Page 1

ELECTRICAL

SS-10T

SS-10T

SS-10T

SS-10TD

SS-10TD

208

240

120

208

240SS-10TD

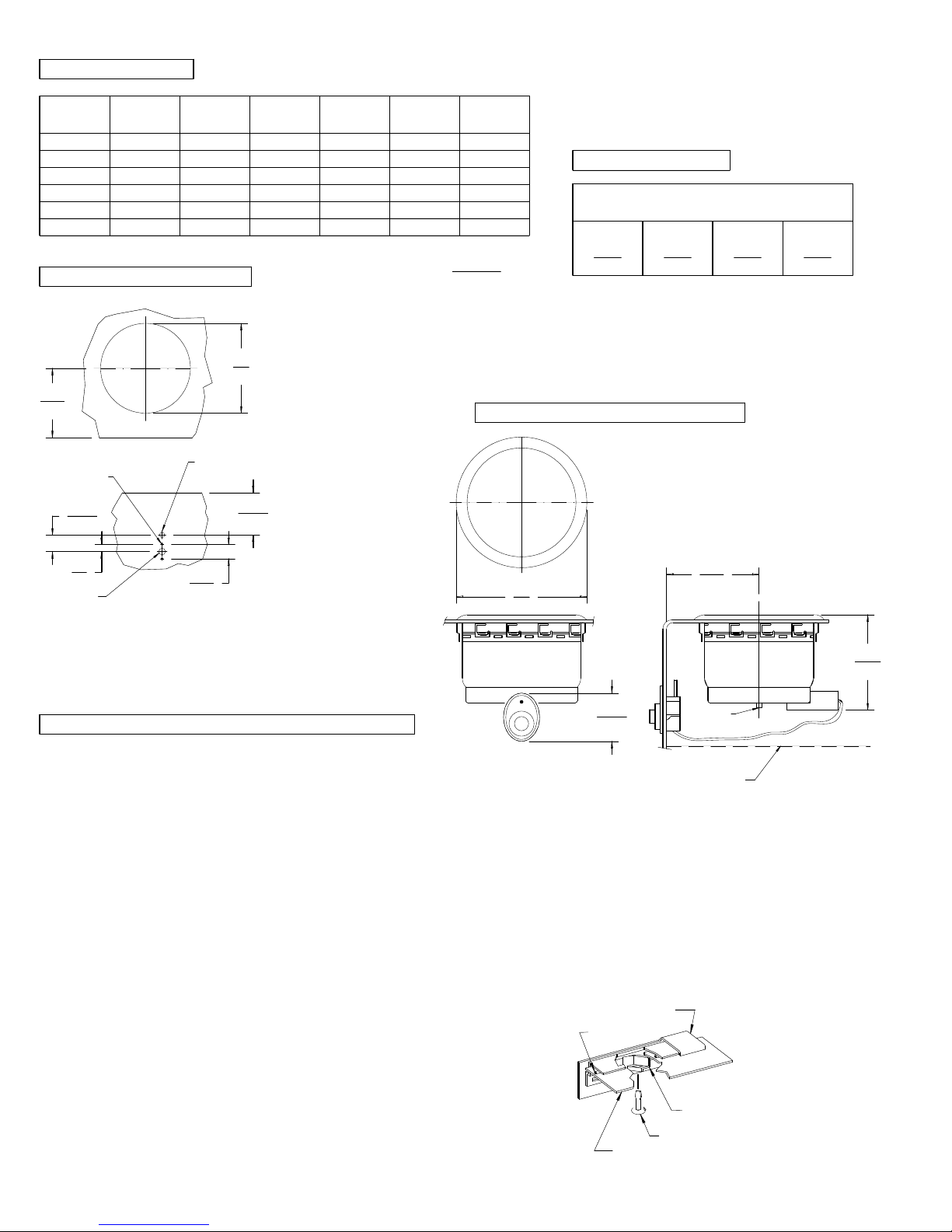

CUTOUT DETAILS

8 1/2

(216)

825120

620

825

825

620

825

11

(279)

6.9

3.0

3.4

6.9

3.0

TOP CUTOUT

SINGLE

SINGLE

SINGLE

SINGLE

SINGLE3.4

FIELD

WIRINGPHASEAMPSWATTSVOLTSMODEL

GAUGE

14 AWB CuSINGLE

14 AWB Cu

14 AWB Cu

14 AWB Cu

14 AWB Cu

TEMP.

