Page 1

Specifications

Power supply

requirements . . . . . . . . . .120V, 60 Hz,

1 phase

Motor duty . . . . . . . . . . .Intermittent

Liquid temperature

range . . . . . . . . . . . . . . . .40°F to 125°F

Max. operating

position . . . . . . . . . . . . . .45ofrom

vertical

Dimensions . . . . . . . . . . .10” X 5” X

4-3/4”

Discharge . . . . . . . . . . . . .3/8"ID

Power cord . . . . . . . . . . .6'

3 conductor

with ground

Reservoir . . . . . . . . . . . . .2 quart

plastic

Description

A condensate unit removes

condensation from air conditioning

and high efficiency furnaces. The

compact design of the unit consists of a

3/8” ID discharge and 6 ft. long power

cord. The unit also contains a safety

switch to automatically shut off pump

in the event of a failure.

Unpacking

Inspect this unit before it is installed.

Occasionally, products are damaged

during shipment. If the pump or

components are damaged, return the

unit to the place of purchase for

replacement. Failure to do so could

result in serious injury or death.

This pump is not

designed to handle

salt water, brine, laundry discharge, or

any other application which may contain

caustic chemicals and/or foreign

materials. Pump damage could occur if

used in these applications and will void

warranty. Use for clear water application

only.

