Page 1

Commercial

Upright Refrigerator & Freezer

Service Manual

Page 2

TABLE OF CONTENS

1. ASSEMBLY …………………………………………………… 4~11

2. PARTS …………………………………………………………… 12~26

3. WIRING DIAGRAM …………………………………………… 27~28

4. PART DETAILS …………………………………………………. 29~33

5. MAIN COMPONENTS …………………………………………. 34~47

6. ELECTRONIC CONTROL INSTRUCTIONS ……………… 48~55

7. REPLACEMENT OF MAIN COMPONENTS ………………. 56~72

8. PART LIST ……………………………………………………… 73~76

.

Page 3

Safety cautions during service

ㆍ When exchanging or repairing electric parts, pull the plug out before

exchanging and repairing.

ㆍ When exchanging electric parts, use a rating part.

- Be sure to check marks such as MODEL name, rating voltage,

rating currents, movement temperature etc.

ㆍ During repairing, make sure wirings such as HARNESS, WIRE JOINT are

sturdy

so that it is free of danger due to disclosure of core wire.

- Don’t let it derail when certain strength is put on.

ㆍ When repairing, take out the dust or foreign body (Housing part, wiring part,

contact point part).

- It prevents danger of fire such as TRACKING, SHORT.

ㆍ Check whether water has gone into the electric parts.

- When there are traces of water, exchange the parts or enact the TRACKING

prevention device.

ㆍ After repairing, check the assembly status of the parts.

- Keep the status as it was before the repairing. .

ㆍ After checking the usage environment of the product and if the installation is

unstable, change the usage location.

- For installations in places with moisture, water and for heat devices, prevent

placing products near igniting materials etc.

ㆍ When earthing is needed, earth it.

- For cases when electric leakage is concerned due to moisture or water,

be sure to earth it.

ㆍ For products that consumes power such as electric products, make sure

numerous plugs are not used in a single outlet.

