Page 1

INTEGRITY SERIES

SATELLITE

COFFEE BREWING SYSTEM

OWNER’S MANUAL

OPERATING INSTRUCTIONS

MAINTENANCE INSTRUCTIONS

AND PARTS LISTS

71252

9102-M

MODEL

9102 Auto w/Faucet 120V

9104 Auto w/Faucet 115/230

BLOOMFIELD INDUSTRIES

2 ERIK CIRCLE, P.O. BOX 280

VERDI, NEVADA 89439

FAX (800) 356-5142

Page 2

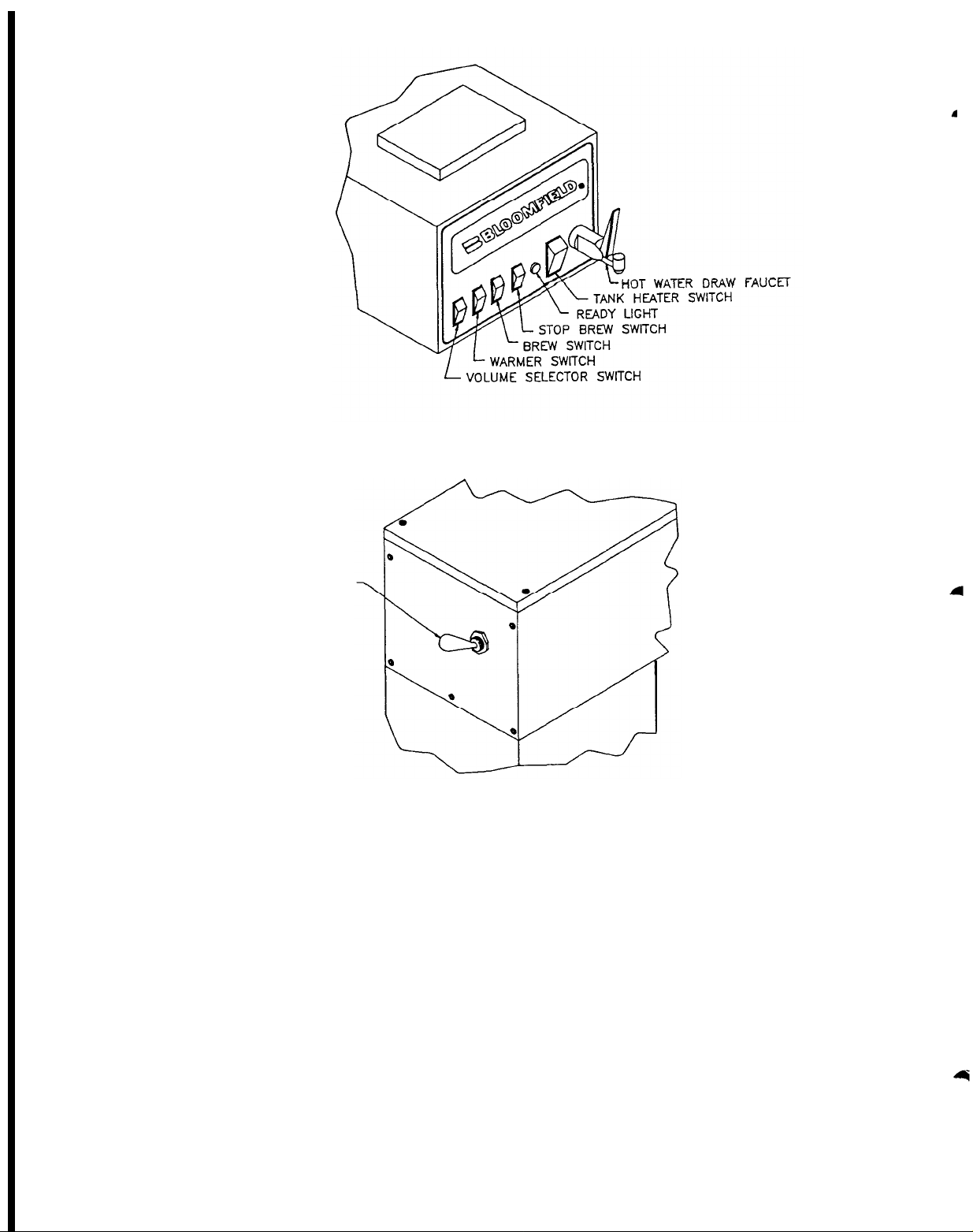

(Figure 1)

FRONT

VIEW

FAUCET

REAR

MAIN POWER SWITCH

(Figure 2)

The

INTEGRITY BREWERS

have

been

flexibility to cover a wide spectrum of

Adjustments on the running thermostat and inlet timer are simple

adjustments

COVERED UNDER ANY WARRANTY SERVICE AGREEMENT.

Brewers must

instructions

easily

accomplished by the purchaser,

be installed in accordance with installation

in the owner's manual for the warranty to be valid.

VIEW

designed with

customer

adjustment

needs.

but NOT

WARNING: DO

INSTALLATION INSTRUCTIONS ARE READ AND FOLLOWED.

NOT

PLUG IN OR

ENERGIZE

THIS

UNIT

UNTIL

Page 3

WARNING:

DO NO PLUG IN OR ENERGIZE THIS UNIT UNTIL INSTALLATION

INSTRUCTIONS ARE READ AND FOLLOWED.