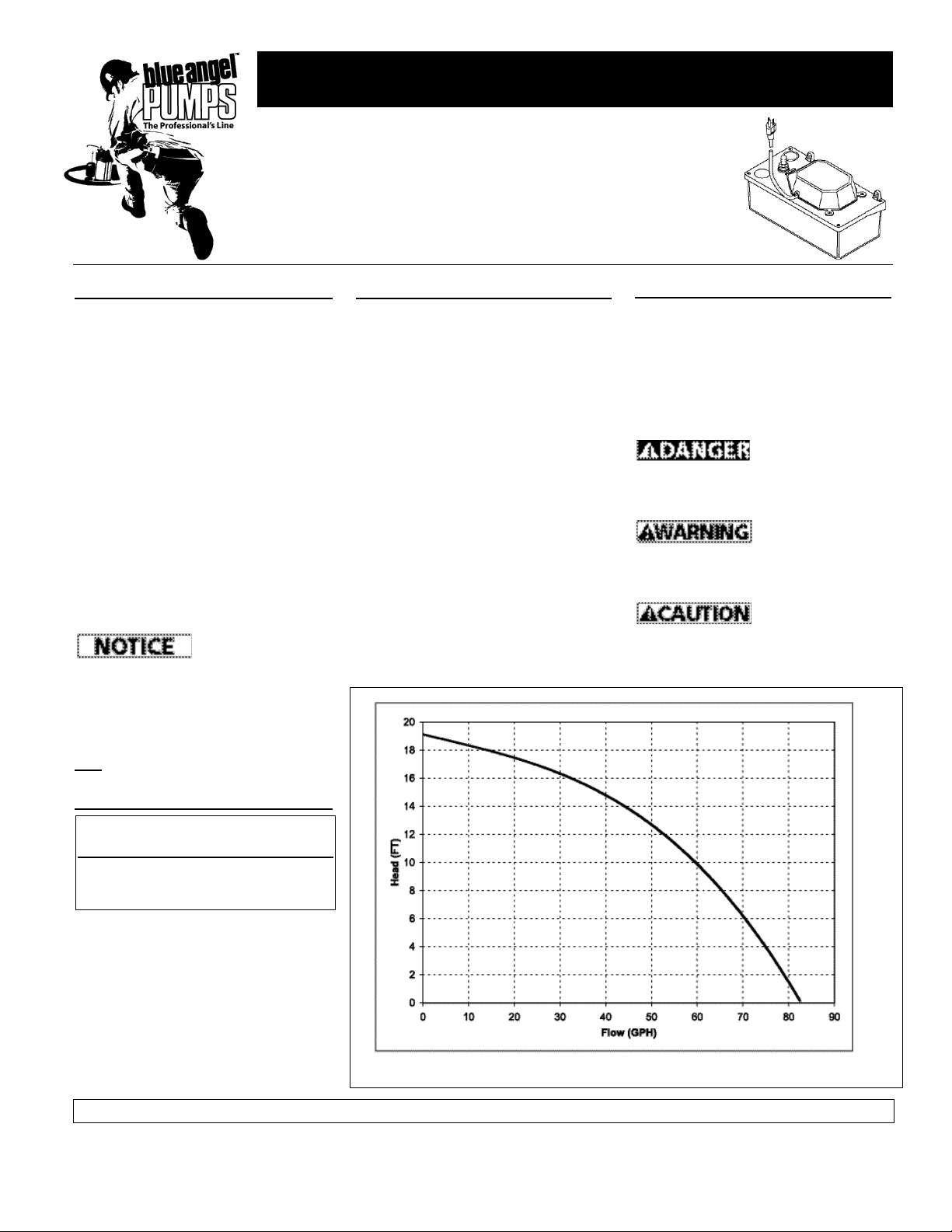

Performance

Operating Instructions and Parts Manual Model BCP20ULS

370103-002 1/07

Safety Guidelines

This manual contains information that

is very important to know and

understand. This information is

provided for SAFETY and to PREVENT

EQUIPMENT PROBLEMS. To help

recognize this information, observe the

following symbols.

Danger indicates

an imminently

hazardous situation which, if not

avoided, will result in death or serious

injury.

Warning indicates

a potentially

hazardous situation which, if not

avoided, could result in death or serious

injury.

Caution indicates a

potentially

hazardous situation which, if not

avoided, MAY result in minor or

moderate injury.

© 2007 Blue Angel ™ Pumps

Condensate Unit

GALLONS PER HOUR

AT TOTAL HEAD IN FEET

Head (ft) 2 6 8 10 19

Flow (GPH) 78 72 66 59 0

For parts, product & service information

visit www.blueangelpumps.com

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

Figure 1 - Performance Chart

Please read and save these instructions. Read carefully before attempting to assemble,

install, operate or maintain the product described. Protect yourself and others by

observing all safety information. Failure to comply with instructions could result in

personal injury and/or property damage! Retain instructions for future reference.

Page 2

be shut-off or obstructed.

9. Personal Safety:

a. Wear safety glasses at all times

when working with pumps.

b. Keep work area clean,

uncluttered and properly lighted;

replace all unused tools and

equipment.

c. Keep visitors a safe distance from

the work area. Make workshop

child-proof with pad locks, master

switch es, and by re mov ing starter

keys.

10. When wiring an elec tri cal ly driven

pump such as this, fol low all electrical

and safety codes, as well as the most

recent National Electrical Code (NEC)

and the Oc cu pa tion al Safety and

Health Act (OSHA).

Risk of electric shock! Never

connect the green (or green

and yellow) wire to a live

terminal!

