Page 1

®

®

®

®

®

GAS

CONVEYOR OVEN

MODEL

UM1854-NAT/-LP

UM1854Q-NAT/-LP

UM1854-NATX/-LPX

Installation and

Operation

Instructions

2M-Z5649 Rev. L 10/20/2010

UM1854

Page 2

2

These symbols are intended to alert the user to the presence of

important operating and maintenance instructions in the manual

accompanying the appliance.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

NOTICE

Using any part other than genuine Star factory supplied parts relieves the

manufacturer of all liability.

Star reserves the right to change specications and product design without

notice. Such revisions do not entitle the buyer to corresponding changes,

improvements, additions or replacements for previously purchased

equipment.

Due to periodic changes in designs, methods, procedures, policies and

regulations, the specications contained in this sheet are subject to change

without notice. While Star International Holdings Inc., Company exercises

good faith efforts to provide information that is accurate, we are not

responsible for errors or omissions in information provided or conclusions

reached as a result of using the specications. By using the information

provided, the user assumes all risks in connection with such use.

MAINTENANCE AND REPAIRS

Contact your local authorized service agent for service or required maintenance.

Please record the model number, serial number, voltage and purchase date in the area below and have it ready when

you call to ensure a faster service.

SAFETY SYMBOL

Model No.

Serial No.

Voltage

Purchase Date

Business

8:00 am to 4:30 p.m. Central Standard Time

Hours:

Telephone: (800) 264-7827 Local (314) 781-2777

Fax: (800) 396-2677 Local (314) 781-2714

E-mail Parts@star-mfg.com

Service@star-mfg.com

Warranty@star-mfg.com

Website: www.star-mfg.com

Service Help Desk

Authorized Service Agent Listing

Reference the listing provided with the unit

or

for an updated listing go to:

Website: www.star-mfg.com

E-mail Service@star-mfg.com

Telephone: (800) 807-9054 Local (314) 781-2777

Mailing Address: Star International Holdings Inc., Company

10 Sunnen Drive

St. Louis, MO 63143

U.S.A

3

Page 3

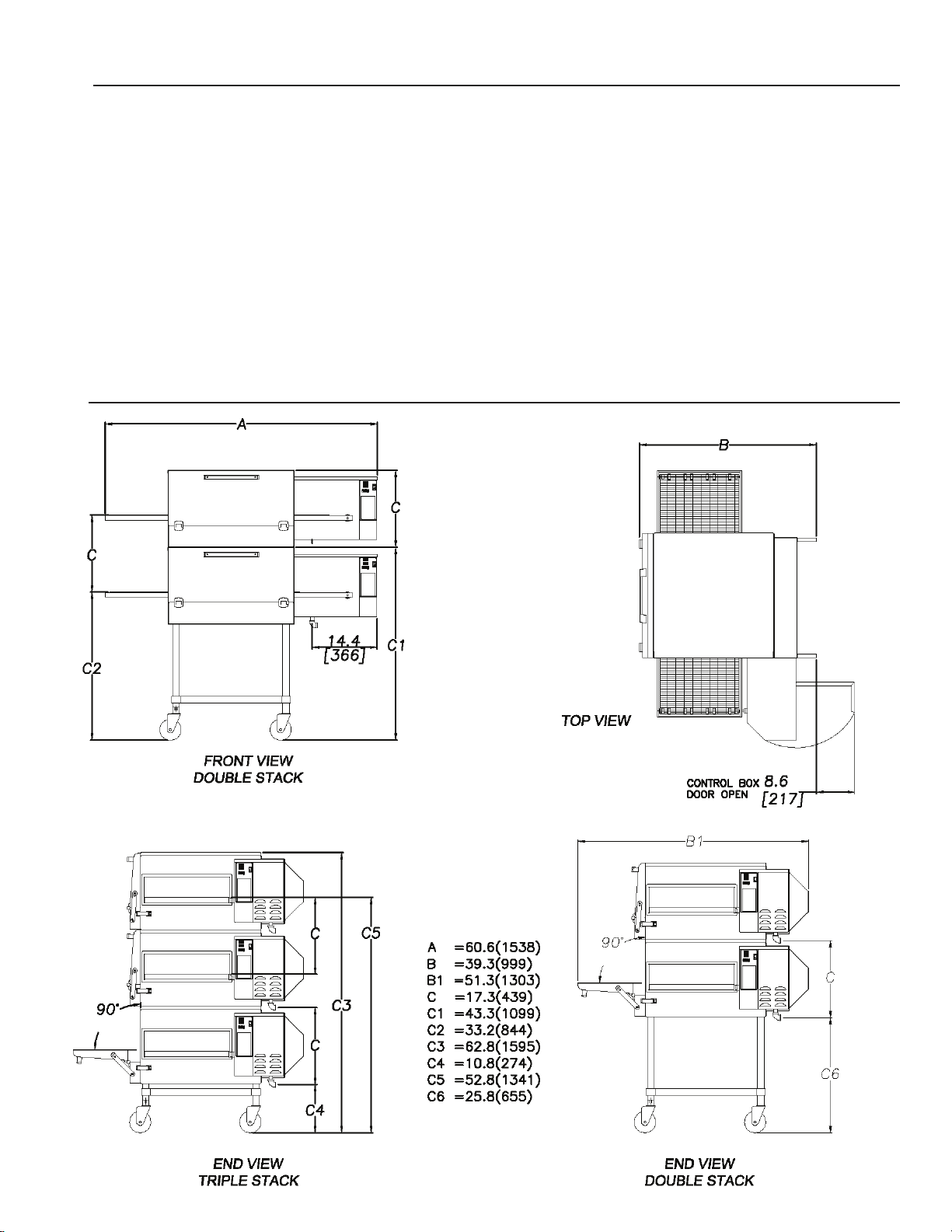

SPECIFICATIONS

UM1854-NAT, UM1854-LP

Gas Rating/Connection: 40,000 BTU/hr (10080 kCal/min)(703kW)

1/2" NPT male pipe connection

Gas Supply Pressure: Natural - 5-6" water column (15-30 mBar)

Propane - 11-12" water column (27.5-30 mBar)

Electrical Supply: Separate 15 Amp 110VAC, single phase, 50/60 Hz service per Oven

Approximate Weight (Single Oven with Cart): Installed - 280 Lbs (127.27 kg), Shipping - 350 Lbs (159.09 kg)

Dimensions: Width: 60.6" (153.9 cm)

Depth: 39.9" (99.82 cm) - Front Door(s) Closed

51.3" (130.3 cm) - Front Door(s) Open

Height: 43.3" (110.0 cm) - Single Oven with Stand

60.6" (153.9 cm) - Double Oven with Stand

62.8" (159.5 cm) - Triple Oven with Dolly

Recommended Minimum Clearances:

Rear of Oven to Wall 0" (0 cm)

Conveyor Extensions to Wall 6" (15.2 cm)

3

Page 4

CAUTION

GENERAL INFORMATION

This equipment is designed and sold for commercial use only by personnel trained and experienced in

its operation and is not sold for consumer use in and around the home nor for use directly by the general

public in food service locations.