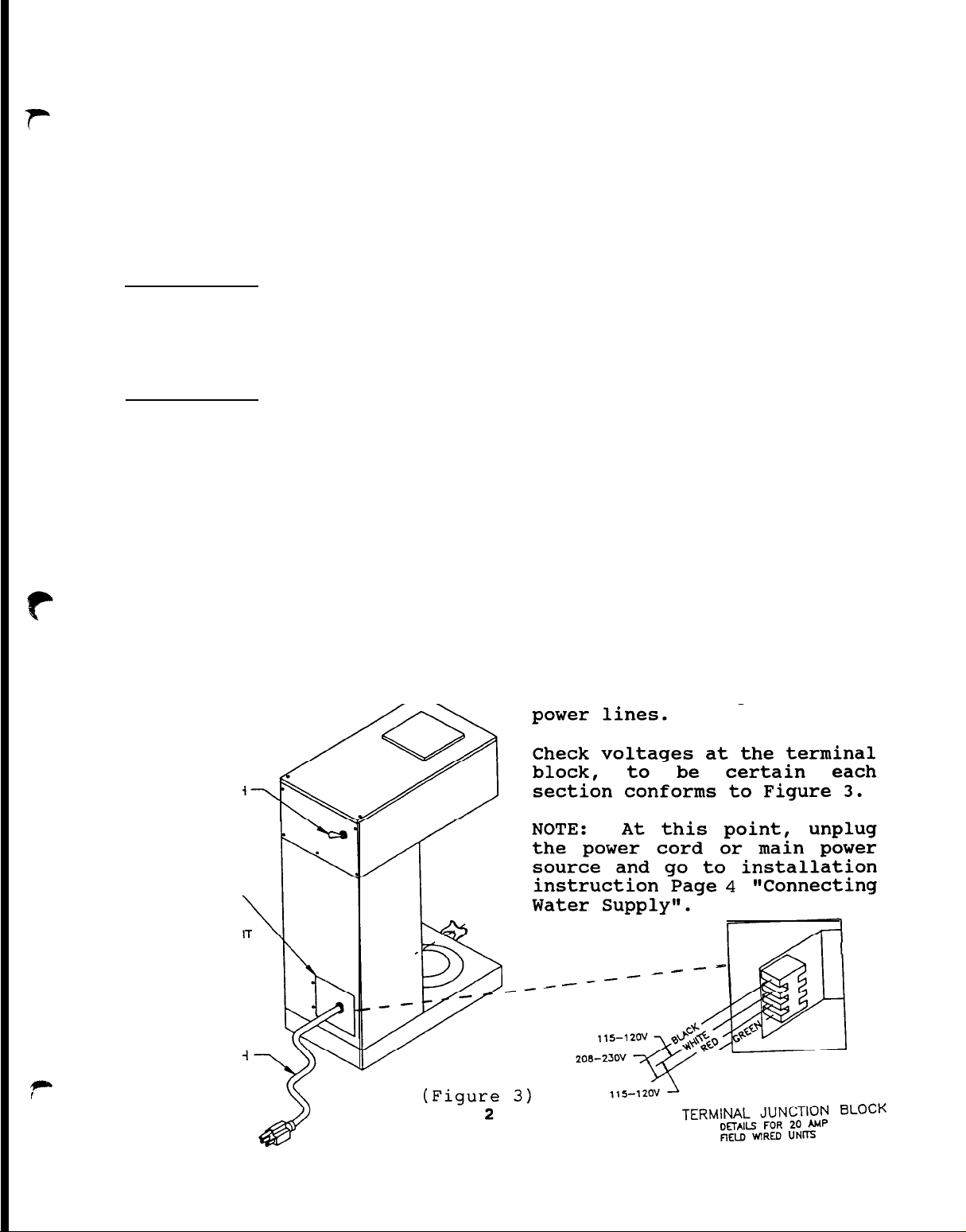

ELECTRICAL INSTALLATION

IMPORTANT: Prior to starting

the electrical hook-up, check

power source and electrical

receptacle for proper single

phase voltage supply.

Figure

3 details:

Models 9104 Unit with 3 wire

plus ground requires: 120/208

Volt or 115/230 Volt A.C. 60

HZ.,

Wire,

Single Phase, (3) Three

20 AMP service.

Models 9102 Unit with 2 wire

plus ground, is equipped, (from

the factory),

with power cord

and plug attached. It requires

120 Volt, A.C., 60 Hz., Single

phase (2) Two wire, grounded,

15 AMP service.

CAUTION: DO NOT CONNECT TO A

THREE (3) PHASE POWER SOURCE OR

ANY OTHER THAN AS NOTED IN

FIGURE 3, AS DAMAGES TO THE

UNIT CAN OCCUR THAT ARE NOT THE

RESPONSIBILITY OF

THE

MANUFACTURER OF THE UNIT.

IMPORTANT:

For Power supply,

use #12AWG wire suitable for 75

degrees C.

ONLY.

Wire, plug and connector

must be

Use copper wire

supplied by

the

ELECTRICIAN, for 20 AMP. units.

1.

Recheck at this point, the

Main Power Switch and the

Tank Heater Switch on the

unit front panel must be

in the OFF position.

2.

For

units

electrician

requiring

installed

power cord, remove two (2)

screws from rear access

panels of

brewer

for

access to the installation

junction block.

All wiring must be

accordance with

local

electrical codes.

Do not assume the GREEN earth

ground wire can be used as a

neutral.

The GREEN earth

ground is a protection circuit

not intended as part of the

MASTER SWITCH

ACCESS DOOR

TO TERMINAL BLOCK

CONNECTIONS FOR

115/23OV

POWER CORD SUPPLIED WITH

120V, 15A UNiTS ONLY

.

Page 4

GUIDE TO THE INITIAL INSTALLATION

AND TANK FILLING SEQUENCE

NOTE:

THIS UNIT IS PROVIDED

WITH FOUR (4) 4 INCH LEGS.

THESE LEGS ARE TO BE INSTALLED

ON UNIT BY SCREWING THEM INTO

THE

THREADED

HOLES ON

THE

BOTTOM PLATE.

LEVELING THE UNIT

This is a

installation operation

must

ignored.

not be

For proper unit oper-

ation, it is

very

important

that

overlooked or

very

important

that the unit be level when it

is standing in its installed

location.

The 4 inch legs provided with

the unit can be adjusted to

correctly level unit.

NOTE:

THIS FOLLOWING PROCEDURE

MUST BE PERFORMED TO INITIALLY

FILL WATER TANK.

STEP 1.

Check

the

Main

switch, to be sure it

is in the "OFF" position.

The switch is

located on the rear

upper panel of the

unit.

It must remain

"OFF" until the tank

filling procedure has

been read

and

followed.

STEP 2.

CHECK

HEATER

THAT

SWITCH,

TANK

LOCATED ON FRONT OF

BREWER IS IN "OFF"

POSITION.

STEP 5.

STEP 6.

STEP 7.

STEP 8.

STEP 9.

STEP 10.

STEP 11.

Turn brew selection

switch,

on

front

panel of unit to the

1 gallon position.

Slide brew chamber

into place and place

an

empty

satellite

container on warmer.

CHECK THAT FAUCET IS

CLOSED.

Turn on

water

and

electric at source.

Turn on main power

switch

on back of

brewer.

Press

switch,

brew

wait

start

(2)

minutes and repeat.

Water

flowing

chamber

third

should

from brew

during

cycle

start

the

indicating the tank

is filled with water.

After

remove,

water

empty

stops,

and

replacethe satellite

container under the

brew chamber.

Follow

instructions

for initial brewing

cycle set-up

operation

and

guide.

Page (5).

STEP 3.

STEP 4.

Connect

source to unit.

electrical

(SEE

INSTRUCTIONS - PAGE

2) l

Connect water supply

to

unit.

(SEE

INSTRUCTIONS - PAGE

(4)) -

3

Page 5

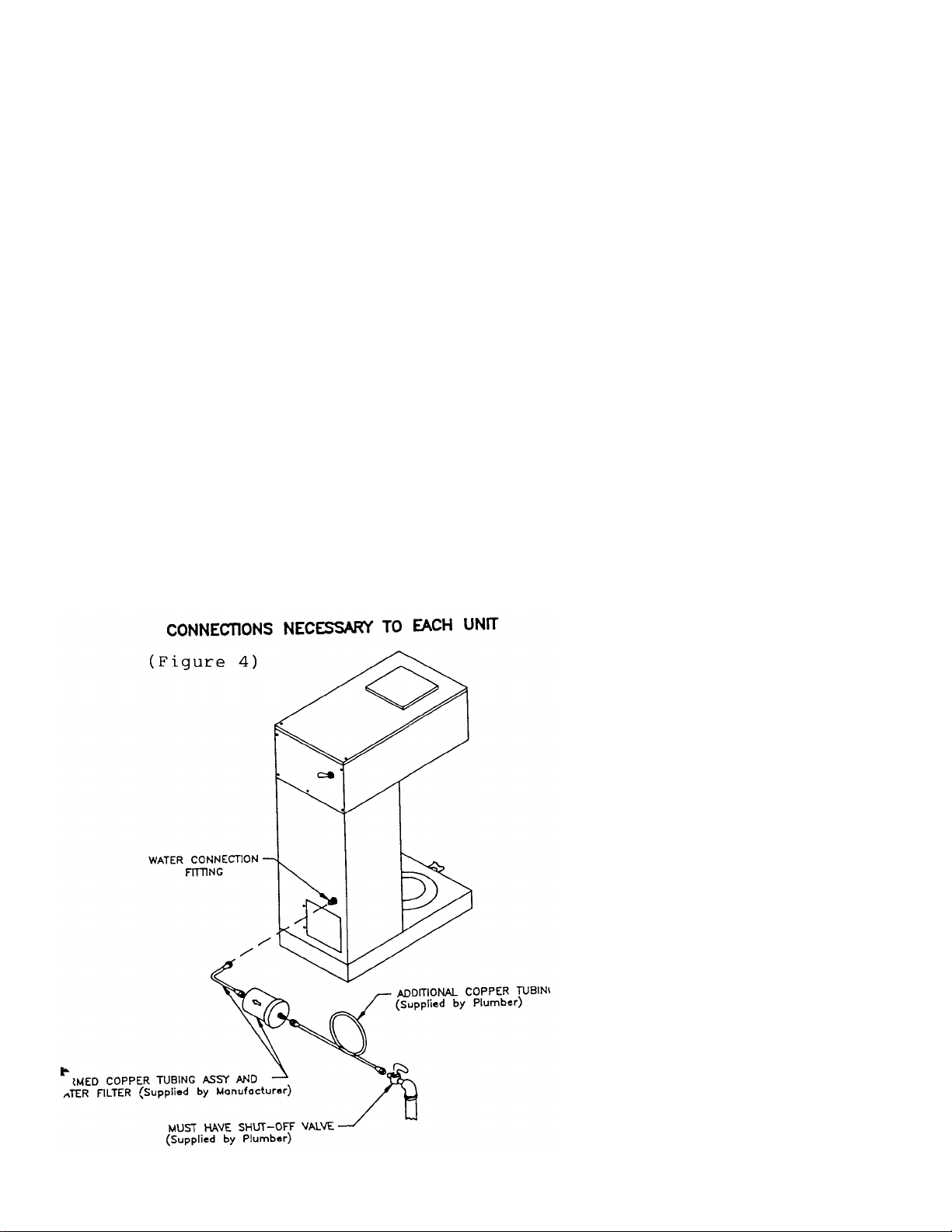

CONNECTING WATER SUPPLY LINE TO UNIT

4

Complete the electrical installation

before starting the water connections.

