Blue Angel BCSE50T, BCAPSE50-2, BCSE50M, BCAPSE50 Operating Instructions And Parts Manual

Operating Instructions and Parts Manual

The Professio nal’ s Line

Please read and save these instructions. Read carefully before

attempting to assemble, install, operate or maintain the product

described. Protect yourself and others by observing all safety

information. Failure to comply with instructions could result in

personal injury and/or property damage! Retain instructions for

future reference.

Sewage Pump

BCSE50T, BCSE50M

BCAPSE50 and BCAPSE50-2

Description

A sewage system consists of a pump,

control switch, and a ba sin for use in ap plica tions where less than six toilets (units)

are dis charged into the basin. The sys tem is

generally con trolled by a float switch with a

plug-in-plug which accepts the pump plug

and in turn plugs into a 120 volt outlet.

BCSE50T models utilize a wide angle

differential float switch that rises with the

liquid level and turns the pump on. As

the liquid level decreases the float lowers

and turns the pump off. The BCAPSE50

is provided with a solid-state electronic

capacitive water level control. When

water is detected, the pump will start

automatically. This pump is in tend ed for

use in do mes tic sewage lift stations. It is

suitable for pumping sewage, effluent,

wastewater, groundwater and other non

-ex plo sive, non-cor ro sive liquids with up

to 2 inch solids. Not approved for outdoor

use. Pump contains oil which is poisonous

to aquatic life. Do not use in ponds or

water features.

Specifications BCSE50M & BCSE50T

Power supply requirements 120V, 60 hz 120V, 60hz

Circuit requirements 15 amps (min) 15 amps (min)

Motor duty Intermittent Intermittent

Motor 120V, 1 Phase 120V, 1 Phase

Horsepower 1/2 1/2

Motor full load 8.7 amps 8.7 amps

Liquid temperature range 40°F to 120°F 40°F to 120°F

Max. operating position 45° from vertical 45° from vertical

Dimensions 14 inch x 12 inch 14 inch x 12 inch

Intake 2 inch 2 inch

Discharge 2 inch NPT female 2 inch NPT female

Cut-in level (factory set) 19 inch 11 inch

Cut-out level (factory set) 9 inch 3 inch

Differential 10 inch 7 inch

Switch 90° wide angle

mechanical tether switch

Power cord 16 gauge 3 conductor

with plug

Unpacking

Inspect this unit before it is used.

Occasionally, products are damaged

during shipment. If the pump or

components are damaged, return

the unit to the place of purchase for

replacement. Failure to do so could

result in serious injury or death.

Safety Guidelines

This manual contains information

that is very important to know and

understand. This information is

provided for SAFETY and to PREVENT

EQUIPMENT PROBLEMS. To help

recognize this information, observe the

following symbols.

Danger indicates

an imminently

hazardous situation which, if not avoided,

WILL result in death or serious injury.

Warning indicates

a potentially

hazardous situation which, if not avoided,

COULD result in death or serious injury.

BCAPSE50 &

BCAPSE50-2

Capacitive water sensor

16 gauge 3 conductor

with plug

Caution indicates

a potentially

hazardous situation which, if not avoided,

MAY result in minor or moderate injury.

Notice indicates

important

information, that if not followed, may

cause damage to equipment.

General Safety

Information

CALIFORNIA PROPOSITION 65

This product or its

power cord contains

chemicals known to the State of

California to cause cancer and birth

defects or other reproductive harm.

Wash hands after handling.

GENERAL SAFETY

1. Know the pump application,

limitations, and po ten tial hazards.

Do not

use to

pump flammable or

explosive fluids such

as gasoline, fuel oil,

kerosene, etc. Do not

use in a flammable and/or explosive

atmosphere. Use pump only with liquids

compatible with pump component

materials. Failure to follow this

warning can result in personal injury

and/or property damage.