First and foremost, each crate should be examined before signing the Bill of Lading to report any visible

damage by the trucker in transit and to account for the proper number of crates. If there is apparent

damage, arrangements should be made to le a claim against the carrier. Interstate Commerce

Regulations require that the claim must be initiated by the consignee. Proper and secure storage

facilities should be arranged for the oven(s) if necessary to protect it from outdoor or damp conditions

at all times before installation.

-IMPORTANT-

When you have all the crates unloaded, open the crates and remove all plastic covers. Inspect at once

for concealed damage. If anything appears to be damaged, contact the appropriate persons immediately

to le a damage claim. After completing this inspection, nish unpacking the oven. Be sure to remove

all paper protection and packing material from the unit prior to lighting.

FOR YOUR SAFETY DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

VAPORS AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

The installation of the Appliance must conform to the NATIONAL FUEL GAS CODE

"ANSI Z223.1 - LATEST EDITION" AND ALL LOCAL GAS COMPANY RULES AND

REGULATIONS.

IN CANADA INSTALLATION SHALL BE IN ACCORDANCE WITH THE CURRENT CAN/

CGA-B149.1 NATURAL GAS INSTALLATION CODE OR CAN/CGA-B149.2 PROPANE

INSTALLATION CODE AND LOCAL CODES WHERE APPLICABLE.

NOTICE

This appliance must be installed with a stand and casters designed by Star Manufacturing as part of a

complete installation. The installation must also include a connector complying with either ANSI Z21.69

or CAN/CGA-6.16 and a quick-disconnect device complying with either ANSI Z21.41 or CAN1-6.9. It

must also be installed with restraining means to guard against transmission of strain to the connector

as specied in the appliance manufacturer's instructions.

For your protection, we recommend a qualied installing agency install this appliance. They should be

familiar with gas installations and your local gas requirements. In any case, your gas company should

be called to approve the nal installation.

This appliance, its pressure regulator, and its individual shutoff valve must be disconnected from the

gas supply piping system during any pressure testing of that system at test pressures in excess of 1/2

PSIG. This appliance and its pressure regulator must be isolated from the gas supply piping system by

closing its individual manual shutoff valve during any pressure testing of the gas supply piping system

at test pressures equal to or less than 1/2 PSIG.

4

Page 5

CAUTION

PURCHASER'S RESPONSIBILITY

It is the responsibility of the purchaser:

1. To see that the gas and electric services for the oven are installed on site in accordance

with the manufacturer's specications.

2. To unload, uncrate, and install the oven in its proper location and in accordance with this

installation operation manual.

3. To see that all gas and electric services are connected properly by a qualied installer of your

choice. All such connections must be in accordance with applicable code requirements.

4. To arrange for inspection and operation check-out by an authorized service technician.

The warranty becomes effective upon verication of proper installation.

IMPORTANT SAFETY INFORMATION

Do not attempt to operate the oven until connection of utility service has been fully inspected by an

authorized service technician or a Star Service Representative. This service is required by Star in order

to assist the purchaser in proper start-up of the oven on site. Please note the specic details on the

Warranty and make certain that service connections are made to proper utility services.

The warranty shall not apply if the oven is started up and operated prior to the utilities and oven being

inspected and check-out made by an authorized service technician or a Star Service Representative.

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE, OR

MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY, OR DEATH. READ

ALL INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR SERVICING THIS

EQUIPMENT.

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

Post in a prominent location the emergency telephone number of your local gas

supplier and instructions to be followed in the event you smell gas. If the smell

of gas is detected, immediately call the emergency phone number of your local

gas company. They will have personnel and provisions available to correct the

problem.

It is required that the oven be placed under a ventilation hood to provide for

adequate air supply and ventilation.

Minimum clearances must be maintained from all walls and combustible materials.

Minimum clearances for this unit should be 0 inches from the rear (rear bumpers

provided must be in place) and 6 inches from both sides. Keep the oven free

and clear of all combustible material.

Adequate clearance for air openings to the combustion control chamber on the

right side of the oven is required. Do not obstruct the ventilation holes in the

control panels as these provide the combustion air for the burner and cooling

air for the controls.

The oven is to be operated only on the type of gas and electricity shown on the

specication plate. The burner will not operate and gas will not ow through the

burner without electric power.

5

Page 6

INSTALLATION INFORMATION

THE INSTALLATION INSTRUCTIONS CONTAINED HEREIN ARE FOR THE USE OF

QUALIFIED INSTALLATION AND SERVICE PERSONNEL ONLY. INSTALLATION OR

SERVICE BY OTHER THAN QUALIFIED PERSONNEL MAY RESULT IN DAMAGE

TO THE OVEN AND/OR INJURY TO THE OPERATOR.

Qualied installation personnel are individuals, a rm, a corporation, or a company which either in person

or through a representative are engaged in and responsible for:

1. The installation or replacement of gas piping and the connection, installation, repair, or servicing of

equipment.

2. The installation of electrical wiring from the electric meter, main control box, or service outlet to the

electric appliance.

Qualied installation personnel must be experienced in such work, familiar with all precautions required,

and have complied with all requirements of state or local authorities having jurisdiction.

LOCATION

The well-planned and proper placement of your oven will result in long-term operator convenience and satisfactory

performance.

NOTE: On gas conveyor ovens, routine servicing can usually be accomplished within the limited movement provided

by the gas hose restraint. If the oven needs to be moved further from the wall, the gas must rst be turned off and

disconnected from the oven before removing the restraint. Reconnect the restraint after the oven has been

returned to its regular position.

It is essential that an adequate air supply to the oven be maintained to provide a sufcient ow of

combustion and ventilation air. Follow these guidelines:

1. Place the oven in an area that is free of drafts.

2. Keep the oven area free and clear of all combustibles such as paper, cardboard, ammable liquids,

and solvents.

3. Do not place the oven on a curb base or seal to a wall. This will restrict the ow of air and prevent

proper ventilation to the blower motors. This condition must be corrected to prevent permanent

damage to the oven.

4. On all models, tripping of the blower motor's thermal overload device indicates an excessive ambient

temperature at the back of the oven. This condition must be corrected to avoid permanent damage

to the oven.

CAUTION

Failure to properly vent the oven can be hazardous to the health of the operator

and may result in operational problems, unsatisfactory baking, and possible

damage to the equipment.

Damage sustained as a direct result of improper ventilation will not be covered by the warranty.

6

Page 7

CAUTION

VENTILATION

A VENT IS REQUIRED: Local codes prevail. These are the "authority having

jurisdiction" as stated by the National Fire Protection Association, Inc. in NFPA

96-Latest Edition. For further ventilation information see below.

A ventilation hood is required to remove heat and cooking odors. For gas ovens, a ventilation hood is

also required to remove the products of combustion. The hood and HVAC installation must meet local

codes to gain approval by the authority having jurisdiction. Requirements may vary throughout the

country depending on the location by city, county, and state. Obtain information from the authority having

jurisdiction to determine the requirements for your installation. Obtain information and review copies

of codes or documents that will be used to inspect and approve your installation. Your ventilation hood

supplier and HVAC contractor should be contacted to provide guidance. A properly engineered and

installed ventilation hood and HVAC system will expedite approval and reduce oven maintenance costs.