RATING

90°C

90°C

90°C

90°C

90°C

90°C14 AWB Cu

INCHES

(MM)

INSTALLATION INSTRUCTIONS

BUILT-IN ROUND FOOD WARMERS

CLEARANCES

SUGGESTED CLEARANCES

UNIT TO THE NEAREST SURFACE

BACK SIDE BOTTOM FRONT

1 1

(25)

SEE CONDITIONS OF ACCEPTIBILITY BELOW

WHEN CONTROL BOX IS LOCATED BELOW THE

UNIT, FRONT CLEARANCE CAN BE 2 INCHES.

NOTE: DEPENDING ON THE INSTALLATION,

CLEARANCES CAN BE FURTHER REDUCED

UPON EVALUATIONS TO UL STANDARDS.

(25) (216)

8 1/2

PRODUCT DIMENSIONS

MODELS SS-10T (D)

4

(102)

17/64 DIA

2 PL

2 1/32

(52)

7/8

(22)

13/32 DIA

5/16 DIA

5 3/16

(132)

FRONT PANEL CUTOUT

1 3/4

(44)

INSTALLATION INSTRUCTIONS

UNIT MUST BE INSTALLED IN AN ALL METAL COUNTER.

THE INSTALLATION OF RECOGNIZED COMPONENT UNITS

REQUIRES ADDITIONAL EVALUATIONS TO UNDERWRITERS

LABORATORIES INC. STANDARDS.

INSTALLER MUST MEET CONDITIONS OF ACCEPTABILITY

OUTLINED BELOW UPON INSTALLATION:

1. This appliance shall be installed in an all metal counter

with suitable wiring and control enclosures conforming to

national and local electrical codes.

2. Electrical component temperatures, including wiring, within

and surrounding the appliance must be monitored in the

end use installation for suitability.

3. Electrical grounding of all dead metal parts must be

reliably connected to the grounding means of the appliance

and must comply with the requirements outlined in the

appropriate Underwriters Laboratories Inc. classification,

national and local electrical codes.

4. Increased clearances are required if storage of

combustible materials is in close proximity to this appliance.

5. Unit shall be accessible for servicing from the bottom.

6. The name/rating plate information shall be accessible.

7. For water and waste connections: This appliance is to

be installed to comply with the applicable federal, state or

local plumbing codes.

TO FABRICATE:

1. Lay out "cutout" dimensions on countertop and front

apron as shown in cutout details above.

2. Cut and/or drill holes as required in countertop and

3. Must be accessible for servicing from the bottom.

WELLS/BLOOMFIELD * VERDI, NV

NOTE: * CONTROL MUST NOT BE MOUNTED

IN THIS HIGH TEMPERATURE AREA.

8 1/2

12

(305)

(216)

*

4 7/16

(113)

TO INSTALL:

IMPORTANT - DO NOT disconnect lead wires from the

Control Panel when installing.

1. Locate the warmer and control panel over the

countertop cutout. Pass the control through the opening,

then mount the control to the rear of the apron.

2. Apply a bead of silicone adhesive/sealant to the gasket

supplied on the underside of the warmer flange, then seat

the warmer onto the countertop. Properly position.

3. From underneath, insert a screwdriver into the "slots" on

the wellslok frame and twist the "ears" outward to secure

the flange tightly to the countertop (see detail).

4. Mount the master control panel to the front of the

counter apron using the screws supplied.

WARMER FLANGE

GASKET

COUNTERTOP

1/2 NPT

(TD MODELS)

METAL SHIELD

WELLSLOK

SCREWDRIVER

41941-2 REV (-)

8 3/4

(222)

Loading...

Loading...