Construction

Motor

body material .......... Cold rolled steel

Motor housing ...................... Cast iron

Volute .................................... Cast iron

Impeller .............. Glass reinforced PBT

Seal plate .............................. Cast Iron

Shaft seal ........................... Mechanical

Performance

GALLONS PER MINUTE AT TOTAL

HEAD IN FEET

5 10 15

113 90 33

REMINDER: Keep your dated proof of purchase for warranty purposes!

Attach it to this manual or file it for safekeeping.

© 2009 Blue Angel™ Pumps

For parts, product & service information

visit www.blueangelpumps.com

330505-002 12/09

Operating Instructions and Parts Manual

TEST

RESET

General Safety

Information

(continued)

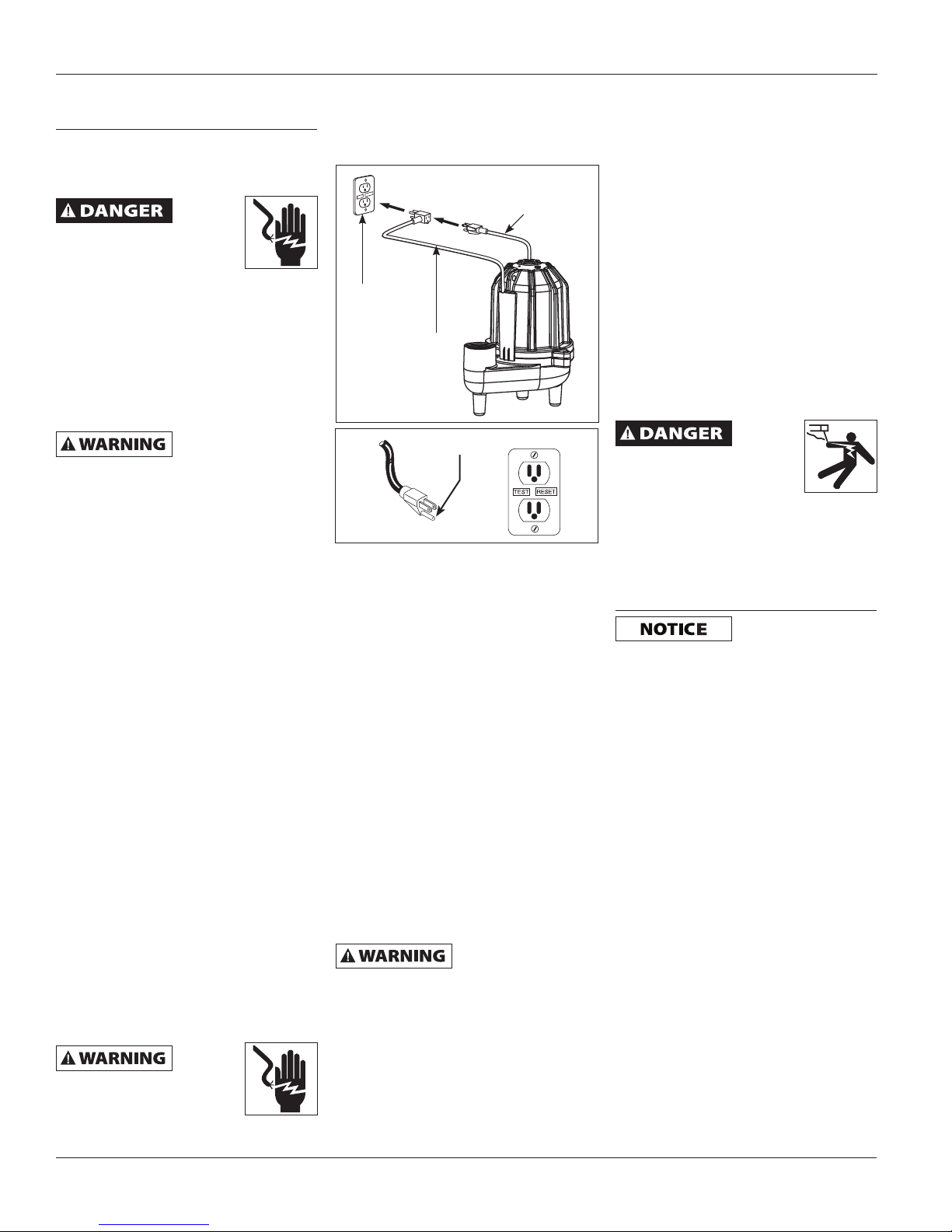

11. This equipment is only for use on

120 volt (single-phase) and is

equipped with an ap proved 3-con ductor cord and 3-prong, grounding-type

2. Make certain that the power source

plug as shown in Fig ure 1A and 1B.

