Blue Angel Pumps BPC2 User Manual

The Professional’s Line

Operating Instructions & Parts Manual BPC1 and BPC2 Series

MANUAL

Please read and save these instructions. Read carefully before attempting to assemble, install,

operate or maintain the product described. Protect yourself and others by observing all safety

information. Failure to comply with instructions could result in personal injury and/or property

damage! Retain instructions for future reference.

Self-Priming Transfer

Pumps

Table of Contents

Description . . . . . . . . . . . . . . . . . . . . . .1

Unpacking . . . . . . . . . . . . . . . . . . . . . . .1

Safety Guidelines . . . . . . . . . . . . . . . . .

General Safety Information . . . . . . . . .

Installation. . . . . . . . . . . . . . . . . . . . . . .2

Operation . . . . . . . . . . . . . . . . . . . . . . .2

Maintenance . . . . . . . . . . . . . . . . . . . . .3

Troubleshooting Chart

Replacement Part Information

. . . . . . . . . . . . .4

. . . . 6-7

Warranty . . . . . . . . . . . . . . . . . . . . . . . .8

Description

These self-priming transfer pumps are

designed to easily transfer water from

one point to another. Model BPC1, 12

Volt Transfer Pump is convenient when

normal power is not readily available.

Typical applications include removing

water from pool covers, clogged

drains, stock tanks, water basins, boats,

cisterns, etc. Model BPC2, 120 Volt

Transfer Pump is great for household

usage. Typical applications include

removing water from waterbeds,

clogged sinks, basements, etc. Note:

Do NOT use BPC2 in pool areas. The

motors on both models BPC1 and BPC2

are non-submersible with overload

protection.

REMINDER: Keep your dated proof of purchase for warranty purposes!

Unpacking

Inspect this unit before it is used.

Occasionally, products are damaged

during shipment. If the pump or

1

components are damaged, return

1

the unit to the place of purchase for

replacement. Failure to do so could

result in serious injury or death.

READ & FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

DO NOT DISCARD

Safety Guidelines

This manual contains information

that is very important to know and

understand. This information is

provided for SAFETY and to PREVENT

EQUIPMENT PROBLEMS. To help

recognize this information, observe the

following symbols.

Danger indicates an

imminently

hazardous situation which, if not

avoided, WILL result in death or serious

injury.

Warning indicates a

potentially

hazardous situation which, if not

avoided, COULD result in death or

serious injury.

Caution indicates a

potentially

hazardous situation which, if not

avoided, MAY result in minor or

moderate injury.

Notice indicates

important

information, that if not followed, may

cause damage to equipment.

NOTE: Information that requires special

attention.

Attach it to this manual or file it for safekeeping.

General Safety Information

CALIFORNIA PROPOSITION 65

This product or

its power cord may

contain chemicals known to the State

of California to cause cancer and birth

defects or other reproductive harm.

Wash hands after handling.

GENERAL SAFETY

Do not submerge

motor or allow

motor to be exposed to water. Personal

injury and/or death could result. Keep

pump and power cords away from

liquids. Model BPC1 becomes very hot

during operation.

Do not pump gasoline or

other explosive liquids. Do

not operate pump where

flammable or explosive fumes or gases

are present as a fire or explosion could

result. Pump should only be used to

pump clear water. Do not run pump

dry.

1. Read all instructions

before operation.

2. Protect electrical cord

from sharp objects, hot

surfaces, oil and chemicals. Avoid

kinking the cord and replace

damaged cords immediately.

This pump has been

evaluated for use

with water only.

© 2008 Blue Angel™ Pumps

For parts, product & service information

visit www.blueangelpumps.com

321201-002 11/08

Operating Instructions and Parts Manual

Installation

Models BPC1 and BPC2 include a

6’ suction hose, a water suction

attachment, and a replacement parts kit

which includes: impeller, gasket, shaft

seal, and two motor brushes. Models

BPC1 and BPC2 can be used without the

water suction attachment.

Always disconnect power

source before attempting to

install, service, or maintain

the pump. Never handle a pump with

wet hands or when standing on wet

or damp surface or in water. Fatal

electrical shock could occur.

1. A ground fault circuit interrupter

(GFCI) is required for Model BPC2.

Risk of electrical shock! This

pump is supplied with a

grounding conductor and

grounding type attachment plug. A

grounded receptacle in conformance

with current NEC and local codes must

be used (See Figure 1). Do not use

model BPC2, 120 V Transfer Pump in

swimming pool areas.

