Blue Angel Pumps BSS20 User Manual [en, es, fr]

Operating Instructions and Parts Manual BSS10, BSS20, BSS25, BSSF50

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or

maintain the product described. Protect yourself and others by observing all safety information. Failure to

comply with instructions could result in personal injury and/or property damage! Retain instructions for

future reference.

The Professional’s Line

Submersible Sump

System

Description

This submersible sump system is

designed for indoor home sump

applications. The system consists of

a primary sump pump and a back-up

sump pump.

The primary system operates on

120-volt household electric power. It

is equipped with a 3-prong grounding

type power cord. The motor is dielectric

oil filled and sealed for cooler running

and is designed to operate under water.

The battery operated back-up sump

pump is included in the event that

the primary pump cannot function. It

does not replace the primary pump.

A float switch automatically turns on

the backup sump pump when water

activates the float. A battery (not

included) must be installed to operate

the back-up sump pump.

Unpacking

Inspect this unit before it is used.

Occasionally, products are damaged

during shipment. If the pump or

components are damaged, call our

customer service department at

1-888-636-6628.

Specifications

BSS10 BSS20 BSS25 BSSF50

Power Supply

Requirements

Motor Single Phase,

Liquid

Temperature

Range

Circuit

Requirements

Dimensions 11 in. high x

120 V, 60 Hz s

12 V DC l

Dielectric Oil

Filled s

40°F to 120°F 40°F to 120°F 40°F to 120°F 40°F to 120°F

15 A (min) s 15 A (min) s 15 A (min) s 15 A (min) s

9 in. base

120 V, 60 Hz s

12 V DC l

Single Phase,

Dielectric Oil

Filled s

11-1/2 in. high x

9-3/4 in. base

120 V, 60 Hz s

12 V DC l

Single Phase,

Dielectric Oil

Filled s

11-1/2 in. high x

12 in. base

120 V, 60 Hz s

12 V DC l

Single Phase,

Dielectric Oil

Filled s

11-1/2 in. high x

12 in. base

Construction

BSS10 BSS20 BSS25 BSSF50

Motor

Housing

Volute Thermoplastic

Impeller Glass Reinforced

Shaft Steel Steel Steel Steel

Discharge 1-1/2 in. NPT s

Glass Reinforced

Thermoplastic

sl

sl

Thermoplastic

1-1/4 in. or

1-1/2 in. socket l

Cold Rolled Steel

s

Glass Reinforced

Thermoplastic l

Cast Iron s

Glass Reinforced

Thermoplastic l

Glass Reinforced

Thermoplastic

1-1/2 in. NPT s

1-1/4 in. or

1-1/2 in. socket l

Cold Rolled Steel

s

Glass Reinforced

Thermoplastic l

Cast Iron s

Glass Reinforced

Thermoplastic l

Glass Reinforced

Thermoplastic

1-1/2 in. NPT s

1-1/2 in. socket l

Cold Rolled Steel

s

Glass Reinforced

Thermoplastic l

Cast Iron s

Glass Reinforced

Thermoplastic l

Glass Reinforced

Thermoplastic

1-1/2 in. NPT s

1-1/2 in. socket l

REMINDER: Keep your dated proof of purchase for warranty purposes!

© 2011, Blue Angel Pumps,

Harrison, Ohio

sPrimary pump lBack-up pump

Attach it to this manual or file it for safekeeping.

For parts, product & service information

visit www.blueangelpumps.com

353502-002 4/11

Operating Instructions and Parts Manual

Safety Guidelines

This manual contains information

that is very important to know and

understand. This information is

provided for SAFETY and to PREVENT

EQUIPMENT PROBLEMS. To help

recognize this information, observe the

following symbols.

DANGER indicates

an imminently

hazardous situation which, if NOT

avoided, WILL result in death or serious

injury.

WARNING indicates

a potentially

hazardous situation which, if NOT

avoided, COULD result in death or

serious injury.

CAUTION indicates

a potentially

hazardous situation which, if NOT

avoided, MAY result in minor or

moderate injury.

NOTICE indicates

important

information, that if NOT followed, MAY

cause damage to equipment.

General Safety Information

CALIFORNIA PROPOSITION 65

This product or its

power cord contains

chemicals known to the State of

California to cause cancer and birth

defects or other reproductive harm.

Wash hands after handling.

GENERAL SAFETY

Do NOT

use to

pump flammable or

explosive fluids such

as gasoline, fuel oil,

kerosene, etc. Do NOT

use in a flammable and/or explosive

atmosphere. Pump SHOULD only be used

to pump clear water. Personal injury

and/or property damage COULD result.

All wiring must be

performed by a

qualified electrician. Failure to follow

this warning could result in fatal

electrical shock.

If the

basement

has water or moisture on

the floor, do NOT walk on

wet area until all power is

turned off. If the shutoff box

is in the basement, call an electrician.

Remove pump and either repair or

replace. Failure to follow this warning

COULD result in fatal electrical shock.

Do not

expose

battery to sparks or flames

as an explosion or fire could

result.

Battery

acid is

corrosive. Avoid spilling

on skin or clothing. Eye

protection must be worn

when handling the battery.

A ground fault

circuit interrupter is

required.

This pump must only

be used to pump

clear water. This pump is not designed

to handle effluent, salt water, brine,

laundry discharge or any other

application which MAY contain caustic

chemicals and/or foreign materials.

Pump damage MAY occur if used in

these applications and WILL void

warranty.

Back-up Pump Battery

Requirements

1. Use only a new fully charged 12

volt deep cycle battery. Electrolyte

level must be checked and

maintained in accordance with

manufacturer’s guidelines.