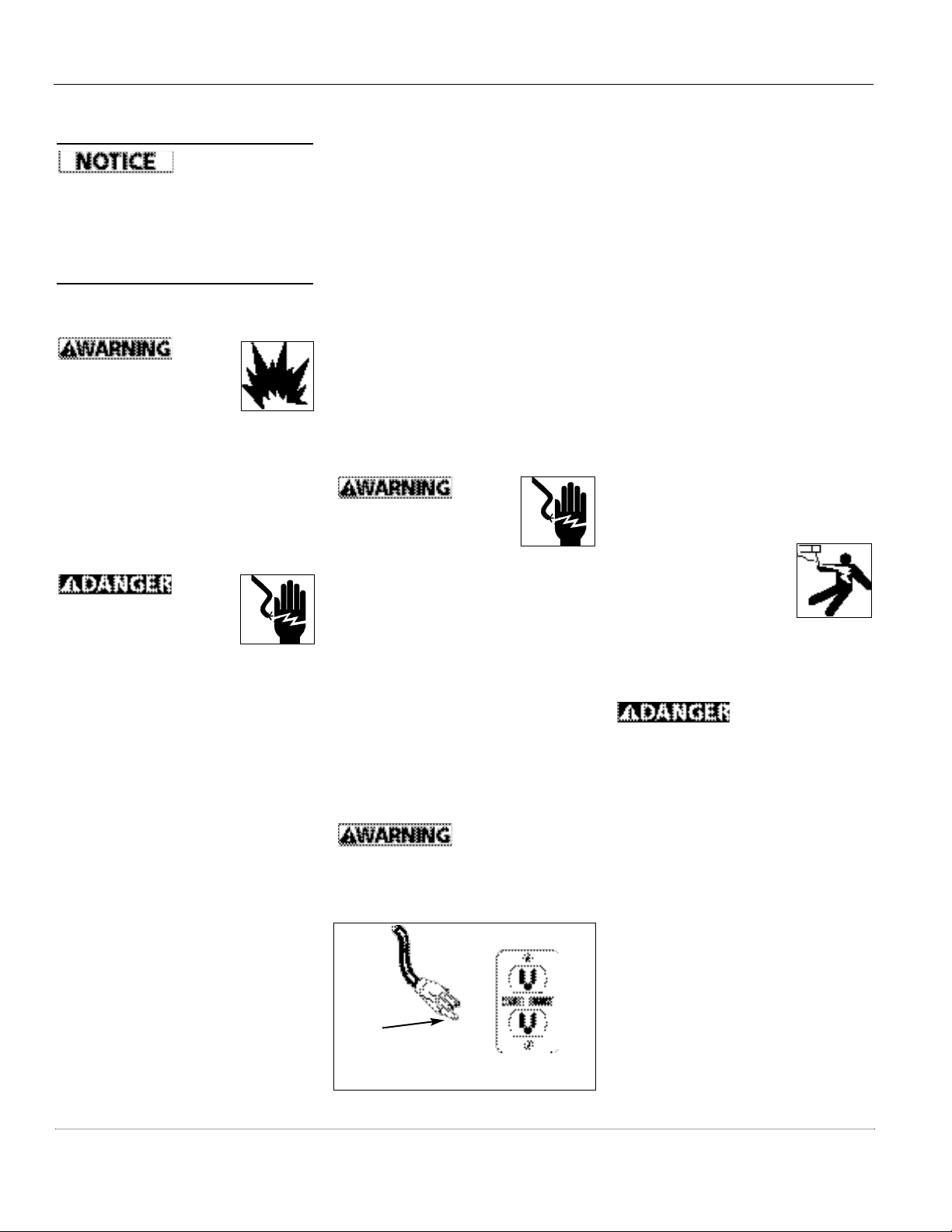

11. This equipment is only for use on

120 volt (single-phase) and is

equipped with an ap proved 3-con duc tor cord and 3-prong,

grounding-type plug as shown in

Fig ure 2.

To reduce the risk of electric shock, the

motor must be securely and adequately

grounded. This can be ac com plished by

inserting plug directly into a properly

installed and grounded 3-prong,

grounding-type re cep ta cle (as shown in

Figure 2).

Risk of electrical

shock! This pump is

supplied with a grounding conductor

and grounding type attachment plug.

Use a grounded receptacle to reduce

the risk of fatal electric shock.

Safety Guidelines

(Continued)

Notice indicates

indicates important

information, that if not followed, may

cause damage to equipment.

General Safety

Information

1. Know the pump application,

limitations, and po ten tial hazards.

Do not

use to

pump flammable or explosive

fluids such as gasoline, fuel

oil, kerosene, etc. Do not use

in flammable and/or explosive

atmospheres. Use pump only with liquids

compatible with pump component

materials. Failure to follow this warning

can result in personal injury and/or

property damage.

2. Make certain that the power supply

conforms to the requirements of

the unit.

Disconnect power before

servicing. If the power dis con nect is out of sight, lock

in the open po si tion and tag it to

prevent unexpected application of

power. Failure to do so could result in

fatal electrical shock!

3. Release all pressure within the

system before ser vic ing any

component.

4. Drain all liquids from the system

before servicing.

