Page 1

Operating Instructions & Parts Manual BWST, BWSF and BWSCAP Series

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or

maintain the product described. Protect yourself and others by observing all safety information. Failure to

comply with instructions could result in personal injury and/or property damage! Retain instructions for future

reference.

The Professional’s Line

Submersible

Sump Pump

Description

The submersible pump is designed

for indoor home sump applications.

The unit is equipped with an 8-ft

long, 3-prong grounding type power

cord. Motor is oil filled and sealed

for cooler running and designed to

operate under water. A float switch

or solid-state electronic water level

control is provided for automatic pump

operation. This pump is not suitable for

aquatic life.

Unpacking

After unpacking the unit, inspect

carefully for any damage that may

have occurred during transit. Make sure

to tighten fittings, bolts, etc., before

putting unit into service.

Safety Guidelines

This manual contains information

that is very important to know and

understand. This information is

provided for SAFETY and to PREVENT

EQUIPMENT PROBLEMS. To help

recognize this information, observe the

following symbols.

Danger indicates an

imminently

hazardous situation which, if not

avoided, WILL result in death or serious

injury.

Warning indicates a

potentially

hazardous situation which, if not

avoided, COULD result in death or

serious injury.

Caution indicates a

potentially

hazardous situation which, if not

avoided, MAY result in minor or

moderate injury.

Notice indicates

important

information, that if not followed, may

cause damage to equipment.

IMPORTANT: Information that requires

special attention.

General Safety Information

CALIFORNIA PROPOSITION 65

This product or

its power cord may

contain chemicals known to the State

of California to cause cancer and birth

defects or other reproductive harm.

Wash hands after handling.

GENERAL SAFETY

Read these rules and

instructions carefully. Failure

to follow these instuctions

could cause serious bodily

injury and/or property

MANUAL

All wiring must be

qualifi ed electrician. Failure to follow

this warning could result in fatal

electrical shock.

If the

has water or moisture on

the fl oor, do not walk on

wet area until all power is

turned off. If the shutoff box is in the

basement, call an electrician. Remove

pump and either repair or replace.

Failure to follow this warning could

result in fatal electrical shock.

A backup system

Angel offers Model BSP15 and BSP25.

Assembly

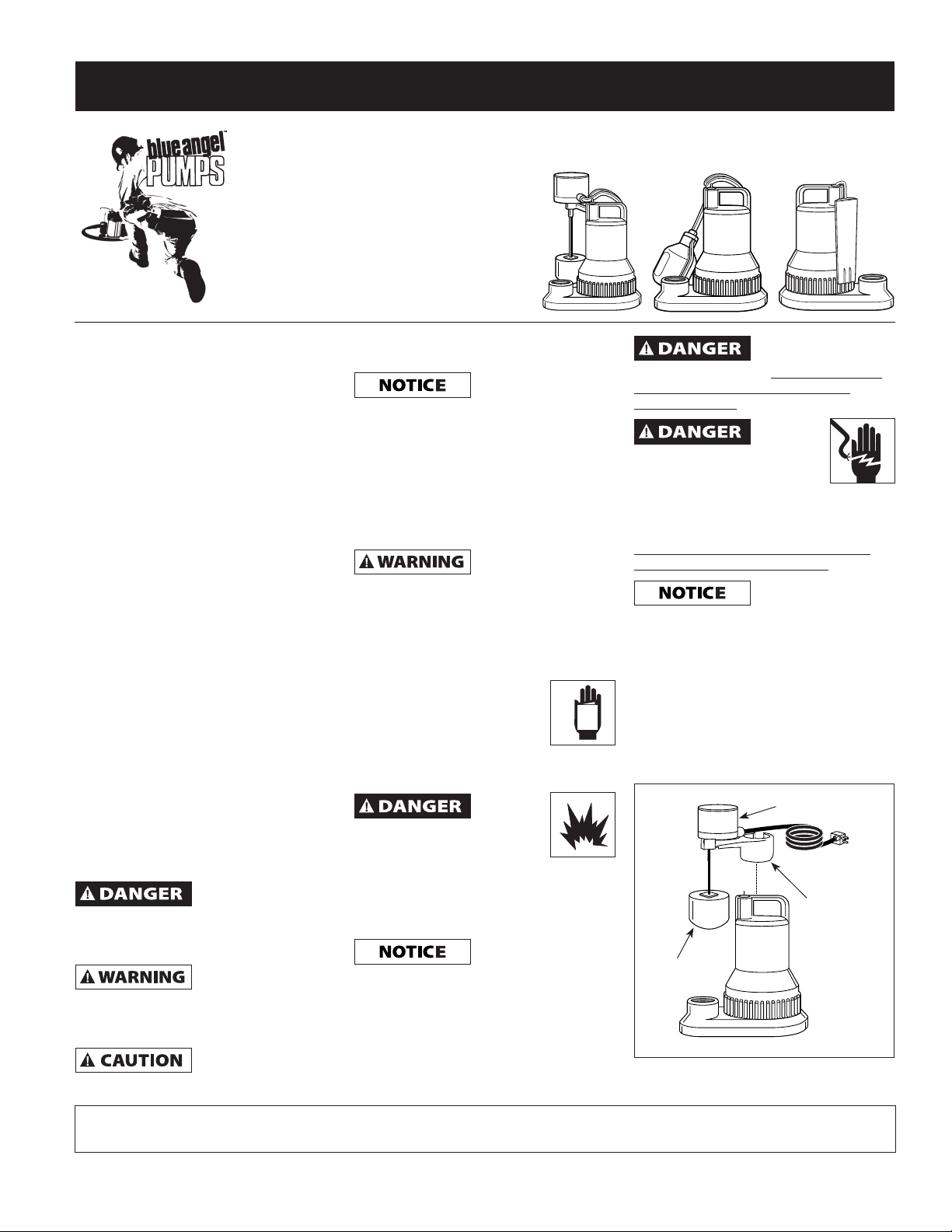

VERTICAL FLOAT SWITCH (BWSF

ONLY)

Place the float bracket onto the handle

of the motor housing and slide the

switch assembly securely into place.

damage.

Do not

use to

pump fl ammable or explosive

fl uids such as gasoline, fuel

oil, kerosene, etc. Do not

use in a fl ammable and/or explosive

atmosphere. Pump should only be used

to pump clear water. Personal injury

and/or property damage could result

This pump is

not designed

to handle salt water, brine, laundry

discharge or any other application

which may contain caustic chemicals

and/or foreign materials. Pump damage

could occur if used in these application

and will void warranty.

Float

Figure 1

performed by a

basement

should be used. Blue

Switch housing

Float

bracket

© 2008 Blue Angel™ Pumps

REMINDER: Keep your dated proof of purchase for warranty purposes!

Attach it to this manual or file it for safekeeping.