Proper ventilation is the responsibility of the oven's owner.

The ventilation hood must operate in harmony with the building HVAC system. It typically requires between

750 and 2500 CFM exhaust. (The efciency of various hood designs makes it necessary to specify such

a wide range of ventilator CFM.) Make-up air must be supplied by either a hood design or the HVAC

system to avoid a negative pressure condition. This will vary with hoods from various manufacturers.

Prevent airow through the cooking tunnel. Air must NOT be directed onto the

oven's front or rear or to the sides of the cooking area.

The following drawing shows a typical installation

and is intended to be a guideline. This is not a rigid

specication. Hood dimensions and positioning

over the oven will vary with hood manufacturer.

SMOKE CANDLE TEST

In order to verify the proper function of your

ventilation system, a smoke candle test should

be done. If testing a multiple oven system, this

test should be done on the bottom oven. The

conveyor coupling should be disconnected and

the oven temperature must be set and operating

at a minimum of 480°F (249°C).

Test Procedure:

1. Wear heat-resistant gloves to prevent burns.

2. Put the smoke candle in an 8"x8"x2" cake pan.

3. Insert candle through conveyor tunnel or oven door.

(Use Star Smoke Candle 2W-Z5668.)

4. Light the fuse of the smoke candle and immediately center the pan in the oven cavity on the

conveyor belt (keeping the oven door closed).

5. Observe the smoke pattern coming out of all oven openings and the collection of this smoke by the

ventilation system.

6. All smoke from the oven must be captured by the ventilation system.

7

Page 8

GAS SUPPLY RATING AND SIZING

Calculations for pipe sizing must take into account the maximum usage rate of all other appliances in

the kitchen or one or more of the appliances will suffer from inadequate or dangerous performance. The

1/2" NPT connection for the oven is generously sized for use in the control box of the oven. However,

unless the oven installation is within 10 feet of the main building gas supply, the supply must be larger.

For each oven, a 3/4" NPT exible quick connect hose and full port gas shut-off valve is recommended

as a MINIMUM. The main pipe supplying each oven branch may need to be larger depending on the

number of appliances serviced, the number of elbows in the piping, and the pressure. This should be

sized and installed by a professional familiar with any local codes that may also affect the installation.

ACCESS CONSIDERATIONS

Locating the gas valve(s), quick connect hose(s) and electrical outlet(s) at the control box end of the

oven will allow easier access for any service visits. This improved access should make any necessary

service quicker resulting in less kitchen disruption. It will also allow easier disconnection of electricity,

gas, and restraints for cleaning around and behind the oven.

ELECTRICAL CONNECTION

Before making any electrical connections to this unit, check that the power supply is adequate for the

voltage, amperage, and phase requirements stated on the rating plate. A wiring diagram is included

herewith.

When installed, this appliance must be electrically grounded and its installation must comply with the

National Electric Code, ANSI-NFPA 70, latest version, manufacturer's installation instructions, and

applicable local municipal building codes. In Canada, all electrical connections are to be in accordance

with CSA C22.1 - Canadian Electrical Code Part 1 and/or local codes.

CAUTION

PRESSURE REGULATION AND TESTING

Each oven has been adjusted at the factory to operate with natural gas. Parts can be ordered for

conversion for use with propane.

Each oven is supplied with a regulator to maintain the proper gas pressure. The regulator is essential

to the proper operation of the oven and should not be removed. A pressure reading can be taken at one

of the 1/8" NPT test ports on the bottom or side of the combination valve. The reading should be taken

while the oven is heating up. The regulator is located on the bottom of the gas combination valve, just

inside the control box. There is no need to install an additional regulator where the oven connects to

the gas supply unless the supply exceeds the maximum.

NOTE: The supplied regulator is evaluated for a maximum gas supply pressure of

14" water column (34.5 mBar). The recommended maximum gas supply pressure

is 12" water column (29.9 mBar).

Installation must conform with local codes or, in the absence of local codes, with the National Fuel Gas

Code, NFPA54/ANSI Z223.1 - Latest Edition, the Natural Gas Installation Code CAN/CGA-B149.1 or

the Propane Installation Code CAN/CGA-B149.2 as applicable.

During pressure testing note the following:

1. The oven and its individual manual shut-off valve must be disconnected from the gas supply piping

system during any pressure testing of that system at test pressures in excess of 1/2 psig (3.45 kPa).

Turn OFF main gas shut-off valve or main gas supply line.

2. The oven must be isolated from the gas supply piping system by closing its individual manual shutoff valve during any pressure testing of the gas supply piping system at test pressures equal to or

less than 1/2 psig (3.45 kPa).

3. If incoming pressure is over 14" water column, a separate regulator for the oven must be installed

before the gas supply to the oven. For LP it must regulate pressure to 11" water column (27.1 mBar)

maximum and 6" for NAT.

8

Page 9

WARNING: To prevent damage to the control valve regulator during the initial

turn-on of gas, it is very important to open the manual shut-off valve very slowly.

After the initial gas turn-on, the manual shut-off valve must remain open except

during pressure testing as outlined in the above steps or when necessary during

service maintenance.

STACKING

The following instructions should be followed when

stacking more than one unit.

INSTRUCTIONS

Single Oven (or Bottom) Cart Install:

1. Remove door, conveyor, and nger assemblies.

2. Unbolt unit from shipping crate (2 bolts).

3. Turn unit on front as shown.

4. Slide legs into stand shelf and thread legs into

bottom of oven.

5. Install casters into bottom of legs. Place casters

with brakes to the front.

6. Position shelf as desired and fasten to legs.

7. CAREFULLY lift oven upright.

Stacked Oven Install Preparation:

1. Remove door, conveyor, and nger assemblies.

2. Unbolt unit from shipping crate (4 bolts).

3. Turn unit on front as shown.

4. Remove top of lower oven (4 screws total, 2 each

front and rear) and bolt to stacked oven base using

5/8 - 11 bolts (4 each, included).

5. Place top oven on lower unit and re-attach with

screws for top of lower oven.

6. Use restraint on lowest oven to prevent any high

loads that could tip the oven stack.

9

Page 10

RESTRAINT REQUIREMENT

HOLLOW WALL STUD

OR MASONRY WALL

A

B

C

1. The installation shall be made with a gas connector that

complies with local codes for connectors for movable

gas appliances and a quick-disconnect device that

complies with local codes for such devices in use

with gas fuel.

2. The installation of the restraint must limit the movement

of the oven(s) without depending on the connector,

the quick disconnect device, or associated piping to

limit the oven movement.

3. If the restraint must be disconnected during

maintenance or cleaning, it must be reconnected after

the oven has been returned to its originally installed

position.

OPERATING INSTRUCTIONS

DO NOT ATTEMPT TO OPERATE THE OVEN until

connection of utility service and installation has been fully

inspected (start-up check-out) by an authorized service

technician or a Star Service Technician in order to assure

the oven is properly installed and in working order. The

warranty becomes effective upon verication of

proper installation.