5. Secure the discharge line before

starting the pump. An unsecured

discharge line will whip, possibly

causing personal injury and/or

property damage.

6. Check hoses for weak and worn

condition before each use, making

certain that all connections are

secure.

7. Periodically inspect the pump and

system com po nents. Perform

routine maintenance as required

(See Maintenance Section).

8. Provide a means of pressure relief

for pumps whose discharge line can

Operating Instructions and Parts Manual

Never cut off the round grounding

prong. Cutting the cord or prong

will void the warranty and make

the pump inoperable.

Where a 2-prong wall receptacle is

encountered, it must be replaced with

a properly grounded 3-prong re cep ta cle installed in accordance with the

NEC and local codes and ordinances.

12. All wiring should be performed by a

qualified elec tri cian.

13. It is strongly recommended that this

unit is plugged into a Ground Fault

Circuit Interrupter (GFCI). Con sult a

local electrician for installation and

availability.

14. Protect electrical cord from sharp

objects, hot sur fac es, oil, and

chemicals. Avoid kinking the cord.

Re place or repair damaged or worn

cords im me di ate ly. Use wire of

adequate size to minimize voltage

drop at the motor.

15. Do not handle a pump

or pump motor with

wet hands or when

standing on a wet or

damp surface, or in

water.

16. Do not use an extension cord.

Do not

walk on wet area

until all power has been turned off. If

the shut-off box is in basement, call

the electric company to shut-off service

to the house, or call the local fire

department for instructions. Remove

pump and repair or replace. Failure to

follow this warning can result in fatal

electrical shock.

Grounding

Blade

Figure 2 - Grounding

2

www.blueangelpumps.com

Page 3

3

Model BCP20ULS

www.blueangelpumps.com

Installation

In any installation

where property

damage and/or personal injury might

result from an inoperative or leaking

pump due to power outages, discharge

line blockage or any other reason, use

a backup system(s).

STEP 1: INSTALLATION OF PIPE

A. Insert the discharge pipe or pipe

nipple into the 3/8” ID plastic tube.

Before removing

pump from its

mounting position for service, always

disconnect electrical power to pump

and control switch. For any work on

pump or switch, ALWAYS unplug the

power cord. Do not just turn off circuit

break er or unscrew fuse.