2. Battery sizes that will fit into the

battery box are 24C, 24VCM, 27C,

27CM, and 27F.

3. Battery recharge time will be

different at each installation. Under

normal conditions it will take two

to four days to bring a deep cycle

battery back to full charge after it

has been discharged. If electrical

power to the house is lost more

than once a week, consider keeping

a spare, fully-charged battery to

replace an exhausted battery for

the back-up sump pump.

Installation

1. Install in a sump pit per the

minimum diameter required

(BSS10: 11 in., BSS20: 12 in.,

BSS25, BSSF50: 15 in. in diameter).

Construct sump pit of tile, concrete,

steel or plastic. Position primary

pump switch AWAY from any inlets

so that incoming water does not

contact the switch face (see

Figure 1, on Page 3).

2. The unit should be located and

rest on a solid, level foundation.

Do not place pump directly on clay,

earth, gravel, or sandy surface.

These surfaces contain small stones,

gravel, sand, etc. that may clog or

damage the pump and cause pump

failure.

Flood risk. If flexible

discharge hose is

used, make sure pump is secured in

sump pit to prevent movement. Failure

to secure pump COULD allow pump

movement and switch interference and

prevent pump from starting or stopping.

3. Using PVC cement and primer,

connect 1-1/4 in. or 1-1/2 in. (only

1-1/2 in. for BSS25 and BSSF50)

rigid pipe to the systems discharge

fitting.

Support pump

and piping when

assembling and after installation.

Failure to do so COULD cause piping to

break, pump to fail, etc. which COULD

result in property damage and/or

personal injury.

4. Place battery in box. Attach red

cable from battery box control

panel to positive battery terminal.

Attach black cable to the negative

terminal. Place cover on battery

box.

If cables are

reversed, damage to

the control box or battery COULD result

and WILL void the warranty.

5. Place battery box within six feet of

the sump and a 120 VAC separately

fused outlet. The outlet must

be protected by a ground fault

circuit interrupter (GFCI). The area

must also be clean, dry and wellventilated.

6. Plug the float switch, pump and

charger into the control box. The

connections are marked on the

control box.

7. Protect electrical cord from

sharp object, hot surfaces, oil

and chemicals. Avoid kinking the

cord and replace damaged cords

immediately.

8. A sump pit cover must be installed

to prevent debris from clogging or

damaging the pump.

www.blueangelpumps.com

2

BSS10, BSS20, BSS25, BSSF50

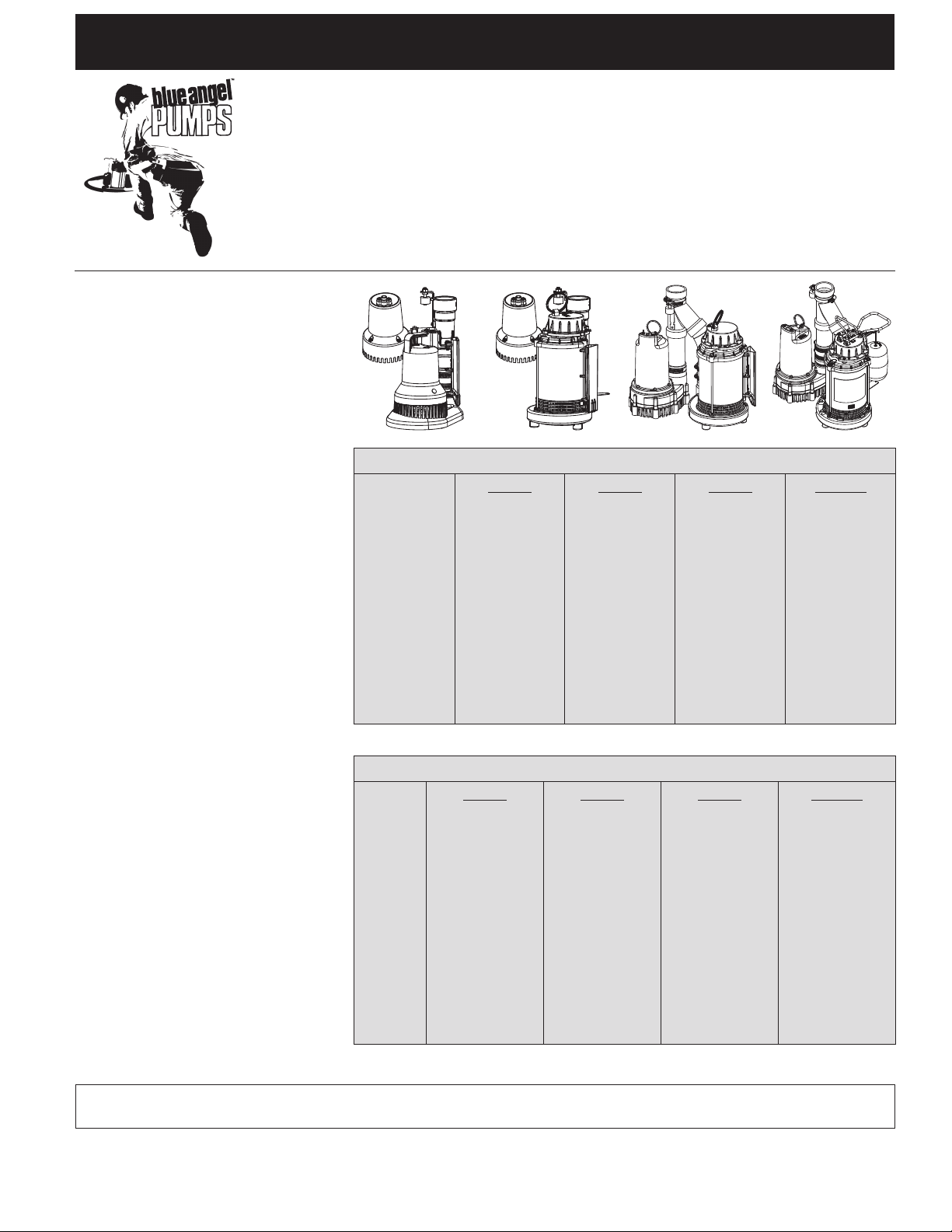

BSS10

GROUNDED

OUTLET

22 IN. MIN.

DISCHARGE PIPE

INLET PIPE

11 IN.

DIAMETER

MIN.

