Page 1

WELLS BLOOMFIELD, LLC

2 ERIK CIRCLE, P. O. Box 280 Verdi, NV 89439

telephone: 775-689-5707

fax: 775-689-5976

www.wellsbloomfield.com

6 0 0

INSTALLATION INSTRUCTIONS

PART # 86280

RETROFIT COTHERM THERMOSTAT

Standard Brewers

Kit #86280 retrofits existing metal-shell thermostat with new hi-tech

resin-bodied thermostat.

PREPARATION:

1. Disconnect brewer from electric power and allow to cool.

Shut off water supply to brewer.

2. Remove top, front and/or back panels as required for

access to thermostat.

3. Disconnect wiring from old thermostat. Loosen two

screws holding thermostat to tank cover.

4. Remove thermobulb gland nut from tank cover. Withdraw

thermobulb from fitting. Discard thermostat assembly.

INSTALLATION:

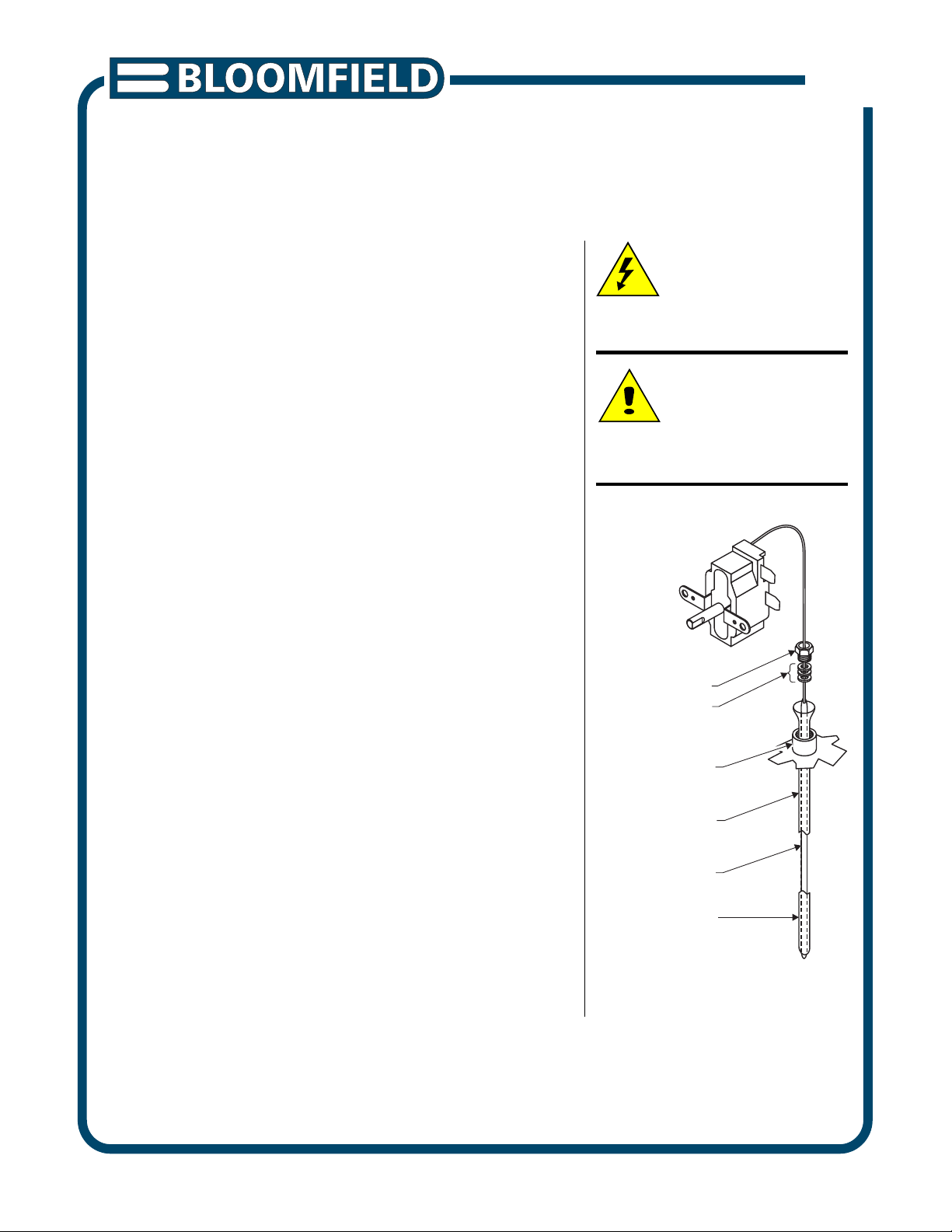

1. Insert bulb well into fitting on tank cover. Be sure well is

fully seated in fitting.

2. Insert thermobulb into bulb well. Be sure bulb is inserted

to the extreme bottom of the well.

3. Carefully insert capillary seal components into tank fitting.

IMPORTANT: Tighten gland nut only enough to prevent

leaks. Over-tightening is not necessary.

4. Mount thermostat body to tank bracket. Reconnect wiring.

5. Reconnect brewer to electrical and water supplies.

Test brewer for proper operation.

Refer to page 2 for temperature adjustment procedure.

Upon completion, reinstall access panels.

CAUTION:

SHOCK HAZARD

Unplug brewer from electric power

before beginning this procedure.

CAUTION:

BURN HAZARD

Allow brewer to cool before

proceeding.

GLAND NUT

CAPILLARY SEAL

TANK FITTING

BULB WELL

THERMOBULB

INSERT BULB

FULLY INTO

BULB WELL

Fig. 1 Thermobulb Installation

PRINTED IN UNITED STATES OF AMERICA

p/n 76697 Rev. A ECN-13394

1 of 2

I

600 080211 cps

Page 2

CAUTION:

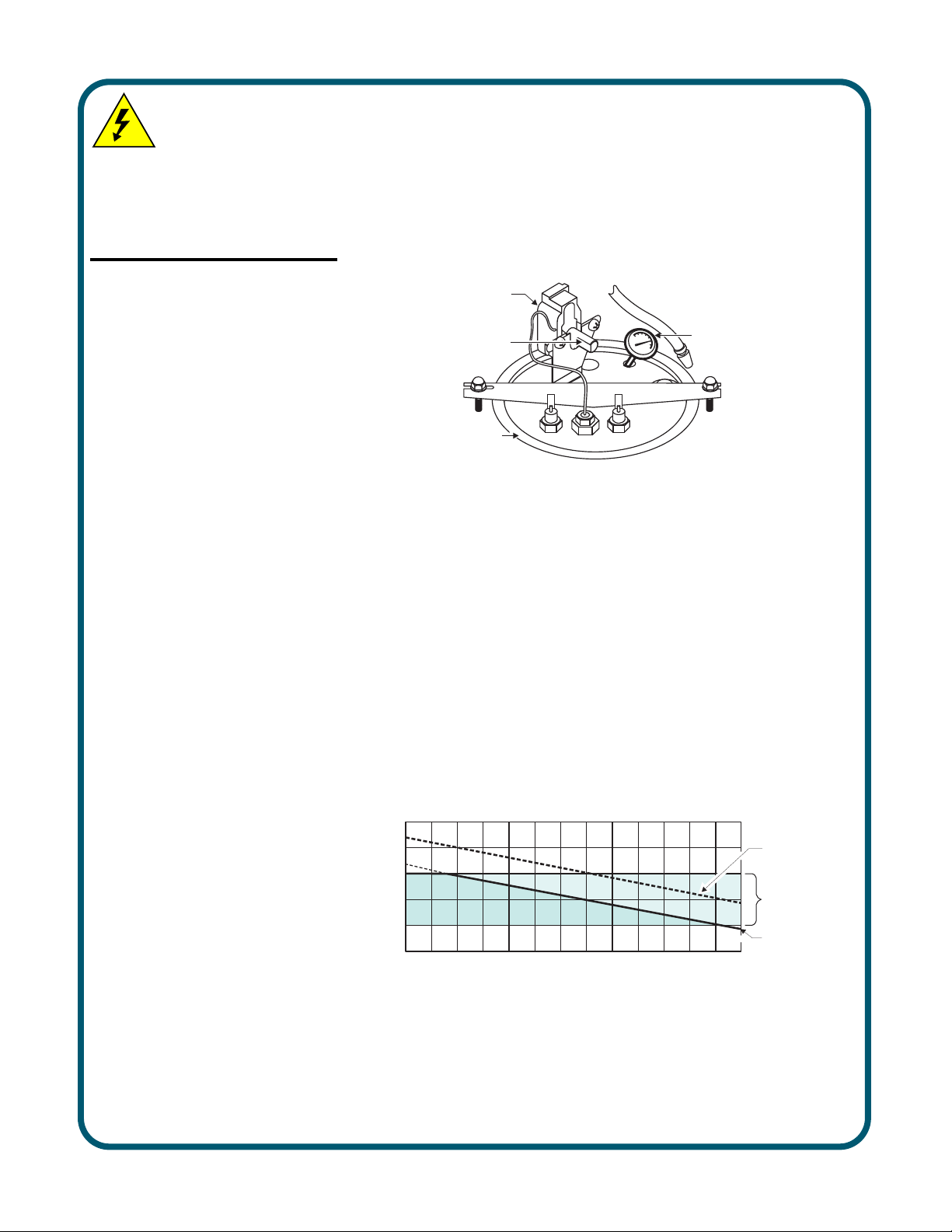

ELEVATION (feet above seal level)

0

500

1,000

1,500

2,000

2,500

3,000

3,500

4,000

4,500

5,000

5,500

6,000

6,500

TEMP. (ºF)

195

200

205

210

190

IDEAL

BREWING

TEMPERATURE

RANGE

MAXIMUM SAFE

TEMPERATURE

SETTING

BOILING

POINT OF

WATER

SHOCK HAZARD

These procedures involve

exposed electrical circuits.

These procedures are to be

performed by qualified

technical personnel only.

NOTE:

Optimum brewing temperature

range is 195ºF to 205ºF (90ºC

to 96ºC).

IMPORTANT:

A mechanical thermostat will

maintain temperature within

±5ºF. To prevent boiling water

in the brewer, thermostat should

be adjusted to a maximum

temperature equal to the local

boiling temperature minus 5ºF.

TEMPERATURE ADJUSTMENT

NOTE: This is a typical adjustment procedure for a standard

displacement brewer. Your exact procedure may vary depending

on the method of adding cold water to the water heater.

1. Disconnect brewer from electric power. Remove top panel.

2. Pull vent tube out of tank lid and insert a thermometer of

known accuracy in vent hole.

THERMOSTAT

ADJUSTING

SHAFT

VENT

DIAL-TYPE

THERMOMETER

IN VENT HOLE

TANK LID

ASSEMBLY

Fig. 2 Checking and Adjusting Brew Temperature

3. Place an empty container under brew chamber.

Reconnect brewer to electrical power. Energize brewer.

Press TANK HEATER switch ON where applicable.

4. Press BREW switch OR pour one decanter (64 oz.) of cold

water into pour-over opening. When READY TO BREW light

glows (or HEAT light goes dark), read temperature displayed

on thermometer.

5. Adjust thermostat by turning shaft;

clockwise increases temperature

counter-clockwise decreases temperature.

NOTE: 1/8 turn = approximately 10ºF.

Refer to Table 1 below for proper brewing temperature based

on altitude.

600 76697 Instr Retro Cotherm Thermo

Table 1 Boiling Temperature by Altitude

6. Upon completion, remove thermometer and reinstall vent tube.

2 of 2

Loading...

Loading...