Page 1

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

Please read and save these instructions. Read carefully before attempting

to assemble, install, operate or maintain the product described. Protect

yourself and others by observing all safety information. Failure to comply

with instructions could result in personal injury and/or property damage!

Retain instructions for future reference.

Description

The BSP45 is a battery operated back-up

sump pump. It does not replace a

regular pump. It is designed to provide

protection in the event household

electrical power fails or main pump fails.

Unpacking

Inspect this unit before it is used.

Occasionally, products are damaged

during shipment. If the pump or

components are damaged, return the

unit to the place of purchase for

replacement. Failure to do so could

result in serious injury or death.

Safety Guidelines

This manual contains information that

is very important to know and

understand. This information is

provided for SAFETY and to PREVENT

EQUIPMENT PROBLEMS. To help

recognize this information, observe the

following symbols.

Danger indicates an

imminently

hazardous situation which, if not avoided,

will result in death or serious injury.

Warning indicates a

potentially

hazardous situation which, if not avoided,

could result in death or serious injury.

Caution indicates a

potentially

hazardous situation which, if not avoided,

may result in minor or moderate injury.

Notice indicates

important

information, that if not followed, may

cause damage to equipment.

Operating Instruction and Parts Manual BSP45

353601-002 7/08

General Safety

Information

CALIFORNIA PROPOSITION 65

This product or its

power cord may

contain chemicals known to the State of

California to cause cancer and birth

defects or other reproductive harm. Wash

hands after handling.

GENERAL SAFETY

Do not use to pump

flammable or explosive fluids

such as gasoline, fuel oil,

kerosene, etc. Do not use in a

flammable and/or explosive

atmosphere. Pump should only be used

to pump clear water. Fatal injury and/or

property damage could result.

If the basement has water or

moisture on the floor, do not

walk on wet area until all

power is turned off. If the shutoff box

is in the basement, call an electrician.

Remove pump and either repair or

replace. Failure to follow this warning

could result in fatal electrical shock.

All wiring must be

performed by a

qualified electrician.

Do not expose battery to

sparks or flames as an

explosion or fire could result.

Battery acid is corrosive.

Avoid spilling on skin or

clothing. Eye protection must

be worn when handling the battery.

A check valve must

be used on the

primary sump pump discharge.

A ground fault

circuit interrupter is

required.

This pump must

only be used to

pump clear water. This pump is not

designed to handle effluent, salt

water, brine, laundry discharge or any

other application which may contain

caustic chemicals and/or foreign

materials. Pump damage may occur if

used in these applications and will void

warranty.

24-Volt Backup

Sump Pump

© 2008 Blue Angel™ Pumps

The Professional’s Line

For parts, product & service information

visit www.blueangelpumps.com

Pump Specifications

Pump Construction

Motor housing, volute, seal plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Cast Iron

Impeller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Thermoplastic

Shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Stainless Steel

Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1

/2in. NPT

Float switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Reed Style

Power supply requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120V, 60 Hz

Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Perminent Magnet DC Motor

Normal water removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48 GPM @ 5 Feet @ 26V DC

Liquid temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40°F to 120°F

Circuit requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 amps AC (min)

Pump Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 in. high x 8

3

/4in. base

Pump run time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 Seconds

Page 2

Battery Information

The system is designed to operate most

efficiently with sealed lead acid (SLA)

batteries. Deep cycle marine batteries

can also be used.

Sealed lead acid batteries cost slightly

more, but they can last longer. Blue

Angel™ offers a 40 amp hour battery

BSB1240 and a 75 amp hour battery

BSB1275.

The oversize battery case (included) will

accommodate two 12-volt SLA batteries

or two 12-volt deep cycle marine batteries

(up to a 27-frame size).

Retain blue foam pad to support Blue

Angel™ sealed lead-acid batteries. Use

new, identical batteries (from the same

manufacturer and of the same capacity).