CAPACITIVE SWITCH

ON @ APPROXIMATELY 8 IN.

OFF @ APPROXIMATELY 4 IN.

GROUNDED

OUTLET

CHECK

VALVE

BSS20

GROUNDED

OUTLET

22 IN. MIN.

DISCHARGE PIPE

INLET PIPE

12 IN.

DIAMETER

MIN.

ON @ APPROXIMATELY 8 IN.

OFF @ APPROXIMATELY 4 IN.

GROUNDED

OUTLET

CHECK VALVE

(NOT VISIBLE)

CAPACITIVE SWITCH

BSS25

GROUNDED

OUTLET

22 IN. MIN.

CHECK

Figure 1

DISCHARGE PIPE

INLET PIPE

VALVE

GROUNDED

OUTLET

ISWITCH

ON @ APPROXIMATELY 8 IN.

OFF @ APPROXIMATELY 4 IN.

BSSF50

DISCHARGE PIPE

GROUNDED

OUTLET

INLET PIPE

22 IN. MIN.

CHECK

VALVE

15 IN. DIAMETER MIN.15 IN. DIAMETER MIN.

GROUNDED

OUTLET

FLOAT SWITCH

ON @ APPROXIMATELY 9 IN.

OFF @ APPROXIMATELY 4 IN.

www.blueangelpumps.com

3

Operating Instructions and Parts Manual

Operation - Primary Pump

ALWAYS

disconnect the power source

before attempting to install,

service, relocate or maintain

the pump. NEVER touch sump pump,

pump motor, water or discharge piping

when pump is connected to electrical

power. NEVER handle a pump or pump

motor with wet hands or when standing

on wet or damp surface or in water.

Fatal electrical shock COULD occur.

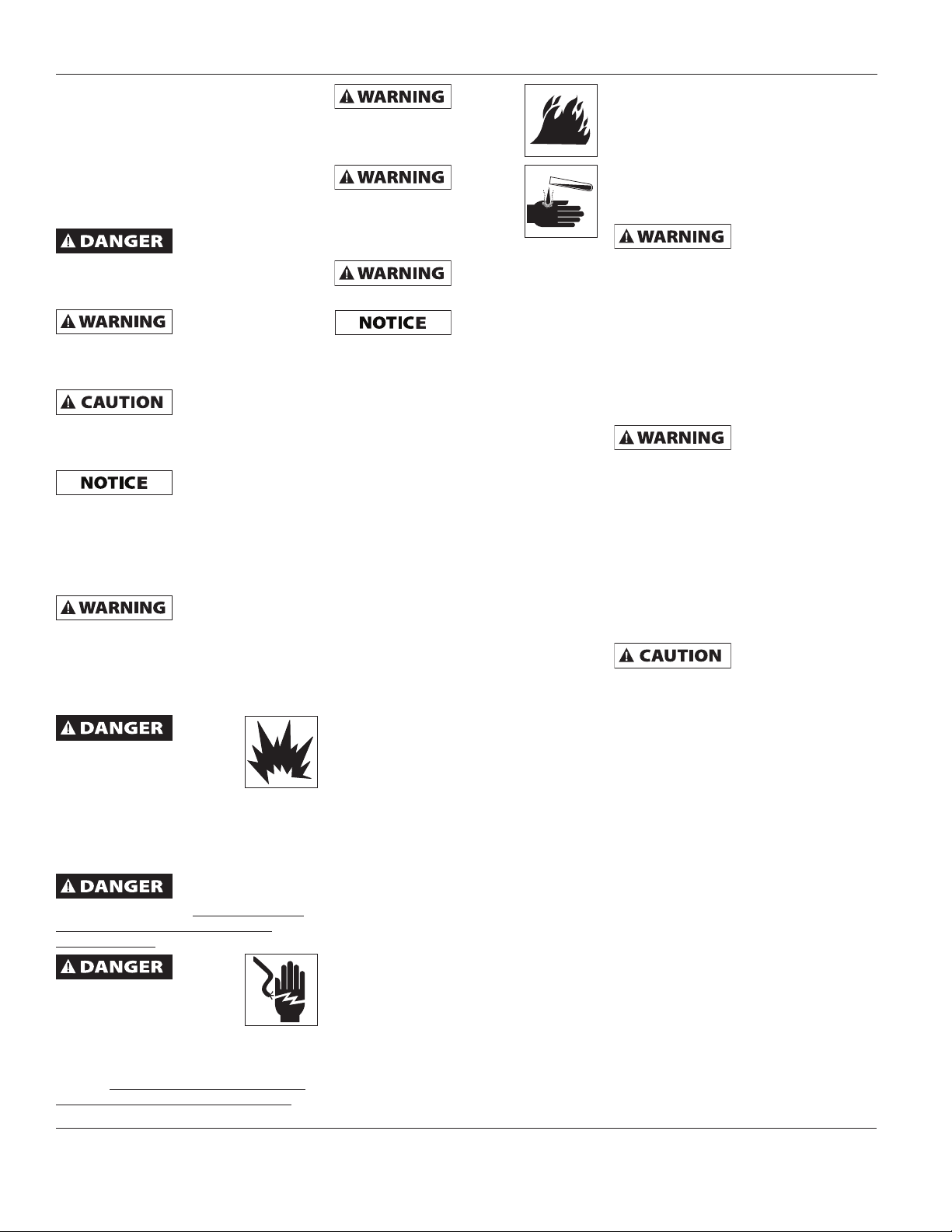

1. A ground fault circuit interrupter

(GFCI) is required (see Figure 2).