For parts, product & service information

visit www.blueangelpumps.com

350704-002 9/08

Page 2

Operating Instructions and Parts Manual

Installation

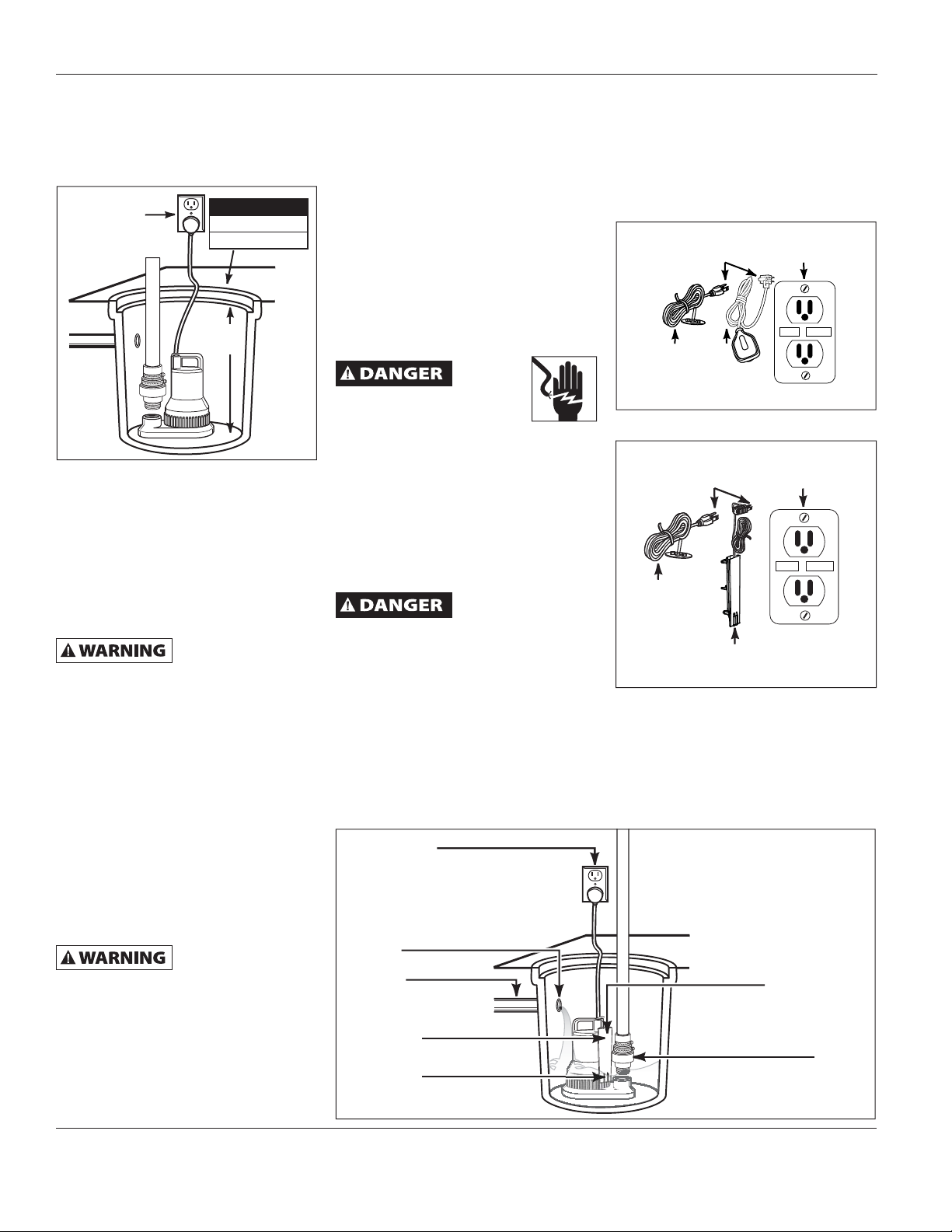

1. Install pump in a sump pit with

minimum size as shown in Figure 2.

Construct sump pit of tile, concrete,

steel or plastic.

Grounded

Outlet

Figure 2

2. The unit should be located and

rest on a solid, level foundation.

Do not place pump directly on clay,

earth, gravel or sandy surface. These

surfaces contain small stones, gravel,

sand, etc. that may clog or damage

the pump and cause pump failure.

Flood risk. If fl exible

used, make sure pump is secured in

sump pit to prevent movement. Failure

to secure pump could allow pump

movement and switch interference

and prevent pump from starting or

stopping.

3. Thread check valve (Blue Angel

offers Model 66005-BLA) into pump

body carefully to avoid stripping

or cross threading. Do not use pipe

joint sealant.

4. Connect 1-1/2 inch rigid pipe to

rubber boot on check valve. Reverse

boot for 1-1/4 inch diameter pipe.

Tighten hose clamps.

Support pump and

assembling and after installation.

Failure to do so could cause piping to

break, pump to fail, etc. which could

result in property damage and/or

personal injury.

5. Protect electrical cord from

sharp object, hot surfaces, oil

and chemicals. Avoid kinking the

Min. Diameter

BWSF 11 in.

BWST 14 in.

24 in.

Min.

discharge hose is

piping when

cord and replace damaged cords

immediately.

IMPORTANT: Make sure there is

adequate room for the switch to

operate.

6. A sump pit cover must be installed

to prevent debris from clogging or

damaging the pump.

7. FOR BWSCAP MODELS ONLY:

Position pump switch AWAY from

the inlet so switch is clear from

incoming water (See Figure 3).

Operation

Always

disconnect

the power source before

attempting to install, service,

relocate or maintain the

pump. Never touch sump pump, pump

motor, water or discharge piping when

pump is connected to electrical power.

Never handle a pump or pump motor

with wet hands or when standing on

wet or damp surface or in water. Fatal

electrical shock could occur.

1. A ground fault circuit interrupter

(GFCI) is required.

Risk of electrical

shock! This pump is

supplied with a grounding conductor

and grounding type attachment plug.

Use a grounded receptacle to reduce the

risk of fatal electrical shock. Never cut

off the round grounding prong. Cutting

the cord or plug will void the warranty

and make the pump inoperable.

2. This pump is only for use on 120 Volt

(single-phase), 60 hz, 15 amp service

and is equipped with a 3-conductor

cord and 3-prong, grounding type

Grounded Outlet

Incoming Water

Inlet Pipe

ON @ 8 inches

OFF @ 3 inches

Figure 3

plug. Insert the float switch cord

plug directly into a 120 volt outlet.

3. Insert the pump power cord plug

directly into the back of the float

switch cord plug or solid-state water

sensor cord plug (See Figures 4a and

4b).

Grounding

Blade

Power

Cord

Figure 4a

Grounding

Blade

Switch

Cord

Grounded

Outlet

RESET

TEST

Grounded

Outlet

RESET

TEST

Power

Cord

Switch

Cord

Figure 4b

4. Fill sump with water. The pump will

start automatically when the water

has filled the sump to the cut-in

level. The pump will stop when the

water reaches the cut-out level. See

Switch

Check Valve

www.blueangelpumps.com

2

Page 3

BWST, BWSF and BWSCAP Series

specifications for cut-in/out levels.

The pump will recycle thereafter as

required.

5. Do not operate the pump unless it

is submerged in water. Dry running

causes pump failure.

6. The motor is equipped with an

automatic reset thermal protector.

7. While the pump is draining the pit,

verify that the discharge piping is

carrying the water to a point several

feet away from the foundation.

8. If pump discharge line is exposed to

freezing temperature, the exposed

line must be pitched to drain.

Trapped water will freeze and

damage the pump.

FOR BWSCAP MODELS ONLY:

9. Sump pump will turn on, when

water is about 1.5 inch from the top

of the switch.

10. Sump pump will run a minimum of 4

seconds, to a maximum of 16 before

stopping.

11. Sump pump run time will be

determined by the sump pit size and

water flow rate into the sump pit.

12. Under flooding conditions, the sump

pump will stop for 1 second, every

16 seconds, and automatically turn

back on.

Maintenance

Always

disconnect

the electrical supply before

attempting to install, service,

relocate or perform any

maintenance. If the power source is out

of sight, lock and tag in the open (off)

position to prevent unexpected power

application. Failure to do so could result

in fatal electrical shock.

Only qualifi ed electricians should repair

this unit. Improper repair could result in

fatal electrical shock.