WARNING:

DO NOT PLUG IN OR ENERGIZE THIS UNIT UNTIL

INSTALLATION INSTRUCTIONS ARE READ AND

FOLLOWED.

IMPORTANT: Flush water line until

water runs clear before installing water

line to filter and the unit. Machine

should be connect to COLD WATER LINE.

Before starting water hook-up, check to

be sure the power cord of the unit is

unplugged, or main power source is off.

Unit must be installed on a water line

with a flowing pressure between 20 PSI

and 90 PSI. If water pressure does not

fall into this range, or varies

greatly, a pressure regulator should be

installed.

AUTOMATIC BREWERS are supplied with

water line filter which has to be

installed between the machine and water

supply line.

For installation, use 1/4" copper

tubing and fittings. A water shut-off

valve must be installed in the supply

line (not included). For connecting of

the brewer to water supply line, refer

to Figure No. 4.

NOTE: Water line connections to

machine must conform to local codes.

After water hook-up is completed,

continue to follow installation

instructions, page 3 "Guide to the

Initial Installation and Tank Filling

Sequence" to finish the installation

and set-up the unit for brewing cycle.

The National Sanitation Foundation

requests a provision be made in the

incoming water line for flexibility.

This is necessary to allow tilting or

moving the machine for proper cleaning

underneath, etc. A tightly coiled

length of copper tubing located on

either side of the water strainer

would help comply with this request.

Page 6

INITIAL BREWING CYCLE SET-UP AND OPERATION GUIDE

This unit is now connected to

water

supply

electric power source.

and to

the

Check

that installations have been

made as described in electrical

and

water

supply

connection

instruction.

1.

Complete each step in the

following sequence:

A.

Check that main power

switch is

II ON II

and

unit is connected to

power source.

heater

remain

switch

"OFF"

Tank

must

until

STEP "F".

B.

Check

that

brew

selector switch is in

the 1 gallon mode.

C.

Check

that

brew

chamber is in place

and an

satellite

empty

container

is under it with its

faucet CLOSED.

D.

Take

an

decanter

under

faucet

faucet

l/2

water.

hot

and

drawing off

decanter of

This avoids

"spitting"

and

empty

hold

water

open

from

faucet due to trapped

air in

the

water

coil.

E.

Turn "ON" the main

power switch, located

on

upper

back of

brewer.

F.

Now turn

the tank

heater switch to the

"ON"

position.

Switch is located on

the front upper panel

of unit.

2.

3.

4.

Water in the tank will

start heating.

Initial

heating time is

approximately

minutes,

brewer model.

15 to 25

depending on

The GREEN

Ready to Brew light will

turn on when water reaches

brewing temperature.

When GREEN Ready to Brew

light turns ON, Press Brew

Start switch.

Hot Water

will start flowing out of

the brew

chamber,

indicating that the tank

is full of water.

After

water stops flowing from

brew chamber, remove and

empty

container,

the satellite

and place it

back under brew chamber,

with faucet closed.

(Be

sure the brew selector

switch is set for 1 gallon

brewing).

Repeat

STEP 3...after

water stops flowing, you

should have approximately

128 ounces

brim

full

slightly over

of water (2

decanters or

l/2 a

satellite container). If

after completion

of the

cycle you do not have 128

ounces of water,

proceed

as follows:

A.

Check water

supply

line pressure.

BREWER WILL

NOT

OPERATE PROPERLY IF

THE LINE PRESSURE IS

BELOW 20 PSI.

(You

may obtain your PSI

pressure by inserting

a

gauge in

the

incoming water line

supplying the unit.)

5

Page 7

Brew Vol.

Number change

Mark change

on Timer Dial

B. Remove Brew Chamber and the

satellite container from

brewer, also the timer

adjustment plug button, (the

2" diameter plug) located on

upper left hand side of

front panel. This allows

access to timer adjustment

knob. Nominal timer setting

for all 3 brew volume

ranges is #4.

C. Turn timer adjusting knob:

switch

Setting

1/2 gal.

1 gal

1 1/2 gal.

1-

on Timer Dial

Plate

11 oz.

22 oz.

33 oz.

1-

Plate

3 oz.

5 1/2 oz.

8 oz.

D. Replace brew chamber and the

empty satellite container with

faucet closed. Set brew selector

switch at 1 gal. and start a brew

cycle.

1. CLOCKWISE: to a higher

number, to increase volume.

2. COUNTER-CLOCKWISE:

to lower number to decrease

volume.

CAUTION!

The timer is very

sensitive, so make

adjustments one (1) mark at

a time!

Approximate changes in

the ounces of water

delivered when knob is

rotated (1) one number

(example #5 to #6) or (1)

one mark (ea. division

between numbers), is as

specified.

E. Check for 128 oz. (1 gal.) water

delivery volume. Repeat

adjustment procedure until

desired water volume (128 oz.) is

achieved during a brew cycle.

F. After water volume has been checked

for proper delivery, check

temperature of brewing water as

follows:

- Ready to Brew light is on

- Run a brew cycle of water and

check the temperature of water with

a thermometer

- Proper operating temperature from

Brew Chamber should be 190 F +/- 5

at mid cycle.

- If thermostat needs adjustment

refer to "Operating Thermostat

Adjustment" Page 9.

BREWING OF COFFEE

Depending on the brewer model, the

brewing capacities are 1/2 - 1 gal.

(9102) and 1-1 1/2 gal. (9104). The

brewing procedure is the same for

either model. Always check the brew

selector switch to be sure it is in the

brew mode you desire.

