Page 1

IL2707

Conveyor Toasters Installation Instructions

These symbols are intended to alert the

user to the presence of important operating

and maintenance instructions in the manual

accompanying the appliance.

Go to:

www.star-mfg.com/scripts/manuals.aspx

to obtain this units installation & operations

manual, warranty & other documents.

NOTICE

Using any part other than genuine Holman factory supplied parts

relieves the manufacturer of all liability.

Holman reserves the right to change specications and product

design without notice. Such revisions do not entitle the buyer to

corresponding changes, improvements, additions or replacements

for previously purchased equipment.

Due to periodic changes in designs, methods, procedures, policies

and regulations, the specications contained in this sheet are subject

to change without notice. While Holman Manufacturing exercises

good faith efforts to provide information that is accurate, we are

not responsible for errors or omissions in information provided

or conclusions reached as a result of using the specications.

By using the information provided, the user assumes all risks in

connection with such use.

CAUTION

This equipment is designed and sold for commercial use only by

personnel trained and experienced in its operation and is not sold

for consumer use in and around the home nor for use directly by

the general public in food service locations.

Before using your new equipment, read and understand all the

instructions & labels associated with the unit prior to putting it into

operation. Make sure all people associated with its use understand

the units operation & safety before they use the unit.

All shipping containers should be checked for freight damage both

visible and concealed. This unit has been tested and carefully

packaged to insure delivery of your unit in perfect condition.

If equipment is received in damaged condition, either apparent or

concealed, a claim must be made with the delivering carrier.

Concealed damage or loss - if damage or loss is not apparent until

after equipment is unpacked, a request for inspection of concealed

damage must be made with carrier within 15 days. Be certain to

retain all contents plus external and internal packaging materials

for inspection. The carrier will make an inspection and will supply

necessary claim forms.

GENERAL SAFETY INFORMATION

MODEL

IRCS2-SBD

Conveyor Toasters

Electronic Controls

GENERAL INSTALLATION INFORMATION

The unit was shipped fully assembled and ready to plug into a

standard outlet specied for its voltage and amp draw. If improper

electrical supply is determined, contact a qualied electrician prior

to using the unit. Removal and replacement of the power cord

and plug will void the warranty. For assistance, contact your local

authorized service agent for service or required maintenance.

Level unit using the adjustable feet under the unit (approximately

1/2" adjustment).

Before using the unit for the rst time, wipe down the exterior with

a damp cloth.

Allow enough space around the toaster for adequate ventilation.

Do not operate the unit without the crumb tray properly positioned.

Overheating and poor toasting may occur. Read all labels on the

unit and follow their instructions.

MAINTENANCE AND REPAIRS

Contact the factory, a service representative or a local

service company for service or required maintenance.

Go to www.star-mfg.com/scripts/manuals.aspx to nd a service

agent near you. Replacement cord sets must be purchased from

Star Manufacturing International, Inc. or our authorized agents.

Should you need any assistance regarding the operation or

maintenance of any Holman equipment; write, phone, fax or

e-mail our service department. In all correspondence mention

the model number and the serial number of your unit, along with

the voltage.

Business Hours: 8 am to 4:30 p.m. Central Standard Time

Telephone: (877) 242-0270

Fax: (314) 781-2714

E-mail: Parts@star-mfg.com

Service@star-mfg.com

Warranty@star-mfg.com

Website: www.star-mfg.com

Mailing Address: Star International Holdings Inc., Company

10 Sunnen Drive

St. Louis, MO 63143

U.S.A.

2M-Z17916, Rev. B 5/23/2014

Page 2

ELECTRICAL CONNECTION

Before making any electrical connection to this unit,

check that the power supply is adequate for the voltage,

amperage and requirements stated on the rating plate.

A wiring diagram is included in the Installation &

Operations manual, which can be downloaded at

www.star-mfg.com/scripts/manuals.aspx.

Disconnect the unit from the power source before installing or

removing any parts.

Be absolutely sure that the ground connection for the receptacle is

properly wired. Do not connect equipment to power without proper

ground connections. Improper grounding may result in personal

injury or fatality.