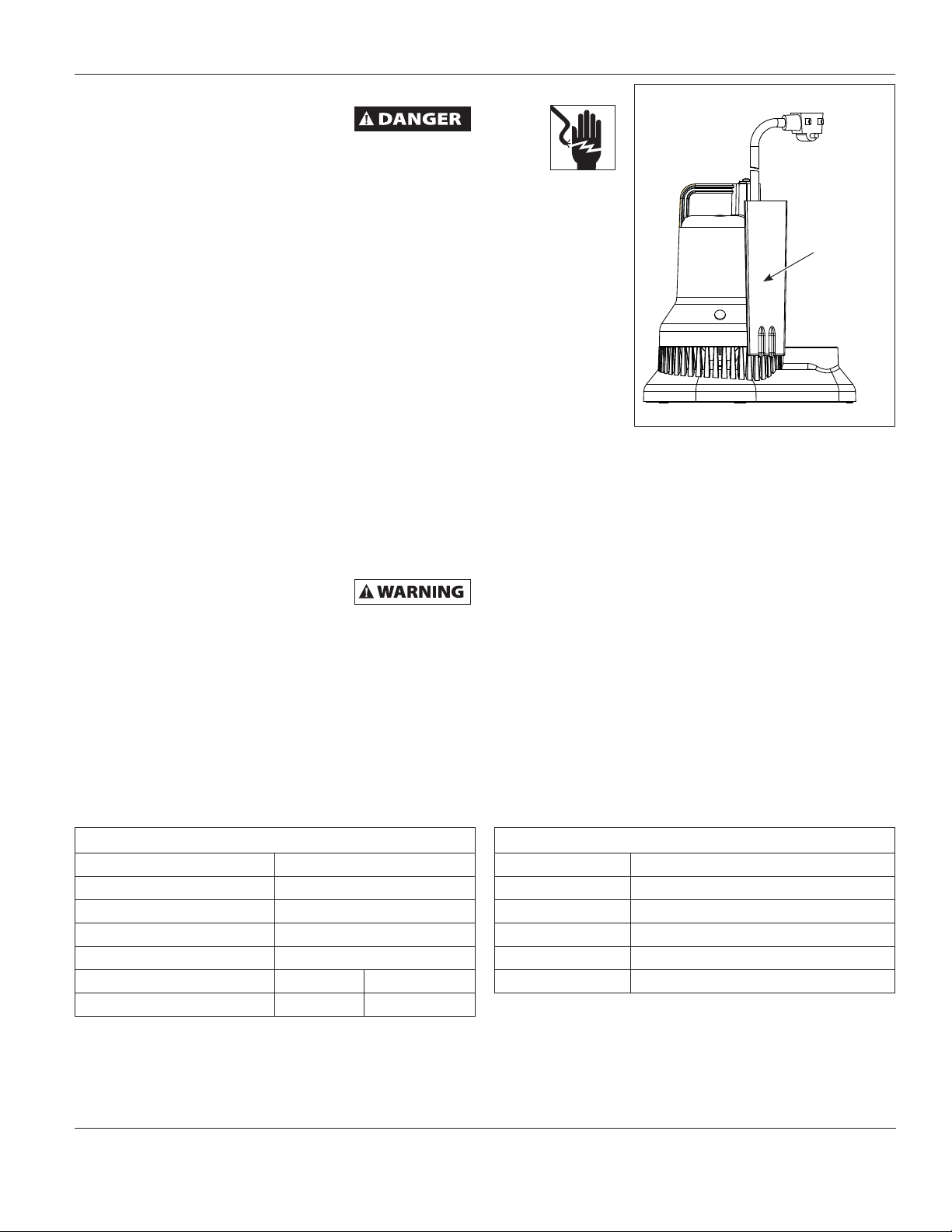

1. Let the pump cool for a minimum of

two hours before servicing because

the pump contains hot oil under

pressure and the motor is hot.

2. Disassembly of the motor prior to

expiration of warranty will void the

warranty. If repairs are required, see

troubleshooting chart.

3. Inlet should be kept clean and free

of all foreign objects and inspect

annually. A clogged inlet will

damage pump.

4.

Pump should be checked monthly for

proper operation.

This pump contains

dielectric oil for

cooling. This oil can be harmful to

the environment. Check the state

environmental laws before disposing

this oil.

Figure 5

Working

surface to

be kept

free of

foreign

material

Specifications

Power supply requirements 120V, 60 hz

Motor Single phase, oil filled

Liquid temperature range 40°F to 120°F

Circuit requirements 15 amps (min)

Dimensions 11 in. high x 9 in. base

Cut-in level (factory set) BWST = 14" BWSF = 7”

Cut-out level (factory set) BWST = 7” BWSF = 2-1/2”

Construction

Motor housing Glass reinforced thermoplastic

Volute Thermoplastic

Impeller Glass reinforced thermoplastic

Shaft 416 Stainless steel

Seals Buna N

Discharge 11/2” NPT

www.blueangelpumps.com

3

Page 4

Operating Instructions and Parts Manual

For Replacement Parts or Technical Assistance,

Call 1-888-636-6628

Please provide following information: Address any correspondence to:

- Model number Blue Angel

- Serial number (if any) 101 Production Drive

- Part description and number as shown in parts list Harrison, OH 45030 U.S.A.

7

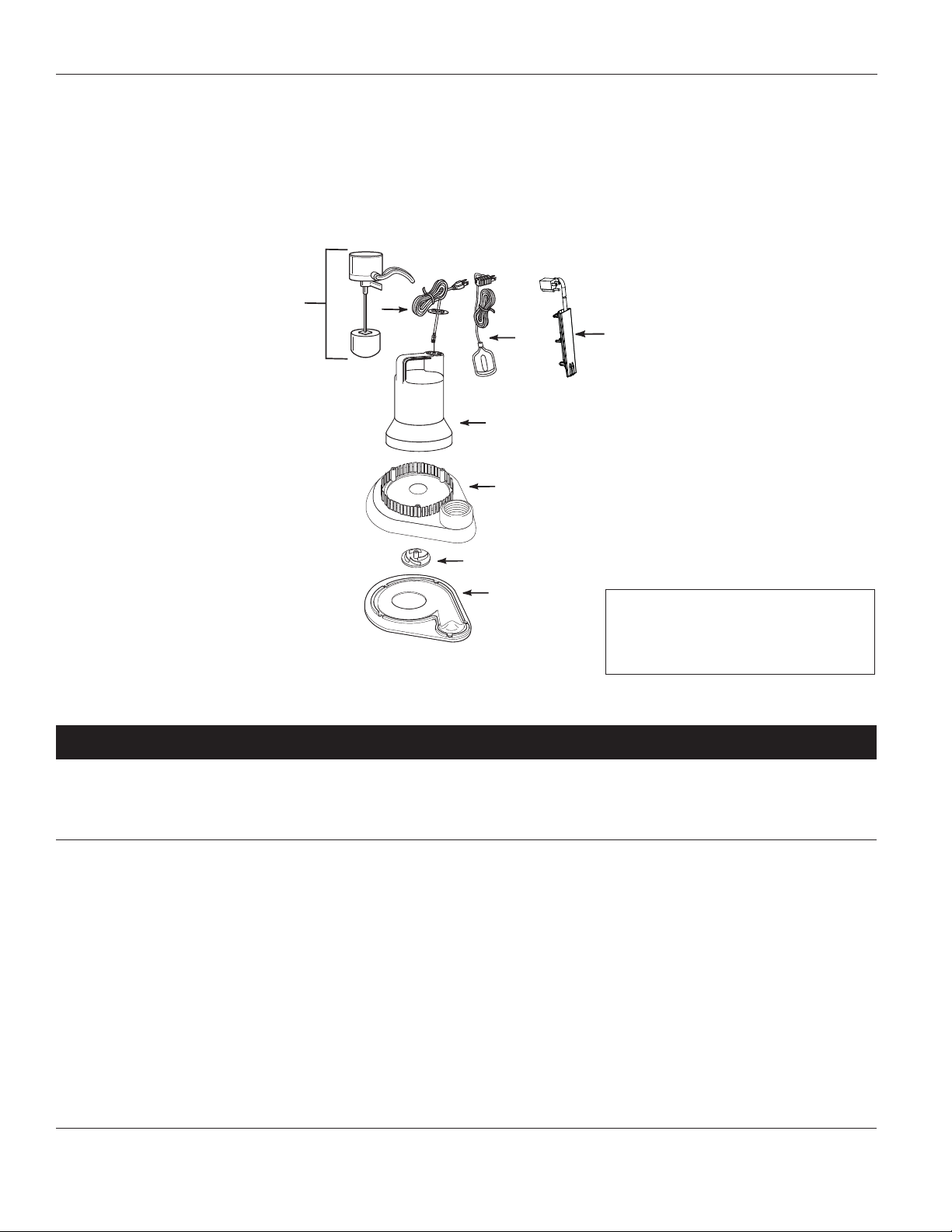

Figure 5 – Replacement Parts Illustration for BWST, BWSF and BWSCAP Series

6

1

2

4

3

5

8

IMPORTANT: Only use factory parts

to repair this pump.

Replacement Parts List for BWST, BWSF and BWSCAP Series

Reference BWSF25, BWSF30

Number Description BWST25, BWST30 BWST50 BWSCAP30

1 Tether Float Switch Kit (BWST) 60022-001 60022-001 – – –

2 Motor Assy Kit 60047-001 60049-001 60047-001

3 Impeller Kit 66011-001 66013-001 66011-001

4 Volute 28416-001 28416-001 28416-001

5 Base 28418-001 28418-001 28418-001

6 Power Cord Kit 62003-001 62003-001 62003-001

7 Vertical Float Switch Kit (BWSF) 60051-001 – – – – – –

8 Capacitive Water Sensor (BWSCAP) – – – – – – 30037-001

www.blueangelpumps.com

4

Page 5

BWST, BWSF and BWSCAP Series

Troubleshooting Chart

Symptom Possible Cause(s) Corrective Action

Pump will not start or run 1. Blown fuse 1. If blown, replace with proper sized fuse or reset

breaker

2. Low line voltage 2. If voltage is under 108 volts, check wiring size

3. Defective motor 3. Replace pump

4. Defective float switch 4. Replace float switch

5. Impeller bound-up 5. If impeller will not turn, remove housing and

remove blockage

6. Float obstructed 6. Make sure float move freely up and down

Pump starts and stops too

often

Pump will not shut off or

thermal protector turns off

Pump operates but delivers

little or no water

Gurgling sound from pump at

end of cycle

1. Backflow of water from piping 1. Install or replace check valve (Blue Angel check

valve kit #66005-BLA)

2. Faulty float switch 2. Replace float switch

3. Incoming water is draining on

sensor face

1. Defective float switch 1. Replace float switch

2. Obstacle in piping 2. Remove pump and clean pump and piping

3. Float obstructed 3. Make sure float move freely up and down

4. Low line voltage 4. If voltage is under 108 volts, check wiring size

5. Too many appliances on circuit 5. Install pump on dedicated circuit.

6. Dirty Solid-State Water Sensor 6. Clean sensor face (see Figure 5)

7. Incoming water is draining on

sensor face

1. Low line voltage 1. If voltage is under 108 volts, check wiring size

2. Plugged impeller 2. Clean out impeller

3. Check valve installed backwards 3. Reverse position of check valve

4. Pump airlocked 4. Drill 1/8 inch hole in discharge line between

1. Air injested into pump 1. Wipe off surface of sensor (see Figure 5)

2. Time required for pumping is less

than 4 seconds

3. Position pump switch away from the inlet so

switch is clear from incoming water (See Figure

3).