6

Page 8

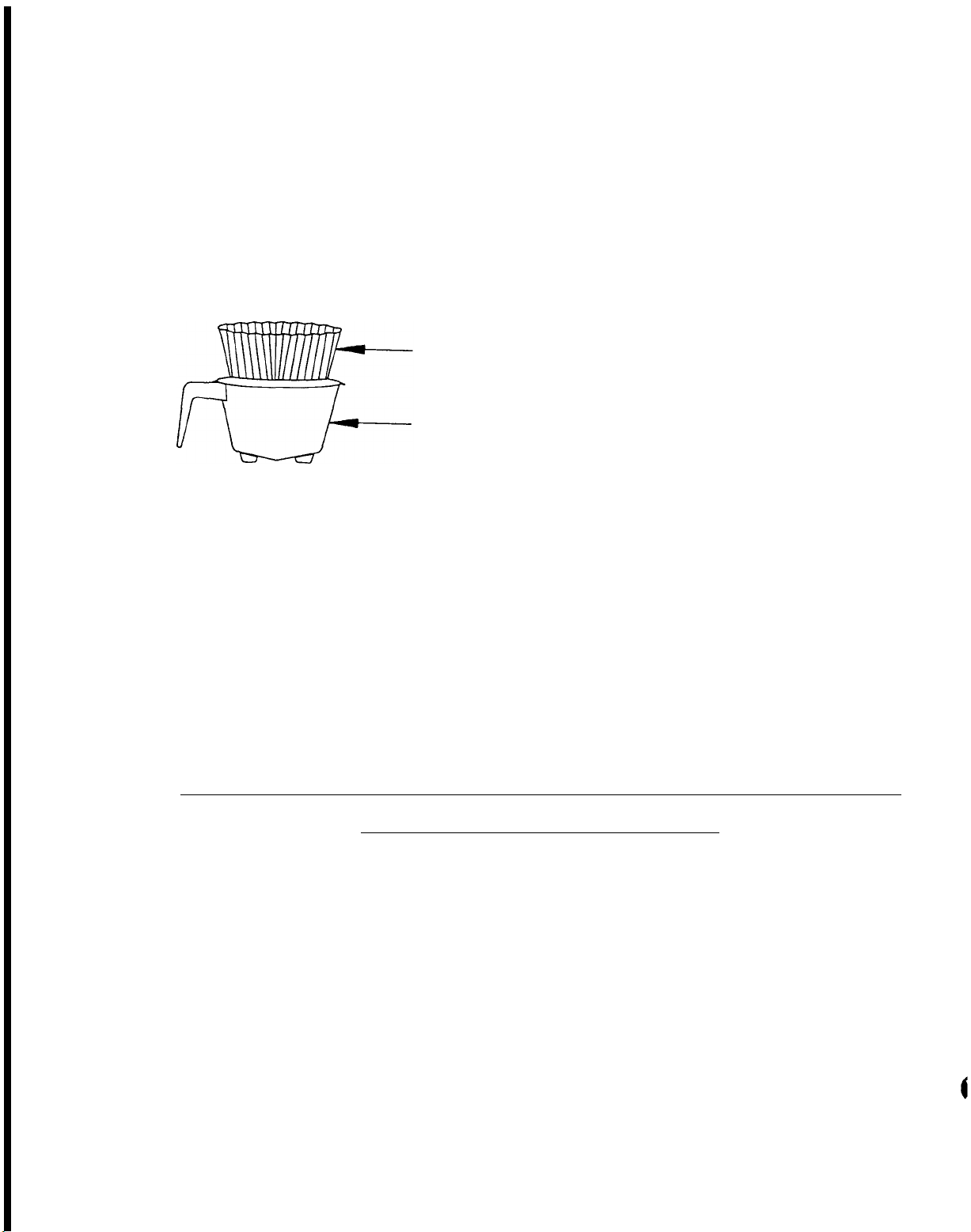

1.

Remove brew chamber from

unit and place

paper

chamber.

filter

Add your choice

of ground coffee.

one (1)

into

brew

Shake

brew chamber to level off

the

coffee,

slide brew

chamber into place.

3.

4.

When GREEN Ready to Brew

light is on, press the

Brew Start switch.

When

coffee stops flowing from

the

brew

chamber the

freshly brewed coffee is

ready.

Remove brew chamber and

discard paper filter and

coffee grounds.

2.

paper filter

brew chamber

Place an empty satellite

container

chamber.

under

brew

Make sure faucet

is closed.

IMPORTANT:

Always use an

empty satellite container

when

starting a

brew

cycle.

5.

When GREEN Ready to Brew

light turns ON again, the

brewer it

ready

another brewing cycle.

6.

To keep the coffee hot,

the brewer is

equipped

with a warmer which is

activated by a

switch

located on the upper front

panel.

glow,

A RED light will

indicating that

warmer is "ON1'.

IMPORTANT:

1. Warmer should be turned

off when not in use.

2.

DO NOT leave empty satel-

lite on warmer that is

"ON" .

3.

DO NOT leave coffee on

warmer over night.

for

BY-PASS:

Model 9104 Uses A By-Pass Valve During Brewing

SET UP AND ADJUSTMENT

The unit leaves the factory

with the By-Pass Valve set at

the 25% by-pass volume which is

the smaller of the flow set

gauges,

however, if

the

location has:

A. Softened Water:

1.

supplied by their

community water source or

2. their own water softener,

7

or

B. The finished brew is too

strong; when:

1.

the correct amount of

coffee grounds is used,

approximately 6 to 8 ounces

and,

2.

the correct volume (128

ounces) of water flows into the

satellite,

Page 9

a

the by-pass valve must be readjusted or opened toward the

larger gauge and size which is

approximately a 50% by-pass of

water volume.

Re-adjustment

of the by-pass

valve prevents the coffee bed

from rising above the filter

paper

finished brew.

and flooding into the

Re-adjustment

also aids in setting the level

of finished brew strength for

local coffee drinking quality.

NOTE:

NEVER BE MADE UNLESS SOFT WATER

CONDITION EXISTS OR AN ADJUST-

MENT FOR COFFEE STRENGTHS IS TO

BE MADE.

WARNING:

THIS ADJUSTMENT MUST

Turn

off

the Tank

Heater Switch and disconnect

power supply to

removal of

Brewer before

any

panel or

replacement of any component.

Remove the two (2) screws

1.

holding the top panel.

Slide panel back and up to

remove.

Lift Water Basin Pan (#7)

2.

and move aside.

Remove

3.

(#16)

counter-clockwise

soft water valve

and

turn

screw

enough

to accept large Flow Set

Gauge.

Replace soft water valve

4.

in brewer.

Replace water basin and

5.

top cover.

Plug in Brewer and turn on

6.

Tank Heater Switch.

NOTE:

Brewing time should be

between 6 and 8 minutes. If

brew time exceeds 8 minutes

after opening valve to 50% open

soft

water

valve

1/8

turn

further and re-time brew cycle.

If brew time still exceeds 8

minutes,

contact

Bloomfield

Industries.