Figure 2

Risk of

electrical shock! This pump

is supplied with a grounding

conductor and grounding

type attachment plug. Use a

grounded receptacle to reduce the risk

of fatal electrical shock.

NEVER cut off the round grounding

prong. Cutting the cord or plug WILL

void the warranty and make the pump

inoperable.

2. The primary pump is only for use

on 120 volt (single phase), 60 Hz,

15 amp service and is equipped

with a 3-conductor cord and

3-prong, grounding type plug.

Insert the switch cord plug directly

into a 120 volt outlet.

3. BSS10, BSS20, BSS25 - Insert the

pump power cord plug directly into

the back of the water sensor cord

plug.

BSSF50 - Plug power directly into

GFCI outlet.

4. Fill sump with water. The pump will

start automatically when the water

has reached the preset switch levels

as indicated in Figure 1, on page 2.

The pump will recycle thereafter as

required.

• Capacitance Switch Models will

run a minimum of 4 seconds,

to a maximum of 16 before

stopping. Sump pump run time

will be determined by the sump

pit size and water flow rate into

the sump pit. Under flooding

conditions, the sump pump

will stop for 1 second, every 16

seconds, and automatically turn

back on.

5. Do not operate the pump unless it

is submerged in water. Dry running

causes pump failure.

6. The motor is equipped with an

automatic reset thermal protector.

7. While the pump is draining the

pit, verify that the discharge

piping is carrying the water to a

point several feet away from the

foundation.

8. If pump discharge line is exposed to

freezing temperature, the exposed

line must be pitched or angled to

drain. Trapped water will freeze

and damage the pump.

Operation - Back-up Pump

Always

disconnect the power source

before attempting to install,

service, relocate or maintain

the pump. Never touch sump

pump, pump motor, water or discharge

piping when pump is connected to

electrical power. Never handle a pump

or pump motor with wet hands or when

standing on wet or damp surface or in

water. Fatal electrical shock could occur.

Risk of

electrical shock! This pump

is supplied with a grounding

conductor and grounding

type attachment plug. Use a

grounded receptacle to reduce the risk

of fatal electrical shock.

Never cut off the round grounding

prong. Cutting the cord or plug will

void the warranty and make the pump

inoperable.

1. Test Backup Pump operation by

filling the sump with water while

the main pump is unplugged. If the

Backup Pump operates properly,

plug the charger into the GFCI

protected outlet to begin charging

the battery.

2. After installation, the standby

pump will start when the water

level rises above the depth that the

primary pump should start.

3. The control box has a DC charger

designed to shorten the recharging

time of your battery, and to

prevent overcharging. In addition,

the control box has a time delay

which keeps the pump from

repeated, short cycles when it

shuts off. This time delay feature

will allow the pump to run 20-25

seconds after the switch reaches

the off position.

4. The control box contains a multicolored indicator light. When AC

power is present, the light will

indicate the charging state, and

not reflect actual battery voltage,

particularly with a defective

battery. In order for the indicator

light to provide an accurate

reading, steps “a” through “d”

must be followed.

a. Unplug main AC pump and the

charger--a power off alert tone

will sound for 30 seconds.

b. Lift and release the float switch

to activate the standby pump.

c. When the pump stops, read the

test light:

Green: Indicates battery is

charged.

Yellow: Voltage is low,

indicating battery is partially

charged.

Red: Battery is completely

discharged or defective.

d. Plug in charger and main AC

pump.

When AC power is out, and when

pump has been running, the light

will indicate battery status.

www.blueangelpumps.com

4

BSS10, BSS20, BSS25, BSSF50

Operation - Back-up Pump

(Continued)

5. A chirping sound from the control

box will accompany the red light,

indicating that the battery may

require attention or replacement.

Voltage is only an indicator of

battery condition and may not

reflect the true condition of the

battery. See Maintenance for

instructions on assessing battery

condition.

6. A single thirty-second tone will

sound when power to the system

is interrupted. The unit will reset

automatically when power is

restored. A three-second tone will

sound every time the pump starts.

Maintenance - Primary Pump

ALWAYS

disconnect the power source

before attempting to install,

service, relocate or maintain

the pump. NEVER touch sump pump,

pump motor, water or discharge piping

when pump is connected to electrical

power. NEVER handle a pump or pump

motor with wet hands or when standing

on wet or damp surface or in water.

Fatal electrical shock could occur.

1. Let the pump cool for a minimum

of two hours before servicing

because the pump contains hot oil

under pressure and the motor is

hot.

2. Disassembly of the motor prior to

expiration of warranty will void the

warranty. If repairs are required,

see troubleshooting chart.

3. Inlet should be kept clean and free

of all foreign objects and inspect

annually. A clogged inlet will

damage pump.

4. Pump should be checked monthly

for proper operation. CHECK PUMP

BY FOLLOWING STEP 4 LISTED IN

THE OPERATION SECTION (on

page 4).