When batteries wear out replace them as

a set. Chart 1 illustrates the expected

performance with various battery

combinations. Do not use batteries rated

below 40 amp hours.

Be certain that the area around the

batteries is well ventilated. Before

servicing the batteries, blow away

gasses by waving a piece of cardboard

near the batteries.

Dangerous

hydrogen gas can

be released from batteries while

charging. Sparks can ignite the gas in

an enclosed space. Wear safety goggles

when connecting batteries. Battery

connections should be made in a wellventilated area.

Working in the

vicinity of lead acid

batteries can be dangerous. Before

making connections or servicing the

batteries, read and follow instructions in

all applicable instruction manuals. To

reduce the risk of battery explosion,

follow the instructions in this manual

and those published by the battery

manufacturer, as well as those of any

other equipment used in the

surrounding area.

An assistant should be present or close

enough to come to your aid in the

event of an emergency. Have a reliable

source of fresh water and soap nearby

in case battery acid contacts clothing,

skin or eyes.

Wear eye and clothing protection when

working around lead acid batteries.

Avoid touching your eyes when

working around lead acid batteries.

If battery acid

contacts your

eye(s), flush with cold running water

for 10 minutes and seek immediate

medical attention. If acid contacts your

skin or clothing, wash immediately

with soap and water.

Never smoke or

allow a spark or

flame in the vicinity of the battery.

Avoid dropping

metal tools on the

battery posts because they may spark or

short-circuit the system or battery,

causing an explosion.

PS/BC Features

POWER CIRCUITS:

• Power Supply/Battery Charger (PS/BC)

monitors power availability and

automatically switches to battery

operation during power outage.

• Charger will run pump motor or charge

batteries when plugged into AC power

• Automatically charges the batteries

• Operates on 120 VAC and 24 VDC

(Using 2 batteries)

• The PS/BC can be left connected to

the batteries indefinitely

• The PS/BC is designed for the Blue

Angel™ pump only, DO NOT Use For

Any Other Purpose

2

Operating Instructions and Parts Manual

SYSTEM WILL ALARM IF:

• You will hear a beeping alarm if

pump motor is running

• You will hear a continuous alarm if the

pump fuse on front panel is blown

• You will hear a continuous alarm if

the battery voltage drops below 21.6

NOTE: The alarm must be on for the

mute function to activate.

LIGHTS:

• Green Light indicates AC power is

available

• Yellow Light indicates battery is

connected correctly

• Red Light is on when battery voltage

is low or if the pump motor fuse on

the front panel is blown

PUMP:

• The pump will turn on when the

float switch rises. The pump motor

will keep running for 15 seconds

after the float drops

www.blueangelpumps.com

12V

Battery

12V

Battery

(Black)

