Page 1

WELLS MANUFACTURING

10 Sunnen Dr., St. Louis, MO 63143

telephone: 314-678-6314

fax: 314-781-2714

www.wellsbloomfield.com

OWNERS MANUAL

BAKING OVEN

FILTRATION ACCESSORY

MODEL

WOV35-SW

526

Manual Includes

INSTALLATION

IL2948

USE & CARE

EXPLODED VIEW

PARTS LIST

WIRING DIAGRAM

IMPORTANT: DO NOT DISCARD THIS MANUAL

This manual is considered to be part of the appliance and is to be given to the OWNER or

MANAGER of the restaurant, or to the person responsible for TRAINING OPERATORS of

this appliance. Additional manuals are available from your WELLS DEALER.

THIS MANUAL MUST BE READ AND UNDERSTOOD BY ALL PERSONS USING OR

INSTALLING THIS APPLIANCE. Contact your WELLS DEALER if you have any

questions concerning installation, operation or maintenance of this equipment.

p/n 2M-Z17443, Rev. A M526 150717

Page 2

LIMITED WARRANTY STATEMENT

Unless otherwise specied, all commercial cooking

equipment manufactured by Wells Manufacturing is

warranted against defects in materials and workmanship

for a period of one year from the date of original installation

or 18 months from the date of shipment from our factory,

whichever comes rst, and is for the benet of the original

purchaser only.

THIS WARRANTY IS THE COMPLETE AND ONLY

WARRANTY, EXPRESSED OR IMPLIED IN LAW

OR IN FACT, INCLUDING BUT NOT LIMITED TO,

WARRANTIES OF MERCHANTABILITY OR FITNESS

FOR ANY PARTICULAR PURPOSE, AND/OR FOR

DIRECT, INDIRECT OR CONSEQUENTIAL DAMAGES

IN CONNECTION WITH WELLS PRODUCTS. This

warranty is void if it is determined that, upon inspection by an

authorized service agency, the equipment has been modied,

misused, misapplied, improperly installed, or damaged in

transit or by re, ood or act of God. It also does not apply

if the serial nameplate has been removed, or if service is

performed by unauthorized personnel. The prices charged

by Wells Manufacturing for its products are based upon the

limitations in this warranty. Seller’s obligation under this

warranty is limited to the repair of defects without charge by

a Wells Manufacturing factory authorized service agency

or one of its sub-service agencies. This service will be

provided on customer’s premises for non-portable models.

Portable models (a device with a cord and plug) must be

taken or shipped to the closest authorized service agency,

transportation charges prepaid, for service. In addition to

restrictions contained in this warranty, specic limitations are

shown in the Service Policy and Procedure Guide. Wells

Manufacturing authorized service agencies are located in

principal cities. This warranty is valid in the United States

and Canada and void elsewhere. Please consult your

classied telephone directory, your food-service equipment

dealer or contact:

Wells Manufacturing

10 Sunnen Dr., St. Louis MO 63143 USA

phone (314) 678-6314 or fax (314) 781-2714

for information and other details concerning warranty.

SERVICE POLICY AND PROCEDURE GUIDE and ADDITIONAL WARRANTY EXCLUSIONS

1. Resetting of safety thermostats, circuit breakers, over

load protectors, and/or fuse replacements are not

covered by this warranty unless warranted conditions

are the cause.

2. All problems due to operation at voltages or phase

other than specied on equipment nameplates are

not covered by this warranty.

Conversion to correct voltage and/or phase must be

the customer’s responsibility.

3. All problems due to electrical connections not made

in accordance with electrical code requirements

and wiring diagrams supplied with the equipment are

not covered by this warranty.

4. Replacement of items subject to normal wear, to

include such items as knobs, light bulbs; and, normal

maintenance functions including adjustments of

thermostats, adjustment of micro switches and

replacement of fuses and indicating lights are not

covered by warranty.

5. Damage to electrical cords and/or plug due to exposure

to excessive heat are not covered by this warranty.

6. Full use, care, and maintenance instructions supplied

with each machine. Noted maintenance and

preventative maintenance items, such as servicing and

cleaning schedules, are customer responsibility. Those

miscellaneous adjustments noted are customer

responsibility. Proper attention to preventative

maintenance and scheduled maintenance procedures

will prolong the life of the appliance.