IMPORTANT: Do not use extension cord to power

pump.

7. Position pump switch away from the inlet so

switch is clear from incoming water (see Figure

3)

pump and check valve

2. Additional run time will not damage pump

www.blueangelpumps.com

5

Page 6

Operating Instructions and Parts Manual

L imited Warranty

For one year for BWST and BWSF models and for two years for BWSCAP models from the date of purchase, Blue Angel will

repair or replace, at its option, for the original purchaser any part or parts of its Sump Pumps or Water Pumps (“Product”)

found upon examination by Blue Angel to be defective in materials or workmanship. Please call Blue Angel (888-636-6628)

for instructions or see your dealer. Be prepared to provide the model number and the serial number when exercising this

warranty. All transportation charges on Products or parts submitted for repair or replacement must be paid by purchaser.

This Limited Warranty does not cover Products which have been damaged as a result of accident, abuse, misuse, neglect,

improper installation, improper maintenance, or failure to operate in accordance with Blue Angel’s written instructions.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM THE DATE OF PURCHASE. THIS IS THE

EXCLUSIVE REMEDY AND ANY LIABILITY FOR ANY AND ALL INDIRECT OR CONSEQUENTIAL DAMAGES OR EXPENSES

WHATSOEVER IS EXCLUDED.

Some states do not allow limitations on how long an implied warranty lasts, or do not allow the exclusions or limitations of

incidental or consequential damages, so the above limitations might not apply to you. This limited warranty gives you specific

legal rights, and you may also have other legal rights which vary from state to state.

In no event, whether as a result of breach of contract warranty, tort (including negligence) or otherwise, shall Blue Angel or

its suppliers be liable for any special, consequential, incidental or penal damages including, but not limited to loss of profit or

revenues, loss of use of the products or any associated equipment, damage to associated equipment, cost of capital, cost of

substitute products, facilities, services or replacement power, downtime costs, or claims of buyer’s customers for such damages.

You MUST retain your purchase receipt along with this form. In the event you need to exercise a warranty claim, you MUST

send a copy of the purchase receipt along with the material or correspondence. Please call Blue Angel (888-636-6628) for

return authorization and instructions.

DO NOT MAIL THIS FORM TO BLUE ANGEL. Use this form only to maintain your records.

MODEL NO._______________ SERIAL NO.__________________________ INSTALLATION DATE_____________

ATTACH YOUR RECEIPT HERE

www.blueangelpumps.com

6

Page 7

Instructions d’Utilisation et Manual de Pièces Séries BWST, BWSF et BWSCAP

Veuillez lire et conserver ces instructions. Lire attentivement avant de commencer à assembler, installer, faire

fonctionner ou entretenir l'appareil décrit. Protégez-vous et les autres en observant toutes les informations

sur la sécurité. Négliger d'appliquer ces instructions peut résulter en des blessures corporelles et/ou en des

dommages matériels ! Conserver ces instructions pour références ultérieures.

The Professional’s Line

Pompe De

Puisard

Immergée

Description

La pompe immergée est conçue pour les

applications d’assèchement de maison

à l’intérieur. Le modèle est équipé avec

un cordon d’alimentation de 2,43 cm

à 3-broches de type mis à la terre. Le

Avis indique de

importante pour éviter le dommage de

l’équipement.

IMPORTANT: L'information qui exige

une particulière attention.

moteur remplit d’huile et scellé est

conçu pour le fonctionnement frais,

sous l’eau. La pompe est fournie avec

un détecteur de niveau d’eau à flotteur,

Généralités sur la Sécurité

PROPOSITION 65 DE CALIFORNIE

Ce produit ou son

électronique à état solide, pour le

fonctionnement automatique. Cette

pompe n’est pas convenable pour les

animaux aquatiques.

Déballage

Dès que l’appareil est déballé,

l’inspecter attentivement pour tout

signe de dommages en transit. S’assurer

de resserrer tous les raccords, boulons,

etc. avant de le mettre en service.

contenir des produits chimiques qui, de

l’avis de l’État de Californie, causent le

cancer et des anomalies congénitales

ou autres problèmes de reproduction.

Lavez-vous les mains après la

manipulation.

GÉNÉRALITÉS SUR LA SÉCURITÉ

Lire attentivement ces règles

et instructions. Le non-respect

de ces instructions pourrait

causer de graves blessures

et/ou des dommages à la

Directives de Sécurité

Ce manuel contient de l’information

très importante qui est fournie pour

la SÉCURITÉ et pour ÉVITER LES

PROBLÈMES D’ÉQUIPEMENT. Rechercher

les symboles suivants pour cette

information.

Danger indique une

situation

hasardeuse imminente qui RÉSULTERA

en perte de vie ou blessures graves.

Avertissement

indique une

situation hasardeuse potentielle

qui PEUT résulter en perte de vie ou

blessures graves.

Attention indique

une situation

hasardeuse potentielle qui PEUT résulter

en blessures.

propriété.

Ne pas

les fl uides explosifs tels

que l’essence, l’huile à

chauffage, le kérosène etc.

Ne pas utiliser dans un atmosphère

infl ammable et/ou explosif. La pompe

devrait être utilisée pour le pompage

de l’eau claire seulement, sinon, il y a

risque de blessures personnelles et/ou

dégâts matériels.

Cette pompe n’est

les substances qui contiennent les

produits chimiques caustiques et/ou les

matières étrangères tels que l’eau salée,

la saumure, le décharge de buanderie.

L’utilisation de ces produits peut

endommager la pompe et peut nier la

garantie.

Toute installation

MÉMENTO: Gardez votre preuve datée d'achat à fin de la garantie!

Joignez-la à ce manuel ou classez-la dans un dossier pour plus de sécurité.

l’information

cordon peuvent

MANUEL

pomper

pas conçue pour

des fi ls doit être

effectuée par un électricien qualifi é.

Manque de suivre cet avertissement

peut résulter en secousse électrique

mortelle.

Ne pas

marcher

sur un plancher de sous-sol

trempe ou humide avant

de couper l’électricité. Si la

boîte de branchement est dans le soussol, contacter un électricien. Enlever

la pompe et la réparer ou remplacer.

Manque de suivre cet avertissement

peut résulter en secousse électrique

mortelle.

Un système de

sauvegarde est

recommandé. Blue Angel offre le

Modèle BSP15 et BSP25.

Montage

INTERRUPTEUR À FLOTTEUR (BWSF

SEULEMENT)

1. Placer le support de flotteur dans

la poignée du carter de moteur et

glisser le montage d’interrupteur en

place avec sûreté.

Envoltura del

interruptor

Abrazadera

Flotante

Figure 1

© 2008 Blue Angel™ Pumps 350704-002 9/08

5-Fr

Page 8

Instructions d’utilisation et manual de pièces

Installation

1. Installer la pompe dans une fosse de

taille minumum indiquée ci-dessous.

Construire la fosse de tuiles, béton,

acier ou plastique (Voir Figure 2).

Prise-Mise À

Grounded

Outlet

La Terre

Dia. Min

BWSF 11 po

BWST 14 po

IMPORTANT: Assurer qu’il y a assez

d’espace pour le fonctionnement de

l’interrupteur.

6. Il est nécessaire d’installer un

7. SEULEMENT POUR LES MODÈLES

Min.

24"

24 po

Min.

Fonctionnement

Figure 2

2. Situer le modèle sur une fondation

solide et égale. Ne pas placer

la pompe directement sur une

surface d’argile, terre, gravier ou

de sable. Ces surfaces contiennent

des particules de gravier et de

sable etc., qui peuvent obstruer ou

endommager la pompe et causer la

panne.

Risque

d’inondation. Si

un tuyau de décharge fl exible est

utilisé, assurer que la pompe est fi xée

à la fosse afi n d’éviter le movement

inattendu. Manque de fi xer la pompe

peut résulter en movement de la pompe

et en interférence de l’interrupteur et

peut empêcher le démarrage ou l’arrêt

de la pompe.

3. Fileter le clapet (Blue Angel vous

offre le Modèle 66005-BLA) dans le

corps de la pompe avec soin pour

éviter le foirage ou l’abattement. Ne

pas utiliser le mastic de fermeture

pour joints.

4. Brancher le tuyau rigide d’1-1/4 po

au manchon de caoutchouc sur le

clapet. L’inverser pour le tuyau de 1

1/2 po. Serrer les colliers de serrage.