Negative

Battery Cable

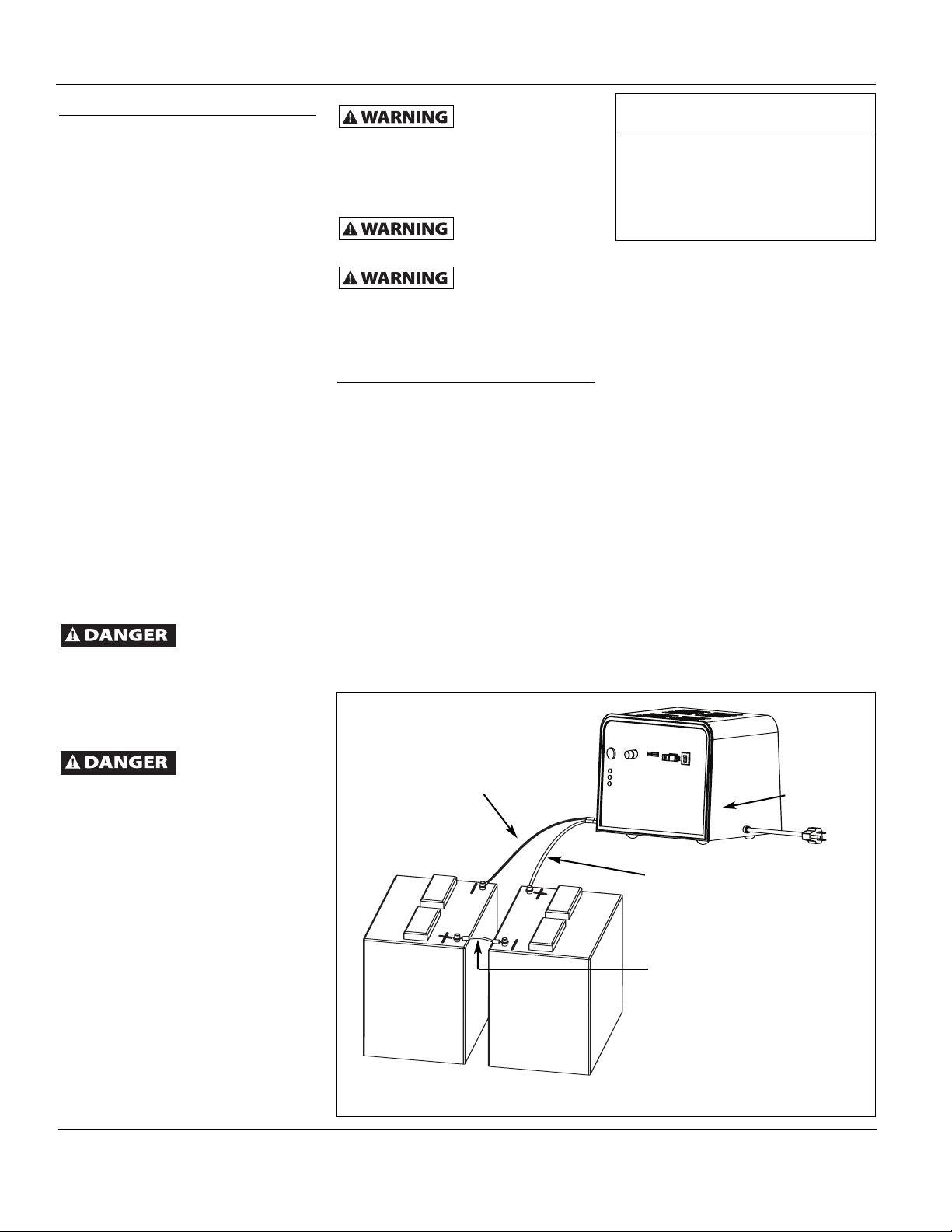

Figure 1 - Battery connection: two 12-volt batteries equals a 24-volt battery

PS/BC

(Red)

Positive Battery Cable

Amp Hours Total Gallons

Per Battery Pumped*

40.0 11,000

80.0 22,000

120.0 33,000

* Assumes the sump pump is lifting water 10’

CHART 1 - STANDBY POWER

PUMPING CAPACITY

Jumper Wire

B

A

Page 3

3

Pump Installation

Installation of this

unit may take

several hours. Before disabling your

main pump, have ready an appropriate

means of evacuating the sump.

1. Turn power to main pump off.

2. Pump must be installed using 1

1

/4”

or 1

1

/2” rigid PVC piping.