(electric motor) conforms to the

requirements of the equipment.

Disconnect power before

servicing. If the power

dis con nect is out of sight,

lock in the open po si tion and tag it

to prevent unexpected application of

power. Failure to do so could result in

fatal electrical shock!

3. Release all pressure within the

system before ser vic ing any

component.

4. Drain all liquids from the system

Grounded

outlet

Capacitive

water sensor

Figure 1A

Pump Power

Cord

Plug

before servicing.

This pump contains

dielectric motor oil for

motor heat transfer. Care should be taken

when disposing of this oil. Do not use this

pump in ponds or fountains because the

motor oil can be harmful to aquatic life.

5. Secure the discharge line before

Figure 1B

Grounding blade

starting the pump. An unsecured

discharge line will whip, possibly

causing personal injury and/or

property damage.

6. Check hoses for weak and worn

condition before each use, making

certain that all connections are secure.

7. Periodically inspect the pump and

system com po nents. Perform routine

maintenance as required (See

Maintenance Section).

8. Provide a means of pressure relief

for pumps whose discharge line can

be shut-off or obstructed.

9. Personal Safety:

a. Wear safety glasses at all times

when working with pumps.

b. Keep work area clean, uncluttered

and properly lighted; replace all

unused tools and equipment.

c. Keep visitors a safe distance from the

work area. Make workshop childproof with pad locks, master switch es,

and by re mov ing starter keys.

10. When wiring an elec tri cal ly driven

pump such as this, fol low all electrical

and safety codes, as well as the most

recent National Electrical Code (NEC)

and the Oc cu pa tion al Safety and

Health Act (OSHA).

Risk of

electric

shock! Never connect the

green (or green and yellow)

wire to a live terminal!

To reduce the risk of electric shock, the

motor must be securely and adequately

grounded. This can be ac com plished by

the following:

• Insertingplugdirectlyintoa

properly installed and grounded

3-prong, grounding-type re ceptacle

(as shown in Figure 1A and 1B).

• Permanentlywiringtheunitwitha

grounded, metal raceway system.

• Othersuitablemeans.

Where a 2-prong wall receptacle is

encountered, it must be replaced with

a properly grounded 3-prong re cep tacle installed in accordance with the NEC

and local codes and ordinances.

12. All wiring should be performed by a

qualified elec tri cian.

13. It is strongly recommended that this

unit is plugged into a Ground Fault

Circuit Interrupter (GFCI). Con sult a

local electrician for installation and

availability.

The pump motor

is equipped with

automatic resetting thermal protector

and may restart unexpectedly. Protector

tripping is an indication of motor

overloading as a result of operating

the pump at low heads (low discharge

restriction), excessively high or low

voltage, inadequate wiring, incorrect motor

conditions, or a defective motor or pump.

14. This pump is designed to transfer

water in cycles. Using this pump in

a continuous duty application by

ma nip u lat ing the switch to stay on,

will affect the per for mance and the

life of the product.

15. Protect electrical cord from sharp

objects, hot sur fac es, oil, and

chemicals. Avoid kinking the cord.

Re place or repair damaged or worn

cords im me di ate ly. Use wire of

adequate size to minimize voltage

drop at the motor.

16. Do not handle a pump or pump

motor with wet hands or when

standing on a wet or damp surface,

or in water.

17. Do not hang this product by the

carry handle. Sewage pumps

should be set firmly on their legs

and supported by rigid piping. This

eliminates twisting and damage

during pump operation.