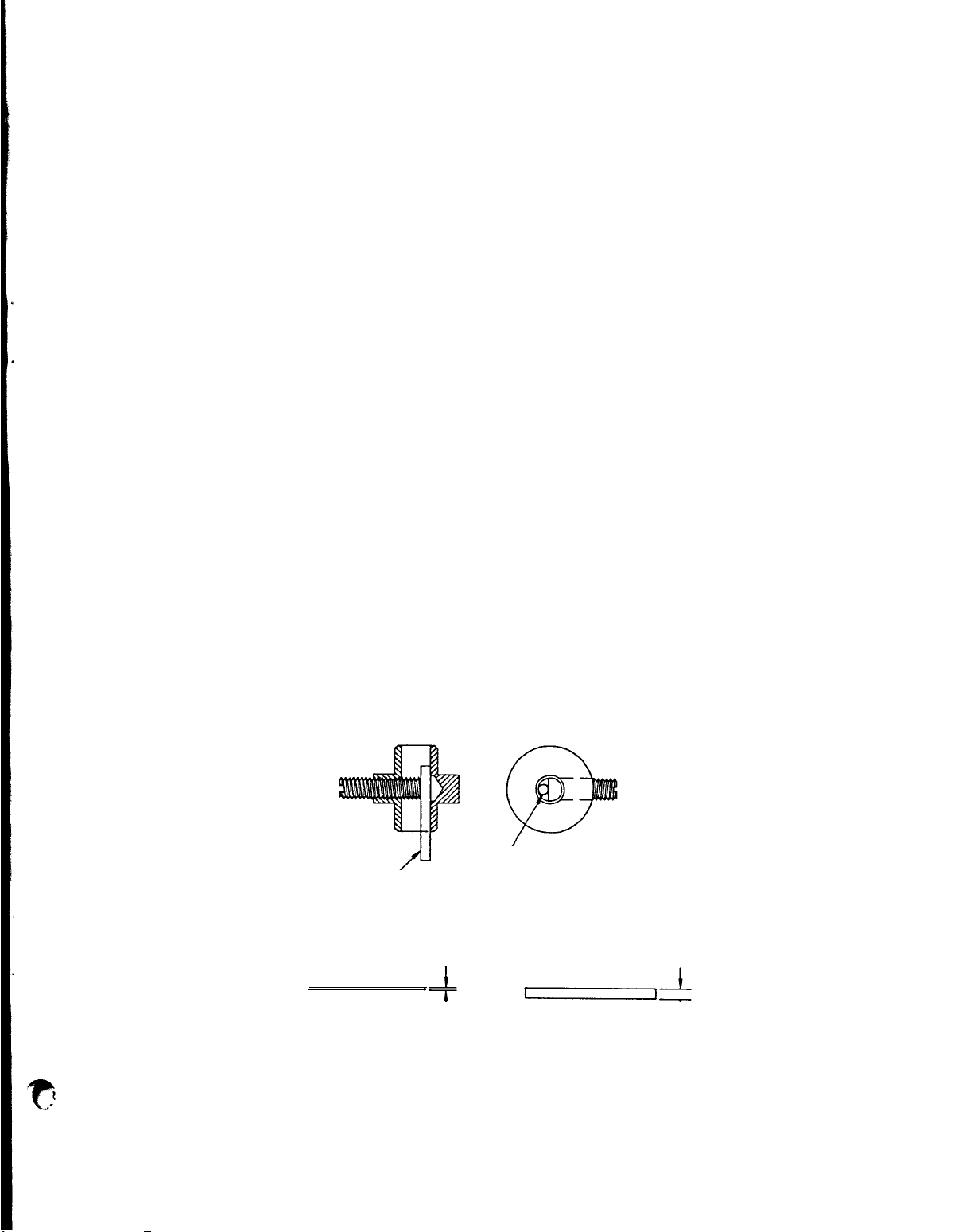

WIRE GAUGE

USE DRILLS OR WIRES OF THE DlAMETERS

SPECIFIED. TO ADJUST BY-PASS SETTlNGS

BY-PASS

25%

BY-PASS VALVE

-/

3/64 DIA I

FLOW SET GAUGES

L

FLOW SET GAUGE

8

BY-PASS

50%.

11/64 DIA

Page 10

IMPORTANT: UNIT MUST BE DISCONNECTED FROM ELECTRICAL SOURCE

BEFORE ANY SERVICE

IS PERFORMED.

FRONT PANEL REMOVAL

To remove the front panel for

service,

remove (6) screws and

lift panel away from body.

BASE COVER/WARMER ELEMENT REMOVAL

Remove

cribed above).

front panel

Loosen faucet

(as des-

support bracket screws and drop

bracket to provide clearance.

Slide base cover forward to

disengage

upward.

clips

Warmer

and

lift

element is

attached to underside of dome

shape by a retaining bracket.

and nut.

sequence.

Reinstall in reverse

Adjust

Faucet

bracket with satellite resting

on warmer.

Bracket end should

just touch faucet shank.

FRONT VIEW

FRONT PAN EL

3.

Slide cover back and lift

off.

4. Turn Thermostat adjusting

shaft.

ments

ature,

clockwise

temperature.

Clockwise adjust-

INCREASES temper-

and

counter-

DECREASES

For proper

operation of the unit and

optimum

extraction of

coffee, thermostat should

cycle off between

195 F

and 205 F.

5. Reconnect power to brewer.

To check temperature, unit must

be energized:

B.

Using a

mercury

thermometer:

1. Remove brew chamber and

spray head.

2.

Leave empty satellite on

lower warmer, with cover

off,

and faucet closed.

3. When ready light comes ON,

press brew button

4. A stream of hot water will

come out of brewer.

the

thermometer

stream

bulb of

into

and

read

Place

the

the

the

temperature.

5. If

previous

desired

necessary,

steps

temperature is

repeat

until

achieved.

SLIDE

FOR’WRD

OPERATINGTHERMOSTATADJUSTMENT

Whenever running

adjustment becomes

thermostat

necessary,

proceed as follows:

A.l. Check that power to brewer

is disconnected.

2. Remove two (2) screws from

top cover.

9

IMPORTANT:

should be

Tank

thermostat

adjusted so

that

water temperature never exceeds

205 F.

REAR

VIEW

-

THEMOSTAT

r

I

ADJUSTING SHAFT

Page 11

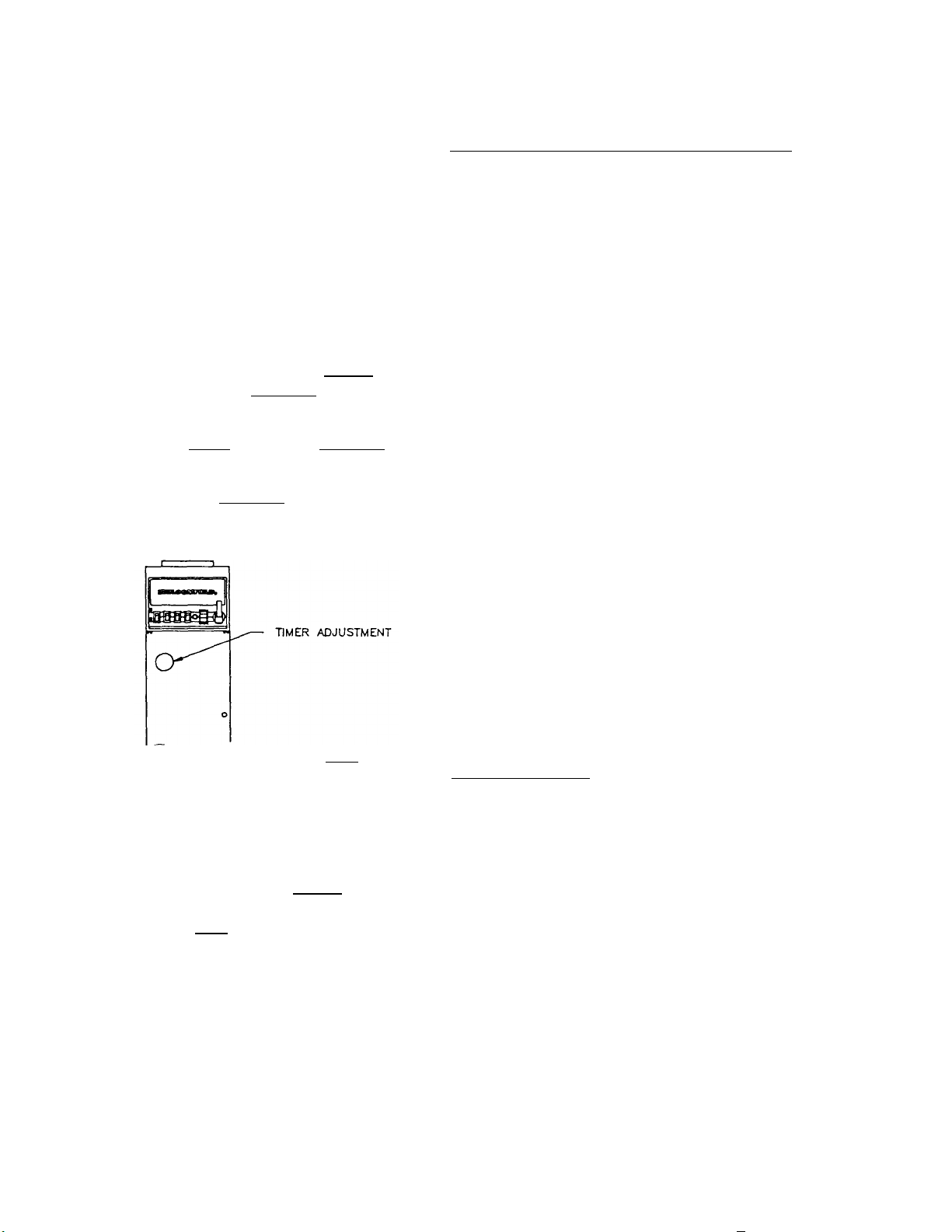

TIMER ADJUSTMENT

Timer adjustments are made with

the brew selector switch in the

1 gallon position. These units

are equipped with an adjustable

timer to permit brewing l/2 -

1 gallons or 1 or 1 l/2 gallons

with

the

flip of a

brew

selector switch, depending upon

brewer

model.

Refer to

detailed instructions on Timer

Adjustments - Page 6 - items

"B" through "E".

Remove brew chamber.

1.

2. Remove timer adjuster plug

button.

3.

To INCREASE time of water

flow, turn timer adjusting

knob

clockwise.

DECREASE time of

To

water

flow, turn timer adjusting

knob counter-clockwise.

Replace plug button and

4.

brew chamber.

TIMER ADJUSTMENT

Slide cover back.

3.

cover aside.

4.

Disconnect

water

hose, elbow, vent tube and

inlet

pan.