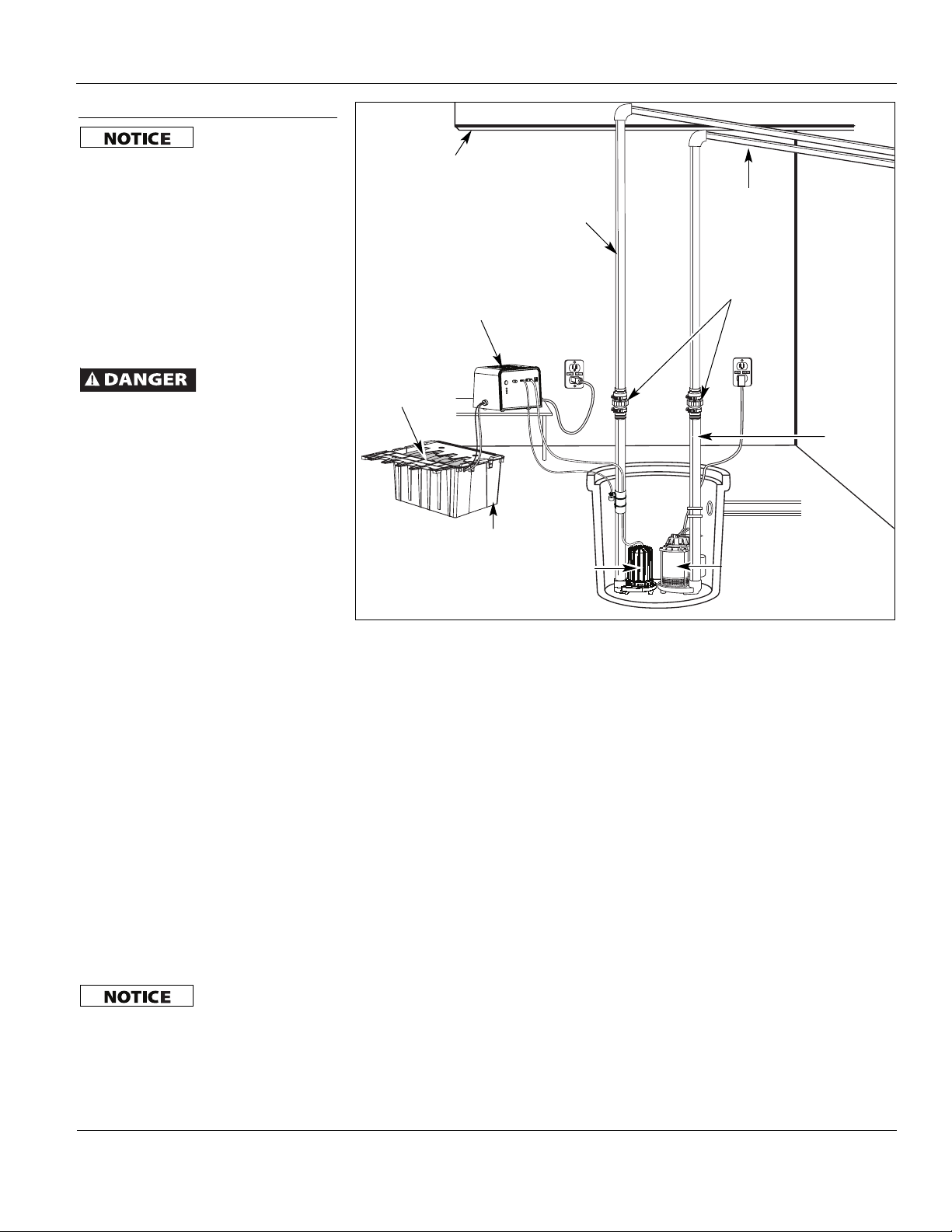

Pump Installation

The BSP45 can be installed as a back up

system with a separate dedicated

discharge line (Method 1), or tied into

an existing sump pump line (Method 2).

Unplug the existing

AC pump. Failure to

follow this warning could result in fatal

electrical shock.

1. Verify that the existing AC pump is

in good working order. If the AC

pump is questionable, it is typically

recommended that the unit be

replaced with a 1/3 or 1/2 HP pump.

2. Remove any silt or accumulated

debris from the sump pit and

surrounding area.

Method 1 (Preferred)

1. Locate the BSP45 on a solid, level

surface in the sump pit. Do not

place the pump on a loose or sandy

surface. Small stones or sand may

damage the pump resulting in

potential pump failure.

2. This pump has a 1

1

/2” NPT discharge.