7. Travel mileage is limited to sixty (60) miles from an

Authorized Service Agency or one of its sub-service

agencies.

8. All labor shall be performed during regular working

hours. Overtime premium will be charged to the buyer.

9. All genuine Wells replacement parts are warranted

for ninety (90) days from date of purchase on non-

warranty equipment. This parts warranty is limited only

to replacement of the defective part(s). Any use of

non-genuine Wells parts completely voids any

warranty.

10. Installation, labor, and job check-outs are not

considered warranty and are thus not covered by this

warranty.

11. Charges incurred by delays, waiting time or operating

restrictions that hinder the service technician’s ability to

perform service are not covered by warranty. This

includes institutional and correctional facilities.

SHIPPING DAMAGE CLAIM PROCEDURE

NOTE: For your protection, please note that equipment

in this shipment was carefully inspected and packaged

by skilled personnel before leaving the factory. Upon

acceptance of this shipment, the transportation company

assumes full responsibility for its safe delivery.

IF SHIPMENT ARRIVES DAMAGED:

1. VISIBLE LOSS OR DAMAGE: Be certain that any

visible loss or damage is noted on the freight bill or

express receipt, and that the note of loss or damage is

signed by the delivery person.

2. FILE CLAIM FOR DAMAGE IMMEDIATELY:

Regardless of the extent of the damage.

3. CONCEALED LOSS OR DAMAGE: if damage is

unnoticed until the merchandise is unpacked, notify the

transportation company or carrier immediately, and le

“CONCEALED DAMAGE” claim with them. This

should be done within fteen (15) days from the date

the delivery was made to you. Be sure to retain the

container for inspection.

Wells Manufacturing cannot assume liability for damage or

loss incurred in transit. We will, however, at your request,

supply you with the necessary documents to support your

claim.

xi

Page 3

TABLE OF CONTENTS

WARRANTY xi

ELECTRICAL SPECIFICATIONS 1

WARNINGS - ENGLISH 2

WARNINGS - FRENCH 3

CLEARANCES 4

FEATURES & OPERATING CONTROLS 4-5

PRECAUTIONS & GENERAL INFORMATION 6

AGENCY LISTING INFORMATION 7

INSTALLATION 7

Unpacking & inspecting 7

Filter Installation 8

OPERATION 9

CLEANING INSTRUCTIONS 10

WIRING DIAGRAM 11

EXPLODED VIEW & PARTS LIST 12 - 14

PARTS & SERVICE 15

CUSTOMER SERVICE DATA 15

INTRODUCTION

Thank You for purchasing this Wells Manufacturing appliance.

Proper installation, professional operation and consistent maintenance of this appliance will ensure

that it gives you the very best performance and a long, economical service life.

This manual contains information and instructions for the oven lter system, its use and care.

For information regarding cooking appliance(s), please refer to the manufacturer’s operation manual.

ELECTRICAL SPECIFICATIONS

Model Voltage Amps

WOV35-SW

120V 1.0

230V 0.56 270 CFM 8ft. IEC, CEE-7 Euro

Horse

Power

Kilowatts

1/12 0.12

This appliance is intended for use with ovens preparing baked goods and other food products

that do not produce grease laden vapors above the threshold established by NFPA 96 the

Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations.

Typical

Airow

290 CFM

Clearance to

Combustibles

N/A

Cord & Plug

6 ft. NEMA 5-15P

M526 p/n 2M-Z17443 OpM WOV35-SW- Oven Mounted Filtration

1

Page 4

WARNINGS - ENGLISH

IMPORTANT: DO NOT DISCARD THIS MANUAL

This manual is considered to be part of the appliance and is to be given to the OWNER or

MANAGER of the restaurant, or to the person responsible for TRAINING OPERATORS of this

appliance. Additional manuals are available from your WELLS DEALER.

THIS MANUAL MUST BE READ AND UNDERSTOOD BY ALL PERSONS USING OR INSTALLING THIS

APPLIANCE. Contact your WELLS DEALER if you have any questions concerning installation, operation

or maintenance of this equipment.