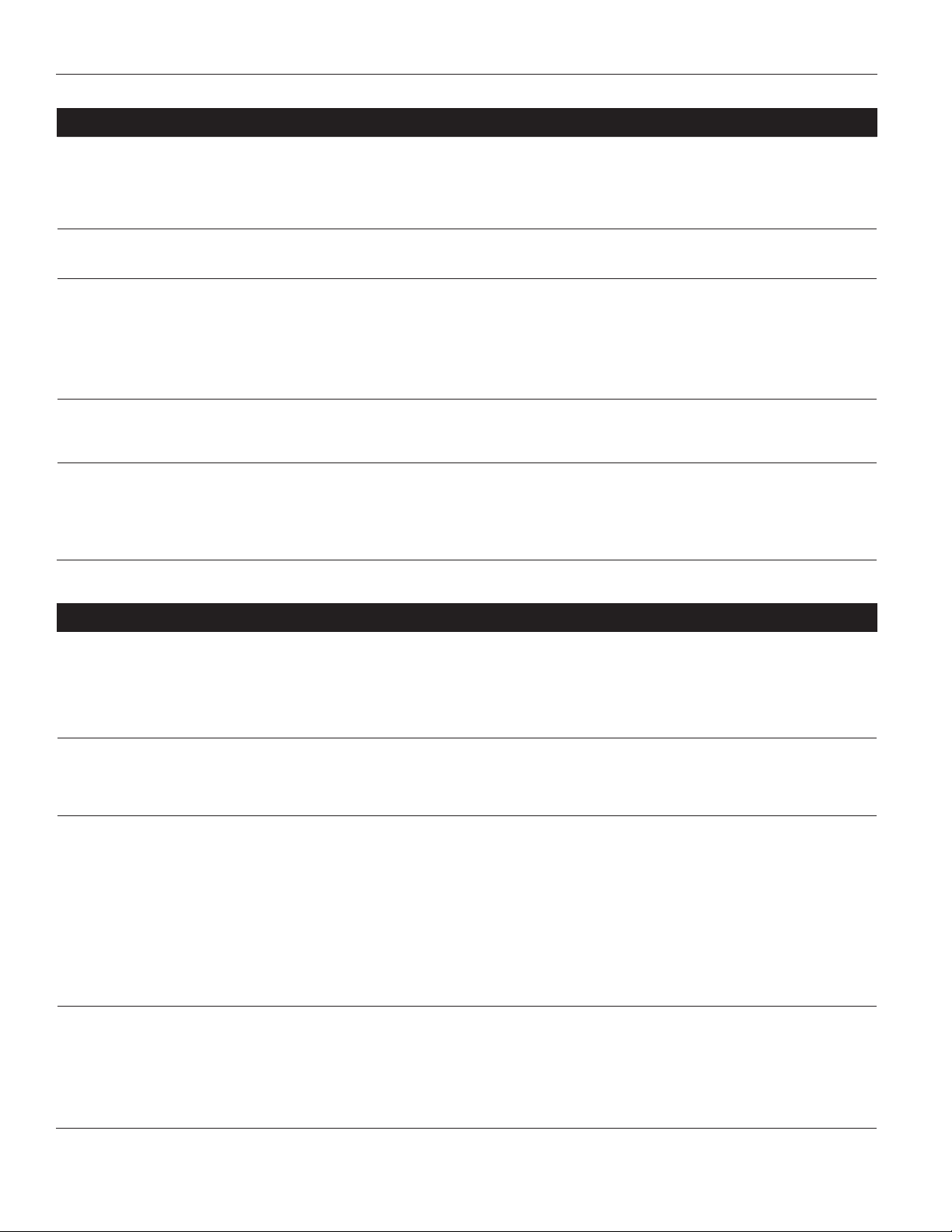

5. Wipe water sensor surface regularly

to prevent silt or other coatings

from building up on sensor face

(see Figure 3).

Working surface

of sensor to be

kept free of

foreign material.

Maintenance - Back-up Pump

ALWAYS

disconnect the power source

before attempting to install,

service, relocate or maintain

the pump. NEVER touch sump pump,

pump motor, water or discharge piping

when pump is connected to electrical

power. NEVER handle a pump or pump

motor with wet hands or when standing

on wet or damp surface or in water.

Fatal electrical shock could occur.

1. Once a month, check battery

condition.

2. Unplug the wall charger.

3. For batteries with top caps that

can be removed, the electrolyte

level should be checked and filled

to manufacturer’s specifications.

The charge for each cell should

be checked with a hydrometer. A

specific gravity of 1.265 indicates

the battery is at full charge. If the

specific gravity of any of the cells

varies more than .050, the battery

should be replaced.

NOTE: An inexpensive hydrometer

can be purchased at an automotive

parts dealer.

4. Inspect the terminals and clamps

for corrosion and tightness. Clean

and tighten as required.

5. Unplug the main pump and fill

sump with water until back up

pump turns on. Repeat process two

times to be sure pump is operating

normally.

6. If pump operates normally,

plug charger into wall outlet,

turn on main pump. If pump

fails to operate normally, see

Troubleshooting guide and correct

problem. Repeat step 5.

Figure 3

6. Make sure Float Type Switches are

free to move without obstruction.