CAUTION

DO NOT WORK AROUND THE CONVEYOR

BELT WITH LONG HAIR, LOOSE CLOTHING,

OR DANGLING JEWELRY. GETTING

CAUGHT IN THE BELT COULD RESULT IN

DISMEMBERMENT OR FATAL INJURY.

Unless specied otherwise, conveyor travel is factory

set for left to right operation when facing the front of the

oven. If a direction change is required, refer to "DISPLAY

INFORMATION," section 3 for instructions on how to

program the controller for a direction change. In addition,

the conveyor belt must be changed to travel in the new

direction.

SAFETY OPERATING INSTRUCTIONS

The information contained in this section is provided

for the use of qualied operating personnel. Qualied

operating personnel are those who have carefully read

the information contained in this manual, are familiar

with the functions of the oven and/or have had previous

experience with the operation of the equipment described.

Adherence to the procedures recommended herein will

assure the achievement of optimum performance and

long, trouble-free service.

10

Page 11

Please take time to read the following safety

3) Press the up button ( ) to increase

or the down button ( ) to decrease

TIME or TEMPERATURE. Hold

button down for faster display

changes.

4) After five seconds, the new numbers

will be saved and the oven will display

new settings.

4) Après cinq secondes, les nouveaux

nombres seront sauvés et le four montrera

de nouveaux arrangements.

3) Tenez "vers le haut" bouton ( ) pour

augmenter ou "vers le bas" boutonnez ( )

pour diminution de le TEMPS ou

TEMPÉRATURE. Maintenez le bouton pour

des changements plus rapides.

1) Press the up and down buttons

( ) at the same time, hold for four

seconds until TIME display is blank.

2) Press the enter button ( ) to

switch between TIME and

TEMPERATURE.

Adjusting TIME and TEMPERATURE:

If burner does not light in one minute

push the power switch to the "OFF"

position and wait five minutes.

After five minutes, retry.

Push power switch "ON."

To Start:

2) Appuyez sur le bouton de "entrée" ( )

pour commuter entre le TEMPS et la

TEMPÉRATURE.

1) Tenez "vers le haut" et "vers le bas"

boutonne ( ) en même temps. Tenez

les boutons pendant quatre secondes

jusqu'à ce que l'affichage de la

TEMPS soit blanc.

Après cinq minutes, nouvelle tentative.

Si le brûleur n'allume pas en une minute,

poussée le commutateur de puissance dans

la position de "ARRÊTE" et attend 5 minutes.

Poussez le commutateur de puissance à

"MARCHE."

OFF / ARRÊTE

Ajustement du TEMPS et de la

TEMPÉRATURE:

Pour Commencer:

ON / MARCHE

SWITCH CUTOUT

IL1050

operating instructions. They are the key to the

successful operation of your Ultra-Max Conveyor

Oven.

SAFETY TIPS

For your safety, read before operating.

If you smell gas:

1. DO

NOT try to light any appliance.

2. DO NOT touch any electrical switches.

3. Use an exterior phone to call your gas supplier

immediately.

4. If

you cannot reach your gas supplier, call the

re department.

In the event of a power failure:

1. Turn all switches off.

2. DO NOT attempt to operate the oven until the

power is restored.

NOTE: In the event of a shut-down of any

kind, allow a ve (5) minute shut-off period

before attempting to restart the oven.

General Safety Tips:

1. DO NOT use tools to turn off the gas control. If

2. If the oven needs to be moved for any reason,

3. DO NOT remove the control box cover unless

the gas cannot be turned off manually do not try

to repair it. Call a qualied service technician.

the gas must be turned off and disconnected

from the unit before moving the restraint cable.

Reconnect the restraint after the oven has been

returned to its original location.

the oven is unplugged.

To adjust the time and temperature:

1. Press the DOWN and UP arrows ( ) at

the same time. Hold for four seconds until the

TIME display goes blank.

2. Press the ENTER button (

) to switch between

TIME and TEMPERATURE.

3. Press the UP arrow (

DOWN arrow (

) to decrease the TIME or

) to increase or the

TEMPERATURE. Hold either button down for

faster display changes.

4. After ve seconds, the new numbers will be saved

and the oven will display the new settings.

To turn the oven off:

1. Push the power switch to "OFF." The oven is

equipped with a cool-down feature for motor

shaft and bearing protection. This enables the

blower motor(s) to run regardless of the controller

status. The blower(s) continue to run until the

oven cools to a safe temperature.

OPERATION

To turn the oven on:

1. Push the power switch to "ON."

2. If the burner does not light in one minute, push

the power switch to the "OFF" position and wait

ve minutes.

3. After ve minutes, retry.

11

Page 12

DISPLAY INFORMATION

When operating the oven, there are different

levels of access:

1. Store Level - General employees would know

these functions and how to change them. While

the oven is running, enter this mode by holding the

DOWN and UP arrows ( ) simultaneously for

four seconds. The TIME display goes blank and the

TEMP setpoint is displayed. Adjust with the DOWN

or UP arrows. The ENTER button (

between TIME and TEMP. The parameter that can

be adjusted is displayed, the other is blank. When

TIME and TEMP are adjusted as needed, wait ve

seconds and SAVE is displayed. The values are

accepted and the controller begins controlling to these

new values. The conveyor continues to operate at

the same speed until a new value is accepted. The

temperature control output should be OFF during

changes.

2. Manager Level - This is a lock so that TIME and

TEMP cannot be changed even at the Store Level.

While the oven is running, enter this mode by holding

the DOWN and UP arrows simultaneously for 4

seconds. The TIME display goes blank and the TEMP

setpoint is displayed. Release the UP arrow and

continue to hold the DOWN arrow for an additional

4 seconds. The TEMP display shows LOC as the

TIME display shows nO, which indicates that the

TIME/TEMP parameters can be changed. af ter

reaching the STORE level. yES indicates that the

parameters cannot be changed even after entering

the STORE level. The LOC setting can be toggled

using the ENTER button ( ).

) toggles

ADDITIONAL FUNCTIONS

The conveyor belt direction and the temperature display can

be changed on the conveyor oven by a qualied technician.

To change the belt direction, the technician must reverse the

motor direction and rotate the conveyor belt for proper oven

function. A technician can also change the temperature display

from Fahrenheit to Celsius. These changes can be made by

the technician during the start-up/check-out or at a later date.

ERROR CODES

Error codes will display as ashing text messages for diagnostic

purposes. Any temperature or thermocouple error should turn

the temperature output OFF and leave the conveyor running

at the same speed. The belt error should turn the temperature

output OFF. The speed error should display when the motor is

unable to settle at the chosen speed. This might occur if a fast

speed is chosen that the motor is unable to spin fast enough

to achieve. The speed signal output will remain the same but

the display will ash the error message.

12

Page 13

BAKE TIME VERSUS TEMPERATURE

BAKE vs. DELIVERY TIME

Time to Delivery changes with product

but

Bake Time remains constant

at a steady conveyor speed.