DO NOT CUT OR REMOVE THIS PLUG OR

WARNING

WARNING

CAUTION

WARNING

GROUNDING PRONG FROM THE PLUG.

CONNECT/PLUG UNIT INTO DEDICATED

A.C. LINE ONLY SPECIFIED ON THE DATA

PLATE OF THE UNIT.

CERTAIN SURFACES ARE EXTREMELY HOT

DURING OPERATION AND CARE SHOULD

BE TAKEN WHILE USING THIS UNIT.

DO NOT IMMERSE OR LET THE UNIT STAND

IN WATER.

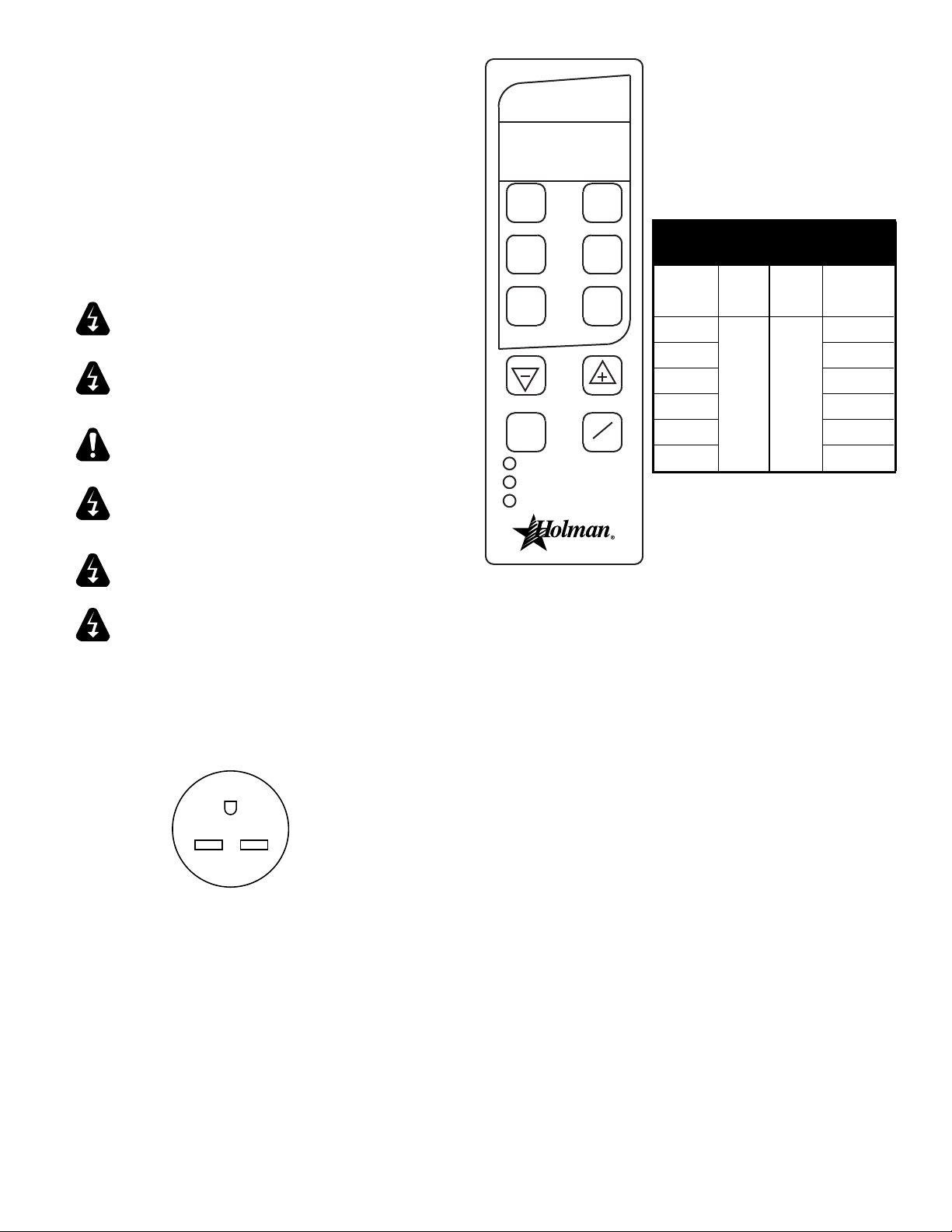

ELECTRONIC

RADIANT-IMPINGEMENT SYSTEM

T1 T2

T3 T4

T5 T6

SAVER

TOP HEAT

BOTTOM HEAT

CONVEYOR SPEED

ON

OFF

The Holman IRCS conveyor toaster

comes with pre-programmed factory

default settings for ALL MENU

BUTTONS.

Factory default settings are as follow:

IRCS2-SBD DEFAULT

SETTINGS

Menu

Buttons

T1

Top

Heat

Bottom

Heat

Conveyor

Speed

45

T2 87

T3 23

8 10

T4 90

T5 70

T6 99

DO NOT HOSE DOWN THE UNIT OR THE

TABLE/COUNTER IF THE UNIT IS ON THE

WARNING

TABLE/COUNTER.

KEEP AWAY FROM RUNNING WATER.

WARNING

INSTALLATION REQUIREMENTS

1. Space: 16”x24”x18” (width x depth x height) in

Specialty Board of Breakfast Toaster Cart

2. Electricity: 208/240 Volts, 30 Amps, NEMA 6-30R

Recepticale

NEMA 6-30R

NOTE: Ensure to clean the toaster properly before

using it for the rst time. Refer to the Cleaning

Procedure document for cleaning instructions.

IL2711

POWER SAVER SWITCH

There are three Power Saver modes:

ON: Unit is in pre-programmed power saving setting.

OFF: Power Saver mode is turned off.

AUTO ON: Power Saver turns on when there has been no activity

for a programmed length of time.

The operator may adjust the level of power reduction for the saver

mode. (Note: conveyor may move slowly when in saver mode.)

Two buttons (+) and (-) are used when increasing or decreasing the

value of each programmable setting.

A red LED light located at the lower portion of the control panel label

will indicate if the value for top heat, bottom heat or conveyor speed