Il est nécessaire

de soutenir la

pompe et la tuyauterie pendant

l’assemblage et après l’installation afi n

d’éviter la rupture du tuyau ou la panne

de la pompe etc, ce qui peut résulter

en dégâts matériels et/ou blessures

personnelles.

5. Protéger les cordons d’alimentation

Toujours débrancher la source

de puissance avant d’essayer

d’installer, de déplacer ou de

procéder à l’entretien de la

pompe. Ne jamais toucher la pompe de

puisard, le moteur de la pompe, l’eau ou

la tuyauterie de décharge si la pompe

est branchée à une source électrique.

Ne jamais manipuler la pompe avec les

mains trempes ou si vous êtes sur un

plancher trempe ou humide. Ceci peut

résulter en secousse électrique mortelle.

1. Un interrupteur DDFT est exigé.

Risque de secousse

pompe est fournie avec un fi l de terre

et une fi che de prise de poste mise à

la terre. Utiliser une prise de courant

mise à la terre pour réduire le risque de

secousse électrique mortelle.

Ne jamais enlever la broche de terre

ronde. Le coupage du cordon ou de la

fi che sert à annuler la garantie et la

pompe ne fonctionnera pas.

Figure 3

contre les objets pointus, surfaces

chaudes, l’huile et les produits

chimiques. Éviter le tortillement du

cordon et remplacer les cordons

endommagés immédiatement.

couvercle de réservoir afin

d’empêcher l’obstruction ou le

dommage à la pompe par le débris.

BWSCAP : Placer l’interrupteur de

la pompe LOIN de l’entrée pour que

l’interrupteur soit loin de l’entrée

d’eau (voir la Figure 3).

électrique! Cette

Prise-Mise À La Terre

Grounded Outlet

Incoming Water

Entrée d’eau

Inlet Pipe

Tuyau d’entrée

ON @ 8 inches

Marche @ 20 cm (8 po)

Arrêt @ environ 7,6 cm (3 po)

OFF @ 3 inches

2. Cette pompe est fabriquée pour le

service de 120 volts (monophasé), 60

hz, 15 A seulement et est équipée

avec un cordon à 3 fils et une fiche à

3 broches de terre. Introduire la fiche

de l’interrupteur flotteur directement dans une prise de 120 volts.

3. Introduire le cordon d’alimentation

de la pompe directement en

arrière de la fiche de l’interrupteur

flotteur ou de la prise du cordon du

détecteur d’eau à état solide (Voir

Figures 4a et 4b).

Power

Cordon

Cord

D’Alimentation

D’Interrupteur

Figure 4a

Grounding

Broche De

Grounding

Terre

Blade

Cordon

Blade

Switch

Cord

Prise-Mise

Grounded

À La Terre

Outlet

RESET

TEST

Grounded

Outlet

RESET

TEST

Power

Cord

Switch

Cord

Figure 4b

Interrupteur

Switch

Clapet

Check Valve

8-Fr

Page 9

Séries BWST, BWSF et BWSCAP

Fonctionnement (Suite)

4. Remplir le puisard d’eau. La pompe

se démarrera automatiquement une

fois que l’eau atteint le niveau d’eau

de démarrage et s’arrêtera quand

l’eau atteint le niveau de coupage.

Se référer aux Spécifications

pour les niveaux de démarrage/

coupage. La pompe fonctionnera

automatiquement si exigée.

5. Ne pas faire fonctionner la pompe si

elle n’est pas submergée dans l’eau.

Le fonctionnement sec peut causer

la panne de la pompe.

6. Le moteur est équipé avec un

protecteur thermique automatique.

7. Vérifier que le tuyau de décharge

transporte l’eau à un endroit

plusieurs pieds de la fondation

pendant son fonctionnement.

8. Si la ligne de décharge est exposée

à la gelée, elle doit être inclinée.

Les poches d’eau peuvent geler et

endommager la pompe.

SEULEMENT POUR LES MODÈLES

BWSCAP :

9. Le puisard se mettra en marche

lorsque l’eau est à 3,81 cm (1,5 po)

du dessus de l’interrupteur.

10. La pompe de puis

pendant au moins 4 secondes à un

maximum de 16 secondes avant de

s’arrêter.

11. Le temps de fonctionnement de la

pompe de puisard sera déterminé

par la taille du puisard et le rythme

d’écoulement d’eau dans le puisard.

12. Pendant les inondations, la pompe

s’arrêtera pendant 1 seconde, toutes

les 16 secondes et se remettra en

marche automatiquement.

ard fonctionnera

Entretien

Toujours débrancher la source

d’électricité avant d’essayer

d’installer, de déplacer ou de

procéder à l’entretien. Si la source de

puissance est hors vue, verrouiller et

étiquetter dans la position ouverte (off)

pour éviter l’alimentation inattendu.

Manque de suivre ces directives peut

résulter en secousse électrique mortelle.

Seul un électricien qualifi é devrait

réparer ce modèle. La réparation

incorrecte peut résulter en secousse

électrique mortelle.

1. Laisser la pompe refroidir pour un

minimum de deux heures avant de

procéder à l’entretien. La pompe

contient de l’huile chaude sous

pression et le moteur est chaud.

2. Le démontage du moteur avant la

date d’expiration de la garantie sert

à annuler la garantie. Se référer au

guide de dépannage.

3. Garder l’arrivée propre et libre

de tous matériaux et l’inspecter

annuellement. Une arrivée obstruée

peut endommager la pompe.

La pompe devrait être inspectée

4.

mensuellement afin d’assurer le

fonctionnement correct.

Cette pompe

diélectrique pour le refroidissement.

Cette huile peut être nocif à

l’environnement. Se référer aux lois

d’environnement avant la mise au rebut

de cette huile.

contient de l’huile

Figure 5

La surface

de travail

du

capteur

doit rester

libre de

toute

matière

étrangère.

Spécifications

Exigences d’alimentation 120V, 60 hz

Moteur Monophasé, rempli d’huile

Gamme de température de

liquides

Exigence de circuit 15 A (min)

Dimensions Hauteur 11 po x Base de

Niveau de démarrage (réglé

à l’usine)

Niveau d’arrêt (réglé à

l’usine)

4,5º C à 49,3º C

9 po

BWST =

14 po

BWST =

7 po

BWSF =

7 po

BWSF =

2-1/2 po

Fabrication

Carter du moteur Thermoplastique renforcé de verre

Volute Thermoplastique

Turbine Thermoplastique renforcé de verre

Arbre Acier inoxydable 416

Joints Buna N

Débit 1-1/2 po NPT

9-Fr

Page 10

Instructions d’utilisation et manual de pièces

Pour pièces de rechange ou assistance technique,

appeler 1-888-636-6628

S’il vous plaît fournir l’information suivante: Adresser toute correspondance à :

- Numéro de Modèle Blue Angel

- Numéro de série (si présent) 101 Production Drive

- Description et numéro de la pièce Harrison, OH 45030 U.S.A.

7

Figure 5 – Illustration de pièces de rechange pour séries BWST, BWSF and BWSCAP

6

1

2

4

3

5

8

Avis: Utiliser seulement les pièces

de l’usine pour la réparation de

cette pompe.

Liste de pièces de rechange pour séries BWST, BWSF and BWSCAP

Numéro de BWSF25, BWSF30

référence Description BWST25, BWST30 BWST50 BWSCAP

1 Jeu d’interrupteur flotteur (BWST) 60022-001 60022-001 – – –

2 Jeu d’assem. de moteur 60047-001 60049-001 60047-001

3 Jeu de turbine 66011-001 66013-001 66011-001

4 Volute 28416-001 28416-001 28416-001

5 Base 28418-001 28418-001 28418-001

6 Jeu de cordon d’alimentation 62003-001 62003-001 62003-001

7 Jeu d’interrupteur à flotteur (BWSF) 60051-001 – – – – – –

8 Le capteur d’eau capacitif (BWSCAP) – – – – – – 30037-001

10-Fr

Page 11

Séries BWST, BWSF et BWSCAP

Guia Geral de Solução de Problemas

Problema Possíveis causas Ação corretiva

La pompe ne se démarre pas

et ne fonctionne pas

La pompe se démarre et

s’arrête trops souvant

La pompe ne s’arrête pas

ou le protecteur thermique

s’arrête

La pompe fonctionne mais

refoule peu ou pas d’eau

1. Fusible sauté 1. Si sauté, le remplacer avec un fusible de

taille correcte ou rajuster le disjoncteur

2. Tension de ligne basse 2. Si la tension est sous 108 volts, vérifier la

taille des fils

3. Moteur défectueux 3. Remplacer la pompe

4. Interrupteur flotteur défectueux 4. Remplacer l’interrupteur flotteur

5. Turbine gripée 5. Si la turbine ne tourne pas, enlever le carter

et enlever l’obstruction

6. Flotteur obstrué 6. Assurer le movement libre du flotteur

1. Refoulement d’eau du tuyau 1. Installer ou remplacer le clapet (Jeu de

clapet Blue Angel #66005-BLA)