DANGER:

SUFFOCATION HAZARD

“Do not attempt to use this lter with gasred units. This lter will not remove

products of combustion. Unvented exhaust

gases can be deadly.”

WARNING:

SHOCK HAZARD

All servicing requiring access to non-insulated

electrical components must be performed by

a factory authorized technician.

DO NOT open any access panel which

requires the use of tools. Failure to follow this

warning can result in severe electrical shock.

WARNING:

RISK OF INJURY

Installation procedures must be performed by

a qualied technician with full knowledge of all

applicable electrical codes. Failure can result

in personal injury and property damage.

WARNING:

DO NOT attempt to wash the PLEATED /

CHARCOAL lter pack or pre-lter. Water

absorption will render the lter unusable.

Use of a wet or clogged lter will cause the

ltration system to shut down. Use only

new, clean Wells® Authorized Service Parts.

Keep spare lter packs on hand to avoid

disruptions.

Service Department 1-314-678-6314.

Exposed surfaces can be hot to the touch and

may cause burns. Allow unit to cool before

cleaning or servicing.

M526 p/n 2M-Z17443 OpM WOV35-SW- Oven Mounted Filtration

2

Page 5

WARNINGS - FRENCH

IMPORTANT : NE JETEZ PAS CE MANUEL

Ce manuel fait partie intégrante de l’appareil et doit être remis au PROPRIÉTAIRE, au GÉRANT

du restaurant ou au responsable de la FORMATION DES UTILISATEURS. Des manuels

supplémentaires sont disponibles auprès de votre concessionnaire WELLS.

TOUTE PERSONNE INSTALLANT OU UTILISANT CET APPAREIL DOIT LIRE CE MANUEL ET

S’ASSURER DE L’AVOIR COMPRIS.

Veuillez contacter votre CONCESSIONNAIRE WELLS pour toute question concernant

l’installation, l’utilisation ou l’entretien de cet équipement.

DANGER :

RISQUE DE SUFFOCATION

“Ce ltration ne doit pas être utilisé avec

des appareils à gaz. Il n’absorbe pas les

produits de combustion. En l’absence de

sortie d’aération, les gaz de combustion

peuvent être mortels.”

AVERTISSEMENT :

RISQUE DE DÉCHARGE ÉLECTRIQUE

Toute intervention nécessitant d’accéder à des

composants électriques non isolés doit être

effectuée par un technicien agréé usine.

N’ouvrez AUCUN panneau d’accès nécessitant

l’utilisation d’un outil. Le non-respect de cet

avertissement peut exposer à une décharge

électrique sévère.

AVERTISSEMENT :

RISQUE DE BLESSURE

Les procédures d’installation doivent être

effectuées par un technicien qualié ayant pleine

connaissance des réglementations applicables. Le

non-respect de cet avertissement peut provoquer

des blessures et des dommages matériels.

AVERTISSEMENT :

N’essayez PAS de nettoyer le ltre ou le pré-ltre

plissé ou à CHARBON. L’eau absorbée rendrait

le ltre inutilisable. Un ltre humide ou colmaté

provoque l’arrêt du système de ltration. Utilisez

uniquement des pièces neuves et propres,

homologuées par Wells®. Conservez des

ltres de rechange pour éviter l’interruption du

fonctionnement.

Service clientèle : +1-314-678-6314.

