Page 1

Operating Instructions 2 HP Grinder Pumps

Please read and save these instructions. Read carefully before attempting to assemble, install,

operate or maintain the product described. Protect yourself and others by observing all safety

information. Failure to comply with instructions could result in personal injury and/or property

damage! Retain instructions for future reference.

2 HP Grinder Pump

Description

The 2 HP Grinder is a submersible

wastewater pump designed specifically

for pumping domestic sewage. One

pump can handle the sewage for a

maximum of 2 homes. These pumps are

not to be used for pumping commercial

or industrial sewage from factories,

schools, motels, apartments, etc. This

pump is not for use in hazardous

locations!

UNPACKING AND INSPECTION

Inspect this unit before it is used.

Occasionally, products are damaged

during shipment. If the pump or

components are damaged, return

the unit to the place of purchase for

replacement. Failure to do so could

result in serious injury or death.

Safety Guidelines

This manual contains information that is

very important to know and understand.

This information is provided for SAFETY

and to PREVENT EQUIPMENT PROBLEMS.

To help recognize this information,

observe the following symbols.

Danger indicates an

imminently

hazardous situation which, if not avoided,

will result in death or serious injury.

Warning indicates a

potentially

hazardous situation which, if not avoided,

could result in death or serious injury.

Caution indicates a

potentially hazardous

situation which, if not avoided, may result

in minor or moderate injury.

Notice indicates

important

information, that if not followed, may

cause damage to equipment.

NOTE: Information that requires special

attention.

General Safety

Information

CALIFORNIA PROPOSITION 65

This product or its

power cord may

contain chemicals known to the State

of California to cause cancer and birth

defects or other reproductive harm.

Wash hands after handling.

1. Know the pump application,

limitations and potential hazards.

Do not use to

pump flammable or

explosive fluids such as gasoline, fuel oil,

kerosene, etc. Do not use in flammable

and/or explosive atmospheres. Use to

pump only with liquids compatible with

pump components materials. Failure

to follow this warning can result in

personal injury and/or property damage.

2. Only qualified personnel should

install, operate and repair this pump.

3. Make certain that the power source

conforms to the requirement of the

equipment.

Disconnect power

before servicing. If

the power disconnect is out of sight,

lock in the open position and tag it

to prevent unexpected application of

power. Failure to do so could result in

fatal electrical shock!

4. Release all pressure within the

system before servicing any

component.

5. Drain all liquids from the system

before servicing.

This pump contains

dielectric motor oil

for motor heat transfer. Care should be

taken when disposing of this oil. Do

not use this pump in ponds or fountains

because the motor oil can be harmful to

aquatic life.

6. Check your local codes before installing.

You must comply with local rules.

Figure 1

7. Vent any sewage or septic tank

according to local codes.

8. Always keep the shut-off valve

completely open when the system

is in operation (unless advised

otherwise by the proper authorities).

Before removing the pump form the

basin, be sure to close the shut-off

valve. (This prevents back-flow from

the pressure sewer.)

9. Keep the control panel locked or

confined to prevent unauthorized

access to it.

10. Secure the discharge line before

starting the pump. An unsecured

discharge line will whip, possibly

causing personal injury and/or

property damage.

11. Periodically inspect the pump

and system components. Perform

maintenance as required. If the

pump is idle for long periods

of time, add water to the basin

occasionally to start the pump.

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

© 2009 Blue Angel™ Pumps For parts, product & service information

visit www.waynewatersystems.com

332304-002 10/09

Page 2

Operating Instructions

2 HP Grinder Pumps

12. Provide a means of pressure relief

for pumps whose discharge line can

be shutoff or obstructed.

13. Do not install the pump in any

location classified as hazardous by

National Electric Code, ANSI/NFPA

70-1984.

14. Secure the pump in its operating

position so it cannot tip over, fall or

slide. Install this pump in the vertical

position only.

15. Make sure lifting handles are securely

fastened each time before lifting. Do

not operate pump without safety

devices in place. Always replace safety

devices that have been removed

during service or repair. DO NOT LIFT

PUMP BY POWER CORD.

16. Do not run the pump dry. Dry

running can overheat the pump and

will void the warranty.