18. Do not use an extension cord.

Do not

walk on

wet area until all power has

been turned off. If the shutoff box is in basement, call

the electric company to shut-off service to

the house, or call the local fire department

for instructions. Remove pump and repair

or replace. Failure to follow this warning

can result in fatal electrical shock.

Installation

In any installation

where property

damage and/or personal injury might result

from an inoperative or leaking pump due to

power outages, discharge line blockage or

any other reason, use a backup system(s).

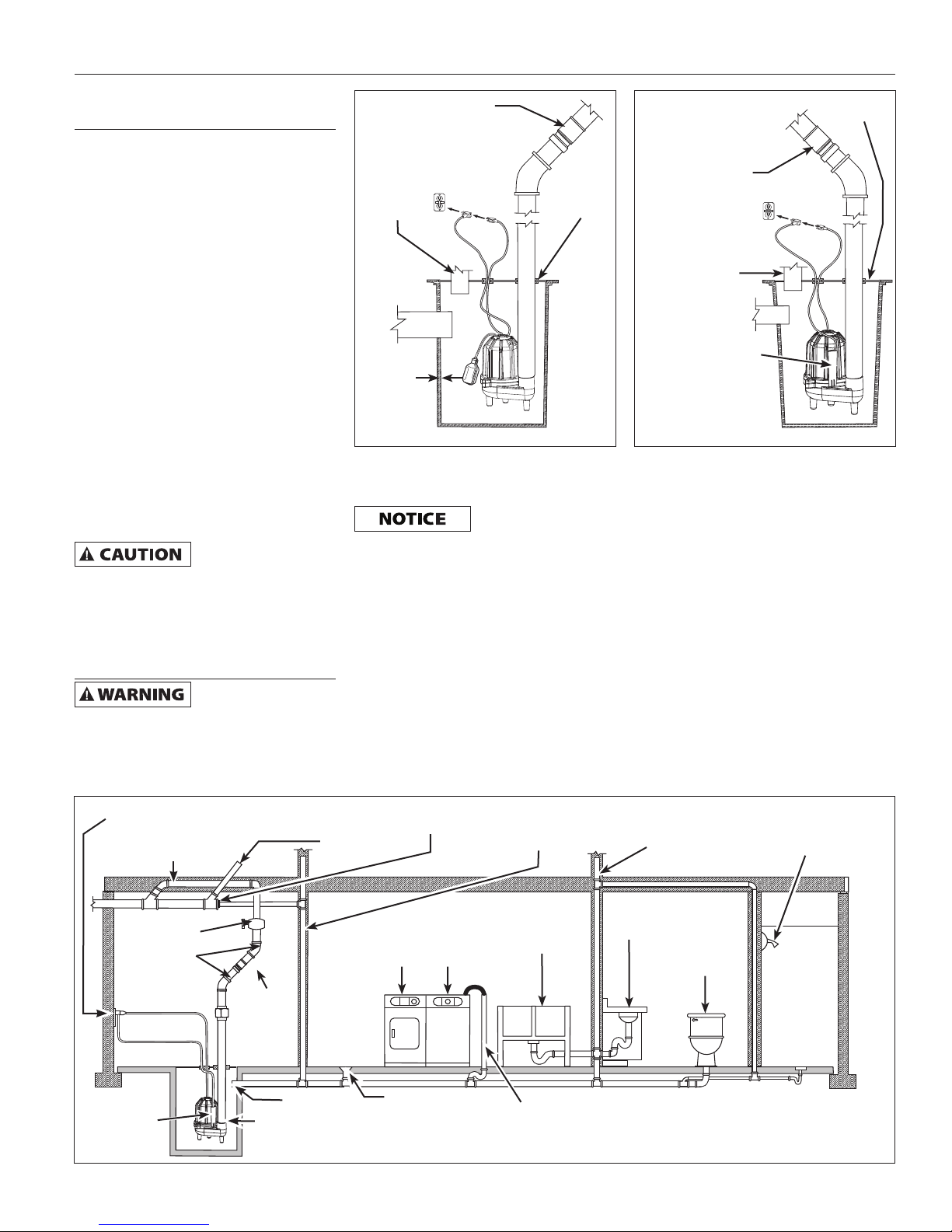

1. Thread the discharge pipe or

pipe nipple into the dis charge

connection.