M526 p/n 2M-Z17443 OpM WOV35-SW- Oven Mounted Filtration

3

Page 6

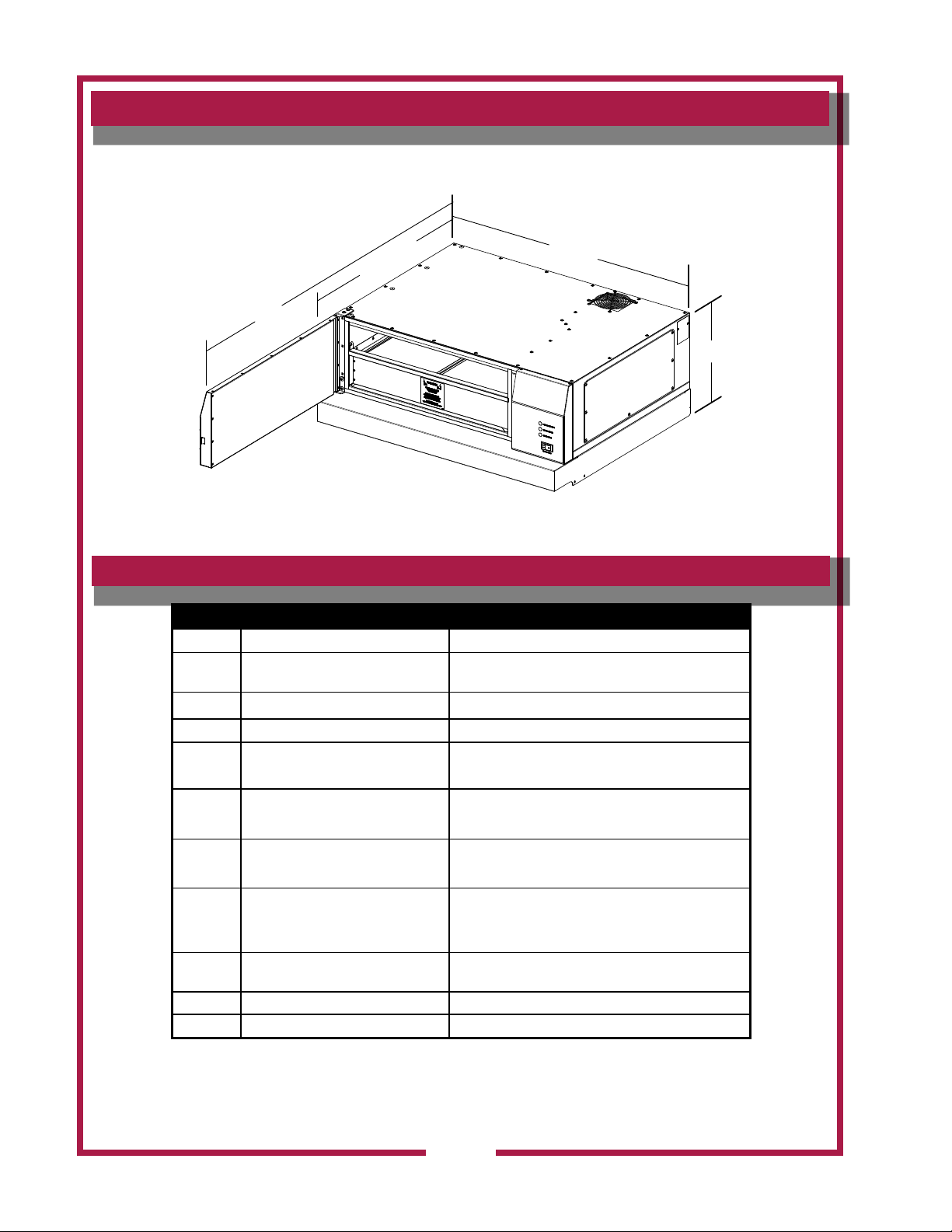

CLEARANCES

35 3/8”

29 7/16”

53”

14 1/2”

IL2949

FEATURES & OPERATING CONTROLS

FEATURES & OPERATION CONTROLS

ITEM NO DESCRIPTION COMMENT

1 VENTILATOR EXHAUST DUCT TOP

2 VENTILATOR FAN Provides air movement for ventilation

3 INDICATOR LIGHTS Filter Condition Indicator

4 POWER SWITCH Energizes System

HI-EFFICIENCY PLEATED / CHAR-

5

COAL FILTER PACK

6 FILTER PACK SWITCH

7 UNIT SHUT-DOWN SWITCH

8 FILTER INTERLOCK SWITCHES

9 EQUIPMENT SHUT-DOWN RELAY Oven Interface Electrical Connection

10 POWER INLET Cord Assembly Entrance

Exit point for ventilator airow - on top of unit.

DO NOT BLOCK

Removes smoke & cooking odors

Monitors the lter pack and indicates when it needs

replacing, if ignored it will lead to unit shut down

Shuts down the unit and appliances when the lack of

air ow reaches a certain level, triggers a service unit

indicator.