is being adjusted.

Page 3

CERTAIN SURFACES ARE EXTREMELY HOT

DURING OPERATION AND CARE SHOULD

CAUTION

BE TAKEN WHILE USING THIS UNIT.

START UP

When the toaster has been plugged into a suitable outlet and power

supply, the word OFF will be displayed on the L.E.D. read out.

A. Press the ON/OFF button once to turn on the toaster. The

toaster will now enter into pre-heat and “PREHT” will be

displayed (the elements will begin to glow but the conveyor

and fan motor will not turn on).

B. After one minute, the fan motor will turn on and the conveyor

will begin turning at the previously saved setting (for initial

start up, the drive motor will operate at the factory default

setting).

C. After 14 minutes, the display will show the last used program

selection i.e. (for initial startup, CROIS, MUFFIN, will be the

last program selected).

DAILY OPERATION

Check the power cord to insure that it is plugged into a proper

outlet.

Press the ON/OFF button once to turn the toaster on.

Press the button a second time to turn the toaster off.

NOTE: When the toaster is turned off, the fan and conveyor motors

will continue to run for ve minutes. The words COOL and DOWN will

be alternately displayed during that time. After ve minutes, the word

OFF will be displayed until the ON/OFF button is pressed again.

Once the toaster has been pre-heated, the menu buttons can be

pressed to change to T1, T2, T3, T4, T5, T6

OPERATING HINTS AND SAFETY

IMPORTANT: If “HIGH TEMP” shows on the display

1. Turn off the toaster and allow it to fully cool down.

2. Inspect the fan inlet on the bottom of the toaster

and remove anyting blocking the cooling fan inlet.

3. Press the red high temperaure limit reset button on

the back of the toaster. (Note: There is one reset

on each side). (Note: the toaster must be fully cool

in order for the limit switch to reset).