5.

Disconnect

elbow

Remove basin pan.

from basin

flare

fitting on the following

tubing assemblies:

A. Tube assembly: needle

valve to tank cover - dis-

connect at needle valve.

B.

Tube assembly:

cover to faucet.

Discon-

nect at faucet valve.

6.

Disconnect wires

thermostat.

7.

Disconnect wires

heating element.

On 120

Volt unit also disconnect

wires from the high limit

control.

8.

Loosen center

screw on

tank hold down bracket.

Remove hold down bracket

9.

by

sliding

slotted end

the

off

locking stud.

Remove cover assembly from

10.

tank by lifting it out.

Set

inlet

nut

tank

from

from

short

the

TO REPLACE TIMER ASSEMBLY

Disconnect cord from elec-

1.

trical

outlet/turn

off

power source.

Remove front panel.

2.

Remove timer knob and the

3.

three (3) screws holding

timer to bracket.

Disconnect timer wires.

4.

5. Replace

timer

following

reverse procedures.

TO REPLACE WATER COIL AND/OR

HEATING ELEMENT ASSEMBLY

1. Disconnect unit from power

supply and shut off water.

Open faucet momentarily,

to relieve pressure.

2.

Remove two (2) screws from

rear of top cover.

TO REMOVE

HEATING

ELEMENT

ASSEMBLY

1. Remove tank lid assembly

- see steps 1 through 10 of

"To

Replace

Heating

Element Assembly".

2. Remove two (2) hex nuts

and pull out

elements from

heating

mounting

holes in cover.

TO REMOVE WATER COIL ON WATER

FAUCET MODEL

TO REMOVE WATER COIL ASSEMBLY

Remove tank

1.

lid -

see

steps 1 through 10.

Remove both copper tubing

2.

assemblies fromwater coil

fittings.

3.

Remove

two

(2)

nuts

holding water coil to tank

lid assembly.

10

Page 12

NOTE:

On the Model 9104 it is

necessary to remove the tank

heating element before removing

the water coil.

TO REPLACE THERMOSTAT

1. Disconnect power supply to

brewer.

2.

Remove two (2) screws from

rear of top cover.

3.

Slide cover back.

Set

cover aside.

4.

Disconnect

wires

from

thermostat.

5. Loosen two

securing

(2)

thermostat to

screws

bracket.

6. Loosen and remove jam nut

from

fitting,

securing

thermostat capillary line

into the top of the cover.

7.

Lift out the thermostat

capillary

sensing

bulb

from the cover.

IMPORTANT:

thermostat

When remounting a

capillary

sensing

bulb through the cover, be sure

a new seal washer

below

capillary

capillary

the

fitting on

line.

line

is placed

Push

through

the

the

the

cover until the fitting seats.

Tighten the capillary locking

nut enough to insure no water

leakage.

Extreme tightening is

not necessary.

When replacing heating element

assembly or water coil,

should

gaskets.

list.)

also

replace

(Refer to parts

Before

setting

you

the

the

cover assembly to the tank,

make sure the tank cover gasket

is

properly

seated in

the

flange of the cover.

TO REPLACE READY LIGHT

1. Disconnect cord from electrical

outlet/turn

off

power source.

2.

Using thin screw driver,

pry out pilot light from

mounting hole, disconnect

leads.

3.

Replace pilot light fol-

lowing reverse procedure.

TO REPLACE WARMER AND BREW

SWITCHES

1. Disconnect cord from electrical

outlet/turn

off

power source.

2.

Using thin screw driver,

pry

out

switch

from

mounting hole, disconnect

leads.

3.

Replace switch following

reverse procedure.

TO REPLACE SOLENOID VALVE AND

WATER CUSHION TUBE ASSEMBLY

1. Disconnect cord from electrical

outlet/turn

off

power source.

2.

Turn off water supply.

3.

Remove

water

connection

and hex nut holding inlet

fitting into back of unit.

4.

Remove front panel.

5.

Remove

the flare

connection from the "T"

top outlet and gently move

tubing aside.

6.

Pull

solenoid

forward

slightly and lift up to

release

mounting

disengage

it

from

bracket

inlet

the

and

fitting

from hole in back panel.

7.

Carefully pull

assembly

out to

access to

solenoid

wiring

gain

and

rubber tube.

8.

Remove

wires

from

solenoid.

9.

Remove rubber tube.

10.

Solenoid

assembly

with

water cushion tube can now

be removed for complete

servicing.

11.

Replace assembly by fol-

lowing reverse procedure.

TO REPLACE TANK

1. Disconnect cord from electrical

outlet/turn

off

power source.

2.

Turn off water supply and

remove

water

connection

11

Page 13

from

inlet

fitting on

back of brewer.

Position

3.

drain

fitting

over drain facility and

unscrew

CAUTION!

drain

WATER MAY BE

cap.

HOT.

4.

Remove

back panel,

the

projects,

the

lower

through which

drain

by removing the

body

fitting

two (2) screws.

5.

Remove

the

basin

back

panel panel, by removing

the five (5) screws and

carefully drop downward,

make sure wiring to main

switch is protected and

not subject to damage.

6.

Proceed

#2

with

through

operations

# 10 ,

described in "TO REPLACE:

WATER

MENT",

7.

Remove the two (2) nuts

COIL/HEATING

Page 10.

ELE-

securing tank retaining

brackets to tank screws.

Remove the two (2) nuts

a.

securing the two (2) tank

retaining

basin

bottom.

brackets to

Remove

brackets.

9.

Rotate

tank

counter-clockwise,

the left) 90

until

drain

assembly

(l/4

turn)

tube is

(to

centered on slot in tank

mounting tray.

out

carefully,

Then lift

making

sure drain tube passes

through

slot and clears

needle valve.

10. Assemble

in

reverse

sequence.

HI-LIMIT TEMPERATURE,

SAFETY

CONTROLS

MODEL 9102-120 V, 15 AMP UNIT

This

model

has a

self

resetting control, mounted on

the

tank

cover,

automatically

and will

"OPEN"

when

normal tank temperatures have

been

when

exceeded,

tank

has

and

sufficiently

"RESET"

cooled down.

1. Disconnect cord from electrical

outlet/turn

off

power source.

Remove two (2) screws from

2.

rear of

top

cover

and

slide cover aside.

Remove wires from Hi-Limit

3.

Control,

mounted

under

clip on tank cover.

4.

Slide

from under

Hi-Limit

clip

Control

and

replace with new control.

Make sure that there is

sufficient

tension

from

the clip to insure proper

contact between tank cover

and bottom of Hi-Limit

Control.

5. Reconnect wires.

NOTE:

IF TERMINALS OR WIRING

APPEARS DISCOLORED

FROM

HEATING, REPLACE TERMINAL

ON NON-OXIDIZED WIRE ENDS.

MODEL

9104-115/230

V, 20 AMP

UNITS

This

model

resetable

has a

control,

against the tank body.

automatically

"OPEN"

manually

mounted

It will

when

normal tank temperatures have

been

exceeded,

but must be

manually reset to restore elec-

trical

heating,

continuity

for

when tank has suffi-

tank

ciently cooled down.

RESETTING THE HI-LIMIT SAFETY

CONTROL

1.

Pry

out the small plug

button in the front panel

of the body.

2. Using a non-electrically

conductive dowel or rod,

(i.e.

eraser

end of a

wooden pencil) press the

small reset button located

in

the

center of

the

12

Page 14

control.

sufficiently cooled down,

the control will "SNAP" to

the

restore power to the tank

heater.

3.

Replace plug button.

REPLACEMENT

CONTROLS

1.

Disconnect

power source.

Remove body front panel,by

2.

removing

and

lifting panel

from body.

3.

Loosen

bracket

Control,

slide assembly from its

mounting bracket.

Disconnect

4.

safety control.

Remove

5.

Limit Control on bracket,

as shown in Figure

using the screws and nuts

originally supplied.