Page 4

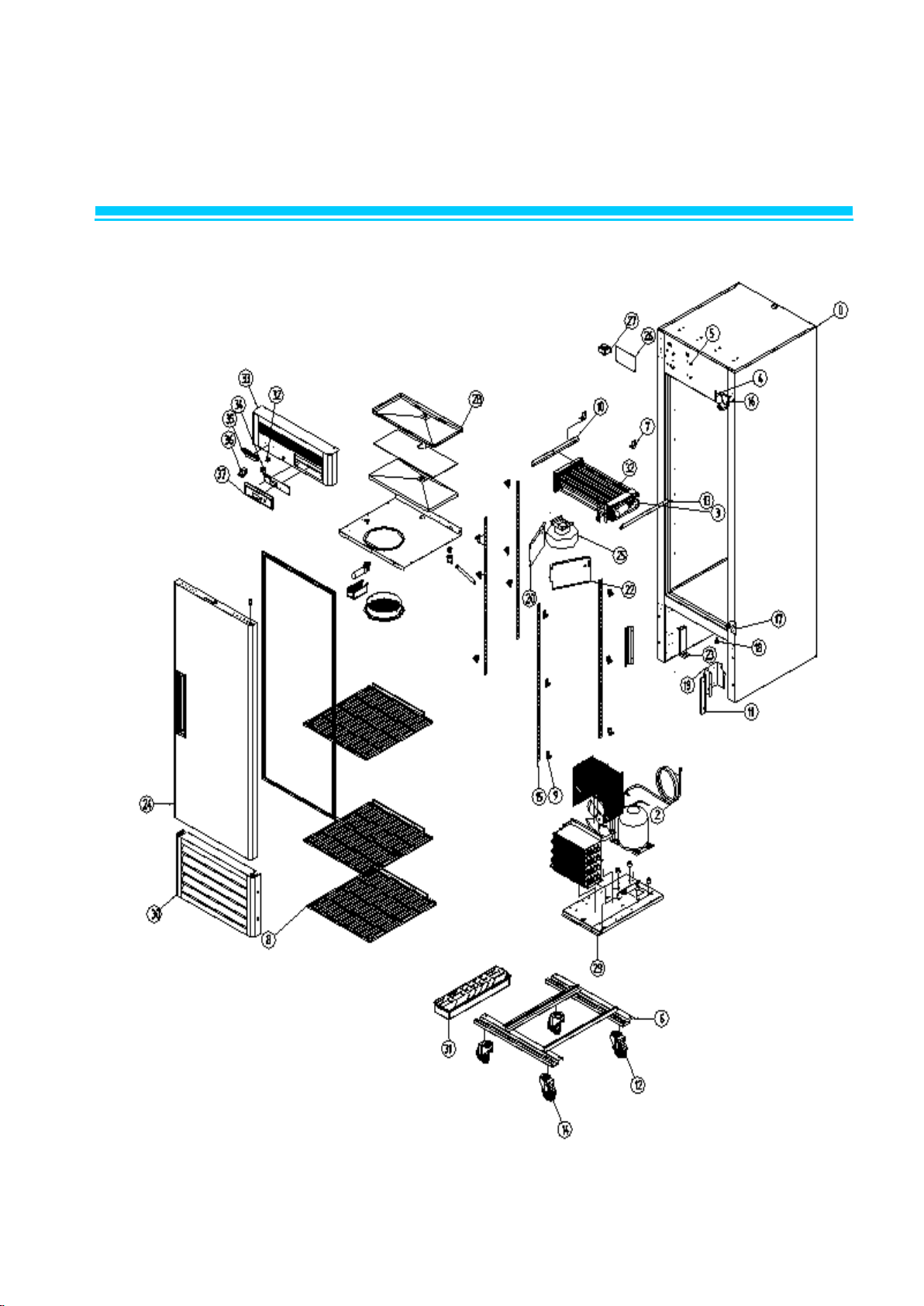

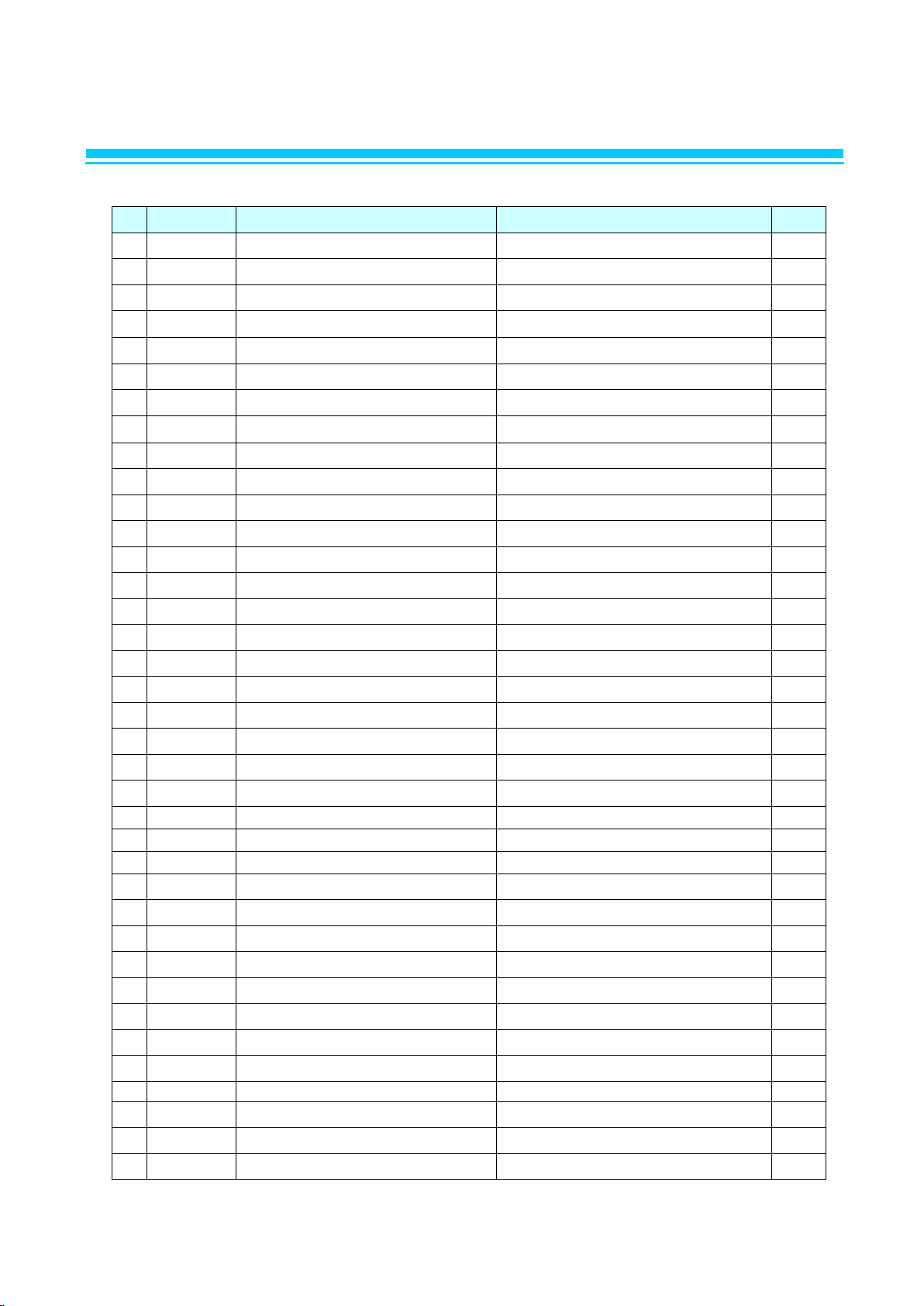

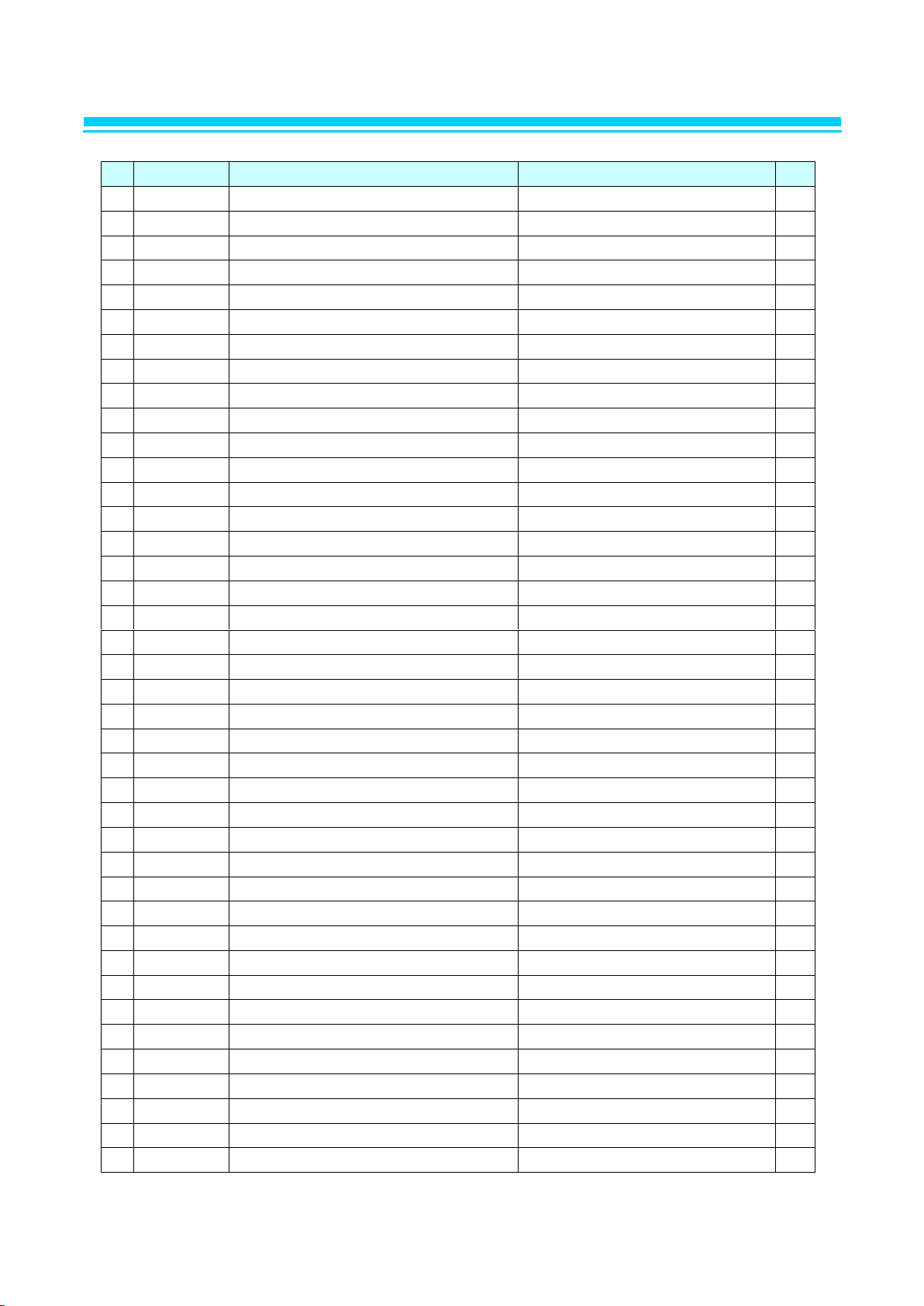

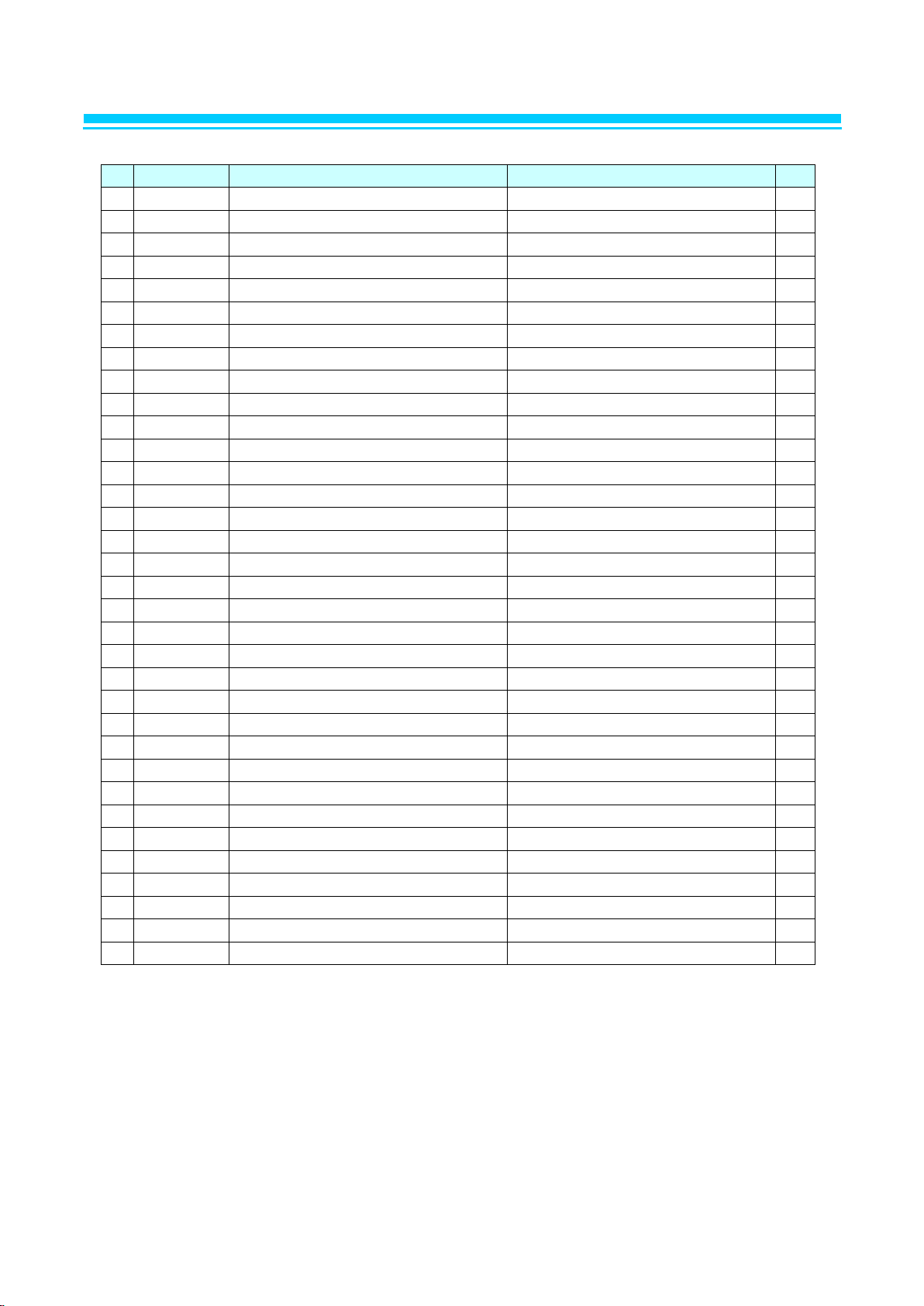

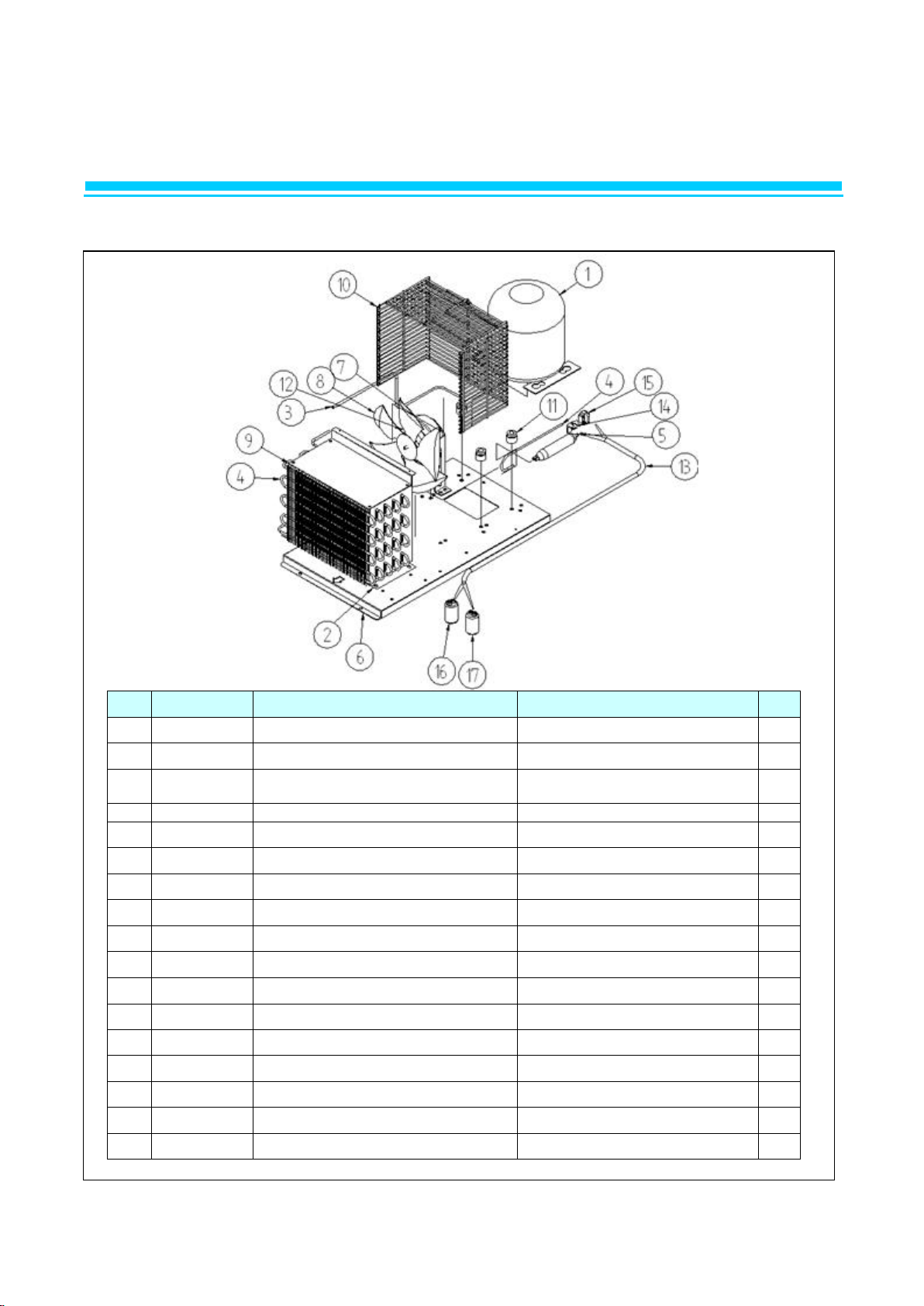

1. ASSEMBLY (BSR23)

Page 5

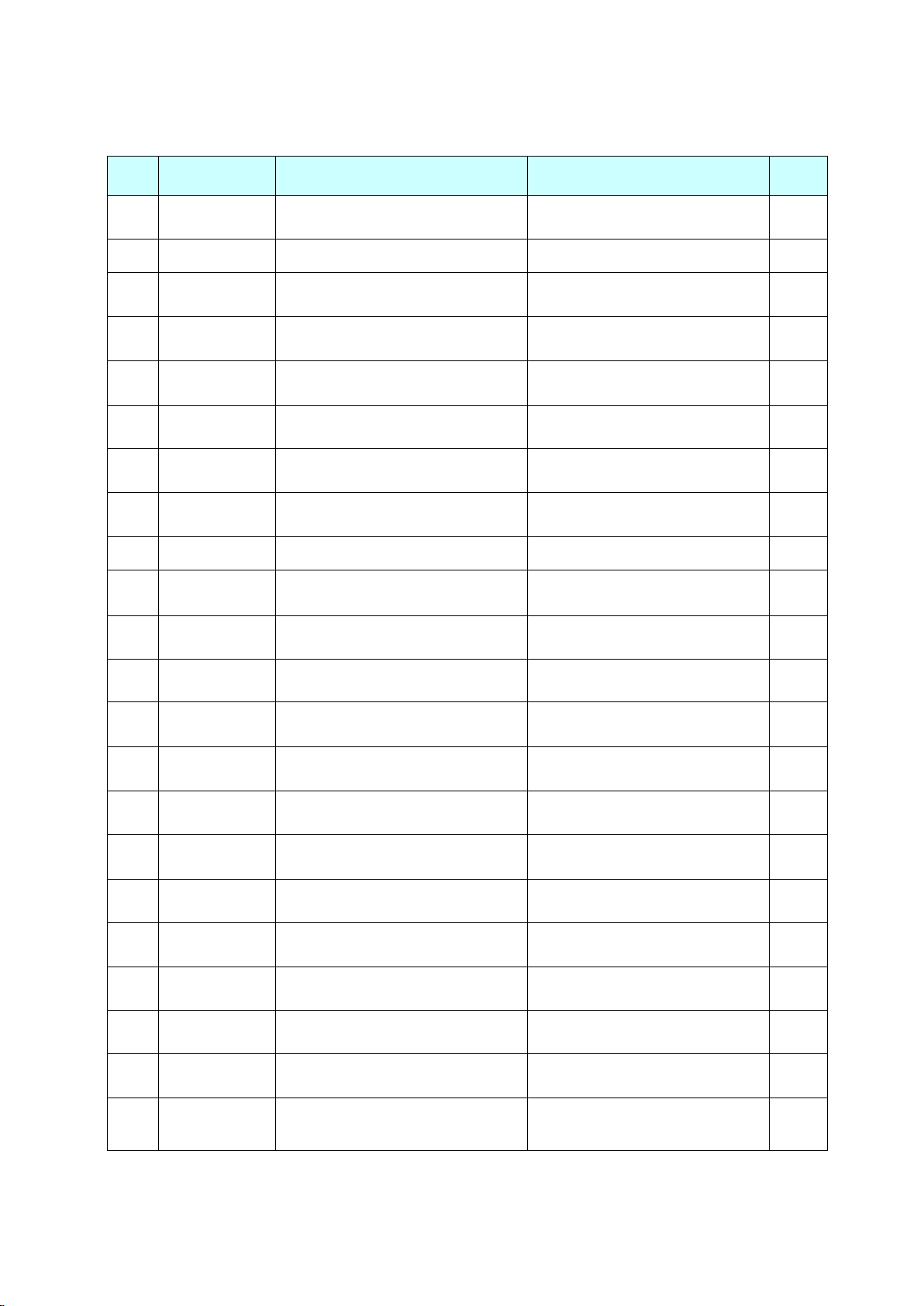

NO

CODE-No

Title

Subject

Q'TY

1

R827A-020

ASSY CABI URT

R23 1 2

R2103-445

COMPRESSOR PULL OUT

CU-PIPE. OD9.52*T0.6*1716

1

3

R8613-354

EVAPORATOR ASSY

AL

1

4

R858A-410

SHAFT TOP HINGE AS

SUM24L. ¢15*114

1

5

C3379-240

SUPPORT

SDSAA-9N

4

6

R3212-231

FRAME ASSY 23

WELDING 600LT

1

7

R3314-282

TOP FRAME B/K

GI. T1.0*30*59.6

2

8

R3233-200

SHELF 23

MSWR10. NSF

3

9

R3313-152

SHELF CLIP

POM. WHT

12

10

R3313-271

EVAPORATOR B/K LF

STS304-2B. T1.0*408*37.5

1

11

R315A-060

BRACKET GRILLE

GI. T1.0*110*102.5

2

12

R3323-230

CASTER 4"

4" MOVE

2

13

R3313-271

EVAP COVER B/K LF

STS304-2B. T1.0*408*37.5

1

14

R3323-240

CASTER 4"

4" STOP

2

15

R3373-630

SHELF STANDARD L

AL. T1.2*930

4

16

R828A-062

ASSY HINGE TOP RH

STS304 T=4.0

1

17

R828A-020

ASSY HINGE BOTTOM RH

STS304 T=4.0

1

18

R375A-030

STOPPER DOOR RH

POM (FW700S)

1

19

R3813-351

COVER CAPACITOR

GI. T0.8*255.2*135

1

20

R3853-110

EVAPORATOR AIR GUIDE LF

AL WHITE T0.5*162*247

1

22

R3853-090

EVAPORATOR AIR GUIDE RIGHT

AL WHITE T0.5*162*247

1

23

R3854-210

EVAPORATOR DRAIN HOSE GUIDE

GI. T1.0*225*60

1

24

R817A-340

DOOR ASSY 23

R23

1

25

R8329-060

EVAPORATOR FAN MOTOR ASSY

115V 60HZ

1

26

R7109-780

MAIN PCB (115. ℉)

