you need to exercise a warranty claim, you MUST

send a copy of the purchase receipt along with the material or correspondence. Please call Blue Angel (888-636-6628) for

return authorization and instructions.

DO NOT MAIL THIS FORM TO BLUE ANGEL. Use this form only to maintain your records.

MODEL NO. _____________________ SERIAL NO. ________________________ INSTALLATION DATE _____________________

ATTACH YOUR RECEIPT HERE

www.blueangelpumps.com

Loading...

Loading...