17. Personal Safety:

a. Wear safety glasses at all times

when working with pumps.

This pump is designed to

handle materials that could

cause illness or disease through

direct exposure. Wear and

use protective clothing when

working on the pump or piping.

b. Do not wear loose clothing that

may become entangled in the

impeller or other moving parts.

c. Keep clear of suction and

discharge openings. DO NOT

insert fingers in the pump with

power connected.

d. Keep work are clean,

uncluttered and properly

lighted: replace all unused tools

and equipment.

e. Keep visitors a safe distance

from the work area. Make

workshop childproof with

padlocks, master switches, and

by removing starter keys.

18. A qualified electrician should

perform all wiring of this pump.

When wiring an electrically driven

pump such as this, follow all

electrical and safety codes, as well

as the most recent National Electric

Code (NEC) and the Occupational

Safety and Health Act (OSHA).

Risk of Electric Shock!

Never connect the

green (or green and yellow) wire to a

live terminal!

This unit is not

designed for

application involving salt water or brine.

Use with salt water or brine will void

warranty.

Installation

This pump may be installed on a guiderail lift-out system for ease of inspection

and service. Guide-rails allow removal

of the pump without disturbing the

piping and eliminates the need to enter

the basin. If installed with a guide-rail

system, place the pump opposite the

influent opening to prevent stagnant

areas where solids can settle.

Install the pump on a hard, level surface.

Never place the pump directly on earth,

clay or gravel surfaces. The basin must be

at least 18” in diameter and 30” deep.

The discharge pipe must not be smaller

than the pump discharge.

The motor is provided with a thermal

overload switch (Single Phase Pump

Motors Only). If the motor overloads

or overheats for any reason, the switch

opens, stopping the motor. As soon as the

motor cools to normal temperature, the

switch automatically closes and restarts the

motor. On 3-Phase pumps, the installer

must provide the Motor Protection. In

accordance with the National Electric

Code, all 3-phase pumps must be

installed with magnetic starters having

3 leg overload protection. For duplex

installations, both pump motors must

have separate overload protection.

Hazardous voltage.

Can shock, burn, start

a fire or kill. When installing, operating or

servicing this pump, follow electrical safety

instructions below. Only trained service

personnel should install or service this pump.

Motor

Model Number

BAGP1-115 2 115 60 1 15.0

BAGP1-2021 2 230 60 1 14.5

BADSGP1-115 2 115 60 1 20.0

BARDSGP1-2021 2 230 60 1 14.5

BADSGP1-2001 2 200/208 60 1 16.9

BARDSGP1-2023 2 230 60 3 8.8

BAHGP2-2021 2 230 60 1 24.0

BAHGP2-2021C 2 230 60 1 24.0

BAHGP2-2021E1 2 230 60 1 14.8

BAHGP2-2023 2 230 60 3 12.2

Chart 1 - Motor Specifications

HP Voltage

1. Do not splice the power cord.

2. Do not handle or service this pump

while it is connected to the power

supply.

3. Do not operate the pump unless it is

properly grounded. Connect the pump

according to all applicable codes.

4. Incorrect voltage can cause a fire

or seriously damage the motor and

voids the warranty. Make sure that

the frequency and voltage shown

on the nameplate corresponds to

the frequency and voltage of the

electrical supply.