115V. REF 2010 Energy Star

1

27

R7504-060

POWER TRANS

120V 60HZ. DT-1213

1

28

R8139-110

EVAPORATOR HOUSING ASSY

R23

1

29

R815A-010

ASSY UNIT

R23 1 30

R818A-310

ASSY GRILLE BOTTOM_23

23R/F

1

31

R8199-080

EVAPORATOR DRAIN WATER S ASSY

R/F23

1

32

R7204-070

POWER SWITCH

SL112A. 125V 15A

1

33

R818A-340

ASSY GRILL TOP_23

23F/R BLUE

1

34

R3734-030

DOOR LOCKING ASSY

ZDC. ZCR

1

35

R514A-031

MASCOT

T3.8*90*64

1

36

R7203-020

DOOR SWITCH

WHT. SP201R-9D

1

37

R832A-030

ASSY CONTROL BOARD 23

R/F 23

1

38

R7213-112

TEMP-DISPLAY SENSOR. REF

R23

1

1-1. PART LIST : BSR23

Page 6

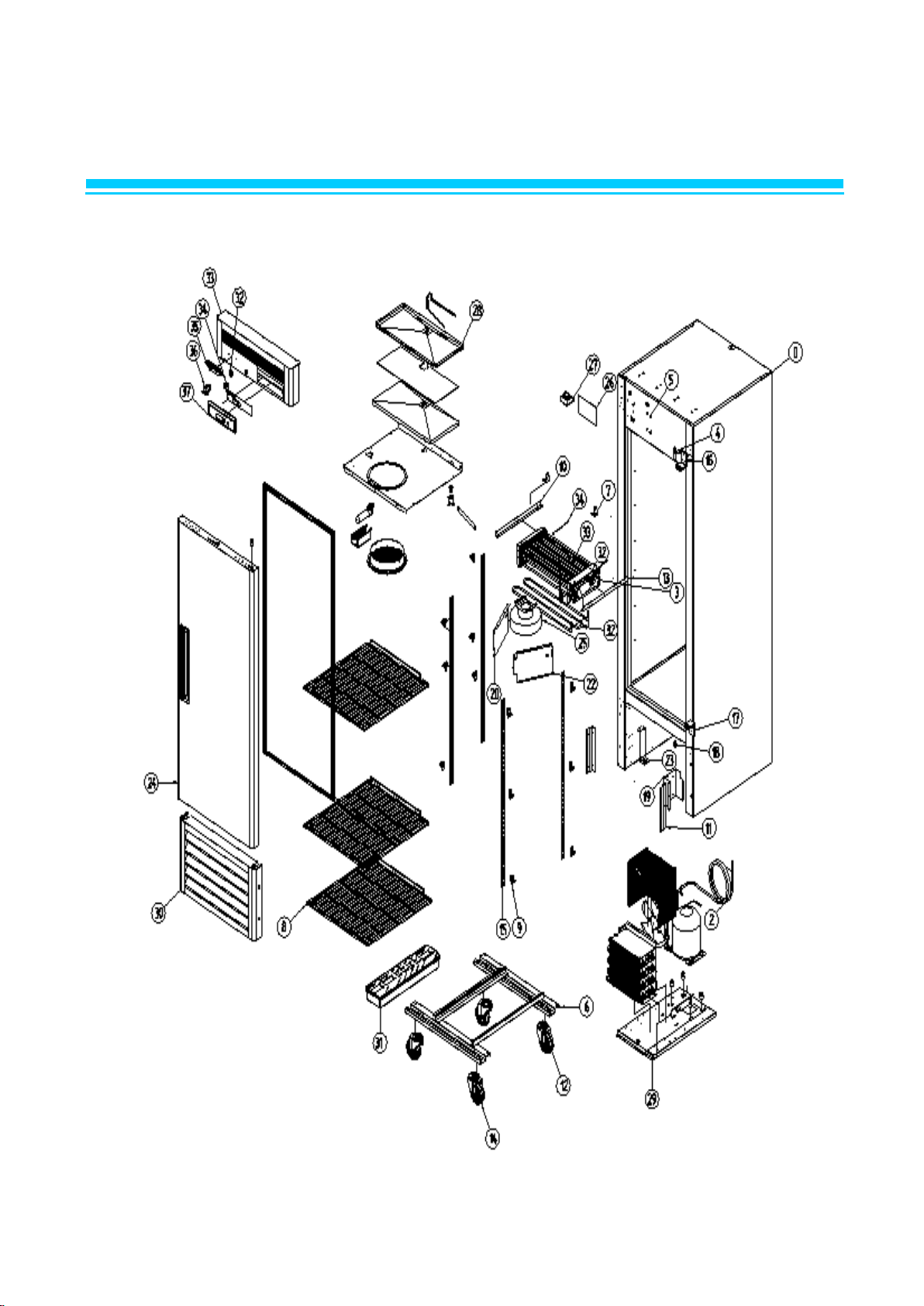

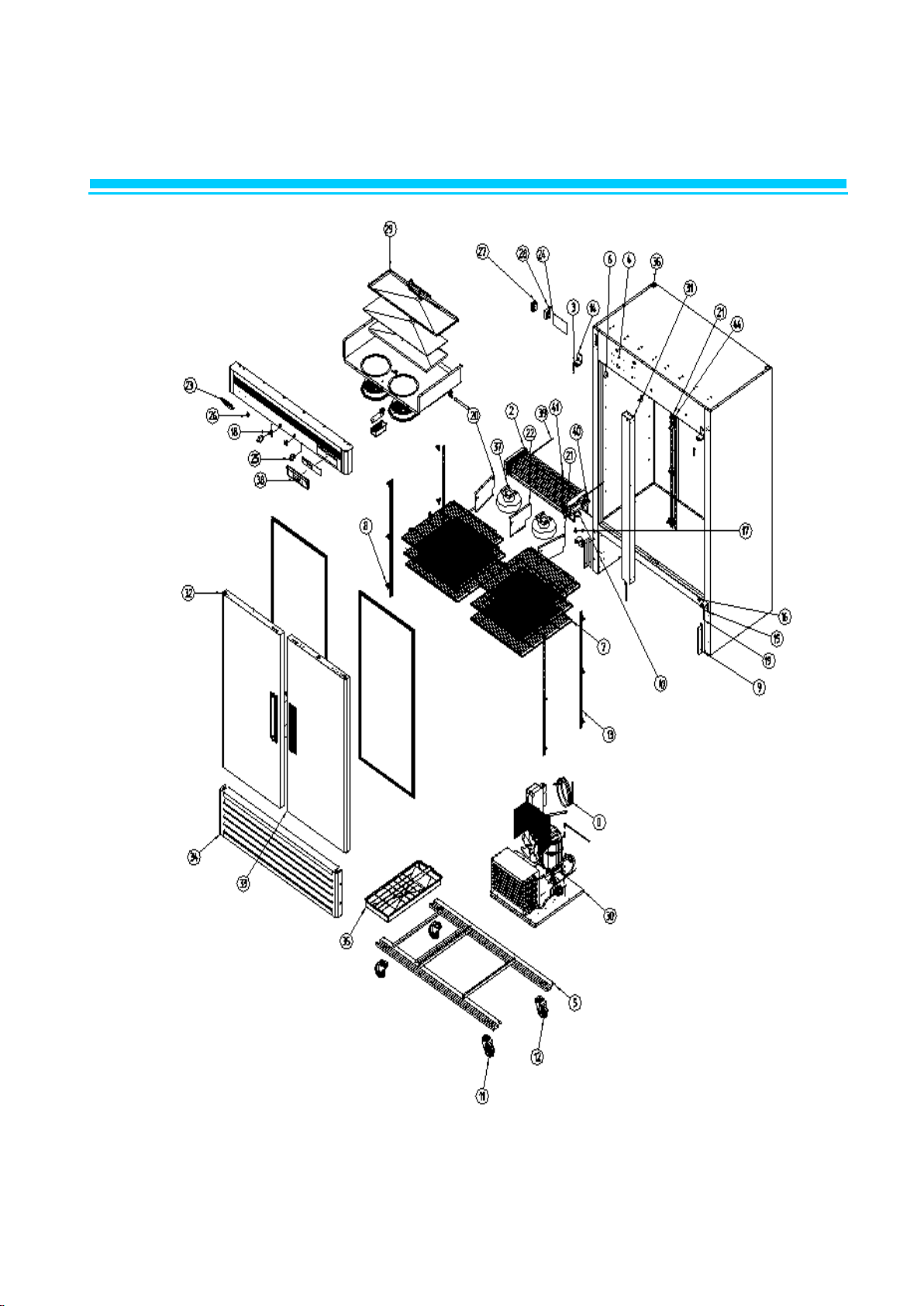

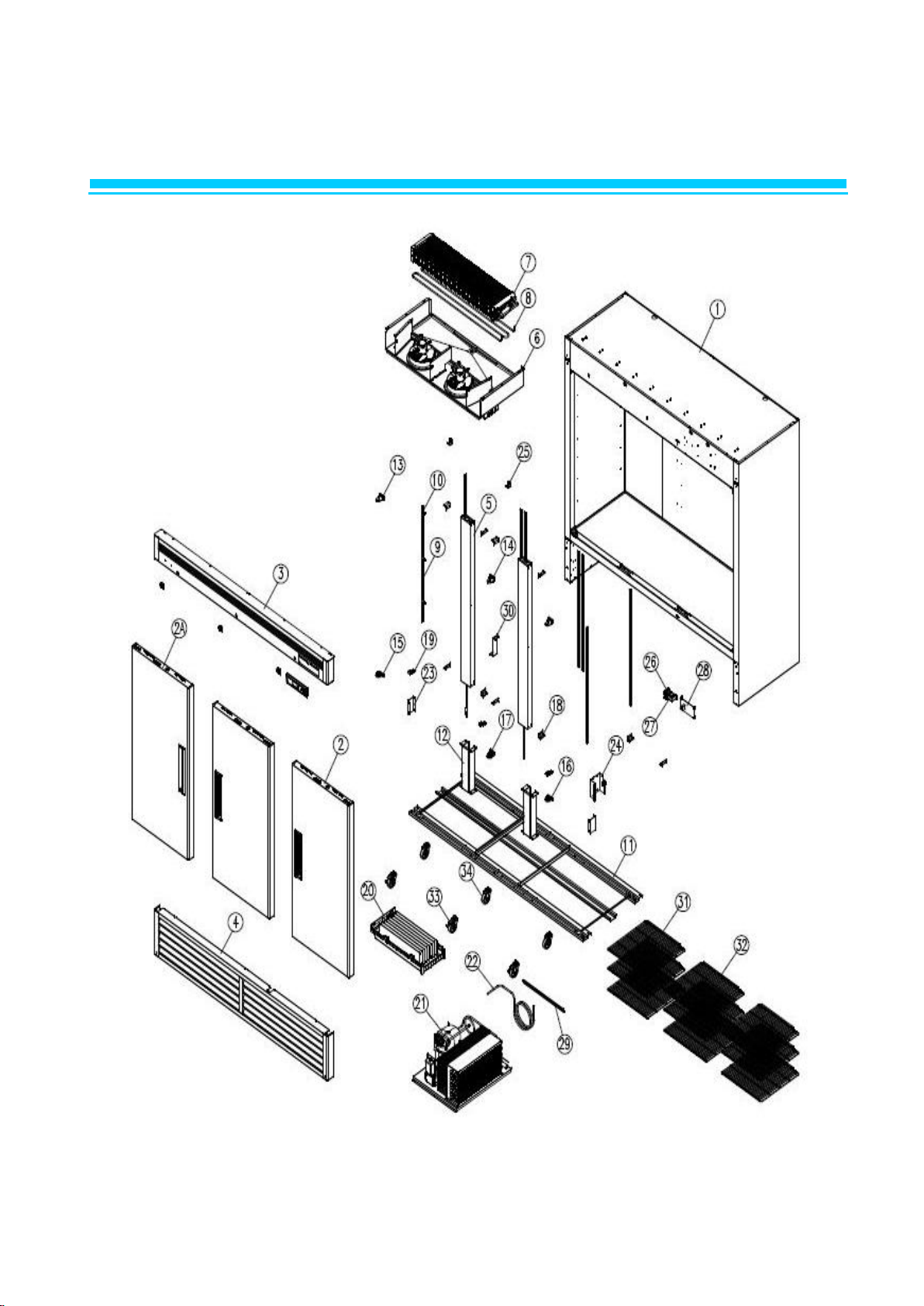

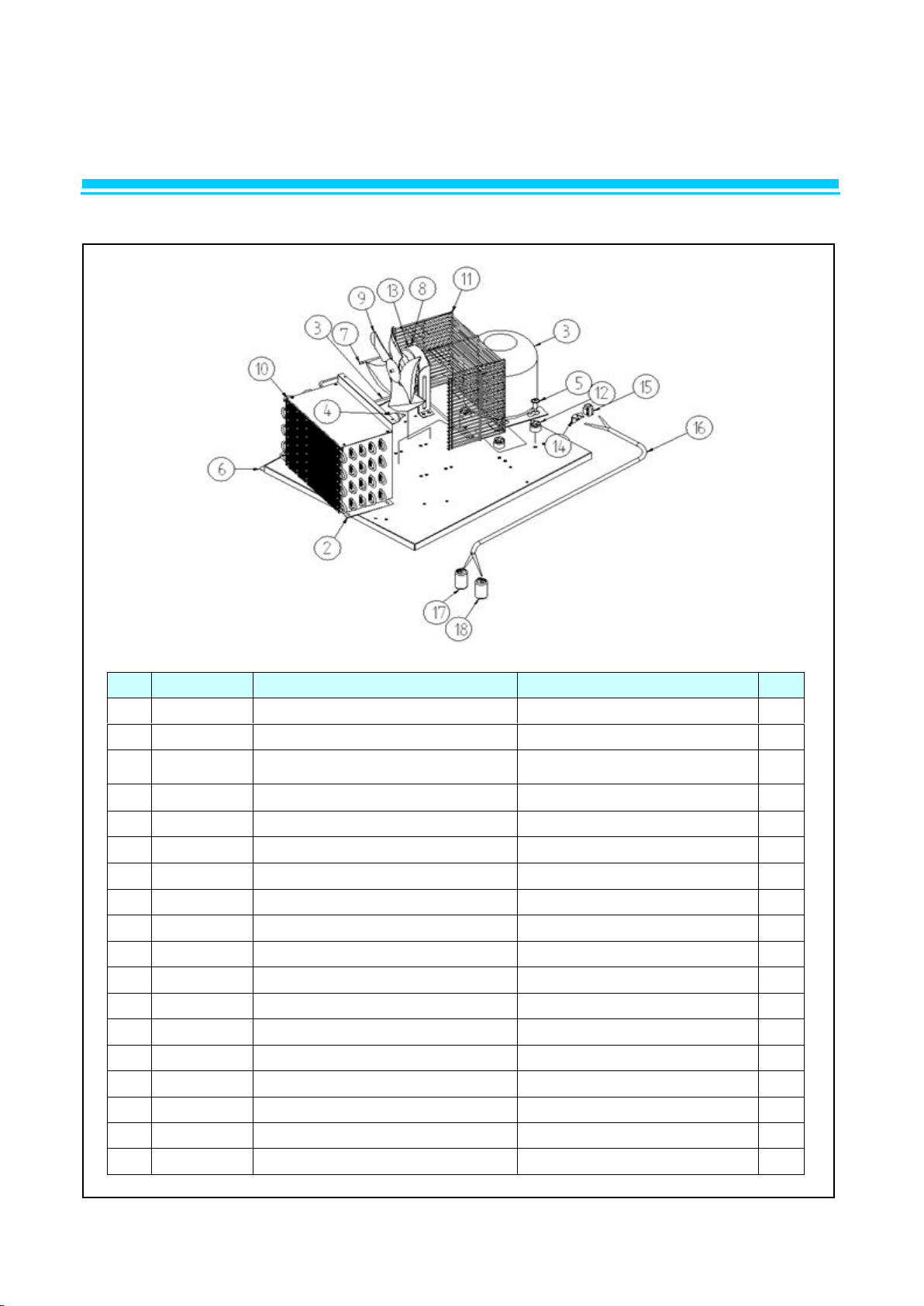

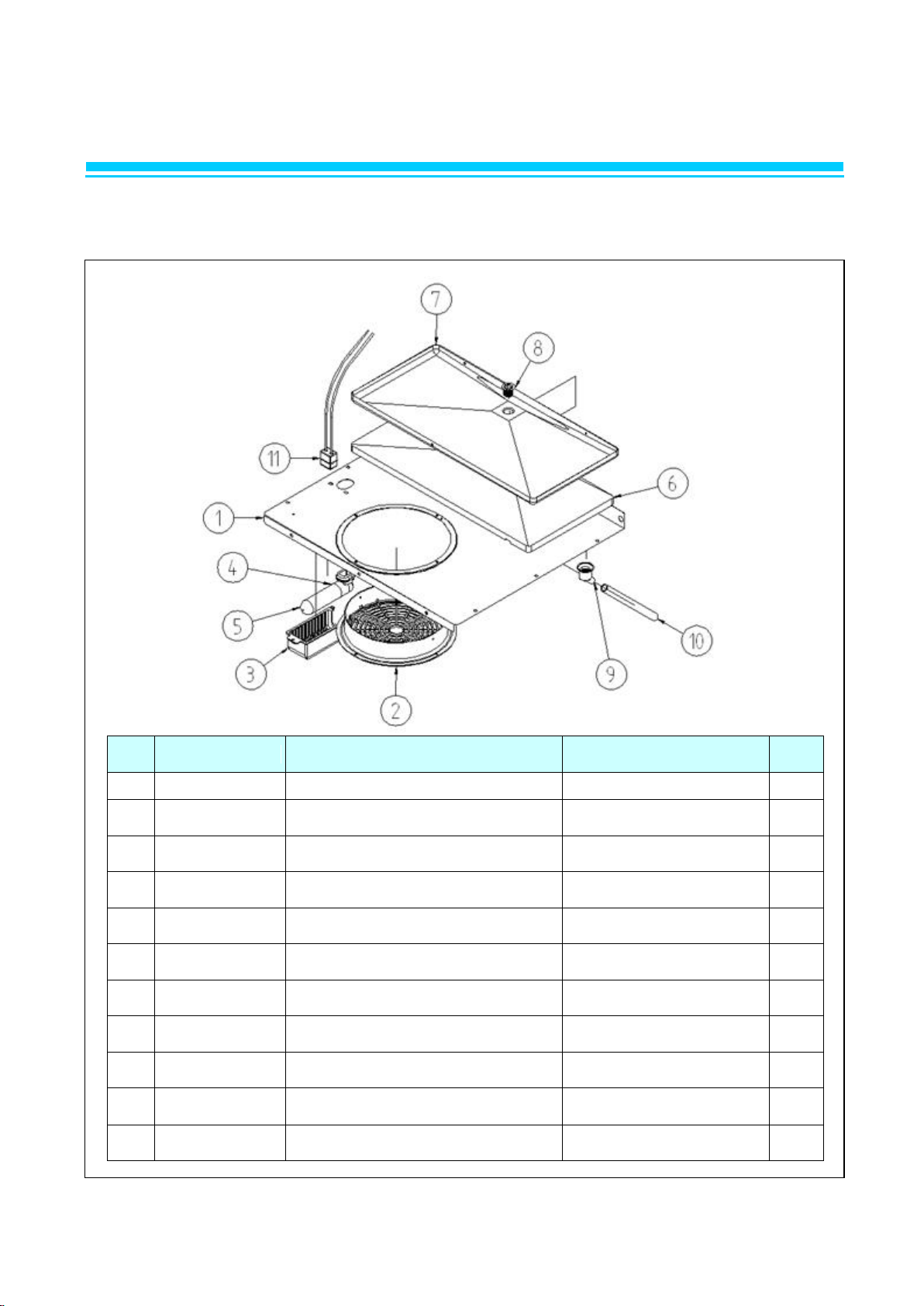

1. ASSEMBLY (BSF23)

Page 7

NO

CODE-No

Title

Subject

Q'TY

1

R827A-030

ASSY CABI FOAM

F23 1 2

R2103-445

COMPRESSOR PULL OUT

CU-PIPE. OD9.52*T0.6*1716

1 3 R2263-038

EVAPORATOR

CU+AL. 23F

1

4

R858A-410

SHAFT TOP HINGE AS

SUM24L Ø15*114

1

5

C3379-240

SUPPORT

SDSAA-9N

4 6 R3212-231

FRAME ASSY 23

WELDING 600LT

1 7 R3314-282

TOP FRAME B/K

GI. T1.0*30*59.6

2

8

R3233-200

SHELF 23

MSWR10. NSF

3

9

R3313-151

SHELF CLIP

POM. WHT

12

10

R3313-271

EVAPORATOR B/K LF

STS304-2B. T1.0*408*37.5

1

11

R315A-060

BRACKET GRILLE

GI. T1.0*110*102.5

2

12

R3323-230

CASTER 4"

4" MOVE

2

13

R3313-271

EVAP COVER B/K LF

STS304-2B. T1.0*408*37.5

1

14

R3323-240

CASTER 4"

4" STOP

2

15

R3373-630

SHELF STANDARD L

AL. T1.2*930

4

16

R828A-062

ASSY HINGE TOP RH

STS304 T=4.0

1

17

R828A-020

ASSY HINGE BOTTOM RH

STS304 T=4.0

1

18

R375A-030

STOPPER DOOR RH

POM (FW700S)

1

19

R3813-350

COVER CAPACITOR

GI. T0.8*255.2*135

1

20

R3853-110

EVAPORATOR AIR GUIDE LF

AL WHITE T0.5*162*247

1

22

R3853-090

EVAPORATOR AIR GUIDE RIGHT

AL WHITE T0.5*162*247

1

23

R3854-210

EVAPORATOR DRAIN HOSE GUIDE

GI. T1.0*225*60

1

24

R817A-340

DOOR ASSY 23

R23 1 25

R8329-060

EVAPORATOR FAN MOTOR ASSY

115V 60HZ

1

26

R7109-790

MAIN PCB (115. ℉)

115V. FRE 2010 Energy Star

1

27

R7504-060

POWER TRANS

120V 60HZ. DT-1213

1

28

R8139-090

EVAPORATOR HOUSING ASSY

F23 1 29

R815A-020

ASSY UNIT

F23 1 30

R818A-310

ASSY GRILLE BOTTOM_23

23R/F

1

31

R8199-080

EVAPORATOR DRAIN WATER S ASSY

R/F23

1

32

R7204-070

POWER SWITCH

SL112A. 125V 15A

1

33

R818A-340

ASSY GRILL TOP_23

23F/R BLUE

1

34

R3734-030

DOOR LOCKING ASSY

ZDC. ZCR

1

35

R514A-031

MASCOT

T3.8*90*64

1

36

R7203-020

DOOR SWITCH

WHT. SP201R-9D

1

37

R832A-030

ASSY CONTROL BOARD 23

R/F 23

1

38

R7303-402

DEFROST HEATER

F23 1 39

R7213-082

TEMP-THERMISTOR,FRE

F23 1 40

R7213-210

D-SENSOR

F23 1 41

R7253-052

EVAPORATOR THERMAL FUSE

F23

1

1-2. PART LIST : BSF23

Page 8

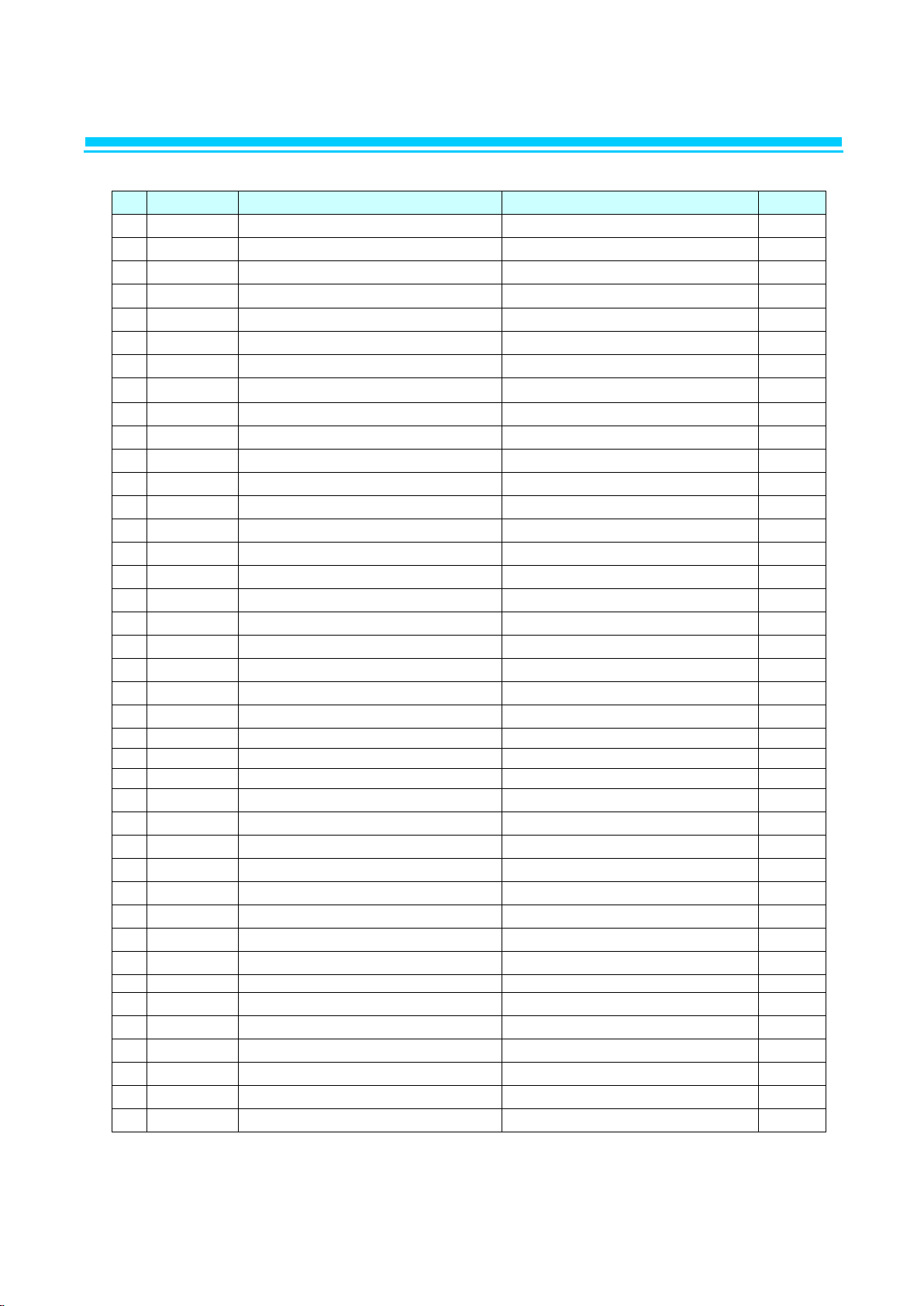

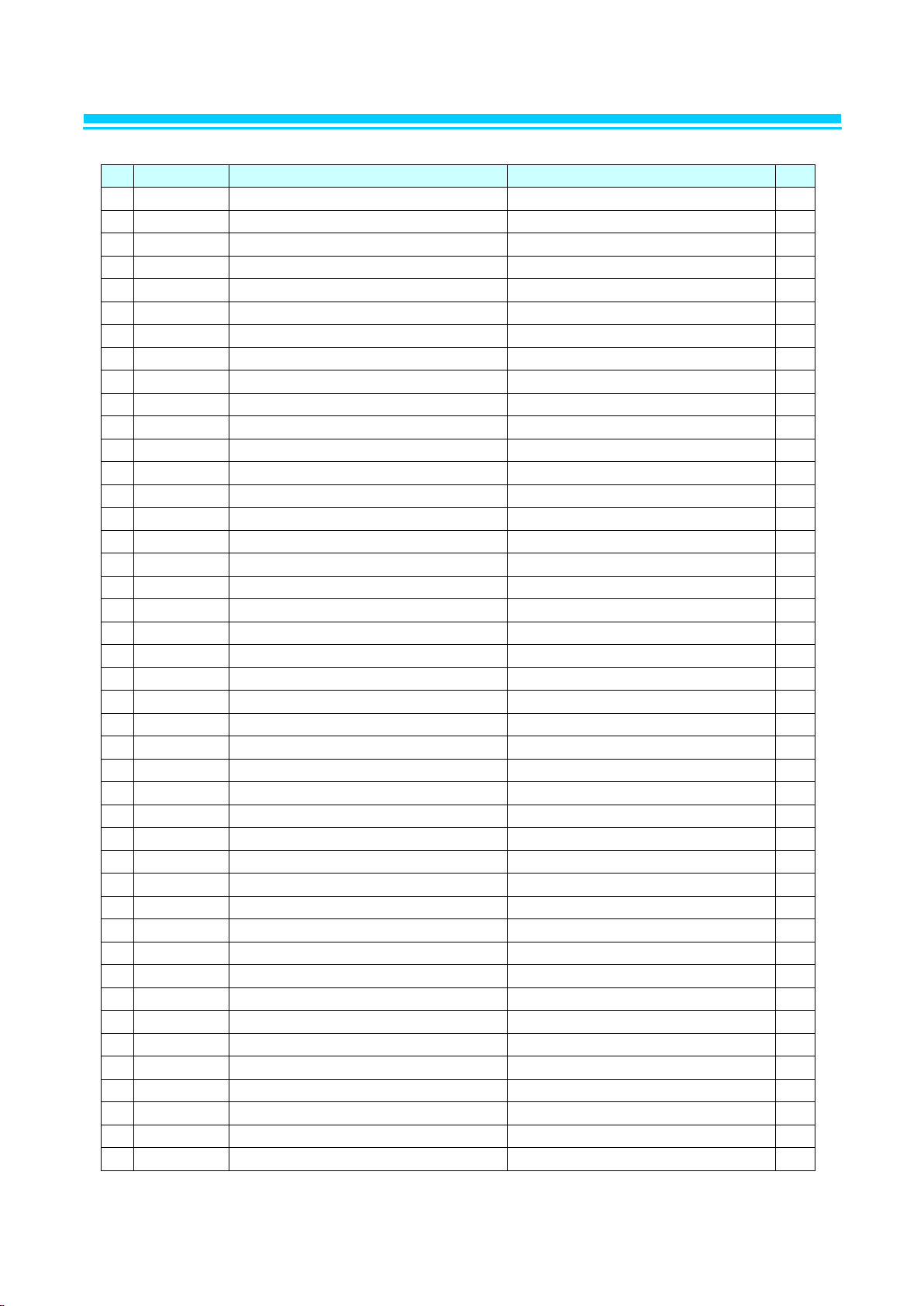

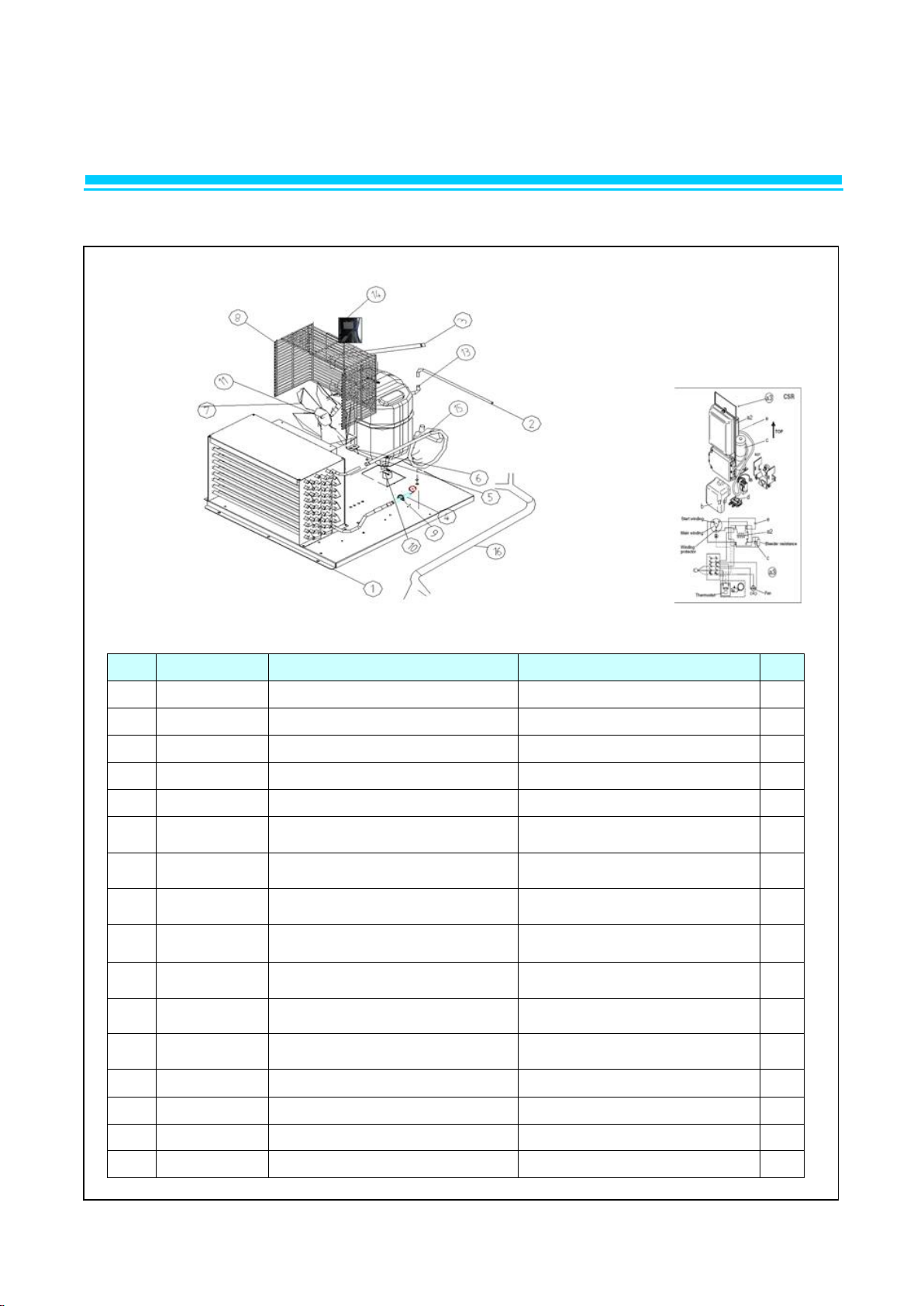

1. ASSEMBLY (BSR49)

Page 9

1-3. PART LIST : BSR49

NO

CODE-No

Title

Subject

Q'TY

1

R2103-942

COMPRESSOR PULL OUT

CU-PIPE. T0.7*OD9.52*1566

1 2 R8613-343

EVAPORATOR ASSY

R49 1 3

R858A-410

SHAFT TOP HINGE AS

SUM24L Ø15*114

2

4

C3379-240

SUPPORT

DSAA-9N

4 5 R3212-250

FRAME ASSY (49)

717.5*1408

1 6 R3314-282

TOP FRAME B/K

GI. T1.0*30*59.6

3 7 R3233-210

ASSY SHELF -49

MSWR10+PE

6 8 R3313-152

SHELF CLIP

POM. WHT

26

9

R315A-060

BRACKET GRILLE

GI. T1.0*110*102.5

2

10

R7213-112

RT-SENSOR

TH310H34GANR WHITE. L=200

1

11

R3323-230

CASTER 4"

4" MOVE

2

12

R3323-240

CASTER 4"

4" STOP

2

13

R3373-630

SHELF STANDARD L

AL. T1.2*930

6

14

R828A-062

ASSY HINGE TOP RH

STS304 T=4.0

1

15

R828A-020

ASSY HINGE BOTTOM RH

STS304 T=4.0

1

16

R375A-030

STOPPER DOOR RH

POM (FW700S)

1

17

R375A-040

STOPPER DOOR LF

POM (FW700S)