Proper installation of bafe lter and lter pack closes

these switches in ventilator sensor circuit

M526 p/n 2M-Z17443 OpM WOV35-SW- Oven Mounted Filtration

4

Page 7

FEATURES & OPERATING CONTROLS

1

2

5

3

4

FRONT

M526 p/n 2M-Z17443 OpM WOV35-SW- Oven Mounted Filtration

Baking Oven Filtration Operating Features & Controls

6

7

8

IL2950a

9

10

5

Page 8

PRECAUTIONS AND GENERAL INFORMATION

This lter system is part of an engineered system and is intended for

use in commercial establishments only.

This lter system is intended

DANGER:

SUFFOCATION HAZARD

Do not attempt to use this

lter system with gas-red

units.

This ltration system will

not remove products of

combustion. Unvented

exhaust gases can be deadly.

WARNING:

SHOCK HAZARD

All servicing requiring

access to non-insulated

electrical components must

be performed by a factory

authorized technician.

DO NOT open any access

panel which requires the use

of tools. Failure to follow this

warning can result in severe

electrical shock.

IMPORTANT:

The lter system is disabled

when the lters are plugged

to the point of insufcient

airow for proper operation.

It is the responsibility of

the store management to

maintain sufcient spares of

lter packs.

Spare lters can be

purchased from any

authorized Wells servicer or

calling Wells.

in the preparation of food for human consumption. No other use is

recommended or authorized by the manufacturer or its agents.

Operators of this appliance must be familiar with the appliance use,

limitations and associated restrictions. Operating instructions must be

read and understood by all persons using or installing this appliance.

This lter system is designed to reduce odor emissions, but will not

completely eliminate all cooking odors.

This appliance is intended for use with ovens preparing baked

goods and other food products that do not produce grease laden

vapors above the threshold established by NFPA 96 the Standard

for Ventilation Control and Fire Protection of Commercial Cooking

Operations.

Do not connect or energize this appliance until all installation

instructions are read and understood. Property damage or bodily

injury may result if these instructions are not followed. Disconnect this

appliance from electrical power before performing any maintenance or

servicing.

Cleanliness of this appliance is essential to good sanitation. Read and

follow all included cleaning instructions and schedules to ensure the

safety of the food product.

This appliance is not jet steam approved. Do not direct water jet or

steam jet at this appliance, or at any control panel or wiring.

Do not splash or pour water on, in or over any controls, control panel or

wiring. Do not attempt to wash lter packs. Water will cause their

immediate failure and disable the lter.

Exposed surfaces of this appliance can be hot to the touch and may

cause burns.

Avoid storing ammable or combustible materials in, on or near the

lter system or associated cooking appliance.

The technical content of this manual, including any wiring diagrams,

schematics, parts breakdown illustrations and/or adjustment

procedures, is intended for use by qualied technical personnel.

Any procedure which requires the use of tools must be performed by a

qualied technician.

All supplied instructions, diagrams, schematics, parts breakdown

illustrations, notices and labels must remain with the appliance if the

unit is sold or moved to another location.

This appliance is made in the USA. Unless otherwise noted, this

appliance has American sizes on all hardware.

for commercial establishments for use

M526 p/n 2M-Z17443 OpM WOV35-SW- Oven Mounted Filtration

6

Page 9

AGENCY LISTING INFORMATION

This appliance conforms to NSF Standard 4 for sanitation only if

installed in accordance with the supplied Installation Instructions

and operated and maintained in accordance with the instructions in this

manual.

This appliance is ETL listed.

3108971 3108971

INSTALLATION

UNPACKING & INSPECTION

Carefully remove the appliance from the carton. Remove all

protective plastic lm, packing materials and accessories from the

appliance before connecting electrical power or otherwise performing

any installation procedure.

Carefully read all instructions in this manual and any other documents

packed with the appliance before starting any installation.

All documentation should remain with the equipment operator for future

reference.

Read and understand all labels and diagrams attached to the unit.

Carefully account for all components and accessories before

discarding packing materials.

COMPONENTS

Charcoal Filter pack 1 ea.

Store these components in a convenient place for later use.