5. Connect the pump to its own

circuit with nothing else on the

circuit. See Chart 1 for pump motor

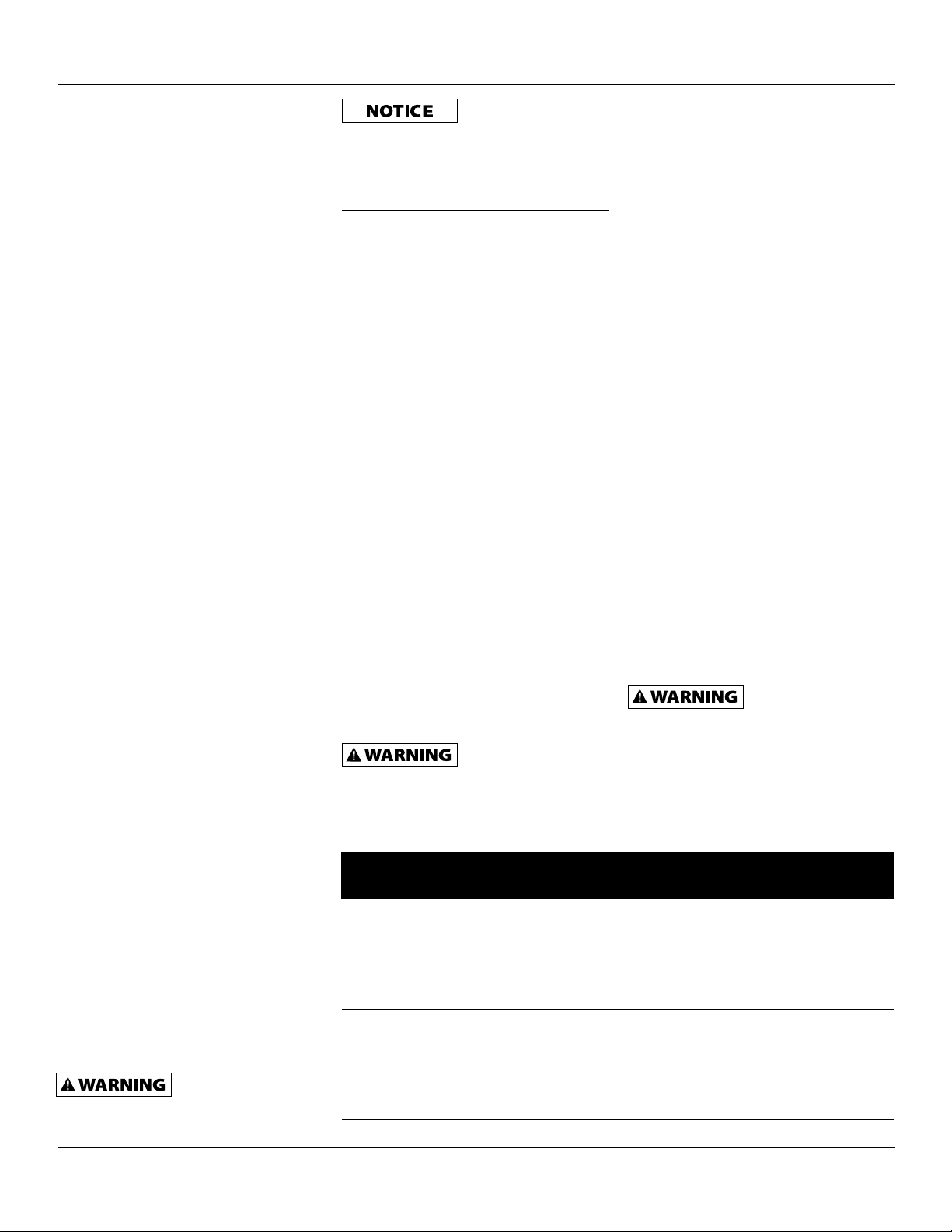

specifications. See Figure 2 for wiring

diagram. Use a Control Panel sized

to match the pump. Refer to Control

Panel installation instructions for

wiring connections information.

6. The pump rotation must be

clockwise as viewed from the top of

the pump. If a three-phase unit runs

backwards, interchange two of the

three power supply wires to reverse

the motor’s direction of rotation.

7. Install the pump in accordance with

all electrical codes that apply. Install

a fused disconnect switch or circuit

breaker in accordance with local

codes.

Risk of electrical

supplied with a grounding conductor on the

power cord. The grounding conductor is the

GREEN lead. To reduce the risk of electric

shock, be certain the ground conductor

is connected in the control box to the

grounding bar, which in connected to a

good suitable ground. The pump is not safe

to operate unless it is properly grounded.

Frequency

Hz Phase

shock. Pumps are

Motor Full

Load Amps

www.waynewatersystems.com

2

Page 3

Start Windings

Main Windings

Run Cap.

Start Cap.

Cent Switch

1. WHITE

2. BLACK

3. RED

BAGP1

BADSGP1

1

2 3

7 8 9

4 5 6

1. WHITE

2. BLACK

3. RED

BLUE

Moisture Sensor

Thermal Sensor

WHITE

BROWN

230 Volt 3 Phase

60Hz

BARDSGP1-2023

1. WHITE

2. BLACK

Start Windings

Main Windings

5

2

1

3. RED

Run Cap.