2. Flotteur défectueux 2. Remplacer l’interrupteur flotteur

L’eau en entrée décharge sur la surface

3.

du détecteur

1. Interrupteur flotteur défectueux 1. Remplacer l’interrupteur flotteur

2. Obstruction de la tuyauterie 2. Enlever la pompe et nettoyer la pompe et la

3. Flotteur obstrué 3. Assurer le movement libre du flotteur

4. Basse tension 4. Si la tension est inférieure à 108 volts,

5. Trop d’appareils sur le circuit 5. Installer la pompe sur un circuit réservé

6. Capteur d’eau à semi-conducteur sale 6. Nettoyer la face du capteur (voir la Figure

7. Entrée d’eau draine sur la face du

capteur

1. Tension de ligne basse 1. Si la tension est sous 108 volts, vérifier la

3. Placer l’interrupteur de la pompe loin

de l’entrée d’eau de manière à ce que

l’interrupteur soit libre de l’eau en entrée

(voir Figure 3).

tuyauterie

vérifier la taille du câblage

IMPORTANT: Ne pas utiliser de rallonges pour

alimenter la pompe.

5).

7. Placer l’interrupteur de la pompe loin de

l’entrée pour que l’interrupteur soit loin

de l’entrée d’eau (voir la Figure 3).

taille des fils

Son de gargouillis de la

pompe à la fin du cycle

2. Turbine obstruée 2. Nettoyer la turbine

3. Clapet installé à l’envers 3. Inverser la position du clapet

4. Poche d’air dans la pompe 4. Percer un trou de 3,1 mm (1/8 po) dans la

conduite de décharge entre la pompe et le

clapet

1. Air injecté dans la pompe 1. Essuyer la surface du capteur (voir Figure 5)

2. Le temps requis pour pomper est de

moins de 4 secondes

11-Fr

2. Un temps de fonctionnement

supplémentaire n’endommagera pas la

pompe

Page 12

Instructions d’utilisation et manual de pièces

Garantie Limitée

Pendant un an pour les modèles BWST et BWSF, et pendant deux ans pour les modèles BWSCAP, à partir de la date d’achat,

Blue Angel vas réparer ou remplacer, à son option, pour l’acheteur originel n’importe quelle pièce ou pièces de ces Pompes

(“Produit”) déterminées défectueuses, par Blue Angel, en matière ou en fabrication. S’il vous plaît appeler Blue Angel

(888-636-6628) pour instructions ou contacter votre marchand. Assurer d’avoir, à votre disposition, le numéro du modèle afin

d’effecture cette garantie. Les frais de transportation des Produits ou pièces soumis pour la réparation ou le remplacement

sont la responsabilité de l’acheteur.

Cette Garantie Limitée ne traite pas les Produits qui se sont fait endommagés en résultat d’un accident, traitement en

rigueur, mauvais usage, négligence, l’installation incorrecte, entretien incorrect, ou manque d’utilisation conformément aux

instructions écrit de Blue Angel.

IL N’EXISTE AUCUNE AUTRE GARANTIE OU AFFIRMATION. LES GARANTIES EXPRIMÉES, Y COMPRIS CELLES QUI

INDIQUE SI LE PRODUIT EST VENDABLE OU CONVENABLE À UN USAGE PARTICULIER, SONT LIMITÉS À UN AN À

COMPTER DE LA DATE D’ACHAT. CECI EST LA REMÈDE EXCLUSIVE ET N’IMPORTE QUELLE RESPONSABILITÉ POUR

N’IMPORTE QUEL ET TOUT DOMMAGES INDIRECTS OU DÉPENSES QUOI QUE SE SOIT EST EXCLUS.

Certaines Provinces n’autorisent pas de limitations de durée pour les garanties implicites, ni l’exclusion ni la limitation des

dommages fortuits ou indirects. Les limitations précédentes peuvent donc ne pas s’appliquer. Cette garantie limitée donne, à

l’acheteur, des droits légales précis, et vous pouvez avoir autres droits légales qui sont variable d’une Province ou d’un État à

l’autre.

En aucun cas, soit par suite d’un rupture de contrat de garantie, acte dommageable (y compris la négligence) ou autrement,

ni Blue Angel ou ses fournisseurs seront responsables pour aucune dommage spéciale, incidentel ou pénal, y compris, mais

pas limité à la perte de profits ou recettes, la perte d’usage des produits ou n’importe quel équipement associé, dommage à

l’équipement associé, coût de capital, coût de produits remplaçants, aménagements, services ou abilité de remplaçement, coût

de temps que le produit n’est pas en service, ou la réclamation des clients de l’acheteur pour ces dommages.

Vous DEVEZ garder votre recette d’achat avec ce bulletin. Il est NÉCESSAIRE d’envoyer une copie de la recette d’achat

avec le matériel ou correspondance afin d’effectuer une réclamation de la garantie. S’il vous plaît appeler Blue Angel

(888-636-6628) pour l’autorisation et instructions concernant le renvoi.

NE PAS ENVOYER, PAR LA POSTE, CE BULLETIN À BLUE ANGEL. Utiliser ce bulletin seulement pour vos archives.

Nº DU MODÈLE ______________________ Nº DE SÉRIE______________________ DATE D’INSTALLATION ______________________

CORDÓN DEL INTERRUPTOR

12-Fr

Page 13

Manual de Instrucciones de Operación y Lista de Partes Series BWST, BWSF y BWSCAP

Por favor lea y guarde estas instrucciones. Léalas cuidadosamente antes de tratar de montar, instalar, operar

o dar mantenimiento al producto aquí descrito. Protéjase usted mismo y a los demás observando toda la

información de seguridad. ¡El no cumplir con las instrucciones puede ocasionar daños, tanto personales como a

la propiedad! Guarde estas instrucciones para referencia en el futuro.

The Professional’s Line

Bomba

sumergible

para sumideros

Descripción

La bomba sumergible está diseñada

para aplicaciones de sumidero

domésticas al interior. Esta unidad le

ofrece un cordón eléctrico de 2,43 cm (8

pies) de longitud, con 3 terminales para

conexión a tierra. El motor viene lleno

de aceite y sellado de fábrica y está

diseñado para funcionar a temperaturas

más bajas y sumergido en agua.

Para el funcionamiento automático de

la bomba, se proporciona un interruptor

de control del nivel del agua, de

flotador, electrónico y de estado sólido.

Esta bomba no esta diseñada para

usarse en peceras.

Desempaque

Al desempacar este producto, revíselo

con cuidado para cerciorarse de que

esté en perfecto estado. Cericiórese de

apretar todas las conexiones, pernos,

etc. antes de comenzar a utilizar la

unidad.

Medidas de Seguridad

Este manual contiene información

que es muy importante que sepa

y comprenda. Esta información se

la suministramos como medida de

SEGURIDAD y para EVITAR PROBLEMAS

CON EL EQUIPO. Debe reconocer los

siguientes símbolos.

Ésto le indica que

hay una situación

inmediata que LE OCASIONARIA la

muerte o heridas de gravedad.

Ésto le indica

que hay una

situación que PODRIA ocasionarle la

muerte o heridas de gravedad.

Ésto le indica

que hay una

situación que PODRIA ocasionarle

heridas no muy graves.

Ésto le indica una

importante, que de no seguirla, le

podría ocasionar daños al equipo.

información

IMPORTANTE: Información que

requiere la atención especial.

Informaciones Generales de

Seguridad

PROPOSICIÓN 65 DE CALIFORNIA

Este producto, o

puede contener productos químicos

conocidos por el estado de California

como causantes de cáncer y defectos de

nacimiento u otros daños reproductivos.

Lave sus manos después de usar.

INFORMACIONES

GENERALES DE

SEGURIDAD

Lea estas instrucciones con

su cordón eléctrico,

MANUAL

Todos los trabajos

debe hacer un electricista califi cado.

Si no sigue estas advertencias podría

electrocutarse.

Si el piso

no está húmedo o inundado,

no entre hasta que haya

desconectado la electricidad.

Si la caja de fusibles está en el sótano,

llame a un electricista. Desconecte la

bomba y repárela o reemplácela. Si

no sigue estas advertencias podría

electrocutarse.

Siempre debe usar

emergencia. Blue Angel le ofrece el

Modelo BSP15 y BSP25.

Ensamblaje

INTERRUPTOR FLOTANTE VERTICAL

(SOLO EN EL MODELO BWSF)

1. Conecte la abrazadera del flotante

cuidado. Si no sigue estas

instrucciones podría sufrir

heridas de gravedad y/o

daños a su propiedad.

use esta bomba para bombear líquidos

infl amables o explosivos tales como

gasolina, combustibles, kerosene,

etc. No la use donde haya peligro de

explosión. Úsela sólo para drenar agua.