28 (BAKE)

36 (DELIVERY)

44 (DELIVERY)

6:00 (BAKE)

7:43 (DELIVERY)

9:26 (DELIVERY)

1. Bake time is actually conveyor speed and is dened

as the time the product is actually in the oven. This is

measured by noting the time when the leading edge of

the product enters the oven and the time the leading

edge of the product leaves the oven. This is adjusted

by using the conveyor speed controller.

2. Bake temperature is adjusted by changing the setpoint

of the temperature controller to the desired bake

temperature. When the oven reaches the desired

temperature, the red dot in the lower right corner of the

temperature display will turn off and on as the controller

maintains the temperature.

3. When establishing a bake time and temperature for a

given product, the general rule shall be as the bake

time increases the bake temperature decreases and the

reverse is also true; increase temperature, decrease time.

However, there are limits to the above rule. Going to

extremes will result in a burnt exterior and raw interior or it

will result in a very light color but over-baked product.

4. Once a good bake has been established, the ne

adjustments should be made by holding either the bake

time or bake temperature constant, then varying the

other.

CONVEYOR SPEED

Bake Time (Conveyor Speed) - As stated previously, bake

time (conveyor speed) is dened as the amount of time

elapsed between the time the leading edge of the product

enters the oven and the leading edge of the product exits

the oven. Bake time is controlled by adjusting the digital

speed controller. The setting on the control panel indicates

the actual bake time.

Bake time will be the same for any size product.

TIME OF DELIVERY

The time of delivery is the amount of elapsed time between

the period when the leading edge of the product enters the

oven and the trailing edge of the product is fully discharged

and is ready to be delivered to the customer.

Time of delivery changes if the product size changes.

Tip: Train yourself not to pull the product out of the oven

when the leading edge comes out. Always wait until the entire

product is out - the product needs this time to fully bake.

13

Page 14

WARNING

CAUTION

CAUTION

MAINTENANCE INSTRUCTIONS

DISCONNECT THE POWER SUPPLY BEFORE SERVICING OR CLEANING THIS

OVEN. SAFEGUARD THE POWER SO IT CANNOT BE ACCIDENTALLY RESTORED.

FAILURE TO DO SO COULD RESULT IN DISMEMBERMENT, ELECTROCUTION,

OR FATAL INJURY. THERE IS MORE THAN ONE POWER SUPPLY CONNECTION

POINT WHEN OVENS ARE STACKED, SO MAKE SURE THAT ALL SWITCHES ARE

IN THE OFF POSITION BEFORE CLEANING OR MAINTENANCE.

No electrical components should be subjected to moisture. It is therefore important that the oven is wiped

down carefully. NEVER throw buckets of water over the oven or subject it to pressure washing from a

hose or a pressure spray. If water or other liquid is spilled on the oven, make sure that none of it has

entered the control box area before switching the oven ON. If in doubt, call your service company.

Adhere to the following warnings when cleaning or maintaining your gas conveyor oven:

1. The oven must be cool. Do not use power cleaning equipment, steel wool, or wire brushes on

stainless steel surfaces.

2. Do not use a caustic or an alkaline base cleaner on the interior of the oven. This will ruin the

aluminized nish of the oven interior.

3. When using cleaning solutions, be sure they meet local and national health standards.

If the gas oven needs to be moved, the gas must be turned off and disconnected

from the unit before moving the restraint. Reconnect the restraint after the oven

has been returned to its original location.

Follow this recommended cleaning schedule for proper oven performance:

DAILY

1. Clean the conveyor belt using a nylon brush. Allow any foreign material to drop into the crumb

pans.

2. Empty and clean the crumb pans. Use a hot water and detergent mix.

Rinse with clean water.

EVERY MONTH

1. Brush and clean the guard on the motor cooling fan.

EVERY THREE MONTHS

1. Unplug the oven and disconnect gas connections.

2. Remove the crumb pans.

3. Remove the conveyor assembly.

4. Unlatch and remove the front door. Remove all internal airow components.

5. Clean the oven interior with an appropriate oven cleaner.

6. Clean the conveyor assembly, crumb pans, and other removable components. Wash in a hot water,

detergent mix and rinse with clean water. For difcult cleaning areas, use a heavy-duty de-greaser

or oven cleaner.

7. Move the oven and clean under it. Be careful not to damage the oven's gas hose or electrical cords

when moving.

8. Reassemble the oven.

EVERY TWELVE MONTHS

A factory authorized service person should:

1. Open and clean the inside of the control box.

2. Check and tighten all electrical components.

If maintenance is required, contact your local service company, a factory representative,

or Star Manufacturing.

14

Page 15

DIRECTIONS FOR DISASSEMBLY

1. Remove crumb trays and

shelves from both ends.

4. Finish removing the conveyor

assembly from the right end of

the oven.

2. Push the spring-loaded coupling

in to disengage the pin in the

shaft. Rotate the shaft so the pin

will not go back in the coupling

slots.

5. Upper nger assembly can be

removed complete or the small

handle (left) can be used to slide

nozzle and columnating plate

out before removing the main

body.

3. Lift up the left end of the conveyor

frame so the crumb tray supports

clear the tunnel opening. Push

the conveyor frame through the

tunnel opening.

6. Upper nozzle (with slot) and

columnating plates (with tab).

Extruded holes all point in the

same direction (down toward

the conveyor).

7. The lower nger assembly can

be removed complete or the

nozzle can be slid off to reveal

the recessed columnating

plate.

8. The columnating plate also has

a slot that must align with a tab

on the nger to ensure proper

orientation. Extruded holes

point up toward the bottom of

the conveyor.

15

9. The oven body is now ready to

be wiped clean. Reassemble

the nger and conveyor parts

in the reverse order after

cleaning.

Page 16

CONVEYOR BELT TENSION

The conveyor belt of the Ultra-Max Gas Conveyor Oven

does not have a tension adjustment. If the belt becomes

too loose, a link will have to be removed to tighten. A

belt that is too tight will also cause operational problems

due to excessive drag. We suggest that you have a

qualied service technician perform this adjustment.

CAUTION

Careful consideration should be exercised prior

to removing a belt link because a belt that is

too tight will impede the smooth operation of

the conveyor.

CONVEYOR BELT LINK REMOVAL

An entire link can be removed with the conveyor

assembly either in or out of the oven. This may be

necessary as the belt stretches after continuous

use. Following are the necessary steps for

removing links:

1. Move the splice clips to either end of the oven

for easy access.

2. Unhook the splice clips using long nose

pliers.

3. Unhook

out. Do not discard the link removed as it may

be used for making spare splice clips.

4. Reconnect the inside splice clips.

5. Reconnect the outside splice clips.

6. Replace all parts removed from the oven.

7. Straighten any bent wires to ensure smooth

sprocket engagement.

the full link to be removed and slide it

Remove the outside master links on the right and left

sides of the conveyor belt. Remove the center splice

clips next.

Unhook the end loop and pull up on the link section.

Save this link as it may be used for making splice

clips.

Check the

should be up). The belt shown is the top section,

ready for left-to-right travel.

orientation of the splice clips (the hooks

16

Page 17

2M-4497-2 10/2010

The foregoing warranty is in lieu of any and all other warranties expressed or implied and constitutes the entire warranty.