Start Cap.

4. BLUE

Moisture Sensor

BARDSGP1-2021

230 VAC, 1 Phase 60 Hz

Start Relay

Main Windings

Main Windings

Start Windings

4

1

3

2

Start Cap.

Run Cap.

Thermal Sensor

1. WHITE

2. BLACK

4. LEAD

3. RED

230 Volt 1 Phase

60Hz

BAHGP2-2021

230 Volt 3 Phase

60Hz

4 5

718

2

1. WHITE

2. BLACK

6

9

3

3. RED

BAHGP2-2023

4. BLUE

Moisture Sensor

BADSGP1

(only)

Operating Instructions

The double seal grinder pumps contain

an electrode for detecting water within

the unit. The electrode is housed within

the seal chamber, isolated from the

motor chamber by a mechanical shaft

seal. If the electrode detects water

within the oil-filled housing, it will close

the circuit to the alarm light in the

control panel, indicating the motor must

be serviced before the upper mechanical

shaft seal fails. The BLUE conductor is

connected to the seal leak probe.

Refer to Wiring Diagrams for model

specific wiring directions (See Figure 2).

Control Panel and

Level Sensing

BAGP1 & BADSGP1 grinder pumps

have internal start and run capacitors.

No control panel is required for

operating the pump. An alarm box is

recommended for high water alarm.

See Chart 2 for starting component

specifications per model.

BARDSGP1 and BAHGP2 models require

control boxes containing properly sized

start and run capacitors. Single-phase

models require a Single-Phase Control

Box with starting components equal to

specifications listed in Chart 2.

The three-phase models require a ThreePhase Control Box with circuit breaker

and overload heaters per the chart.

Intrinsically safe type float controls are

recommended for all applications. An

intrinsically safe control panel relay will

limit the current and voltage to the level

controls. A control panel can be supplied

with this type of circuitry.

Recommended level sensing settings:

1. The lower “turn-off” control should

be set so the pump stops with the

liquid level at the top of the motor

housing.

2. The upper “turn-on” control should

be set approximately 8” above the

“turn-off” control. This should limit

the number of pump starts to not

exceed 10 starts per hour.

3. The “lag-on” control for duplex

operation should be set 4” above

the “turn-on” control.

4. The “alarm” control is set 10” above

the “turn-on” control.

5. No control should be set above the

inlet pipe.

Figure 2 - Wiring Diagram

Model # Start

BAGP1-115

BADSGP1-115

BAGP1-2021

BADSGP1-2001

BARDSGP1-2021 270-300mF

BAHGP2-2021

BAHGP2-2021C

BAHCP2-2021E1

Chart 2

Capacitor

200mF

250 Vac

270-300mF

250-370 Vac

250-370 Vac

400mF

250 Vac

2 HP Grinder Pumps

Run

Capacitor

70mF

250 Vac

30mF

300 Vac

30mF

300 Vac

90mF

250 Vac

www.waynewatersystems.com

Starting

Relay

NA

NA

GE

3ARR3J3G3

Stearns

477104012401

3

Page 4

Operating Instructions

HP Voltage Phase Breaker Size Heater Size

2 230 3 20 Amp K-50

2 460 3 15 Amp K-33

Chart 3

2 HP Grinder Pumps

Note: If pump is not mounted on a

lift-out rail system, the leg kit needs

to be installed. Set leg height so a 3”

– 4” clearance is achieved between the

bottom pump inlet and basin bottom.

Figure 3 - Leg Kit

Maintenance

Only qualified mechanics with proper

tools and knowledge should attempt to

service this pump.

REPLACING GRINDER IMPELLER AND

SHREDDING RING

Note: This is the only disassembly

operation permitted in the field. All

other repairs must be performed at an

authorized service center or the factory.

Standard Tools Required:

• Standardsocketwrenchset

• Standardsetofopen-end

wrenches

• Hammer

• Visegrippliers

• Allenheadsocketset

• Screwdrivers

• Wirebrush

Disconnect all power

and control wires to

motor at the control panel before starting

the disassembly operations. Do not rely

upon opening the circuit breaker only.