5

www.blueangelpumps.com

Operating Instructions and Parts Manual

Troubleshooting Chart - Primary Pump

Symptom Possible Cause(s) Corrective Action

Pump will not start

or run

Pump starts and

stops too often

Pump will not shut

off or thermal

protector turns off

Pump operates but

delivers little or no

water

Gurgling sound

from pump at end

of cycle

1. Blown fuse or tripped circuit breaker

2. Low line voltage

3. Motor

4. Obstructed impeller

5. Switch

1. Backflow of water from piping

2. Incoming water is draining on

sensor face

1. Obstacle in piping

2. Low Line Voltage

3. Too many appliances on circuit

4. Dirty water sensor

5. Incoming water is draining on

sensor face

6. Defective switch

1. Plugged impeller

2. Check valve installed backwards

3. Pump airlocked

4. Low line voltage

1. Air injested into pump

2. Time required for pumping is less

than 4 seconds

1. If blown, replace with proper sized fuse or reset breaker

2. If voltage is under 108 Volts, check wiring size

3. Replace pump

4. If impeller will not turn, remove housing and remove blockage

5. Check / replace switch (Switches should be replaced every two years to

maintain proper operation)

1. Install or replace check valve

2. Position pump switch away from the inlet so switch is clear from

incoming water (see Figure 1, on page 2)

1. Remove pump and clean pump and piping

2. If voltage is under 108 volts, check wiring size

3. Install pump on dedicated circuit.

IMPORTANT: Do not use extension cord to power pump.

4. Clean sensor face (see Figure 3, on page 5)

5. Position pump switch away from the inlet so switch is clear from

incoming water (see Figure 1, on page 2)

6. Replace switch

1. Clean out impeller

2. Reverse position of check valve

3. Drill 1/8 in. hole in discharge line between pump and check valve

4. If voltage is under 108 volts, check wiring size

1. Wipe off surface of sensor (see Figure 3, on page 5)

2. Additional run time will not damage pump

Troubleshooting Chart - Back-up Pump

Symptom Possible Cause(s) Corrective Action

Pump will not run 1. Connections not secure

Motor hums but

pump won’t run

Pump runs but

pumps very little or

no water

Pump cycles too

frequently

2. Low or defective battery

3. Float switch stuck

4. Defective or blown fuse

1. Defective battery

2. Impeller is obstructed

1. Check valve missing or improperly

installed

2. Obstruction in discharge pipe

3. Pump not rotated 30˚

4. Pump air locked

5. Discharge pipe length and / or

height exceeds capacity of pump

6. Low or defective battery

1. Main check valve located between

the discharge of the primary

pump and the Back-up Sump

Pump tee fitting or the Back-up

Sump Pump flapper valve not

installed or working properly

1. Check all connections

2. Check battery and replace if low or defective

3. Make sure nothing is interfering with the operation of the

switch

4. Check internal fuse located inside the control box. Pull the

charger from the wall outlet and remove. If the fuse is blown,

replace it with a 15 amp automotive type fuse

1. Check battery and replace if low or defective

2. Unplug pump and check to see if impeller is free to turn.

If impeller is locked, remove the 4 screws on the bottom of the

pump to release the housing around the impeller. Remove the

obstruction. Reassemble pump and reconnect

1. Check to make sure a check valve is installed and functioning

between primary pump discharge and Standby Sump Pump

tee fitting

2. Check for obstruction and clear if necessary

3. Check that pump is rotated 30˚ in tee fitting

4. The impeller housing has a small hole on its side. This hole

must be open for the pump to prime. With the pump

unplugged, remove the 4 screws on the bottom of the pump to

release the housing around the impeller. Clean out the hole

and replace cover

5. If discharge is too high, a separate line may be required with a

lower discharge height

6. Check battery and replace if low or defective

1. Install check valve or repair as required

www.blueangelpumps.com

6

BSS10, BSS20, BSS25, BSSF50

For Replacement Parts, call 1-888-636-6628

Please provide following information:

- Model number

- Serial number (if any)

- Part description and number as shown in parts list

2

Address parts correspondence to:

Blue Angel Pumps

101 Production Drive

Harrison, OH 45030 U.S.A.