If a 1

1

/4” discharge pipe is desired,

an adapter (not included) will be

necessary. Smaller diameter piping

will reduce pump flow, rate and

performance.

3. Cut a 4’ section of 1

1

/4" or 11/2"

diameter rigid PVC pipe. Cement

1

1

/4" pipe to a threaded fitting.

Cement 1

1

/4" pipe into pipe

coupling. Attach 1

1

/4" pipe section

to the BSP45 discharge adapter.

4. Screw on to pump discharge.

Be careful not to

strip or cross thread

plastic fittings or check valves. Flex hose

is not recommended. Rigid PVC or metal

pipe is required for a permanent

installation.

BSP45

www.blueangelpumps.com

Figure 2 - Method 1

Floor

Joist

Ridgid

PVC

Pipe

1

1

/4” or

1

1

/2”

PVC Pipe

BSP45

Pump

Existing Pump

Check Valve

(See Step 6)

Slope

Pipe

Down

PS/BC

5. Place the pump with the 4’ section of

PVC pipe on a solid, level surface in

the sump pit on an elevated surface.

6. Attach a rubber check valve (sold

separately) to the top of the

discharge pipe. This will allow the

pump or check valve to be removed

easily for servicing.

7. Check valve is required for effective

operation of system.

NOTE: Check valves can be placed

directly in the pump discharge if

desired. However, for ease of

disassembly, it is recommended that

check valves be placed above the sump

as shown in Figure 2.

The remainder of the discharge pipe

installation will vary depending on

individual circumstances. Using sound

plumbing practices, route the

discharge pipe to an exterior wall by

the shortest path. Keep turns to a

minimum because they reduce flow

output of the pump. The pipe that

exits the building structure should be

sloped downward so that water will

not freeze in the pipe.

When installing the separate discharge

pipe, drill through the outside wall with

appropriate drilling equipment. Seal the

hole to prevent water from entering.

Method 2

If a separate, dedicated discharge is

not possible as in Method 1, the BSP45

pump can be tied in to the ACoperated pump’s discharge pipe by

installing a “Y” connector. Two check

valves will be required.

1. Locate the BSP45 on a solid, level

surface in the sump pit. Do not

place the pump on a loose or sandy

surface. Small stones or sand may

damage the pump resulting in

potential pump failure.

2. This pump has a 1

1

/2” NPT discharge.

If a 1

1

/4” discharge pipe is desired,

an adapter (not included) will be

necessary. Smaller diameter piping

will reduce pump flow, rate and

performance.

Batteries

Battery

Box

Page 4

4

Operating Instructions and Parts Manual

3. A check valve will be required in

the discharge line of BOTH the

Main AC pump and the BSP45

pump to prevent recirculation of

water into the sump pit. System will

not function without two check

valves.

4. Cut a 4’ section of 1

1

/4" or 11/2"

diameter rigid PVC pipe. Cement

1

1

/2" pipe to a threaded fitting.

Cement 1

1

/4" pipe into pipe

coupling. Attach 1

1

/4" pipe section

to the BSP45 discharge adapter.

5. Screw on to pump discharge.

Be careful not to

strip or cross thread

plastic fittings or check valves. Flex hose

is not recommended. Rigid PVC or metal

pipe is required for a permanent

installation.

6. Place the pump with the 4’ section

of PVC pipe on the sump floor or

on an elevated surface if required.

7. Attach a rubber check valve (sold

separately) to the top of the

discharge pipe. This will allow the

pump or check valve to be removed

easily for servicing.

8. Duplicate the discharge piping

arrangement for the primary AC

pump if the existing discharge line

has to be adjusted to accommodate

a second pump.

9. Glue a 45º elbow to the short pipe

on the BSP45 pump. Glue a “Y”

adapter to the short pipe on the

existing pump, as shown in

illustration for Method 2.

10. Glue a short piece of PVC pipe

between the 45º elbow and the “Y”.