4. Turn on the toaster and check for proper operation.

5. If cleaning the cooling fan inlet does not correct

the problem, contact the factory or an authorized

service agency for required maintenance.

Disconnect power to the unit with the ON/OFF button at the end of

each day of operation.

Do not leave the unit in operation without an attendant.

Do not leave the unit at high temperature when not in use or during

idle periods. This will cause food particles and grease lm to

carbonize.

The cooling fan will continue to run until the toaster has completely

cooled. If the toaster MUST be moved after using, allow the cooling

fan to turn OFF before unplugging.

PROGRAMMING

A. CONVEYOR SPEED (temporary setting)

The conveyor speed is programmable with a range from 1 to 99 with

1 being the slowest and 99 being the fastest. Each menu item can

have independent conveyor speed settings.

B. PROGRAMMING VALUES FOR MENU ITEMS

To make a program change to the top & bottom elements, or conveyor

speed, you must rst be in the menu item you want changed.

Example: to change the programmed conveyor speed for croissants,

the display must read CROIS. To change the programmed conveyor

speed for MUFFIN, the display must read MUFFIN and so on for

each menu item.

1) Select the menu item you want to change i.e. T1, T2, T3, T4,

T5 or T6.

2) Press and hold both ( + ) AND ( - ) buttons for 3 seconds until

the display goes blank, release the buttons and the display

will show three characters for the menu item elected and the

last two characters for the current value setting, i.e. T1, T2,

T3, T4, T5 of T6. The red L.E.D. light for upper front element

at the bottom of the label will ash.

3) Press the ( + ) or ( - ) buttons to increase or decrease the

setting for the upper element.

4) Press the button for the menu button again and the red L.E.D.

for the up lower element will ash.

5) Press the ( + ) or ( - ) buttons to increase or decrease the

setting for the lower element.

6) Press the button for the menu button again and the red L.E.D.

for the conveyor speed will ash.

7) Press the ( + ) or ( - ) buttons to increase or decrease the

setting for the conveyor speed.

8) To skip one feature setting with out making any changes,

press the menu item button one time and the red L.E.D. light

for the next item will now ash.

9) To change the POWER SAVER values press the SAVER

button or to save your new setting(s), and exit the program

mode press the menu button.

10) The last two characters in the display will show MN for

minutes.

11) The rst three characters will be numerical to represent the

time setting.

12) When set to “OFF” the Saver button will be disabled during

operation. The PowerSaver can be set to “OFF” or using the

( + ) or ( - ) set the time from 15 to 480 minutes.

13) Press the SAVER button to change the power reduction using

the ( + ) or ( - ) buttons to increase or decrease the setting.

14) Press the POWER SAVER button to save changes and to

exit.

Page 4

CLEANING

STAR INTERNATIONAL HOLDINGS INC. COMPANY

Preventive maintenance for your Holman toaster consists of the

following recommended cleaning procedures. To keep your toaster

in its top operating condition, these steps should be performed on a

daily or weekly basis as required.

Supplies

KAY® QSR Oven Cleaner

KAY® QSR Heavy Duty Multi-Purpose Sink Detergent

(dispensed use solution)

KAY® Sink Sanitizer (use solution prepared at the sink)

No Scratch Pad

Red Cloth

Daily Procedure:

1. Turn toaster off, conveyor will continue to run until cooled

down (approx. 5-10 minutes)

2. Immediately spray the oven cleaner onto the No Scratch

Pad and scrub the conveyor chain while it is still warm and

moving.

NOTE: DO NOT SPRAY directly onto the conveyor

belt or into the cooking chamber. Overspray onto the

heating elements can damage or shorten the life of the

elements.

3. Wash the No Scratch pad at the 3 compartment sink and then

soak with Multi-Purpose Sink Detergent. Ring the pad out so

that it is only damp and continue to scrub the conveyor belt

while it’s still moving.

4. Rinse the No Scratch pad at the 3 compartment sink to remove

all detergent and then soak with clean warm water. Ring

the pad out so that it is only damp and continue to scrub the

conveyor belt while it still moving.