1

1

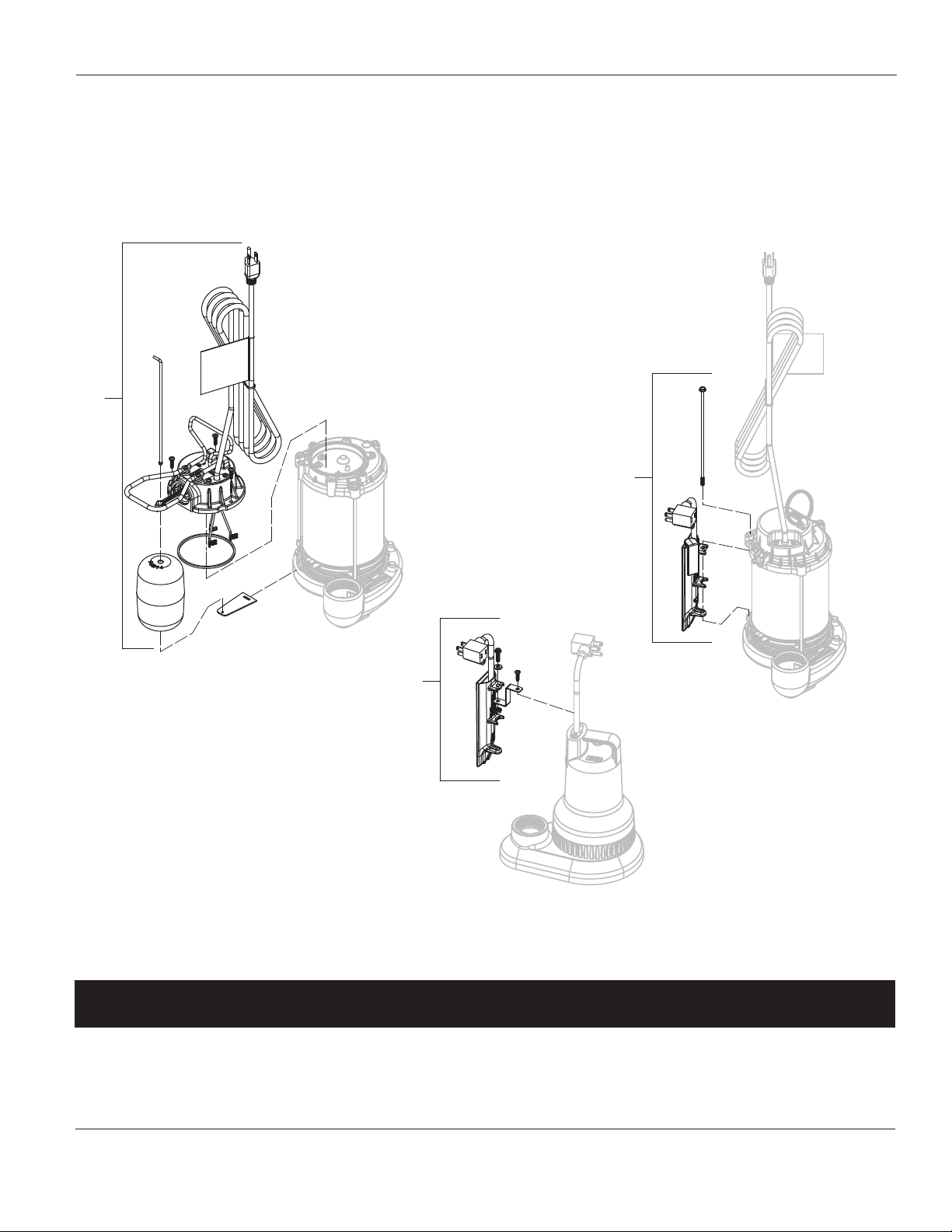

Figure 4 – Primary Pump, Models BSS10, BSS20, BSS25, and BSSF50

Repair Parts List

Reference

Number Description Part Number Quantity

1 Capacitive Switch Water Sensor 30037-001 1

2 Float Kit 60042-001 1

www.blueangelpumps.com

7

Operating Instructions and Parts Manual

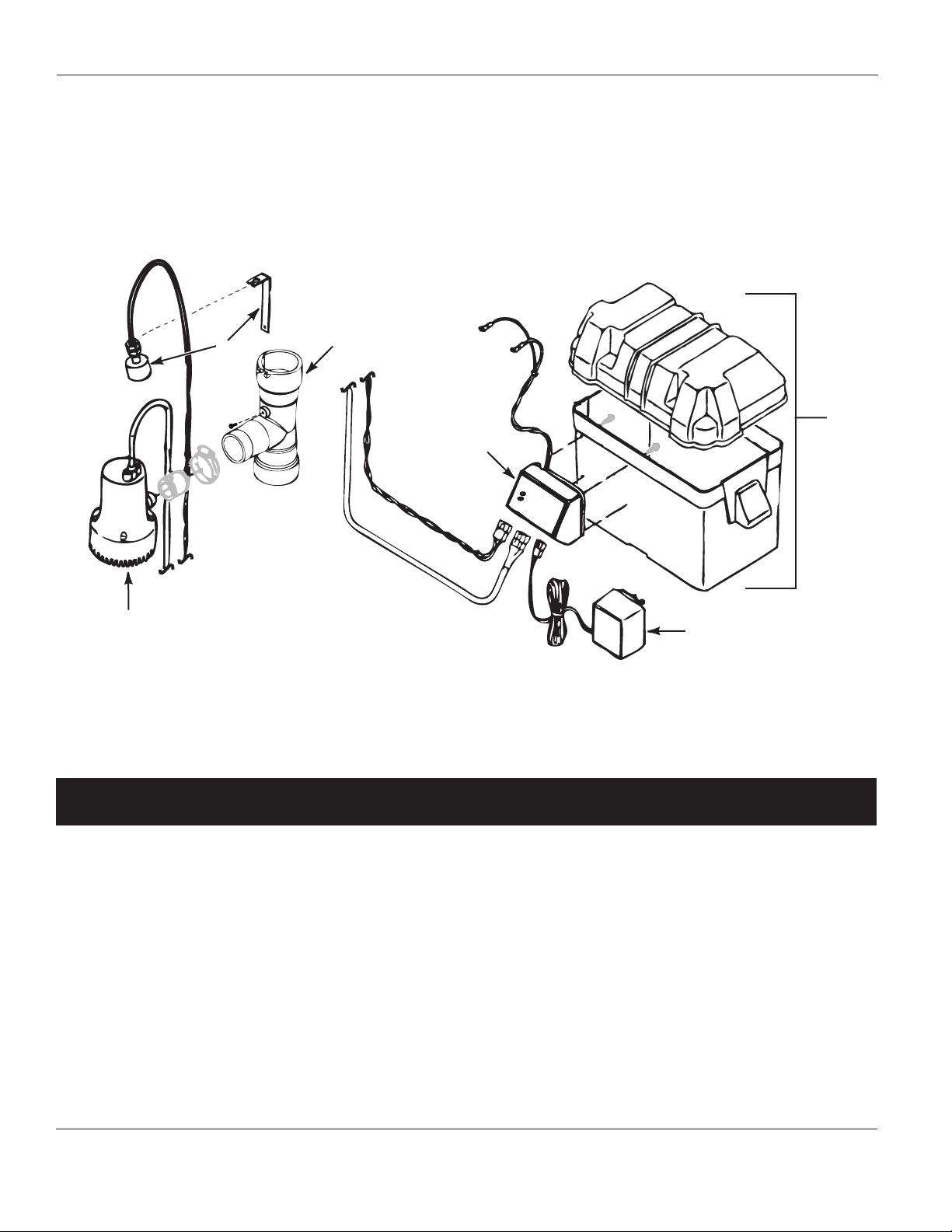

For Replacement Parts, call 1-888-636-6628

Please provide following information:

- Model number

- Serial number (if any)

- Part description and number as shown in parts list

1

2

Address parts correspondence to:

Blue Angel Pumps

101 Production Drive

Harrison, OH 45030 U.S.A.