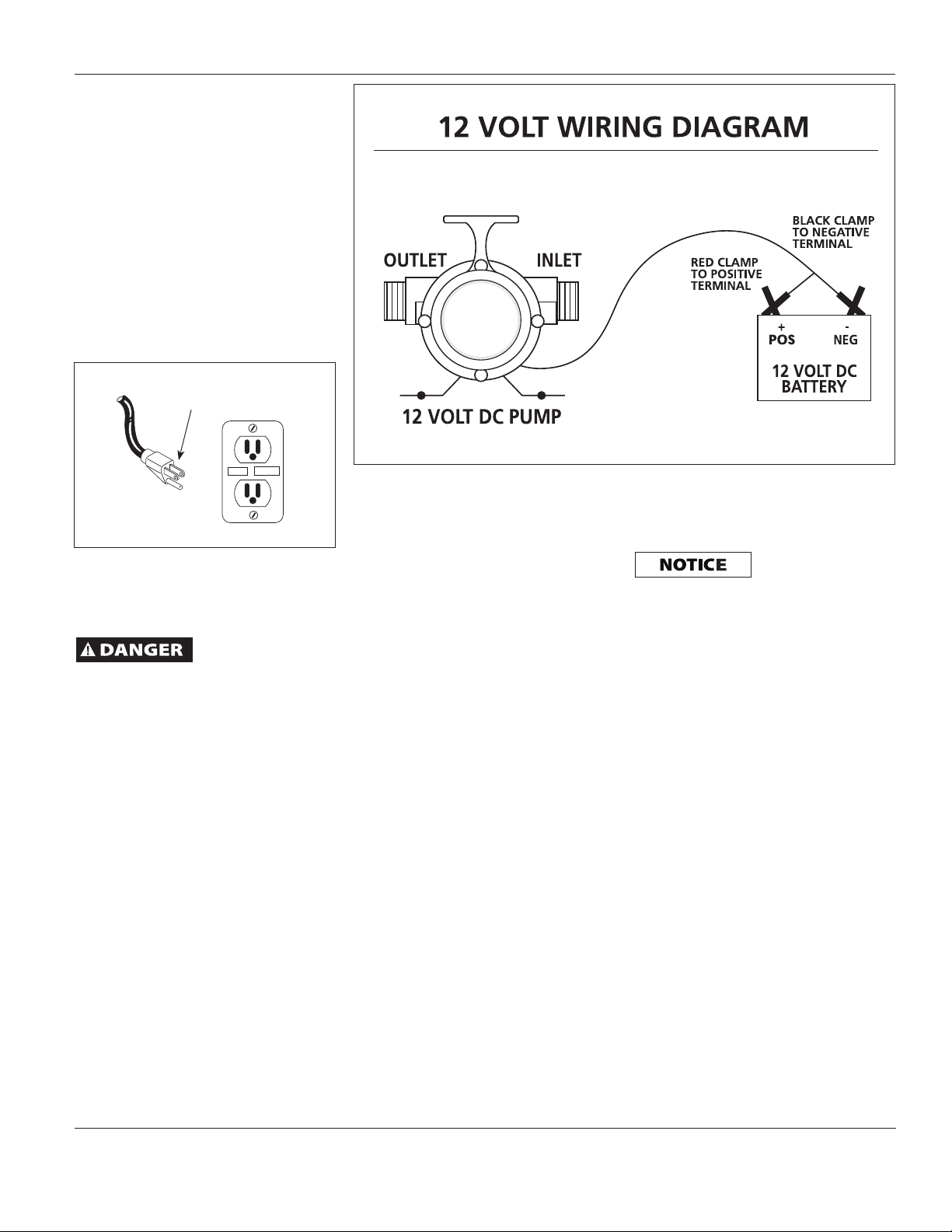

2. Model BPC1 operates on 12V DC

only. Model BPC2 operates on 120V

only. Voltage and current of power

supply must match the requirements

of the pump. Model BPC1 has

color-coded battery clamps for 12V

operation. Model BPC1 requires 14

amps at 12 VDC.

3. Never use an extension cord to

power this unit.

Risk of fatal electrical shock.

Never cut off the round

grounding prong. Cutting

the cord or plug will void the warranty

and make the pump inoperable.

4. Use a strainer when pumping from a

creek, pond, or source where foreign

objects may be sucked into the

pump. The strainer should prevent

solids from entering the inlet line.

5. A regular garden hose may be used

as a discharge line.

6. Pump operation will be seriously

hindered or prevented if the inlet

hose is over 15 feet long or if the

vertical pumping distance exceeds 10

feet.

7. At times, an overload due to

overheating, low voltage, jammed

impeller, etc. may shut the pump off.

Unplug or turn off the pump and

wait at least ten minutes. The pump

will cool and automatically reset.

(Model BPC2 only)

8. Motor should never be operated

for more than 2 hours continuously.

Critical heating can occur and might

severely damage the pump and void

warranty.

Operation

1. Add 1 tablespoon of vegetable oil

to both inlet and outlet to prime.