If tank has

"ON"

position

OF

HI-LIMIT

brewer

six (6) screws

screw

with

holding

Hi-Limit

to the unit, and

wires

and

replace Hi-

and

from

away

from

"A"

CLEANING THE SPRAY HEAD

1. Remove brew chamber.

2. Rotate spray head ears out

of locking cup by pushing

up as you rotate it out of

locking groove.

3.

Clean lime and wipe oil

from both sides of spray

head, being sure all spray

head holes are fully open.

4.

Clean

entire area

over

brew chamber with a damp

cloth.

5. Replace spray head, being

sure spray head gasket is

in place in cup.

Spray

head tabs must be in the

UP position.

Rotate fully

into locking grooves.

6. Reinstall bracket assembly

into its mounting bracket

and position the face of

the

safety

control

directly against the side

of the tank, so control is

firmly

Tighten

touching

mounting

tank.

screw,

making sure that Hi limit

Control is

still

-tight

against tank body.

7. Replace front panel.

13

Page 15

HOT WATER FAUCET SYSTEM PARTS LIST

REF

PART NO.

DESCRIPTION

1

8551

-

250 FAUCET (INCLUDES

#2

, #3 &.

#4 )

2

8551

-

100A

WASHER

3

8551

-

100B

7/16

EXTERNAL TOOTH LOCK WASHER

4

8551

-

100C

HEX LOCK NUT

5

9102

-37

FAUCET TUBE ASSEMBLY

6

9102

-58

FORMED I

NLET TUBE ASSEMBLY

7

8551

-30

1/4

MALE FLARE x

1/8

FPT FITTING

8

8514

-26

NEEDLE VALVE

9

9102

-25

OUTLET TUBE ASSEMBLY

10

8704

-25

WATER CUSHION TUBE ASSEMBLY

11

8812

-57

UNION,

1/4

FLARE

12

9102

-56

COUPLING,

1/4

FEMALE FLARE

13

9102

-55

TEE.

1/4

FLARE (M

-M-F) 14

9102

-38

WATER TUBE ASSEMBLY

15

9102

-8

ELBOW, PIPE TO HOSE

16

8541

-

120 SOLENOID VALVE ASSEMBLY

17

8706

-

102 REDUCER ADAPTOR

18

9012

-24

TEE,

1/4

FLARE x

3/8

MPT

19

8766

-2

WATER INLET HOSE

20

8540

-30

ELBOW

21

8540

-6

HOT WATER COIL ASSEMBLY

22

8043

-30

GASKET

23

8941

-21

7/16

-20 x

3/16

THICK BRASS LOCK NUT

1. 8551-275 Repair Kit (sold as

Kit only)

A.

I

Handle (Color

- Red) B. I

Valve —

Stem C. I

Valve Disc

D.

Kit "0"Ring

- #6. 7, & 8

E. Contains

Tee Nut

G.

I

Guide H. I

Bushing

Instruction Card (Not Shown)

2.

8551-275B Str

eam Straightener (Not Shown)

3.

8551-100A Washer Rubber

4.

8551-100B 7/16

External Tooth Lock Washer

5.

8551-100C Hex. Lock Nut

SEALS AVAILABLE

6.

8551-200B "0"

Ring Stem Seal

5/16

Outside Dia.

7.

8551-200A "0"

Ring Seal

1/4

Outside Dia.

8.

8551-200C

"0"

Ring Spout Seal

3/8

Outside Dia.

C.

8551-275A Valve Disc

TOOL AVAILABLE

9.

8551-200E Adaptor Tool

— Service Wrench

NOTE :

FOR COMPLETE FAUCET ASSEMBLY, ORDER PART NO. 8551-250

INCLUDES ITEMS 1, 2, 3 AND 4.

HOT WATER FAUCET REPLACEMENT LIST

Ref. No. Part No. Description

14

Page 16

THERMOSTAT AND TANK COVER

IDENTIFICATION AND REPLACEMENT INFORMATION

PARTS LISTING FOR TANK COVER ASSEMBLY

REF. NO. PART NO. DESCRIPTION MODELS

1 8512-51 THERMOSTAT ALL

2 8043-11 OUTLET ELBOW ALL

3 8706-20 VENT TUBE ALL

4 8706-6 INLET ELBOW ALL

5 8514-68 TANK COVER SUB ASSEMBLY ALL

6 3-100 #6-32 x 1/4 ROUND HEAD SCREW ALL

7 8043-83 HI-LIMIT THERMOSTAT 9102

8 8543-73 #4-40 x 1 1/2 PAN HEAT SCREW ALL

9 8543-74 #4-40 HEX NUT ALL

10 8706-68 WATER INLET TUBE ALL

11 8760-44 HEATING ELEMENT, 240V-4200 WATTS 9104

12 9102-9 HEATING ELEMENT, 120V-1675 WATTS 9102

13 8043-30 HEATING ELEMENT GASKET ALL

14 8043-12 TANK COVER GASKET ALL

15 8540-6 HOT WATER COIL ALL

16 8941-21 7/16 HEX NUT ALL

17 8043-28 1/2-20 HEX NUT ALL

18 8512-41 SEAL WASHER ALL

15

Page 17

COMPLETE SPARE TANK COVER ASSEMBLIES

(2C)

Seal Ring

(FOR PARTS LIST SEE PAGE 19)

PART NO. DESCRIPTION MODEL

9102-300 Tank Cover Assembly, 1675 W/120V with Water Coil 9102

9104-300 Tank cover Assembly, 4200 W/240V with Water Coil 9104

All parts are mounted to cover

COLD WATER ENTRANCE SOLENOID VALVE PART NO. 8541-120

(Consist of Valve and Flow Control)

SOLENOID VALVE REPLACEMENT PARTS

(For Black Coil Valve)

(No Parts Sold Separately)

(1) 8541-120CS Coil Assembly - 120V

(2) 8541-120K Solenoid Repair Kit

Vacuum Pac consist of :

(2A) Spring

(2B) Plunger

(2C) Seal Ring

(2) 8541-120JS Solenoid Repair Kit

Vacuum Pac consist of :

(2A) Spring

(2B) Plunger

(3) 8541-120KS Solenoid Repair Kit

Vacuum Pac consist of :

(2A) Spring

(2B) Plunger

(2C) Seal Ring

(2D) Service Wrench

(3A) Flow Control

(4) 8541-120F (5A) Flow Control

(5) 8541-120WS (20) Service Wrench

16

Page 18

17

Page 19

REF NO.

PART NO.

REPLACEMENTS PARTS LIST

All Models

DESCRIPTION

MODEL(S)

USED ON

1

2

3

4

5

6

7

8

9

10

11

12

13

8543-52

8593-17

8593-18

9102-4

8201-5

8540-30

9102-18

8043-47

8043-5

8543-23

8593-27

9104-l

9102-l

Screw,

#8x 3/8" LG

Hinged Cover

Hinge Wire

Basin Cover

Nut, #10-24x 3/8" Hex

Elbow -

Plastic

Basin Pan Sub-Assembly

Screw, #l0-32 x l", LG

Hold Down Strap Assembly

Tinnerman Nut

Switch, Main

Switch, Main

Back Panel, Basin

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

9102

9104

ALL

14

15

16

17

18

19

20

21A

21B

3-100 Screw,

8706-111

8706-26

8706-188

9104-15

9102-480

8043-13

9102-7

9104-7

Screw,

By-Pass Valve

Connector Tube

"T" By-Pass Tube Assembly

Tube, Water outlet

Spray Elbow

Basin Welded Assembly

Basin Welded Assembly

#6-32 x l/4", LG

By-Pass Adj.

18

ALL

9104

9104

9104

9104

9102

ALL

9102

9104

Page 20

REF NO.

PART NO.

DESCRIPTION

MODEL(S)

USED ON

22

23

24

25

26

27

28

29

30A

30B

31

32

33

8543-69

8543-42

8543-44

9102-27

8707-28

8707-34

8718-31

8812-79

8707-34

8528-40

8551-250

8551-1OOA

8551-100B

Bushing, Plastic

Gasket,

Sprayer, Disc.

Switch, Vol Select

Switch, Brew

Switch, Warmer

Pilot Light, Green

Switch, Stop

Switch,

Switch, Tank Heater

Faucet,

Washer, Rubber

Lock washer, 7/16" I.D.