Si no sigue estas recomendaciones

podría ocasionarle heridas o daños a

su propiedad.

Esta bomba no

bombear agua de mar, salmuera, agua

con detergentes o cualquier mezcla

de agua con químicos cáusticos y/o

impurezas. Si la utiliza para este tipo

de aplicaciones se podría dañar y la

garantía se cancelaría.

Nunca

está diseñada para

Figura 1

de electricidad los

del sóta-

un sistema de

al mango de la envoltura del motor

y después conecte el ensamblaje

del interruptor de modo que calce

correctamente.

Envoltura del

interruptor

Abrazadera

Flotante

RECORDATORIO: ¡Guarde su comprobante de compra con fecha para fines de la garantía!

Adjúntela a este manual o archívela en lugar seguro.

© 2008 Blue Angel™ Pumps 350704-002 9/08

13-Sp

Page 14

Manual de Instrucciones de Operación y Lista de Partes

Instalación

1. Instale le bomba dentro del foso

del sumidero cuyas dimensiones

mínimas sean las indicadas en la

Figure 2. Construya el foso de

loseta, concreto, acero o plástico.

4. Conéctele una tubería rígida de

3,18 cm (1-1/4”) a la pieza de goma

de la válvula de chequeo. Invierta

la pieza de goma para conectarla a

las tuberías de 3,81 cm (1-1/2”) de

diámetro. Apriete las abrazaderas de

la manguera.

Grounded

Tomacorrientes

Outlet

con conexión a

tierra

Diá. mín.

BWSF 27,94 cm

BWST 35,56 cm

Mín.

24"

Min.

60,96

cm

Tanto la bomba

se deben colocar sobre algo que

las sostenga durante el proceso de

ensamblaje y después de haberlas

instalado. De lo contrario, las tuberías

se podrían romper, la bomba podría

fallar, etc. y podría ocasionarle daños a

su propiedad y/o heridas personales.

5. Proteja el cordón eléctrico contra

objetos afilados, superficies

calientes, aceite y químicos.

Evite que el cordón se enrolle

y reemplácelo inmediatamente

cuando se dañe.

Figura 2

2. La unidad se debe colocar sobre

una base sólida y nivelada. Nunca

la coloque directamente sobre

arcilla, tierra, piedras o arena. Estas

superficies podrían dañar la bomba.

Peligro de

inundación. Si usa

una manguera de descarga fl exible,

cerciórese de que la bomba esté

fi jada al sumidero para evitar que

se mueva. Si la bomba no se fi ja, el

interruptor podría desconectarse con

el movimiento y evitar que la bomba se

encienda o se apague.

IMPORTANTE: Cerciórese de que

haya suficiente espacio para que el

interruptor funcione.

6. Siempre debe tapar el sumidero

para evitar que a la bomba le caigan

desperdicios y la obstruyan o la

dañen.

7. SÓLO PARA LOS MODELOS

BWSCAP: Posicione la bomba LEJOS

de la entrada de agua de manera

que el interruptor no quede cerca de

la entrada de agua (Vea la Figura 3).

Funcionamiento

3. Atorníllele la válvula de chequeo

(Blue Angel le ofrece el Modelo

66005-BLA) a la bomba. Cerciórese

de atornillarla adecuadamente.

No use pegamento (cola) en las

conexiones.

Tomacorrientes con conexión a tierra

Grounded Outlet

Siempre desconecte el

cordón eléctrico antes de

tratar de instalar la bomba,

darle servicio, moverla a otro sitio o

darle mantenimiento. Nunca toque la

como las tuberías

bomba, el motor, el agua o la tubería de

descarga mientras el cordón eléctrico

esté conectado al tomacorrientes.

Nunca toque ni la bomba ni el motor

con las manos mojadas o mientras esté

parado sobre una superfi cie húmeda o

inundada. Podría electrocutarse.

1. Siempre debe usar un cordón que

tenga un interruptor automático

incorporado.

¡ Peligro de

Esta bomba tiene un sistema de

conexión y un terminal para conexión

a tierra. Debe conectarla a un tomacorrientes con conexión a tierra para

reducir el peligro de electrocutamiento.

Nunca le corte el terminal redondo

de conexión a tierra al enchufe. Si le

corta el cordón eléctrico o el enchufe,

la garantía se cancela y la bomba no

funcionará.

electrocutamiento!

2. Esta bomba está diseñada para

usarse en sistemas eléctricos

monofásicos de 120 Volt, 60 hz, 15

amp y tiene un cordón eléctrico

con 3 cables para conexión a tierra

al igual que un enchufe con 3

terminales para conexión a tierra.

El cordón del interruptor/flotante

se debe conectar directamente a un

tomacorrientes de 120 voltios.

3. Conecte el cordón de la bomba al

tomacorrientes ubicado en la parte

Switch

Cord

Tomacorrientes

Grounded

con conexión a

Outlet

tierra

RESET

TEST

Terminal para

conexión a tierra

Power

Cordón

Cord

eléctrico

Figure 4a

Grounding

Blade

Cordón del

interruptor

Incoming Water

Agua en entrada

Inlet Pipe

Tubería de entrada

Activación a 20,32 cm (8 inch)

ON @ 8 inches

OFF @ 3 inches

Apagado a 7,62 cm (3 inch)

Figura 3

Interruptor

Switch

Válvula de retención

Check Valve

14-Sp

Power

Cord

Figure 4b

Grounding

Blade

Switch

Cord

Grounded

Outlet

RESET

TEST

Page 15

Series BWST, BWSF y BWSCAP

Funcionamiento (Continued)

posterior del enchufe del cordón del

flotante o del enchufe del cordón

del sensor de agua de estado sólido

(Vea la Figuras 4a y 4b).

4. Llene el sumidero de agua.

La bomba se encenderá

automáticamente tan pronto como

el nivel de agua haya alcanzado

el nivel mínimo fijado de fábrica.

Vea los niveles de encendido/

interrupción en la sección de

especificaciones. Posteriormente, la

bomba funcionará automáticamente

cuando sea necesario.

5. No utilice la bomba a menos que

esté sumergida en agua. De lo

contrario la bomba se dañará.

6. El motor tiene un protector térmico

automático.

7. La tubería de descarga debe

extenderse a una distancia de varios

pies de las bases de la casa.

8. Si la línea de descarga de la bomba

está expuesta a temperaturas por

debajo del nivel de congelamiento,

cerciórese de que no le quede agua

depositada. Los dépositos de agua se

congelarían y dañarían la bomba.

SÓLO PARA LOS MODELOS BWSCAP:

9. La bomba de sumidero se enciende

cuando el agua es cerca de 1,5 inch

(3,81 cm) desde el extremo superior

del interruptor.

10. La bomba de sumidero trabaja por

un mínimo de 4 segundos, hasta un

máximo de 16 antes de apagarse.

11. El tiempo de funcionamiento de la

bomba de sumidero es determinado

por el tamaño del pozo del sumidero

y el flujo de agua en el pozo de

sumidero.

12. Bajo condiciones de inundación, la

bomba se apaga por 1 segundo cada

16 segundos y vuelve a encenderse

automáticamente.

Mantenimiento

Siempre desconecte el cordón

eléctrico antes de tratar

de instalar la bomba, darle

servicio, moverla a otro sitio o darle

mantenimiento. Si el interruptor está

fuera de su alcance, cerciórese de que

no se pueda activar accidentalmente

(fíjelo en “off”) . Si no sigue estas

recomendaciones podría electrocutarse.

Sólo electricistas califi cados deben

reparar esta unidad. Un electricista

inexperto podría hacer algo indebido

y consecuentemente Ud. podría

electrocutarse.

1. La bomba se debe dejar enfriar por

lo menos 2 horas antes de darle

servicio, ya que el motor se calienta

y la bomba tiene aceite caliente bajo

presión.

2. Si desmantela el motor durante

el período de garantía, ésta se

cancelaría. Si necesita repararla, vea

la guía de diagnóstico de averías.

3. Siempre debe mantener la

entrada limpia y sin desperdicios.

Igualmente, debe inspeccionarla una

vez al año. Si la entrada se obstruye

la bomba se dañará.

Debe chequear la bomba

4.

mensualmente para verificar

que esté en buen estado de

funcionamiento.

Esta bomba

contiene aceite

dieléctrico para enfriarla. Este aceite

puede contaminar el medio ambiente.

Cerciórese de que no está violando

ninguna ley de protección del medio

ambiente cuando vaya a deshacerse del

aceite.

La superficie

de trabajo

del sensor

debe

mantenerse

libre de

material

extraño.