NOTE: DO NOT discard

the carton or other packing

materials until you have

inspected the appliance for

hidden damage and tested it

for proper operation.

Refer to SHIPPING DAMAGE

CLAIM PROCEDURE on the

inside front cover of this

manual.

WARNING:

RISK OF INJURY

Installation procedures must

be performed by a qualied

technician with full knowledge

of all applicable electrical

codes. Failure can result in

personal injury and property

damage.

M526 p/n 2M-Z17443 OpM WOV35-SW- Oven Mounted Filtration

7

Page 10

INSTALLATION

Filter Pack

p/n: WS-WL0652

(Arrows must point Up)

IL2951

FILTER INSTALLATION

Note air ow direction arrow on lter pack. Remove old lter pack

and slide new lter pack fully into the appropriate slot. Verify that

the airow direction arrow points up.

Use only genuine Wells replacement parts and lters,

call (314) 678-6314 or your authorized Wells service agent. Parts

supplied by others will void your warranty and may not provide safe

operation.

NOTE:

The FILTER PACK activates

position switches when they

are properly positioned. They

must be properly installed

for the lter blower to be

energized.

WARNING

CLEAN FILTERS

DO NOT attempt to wash the

lter pack. Water absorption

will render the lter unusable.

Use of a wet or clogged lter

will cause the system to shut

down. Use only clean Wells®

Authorized Service Parts.

Keep spare lter packs on

hand to avoid disruptions.

Wells Parts

Department (314) 678-6314.

8

M526 p/n 2M-Z17443 OpM WOV35-SW- Oven Mounted Filtration

Page 11

OPERATION

CAUTION:

HOT SURFACE

Exposed surfaces can be hot

to the touch and may cause

burns.

IMPORTANT:

The lter system cannot

operate if the lter pack is

removed or clogged.

It is the responsibility of

the store management to

maintain sufcient spares

of lter packs to avoid

prolonged shutdown of the

lter system when this lter is

expended.

Filter packs cannot be

cleaned.

Wells Manufacturing assumes

no liability for loss of business

due to lter related shutdown.

Filters that are not genuine

Wells Replacement Parts

may cause your unit to

operate incorrectly and you

will risk the possibility of

voiding your warranty.

Control Panel

NOTE: Cooking appliances must be operated in accordance with the

manufacturer’s instructions.

During normal operation, the illuminated power switch will be the only

light on the control panel that will be ON.

If the CHECK FILTERS light illuminates, check the FILTER PACK for

proper installation.

If the REPLACE FILTER PACK light illuminates, replace the FILTER

PACK.

NOTE: the REPLACE FILTERS PACK light is a warning that lter pack

is nearing the end of its service life. The lter will continue to operate

for a period of time after the REPLACE FILTER LIGHT turns ON to allow

continued operation through a peak period. However, lter pack must

be replaced within a short time period or it will clog, disabling the lter

system.

If the SERVICE REQUIRED light illuminates, the lter pack is restricted

to the point of insufcient airow for proper operation and the lter

system will shut down until the underlying clogged lter situation has

been corrected. Replace clogged item with a fresh lter to correct the

condition.

Reset the unit by turning FILTER SYSTEM POWER SWITCH to OFF,

then back to ON.

M526 p/n 2M-Z17443 OpM WOV35-SW- Oven Mounted Filtration

SERVICE REQUIRED

REPLACE FILTER

CHECK FILTER

HOOD POWER

IL2952

9

Page 12

CLEANING INSTRUCTIONS

CAUTION:

HOT SURFACE

Exposed surfaces can be hot

to the touch and may cause

burns. Allow unit to cool

before cleaning.

IMPORTANT:

DO NOT clean interior of lter

system by spraying.

Spraying can contaminate the

cooking appliance, and may

cause internal damage to the

air monitoring system.

Clean by wiping only.

PRECAUTIONS: Disconnect unit from electric power and allow to cool

FREQUENCY: Monthly

TOOLS: Mild detergent, clean non-abrasive towels

NOTE: Filter system is to be cleaned in conjunction with cooking

appliance. Refer to appliance user instructions for cleaning procedure.