5. Wipe the conveyor belt with a clean red cloth dampened with

sanitizer solution while it is still moving. Allow to air dry.

6. Rinse the No Scratch pad at the 3 compartment sink and then

soak with clean warm water. Ring the pad out so that it is only

damp and wipe exterior areas of the toaster.

7. Remove interior crumb tray and bottom catch tray and take

to the three compartment sink. Spray the pieces with oven

cleaner and allow to sit on the drain board for a minimum of

ve minutes.

8. Wash, Rinse and Sanitize removable pieces and allow to air

dry before sliding the trays back into the unit.

9. Unit is now ready to turn ON for warm up and use.

OPERATION PROCEDURES

Used to toast croissants and english mufns

To Turn unit ON

1. Ensure toaster is plugged in

2. Press ON/OFF burron on each control panel.

Screen will display “PREHT” for 15 minutes.

DO NOT toast any product while the screen

displays “PREHT”

3. Select the desired menu button.

4. Toast product in corresponding belt.

To Turn unit OFF

1. Ensure there is no product in the toasting chamber

2. Press ON/OFF button on each control panel.

Screen will shufe “COOL” and “DOWN” for 10

minutes.

NOTE: belts will continue to move for the duration of

the cool-down time. Use this time to clean the toaster.

ROUTINELY CHECK

Entering Programming Mode

NOTE: Ensure the toaster is ON

NOTE: Changes to the same product must be repeated

for each belt.

1. Select product

2. Press and hold up and down arrows at the same

time. You will enter programming mode.

3. Use the up and down arrows to select the desired

top heat.

4. Press product button on control

5. Use the up and down arrows to select desired

bottom heat.

6. Press product button on control

7. Usse the top and down arrows to select desired

conveyor speed

8. Press product button on control 2-3 times until you

exit programming mode.

NOTE: Changes in belt speed will be made immediately.

Changes in top/bottom heat will take time to adjust

depending on the specics of the change

DO NOT IMMERSE THE UNIT IN WATER OR LET

WARNING

THE UNIT STAND IN WATER.

DO NOT USE A NON-STICK SPRAY ON THE

CONVEYOR BELT, IT WILL CAUSE A STICKY

CAUTION

BUILD-UP AND INCREASE STICKING.

DO NOT HOSE DOWN THE UNIT OR THE

WARNING

TABLE/COUNTER IF THE UNIT IS ON THE

TABLE/COUNTER.

KEEP AWAY FROM RUNNING WATER.

WARNING

Star - Holman - Lang - Wells - Bloomeld - Toastmaster

10 Sunnen Drive, St. Louis, MO 63143 U.S.A.

(314) 678-6303

www.star-mfg.com

Page 5

FS

5

4

HB1 HT1

11

15A

OT

13

12

120V

240V

240V

120V

35

IF

CF

L1 F1 M1

BLK

10

BLUE (240V)

CM

4

12

OT2 L2 M2 F2 OT1 HB2 HT2

WHT (208V)

FS FAN SWITCH (TSTAT)

OT OVER TEMP (TSTAT)

IF IMPINGEMENT FAN

CF COOLING FAN

M MOTOR CAPACITOR

CM CONVEYOR MOTOR

RR REVERSING RELAY

3

2

1

OT

12

13

OT2 L2 M2 F2 OT1 HB2 HT2

BLUE (240V)

WHT (208V)

11

L1 F1 M1

BLK

CM

120V

240V

240V

120V

GND

HB1 HT1

11

10

15A

WHT BLK

2M-Z17918

Page 6

1

13 12

8

9

10

11

2

6

7

ACCESSORY

3

4

5

37

39

38

40

36

47

46

48

42

43

45

44

41

31

32

23 24

33

34

35

16

25

26

17

27

18

28

14

19

29

15

20

30

21

22

2M-Z17916: Split Conveyor Toaster, IRCS2-SBD

MODEL: IRCS2-SBD:

Split Electronic Conveyor Toaster

SK2720 Rev. A 5/23/14

Page 7

Model: IRCS2-SBD Split Conveyor Toaster

Fig No Part Number Qty Description

1 HC-120334 1 BODY WRAP ASSY IRCS-2-SB

2 HC-Z17531 2 PADDLE HOLDER

3 HC-120333 1 PADDLE (ACCESSORY)

4 HC-Z17540 1 BACK PANEL

5 2U-Z17519 1 BLOWER-IMPINGEMENT

6 HC-Z17546 1 COVER-REAR DUCT

7 HC-Z17547 1 REAR PLENUM

8 HC-120341 1 TOP BAFFLE ASSY IRCS2-SB

9 HC-Z17541 1 COVER-TOP INSULATION

10 HC-Z17542 1 PLENUM-IMPINGEMENT

11 HC-Z17544 1 COVER PLATE-BEARING ACCES

2N-Z16981

12

2N-Z17528 ELEMENT,240V,1400W

2N-Z16982

13

2N-Z17529 ELEMENT, 240V, 100W

14 2E-Z17515 1 USB BOARD

15 2K-Y6764 1 BUSHING - STRAIN RELIEF

16 2E-200566 2 SWITCH, RESET, 0796

17 2K-8043 2 BUSHING HEYCO SB-875-10

18 HC-120342 2 BEARING ASSEMBLY-GRAPHITE

19 2A-Z17509 2 DRIVE SHAFT

20 HA-112261 2 BEARING ASSY 5/16 TEFLON

21 2P-200645 2 SPROCKET, 25B17 X 5/16

22 HC-Z17545 2 BRACKET-CONV SHAFT

23 2K-Z6183 2 BUSHING 1.125

24 2E-200574 1 SWITCH,FAN, CERAMIC,

25 HG-402144 1 FAN SWITCH BRACKET (-T)

2U-Z9657

26

2U-Z9658 DRIVE MOTOR, LEFT

HC-Z17468-1

27

HC-Z17468-2 BRACKET-SPEED SENSOR RT

28 2E-Z17514 2 SPEED SENSOR

29 2P-200648 2 SPROCKET, 25B32 X 5/16

30 2P-150015 2 CHAIN DRIVE #25 ROLLER

31 2R-200709 4 LEG 1 INCH CHROME PLASTIC

32 2E-Z17513 2 POWER BOARD

33 2U-Z17520 1 MUFFIN FAN 130CFM

34 HC-Z17511 1 PLATE-FAN MOUNT

35 2R-200562 1 FAN GUARD

36 HC-Z18521 1 SLIDE OUT TOAST TRAY

37 2R-200787 1 QCS 1&2 CRUMB TRAY GUARD

38 HC-120335 1 CRUMB TRAY ASSY IRCS-2-SB

39 HC-120338 1 RT IMPINGEMENT PANEL ASSY

40 HC-120339 1 LEFT IMPINGEMENT PANEL

2M-Z17916: Split Conveyor Toaster, IRCS2-SBD

41 2A-Z16807 2 IDLER ASSEMBLY R2N

42 2P-200700 4 BEARING-PTFE SPRING LOAD

ELEMENT,208V,1400W

2

ELEMENT 208V,1000W

2

DRIVE MOTOR, RIGHT

1

BRACKET-SPEED SENSOR LT

1

Model: IRCS2-SBD Split Conveyor Toaster

Fig No Part Number Qty Description

43 2P-200736 4 2 INCH BEARING SPRING

44 2E-Z5681 2 FUSEHOLDER, CLASS G

45 2E-200596 4 15 AMP FUSE, TYPE G

46 2M-Z17910 2 LABEL-CONTROL PANEL

47 HC-Z17908 2 CONTROL BOARD, IRCS2-SBD

48 PS-Z16768-43 2 COMP BELT SEGMENT IRCS2

NI D9-Z10878 1 CORDSET L6-30P 12/3 84IN

NI 2E-Z17516 2 USB CABLE

August 13, 2014, Rev B

Page 8

Loading...

Loading...