2. If a check valve is used in a solids

handling system mount the check

valve in a horizontal position or at

a 45º angle with the valve pivot on

top. In a vertical position, solids will

tend to lodge on the valve flapper

and can prevent it from opening.

3. Drill a 1/8 inch hole in the discharge

pipe ap prox i mate ly 1 inch to 2 inch

above the pump discharge when a

check valve is used. The hole prevents

air locking of the pump at the initial

start-up and if it should lose prime.

4. A gate valve should be installed in the

system after the check valve. This gate

valve should be a full port valve which

will pass 2 inch solids or as required

by state and local codes. This gate

valve permits removal of the pump

and/or check valve for servicing.

5. A union should be installed between

the check valve and the pump so the

pump can be removed with least

disturbance of the piping.

www.blueangelpumps.com

2

BCSE50T, BCSE50M

BCAPSE50 and BCAPSE50-2

General Safety

Information

6. BCSE50T models are supplied with

a detachable tether switch with a

piggyback plug (see figure 3A). The

length of the tether (distance of cord

from float to clamp) should not be set

shorter than 3-1/4 inches and should

not be used in a basin smaller than 14

inches in diameter. If using a differential

other than the factory setting, be sure

when the pump shuts off at least 4

inch of fluid is left in the basin so the

impeller remains submerged.

7. BCAPSE50 models are supplied with

an capacitive water sensor. Orient the

pump in the basin so that the water

sensor is 180° away from the inlet.

Make certain the incoming water

stream does not hit the capacitive

surface (See Figure 3B).

8. When a tether switch is used, rigid

dis charge pipe is required. If the

pump is allowed to move, the

tether switch could be re strict ed

by the basin wall, pre vent ing the

pump from operating.

Before removing

for service, always disconnect electrical

power to pump and control switch. For

any work on pump or switch, ALWAYS

unplug the power cord. Do not just turn

off circuit break er or unscrew fuse.

(continued)

pump from basin

Maintenance

Make certain that

unplugged before attempting to service

or remove any component. This pump is

assembled in the factory using special

equipment; therefore only authorized

service dealers or qualified electricians

the pump is

Check valve 45º

Vent

Inlet

1/2 inch

Min.

Clearance

Figure 3A - Prefabricated Basins

should attempt to repair this unit.

Improper repair can cause an electrical

shock hazard.

The pump contains

oil that may be

under pressure because of heat. Let the

pump cool for a minimum of two hours

before servicing this unit.

Gasket

Basin

1. Disassembly of the motor prior to

expiration of war ran ty will void the

warranty. It might also cause internal

leakage and damage to the unit. If

repairs are required, return the pump

to the dealer from whom it was

pur chased or call 1-888-636-6628. If

motor is ever disassembled the o-rings

must be replaced. Care must be taken

to ensure that all seals do not leak.

Gasket

Check

valve 45º

Vent

*Orient the pump so that

the switch is 180° away

from the inlet. Make sure

the incoming water stream

does not hit the switch

surface.

Figure 3B - Prefabricated Basins

Inlet

Basin

2. After the basin cover is removed

and necessary dis charge piping

disconnected, lift pump from basin.

3. Pump should be checked on a

regular basis for proper op er ation. If anything has changed since

unit was new, the unit should be

removed and repaired or replaced.

Only qualified electricians or service

peo ple should at tempt to repair

this unit. Improper repair and/or

assembly can cause an electrical

shock hazard.

4. Place the pump in a suitable area

where it can be cleaned thoroughly.

Remove all scale and deposits on pump.