Attach included 6’ suction hose to

inlet of pump. Attach garden hose

to outlet of pump. There must be a

gasket in place to insure that these

connections are airtight, otherwise

the pump will not prime.

2. Connect water suction attachment

to the open end of inlet hose and

place below water surface. (Water

suction attachment is optional

for both BPC1 and BPC2 models.)

The water suction attachment is

designed to fit the male end of

a garden hose. Place the water

suction attachment as near as

possible to the middle of the water

that is to be pumped.

3. Examine the inlet and outlet hoses

to insure there are no blockages,

kinks or bends. The inlet hose

should be no longer than 15 feet

and the vertical pumping distance

should not be any higher than 10

feet.

Place switch in

“OFF” position

before connecting or disconnecting

battery terminal clamps.

IMPORTANT BATTERY

INFORMATION

Be certain that the area around the

batteries is well ventilated. Before

servicing the batteries, blow away

gasses by waving a piece of cardboard

near the batteries.

Dangerous

hydrogen gas

can be released from batteries while

charging. Sparks can ignite the gas

in an enclosed space. Wear safety

goggles when connecting batteries.

Battery connections should be made

in a well-ventilated area.

Working in

the vicinity of

lead acid batteries can be dangerous.

Before making connections or

servicing the batteries, read and

follow instructions in all applicable

instruction manuals. To reduce the

risk of battery explosion, follow

the instructions in this manual and

those published by the battery

manufacturer, as well as those of

any other equipment used in the

surrounding area.

An assistant should be present or

close enough to come to your aid in

the event of an emergency. Have a

reliable source of fresh water and

soap nearby in case battery acid

contacts clothing, skin or eyes.

Wear eye and clothing protection

when working around lead acid

batteries.

Avoid touching your eyes when

working around lead acid batteries.

If battery acid

contacts your

eye(s), flush with cold running

water for 20 minutes and seek

immediate medical attention. If acid

contacts your skin or clothing, wash

immediately with soap and water.

Never smoke or

allow a spark or

flame in the vicinity of the battery.

Avoid dropping

metal tools on

the battery posts because they may

spark or short-circuit the system or

battery, causing an explosion.

www.blueangelpumps.com

2

Operation (Continued)

TEST

RESET

4 Connect pump to power source,

with pump in a dry location.

BPC1: Motor must be connected to

a fully charged automotive tractor

or marine type battery to operate.

Connect the red clamp to the

positive (+) type battery terminal.

Connect the black clamp to the

negative (-) type battery terminal.

See 12V wiring diagram below

(Figure 2).

Model BPC2: Plug into a

3-prong ground-type AC receptacle.

Grounding Plug

Model

BPC1 and BPC2 Series

Figure 2

Figure 1

Maintenance

Always disconnect

power source

before attempting to install, service, or

maintain the pump.

IMPELLER REPLACEMENT

These parts are designed to handle

most clear, nonflammable liquids with

slight amounts of abrasives. When

impeller vanes become worn from use,

or damaged due to pumping abrasive

liquids or trash, pump performance will

be reduced or prevented altogether.

1. Remove the four cover plate screws

holding motor housing and pump

housing together. Cover plate is

now free and can be removed.

2. Inspect gasket and impeller for

wear and damage. If there is any

evidence of wear or damage, replace

the part(s).

3. Lubricate new impeller with white

grease or lightweight oil and

reinstall by aligning flat on impeller

hub with flat on motor shaft.

4. Reassemble gasket, cover plate, and

cover plate screws.

SHAFT SEAL REPLACEMENT

Motor shafts are sealed with factory

pre-lubricated lip-type seals which are

good for the life of the pump. If the

seal leaks, it is usually because the pump

has handled abrasive liquids. If the

motor shaft is scored (deep grooves),

the complete pump must be replaced.

1. Remove and inspect impeller parts as

specified in the impeller replacement

instructions. Replace worn parts.

2. Remove two pump body mounting

screws and slide pump body from

motor. Pry out seal retaining ring

and push worn shaft seal from inside

of pump body.

3. Lubricate new seal with lightweight

oil, push it into pump body with lip

facing away from motor, and push in

seal retaining ring.

4. Reassemble pump body onto motor

with mounting screws. Follow steps

3 and 4 in Impeller Replacement.

MOTOR BRUSH REPLACEMENT

Brushes for this

pump should be

inspected after 75 hours of operation

and replace if worn. They must be

replaced every 150 hour of operation.

Service one brush at a time.

1. Disconnect pump from power

supply.

2. Remove brush caps with screwdriver.

3. Remove old brush assembly.

4. Insert new brush assembly.

5. Replace brush caps.

www.blueangelpumps.com

3

Loading...

Loading...