1

18

R3734-030

DOOR LOCKING ASSY

ZDC. ZCR

2

19

R3813-351

COVER CAPACITOR

GI. T0.8*255.2*135

1

20

R3853-210

EVAPORATOR AIR GUIDE LF

AL WHITE T0.5*161.8*269

1

21

R3853-120

EVAPORATOR AIR GUIDE RH

AL WHITE T0.5*161.8*269

1

22

R832A-040

ASSY CASE CONTROL BOARD 49

BLUE

1

23

R514A-031

MASCOT

T3.8*90*64

1

24

R7109-780

MAIN PCB (115V. ℉)

115V. REF 2010 Energy Star

1

25

R7203-020

DOOR SWITCH

WHT. SP201R-9D

2

26

R7204-070

POWER SWITCH

SL112A. 125V 15A

1

27

R8329-060

EVAPORATOR FAN MOTOR ASSY

UL. 115V 60HZ

1

28

R7504-060

POWER TRANS

120V 60HZ. DT-1213

1

29

R8139-100

EVAPORATOR HOUSING ASSY

R48

1

30

R815A-030

ASSY UNIT

R49. 115V. REF

1

31

R816A-280

ASSY CROSS BAR

R49

1

32

R817A-330

ASSY DOOR LF-BM

R/F49 BLUE

1

33

R817A-340

ASSY DOOR RH-BM

R/F49 BLUE

1

34

R818A-300

ASSY GRILLE BOTTOM_49

R/F49

1

35

R8199-070

EVAPORATOR DRAIN WATER-L ASSY

R/F49

1

36

R827A-040

CABI FOAM ASSY 49

R49

1

37

R8329-070

CONDENSER FAN MOTOR ASSY

115V 60HZ

1

38

R7213-112

TEMP-DISPLAY SENSOR. REF

TH310H34GANR WHITE. L=200

1

39

R828A-052

ASSY HINGE TOP LF

STS304 T=4.0

1

40

R828A-030

ASSY HINGE BOTTOM LF

STS304 T=4.0

1

Page 10

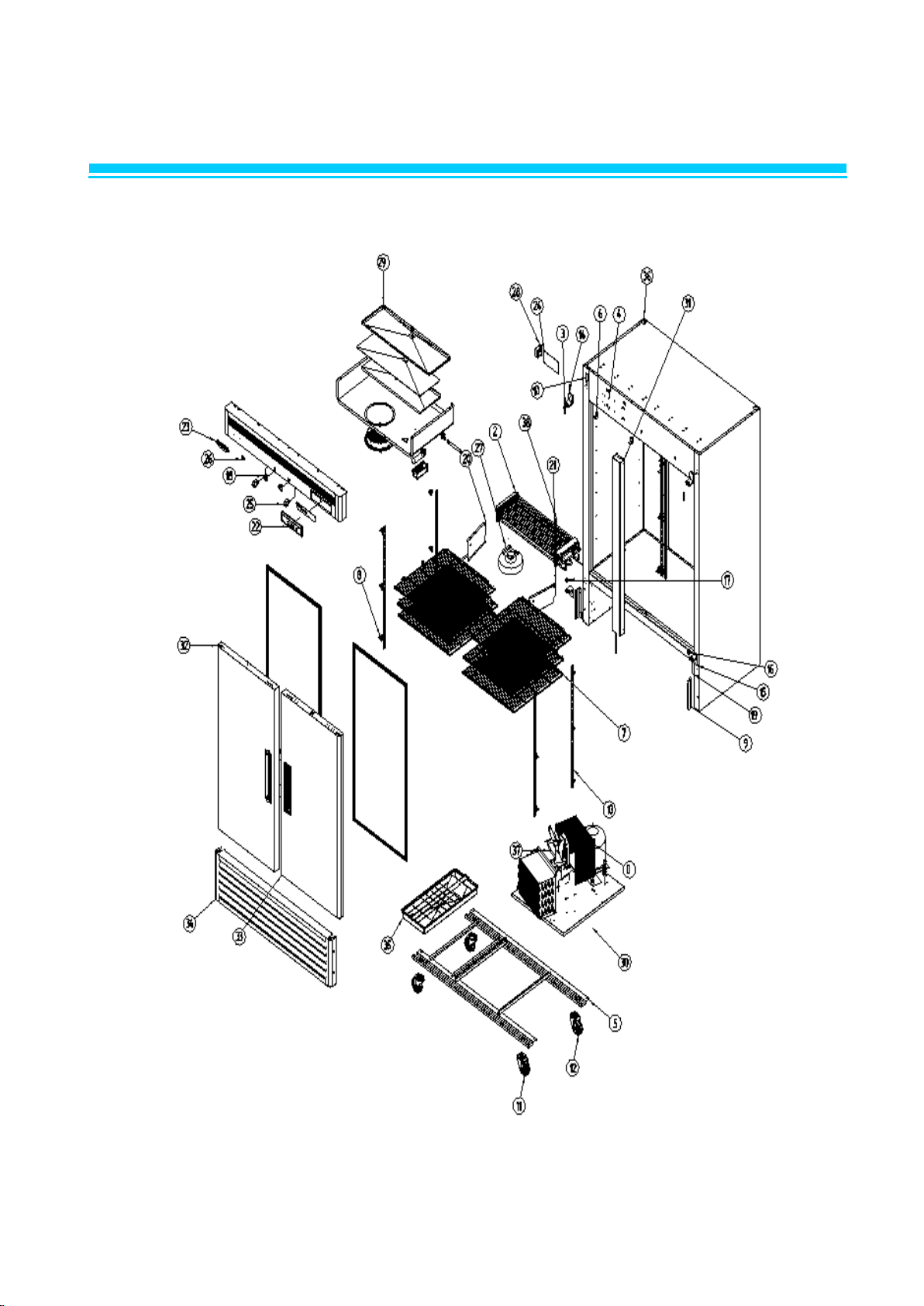

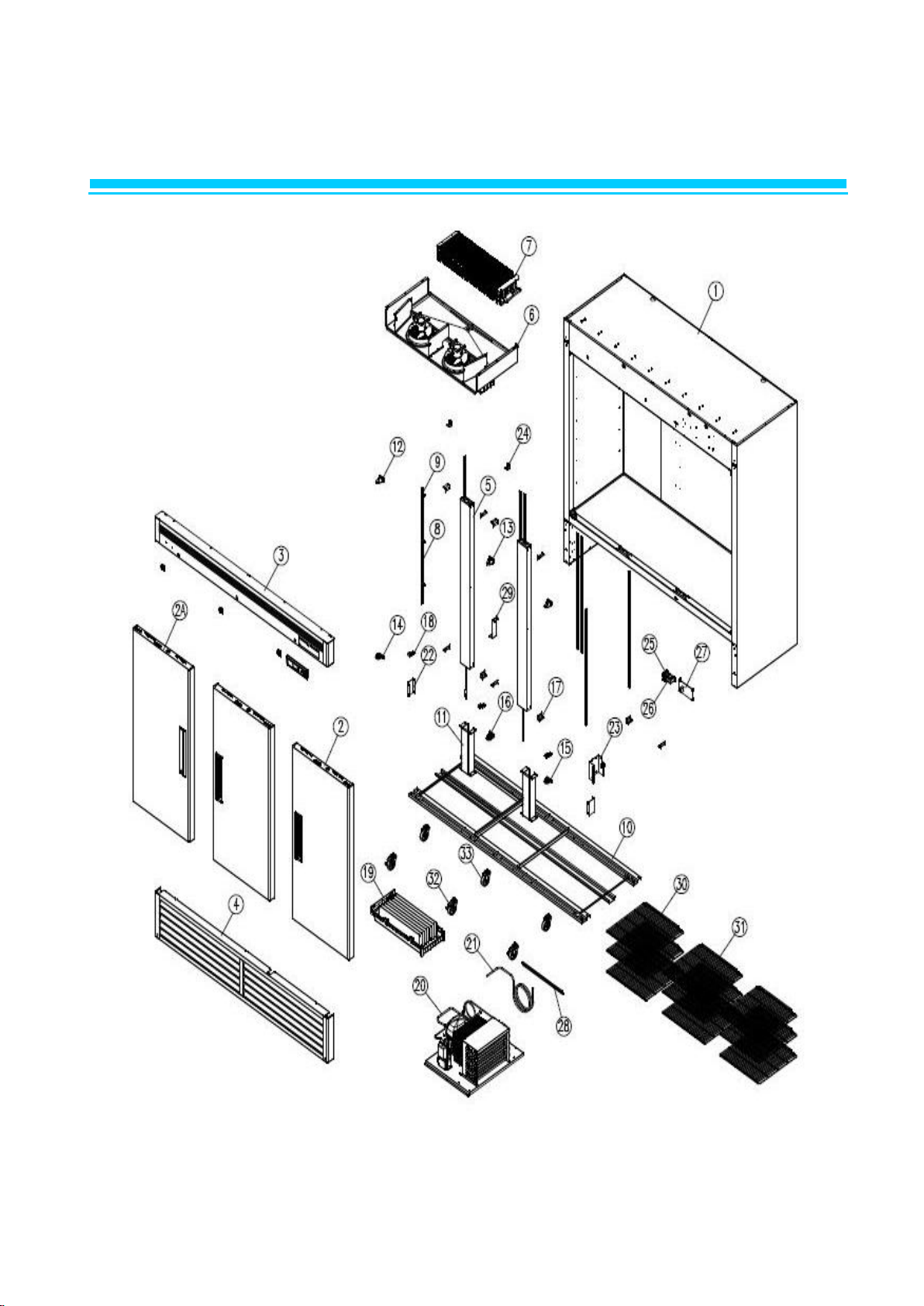

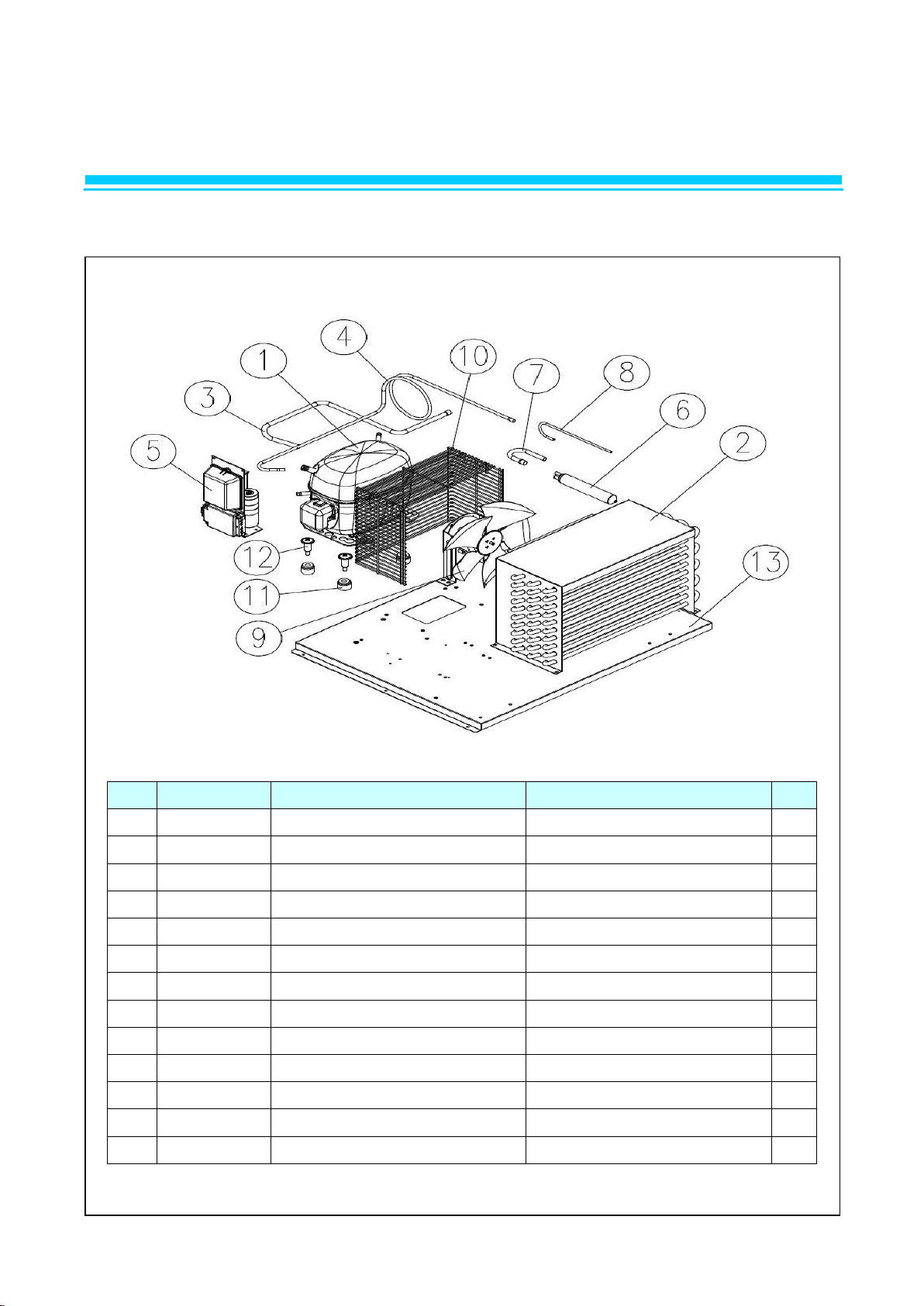

1. ASSEMBLY (BSF49)

Page 11

1-4. PART LIST : BSF49

NO

CODE-No

Title

Subject

Q'TY

1

R2113-580

COMPRESSOR PULL OUT. A

CU-PIPE. T0.7*OD9.52*1900

1

2

R2263-047

EVAPORATOR

F49 1 3

R858A-410

SHAFT TOP HINGE AS

SUM24L Ø15*114

2 4 C3379-240

SUPPORT

DSAA-9N

4 5 R3212-381

FRAME ASSY 49F

717.5*1408

1 6 R3314-282

TOP FRAME B/K

GI. T1.0*30*59.6

3 7 R3233-210

ASSY SHELF 49

MSWR10+PE

6 8 R3313-152

SHELF CLIP

POM. WHT

26 9 R315A-060

BRACKET GRILLE

GI. T1.0*110*102.5

2

10

R7303-412

DEFROST HEATER

UL 115V 600W

1

11

R3323-230

CASTER 4"

4" MOVE

2

12

R3323-240

CASTER 4"

4" STOP

2

13

R3373-630

SHELF STANDARD L

AL. T1.2*930

6

14

R828A-062

ASSY HINGE TOP RH

STS304 T=4.0

1

15

R828A-020

ASSY HINGE BOTTOM RH

STS304 T=4.0

1

16

R375A-030

STOPPER DOOR RH

POM (FW700S)

1

17

R375A-040

STOPPER DOOR LF

POM (FW700S)

1

18

R3734-030

DOOR LOCKING ASSY

ZDC. ZCR

2

19

R3813-351

COVER CAPACITOR

GI. T0.8*255.2*135

1

20

R3853-110

EVAPORATOR AIR GUIDE LF

AL WHITE T0.5*161.8*269

1

21

R3853-090

EVAPORATOR AIR GUIDE RH

AL WHITE T0.5*161.8*269

1

22

R3853-100

EVAPORATOR AIR GUIDE MID

AL WHITE. T0.5*161.8*243

1

23

R514A-031

MASCOT

T3.8*90*64

1

24

R7109-790

MAIN PCB (115. ℉)

115V. FRE 2010 Energy Star

1

25

R7203-020

DOOR SWITCH

WHT. SP201R-9D

2

26

R7204-070

POWER SWITCH

SL112A. 125V 15A

1

27

R7253-080

POWER RELAY

115V

1

28

R7504-060

POWER TRANS

120V 60HZ. DT-1213

1

29

R8139-080

EVAPORATOR HOUSING ASSY

F49

1

30

R8159-940

ASSY UNIT

F49. 115V. FRE

1

31

R816A-290

ASSY CROSS BAR

F49 1 32

R817A-330

ASSY DOOR LF-BM

R/F49 BLUE

1

33

R817A-340

ASSY DOOR RH-BM

R/F49 BLUE

1

34

R818A-300

ASSY GRILLE BOTTOM_49

R/F49

1

35

R8199-070

EVAPORATOR DRAIN WATER-L ASSY

R/F49

1

36

R827A-050

CABI FOAM ASSY 49

F49 1 37

R8329-060

EVAPORATOR FAN MOTOR ASSY

115V 60HZ

2

38

R832A-040

ASSY CASE CONTROL BOARD 49

BLUE

1

39

R7213-210

D-SENSOR

F23 1 40

R7253-052

EVAPORATOR THERMAL FUSE

F23 1 41

R7213-082

TEMP-THERMISTOR. FRE

F23 1 42

R828A-052

ASSY HINGE TOP LF

STS304 T=4.0

1

43

R828A-030

ASSY HINGE BOTTOM LF

STS304 T=4.0

1

Page 12

1. ASSEMBLY (BSR72)

Page 13

1-5. PART LIST : BSR72

NO

CODE-No

Title

Subject

Q'TY

1

R814A-040

ASSY CABI PRE B72R

-

1

2

R817A-140

ASSY DOOR RH BM

- 2 2A

R817A-130

ASSY DOOR LF BM

- 1 3

R858A-560

TOP GRILLE AS B72

- 1 4

R858A-400

BOTTOM GRILLE AS

- 1 5

R816A-210

ASSY CROSS BAR(BM F)

- 2 6

R813A-050

ASSY EVA COVER B72R

- 1 7

R840A-020

ASSY EVA B72R

AL 1 8

R3373-630

SHELF STANDARD L

T1.2*930 ㎜

8 9 R835A-010

ASSY SHELF CLIP

POM. WHT

36

10

R337A-020

FRAME AS B72

PO. T=2.3 707.7*2057

1

11

R376A-020

SUPPORTER FRAME

GI T2.3 395.3*237.4

4

12

R828A-052

ASSY HINGE TOP LF

-

1

13

R828A-062

ASSY HINGE TOP RH

- 2 14

R828A-030

ASSY HINGE BOTTOM LF

- 1 15

R828A-020

ASSY HINGE BOTTOM RH

- 1 16

R828A-040

ASSY HINGE BOTTOM MID

- 1 17

R325A-030

COVER CORNER

ABS(GP35 BASF) 28.5*28.5*53

8

18

R3314-601

U-COVER BRACKET A

EGI 1.2T*81.61*20

3

19

R858A-530

VAPORI AS

-

1

20

R815A-240

ASSY UNIT B72F

- 1 21

R319A-030

PIPE PULL OUT B72

Φ 9.52 * 1914L

1

22

R315A-060

BRACKET GRILLE

GI T=1.0*110*102.5

2

23

R3813-351

COVER CAPACITOR

SGCC-M, T0.8*135*255.2

1

24

R3314-282

TOP FRAME BRACKET

GI, T1.0*30*59.6

3

25

R7253-040

POWER RELAY

G7L-2A-TUB (30281H0310)

1

26

R7504-060

POWER TRANS

120V/60HZ, DT-1213

1

27

R7109-790

MAIN PCB (115. ℉)

115V. FRE 2010 Energy Star

1

28

R315A-100

BRACKET COMP BASE

T=1.0, 473*50.5

1

29

R3854-210

EVAPORATOR DRAIN HOSE GUIDE

GI T1.0X225X60

1

30

R3233-210

ASSY SHELF 49

MSWR10+PE

6

31

R834A-100

ASSY SHELF 72

MSWR10+PE

3

32

R3323-240

CASTER 4"

4" STOP

3

33

R3323-230

CASTER 4"

4" MOVE

3

Page 14

1. ASSEMBLY (BSF72)

Page 15

1-6. PART LIST : BSF72

NO

CODE-No

Title

Subject

Q'TY

1

R814A-040

ASSY CABI PRE B72R

-

1

2

R817A-140

ASSY DOOR RH BM

- 2 2A

R817A-130

ASSY DOOR LF BM

- 1 3

R858A-560

TOP GRILLE AS B72

- 1 4

R858A-400

BOTTOM GRILLE AS

- 1 5

R816A-210

ASSY CROSS BAR(BM F)

- 2 6

R813A-050

ASSY EVA COVER B72R

- 1 7

R840A-030

ASSY EVA B72F

CU 1 8

R7313-440

DEFROST HEATER 60

115V 900W 14.7Ω

1 9 R3373-630

SHELF STANDARD L

T1.2*930 ㎜

8

10

R835A-010

ASSY SHELF CLIP

POM. WHT

36

11

R337A-020

FRAME AS B72

PO. T=2.3 707.7*2057

1

12

R376A-020

SUPPORTER FRAME

GI T2.3 395.3*237.4

4

13

R828A-052

ASSY HINGE TOP LF

- 1 14

R828A-062

ASSY HINGE TOP RH

- 2 15

R828A-030

ASSY HINGE BOTTOM LF

- 1 16

R828A-020

ASSY HINGE BOTTOM RH

- 1 17

R828A-040

ASSY HINGE BOTTOM MID

- 1 18

R325A-030

COVER CORNER

ABS(GP35 BASF) 28.5*28.5*53

8

19

R3314-601

U-COVER BRACKET A

EGI 1.2T*81.61*20

3

20

R858A-530

VAPORI AS

- 1 21

R815A-250

ASSY UNIT B72F

- 1 22

R319A-030

PIPE PULL OUT B72

Φ 9.52 * 1914L

1

23

R315A-060

BRACKET GRILLE

GI T=1.0*110*102.5

2

24

R3813-351

COVER CAPACITOR

SGCC-M, T0.8*135*255.2

1

25

R3314-282

TOP FRAME BRACKET

GI, T1.0*30*59.6

3

26

R7253-040

POWER RELAY

G7L-2A-TUB (30281H0310)