5. Submerge the complete pump in a

disinfectant so lu tion (10% chlorine

bleach solution) for at least one

hour before handling the pump.

Three prong grounded outlet equipped

with a ground fault interruptor

2 inch Discharge pipe

2 inch

Gate Valve

45º Elbow

2 inch

Check

Valve

Float

switch

Flange

Sewage pump passes

2 inch dia. solids

Upper level

drainage

Cleanout

WasherDryer

Floor drain

Vent pipe

Laundry tubs

Washer drain

3

Vent pipe

Lavatory

Shower

Toilet

Figure 2 - Typical Installation

www.blueangelpumps.com

Operating Instructions and Parts Manual

Maintenance (continued)

6. Clean all dirt and deposits from the

pump float. Make sure float moves

freely after cleaning.

7. Clean all dirt and deposits away

from pump inlet and volute.

This pump contains

dielectric motor

oil for lubrication and motor heat

transfer. This oil can be harmful to the

environment. Check state environmental

laws before disposing of this oil. This

oil can be harmful to aquatic life so

consideration should be exercised in the

application of this pump.

Troubleshooting Chart

Symptôm Possible Cause(s) Corrective Action

Pump will not start

or run

Pump starts and

stops too often

1. Water level too low

2. Blown fuse or tripped circuit breaker

3. Low line voltage

4. Defective motor

5. Defective switch

6. Impeller (pump filled with debris)

7. Tangled tether switch

(BCSE50T & BCSE50M)

8. Insufficient liquid level

1. Back flow of water from piping

2. Dirty capacitive water sensor

3. Faulty float switch

4. Check valve not installed or leaking

5. Discharge head is less than

manufacturer's minimum

1. Pump switch will not turn on unless water covers top of pump

2. If blown, replace with proper sized fuse or reset breaker

3. If voltage is under recommended min i mum, check wiring size from the

main switch on property. If OK, contact power company.

4. Return for service or replace motor

5. Replace float switch

6. If impeller will not turn, remove housing and remove debris

7. Arrange switch so the switch moves free ly. Re po si tion pump if

necessary

8. Make sure liquid level is at least 13 inches from the basin floor

1. Install check valve

2. Reposition pump, clean sensor face

3. Replace float switch

4. Remove and examine check valve for prop er in stal la tion and free

operation

5. Recheck all sizing calculations to determine proper pump size

Pump shuts off

and turns on

independently

of switch (trips

thermal overload

protection)

Pump operates

noisily or vibrates

excessively

Pump will not shut

off

Pump operates but

delivers little or no

water

1. Excessive water temperature

2. Defective switch or entangled switch is

causing pump to run dry

(BCSE50T & BCSE50M)

3. Low line voltage

1. Worn bearings

2. Debris in impeller cavity or broken

3. Piping attachments to building

structure too rigid or too loose

1. Float switch movement restricted

2. Restricted discharge (obstruction in

piping)

3. Excessive inflow or pump not properly

sized for application

4. Defective switch

1. Low line voltage

2. Debris caught in impeller or discharge

3. Worn or defective pump parts or

plugged impeller

4. Pump running backwards

5. Pump not properly sized for application

6. Check valve stuck closed or installed

backwards

7. Shut off valve closed

1. Pump should not be used for water above 120º F

2. Replace or reposition pump

Pump may start unexpectedly. Disconnect

power supply before ser vic ing.