3

5

6

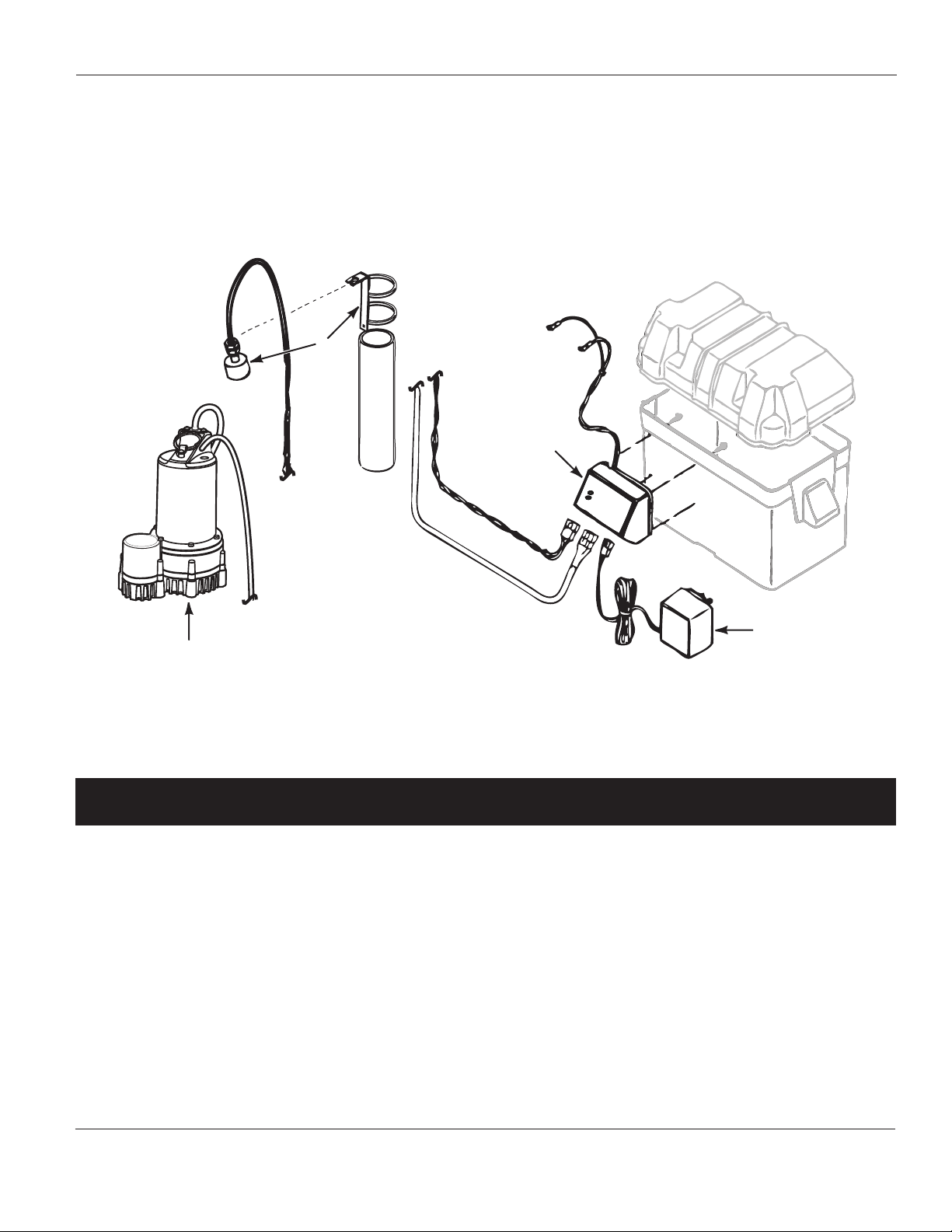

Figure 5 – Back-up Pump, Models BSS10 and BSS20

4

Repair Parts List

Reference

Number Description Part Number Quantity

1 Float switch kit 60108-001 1

2 Tee fitting 17233-002 1

3 Battery box 23217-001 1

4 Charger Kit 17220-004 1

5 Control box 30209-003 1

6 Pump Conversion Kit 17218-003 1

www.blueangelpumps.com

8

BSS10, BSS20, BSS25, BSSF50

For Replacement Parts, call 1-888-636-6628

Please provide following information:

- Model number

- Serial number (if any)

- Part description and number as shown in parts list

1

Address parts correspondence to:

Blue Angel Pumps

101 Production Drive

Harrison, OH 45030 U.S.A.

3

2

4

Figure 6 – Back-up Pump, Model BSS25 and BSSF50

Repair Parts List

Reference

Number Description Part Number Quantity

1 Float switch kit 60108-001 1

2 Charger Kit 30221-001 1

3 Control box 30222-003 1

4 Pump 58324-001 1

www.blueangelpumps.com

9

Operating Instructions and Parts Manual

Notes

www.blueangelpumps.com

10

BSS10, BSS20, BSS25, BSSF50

Service Record

Date Maintenance performed Repair components required

www.blueangelpumps.com

11

Loading...

Loading...