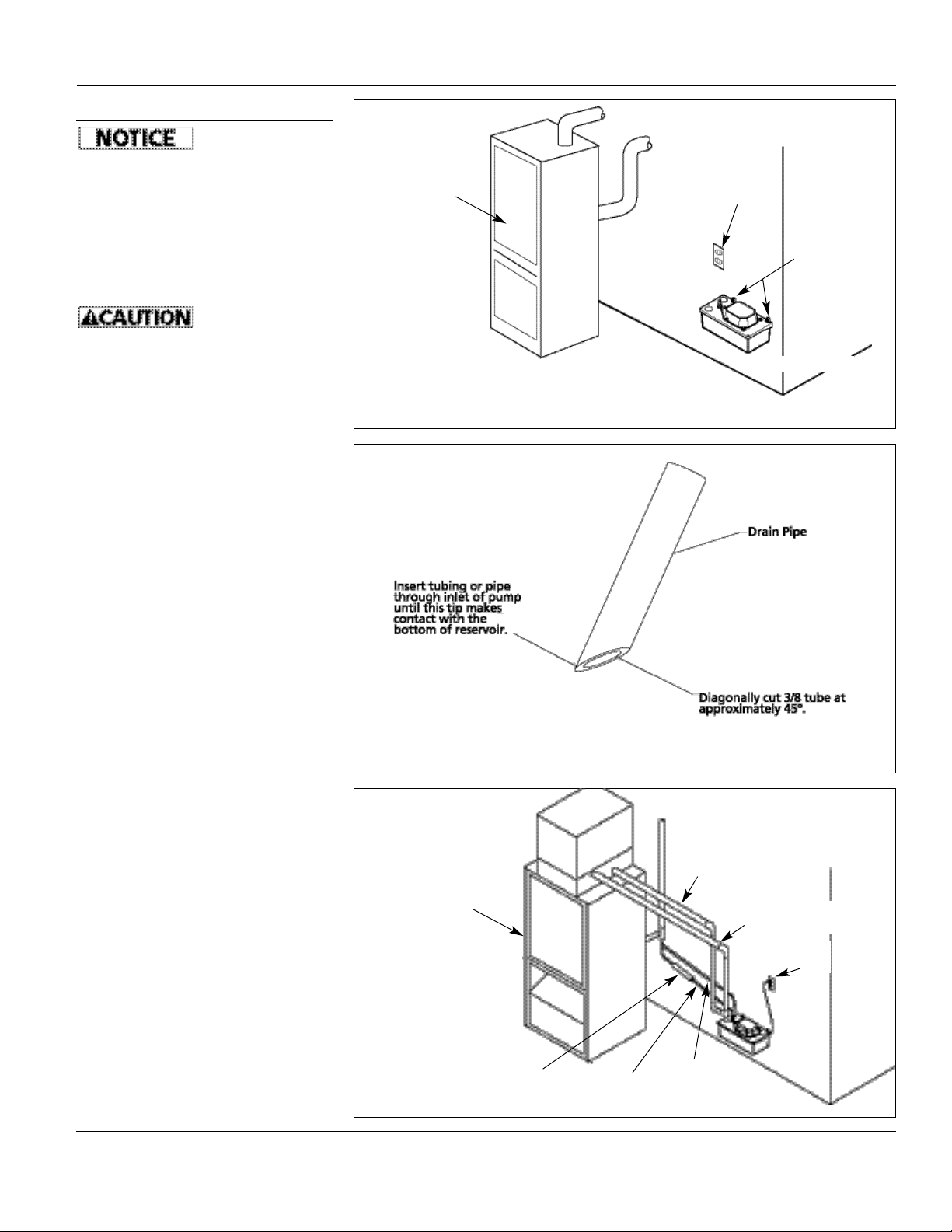

STEP 2: MOUNTING

CONDENSATE UNIT

A. Position the pump below the

evaporator drain and/or furnace

drain.

B. The pump can be installed to the

wall or side of the appliance using

the two mounting brackets. Refer to

Figure 3.

STEP 3: INSTALLATION OF

CONDENSATE DRAIN LINES

A. To prevent pipe blockage in the

reservoir, modify the end of pipe or

tubing as illustrated in Figure 4.

B. Plumb flexible tube or pipe from the

condensate drain, and from the

furnace drain (if applicable), to the

inlet holes on the pump. Refer to

Figure 5.

STEP 4: INSTALLATION OF

DISCHARGE LINE

NOTE: Use 3/8” I.D. (max.) flexible

tubing. A hose clamp is recommended

(not provided).

A. Extend discharge pipe from barbed

check valve to the highest point

possible. Refer to Figure 6.

B. From this point, direct the

discharge line to the location of the

drainage source. Maintain a

continuous downward slope.

NOTE: Construct an inverted “U” (see

Figure 6) at the highest point of

discharge line if a continuous

downward slope is not possible.

Exercise care not to kink or “pinch off”

the flow of condensate liquid.

Figure 3 - Mounting location

Figure 4 - Modification of pipe end to prevent blockage

Figure 5 - Plumbing pipe from drain to inlet holes on pump

GFCI Outlet

Mounting

brackets

6 1/2” above floor

High efficiency

gas furnace

Main Drain from Coil

Overflow Drain from

Coil When Required

GFCI

Outlet

Overflow Drain

from Furnace

Condensate Neutralizer

Cartridge (If Required)

Main Drain

from Furnace

High efficiency

gas furnace

Page 4

Operating Instructions and Parts Manual

4

www.blueangelpumps.com

Installation

(Continued)

STEP 5: INSTALLATION OF

SAFETY SWITCH (IF APPLICABLE)

Connect power cord

to a constant

voltage source. Do not connect to a fan

or other device that may run

intermittently.

A. The pump can be wired directly to

the appliance thermostat to shut

the pump and appliance down in

the event of pump failure. Refer to

Figure 7 for typical wiring diagram.