Figura 5

Especificaciones

Requerimientos eléctricos 120 Voltios, 60 Hz

Motor Monofásico, con aceite

Temperaturas del líquido 4,5º C à 49,3º C

Circuito eléctrico 15 amperios (mínimo)

Dimensiones 27,94 cm alto X 22,86 cm

(base)

Nivel de encendido (fijado

de fábrica)

Nivel de interrupción (fijado

de fábrica)

BWST =

35,56 cm

BWST =

17,78 cm

BWSF =

17,78 cm

BWSF =

6,35 cm

Materiales de fabricación

Envoltura del

motor

Voluta Termoplástico

Impulsor (propela) Termoplástico reforzado con vidrio

Eje Acero inoxidable 416

Sellos Buna N

Orificio de salida 3,81 cm (1-1/2”) NPT

15-Sp

Termoplástico reforzado con vidrio

Page 16

Manual de Instrucciones de Operación y Lista de Partes

Para Ordenar Repuestos o Asistencia Técnica, Sírvase

Llamar al Distribuidor Más Cercano a Su Domicilio

Sirvase darnos la siguiente información: Dirija toda la correspondencia a:

- Número del modelo Blue Angel

- Código impreso 101 Production Drive

- Descripción y número del repuesto según la lista Harrison, OH 45030 U.S.A.

de repuestos

7

Figura 5 – Ilustración de los repuestos los series BWST, BWSF and BWSCAP

6

1

2

4

3

5

8

IMPORTANTE: Use sólo repuestos

legítimos para reparar esta bomba.

Lista de Partes de Reparación para los series BWST, BWSF and BWSCAP

Número de BWSF25, BWSF30

Referencia Descripción BWST25, BWST30 BWST50 BWSCAP

1 Flotante/interruptor (BWST) 60022-001 60022-001 – – –

2 Motor 60047-001 60049-001 60047-001

3 Impulsor (propela) 66011-001 66013-001 66011-001

4 Voluta 28416-001 28416-001 28416-001

5 Base 28418-001 28418-001 28418-001

6 Cordón eléctrico 62003-001 62003-001 62003-001

7 Juego de interruptor/flotante vertical (BWSF) 60051-001 – – – – – –

8 Sensor de agua capacitivo (BWSCAP) – – – – – – 30037-001

16-Sp

Page 17

Series BWST, BWSF y BWSCAP

Tabla de Identificación de Problemas

Síntoma Causa(s) Posible(s) Medida Correctiva

La bomba no se enciende o

no funciona

La bomba se enciende y se

apaga constantemente

La bomba no se apaga o el

protector térmico se apaga

La bomba funciona pero casi

no bombea agua

La bomba emite un ruido de

borboteo al final del ciclo

1. El fusible está quemado 1. Si se quemó, reemplácelo con un fusible

adecuado o conecte el cortacircuito

2. El voltaje es muy bajo 2. Si el voltaje es menos de 108 voltios,

chequée el alambrado

3. El motor está dañado 3. Reemplace la bomba

4. El flotante/interruptor está dañado 4. Reemplace el flotante/interruptor

5. El impulsor está atascado 5. Si el impulsor no gira, destápelo y límpielo

6. El flotante está obstruído 6. Cerciórese de que el flotante puede subir y

bajar sin obstaculos

1. El agua se regresa de las tuberías 1. Instale una válvula de chequeo o

reemplácela (use la válvula de chequeo Blue

Angel #66005-BLA)

2. El flotante/interruptor está dañado 2. Reemplace el flotante/interruptor

La entrada de agua descarga sobre la

3.

superficie del sensor

1. El flotante/interruptor está dañado 1. Reemplace el flotante/interruptor

2. Las tuberías están obstruídas 2. Desconecte la bomba y limpie la bomba y

3. El flotante está obstruído 3. Cerciórese de que el flotante puede subir y

4. Bajo voltaje 4. Si el voltaje está por debajo de 108 voltios,

5. Demasiados electrodomésticos sobre el

circuito eléctrico

6. Sensor de agua de estado sólido sucio 6. Limpie la superficie del sensor (ver Figura 5)

7. La entrada de agua drena en la

superficie del sensor

1. El voltaje es muy bajo 1. Si el voltaje es menos de 108 voltios,

2. El impulsor está obstruído 2. Limpie el impulsor

3. Válvula de retención instalada al revés 3. Invierta la posición de la válvula de

4. Aire en la bomba 4. Taladre un orificio de 3 mm (1/8 inch) en

1. La bomba ha aspirado aire 1. Limpie la superficie del sensor (ver Figura 5).

2. El tiempo requerido para bombear es

menos de 4 segundos

3. Coloque el interruptor de la bomba lejos

de la entrada de agua de manera que el

interruptor no quede expuesto al agua en

entrada (ver Figura 3).

las tuberías

bajar sin obstaculos

verifique el tamaño del cable

5. Instale la bomba en un circuito dedicado.

IMPORTANTE: NO use un cordón eléctrico de

extensión para alimentar la bomba.

7. Posicione la bomba lejos de la entrada

de agua de manera que el interruptor no

quede cerca de la entrada de agua (ver

Figura 3).

chequée el alambrado

retención

la tubería de descarga entre la bomba y la

válvula de retención

2. El tiempo de funcionamiento adicional no

daña la bomba

17-Sp

Page 18

Manual de Instrucciones de Operación y Lista de Partes

Garantía Limitada

Por un año para los modelos BWST y BWSF y por dos años para los modelos BWSCAP a partir de la fecha de compra, Blue

Angel reparará o reemplazará, según lo consideren adecuadon, cualquier pieza de esta bomba para sumideros (“Producto”)

que el comprador original envie a reparación y los empleados o representantes autorizados de Blue Angel determinen

que están defectuosos debido a problemas de materiales o manufactura. Para recibir información sobre los pasos a seguir,

comuníquese directamente con la compañía Blue Angel (888-636-6628, sólo desde EE.UU.), o con el distribuidor autorizado

más cercano a su domicilio. En el momento de reclamar sus derechos bajo esta garantía deberá suministrarnos el número del

modelo. Todos los gastos de flete serán la responsabilidad del comprador.

Esta garantía limitada no cubre los daños debido a accidentes, abusos, uso inadecuado, negligencia, instalación inadecuada,

mantenimiento inadecuado, o funcionamiento sin seguir las instrucciones suministradas por escrito por la compañía Blue

Angel.

NO HAY NINGUNA OTRA GARANTIA EXPRESA O IMPLISITA. INCLUYENDO AQUELLAS SOBRE VENTA O USOS

ESPECIFICOS, Y LAS GARANTIAS ESTAN LIMITADAS A UN AÑO A PARTIR DE LA FECHA DE COMPRA. THIS IS THE

EXCLUSIVE REMEDY AND ANY LIABILITY FOR ANY AND ALL INDIRECT OR CONSEQUENTIAL DAMAGES OR EXPENSES

WHATSOEVER IS EXCLUDED.

Algunos estados no permiten límites en la duración de las garantías, o no permiten que se limiten o excluyan casos por daños

por accidentes o consecuentes, en dichos casos los límites arriba enumerados tal vez no apliquen para Ud. Esta garantía

limitada le otorga a Ud. ciertos derechos que pueden variar de un estado a otro.

Bajo ninguna circunstyancia, aunque sea debido al incumplimiento del contrato de garantía, culpabilidad (incluyendo

negligencia) u otras causas,la compañía Blue Angel o ninguno de sus surtidores serán responsables legalmente por ningún

fallo legal en su contra, incluyendo, pero no limitado apérdida de ganancias, pérdidas del uso del producto o piezas asociadas

con el equipo, pérdidas de capital, gastos para reemplazar los productos dañados, pérdidas por cierre de fábrica, servicios o

pérdida de electricidad, o demandas persentadas por los clientes del comprador por dichos daños.

Ud. DEBE conservar el recibo como prueba de compra junto con esta garantía. En caso de que necesite presentar un

reclamo de sus derechos bajo esta garantía, Ud DEBERA enviar una copia del recibo de la tienda junto con el producto o

correspondencia. Comuníquese con la compañía Blue Angel (888-636-6628, sólo desde EE.UU) para recibir autorización e

instrucciones de como enviar la mercancía.

NO ENVIE ESTOS DATOS A BLUE ANGEL. Conserve esto sólo como datos.

MODEL NO._______________ NO. DE SERIE __________________________ FECHA DE INSTALACION_____________

GRAPE SU RECIBO DE COMPRA AQUI

18-Sp

Page 19

Notes/Notas

BWST, BWSF, BWSCAP

19

Page 20

Operating Instructions and Parts Manual

Manual de Instrucciones de Operación y Lista de Partes

Manuel d’utilisation et de pièces détachées

Notes/Notas

20

Loading...

Loading...