Spray Head

Tank Heater

Hot Water

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

9102

9104

ALL

ALL

ALL

34

35

36

37

38

39

40

41

42

43

44

8551-1OOC

8706-9

8707-3

8707-2

9102-57

8766-2

9102-8

8710-10

8812-57

9102-56

9102-55

Nut, 7/16-20, Faucet

Wire Rack

Screw,

Handle

Brew Chamber Only

Water Inlet Hose

Brass Fitting Elbow

Nut, #7/16-20, Inlet

Fitting

Fitting, Water Inlet

Fitting,

Fitting, Tee

#l0-32 x 5/16", LG.

Coupling

19

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

Page 21

REF NO.

PART NO.

DESCRIPTION

MODEL(S)

USED ON

45

46

47

48

49

50

51

52

53

54

55

9102-38

Tubing Assembly -

Inlet/Solenoid

8704-25

8706-102

8541-120

9012-24

9102-9

Cushion Tube Assembly

Fitting, Reducer

Solenoid Valve, 120V

Fitting, Tee

Tank Element, 1675 Watts,

120v

8540-4

Tubing Assembly, Inlet

9102-9 Tubing Assembly, Sol/N.

Valve

8540-6

8043-30

8514-26

Hot Water Coil Assembly ALL

Gasket,

Element/Water Coil

Needle Seat Valve

ALL

ALL

ALL

ALL

ALL

9102

9104

ALL

ALL

ALL

56

57

58

59

60

61

62

63

64

65

8914-21

8551-30

9102-58

9102-37

8043-11

8512-51

8706-20

8512-41

8043-28

8706-6

Nut, #7/16-20, Water Coil

Brass Fitting - Pipe/Flare

Tubing Assembly - N.

Valve/Coil

Tubing Assembly -

Faucet/with Coil

Outlet Elbow

Thermostat - R.S.

Vent Tube

Seal Washer, Thermostat

Nut, #l/2-20, Element

Inlet Elbow

20

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

ALL

Page 22

REF NO. PART NO. DESCRIPTION MODEL(S)

USED ON

66 8514-68 Tank cover - S/A ALL

67 8043-83 Hi-Limit Thermo 9102

68 8043-12 Gasket, Tank Cover ALL

69 8543-73 Screw, #4-40 hex ALL

70 8543-74 Nut, #4-40 11/2" Lg ALL

71 8706-68 Water Inlet Tube ALL

72 8760-44 Tank Element, 4200W, 240V 9104

73 8043-506 Acorn Nut, #8-32 ALL

74 8942-92 Nut, Hex Keps, #8-32 ALL

75 9102-23 Bracket, Tank Mtg. ALL

76 9102-32 Tank Assembly ALL

77 8593-44 Drain Cap ALL

78 6440-1 Seal, Drain Tube ALL

79 9102-34 Front Panel - Auto. ALL

80 8706-75 Plug Button - Large ALL

81 8033-60 Plug Button - Small ALL

82 9102-20 Base Cover ALL

83 8572-18

84 8704-20 Retainer, Warmer Element ALL

85 6440-57 Nut, #1/4-20 Hex ALL

86 9102-16 Bottom Panel Assembly ALL

87 6407-10 Screw, #10-32 x 1/4", Lg ALL

88 9102-49 Faucet Support ALL

Warmer Element, 100 W, 120 V ALL

89 8861-16 Nut Hex, Keps, #6-32 9104

21

Page 23

REF NO.

PART NO. DESCRIPTION

MODEL(S)

USED ON

90

91

92

93

94A

94B

95

96

97

98

99

100

8552-50

7200-6x

8718-48

8861-23

9102-35

9104-35

9102-28

8516-1500

8552-18

616-5

9102-22

8574-10

Hi-Limit Thermo., Manual

Reset

Screw,

8-32 x 5/16 Lg

Bracket, Hi-Limit

Screw,

#8 x 3/8", Lg

Body & Base S.A.

Body & Base S.A.

Timer,

12OV, with Dial &

Knob

Leg,

Black Plastic, 4" Lg.

Terminal Block

Screw,

Cover,

#6-32 x 3/4", Lg.

Base Back

Back Cover - Electrical

9104

9104

9104

ALL

9102

9104

ALL

ALL

9104

9104

ALL

9104

101

102

103

104

105

SA 9052

9102-53

35-210

6407-15

9102-41

Strainer

Back Cover - Electrical

Cord Grip - Heyco

Cord & Cap Assembly

Brew Chamber Assembly

22

ALL

9102

9102

9102

ALL

Page 24

23

Page 25

REPLACEMENT PARTS LIST

REF. NO.

PART NO.

DESCRIPTION

1

9105-2 SATELLITE COVER ASSEMBLY

REF. NO.

PART NO.

DESCRIPTION

12

8600-17 SHIELD CAP

MODEL NO. 9105 SATELLITE

REPLACEMENT PARTS LIST

MODEL NO. 9105 SATELLITE

2 9105-21 BODY AND TANK WELD ASSEMBLY

3 9105-10 SHOULDER SCREW

4 7200-6X #8-32 x 5/16 PN. P. SS

5 9105-17 WASHERS, BELLEVILLE

6 9105-5 LATCH, SATELLITE COVER

7 8705-2 NYLON WASHER

8 9105-15 BUTTON-LATCH STOP

9 9105-11 HANDLE

10 9102-22 BUSHING

11 9105-20 FAUCET AND SIGHTGLASS ASSEMBLY

REPLACEMENT PARTS LIST

FOR FAUCET ASSY. ONLY - PART NO. 9105-20

13 8700-25 J CAP WASHER

14 8600-20 GAUGE SHIELD (ALUMINUM)

15 8600-22 SHIELD GLASS

16 8705-11 B BASE WASHER

17 8705-11 G SHIELD BASE

18 8600-24 SHANK ASSEMBLY

19 8705-11 L UPPER ASSEMBLY-BLACK BONNET

20 8700-25 L SEAT CUP

21 9105-30 FAUCET BODY

22 9105-25 FAUCET BODY ASSEMBLY

24

Page 26

REPLACEMENT PARTS LIST

MODEL NO. 9106 WARMER

REF NO. PART NO. DESCRIPTION

1 9102-49 FAUCET SUPPORT BRACKET

2 6407-19 SCREW, #10-32 x 1/4 LONG

5 8765-8 LABEL

4 6710-23 ON-OFF SWITCH. 120V

5 9106-4 BOTTOM PLATE SUB-ASSY

6 8543-52 SCREW, #8 x 3/8

7 8033-55 LEG LEVELER

8 8033-56 LEVELER CAP

9 8201-5 HEX. NUT, #10-32 x 1/4

10 8703-26 RETAINER

11 8572-18 HEATING ELEMENT

12 9106-7 TOP AND BODY SUB-ASSY

13 35-210 CORD GRIP

14 8841-8 CORD AND CAP ASSY

25

Page 27

Warranty

BREWER WARRANTY IS VOID IF:

For a period of one (1) year

from date of installation, all

Other than genuine Bloomfield

replacement parts are used.

defective parts on Bloomfield

equipment will be replaced free

of charge, providing parts did

not become defective through

accident, neglect,

installation,

mishandling or

improper

damage in transit. The service

necessary to

replace these

Brewer is plugged into voltage

other than specified on serial

plate.

Recommended Bloomfield

vicing

procedures

are not

ser-

followed.

defective parts will also be

free of charge, provided this

service

is performed by an

authorized BLOOMFIELD service

station,

wherever

authorized

service is available.

How to Order -

Individual uses and owners must order replacement parts thru

their distributors or the local authorized service station.

Terms -

Prices,

terms, designs,

materials,

weights,

specifications and dimensions for equipment or parts are subject

to change without notice.

Service Information

that contained in this manual, call Bloomfield’s toll free number

(800) 621-8556.

Be

prepared to give the Model and Serial Numbers of your brewer,

- To obtain service assistance in addition to

as well as the problem and the trouble-shooting steps already

taken,

to the service technician when calling for assistance.

26

Loading...

Loading...