NOTE: Check valves can be placed

directly in the pump discharge if

desired. However, for ease of

disassembly, it is recommended that

check valves be placed above the sump

as shown in Figure 3.

The remainder of the discharge pipe

installation will vary depending on

individual circumstances. Using sound

plumbing practices, route the

discharge pipe to an exterior wall by

the shortest distance.

Methods 1 and 2

Install float switch at least 10”-12”

above bottom of sump pit so that

backup unit turns on only when the

water level is higher than the normal

“on” level for main pump. Use the hose

clamps provided to secure the switch to

the discharge pipe. Make sure power

wires and hose clamp ends do not

interfere with float switch, pump inlet,

or main pump operation. Backup pump

must not be allowed to run dry.

PS/BC Installation

Use Power Supply/

Battery Charger

(PS/BC) indoors, in a well-ventilated

area. Do not expose PS/BC to rain or

snow. Do not use an extension cord. Do

not disassemble PS/BC. Be sure PS/BC

ventilation holes are unobstructed. If

PS/BC is dropped or damaged, do not

operate; return to manufacturer for

service.

Risk of electrical

shock! Use a GFCI

(Ground Fault Circuit Interrupter)

receptacle to reduce the risk of fatal

electrical shock. Grounded receptacle must

be rated for at least 5 amps.

Always disconnect

AC power and

remove pump fuse before connecting or

disconnecting battery.

1. Select a suitable position on the floor

near the sump pit to place the battery

case. Be certain that the PS/BC power

cord will reach AC power, and that

the sump pump power cord will reach

the PS/BC. Make sure the battery case

vent holes are unobstructed.

ELEVATE PS/BC BY MOUNTING ON

WALL OR SETTING ON A SHELF. SLOTS

IN THE BACK SIDE OF PS/BC ARE

AVAILABLE FOR WALL MOUNTING.

Control Box Installation

If cables are

reversed, damage

to the PS/BC or battery could result,

and warranty will be void.

Dangerous hydrogen gas can be

released from batteries while

charging. Sparks can ignite the gas

in an enclosed space. Wear safety

goggles when connecting batteries.

Battery connections should be

made in a well-ventilated area.

www.blueangelpumps.com

Pump Installation

(Continued)

Figure 3 - Method 2

Floor

Joist

“Y”

Connector

45°

Elbow

Rigid PVC

Pipe

Check Valve

(See Step 10)

PS/BC

BSP45

Pump

Existing Pump

Batteries

Battery

Box

Page 5

5

BSP45

www.blueangelpumps.com

1. Place battery box within six feet of

the sump and a 115 VAC separately

fused outlet. The outlet must be

protected by a ground fault circuit

interrupter (GFCI). The area must also

be clean, dry and well-ventilated.

2. Wave cardboard over batteries to

blow away any gas that may be

present.

3. Connect jumper wire between

batteries as shown on Figure 1.

4. Connect power wires from PS/BC to

battery terminals as shown in

Figure 1. Connect the red wire to

the unconnected positive terminal

of battery A and then connect the

black wire to the unconnected

negative terminal of battery B. The

yellow light should now be on.

5. Plug the pump and then the float

into the PS/BC. The connections are

marked.

6. Test pump operation by filling the

sump with water while the main

pump is unplugged. If the pump

operates properly, plug the PS/BC

into the GFCI protected outlet to

begin charging the battery.

NOTE: Protect electrical cord from sharp

objects, hot surfaces, oil and chemicals.

Avoid kinking the cord and replace

damaged components immediately.

Operation

Always disconnect the power

source before attempting to

install, service, relocate or

maintain the pump. Never touch sump

pump, pump motor, water or discharge

piping when pump is connected to

electrical power. Never handle a pump

or pump motor with wet hands or when

standing on wet or damp surface or in

water. Fatal electrical shock could occur.

Risk of

electrical shock! Use a GFCI

receptacle to reduce the risk of

fatal electrical shock. Cutting

the cord or plug will void the warranty

and make the pump inoperable.