1. TURN POWER SWITCH TO OFF.

2. Remove FILTER PACK.

3. Wipe interior with a clean cloth moistened with warm water and mild

detergent. Rinse by wiping with a clean cloth moistened with warm

water. DO NOT clean by spraying.

4. Dry lter system thoroughly with a clean non-abrasive cloth.

Reinstall FILTER PACK.

5. Uncover the cooking appliance and reconnect unit to electric power.

Procedure is complete

10

M526 p/n 2M-Z17443 OpM WOV35-SW- Oven Mounted Filtration

Page 13

WIRING DIAGRAM

4

WHITE

1

4

2

LIGHT

FILTERS

REPLACE

FILTER PACK

INTERLOCK

N.O.

COM.

12

AMBER

SWITCH

N.C.

3

N.C.

COM.

FILTER

SWITCH

VACUUM

REPLACE

BLOWER

9

2M-Z20252 (REV A)

DOOR

INTERLOCK

N.O.

SWITCH

COM.

SERVICE

2

4

COM. N.O.

RED

REQ LIGHT

12 FLA 125 VOLT

8 FLA 250 VOLT AC

SPNO EQUIPMENT INTERFACE

16

SHUTDOWN

VACUUM

SWITCH

N.O.

COM.

8

11

10

RELAY

5

6

7

1

3

M526 p/n 2M-Z17443 OpM WOV35-SW- Oven Mounted Filtration

LIGHT

CHECK

AMBER

FILTERS

WIRE DIAGRAM WOV35

120V, 230V, OR 208/240V

2

1

MAIN POWER

SWITCH DPST

AC LINE 1

13

BLACK

WHITE

PLUG & CORD

13

IEC

INLET

JUMPER

#15

TERMINAL

BLOCK FOR

OVEN INTERLOCK

SWITCH

INTERNAL

LAMP

14

SHOWN

CORD NOT

19

18

4

3

MAIN POWER

SWITCH DPST

14

MODELS WITH IEC CORD INLET

AC LINE 2

11

Page 14

EXPLODED VIEW

1

2

3

36

37

40

39

38

38

39

41

33

7

8

9

18

4

22

16

10

15

19

5

6

2

8

4

8

29

28

21

25

26

27

24

17

23

10

12

11

14

13

20

21

35

34

42

MODEL: WOV35-SW

BAKING OVEN FILTRATION

30

31

32

M526 p/n 2M-Z17443 OpM WOV35-SW- Oven Mounted Filtration

SK2887 Rev. - 3/16/15

12

Page 15

PARTS LIST

Fig No Part Number Qty Description Application

1 2C-6349 28 SCREW #8X3/8 B THP STL NP

2 2R-200562 2 FAN GUARD FOR MUFFIN FAN

3 N1-Z18916 1 TOP PANEL

4 2E-Z12427 2 SWITCH, SPDT (DOOR)