Hazardous cutter.

Rotation of the cutter

with hands in the cutter area can cause

loss of fingers. Keep hands away from

the pump inlet opening when working

on or handling the pump for any reason.

Pump should be

sanitized with bleach

before starting work.

• Pumpshouldbethoroughly

cleaned of trash and deposits

before starting disassembly

operations.

• Wearprotectiveglovesand

clothing.

• Alwaysusearagontheimpeller

when turning to prevent cutting

hands on the sharp edges of the

shredding ring.

DISASSEMBLY OF SHREDDING RING

AND GRINDER IMPELLER

1. Remove 3 bolts from grinder ring

flange with socket wrench. The

grinder ring is pressed into the

flange for convenient removal.

2. Thread 2 of the bolts (removed from

the grinder ring flange) into the

tapped back-off holes in the flange

and evenly tighten the bolts to back

the grinding ring out of the pump

housing.

3. Hold the grinder impeller by prying

against the impeller cutting bar and

remove the cap screw from the end

of the shaft.

4. Use a large screwdriver to the slot

of the shaft and tap on the cutter

vane with a hammer. Tap in a

counterclockwise direction (thread is

right-hand).

5. If the impeller removes easily, clean

and replace if worn.

6. Make sure the pump impeller has

not loosened when the grinder

impeller was removed. This can be

checked on reassembly of grinder

impeller and shredding ring. The

tips of the impeller cutter vanes

should extend 1/8” below the

bottom of the shredding ring. If

the distance is greater, the pump

impeller has loosened. If the

distance is less, shredding ring is not

properly seated.

7. After the volute case has been

removed, wrap emery cloth around

the shaft and hold with vise grip

pliers. Us a cloth on the impeller and

thread tight against shoulder on

shaft.

8. Clean all threads with a wire

brush and file smooth any nicked

threads. Apply an anti-seize or other

graphite compound on threads

before replacing grinder impeller.

9. Make sure cap screw in bottom of

pump shaft is tight. Hold impeller

with screwdriver between the cutter

bar and teeth of shredding ring

while tightening the cap screw.

10. Make sure the impeller turns freely

by hand after reassembly. Some

drag will be present due to the

shaft seals. There should not be any

binding or tight spots when turning

the grinder impeller.

11. If there is any rub or drag on the

shredding ring, loosen the 3 bolts

in the shredding ring plate and

tap lightly with the hammer to

loosen. Retighten the bolts. Be

sure to tighten the bolts evenly,

applying pressure on all 3 bolts. DO

NOT COMPLETELY TIGHTEN ONE

BOLT BEFORE TIGHTENING THE

OTHER BOLTS. THIS WILL CAUSE

MISALIGNMENT AND LOCKING OF

SHREDDING RING AND GRINDER

IMPELLER.

www.waynewatersystems.com

4

Page 5

Operating Instructions

2 HP Grinder Pumps

Troubleshooting

Symptom Possible Cause(s) Corrective Action

Motor Not Running 1. Motor Protector Tripped 1. Allow motor to cool. Make sure pump is completely submerged.

2. Open circuit breaker or blown fuse 2. Reset breaker. If circuit opens repeatedly, don’t reset it. Call a

3. Impeller clogged 3. Check amp draw. If it is more than twice the nameplate amps, the

4. Cutter clogged 4. Disconnect Power, pull pump and inspect cutter and cutter ring.

5. Power cable damaged 5. Resistance between power cable and ground should be infinity. If

6. Bad control panel 6. Inspect control panel wiring. Call a licensed electrician.

7. Defective liquid level switch 7. With switch disconnected from power, check continuity through

8. Not enough liquid in wet well to

activate controls

9. Liquid level cords tangled 9. Untangle cords for free operation.

10. Automatic controls defective 10. Try running pump in manual mode. If it runs, the automatic

Pump runs continuously 1. Liquid level control cords tangled 1. Untangle cords for free operation.

2. Pump is air-locked 2. Stop pump for about one minute and then restart. Repeat

3. Incoming flow exceeds the pump’s

capacity

4. Clogged line 4. Discharge line could be clogged. Unclog line.

Pump delivers low volume

of liquid

Pump cycles frequently 1. No discharge check valve installed 1. Install discharge check valve.