1. After installation, the backup pump

will start when the water level rises

above the depth that the primary

pump should start.

2. The PS/BC has a DC charger designed

to shorten the recharging time of

your battery, and to prevent

overcharging. In addition, the

control box has a time delay which

keeps the pump from repeated,

short cycles when it shuts off. This

time delay feature will allow the

pump to run 15 seconds after the

switch reaches the off position.

Maintenance

Unplug main AC pump and the

charger. Risk of electrical

shock!

Always disconnect the

electrical supply before

attempting to install, service,

relocate or per-form any maintenance. If

the power source is out of sight, lock and

tag in the open (off) position to prevent

unexpected power application. Failure to

do so could result in fatal electrical

shock. Only qualified electricians should

repair this unit. Improper repair could

result in fatal electrical shock.

Once a month,

check the condition

of the battery. In order to review the

battery condition, follow the steps that

are listed below:

BATTERIES

Dangerous

hydrogen gas can

be released from batteries while

charging. Sparks can ignite the gas in

an enclosed space. Wear safety goggles

when nnecting batteries. Battery

connections should be made in a wellventilated area.

Working in the

vicinity of lead acid

batteries can be dangerous. Before making

connections or servicing the batteries, read

and follow instructions in all applicable

instruction manuals. To reduce the risk of

battery explosion, follow the instructions

in this manual and those published by the

battery manufacturer, as well as those of

any other equipment used in the

surrounding area.

If battery acid contacts your eye(s),

flush with cold running water for 10

minutes and seek immediate medical

attention. If acid contacts your skin or

clothing, wash immediately with soap

and water.

Never smoke or allow a spark or flame

in the vicinity of the battery.

Avoid dropping metal tools on the

battery posts because they may spark

or short-circuit the system or battery,

causing an explosion.

Follow battery manufacturer’s

maintenance procedures and

schedules. Be certain that the area

around the batteries is well ventilated.

Before servicing the batteries, blow

away gasses by waving a piece of

cardboard near the batteries.

1. Unplug the PS/BC.

2. For batteries with top caps that can

be removed, the electrolyte level

should be checked and filled to

manufacturer’s specifications. The

charge for each cell should be

checked with a hydrometer. A

specific gravity of 1.265 indicates

the battery is at full charge. If the

specific gravity of any of the cells

varies more than .050, the battery

should be replaced.

NOTE: An inexpensive hydrometer

can be purchased at an automotive

parts dealer.

PS/BC Installation

(Continued)

CHART 2 - PS/BC STATUS LIGHTS

LIGHT ON WHEN ACTION REQUIRED

Red Low Voltage or Blown Fuse Check Fuse or

Replace Batteries

Yellow Battery OK None

Green AC power on None

Page 6

Troubleshooting Chart

Symptom Possible Cause(s) Corrective Action

Pump won’t run

Motor hums but

pump won’t run

Pump runs but

pumps very little

or no water

Pump cycles too

frequently

No yellow light

Red light is on

with alarm

6

Operating Instructions and Parts Manual

www.blueangelpumps.com

1. Check all connections

2. Check battery and replace if low or defective

3. Make sure nothing is interfering with operation of switch

4. Check internal fuse located on the PS/BC. Pull the charger from

the wall outlet and remove. If the fuse is blown, replace it with

an automotive type fuse of the same amp ratio.