FOR ASSISTANCE

Should you need any assistance regarding the Operation or Maintenance of any Star equipment; write, phone, fax or email our Service Department.

In all correspondence mention the Model number and the Serial number of your unit, and the voltage or type of gas you are using.

ALL:

* Pop-Up Toasters

* Butter Dispensers

* Pretzel Merchandisers

(Model 16PD-A Only)

* Pastry Display Cabinets

* Nacho Chip Merchandisers

* Accessories of any kind

* Sneeze Guards

* Pizza Ovens

(Model PO12 Only)

* Heat Lamps

* Pumps-Manual

Visit our Website at: www.star-mfg.com Email: service@star-mfg.com

THOROUGHLY INSPECT YOUR UNIT ON ARRIVAL

This unit has been tested for proper operation before leaving our plant to insure delivery of your unit in perfect condition. However, there are instances in

which the unit may be damaged in transit. In the event you discover any type of damage to your product upon receipt, you must immediately contact the

transportation company who delivered the item to you and initiate your claim with same. If this procedure is not followed, it may affect the warranty status of

the unit.

LIMITED

EQUIPMENT WARRANTY

All workmanship and material in Star products have a one (1) year limited warranty on parts & labor in the United States and Canada. Such warranty is limited

to the original purchaser only and shall be effective from the date the equipment is placed in service. Star's obligation under this warranty is limited to the repair

of defects without charge, by the factory authorized service agency or one of its sub-agencies. Models that are considered portable (see below) should be taken

to the closest Star service agency, transportation prepaid.

> Star will not assume any responsibility for loss of revenue.

> On all shipments outside the United States and Canada, see International Warranty.

* The warranty period for the JetStar six (6) ounce & Super JetStar eight (8) ounce series popcorn machines is two (2) years.

* The warranty period for the Chrome-Max Griddles is ve (5) years on the griddle surface. See detailed warranty provided with unit.

* The warranty period for Teon/Dura-Tec coatings is one year under normal use and reasonable care. This warranty does not apply if damage occurs to

Teon/Dura-Tec coatings from improper cleaning, maintenance, use of metallic utensils, or abrasive cleaners, abrasive pads, product identiers and

point-of-sale attachments, or any other non-food object tha comes in continuous contact with the roller coating. This warranty does not apply to the

“non-stick” properties of such materials.

> This warranty does not apply to "Special Products" but to regular catalog items only. Star's warranty on "Special Products" is six (6) months on parts

and ninety (90) days on labor.

> This warranty does not apply to any item that is disassembled or tampered with for any purpose other than repair by a Star Authorized Service Center or

the Service Center's sub-agency.

> This warranty does not apply if damage occurs from improper installation, misuse, wrong voltage, wrong gas or operated contrary to the Installation and

Operating instructions.

> This warranty is not valid on Conveyor Ovens unless a "start-up/check-out" has been performed by a Factory Authorized Technician.

PARTS WARRANTY

Parts that are sold to repair out of warranty equipment are warranted for ninety (90) days. The part only is warranted. Labor to replace the part is chargeable to

the customer.

SERVICES

NOT COVERED BY WARRANTY

PORTABLE EQUIPMENT

Star will not honor service bills that include travel time and mileage charges for servicing any products considered "Portable" including items listed below.

These products should be taken to the Service Agency for repair:

1. Travel time and mileage rendered beyond the 50 mile radius limit

2. Mileage and travel time on portable equipment (see below)

3. Labor to replace such items that can be replaced easily during a daily cleaning

routine, ie; removable kettles on fryers, knobs, grease drawers on griddles, etc.

4. Installation of equipment

5. Damages due to improper installation

6. Damages from abuse or misuse

7. Operated contrary to the Operating and Installation Instructions

8. Cleaning of equipment

9. Seasoning of griddle plates

10. Voltage conversions

11. Gas conversions

12. Pilot light adjustment

13. Miscellaneous adjustments

14. Thermostat calibration and by-pass adjustment

15. Resetting of circuit breakers or safety controls or reset buttons

16. Replacement of bulbs

17. Replacement of fuses

18. Repair of damage created during transit, delivery, &

installation OR created by acts of God

* The Model 510FD Fryer.

* The Model 526TOA Toaster Oven.

* The Model J4R, 4 oz. Popcorn Machine.

* The Model 518CMA & 526CMA Cheese Melter.

* The Model 12MC & 15MC & 18MCP Hot Food Merchandisers.

* The Model 12NCPW & 15NCPW Nacho Chip/Popcorn Warmer.

* All Hot Dog Equipment except Roller Grills & Drawer Bun Warmers.

* All Nacho Cheese Warmers except Model 11WLA Series Nacho Cheese Warmer.

* All Condiment Dispensers except the Model HPD & SPD Series Dispenser.

* All Specialty Food Warmers except Model 130R, 11RW Series, and 11WSA Series.

* All QCS/RCS Series Toasters except Model QCS3 & RCS3 Series.

* All Fast Steamer Models except Direct Connect Series.

Page 18

DSIC

SENSE 4

M.V. 3

THS 2

GND

5

1 24VDC RETURN (COMMON)

7 +24VDC

2 DIRECTION

3 ENABLE (ACTIVE LOW)

4 FAULT (ACTIVE LOW)

5 DIRECTION INDICATOR

6 COMMON

8 TACH (12 PPR)

9 VOLTAGE INPUT (SPEED)

10 +5V (USE FOR SPEED POT ONLY)

11 BRAKE (ACTIVE LOW)

12 COMMON

XF1

GM/C

TL1

TS1

TL2

20

27

28

X

X

X

12

11

10

9

8

7

1

2

3

4

5

6

13

42

29

X

X

12

M1

6

4

2

1

3

5

1

BLK

CB

24V

COM 120V

7

19

17

40

16

N

G

L1

BLK

WHT

7

6

DS

2

S1

8

30

15

25

14

34 23

26

37

26

37

TB

4

_

8 9

5

36

10

_

21

41

21

19

_

_

_

30

WHT

--

15

9

32

35

24

SV

DV

GRN

3

FS

SE

33

38

25

40

17

38

24

16

35

PLUG ON BACK OF MOTOR

IS SHOWN ROTATED 180°

12

27

29

28

42

X

34

_

23

25

33

10

CN1 T/C TYPR K

YEL(+) RED(-)

SH (SHIELD)

CN3

TO MOTOR

6 = COM

5 = ENABLE

4 = DIR

3 = SPEED

2 = COM

1 = TACH

1

CN2 (24V)

INPUT

2 = N

1 = H

CN4

CN4

OUTPUT TO

SOLENOID

3 = COM

2 = 24V

1 = N/C

1

CN2

1

CN3

OCB

SECOND GENERATION

CN1

1

CN5 TO

SMALL MOTOR

7 = SPEED (GRD)

6 = SPEED SIGNAL

5 = SPEED (5V REF)

4 = (NOT USED)

3 = TACH (GND)

2 = TACH (+5V)