1. Check valve plugged, stuck shut or

installed backwards

2. Systems head is too high 2. Consult dealer.

3. Pump suction plugged 3. Disconnect power, pull pump, inspect and clear as needed.

4. Wrong voltage or not wired correctly 4. Check pump’s rotation, check nameplate voltage against supply

5. Pump air-locked 5. Stop pump for about one minute and then restart. Repeat

6. Worn or damaged impeller 6. Disconnect Power, pull pump and inspect impeller. Replace if

7. Liquid level controls incorrectly

installed or defective

2. Discharge check valve stuck open 2. Repair or replace check valve as necessary.

3. Sewage basin too small 3. Consult dealer.

4. Liquid level controls incorrectly

installed or defective

5. Pump too small for inlet flow 5. Consult dealer about larger pump or second pump.

Clear debris from volute and impeller.

licensed electrician.

impeller is locked. Bearings and shaft may be damaged. Disconnect

Power, clear debris from volute, impeller and cutter as needed.

Replace if worn.

any reading is less than infinity, call a licensed electrician.

switch while activating liquid level switch. Replace switch if

necessary.

8. Allow the liquid to rise several inches above the switch-on level.

control is at fault.

stopping and starting until the airlock clears. If the airlock

continues, Disconnect Power, pull the pump and drill a 1/8” hole

in the discharge pipe between the pump discharge and the check

valve.

3. A larger pump or additional pumps may be required.

1. Make sure check valve is installed correctly and functioning

correctly.

voltage, consult licensed electrician.

stopping and starting until the airlock clears. If the airlock

continues, Disconnect Power, pull the pump and drill a 1/8” hole

in the discharge pipe between the pump discharge and the check

valve.

necessary.

7. Reposition or replace as necessary.

4. Reposition or replace as necessary.

www.waynewatersystems.com

5

Page 6

Operating Instructions

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

2 HP Grinder Pumps

For Replacement Parts or Technical Assistance, Call 1-888-636-6628

or log onto our web-site at: www .waynewatersystems.com

Please provide following information: Address any correspondence to:

- Model number Blue Angel Pumps

- Serial number (if any) 101 Production Drive

- Part description and number as shown in parts list Harrison, OH 45030 U.S.A.

Service Parts

Figure 4 - BAGP1 Grinder Pump

SERVICE KITS

Cord Cap

Assembly

(1 and 4)

Capacitors

(2 and 3)

Capacitors

(2 and 3)

Motor Assembly

(5, 6, 7, 8, 9, 10,

11, 12 and 14)

Motor Assembly

(5, 6, 7, 8, 9, 10,

11, 12 and 14)

Mechanical Shaft

(13)

Pump Impeller

(15)

Volute

(16)

Grinder Assembly

(17 and 18)

63014-001

63015-001

BAGP1-115

63030-001

BAGP1-2021

63016-001

BAGP1-115

63031-001

BAGP1-2021

63017-001

63018-001

63019-001

63020-001

Service Parts

Figure 5 - BARDSGP1 Grinder Series

www.waynewatersystems.com

SERVICE KITS

Cord Cap

Assembly

63021-001

(1 and 2)

Motor Assembly

(3, 4, 5, 6, 7, 8,

63022-001

10 and 11)

Upper Mechanical

6

Seal (9)

Lower Mechanical

Seal (12)

Lower Seal

Housing (13)

Volute (14) 63026-001

Pump Impeller

(15)

Grinder Assembly

(16 and 17)

Starting

Components

(not shown)

63023-001

63024-001

63025-001

63027-001

63028-001

63060-002

Page 7

Operating Instructions

1

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

Power Cord 1

Capacitor (Run) 2

Capacitor (Start) 3

Cord Cap 4

Start Mechanism 5

Upper Motor Plate 6

Upper Ball Bearing 7

Dielectric Oil 8

Motor Housing 9

Stator 10

Rotor 11

Lower Ball Bearing 12

Upper Mechanical Seal 13

Moisture Detection Probe 14

Upper Seal Housing 15

Lower Seal Housing 16

Lower Mechanical Seal 17

Volute 18

Pump Impeller 19

Flange with Shredding Ring 20

Grinder Impeller 21

2 HP Grinder Pumps

For Replacement Parts or Technical Assistance, Call 1-888-636-6628

or log onto our web-site at: www .waynewatersystems.com

Please provide following information: Address any correspondence to:

- Model number Blue Angel Pumps

- Serial number (if any) 101 Production Drive

- Part description and number as shown in parts list Harrison, OH 45030 U.S.A.