1. Check battery and replace if low or defective

2. Unplug pump, volute, and check to see if impeller is free to turn.

If impeller is locked, remove the obstruction. Reassemble pump

and reconnect

1. Check to make sure check valves installed between primary

pump discharge and Backup Sump Pump are functioning

properly

2. Check for obstruction and clear if necessary

3. If discharge is too high, a separate line may be required with a

lower discharge height

4. Check battery and replace if low or defective

1. Check to make sure check valves installed between primary

pump discharge and Backup Sump Pump are functioning

properly

1. Verify battery connection is correct

1. Check fuse and replace with a fuse of same rating and size

2. Check battery voltage. PS/BC will not charge batteries with a

combined voltage of 21.6 VDC or less

1. Connections not secure

2. Low or defective battery

3. Float switch stuck

4. Defective or blown fuse

1. Defective battery

2. Impeller is locked

1. Check valve missing or improperly

installed

2. Obstruction in discharge pipe

or pump inlet

3. Discharge pipe length and/or

height exceeds capacity of pump

4. Low or defective battery

1. Check valve problem

1. Battery connection problem

1. Blown pump fuse

2. Low battery voltage

Maintenance

(Continued)

3. Inspect the terminals and clamps

for corrosion and tightness. Clean

and tighten as required.

4. Unplug the main pump and fill sump

with water until back up pump turns

on. Repeat process two times to be

sure pump is operating normally.

5. If pump operates normally, plug

PS/BC into wall outlet, turn on main

pump. If pump fails to operate

normally, see Troubleshooting guide

and correct problem. Repeat step 5.

Page 7

7

Address parts correspondence to:

Blue Angel

101 Production Drive

Harrison, OH 45030 U.S.A.

For Replacement Parts, call 1-888-636-6628

Please provide following information:

-Model number

-Serial number (if any)

-Part descriptions and number as shown in parts list

www.blueangelpumps.com

Ref. Part

No. Description Number Qty.

BSP45

1 Pump 06710 1

2 PS/BC (power supply/ battery charger) 30260-001 1

3 Impeller assembly 29884-001 1

4 Wear ring 28183-001 1

5 Impeller plate 15958 1

6 Seal 21203-001 1

*7 Float Kit, ESP45 60120-001 1

* Service Part Only

2

5

4

3

1

6

7

Page 8

8

Operating Instructions and Parts Manual

www.blueangelpumps.com

Limited Warranty

For three years from the date of purchase, Blue Angel™ Pumps will repair or replace, at its option, for the original purchaser

any part or parts of its Sump Pumps or Water Pumps (“Product”) found upon examination by Blue Angel™ to be defective in

materials or workmanship. Please call Blue Angel™ (888-636-6628) for instructions or see your dealer. Be prepared to provide

the model and serial number when exercising this warranty. All transportation charges on Products or parts submitted for

repair or replacement must be paid by purchaser.

This Limited Warranty does not cover Products which have been damaged as a result of accident, abuse, misuse, neglect,

improper installation, improper maintenance, or failure to operate in accordance with Blue Angel’s™ written instructions.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO THREE YEARS FROM THE DATE OF PURCHASE. THIS IS THE

EXCLUSIVE REMEDY AND ANY LIABILITY FOR ANY AND ALL INDIRECT OR CONSEQUENTIAL DAMAGES OR EXPENSES WHATSOEVER IS EXCLUDED.

Some states do not allow limitations on how long an implied warranty lasts, or do not allow the exclusions or limitations of

incidental or consequential damages, so the above limitations might not apply to you. This limited warranty gives you

specific legal rights, and you may also have other legal rights which vary from state to state.

In no event, whether as a result of breach of contract warranty, tort (including negligence) or otherwise, shall Blue Angel™

or its suppliers be liable for any special, consequential, incidental or penal damages including, but not limited to loss of

profit or revenues, loss of use of the products or any associated equipment, damage to associated equipment, cost of capital,

cost of substitute products, facilities, services or replacement power, downtime costs, or claims of buyer’s customers for such

damages.

You MUST retain your purchase receipt along with this form. In the event you need to exercise a warranty claim, you MUST

send a copy of the purchase receipt along with the material or correspondence. Please call Blue Angel™ (888-636-6628) for

return authorization and instructions.

DO NOT MAIL THIS FORM TO WAYNE. Use this form only to maintain your records.

MODEL NO. _____________________ SERIAL NO. ________________________ INSTALLATION DATE _____________________

ATTACH YOUR RECEIPT HERE

Loading...

Loading...