1 = TACH SIGNAL

D

Page 19

1,2: AC IN

3: FG

4,5: -V OUT

6,7: +V OUT

PS

GM/C

C1

DSIC

PS

M1

OCB

TS1

TL2

TL1

CB

SE

FS

DS

S1

XF1

SV

DV

TB

T/C

PR

- GEARMOTOR & CONTROLLER

- CAPACITOR, CIRC FAN MOTOR

- DIRECT SPARK IGNITION CONTROLLER

- POWER SUPPLY, 24VDC 150W PS

- MOTOR, CIRC FAN

- OVEN CONTROL BOARD

- COOL DOWN T-STAT

- CONTROL BOX TEMP LIMIT (MAN RESET)

- COOK CHAMBER TEMP LIMIT (BULB & CAP)

- CIRCUIT BREAKER

- SPARK ELECTRODE

- FLAME SENSOR

- DIFFERENTIAL PRESSURE SWITCH

- SWITCH, MAIN

- TRANSFORMER, 24V

- SINGLE VALVE

- DUAL VALVE (COMBI)

- TERMINAL BLOCKS (2)

- THERMOCOUPLE ASSY

- POWER RESISTOR

361320

41

12

3

4

5

6

7

8

BLK

BRN

BLU

M1

C1

TL1

TL2

TS1

CB

SE

FS

32

37

26

37

TB

5

36

10

41

21

19

30

WHT

--

35

24

DV

SET VOLTAGE SWITCH

TO 115V BEFORE INSTALLING

14

34

_

23

25

33

4

T/C

PR

10

14

"H"

C

NO

NC

"L"

DS

CN1 T/C TYPR K

YEL(+) RED(-)

SH (SHIELD)

INPUT

2 = N

1 = H

CN4

CN4

1

CN2

1

CN1

D

R

MATERIAL

DR.

FINISH

TITLE

STAR MFG. INTERNATIONAL, INC.

#10 SUNNEN DRIVE, ST. LOUIS, MO. 63143, USA

TOLERANCES UNLESS OTHERWISE NOTED

FRACTIONS ±1/64 DECIMALS ±.005 ANGLES ±1°

NO REPRODUCTION OR DISCLOSURE OF ITS CONTENTS IS PERMITTED.

CK.

-

-RDLEE 01-10-02

DATE

RDL

A 08/28/02

CHANGED POWER RESISTOR

AND IT'S WIRING

RDL

B 12/09/02

ADDED PICTURE OF

DIFFERENTIAL PRESSURE SWITCH

RDL

C 11/21/03

UPDATE FOR LOW

VOLTAGE CONTROLLER

CG

D 9/23/04

UPDATED OVEN CONTROL BOARD

MODEL NO. PART NO.

DESCRIPTION OF CHANGE

THIS DRAWING CONTAINS INFORMATION CONFIDENTIAL TO STAR MFG. INT'L INC.

DR

REVISIONS

UM-1854

SK1875

DIAGRAM, GAS OVEN - 115V

LTR DATE

Page 20

1678 2345

1

8

10

29

38

26

23

22

25

27

21

24

39

13

20

17

18

16

15

14

3

4

6

9

5

7

11

12

19

31

32

2

34

33

35

36

37

STAR MANUFACTURING INTERNATIONAL, INC.

MODEL UM1854

SK1905 REV.B 2-7-06

CONTROL BOX ASSEMBLY

SOME ITEMS ARE INCLUDED FOR ILLUSTRATIVE

PURPOSES ONLY AND IN CERTAIN

INSTANCES MAY NOT BE AVAILABLE.

THIS DRAWING CONTAINS INFORMATION CONFIDENTIAL

TO STAR MANUFACTURING INTERNATIONAL, INC.

NO REPRODUCTION OR DISCLOSURE OF ITS CONTENTS IS PERMITTED.

Page 21

PARTS LIST November 22, 2010, Rev. L

Ultra-Max Gas Conveyor Oven

UM1854-NAT/LP CONTROL BOX

Fig No Part No Qty Description Application

1 G9-GC0013 1 CONTROL BOX DOOR

2 PS-Z7718 1 TIME & TEMP CONTROLLER GAS OVEN 120V

3 G9-Z5250 1 POWER SUPPLY BRACKET

4 G9-Z5251 1 GEARMOTOR BRACKET

5 G9-Z5249 1 CONTROL BOX LID

6 2T-Z5175 1 THERMOSTAT, COOL DOWN, 120°F

7 2T-Z5176 1 THERMOSTAT, HI-LIMIT, 140°F

8 2T-Z5177 1 HIGH TEMPERATURE LIMIT

9 2E-Z5206 1 10AMP CIRCUIT BREAKER

10 2E-Z5683 1 VACUUM SWITCH

11 2E-Z1858 1 LIGHTED SWITCH

2E-Z5663 2 POWER RESISTOR BRACKETS

12

2E-Z6607 1 POWER RESISTOR - 5 OHM

13 2J-Z5189 1 THERMOCOUPLE/TEMP PROBE

14 G9-Z6611 1 POWER SUPPLY - 24VDC (115V INPUT)

15 2E-Z5162 1 TRANSFORMER

16 PS-Z11800 1 KIT, IGNITION CONTROLLER

16 PS-Z11801 1 KIT, IGNITION CONTROLLER (CE & UK Versions)

17 G9-Z5661 1 ELECTRODE SET

2U-Z10407

2U-Z5171 GEARMOTOR 500:1 24V DC, mfg before Oct 2010 UM1854-LP, UM1854-NAT

18

2U-Z13292 GEARMOTOR 240:1 120VAC, mfg after Sept 2010 UM1854-LP, UM1854-NAT

2U-Z13498 GEARMOTOR 40:1 120V UM1854Q-LP, UM1854Q-NAT

19 2A-Z6534 1 COUPLING

2F-Z5173

2F-Z5660 BURNER - PROPANE

G9-Z5670 #33 ORIFICE (HI NATURAL)

G9-Z5671 #56 ORIFICE (LO NATURAL)

G9-Z5672 #50 ORIFICE (HI LP)

20

G9-Z5673 #66 ORIFICE (LO LP)

2A-Y1255

2J-Z13829 #68 ORIFICE (LO LP) HIGH ALTITUDE

21 2K-2667 1 PIPE ELBOW

22 2K-Z3381 1 PIPE NIPPLE

23 2K-Z5105 1 COMPRESSION ELBOW

24 2K-Z5106 1 COMPRESSION ELBOW

2V-Z5103 1 GAS COMBINATION VALVE - NATURAL - 24VAC

25

2V-Z5659 KIT PROPANE REGULATOR KIT

26 2V-Z5104 1 GAS SOLENOID VALVE - 24VAC

27 G9-GC0001 1 BULKHEAD FITTING

28 2V-Z5194 2 STAINLESS FLEX TUBE

29 2C-Z5195 1 CONDUIT HANGER

30 2E-Z5187 1 WIRING KIT (COMPLETE)

31 2K-Z1971 4 SPACER (.188)

32 2C-Z5427 4 SPACER (.120)

33 2C-Z0216 2 SCREW M4 (METRIC)