NOTE: The alarm can be wired in the

safety switch at the normally open

(“NO”) contact.

TIPS FOR EASY INSTALLATION

1. After reading instructions, check to

make sure installation does not

exceed a maximum of 15 feet of

vertical lift.

2. Make sure pump is level. No part of

the pump base should be more

than 1/8” off of level plane.

3. Use soapy water on unit when

performing cleaning maintenance.

(Refer to Maintenance guidelines.)

4. For optimum performance, drain

and discharge lines should have a

continuous downward slope. Test

operation of pump to make sure

lines have enough downward slope

for efficient operation.

5. Avoid overtightening of check valve

after cleaning. (Refer to

Maintenance gudelines.)

6. Use constant voltage power source.

Do not plug into a device that runs

intermittently.

7. Locate model number and date

code on pump and take note of

them.

8. To assure proper performance, the

highest point of discharge line

should be higher than 5’ off the

floor.

9. Clean any debris in the pump

reservoir if necessary.

10. Do not handle the pump until you

have disconnected it from the

power source. Follow all guidelines

Figure 6 - Installation of discharge line

Figure 7 - Typical wiring diagram for pumps provided with safety switch

NOTE: The alarm can be wired into the safety

switch at the normally open (“NO”) contact.

for electrical safety discussed in

General Safety.

11. Do not use a pump discharge pipe

smaller than the pump discharge

size.

12. After installation, test pump to

make sure that system is working

properly.

13. Make sure that installation

conforms to all local and national

codes.

14. Local codes may require the use of a

condensate neutralizer when using

this pump.

Maintenance

Make certain that

the pump is

unplugged before attempting to

service or remove any component. This

pump is assembled in the factory using

special equipment; therefore only

authorized service dealers or qualified

electricians should attempt to repair

this unit. Improper repair can cause an

electrical shock hazard.

CLEANING RESERVOIR AND

IMPELLER

1. Unscrew two screws through

mounting brackets, and remove

pump from wall, if mounted.

15 Ft.

Max

Inverted “U”

To Main Drain

Hose clamp

(recommended, not included)

GFCI

Outlet

Do not kink or pinch

3/8” ID Tubing

Typical Thermostat

Typical Thermostat Connections of Appliance

Overflow

Safety Switch

Page 5

5

Model BCP20ULS

www.blueangelpumps.com

Maintenance

(Continued)

2. Remove reservoir from deck by

unscrewing the four screws located

at the corners of the reservoir cover.

3. Remove the impeller cover by

unscrewing the five screws on the

underside of the motor. Pull out the

impeller shaft assembly.

4. Use a damp cloth to wipe off the

gasket and the motor assembly.

5. Reassemble impeller to motor. Then

reassemble reservoir to reservoir

cover.

CLEANING CHECK VALVE

1. Disconnect discharge line from

check valve – see Figure 8.

2. Remove check valve with 9/16”

wrench.

3. Visually check for obstructions or

damage.

4. If check valve is not damaged,

replace valve by hand-tightening.

Then tighten 1/2” turn with 9/16”

wrench.

Do not overtighten.

Damage to O-ring

seal may occur.

Notes

check valve

Figure 8 - Check valve

Page 6

Operating Instructions and Parts Manual

6

www.blueangelpumps.com

Notes

Page 7

7

Model BCP20ULS

www.blueangelpumps.com

Troubleshooting Chart

Pump may start unexpectedly. Disconnect power supply before ser vic ing.

Symptom Possible Cause(s) Corrective Action

Pump fails to run

Pump emits loud noises

when operating

Pump operates but

there is no flow of

liquid

Liquid drains back into

pump from discharge

line

Liquid leaks from

around check valve

1. Pump not plugged in

2. Low voltage, blown fuse, open

circuit

3. Reservoir is absent of

condensate

4. Drain/discharge lines blocked

Foreign material in reservoir

1. Float is sticking

2. Discharge height greater than

15 feet

3. Obstruction in discharge tube

4. Blockage in check valve

5. Damaged check valve

1. Damaged check valve

2. Blockage in check valve

3. Discharge line is 5’ or less

1. Check valve fastened too tight

or too loose

2. Damage to O-ring

1. Plug in.

2. Have a certified electrician check fuse circuit.

3. Make sure that there is adequate condensate level in

reservoir. Check drain lines and/or discharge line for

obstructions.