Service Parts

Figure 6 - BAHGP2 Grinder Series

Service Parts

Figure 7 - BADSGP1 Grinder Series

SERVICE KITS

Upper Volute

63006-001

(1)

Upper Impeller

63007-001

(2)

Motor Assembly

(3, 4, 5, 6, 7, 8, 9,

63008-001

10, 11, 12 and 13)

Lower Mechancial

63009-001

Seal

(12)

Lower Impeller

63010-001

(14)

Lower Volute

63011-001

(15)

Grinder Assembly

63012-001

(16 and 17)

Starting

63013-001

Components

(not shown)

SERVICE KITS

Cord Cap

Assembly

63014-001

(1 and 4)

Capacitors

(2 and 3)

Capacitors

(2 and 3)

Motor Assembly

63013-001

BADSGP1-115

63030-001

BADSGP1-2001

63036-001

(5, 6, 7, 8, 9, 10, 11,

12, 13, 14, and 15)

Upper Mechanical

Seal (13)

Lower Mechanical

63023-001

63024-001

Seal (17)

Volute

63026-001

(18)

Pump Impeller

63027-001

(19)

Grinder Assembly

63029-001

(20 and 21)

www.waynewatersystems.com

7

Page 8

Operating Instructions

Limited Warranty

For two (2) years from date of purchase, Blue Angel Pumps will repair or replace, at its option, for the original

purchaser any part or parts of its Sump Pumps or Water Pumps (”Product“) found upon examination by Blue

Angel Pumps to be defective in materials or workmanship. Please call Blue Angel Pumps (1-888-636-6628) for

instructions or see your dealer. Be prepared to provide the model number when exercising this warranty. All

transportation charges on Products or parts submitted for repair or replacement must be paid by purchaser.

This Limited Warranty does not cover Products which have been damaged as a result of accident, abuse, misuse,

neglect, improper installation, improper maintenance, or failure to operate in accordance with Blue Angel

Pumps’ written instructions.

THERE IS NO OTHER EXPRESS WARRANTY. IM PLIED WARRANTIES, IN CLUD ING THOSE OF MER CHANTABIL I TY AND FITNESS FOR A PARTICULAR PUR POSE, ARE LIMITED TO TWO YEARS FROM THE DATE OF

PUR CHASE. THIS IS THE EXCLUSIVE REM E DY AND ANY LIABILITY FOR ANY AND ALL IN DI RECT OR CON SEQUEN TIAL DAM AG ES OR EX PENS ES WHATSOEVER IS EXCLUDED.

Some states do not allow limitations on how long an implied warranty lasts, or do not allow the exclusions or

limitations of incidental or consequential damages, so the above lim i ta tions might not apply to you. This limited

war ran ty gives you specific legal rights, and you may also have other legal rights which vary from state to state.

In no event, whether as a result of breach of contract warranty, tort (including negligence) or otherwise, shall

Blue Angel Pumps or its suppliers be liable for any special, consequential, incidental or penal damages including,

but not limited to loss of profit or revenues, loss of use of the products or any associated equipment, damage

to associated equipment, cost of capital, cost of substitute products, facilities, services or replacement power,

downtime costs, or claims of buyer’s customers for such damages.

You MUST retain your purchase receipt along with this form. In the event you need to exercise a warranty claim,

you MUST send a COPY of the purchase receipt along with the material or correspondence. Please call Blue

Angel Pumps (1-888-636-6628) for return authorization and instructions.

2 HP Grinder Pumps

DO NOT MAIL THIS FORM TO BLUE ANGEL PUMPS. Use this form only to maintain your records.

MODEL NO.: _______________________________ SERIAL NO.: _______________________________

INSTALLATION DATE: _______________________________

ATTACH YOUR RECEIPT HERE

www.waynewatersystems.com

8

Loading...

Loading...