1

27

R7504-060

POWER TRANS

120V/60HZ, DT-1213

1

28

R7109-790

MAIN PCB (115. ℉)

115V. FRE 2010 Energy Star

1

29

R315A-100

BRACKET COMP BASE

T=1.0, 473*50.5

1

30

R3854-210

EVAPORATOR DRAIN HOSE GUIDE

GI T1.0X225X60

1

31

R3233-210

ASSY SHELF 49

MSWR10+PE

6

32

R834A-100

ASSY SHELF 72

MSWR10+PE

3

33

R3323-240

CASTER 4"

4" STOP

3

34

R3323-230

CASTER 4"

4" MOVE

3

Page 16

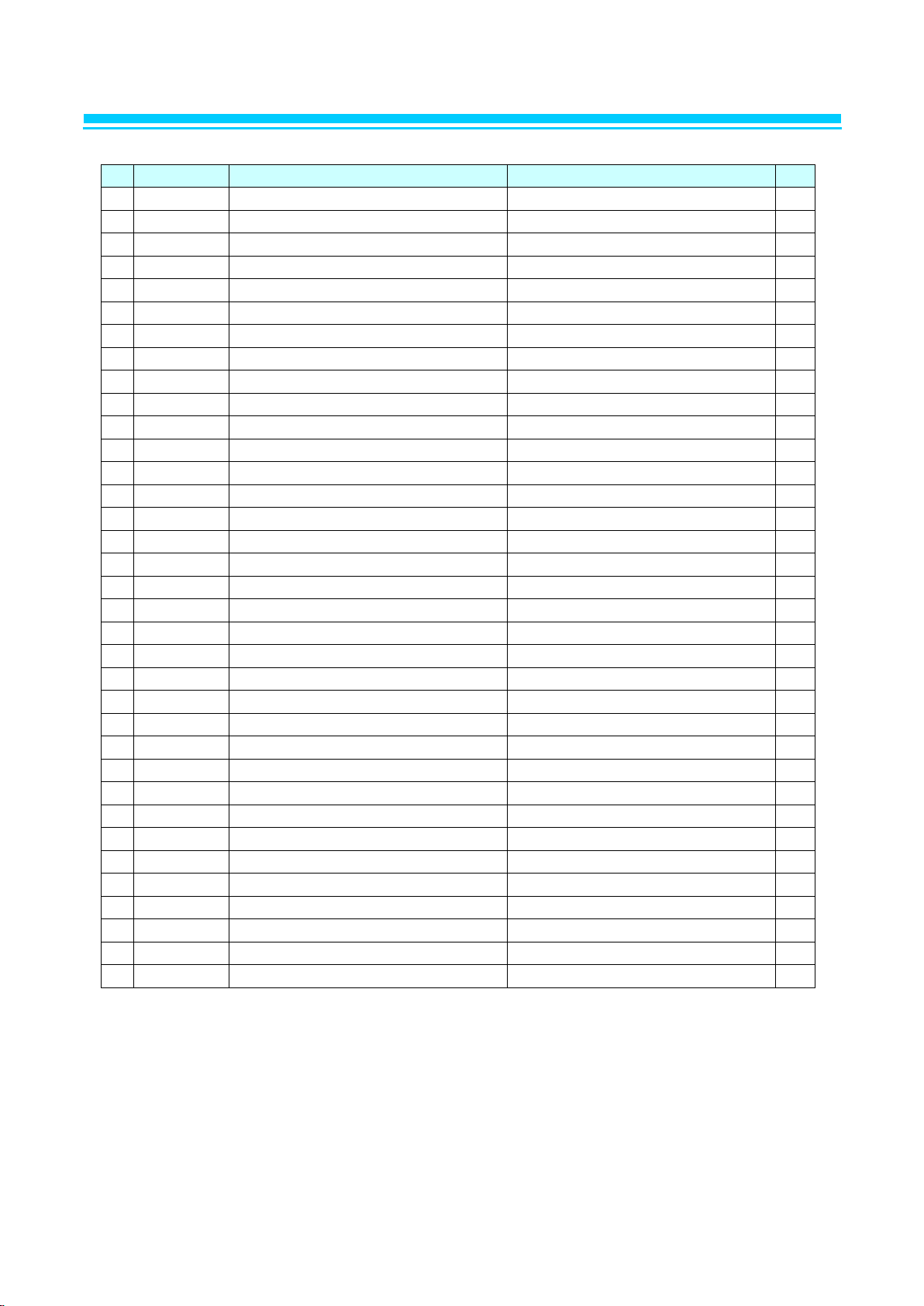

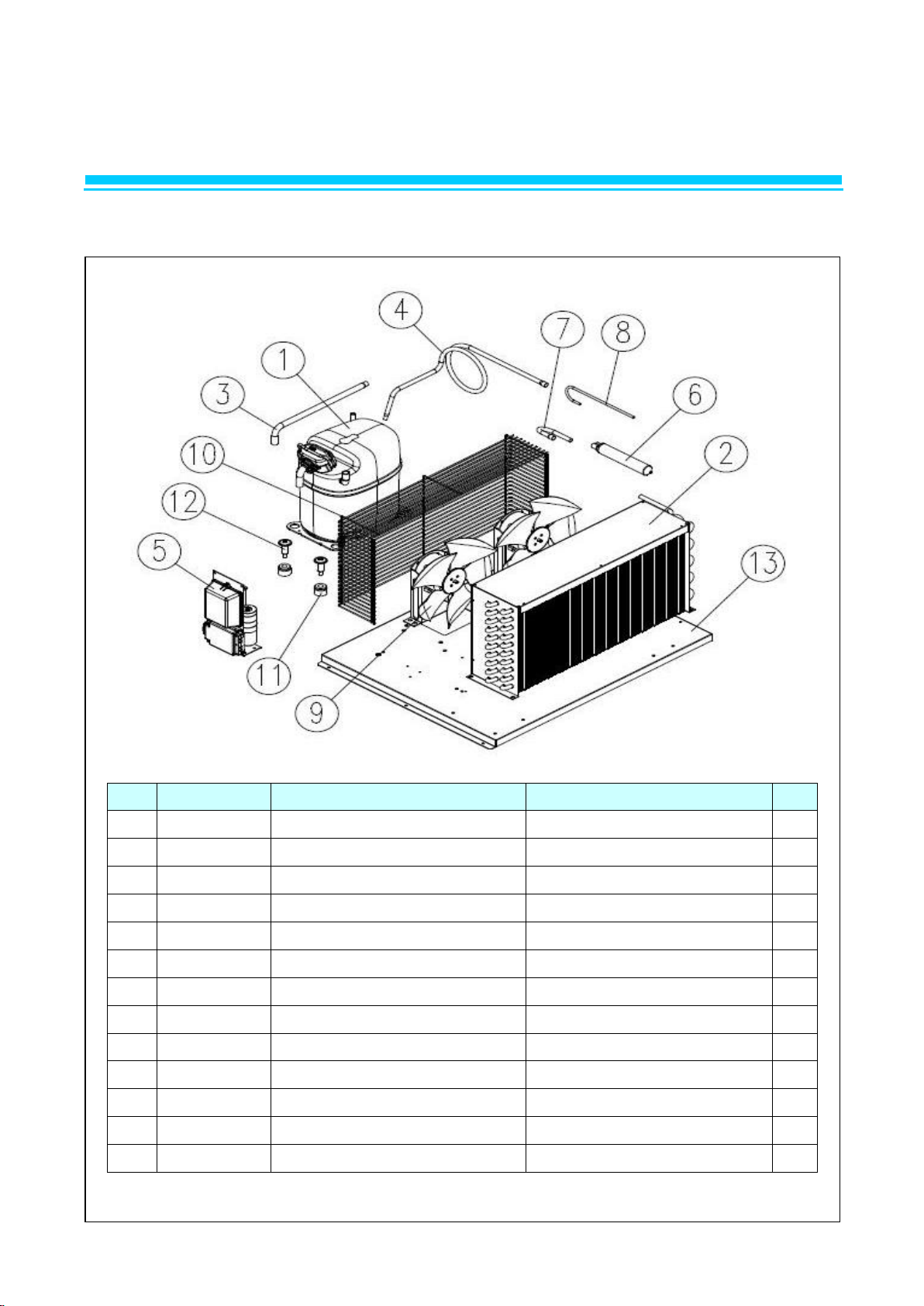

2. PARTS

NO.

CODE-No

Title

Subject

Q'TY

1

R7439-110

COMPRESSOR

SK1A1C-L2W

1

2

R2202-031

CONDENSER COIL

SWST. ¢4.76*13190

1

3

R2114-350

DICHARGE PIPE

CU. T0.6*¢6.35*130

1

4

R2103-433

CONDENSER DRYER PIPE

CU. ¢4.76*368

1

5

R2183-032

DRYER (R-134A. 36G)

36G

1

6

R3202-385

BASE COMP

GI. T1.2*359*605

1 7 R3313-260

CONDENSER FAN MOTOR BRACKET

GI

1

8

R3723-070

CONDENSER FAN BLADE

AL. ¢225. 9" CCW

1

9

R3813-121

CONDENSER COIL COVER

GI. T0.8*265*187

1

10

R3813-150

CONDENSER FAN COVER WIRE

MSWR10. ¢2.5

1

11

R3884-060

GROMMET

NY-6 . ¢12.6*25

4

12

R7423-311

CONDENSER FAN MOTOR

115V 60HZ. DAI-8204DYCA. CW

1

13

R7523-053

HARNESS RELAY B

UL

1

14

R7519-070

O.L.P

4TM795TFB-53

1

15

R7539-190

POSISTOR

SO68-CSR

1

16

R7549-260

RUNNING CAPACITOR

350VAC 50/60HZ 15 ㎌

1

17

R7549-270

CAPACITOR STARTING

160VAC 145 ㎌

1

2-1. UNIT ASSY (BSR23)

Page 17

2. PARTS

NO.

CODE-No

Title

Subject

Q'TY

1

R7439-110

COMPRESSOR

SK1A1C-L2W

1

2

R2202-031

CONDENSER COIL

SWST. ¢4.76*13190

1

3

R2114-350

DICHARGE PIPE

CU. T0.6*¢6.35*130

1

4

R2103-433

CONDENSER DRYER PIPE

CU. ¢4.76*368

1

5

R2183-032

DRYER (R-134A. 36G)

36G

1

6

R3202-385

BASE COMP

GI. T1.2*359*605

1

7

R3313-260

CONDENSER FAN MOTOR BRACKET

GI

1

8

R3723-070

CONDENSER FAN BLADE

AL. ¢225. 9" CCW

1

9

R3813-121

CONDENSER COIL COVER

GI. T0.8*265*187

1

10

R3813-150

CONDENSER FAN COVER WIRE

MSWR10. ¢2.5

1

11

R3884-060

GROMMET

NY-6 . ¢12.6*25

4

12

R7423-311

CONDENSER FAN MOTOR

115V 60HZ. DAI-8204DYCA. CW

1

13

R7483-023

HARNESS RELAY A

UL

1

14

R7519-070

O.L.P

4TM795TFB-53

1

15

R7539-190

POSISTOR

SO68-CSR

1

16

R7549-260

RUNNING CAPACITOR

350VAC 50/60HZ 15 ㎌

1

17

R7549-270

CAPACITOR STARTING

160VAC 145 ㎌

1

2-1. UNIT ASSY (BSF23)

Page 18

2. PARTS

NO.

CODE-No

Title

Subject

Q'TY

1

R7439-110

COMPRESSOR

SK1A1C-L2W

1 2 R2202-031

CONDENSER COIL

SWST. ¢4.76*13190

1

3

R2109-670

CONDENSER DRYER PIPE

CU. ¢4.76*321

1

4

R2183-032

DRYER (R-134A. 36G)

36G

1

5

R3004-270

COMPRESSOR BOLT

STS. M6*30Y. ¢10

4

6

R3202-421

BASE COMP

GI. T1.2*645*574

1 7 R2103-930

CONDENSER PIPE

T0.7*OD4.86*654. CU

1

8

R3313-260

CONDENSER FAN MOTOR BRACKET

GI

1

9

R3723-070

CONDENSER FAN BLADE

AL. ¢225. 9" CCW

1

10

R3813-121

CONDENSER COIL COVER

GI. T0.8*265*187

1

11

R3813-150

CONDENSER FAN COVER WIRE

MSWR10. ¢2.5

1

12

R3884-030

GROMMET COMP

NR-RUBBER. BLK

4

13

R7423-311

CONDENSER FAN MOTOR

115V 60HZ. DAI-8204DYCA. CW

1

14

R7483-033

HARNESS RELAY D

UL

1

15

R7519-070

O.L.P

4TM795TFB-53

1

16

R7539-190

POSISTOR

SO68-CSR

1

17

R7549-260

RUNNING CAPACITOR

350VAC 50/60HZ 15 ㎌

1

18

R7549-270

CAPACITOR STARTING

160VAC 145 ㎌

1

2-1. UNIT ASSY (BSR49)

Page 19

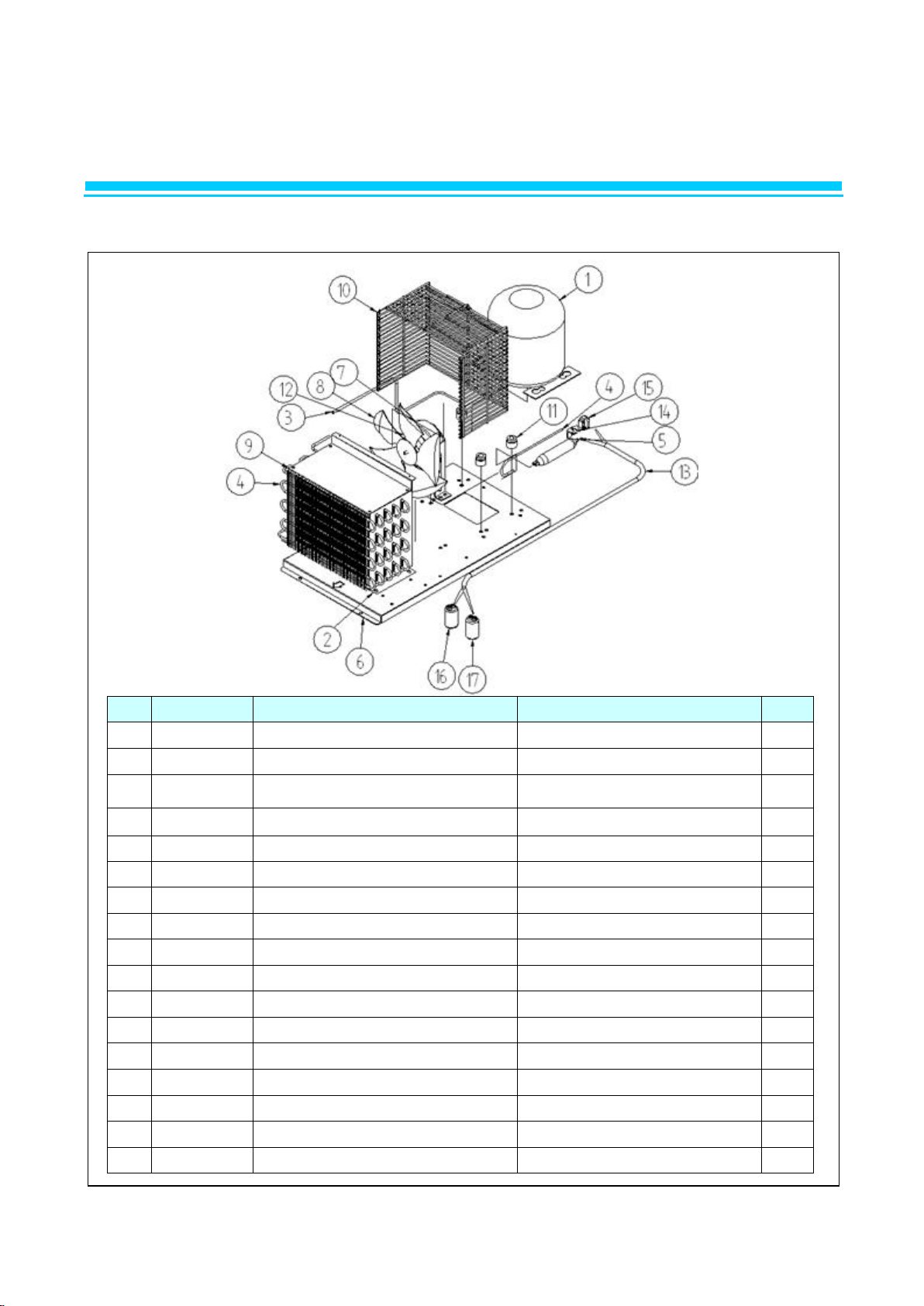

2. PARTS

NO.

CODE-No

Title

Subject

Q'TY

1

R3202-397

BASE COMP

GI. T1.2*555*614

1 2 R2104-460

COMPRESSOR CHARGING PIPE

CU-PIPE. OD6.35*T0.7*200

1 3 R2113-580

COMPRESSOR PULL OUT

1 4

R2183-200

DRIER ASSY

UL

1

5

R3004-270

COMPRESSOR BOLT

STS. M6*30Y. ¢10

4

6

R3313-260

CONDENSER FAN MOTOR

BRACKET

GI

1

7

R3723-070

CONDENSER FAN BLADE

AL. ¢225. 9" CCW

1

8

R3813-160

CONDENSER FAN COVER WIRE

MSWR. ¢2.5

1

9

R3834-130

CABLE CLAMP

DA-18N NYLON-66

1

10

R3884-030

GROMMET COMP

NR-RUBBER. BLK

4

11

R7423-311

CONDENSER FAN MOTOR

UL

1

12

R7439-600

COMPRESSOR

SC18CLX2

1

13

R7549-280

STARTING CAPACITOR

125~165V 410 ㎌

1

14

R7549-290

RUNNING CAPACITOR

280V 23.5 ㎌

1

15

R2103-474

CONDENSER CONNECTOR

UL. OD9.52*T0.7*795

1

16

R7483-014

HARNESS RELAY C

UL

1

2-1. UNIT ASSY (BSF49)

Page 20

2. PARTS

NO.

CODE-No

Title

Subject

Q'TY 1 R714A-010

COMPRESSOR

SC18G

1 2 R2272-013

CONDENSER COIL

370*184

1 3 R319A-020

PIPE PULL OUT B

Φ 9.52

1 4 R2113-570

DISCHARGE CONNECTOR

CU PIPE. ¢6.35*T0.7*1215

1 5 R7539-200

POSISTOR

J531Q35E330M3852. 33Ω. 385V

1 6 R2183-200

DRYER ASSY

¢25.73*0.8T*169. CU-PIPE

1 7 R319A-010

PIPE COND OUTLET

C1220T

1 8 R2104-981

PIPE DRYER

- 1 9

R8329-070

CONDENSER FAN MOTOR ASSY

115V 60 ㎐

1

10

R3813-791

FAN COVER WIRE

MSWR. ¢2.5

1

11

R3884-030

GROMMET COMP

NR-RUBBER,BLK

4

12

R3004-270

COMPRESSOR BOLT

M6*30Y ¢10

4

13

R312A-010

BASE COMP

GI T=1.2 700*556.2

1

2-1. UNIT ASSY (BSR72)

Page 21

2. PARTS

NO.

CODE-No

Title

Subject

Q'TY

1

R714A-020

COMPRESSOR

GS26CLX

1

2

R2272-030

CONDENSER COIL PIN

CU,545*270*140

1

3

R2114-330

COMPRESSOR PULL OUT, B

T0.7*12.7

1 4 R2113-570

DISCHARGE CONNECTOR

CU PIPE. ¢6.35*T0.7*1215

1

5

R7539-200

POSISTOR

J531Q35E330M3852. 33Ω. 385V

1

6

R2183-200

DRYER ASSY

¢25.73*0.8T*169. CU-PIPE

1

7

R319A-010

PIPE COND OUTLET

C1220T

1

8

R2104-981

PIPE DRYER

-

1

9

R8329-070

CONDENSER FAN MOTOR ASSY

115V 60 ㎐

2

10

R3813-770

FAN COVER WIRE-B

MSWR10, OD2.6

1

11

R3884-030

GROMMET COMP

NR-RUBBER,BLK

4

12

R3004-270

COMPRESSOR BOLT

M6*30Y ¢10

4

13

R312A-010

BASE COMP

GI T=1.2 700*556.2

1

2-1. UNIT ASSY (BSF72)

Page 22

2. PARTS

NO.