4. Check drain lines and/or discharge line for obstructions.

Refer to Maintenance section for cleaning instructions.

1. Refer to Maintenance section for cleaning instructions.

2. Measure from bottom of pump to highest point. Rework

discharge if height is greater than 15’. Refer to Installation

Step 4 for instructions.

3. Check discharge line for blockage. Remove debris.

4. Refer to Maintenance section for cleaning instructions.

5. Contact Blue Angel Pumps.

1. Contact Blue Angel Pumps.

2. Refer to Maintenance section for cleaning instructions.

3. Condensate liquid may drain out of line into reservoir due

to discharge height. This is normal. No action is necessary.

1. Check valve should be hand-tightened, then tightened an

additional 1/2 turn with a 9/16” wrench.

2. Replace with a 1/2” ID x 11/16” OD x 3/32” thick O-ring or

contact Blue Angel Technical Service at 1-800-237-0987,

Before servicing a pump, always shut off the main power breaker and then unplug the pump.

Make sure you are not standing in water. Make sure you are wearing insulated, protectivesoled shoes. Under flooded conditions, check your local electric company or a qualified licensed electrician for

disconnecting electrical service prior to pump removal. If the above checklist does not solve the problem, contact

Blue Angel Technical Service at 1-800-237-0987.

Page 8

Limited Warranty

For one year from the date of purchase, Blue Angel will repair or re place, at its option, for the original purchaser any part

or parts of its Sump Pumps or Water Pumps (“Product”) found upon examination by Blue Angel to be defective in

materials or work man ship. Please call Blue Angel (800-237-0987) for instructions or see your dealer. Be pre pared to provide

the model number and the serial number when exercising this warranty. All transportation charges on Products or parts

submitted for repair or replacement must be paid by purchaser.

This Limited Warranty does not cover Products which have been damaged as a result of accident, abuse, misuse, neglect,

improper installation, improper maintenance, or failure to operate in accordance with Blue Angel’s written instructions.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, IN CLUD ING THOSE OF MER CHANT ABIL I TY AND

FITNESS FOR A PARTICULAR PUR POSE, ARE LIMITED TO ONE YEAR FROM THE DATE OF PURCHASE. THIS IS THE

EXCLUSIVE REM E DY AND ANY LIABILITY FOR ANY AND ALL INDIRECT OR CONSEQUENTIAL DAM AG ES OR

EXPENSES WHATSOEVER IS EXCLUDED.

Some states do not allow limitations on how long an implied warranty lasts, or do not allow the exclusions or limitations of

incidental or consequential damages, so the above lim i ta tions might not apply to you. This limited war ran ty gives you

specific legal rights, and you may also have other legal rights which vary from state to state.

In no event, whether as a result of breach of contract warranty, tort (in clud ing negligence) or otherwise, shall Blue Angel

or its suppliers be liable for any special, consequential, incidental or penal damages including, but not limited to loss of

profit or revenues, loss of use of the products or any associated equipment, damage to associated equip ment, cost of

capital, cost of substitute products, facilities, services or replacement power, downtime costs, or claims of buyer’s cus tom ers

for such damages.

You MUST retain your purchase receipt along with this form. In the event you need to exercise a warranty claim, you

MUST send a copy of the purchase receipt along with the material or correspondence. Please call Blue Angel (800-237-

0987) for return authorization and instructions.

DO NOT MAIL THIS FORM TO BLUE ANGEL. Use this form only to maintain your records.

MODEL NO._______________ SERIAL NO.__________________________ INSTALLATION DATE_____________

ATTACH YOUR RECEIPT HERE

8

Operating Instructions and Parts Manual

www.blueangelpumps.com

Loading...

Loading...