5 2C-2555 4 NUT 8-32 ACHD BRS NP

6 2C-2556 8 NUT 8-32 HEX STL NP

7 N1-Z18923 1 MOUNTING PLATE,VACUUM

8 2C-31053 5 NUT 8-32 KEPS MS NICKEL

9 2K-302631 1 ADAPTER 3/8 TUBE 1/4 MALE

10 2J-302629 2 Ft HOSE.18IDX.31ODXCOIL CLR

11 2C-6517 3 NUT 1/4-20 HEX STL NP

N1-WL0712

12

N1-WL0740 BLOWER ASSY, 50/60 Hz 230/240V

13 2C-200005 2 SCREW 6-32X1/2 THP SS

2E-44514

14

2E-Z15353 RELAY, 120V COIL, SPNO 120V

15 2K-302630 2 TEE NYLON 3/16

16 2C-1493 4 SCREW 8-32X3/8 RHP STL NP

17 2E-Z19328 1 PRESSURE SWITCH, .15 WC, SHUTDOWN

18 2E-Z19327 1 PRESSURE SWITCH, .22 WC, FILTER REPLACEMENT CK LIGHT

2K-Y2967

19

2E-Z3034 IEC CORD INLET HOT 230V

20 N1-Z18922 1 SERVICE PANEL,RIGHT

21 2C-35487 13 SCREW 8-32X5/16 PH TR HD

22 N1-Z19263 1 BRACKET,TERMINAL BLOCK

23 2E-Y1654 1 BLOCK-TERMINAL

24 2C-08-07-0042 2 SCREW 8-32 S 5/8 RHP STL NP

25 2C-Z2594

26 N1-Z18924 1 MOUNTING PLATE,INDICATOR

27 2L-Z19081 2 SPACER 1/8,NYLON

28 2J-30516 2 LIGHT SIGNAL AMBER M3938P

M526 p/n 2M-Z17443 OpM WOV35-SW- Oven Mounted Filtration

29 2J-31157 1 LIGHT SIGNAL RED M3938PR

30 N1-WL0647 1 CONTROL PANEL ASSEMBLY

July 17, 2015, Rev. A

Model: WOV35-SW BAKING OVEN FILTRATION ACCESSORY

BLOWER ASSY 120V

1

RELAY, 208-240V COIL 230V

1

BUSHING HEYCO 7K-2 BLK 120V

1

2

NUT 6-32 HEX W STL NP

4 230V

120V

13

Page 16

PARTS LIST continued

July 17, 2015, Rev. A

Model: WOV35-SW BAKING OVEN FILTRATION ACCESSORY

Fig No Part Number Qty Description Application

31 2M-Z19374 1 GRAPHIC OVERLAY,CTRL PANEL

32 2E-305295 1 SWITCH ROCKER 250V 10A GR

33 N1-Z18935 1 BRACKET,DOOR PLUNGER

34 2R-Z19835 1 LATCH,DOOR BLACK

35 2M-Z19375 1 GRAPHIC OVERLAY,FILTER DOOR

36 N1-WL0646 1 FILTER DOOR ASSEMBLY

37 N1-WL0652 1 FILTER PACK ASSEMBLY

38 2C-42067 4 SCREW 10-32X3/8 PH TR HD

39 2C-6260 4 WASHER #10 INT STL NP

40 N1-Z18921 1 HINGE BRACKET,BOTTOM

41 N1-Z18920 1 HINGE PLATE,TOP

42 N1-WL0653 1 SKIRT ASSY, NU-VU X5 OVEN WOV35-SW

NI 2E-Z0512 1 CORD SET, CONT. EUR 10A 230V

NI 2E-Z19304 1 CORD SET, 5-15P 125V 15A 120V

14

M526 p/n 2M-Z17443 OpM WOV35-SW- Oven Mounted Filtration

Page 17

NOTES

M526 p/n 2M-Z17443 OpM WOV35-SW- Oven Mounted Filtration

15

Page 18

NOTES

16

M526 p/n 2M-Z17443 OpM WOV35-SW- Oven Mounted Filtration

Page 19

PARTS & SERVICE

DESCRIPTION PART NO.

FILTER PACK ASSEMBLY N1-WL0652

IMPORTANT: Use only

factory authorized service parts

and replacement lters.

For factory authorized service,

or to order factory authorized

replacement parts, contact

your Wells authorized service

agency, or call:

Wells Manufacturing

10 Sunnen Dr.

St. Louis MO 63143 USA

Service Dept.

phone: (314) 678-6314

fax: (314) 781-2714

Service Parts Department

can supply you with the name

and telephone number of

the WELLS AUTHORIZED

SERVICE AGENCY

nearest you.

RESTAURANT _____________________________ LOCATION _____________

INSTALLATION DATE ________________________ TECHNICIAN ___________

SERVICE COMPANY ________________________________________________

ADDRESS ___________________________ STATE ______ ZIP__________

TELEPHONE NUMBER (_____)_____-_________

EQUIPMENT MODEL NO. _____________EQUIPMENT SERIAL NO. _______________

VOLTAGE: (check one) 120 230

M526 p/n 2M-Z17443 OpM WOV35-SW- Oven Mounted Filtration

CUSTOMER SERVICE DATA

Please have this information available if calling for service

17

Page 20

WELLS MANUFACTURING

10 Sunnen Dr., St. Louis, MO 63143

telephone: 314-678-6314

fax: 314-781-2714

www.wellsbloomfield.com

Loading...

Loading...