CODE-No

Title

Subject

Q'TY

1

R359A-380

Plate Cross Bar Front

STS443CT T=0.5 1345.2*118.2

1

2

R359A-390

Plate Cross Bar Rear

STS443CT T=0.5 1354.2*118.2

1 3 R365A-021

Reinf Cross Bar T72

GI T0.8*1180*103.6

1

4

R3069-010

Rivet Blind

Ø3.2

4

5

R320A-010

Cap End Top T72

EPS T30*110*24.5

2 6 R7303-125

Heater Cord Cross Bar

30w

1

7

R320A-020

Cap End Bottom T72

EPS T30*90*49

1

8

R1129-310

Tape Aluminium

W80

2.5M

9

R368A-240

SASH CROSS BM

ABS L=1315MM

2

10

R3373-630

Shelf Standard L

T1.2*930mm

2

11

R4213-030

Screw FH M4*16 직결

M4X16

12

12

R1129-010

Kraft Tape

W25

2.4

2-2. CROSS BAR ASSY (49R,72R)

Page 23

2. PARTS

NO.

CODE-No

Title

Subject

Q'TY 1 R359A-380

Plate Cross Bar Front

STS443CT T=0.5 1345.2*118.2

1 2 R359A-390

Plate Cross Bar Rear

STS443CT T=0.5 1354.2*118.2

1 3 R365A-021

Reinf Cross Bar T72

GI T0.8*1180*103.6

1 4 R3069-010

Rivet Blind

Ø3.2

4 5 R320A-010

Cap End Top T72

EPS T30*110*24.5

2 6 R7303-115

Heater Cord Cross Bar

38w

1 7 R320A-020

Cap End Bottom T72

EPS T30*90*49

1 8 R1129-310

Tape Aluminium

W80

2.5M

9

R368A-240

SASH CROSS BM

ABS L=1315MM

2

10

R3373-630

Shelf Standard L

T1.2*930mm

2

11

R4213-030

Screw FH M4*16 직결

M4X16

12

12

R1129-010

Kraft Tape

W25

2.4

2-2. CROSS BAR ASSY (49F,72F)

Page 24

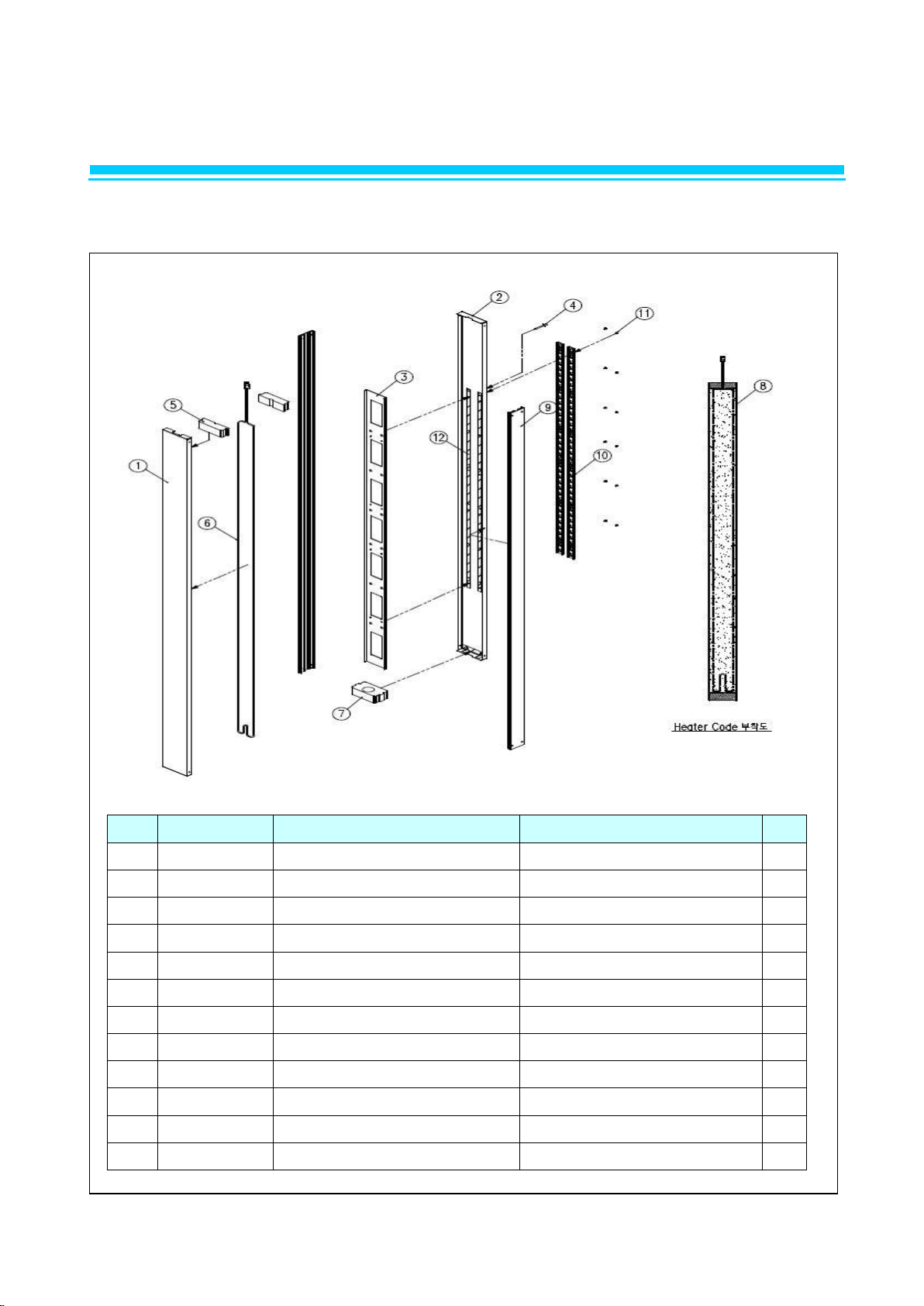

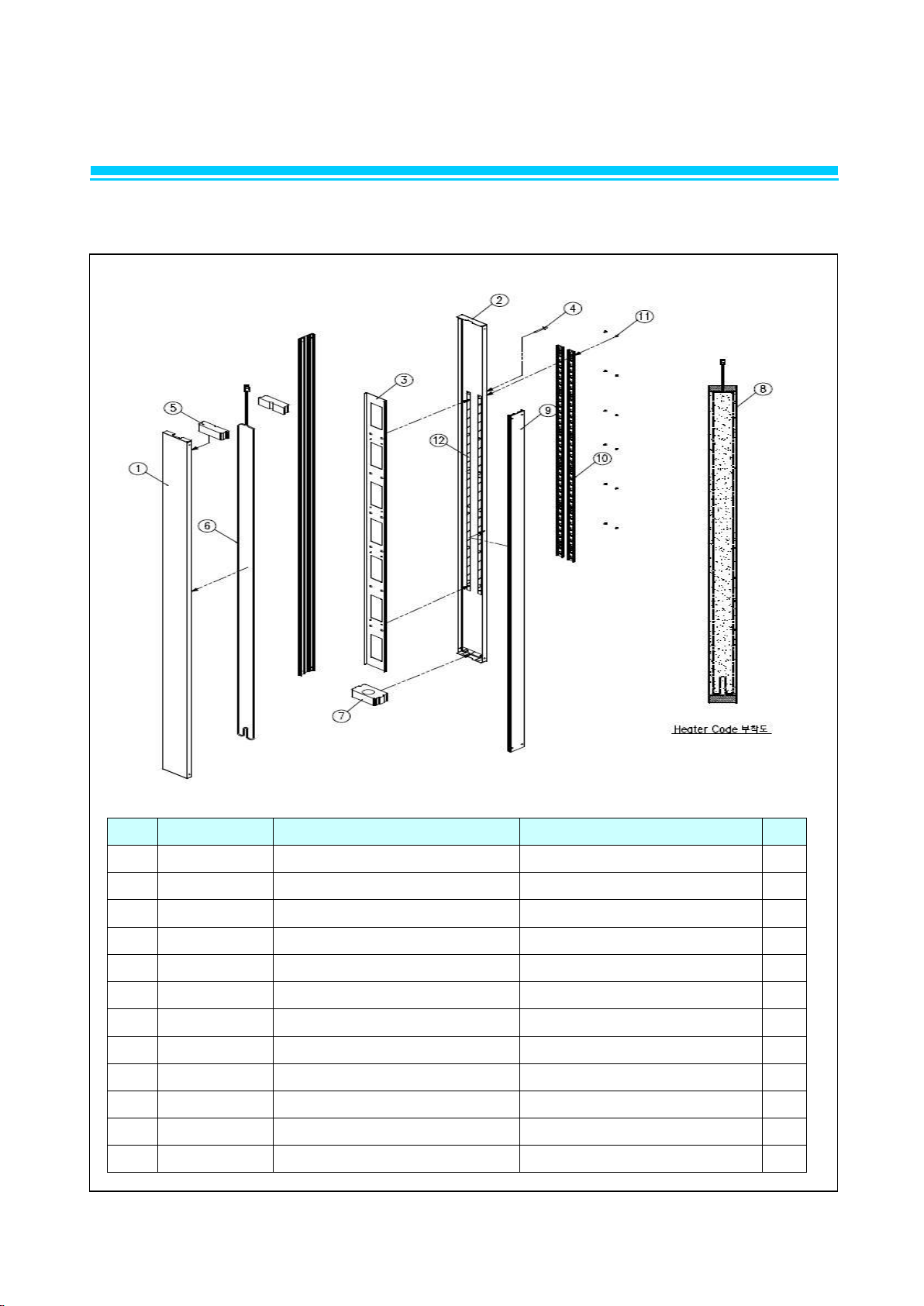

2. PARTS

2-3. DOOR ASSY (BSR/F23, BSR/F49, BSR/F72)

Page 25

NO.

CODE-No

Title

Subject

Q'TY

1

R359A-410

PLATE DOOR BLUE

STS430-#4 T0.5*1514*823

1

2

R342A-011

HANDEL DOOR

PC-ABS (GN5201F)

1

3

R858A-410

SHAFT TOP HINGE AS

SUM24L Ø15*114

2

4

R375A-041

STOPPER DOOR LF

POM (700S)

1

5

R1129-140

COTTON TAPE (W50)

W50

1.5M

6

R1129-060

AL TAPE

W50

1.5M

7

R313A-011

BODY DOOR SPRING

ZNDC 97*70*26

1 8 R375A-031

STOPPER DOOR RH

POM (700S)

1

9 SCREW

FH5*15

4

10

R313A-011

BODY DOOR SPRING

ZNDC 97*70*26

1

11

R374A-020

SPRING DOOR RH

SW-C Ø2.3

1

12

R374A-010

SPRING DOOR LF

SW-C Ø2.3

1

13

R3932-360

CAP DOOR LOCK

ABS 69.8*21.8

2

14

R3932-380

BODY DOOR LOCK

ABS 78*60*10.3

2

15

R368A-050

SASH DOOR ST72

ABS L=643

2

16

R368A-260

SASH DOOR L BM

ABS L=1386

2

17

R1129-140

COTTON TAPE

W50

0.5M

18

R1129-160

TAPE TWO FACE

4.2M

19

R359A-400

PLATE DOOR REAR BM

STS443CT T0.4*1331*588

1

20

R338A-040

GASKET DOOR BM

난연 PVC 1353*610

1

21

R1254-051

DOOR RUBBER LEG

SILICON Ø16*12

2

22

R4213-030

SCREW

FH M4*16

2

Page 26

2. PARTS

NO.

CODE-No

Title

Subject

Q'TY

1

R3813-472

EVAPORATOR HOUSING

STS443CT. T0.5X575X558

1

2

R3812-141

EVAPORATOR FAN MOTMOR GUARD

HIPS (VH-1800EX). UL

1 3 R325A-041

LAMP COVER

MIPS(HIPS B-5676). WHT

1

4

R7393-021

LAMP SOCKET

250V 660W

1

5

R7394-010

LAMP BULB

25T10. 120V 25W

1

6

R1143-202

INSUL DRAIN 23

EPS. 17*530*256

1 7 R3743-051

EVAPORATOR DRAIN PAN SMALL

AL. T0.8

1 8 R3744-091

EVAPORATOR DRAIN ELBOW UPP

PP. WHT

1

9

R3744-101

EVAPORATOR DRAIN ELBOW LOW

PP. WHT

1

10

R2124-021

EVAPORATOR DRAIN HOSE A

SILICON. CLEAR. 16*12.

L=213

1

11

R7403-111

HARNESS LAMP, L

UL

1

2-4. EVAPORATOR HOUSING ASSY (BSR23)

Page 27

2. PARTS

NO.

CODE-No

Title

Subject

Q'TY 1 R3813-472

EVAPORATOR HOUSING

STS443CT. T0.5X575X558

1 2 R3812-141

EVAPORATOR FAN MOTMOR GUARD

HIPS (VH-1800EX). UL

1 3 R325A-041

LAMP COVER

MIPS(HIPS B-5676). WHT

1 4 R7393-021

LAMP SOCKET

250V 660W

1 5 R7394-010

LAMP BULB

25T10. 120V 25W

1 6 R1143-202

INSUL DRAIN 23

EPS. 17*530*256

1 7 R3743-051

EVAPORATOR DRAIN PAN SMALL

AL. T0.8

1 8 R3744-091

EVAPORATOR DRAIN ELBOW UPP

PP. WHT

1 9 R3744-101

EVAPORATOR DRAIN ELBOW LOW

PP. WHT

1

10

R7303-174

HEATER DRAIN PAN

115V 90W. UL

1

11

R2124-021

EVAPORATOR DRAIN HOSE A

SILICON. CLEAR. 16*12.L=213

1

12

R8393-030

HEATER CORD DRAIN HOSE ASSY

UL 10W

1

13

R7403-111

HARNESS LAMP, L

UL

1

2-4. EVAPORATOR HOUSING ASSY (BSF23)

Page 28

2. PARTS

NO.

CODE-No

Title

Subject

Q'TY 1 R3813-313

EVAP COVER

STS443CT. T0.8X1048X560

1 2 R1143-222

INSUL DRAIN R49

EPS. 17*622*256

1

3

R3743-041

EVAPORATOR DRAIN PAN MID

AL. T0.8

1

4

R3812-141

EVAPORATOR FAN MOTMOR GUARD

HIPS (VH-1800EX). UL

1

5

R3744-091

EVAPORATOR DRAIN ELBOW UPP

PP. WHT

1 6 R3744-101

EVAPORATOR DRAIN ELBOW LOW

PP. WHT

1

7

R7393-021

LAMP SOCKET

250V 660W

1 8 R7394-010

LAMP BULB

25T10. 120V 25W

1 9 R325A-041

LAMP COVER

MIPS(HIPS B-5676). WHT

1

12

R2124-021

EVAPORATOR DRAIN HOSE A

SILICON. CLEAR. 16*12.L=213

1

13

R7403-110

HARNESS LAMP, L

UL

1

2-4. EVAPORATOR HOUSING ASSY (BSR49)

Page 29

2. PARTS

NO.

CODE-No

Title

Subject

Q'TY

1

R3813-323

EVAP COVER

STS443CT. T0.5*1191X560

1

4

R3812-141

EVAPORATOR FAN MOTMOR GUARD

HIPS (VH-1800EX). UL

2 5 R7393-021

LAMP SOCKET

250V 660W

1

6

R7394-010

LAMP BULB

25T10. 120V 25W

1

7

R325A-041

LAMP COVER

MIPS(HIPS B-5676). WHT

1 8 R1143-212

INSUL DRAIN 49

EPS. 17*800*256

1

9

R3743-031

EVAPORATOR DRAIN PAN-LARGE F49

AL. T0.8

1

10

R3744-091

EVAPORATOR DRAIN ELBOW UPP

PP. WHT

1

11

R3744-101

EVAPORATOR DRAIN ELBOW LOW

PP. WHT

1

12

R8393-040

HEATER CORD DRAIN HOSE ASSY

UL 10W

1

13

R2124-021

EVAPORATOR DRAIN HOSE A

SILICON. CLEAR.

16*12.L=213

1

14

R7303-184

HEATER DRAIN PAN

115V 140W

1

15

R7403-111

HARNESS LAMP, L

UL

1

2-4. EVAPORATOR HOUSING ASSY (BSF49)

Page 30

2. PARTS

NO.

CODE-No

Title

Subject

Q'TY

1

R325A-070

COVER EVA B72R

STS443CT T0.5 1191*560

1 2 R3812-141

EVAPORATOR FAN MOTOR GUARD

HIPS (VH-1800EX)

2

3

R1143-212

EVAPORATOR DRAIN INSUL-L

T17*256*800, FOAM-PS

1

4

R3743-031

EVAPORATOR DRAIN PAN-LARGE

AL+COATING

1 5 R3314-350

BRACKET-DRAIN

STS304-2B, T0.5*25*57(P)

2 6 R3744-090

EVAPORATOR DRAIN ELBOW-UPP

PP WHITE(30209L0200)

1 7 R3744-100

EVAPORATOR DRAIN ELBOW-LOW

PP WHITE(30225L0100)

1 8 R2124-021

EVAPORATOR DRAIN HOSE A

SILICON. CLEAR. 16*12.L=213

1 9 R7393-021

LAMP SOCKET

L-125B 660W 20V

2

10

R7394-010

LAMP BULB

25T10. 120V 25W

2

11

R325A-041

LAMP COVER

MIPS(HIPS B-5676). WHT

2

12

R7403-111

HARNESS LAMP, L

UL

2

2-4. EVAPORATOR HOUSING ASSY (BSR72)

Page 31

2. PARTS

NO.

CODE-No

Title

Subject

Q'TY

1

R325A-060

COVER EVA B72F

STS443CT T=0.5*1405.8*559.7

1 2 R3812-141

EVAPORATOR FAN MOTOR GUARD

HIPS (VH-1800EX)

2 3 R1143-380

EVAPORATOR DRAIN INSUL-L

T17*256*800, FOAM-PS

1 4 R7313-431

HEATER DRAIN PAN

115V 90W

1 5 R3743-240

EVAP DRAIN PAN,L

AL,T0.8*1040*258,GST-72TF

1 6 R3314-350

BRACKET-DRAIN

STS304-2B, T0.5*25*57(P)

2 7 R3744-090

EVAPORATOR DRAIN ELBOW-UPP

PP WHITE(30209L0200)

1 8 R3744-100

EVAPORATOR DRAIN ELBOW-LOW

PP WHITE(30225L0100)

1 9 R2124-021

EVAPORATOR DRAIN HOSE A

SILICON. CLEAR. 16*12.L=213

1

10

R7313-490

HEATER CORD DRAIN HOSE

115V 10W

1

11

R7394-010

LAMP BULB

25T10. 120V 25W

2

12

R325A-041

LAMP COVER

MIPS(HIPS B-5676). WHT

2

13

R7393-021

LAMP SOCKET

L-125B 660W 20V

2

14

R7403-111

HARNESS LAMP, L

UL

2

2-4. EVAPORATOR HOUSING ASSY (BSF72)

Page 32

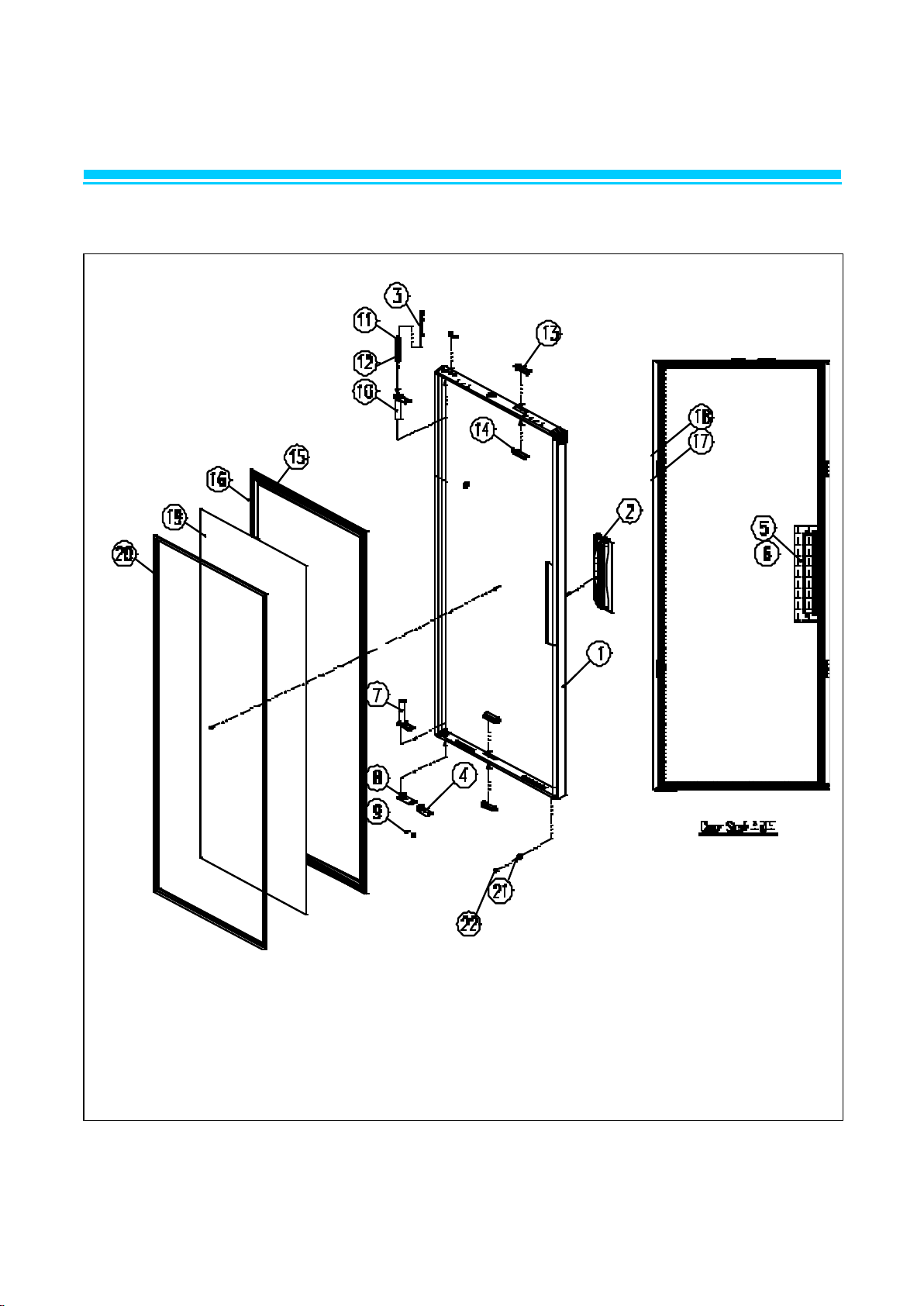

2. PARTS

NO.