3. If voltage is under recommended min i mum, check wiring size from the

main switch on property. If OK, contact power company

1. Return for service or replace

2. Remove housing, clean impeller and/or replace broken impeller

3. Replace portion of discharge pipe with flexible connector

1. Reposition pump or clean basin as required to provide adequate

clearance for float

2. Remove pump and clean pump & piping

3. Recheck all sizing calculation to determine proper pump size

4. Replace float switch

1. If voltage is under rec om mend ed minimum, check wiring size from the

main switch on prop er ty. If OK, contact power company

2. Remove, clean and check for tight ness

3. Replace worn parts or entire pump. Clean parts if required

4. Check rotation. (CCW from bottom) Return if CW

5. Recheck all sizing calculations to determine proper pump size

6. Remove and examine check valve for proper installation and free

operation

7. Open valve

www.blueangelpumps.com

4

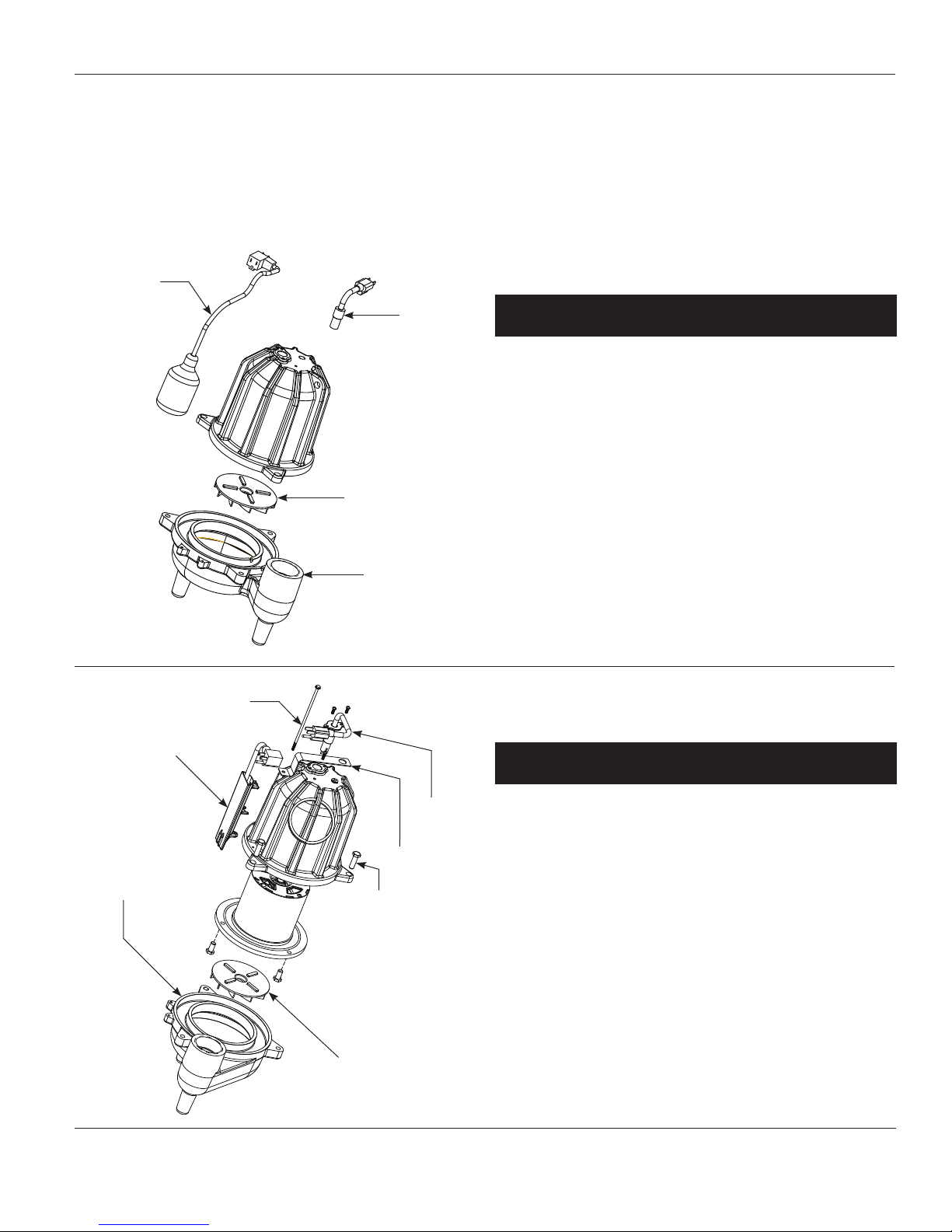

BCAPSE50 and BCAPSE50-2

For replacement parts or technical assistance,

call 1-888-636-6628

BCSE50T, BCSE50M

Please provide following information:

- Model number

- Serial number (if any)

- Part description and number as shown in parts list

1

2

3

4

Address parts correspondence to:

Blue Angel Pumps

101 Production Drive

Harrison, OH 45030 U.S.A.