34 2E-Z4597 2 TERMINAL BLOCK

35 2C-Y2344 1 GROUND TERMINAL

36 2K-Y2968 1 BUSHING, CORD STRAIN RELIEF

37 2E-Z5172 1 CORD SET

38 2E-Z5181 1 CAPACITOR - FAN MOTOR

39 2V-Z5194 2 SS FLEX 3/8 X 1/2

NI 2E-Z5187 1 WIRING HARNESS, GEARMOTOR

NI 2N-Z5668 1 CANDLE, WHITE SMOKE, CONVEYOR OVEN START UP

GEARMOTOR 40:1 UM1854Q-NATX, UM1854Q-LPX

1

BURNER - NATURAL

1

#52 ORIFICE (HI LP) HIGH

1

HIGH ALTITUDE LP

ALTITUDE

(INCLUDED IN BURNER)

(INCLUDED IN PROPANE BURNER)

Page 22

1

2

3

41

4

5

6

8

7

16

17

18

19

20

21

22

23

24

25

26

30

31

32

33

34

35

36

40

38

A Star Manufacturing Company

4) After five seconds, the new numbers will be saved and the oven

will display new settings.

If burner does not lght in one minute push the power

Adjusting TIME and TEMPERATURE:

2) Press the enter button ( ) to switch between TIME

1) Press the up and down buttons (

Ý ß

) at the same time,

hold for four seconds until TEMPERATURE display goes blank.

3) Press the up button (

Ý

) to increase or the down button (ß) to

decrease TIME or TEMPERATURE. Hold button down for

switch to the"OFF" position and wait five minutes.

To Start:

Push power switch "ON".

After five minutes, retry.

and TEMPERATURE.

faster display changes.

ON

OFF

39

9

10

15

11

13

14

27

28

29

SOME ITEMS ARE INCLUDED FOR ILLUSTRATIVE

PURPOSES ONLY AND IN CERTAIN

INSTANCES MAY NOT BE AVAILABLE.

THIS DRAWING CONTAINS INFORMATION CONFIDENTIAL

TO STAR MANUFACTURING INTERNATIONAL, INC.

NO REPRODUCTION OR DISCLOSURE OF ITS CONTENTS IS PERMITTED.

STAR MANUFACTURING INTERNATIONAL, INC.

MODEL UM1854

SK1906 Rev. D 5-23-08

MAIN ASSEMBLY

Page 23

PARTS LIST September 20, 2010, Rev. L

Ultra-Max Gas Conveyor Oven

UM1854-NAT/LP MAIN ASSEMBLY

Fig No Part No Qty Description Application

1 2C-Z3780 4 CONDUIT RETAINER

2 2R-Z5188 2 LATCH KEEPER

3 2R-Z5174 2 LATCH

4 G9-Z5309 2 DOOR BRACE

5 2P-09-WB-0003 4 PLUG CAP

6 2V-Z5293 1 HANDLE TUBE

7 2R-Z5279 1 HANDLE SUPPORT (PAIR)

8 2P-Z5303 2 HANDLE INSERT PLUG

9 G9-GC0024 1 CONVEYOR WELDMENT

2A-Z6538

10

2A-Z6539 Serial Numbers before: COG450107B0011

11 2A-Z5586 1 IDLER SHAFT ASSEMBLY W/ SPROCKETS

13 2B-Z5169 1 BELT - 10’ SECTION

14 2B-Z5170 4 BELT SPLICE CLIP

15 2P-Z5168 4 BEARING

16 G9-GC0040 1 FAN INLET PLATE

17 G9-Z5338 1 FAN INLET BELL

18 2A-Z5551 4 FAN INLET SPACER

19 G9-Z5549 2 REAR BUMPER

20 G9-GC0041 1 REAR COVER

21 PS-Z8749 1 BLOWER MOTOR HEAT SHIELD KIT (115V)

22 2B-Z5607 1 REAR FAN GUARD

23 2C-Z5380 1 RESTRAINT EYEBOLT

24 2C-Z3350 2 HALF CLAMP

25 2C-Z5427 4 SPACER

26 2K-H5417 1 BUSHING

27 G9-Z5281 1 PAN STOP

G9-Z11231

28

G9-Z5282 before serial no. COG541007B0011

G9-Z11232

29

G9-Z5283 before serial no. COG541007B0011

30 G9-Z5219 2 TUNNEL SHROUD

31 2V-Z5573 1 DRAFT TUBE

32 G9-Z5574 1 DRAFT TUBE HOSE

33 2V-Z5575 1 HIGH LIMIT TUBE

34 G9-Z5618 1 DRAFT TUBE CLAMP

35 G9-GC0045 1 FLAME BAFFLE

36 2C-Z5182 4 THUMB SCREW

37 2C-Z5179 1 PLUNGER SETSCREW

38 2P-Z1735 1 PLUG CAP

39 2M-Z5569 1 INSTRUCTION LABEL

40 2C-6349 4 SCREW #8X3/8 B THP STL NP

41 G9-GC0029 1 DOOR ASSEMBLY, FRONT

1

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

1

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

1 DRIVE SHAFT ASSEMBLY W/ SPROCKETS

1 CRUMB TRAY, NARROW

1 CRUMB TRAY, WIDE

Serial Number COG450107B0011 or after

on or after serial no. COG541007B0011

on or after serial no. COG541007B0011

Page 24

3

6

7

8

1

2

4

5

SOME ITEMS ARE INCLUDED FOR ILLUSTRATIVE

PURPOSES ONLY AND IN CERTAIN

INSTANCES MAY NOT BE AVAILABLE.

THIS DRAWING CONTAINS INFORMATION CONFIDENTIAL

TO STAR MANUFACTURING INTERNATIONAL, INC.

NO REPRODUCTION OR DISCLOSURE OF ITS CONTENTS IS PERMITTED.

STAR MANUFACTURING INTERNATIONAL, INC.

MODEL UM1854

SK1908 Rev. A 3/5/07

FINGER ASSEMBLY

Page 25

PARTS LIST September 20, 2010, Rev. L

Ultra-Max Gas Conveyor Oven

UM1854-NAT/LP FINGER ASSEMBLY

Fig No Part No Qty Description Application

1 G9-Z5516 1 LOWER FINGER BAFFLE

2 G9-GC0037 1 LOWER FINGER DIVERTER ASSEMBLY

3 G9-GC0035 1 LOWER FINGER WELDMENT

4 G9-GC0043 1 LOWER COLUMNATING PLATE

5 G9-Z5432 1 LOWER-FULL NOZZLE, PLATE

6 G9-Z5433 1 UPPER-FULL NOZZLE, PLATE

7 G9-GC0055 1 UPPER COLUMNATING PLATE ASSY

8 G9-GC0044 1 FINGER, UPPER - ASSY

1

IMPORTANT: WHEN ORDERING, SPECIFY VOLTAGE OR TYPE GAS DESIRED PAGE

1

INCLUDE MODEL AND SERIAL NUMBER OF

Some items are included for illustrative purposes only and in certain instances may not be available.

Loading...

Loading...