CODE-No

Title

Subject

Q'TY

1

R359A-600

PLATE FRAME LOW

STS430-#4. T0.6*199*679

1 2 R3153-151

TOP FRAME MID PIECE-S

ABS. BLK. L=571

1

3

R359A-480

PLATE FRAME UPP

STS430-#4. T0.6*679*159.3

1 4 R359A-430

PLATE TOP GRILL SIDE

STS430-#4. T0.6*209*148

2

5

R514A-031

MASCOT

T3.8*90*64

1

6

R3734-030

DOOR LOCKING ASSY

ZDC. ZCR

1 7 R4142-122

CONTROL BOARD

(DIGITAL DISPLAY)

ABS. BLK. T2*242*72

1 8 R7113-210

DISPLAY PCB (℉)

88 SEGMENT. ℉

1

9

R7203-020

DOOR SWITCH

WHT. SP201R-9D

1

10

R7204-070

POWER SWITCH

SL112A. 125V 15A

1

11

R818A-340

ASSY GRILL TOP

23 BLUE

1

2-5. TOP FRAME ASSY (BSR/BSF23)

Page 33

2. PARTS

NO.

CODE-No

Title

Subject

Q'TY

1

R3153-141

TOP FRAME MID PIECE, L

ABS, BLK, L=1260

1

2

R359A-490

TOP FRAME UPP 49

STS430-#4. T0.6*1368*159.3

1

3

R359A-610

PLATE FRAME LOW_49

STS430-#4. T0.6*188*1368

1 4 R359A-430

PLATE TOP GRILL SIDE

STS430-#4. T0.6*209*148

2

5

R514A-031

MASCOT

T3.8*90*64

1 6 R3734-030

DOOR LOCKING ASSY

ZDC. ZCR

2

7

R4142-122

CONTROL BOARD (DIGITAL

DISPLAY)

ABS. BLK. T2*242*72

1 8 R7113-210

DISPLAY PCB (℉)

88 SEGMENT. ℉

1

9

R7204-070

POWER SWITCH

SL112A. 125V 15A

1

10

R7203-020

DOOR SWITCH

WHT. SP201R-9D

2

11

R818A-350

ASSY GRILL TOP

49 BLUE

1

2-5. TOP FRAME ASSY (BSR/BSF49)

Page 34

2. PARTS

NO.

CODE-No

Title

Subject

Q'TY

1

R359A-450

PLATE TOP GRILL UPPER

STS430 T=0.6*2057*158.9

1

2

R359A-440

PLATE TOP GRILL LOW

STS430 T=0.6*2057*194.9

1

3

R359A-430

PLATE TOP GRILL SIDE

STS430 T=0.6

2 4 R337A-010

FRAME TOP MID PIECE 72

ABS BLK L=1950

1 5 R7113-210

DISPLAY PCB (℉)

88 SEGMENT. ℉

1

6

R4142-122

CONTROL BOARD

ABS. BLK. T2*242*72

1 7 R7203-020

DOOR SWITCH

WHT. SP201R-9D

3

8

R3734-030

DOOR LOCKING ASSY

ZDC. ZCR

3

9

R7204-070

POWER SWITCH

SL112A. 125V 15A

1

10

R514A-031

MASCOT

T3.8*90*64

1

2-5. TOP FRAME ASSY (BSR/BSF72)

Page 35

2. PARTS

NO.

CODE-No

Title

Subject

Q'TY

1

R3743-060

TRAY-DRAIN WATER S

ABS, BLK

1 2 R3853-230

EVAPORATOR WICKING GUIDE

P.P. WHT. T2.0*569*40

1

3

R1154-010

DRAIN WICKING P/K

P.P. T2.5*99*103

7

4

C3009-100

SCREW THT2 4*6Y

THT2 46Y

4

NO.

CODE-No

Title

Subject

Q'TY

1

R3743-070

TRAY-DRAIN WATER L

ABS, BLK

1

2

R3853-240

EVAPORATOR WICKING GUIDE

P.P. WHT. T2.0*657*40

1

3

R1154-020

PAPER-KIT

P.P. T2.5*180*83

7 4 C3009-100

SCREW THT2 4*6Y

THT2 46Y

4

2-6. EVAPORATOR DRAIN WATER-S ASSY

MODEL : BSR23, BSF23

MODEL : BSR49, BSF49

Page 36

2. PARTS

NO.

CODE-No

Title

Subject

Q'TY

1

R3422-012

CASE VAPORI T49

ABS. 602.5*275*106.5

1 2 R110A-010

CLOTH WICKING DRAIN WATER

T=2.5*480*120

8 3 R3853-780

GUIDE WICKING

PP(WHITE). 1.5T*269*40

2

2-6. EVAPORATOR DRAIN WATER-S ASSY (BSR72, BSF72)

Page 37

3. WIRING DIAGRAM

3-1. 23Model

◇ BSR23

◇ BSF23

Page 38

3. WIRING DIAGRAM

3-2. 49Model

◇ BSR49

◇ BSF49

Page 39

3. WIRING DIAGRAM

3-2. 72Model

◇ BSR72

◇ BSF72

Page 40

4. PART DETAILS

4-1. TOP PANEL

◇ Display PCB

◇ Main PCB

Page 41

4. PART DETAILS

4-2. COMPRESSOR COMPARTMENT

◇ Condensing Unit

BSR49

BSF49

BSR23, BSF23

Page 42

4. PART DETAILS

4-3. DOOR

◇ Door Gasket

4-4. COOLING COMPARTMENT

◇ Evaporator Housing (Duct) (BSF49)

◇ Refrigerator Evaporator (BSF49)

Page 43

4. PART DETAILS

◇ Condensate Drain Pan

◇ Condenser Fan Motor Assembly

◇ Compressor Capacitor (Running & Starting Capacitor)

.

Page 44

4. PART DETAILS

BSF49

BSF23

◇ Evaporator Housing (Duct) (BSR23, BSF23)

◇ Coil Evaporator (BSF23)

◇ Evaporator Defrost Heater (BSF23, BSF49)

Page 45

5. MAIN COMPONENTS

MODEL

BSR23

BSF23

BSR49

S49F

Refrigerant

R-134a

R-134a

R-134a

R-404a

Voltage

115V

115V

115V

115V

Comp.

Model

SK1A1C-L2W

SK1A1C-L2W

SK1A1C-L2W

SC18CLX2

Part

code

(DY)

R7439-110

R7439-110

R7439-110

R7439-600

Image

MODEL

BSR23, BSF23

S49R

S49F

Voltage - 115V/60Hz

Relay Model - G7L-2A-TUB

Part

code

(DY)

-

R7253-040

Image

MODEL

BSR23

BSF23

BSR49

BSF49

Spec

160VAC

145 ㎌

160VAC

145 ㎌

160VAC

145 ㎌

125~165VAC

410 ㎌

Part

code

(DY)

R7549-270

R7549-270

R7549-270

R7549-280

Image

Assy

117U5043

5-1.COMPRESSOR

5-2.POWER-RELAY(COMP. RELAY)

5-3. STARTING CAPACITOR

Page 46

5-4. RUNNING CAPACITOR

MODEL

BSR23

BSF23

BSR49

BSF49

Spec

350VAC

15 ㎌

350VAC

15 ㎌

350VAC

15 ㎌

280VAC

23.5 ㎌

Part

code

(DY)

R3153-341

R3153-341

R3153-341

R7549-290

Image

Assy

117-7114

MODEL

BSR23

BSR49

BSF23

BSF49

Refrigerant

R-134a

R-404a

Spec

36GR

24G

Part

code

(DY)

R2183-032

R2183-200

Image

MODEL

BSR23

BSR49

BSF23

BSF49

Spec

4.76*13190

CU.OD9.52

Part

code

(DY)

R2202-031

R2272-013

Image

MODEL

BSR23

BSR49

BSF23

BSF49

Spec

AL. ¢225. 9" CCW

Part

code

(DY)

R3723-070

Image

5-5.CONDENSER DRYER

5-6.CONDENSER COIL

5-7. CONDENSER FAN BLADE

Page 47

5-8. CONDENSER FAN MOTOR

MODEL

BSR23

BSR49

BSF23

BSF49

Voltage

115V/60Hz

Motor Model

DAI-8204DYCA

Part

code

(DY)

R7423-311

Image

MODEL

BSR23

BSR49

BSF23

BSF49

Spec

SBHGI. T2.0*164

Part

code

(DY)

R3313-260

Image

MODEL

BSR23

BSR49

BSF23

BSF49

Voltage

115V/60Hz

Motor Model

DAI-8204DYCA-1

Part

code

(DY)

R7423-301

Image

5-9. CONDENSER FAN MOTOR BRACKET

5-10.EVAPORATOR FAN MOTOR

Page 48

5-11.EVAPORATOR COIL

MODEL

BSR23

BSR49

BSF23G

BSF49

Spec

CU+AL

CU+AL

CU+AL

CU+AL

Part

code

(DY)

R8613-354

R8613-343

R2263-038

R2263-047

Image

MODEL

BSR23

BSR49

BSF23

BSF49

Voltage

115V/60Hz

Spec

-

445W

600W

Part

code

(DY) - R7303-402

R7303-412

Image

MODEL

BSR23

BSR49

BSF23

BSF49

Spec

8". C.C.W

Part

code

(DY)

R3729-010

Image

5-12. EVAPORATOR DEFROST HEATER

5-13. FAN BLADE

Page 49

5-14. EVAPORATOR FAN GUARD

MODEL

BSR23

BSR49

BSF23

BSF49

Spec

HIPS (VH-1800EX)

Part

code

(DY)

R3812-141

Image

MODEL

BSR23

BSR49

BSF23

BSF49

Spec

STS-304. T1.0*120*90

Part

code

(DY)

R3204-360

Image

MODEL

BSR23, BSR49

BSF23, BSF49

Voltage

115V/60Hz

Part

code

(DY)

R725A-130

R725A-130

Image

MODEL

BSR23

BSR49

BSF23

BSF49

Spec

88 SEGMENT. ℉

Part

code

(DY)

R7113-210

Image

5-15. EVAPORATOR FAN MOTOR BRACKET

5-16. MAIN PCB

5-17. DISPLAY PCB

Page 50

5-18. INLAY CONTROL

MODEL

BSR23

BSR49

BSF23

BSF49

Spec

PC-SHEET

Part

code

(DY)

R511A-030

Image

MODEL

BSR23

BSR49

BSF23

BSF49

Spec

UL AWG 18

Part

cod

e

(DY)

R7523

-053

R7483

-033

R7483

-023

R7483

-014

Image

MODEL

BSR23

BSR49

BSF23

BSF49

Spec

BLK, SJT. L=3000mm.115V 15A

Part

code

(DY)

R729A-030

Image

MODEL

BSR23

BSR49

BSF23

BSF49

Spec

- -

Part

code

(DY)

-

-

R7253-052

R7253-052

Image

5-19. HARNESS RELAY

5-20. POWER CORD

5-21. EVAPORATOR THERMAL FUSE (BIMETAL)

Page 51

MODEL

BSR23

BSR49

BSF23

BSF49

Spec

-

-

YELLOW

Part

code

(DY)

- - R7213-082

Image

MODEL

BSR23

BSR49

BSF23

BSF49

Spec

- - BLACK. L=180mm

Part

code

(DY)

- - R7213-210

Image

MODEL

BSR23

BSR49

BSF23

BSF49

Spec

WHITE

WHITE

Part

code

(DY)

R7213-112

R7213-112

Image

MODEL

BSR23

BSR49

BSF23

BSF49

Spec

UL AWG 18

Part

code

(DY)

R7403-091

R7403-080

R7483-140

R7483-130

Image

5-22. TEMP-THERMISTOR, FRE

5-23. DEFROST SENSOR (D-SENSOR)

5-24. TEMP-DISPLAY SENSOR, REF

5-25. HARNESS SWITCH

Page 52

MODEL

BSR23

BSR49

BSF23

BSF49

Spec

23

49

23

49

Part

code

(DY)

R8119-080

R8199-070

R8119-080

R8199-070

Image

MODEL

BSR23

BSR49

BSF23

BSF49

Spec

ABS. BLK

ABS. BLK

ABS. BLK

ABS. BLK

Part

code

(DY)

R3743-060

R3742-070

R3743-060

R3742-070

Image

MODEL

BSR23

BSR49

BSF23

BSF49

Spec

PP.WHT

T2.0*40*569

PP.WHT

T2.0*40*657

PP.WHT

T2.0*40*569

PP.WHT

T2.0*40*657

Part

code

(DY)

R3853-230

R3853-240

R3853-230

R3853-240

Image

MODEL

BSR23

BSR49

BSF23

BSF49

Spec

PP.

T2.5*99*103

PP.

T2.5*93*180

PP.

T2.5*99*103

PP.

T2.5*93*180

Part

code

(DY)

R1154-010

R1154-020

R1154-010

R1154-020

Image

5-26. EVAPORATOR DRAIN WATER-ASSY

5-27. DRAIN PAN

5-28. DRAIN WICKING BAR

5-29. DRAIN WICKING KIT

Page 53

MODEL

BSR23

BSR49

BSF23

BSF49

Spec

-

-

115V 90W

115V 140W

Part

code

(DY)

-

-

R7303-174

R7303-184

Image

MODEL

BSR23

BSR49

BSF23

BSF49

Spec

PP. WHT

Part

code

(DY)

R3314-192

Image

MODEL

BSR23

BSR49

BSF23

BSF49F

Spec

SPCC 4"

Part

code

(DY)

R3323-240, R3323-230

Image

MODEL

BSR23

BSR49

BSF23

BSF49

Spec

WHITE. SP201R-9D

Part

code

(DY)

R7203-020

Image

5-30. HEATER DRAIN PAN

5-31. SENSOR BRACKET

5-32. CASTER

5-33. DOOR SWITCH

Page 54

MODEL

BSR23

BSR49

BSF23

BSF49

Spec

ZDC. ZCR

Part

code

(DY)

R3739-010

Image

MODEL

BSR23

BSR49

BSF23

BSF49

Spec

SL112A. 125V 15A

Part

code

(DY)

R7204-070

Image

MODEL

BSR23

BSR49

BSF23

BSF49

Spec

16 SET

32 SET

16 SET

32 SET

Part

code

(DY)

R8429-060

R8429-080

R8429-060

R8429-080

mage

MODEL

BSR23

BSR49

BSF23

BSF49

Spec

T1.2*930

Part

code

(DY)

R3373-630

Image

5-34. DOOR LOCK

5-35. POWER SWITCH

5-36. ASSY SHELF CLIP

5-37. SHELF STANDARD. L

Page 55

MODEL

BSR23

BSR49

BSF23

BSF49

Spec

RD-PVC.BLK

Part

code

(DY)

R338A-040

Image

MODEL

BSR23, BSR49, BSF23, BSF49

Spec

POM(FW700S) 45.5*31*8

POM(FW700S)

Part

code

(DY)

R375A-010 RH

R375A-020 LF

R375A-030 RH

R375A-040 LF

Image

MODEL

BSR23, BSR49, BSF23, BSF49

Spec

STS304 T=4.0

Part

code

(DY)

R828A-062 RH

R828A-052 LF

Image

5-38. DOOR GASKET

5-39. STOPPER HINGE/STOPPER DOOR

5-40. ASSY HINGE TOP

Page 56

MODEL

BSR23, BSR49, BSF23, BSF49

Spec

STS304 T=4.0

Part

code

(DY)

R828A-020 RH

R828A-030 LF

Image

MODEL

BSR23, BSR49, BSF23, BSF49

Spec

SUM24L(쾌삭강)+아연도금¢5*22

Part

code

(DY)

R412A-020

Image

5-41. ASSY HINGE BOTTOM

5-42. PIN TENSION

Page 57

5-43. BOTTOM GRILL

MODEL

BSR23

BSR49

BSF23

BSF49

Spec

STAINLESS

STAINLESS

STAINLESS

STAINLESS

Part

code

(DY)

R818A-310

R818A-300

R818A-310

R818A-300

Image

MODEL

BSR/F23, BSR/F49

BSR/F23, BSR/F49

BSR/F23, BSR/F49

Spec

SUM24L¢15*114

SW-C ¢2.3 WHITE

SW-C ¢2.3

Part

code

(DY)

R858A-410

R374A-020 RH

R374A-010 LF

Image

5-44. SHAFT TOP HINGE AS/SPRING DOOR

Page 58

5-45. ASSY CROSS BAR

MODEL

BSR23

BSF23

BSR49

BSF49

Spec

-

-

115V, 30W

115V, 38

Part

code

(DY)

-

-

R816A-280

R816A-290

Image

-

-

-

MODEL

BSR23

BSR49

BSF23

BSF49

Spec

BR1, BF1

RH, LF

BR1, BF1

RH, LF

Part

code

(DY)

R817A-340

R817A-340

R817A-330

R817A-340

R817A-340

R817A-330

Image

MODEL

BSR23

BSR49

BSF23

BSF49

SPEC

ZNDC 97*70*26

Part

Code

(DY)

R313A-011

Image

5-46. DOOR ASSY

5-47. BODY DOOR SPRING

Page 59

6. ELECTRONIC CONTROL INSTRUCTIONS

6-1. FREEZER CONTROL

6-1-1. HOW TO USE THE DISPLAY PCB PANEL

Page 60

6. ELECTRONIC CONTROL INSTRUCTIONS

NO

Function

Controlled

Part

Description

1

Initial

Operation

1. LED displays inside temperature.

2. Begins to run immediately if higher than 50℉ and

begins to run after 5 minutes pause if lower

than 50℉.

2

Temperatur

e

Control

Compressor

LED

1. The Temperature can be changed by pushing up/down

buttons.

2. LED displays inside temperature

3. Buzzer buzzes 1 time whenever a button is pressed

4. Compressor automatically turns on and off by C-sensor

(Except error mode)

5. Comp. On/off temperature at C-sensor (℉)

Setting5.03.01.0-1.0-2.0

Comp On86321

Comp Off20-3-4-5

Setting-3.0-5.0-7.0-9.0

Comp On0-2-4-6

Comp Off-6-7-9-10.5

3

Defrost

Function

Heater

Compressor

1) Defrost function is controlled time interval setting.

2) Factory setting is every 8 hours.

3) If it becomes defrost cycle time, Defrost heater is

operated when D-sensor senses below 23℉.

4) Defrost heater terminates when D-sensor temperature

comes to above 53℉, then compressor will start after

10 minutes.

5) During defrost period, LED displays dF.

6) If D-sensor does not cut off defrost heater, main pcb

has a back up for defrost time, the maximum is

40 minutes.

7) Defrost can be set by pushing the button for 3 seconds.

(3h, 6h, 9h, 10h(ah) )

4

Error

Display

LED

1) Press `up' button 3 times while pressing and holding

`down´ button.

Above procedure switches normal display to error

display mode. And then 88 LED indicates, `(D1)' or

`(F3)'

or `(C1)' respectively.

2) 10 seconds after the last button pressed, error display

mode will be switched to normal display mode.

6-1-2. FUNCTION TABLE & MANUAL DEFROST

Page 61

NO

Function

Relative

Model

Description

1

Forced "Df"

(To Force

the Defrost)

Freezer

1. Press both “UP” & “DN” keys simultaneously more

than 3 seconds.