Ref. Part

No. Description Number Qty

1 Mechanical switch Kit

(CSE40T) 30000-009 1

Mechanical switch Kit

(CSE40T-2) 30000-003 1

2 Power cord (CSE40T) 31035-001 1

Power cord

(CSE40M, CSE40T-2) 31036-001 1

3 Impeller 17317-001 1

4 Volute 41027-001 1

7

1

2

5

4

6

3

Ref. Part

No. Description Number Qty

1 Capacitive Water Sensor 30037-002 1

(CBCAPSE50)

Capacitive Water Sensor 30037-004 1

(BCAPSE50-2)

2 Power Cord (BCAPSE50) 31035-001 1

Power Cord (BCAPSE50-2) 31036-001 1

3 Impeller 17317-001 1

4 Volute 41027-001 1

5 Bracket 7434 1

6 Through Bolt 16836-004 1

7 Screw 67050-001 3

www.blueangelpumps.com

5

Operating Instructions and Parts Manual

Limited Warranty

For two years for BCSE50M and BCSE50T and five years for BCAPSE50, BCAPSE50-2 from the date of

purchase, Blue Angel will repair or re place, at its option, for the original purchaser any part or parts of

its Sump Pumps or Water Pumps (“Product”) found upon examination by Blue Angel to be defective in

materials or work man ship. Warranty is limited to a one time replacement. Please call Blue Angel (888-636-

6628) for instructions or see your dealer. Be pre pared to provide the model number, serial number and

dated receipt when exercising this warranty. All transportation charges on Products or parts submitted for

repair or replacement must be paid by purchaser.

This Limited Warranty does not cover Products which have been damaged as a result of accident, abuse,

misuse, neglect, improper installation, improper maintenance, or failure to operate in accordance with Blue

Angel’s written instructions.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, IN CLUD ING THOSE OF MER CHANTABIL I TY AND FITNESS FOR A PARTICULAR PUR POSE, ARE LIMITED TO TWO YEARS FOR BCSE50M AND

BCSE50T, AND FIVE YEARS FOR BCAPSE50 FROM THE DATE OF PURCHASE. THIS IS THE EXCLUSIVE

REM E DY AND ANY LIABILITY FOR ANY AND ALL INDIRECT OR CONSEQUENTIAL DAM AG ES OR

EXPENSES WHATSOEVER IS EXCLUDED.

Some states do not allow limitations on how long an implied warranty lasts, or do not allow the exclusions

or limitations of incidental or consequential damages, so the above lim i ta tions might not apply to you. This

limited warran ty gives you specific legal rights, and you may also have other legal rights which vary from

state to state.

In no event, whether as a result of breach of contract warranty, tort (in clud ing negligence) or otherwise,

shall Blue Angel or its suppliers be liable for any special, consequential, incidental or penal damages

including, but not limited to loss of profit or revenues, loss of use of the products or any associated

equipment, damage to associated equip ment, cost of capital, cost of substitute products, facilities, services

or replacement power, downtime costs, or claims of buyer’s cus tom ers for such damages.

You MUST retain your purchase receipt along with this form. In the event you need to exercise a warranty

claim, you MUST send a copy of the purchase receipt along with the material or correspondence. Please call

Blue Angel (888-636-6628) for return authorization and instructions.

DO NOT MAIL THIS FORM TO Blue Angel. Use this form only to maintain your records.

MODEL NO.__________________ SERIAL NO.____________________ INSTALLATION DATE_____________________

ATTACH YOUR RECEIPT HERE

www.blueangelpumps.com

6

Loading...

Loading...