2. “Df” will show up in the display.

3. Comp will stop.

4. Heater will turn on (Defrost heater, Drain Fan

Heater, and Hose Heater).

5. Room Fan will stop.

2

To Turn off

the Forced

Defrost

(To release

the Defrost)

Freezer ,

Refrigerator

1. Press both “UP” & “DN” keys simultaneously more

than 3 seconds.

2. Temperature will show up in the display with the

beep sounds.

3

Forced "Df"

(To Force

the Defrost)

Refrigerator

1. Press both “UP” & “DN” keys simultaneously more

than 3 seconds.

2. “Df” will show up in the display.

3. Comp will stop.

4. Room Fan will start.

4

To Change

the Defrost

Interval

Time

1. Press both “UP” & “DN” keys simultaneously more

than 3 seconds.

2. “Df” will show up in the display.

3. Press the “UP” key more than 3 seconds.

4. The current interval time will show up in the display

(Factory default setup will 8 Hr)

5. Press the “UP” key to change the interval to the

other (5Hr, 6Hr, 8Hr, 10Hr (aH).

Page 62

6. ELECTRONIC CONTROL INSTRUCTIONS

CODE

Content

Indicates

Refrigeration state

CO

C-sensor

- OPEN

- Normal operation

- Time control

Comp ON : 6 MINUTES

Comp OFF: 11 MINUTES

CS

- SHORT

(D1) (F3) (C1)

D-sensor

- OPEN

- SHORT

Sensor

Model

Role

Wire

Color

D-sensor

Freezer

Detect Evap coil's temp. to start and terminate

defrosting.

WHT

C-sensor

Freezer

Detect inside air temp. to operate comp and to

indicate the inside temp. on the display PCB

YELLOW

T-sensor

Refrigerator

Detect inside air temp. to indicate the inside temp on

the display PCB

WHT

6-1-3. ERROR CODE TABLE

6-1-4. SENSOR DESCRIPTION

Page 63

6. ELECTRONIC CONTROL INSTRUCTIONS

6-2. REFRIGERATOR CONTROL

6-2-1. HOW TO USE THE DISPLAY PCB PANEL

Page 64

6. ELECTRONIC CONTROL INSTRUCTIONS

NO

Function

Controlled

Part

Description

1

Initial

Operation

1. LED displays inside temperature.

2. Begins to run immediately if higher than 41℉ and

begin to run after 5 minutes pause if lower than 41℉.

2

Temperature

Control

Compressor

LED

2. LED displays inside temperature

3. Buzzer buzzes 1 time whenever a button is pressed

4. Compressor automatically turns on and off by C-sensor

(Except error mode)

5. Comp. On/off temperature at C-sensor(℉)

Setting 39 38 37 36 35

Comp On 42 41 40 39 38

Comp Off 36 35 34 33 32

Setting 34 32 30 28

Comp On 37 35 34 32

Comp Off 31 29 28 26

3

Error

Display

LED

1) Press `up' button 3 times while pressing and holding

`down´ button.

Above procedure switches normal display to error

display mode. And then 88 LED indicates, `(D1)' or

`(C1)' respectively.

2) 10 seconds after the last button pressed, error display

mode will be switched to normal display mode.

4

Defrost

Function

Compressor

1) Defrost can be set by pushing the button for 3

seconds. (3h, 6h, 9h, 10h(ah) )

2) While the compressor runs for over 3 hours, defrost

system will

automatically be driven without any additional control

order.

6-2-2. FUNCTION TABLE

Page 65

NO

Description

4

How to control the

Defrost interval

1. Press the Up key for 3 seconds.

2. The Defrost interval currently set will be displayed

(Factory default : 8H).

3. Select the other interval by pushing the Up Key.

(5H → 6H → 8H → 5H in rotation)

4. Leaving it untouched for 3 seconds will

resume the normal operation.

5

Forced Defrost

1. Press Up/Down simultaneously for 3 seconds to activate

the

Defrost manually.

2. The 'dF" will get displayed and the defrost will start.

3. To change or see the Defrost duration, press Up key.

4. Leaving the Key untouched for 3seconds will

resume the letter "dF"

5. To deactivate the Defrost press the Up/Down key

simultaneously for 3seconds. Otherwise the defrost will]

continue for the duration set in 3).

6

How to change the

setup of Box Heater

Control (Power

Duration)

1. Press the Down key for 3 seconds to activate the setup.

2. The initial control value will be displayed (Default value : 1)

3. Change the value by pressing the Down Key

(1->2->3->4->1 in rotation)

4. The temperature will be displayed 3seconds after leaving the

key untouched.

Meaning :

1-> On 10 min. / Off 10 min.

2-> On 15 min. / Off 10 min.

3-> On 20 min. / Off 10 min.

4-> On 25 min. / Off 15 min.

Page 66

6. ELECTRONIC CONTROL INSTRUCTIONS

CODE

Content

Indicates

Refrigeration state

tO

T-sensor

- OPEN

- Normal operation

- Time control

Comp ON : 18 MINUTES

Comp OFF : 6 MINUTES

ts

- SHORT

(D1)

C-sensor

- OPEN

(C1)

- SHORT

6-2-3. ERROR CODE

Page 67

7. REPLACEMENT OF MAIN COMPONENTS

■ CAUTION

- DISCONNECT FROM POWER SOURCE BEFORE SERVICING

7-1. TOP PANEL PARTS

- MAIN PCB

- LOCK ASSEMBLY or POWER SWITCH

- DOOR SWITCH

A. Remove the screws located on top grill panel.

.

Page 68

7. REPLACEMENT OF MAIN COMPONENTS

■ CAUTION

- DISCONNECT FROM POWER SOURCE BEFORE SERVICING

B. Remove the screws located on bottom of top panel.

# caution : When unscrewing, hold the top panel.

POWER TRANSFORMER

C. Place the top panel on top of the cabinet.

Page 69

7. REPLACEMENT OF MAIN COMPONENTS

■ CAUTION

- DISCONNECT FROM POWER SOURCE BEFORE SERVICING

E. Pull out the harness located on back of top panel.

You can separate top panel out of the unit.

You can replace power switch, lamp switch and display PCB.

Page 70

7. REPLACEMENT OF MAIN COMPONENTS

■ CAUTION

- DISCONNECT FROM POWER SOURCE BEFORE SERVICING

7-2. REPLACING DOOR

A. Disassemble top panel as described section 6-1 A,B

B. Remove bottom grill by unscrewing the four screws located on each side

of bottom grill.

C. Open the capacitor cover.

■ CAUTION

Page 71

7. REPLACEMENT OF MAIN COMPONENTS

■ CAUTION

- DISCONNECT FROM POWER SOURCE BEFORE SERVICING

D. Remove the hinge.

Page 72

7. REPLACEMENT OF MAIN COMPONENTS

■ CAUTION

- DISCONNECT FROM POWER SOURCE BEFORE SERVICING

PIN TENSION

PIN HINGE TOP

ASSY

HINGE

TOP

TOOL

DOOR

HINGE

SCREW

ASSY HINGE TOP

TOOL

REMOVER

7-3. DOOR SPRING ADJUSTMENT

A. Detailed structure of DOOR HINGE

B. Coordinated principle od DOOR TENSION

After Putting Tool for revolving DOOR-HINGE STOP-PIN HOLE, Insert

Door Hinge STOP-PIN into the hole after revolving up to the requested

TENSION.

Page 73

■ CAUTION

- DISCONNECT FROM POWER SOURCE BEFORE SERVICING

7. REPLACEMENT OF MAIN COMPONENTS

C. Remove the door hinge stop pin.

D. Place the door hinge stop pin and adjust the strength of the door spring.

Page 74

7. REPLACEMENT OF MAIN COMPONENTS

7-4.REFRIGERATION COMPARTMENT'S PARTS

- EVAPORATOR FAN MOTOR

- EVAPORATOR DEFROST HEATER

- EVAPORATOR COIL

- D-SENSOR, C-SENSOR, T-SENSOR

? DRAIN HOSE HEATER

A. Disassemble lamp shield

B. Disassemble Evaporator Panel

Page 75

7. REPLACEMENT OF MAIN COMPONENTS

C. Pull out the lamp

D. Replacing evaporator fan motor.

A-1. Disconnect the fan motor's harness.

A-2. Remove the four screws that are located on bottom of fan motor.

Page 76

7. REPLACEMENT OF MAIN COMPONENTS

E. Replacing sensor

E-1. FREEZER C-sensor : Remove as illustrated below and pull-out the

FREEZER C-sensor from the cover.

E-2. FREEZER D-sensor

Page 77

7. REPLACEMENT OF MAIN COMPONENTS

F. Drain hose heater

F-1. After separating Evaporator cover from the freezer, set aside the screws.

F-2. Pull out the heater for drain hose from the Evaporator.

Cover and eliminate it with care in the direction of front side.

F-3. Install the new heater for drain hose in reverse order.

Page 78

7. REPLACEMENT OF MAIN COMPONENTS

1. Open Door

2. Removal Screw

3. Screw The Front

7-5. UNIT - PARTS

A. How to replace the COMPRESSOR, its Parts and Refrigerant.

A-1. Remove the Mounting Screws from the sides of the front BOTTOM GRILL.

A-2. Remove the BOTTOM GRILLE as the picture

Page 79

7. REPLACEMENT OF MAIN COMPONENTS

A-3. Remove the front Screws for the UNIT BASE.

A-4. Pull out the UNIT BASE to the front side.

Page 80

7. REPLACEMENT OF MAIN COMPONENTS

A-5. Remove the pipe connected to the COMPRESSOR.

A-6. Remove the COMPRESSOR Mounting SCREWs, Replace the COMPRESSOR

and weld the piping.

Page 81

7. REPLACEMENT OF MAIN COMPONENTS

A-7. Remove the side Cover of the COMPRESSOR.

A-8. Replace the O.L.P/PTC RELAYS.

Page 82

7. REPLACEMENT OF MAIN COMPONENTS

A-9. Vacuum the Pipe at least 30 ~ 40 minutes and make enough vacuum.

A-10. Fill up the Refrigerant in the volume set forth in the service manual.

A-11. After the refrigerat is filled up, check any gas leakage with soap bubbles.

A-12. Put all the parts together in the retro sequence of the disassembly.

Page 83

7. REPLACEMENT OF MAIN COMPONENTS

B. BALLAST

1. Remove four screws securing the sign frame end separate sign frame end.

2. Separate connector of the Ballast.

3. Remove two screws for separating the Ballast.

Page 84

8. PART-LIST

R23 F23 R49 F49 23G 49G 72R 72F

CAST ER M OVE R3323-230 SPCC 4" 2 2 2 2 2 2 3 3

CAST ER STOP R3323-240 SPCC 4" 2 2 2 2 2 2 3 3

COMPRESSOR R7439-600 SC18CLX2 1 1

COMPRESSOR R714A-020 GS26CLX 1

COMPRESSOR R7439-110 SK1A1C-L2W 1 1 1 1

COMPRESSOR R7439-360 CAJ4476 1

STARTING CAPACIT OR R7549-270 160VAC 145㎌ 1 1 1 1

STARTING CAPACIT OR R7549-280 125~165AC 410㎌ 1

RUNNING CAPACITOR R7549-260 230VAC 15㎌ 1 1 1 1

RUNNING CAPACITOR R7549-290 280VAC 23.5㎌

HARNESS RELAY A R7483-023 UL AWG 18 1

HARNESS RELAY B R7523-053 UL AWG 18 1

HARNESS RELAY C R7483-014 UL AWG 18 1

HARNESS RELAY D R7483-033 UL AWG 18 1

HARNESS RELAY E R719A-290 UL AWG 18 1

HARNESS RELAY F R719A-280 UL AWG 18 1

HARNESS RELAY GA R7483-051 UL AWG 18 1

HARNESS RELAY GB R7483-062 UL AWG 18 1

POWER-CORD R729A-030 SJT . L=2950mm. 115V 15A 1 1 1 1 1 1 1

POWER-CORD R8393-010 BLK, 12-4 SJT L=3050 1

CONDENSER COIL R2202-031 S WST ¢4.76*13190 1 1 1 1

CONDENSER COIL PIN R2272-030 CU,545*270*140 1

PIN-CONDENSER R2273-013 S49F 1 1

PIN-CONDENSER R2273-021 S49RG 1

DRYER R2183-032 25.4*169*0.635 1 1 1 1

DRYER ASSY R2183-200 ¢25.73*0.8T*169. CU-PIPE 1 1 1 1

CONDENSER FAN M OTOR R7423-311 AC 115V 60HZ DAI-8204DYCA CW 1 1 1 1 1 1 1 2

CONDENSER FAN BLADE R3723-070 AL ¢225 9" CCW 1 1 1 1 1 1 1 2

CONDENSER FAN M OTOR BRACKET R3313-260 SBHGI-0 T2.0*164 1 1 1 1 1 1 1 2

EVAPORATOR DRAIN WATER SMALL R3743-060 ABS BLK (30211L0700) 1 1 1

CLOT H WICKING DRAIN WATER R110A-010 부직포, T=2.5*480*120 8 8

DRAIN PAN R3742-070 ABS BLK (3011J0102) 1 1 1

DRAIN WICKING BAR R3853-230 PP WHT T2.0*40*569 1 1 1

DRAIN WICKING BAR R3853-240 PP WHT T2.0*40*657 1 1 1

GUIDE WICKING R3853-780 PP(WHITE). 1.5T*269*40 2 2

DRAIN WICKING KIT R1154-010 PP T2.5*99*103 1 1 1

CASE VAPORI T49 R3422-012 ABS. 602.5*275*106.5 1 1

CONDENSER FAN

DRAIN

Par t na m e

Code

De s cr ipti on

CAST ER BOX ASSY

COMPRESSOR

CONDENSER

Sol id / Gla s s

Page 85

R23 F23 R49 49F 23G 49G 72R 72F

EVAPORATOR COIL (EVAPORATOR) R2263-047 CU+AL

EVAPORATOR COIL (EVAPORATOR ASSY) R8613-343 CU+AL

EVAPORATOR COIL (EVAPORATOR) R2263-038 CU+AL 1 1

EVAPORATOR COIL (EVAPORATOR ASSY) R8613-354 AL 1

ASSY EVA B72R R840A-020 AL 1

ASSY EVA B72F R840A-030 CU+AL 1

DEFROST HEAT ER R7303-412 UL 115V 600W 1

DEFROST HEAT ER R7303-402 UL 115V 445W 1

DEFROST HEAT ER 60 R7313-440 115V 900W 14.7Ω 1

HEATE R DRAIN PAN R7303-184 115V 140W 1

HEATE R DRAIN PAN R7303-174 115V 90W 1

HEATE R DRAIN PAN (GST-60TF) R7313-431 115V 90W 1

SEN SOR BRACKET R3314-192 P.P, WHT 2 2 2 1 1 2 2 2

EVAPORATOR THERMAL FUSE (BIM ET AL) R7253-052 1 1

EVAPORATOR FAN MOTOR R7423-301 AC 115V 60HZ DAI-8204DYCA-1 CCW 1 1 1 2 1 2 2 2

FAN BLADE R3729-010 8" C.C.W 1 1 1 2 1 2 2 2

EVAPORATOR FAN MOTOR BRACKET R3204-360 STS-304 T1.0*120*90 1 1 1 2 1 2 2 2

TEMP-T HERMISTOR,FRE R7213-082 YEL LOW 1 1 1

DEFROST SENSOR (D-SENSOR) R7213-210 BLACK. L=180mm 1 1 1

TEMP-DISPLAY SENSOR,REF R7213-112 WHITE 1 1 1 1 1

ASSY GRILL TOP R818A-340 STAINLESS 1 1

TOP GRILL ASSY R8182-200 STAINLESS 1

ASSY GRILL TOP R818A-350 STAINLESS 1 1

TOP GRILL ASSY R8182-510 STAINLESS 1

TOP GRILLE AS B72 R858A-560 STAINLESS 1 1

MASCOT (BLUE AIR) R514A-031 T 3.8 *90*64 1 1 1 1 1 1 1 1

FREEZER MAIN PCB R725A-130 FRE. 115V 1 1 1

REFRIGERAT OR MAIN PCB R725A-120 REF. 115V 1 1 1

REFRIGERAT OR MAIN PCB R7109-770 REF. 115V 1 1

CONT ROL BOARD (DIGITAL DISPLAY) R4142-122 ABS,BLACK. T2*242*72 1 1 1 1 1 1 1 1

DISPLAY PCB (℉) R7113-210 88 SEGM ENT. ℉ 1 1 1 1 1 1

INLAY CONT ROL R511A-010 PC-SHEET 1 1 1 1 1 1

SUPPORTER C3379-240 DSAA-9N 4 4 4 4 4 4

POWER RELAY R7253-060 OMRON G7L-1A-T UB 1 1

DOOR SWITCH R7203-020 WHT. SP201R-9D 1 1 2 2 1 2

HARNESS SWITCH A R7403-080 UL, AWG 18 1

HARNESS SWITCH B R7403-091 UL, AWG 18 1

HARNESS SWITCH C R7483-131 UL, AWG 18 1 1

HARNESS SWITCH D R7483-140 UL, AWG 18 1 1

HARNESS SWITCH B72 R719A-300 1 1

DOOR LOCK R3739-010 ZDC, ZCR 1 1 2 2 1 2 3 3

EVAPORATOR

TOP PANEL

De s cr ipti on

Sol id / Gla s s

Par t na m e

Code

Page 86

R23 F23 R49 F49 23G 49G 72R 72F

ASSY GRILLE BOTTOM R818A-310 ST AINLESS 1 1

ASSY GRILLE BOTTOM R818A-300 ST AINLESS 1 1

BOTT OM GRILL ASSY R8182-380 ST AINLESS 1

BOTT OM GRILL ASSY R8182-520 ST AINLESS 1

BOTT OM GRILL ASSY R858A-400 ST AINLE SS 1 1

ASSY SHELF CLIP R8429-080 32 SET 1 1 1

ASSY SHELF CLIP R8429-060 16 SET 1 1 1

ASSY SHELF CLIP R835A-020 50SET 1 1

SHELF ST ANDARD, L R3373-630 T1.2*930mm 4 4 8 8 4 8 8 8

ASSY DOOR RH-BM R817A-340 ST AINLESS 1 1 1 1 2 2

ASSY DOOR LF-BM R817A-330 ST AINLESS 1 1 1 1

GLASS DOOR ASSY R8172-670 GLASS 1

DOOR ASSY RH R8172-640 GLASS 1

DOOR ASSY LF R8172-630 GLASS 1

GASKET DOOR BM R338A-040 RD-PVC BLACK 1 1 2 2 3 3

DOOR GASKET, ASSY R3903-552 RD-PVC BLACK 1 2

ASSY CROSS BAR R816A-280 115V 30W 1 2

ASSY CROSS BAR R816A-290 115V 38W 1 2

ASSY HINGE T OP RH R828A-062 ST S304- T=4.0 1 1 1 1 2 2

ASSY HINGE T OP LF R828A-052 ST S304- T =4.0 1 1 1 1

SHAFT T OP HINGE AS R858A-410 SUM24L Ø15*114 1 1 2 2 3 3

PIN T ENSION R412A-020 SUM24L Ø5*22 1 1 2 2 3 3

ASSY HINGE BOT TOM RH R828A-020 ST S304 T=4.0 1 1 1 1 1 1

ASSY HINGE BOT TOM LF R828A-030 ST S304 T=4.0 1 1 1 1

ASSY HINGE BOT TOM MID R828A-040 ST S304 T=4.0 1 1

STOPPER HINGE LF R375A-020 POM (FW700S) 45.5*31*8 1 1 1 1

STOPPER HINGE RH R375A-010 POM (FW700S) 45.5*31*8 1 1 1 1 2 2

STOPPER DOOR RH R375A-030 POM (FW700S) 1 1 1 1 2 2

STOPPER DOOR LF R375A-040 POM (FW700S) 1 1 1 1

DOOR HINGE BOTT OM RH R3393-341 T10*48*64*63 ZDC 2 1 1

DOOR HINGE BOTT OM LF R3393-351 T10*48*64*63 ZDC 2 1

DOOR HINGE TOP R3393-312 T 10*48*64*63 ZDC 2 1 2

DOOR HINGE STOP PIN R3044-040 STS304 ¢3*30 1 2

LAM P BULB R7394-010 25T 10/120V 25W 1 1 1 1 2 2

FLUORESCENT LAMP R7393-150 32W 1 1

BALLAST R7553-050 115V 60HZ 32W 1 1

EVAPORATOR FAN (M OTOR) GUARD

R3812-141 HIPS (VH-1800EX) 1 1 1 2 1 2 2 2

KEY SET S R3739-010 ZDC, ZCR 1 1 2 2 1 2 3 3

POWER SWITCH R7204-070 SL112A, 125V 15A 1 1 1 1 2 2 1 1

BOTT OM GRILL

SHELF

Par t na m e

DOOR

Sol id / Gla s s

Code

De s cr ipti on

LAM P

FLUORESCENT LAMP

Loading...

Loading...