Page 1

WELLS BLOOMFIELD, LLC

2 ERIK CIRCLE, P. O. Box 280 Verdi, NV 89439

telephone: 775-689-5707

www.wellsbloomfield.com

fax: 775-689-5976

601

OWNERS MANUAL

for

INTEGRITY™

DECANTER

COFFEE BREWERS

MODELS

9010 9012

9016

Includes:

Installation

Use & Care

Servicing Instructions

Model 9012 Brewers

8900-Series Glass Decanters

p/n 75815 Rev. F ECN-13387 M601 071112 cps

with optional

PRINTED IN UNITED STATES OF AMERICA

Page 2

WARRANTY STATEMENT

All electrical equipment manufactured by WELLS

BLOOMFIELD, LLC is warranted against defects in materials

and workmanship for a period of one year from the date of

original installation or eighteen (18) months from the date of

shipment from our factory, whichever comes first, and is for

the benefit of the original purchaser, except that:

a. airpots carry a 30 day parts warranty only.

b. dispensers; i.e., tea and coffee carry a 90 days parts

warranty only, excludes decanters.

THE FOREGOING OBLIGATION IS EXPRESSLY GIVEN IN

LIEU OF ANY OTHER WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE, WHICH ARE HEREBY EXCLUDED.

WELLS BLOOMFIELD, LLC

FOR INDIRECT, INCIDENTAL OR

DAMAGES OR LOSSES FROM ANY CAUSE

WHATSOEVER.

This warranty is void if it is determined that upon inspection by

an Authorized Service Agency that the equipment has been

modified, misused, misapplied, improperly installed, or

damaged in transit or by fire, flood or act of God.

SHALL

NOT BE LIABLE

CONSEQUENTIAL

It also does not apply if the serial nameplate has been

removed or unauthorized service personnel perform service.

The prices charged by Bloomfield Industries for its products

are based upon the limitations in this warranty. Seller’s

obligation under this warranty is limited to the repair of defects

without charge by a Bloomfield Authorized Service Agency or

one of its sub-agencies. This service will be provided on

customer’s premises for non-portable models. Portable

models (a device with a cord and plug) must be taken or

shipped to the closest Authorized Service Agency, transportation charges prepaid, for services.

In addition to restrictions contained in this warranty, specific

limitations are shown below (Additional Warranty Exclusions).

Bloomfield Industries Authorized Service Agencies are located

in principal cities.

This warranty is valid in the United States and void elsewhere.

Please consult your classified telephone directory or your food

service equipment dealer; or, for information and other details

concerning warranty, write to:

Phone: (775) 689-5707 Fax: (775) 689-5976

SERVICE POLICY AND PROCEDURE GUIDE

ADDITIONAL WARRANTY EXCLUSIONS

1. Resetting of safety thermostats, circuit breakers,

overload protectors, or fuse replacements unless

warranted conditions are the cause.

2. All problems due to operation at voltages other than

specified on equipment nameplates; conversion to

correct voltage must be the customer’s responsibility.

3. All problems due to electrical connections not made in

accordance with electrical code requirements and

wiring diagrams supplied with the equipment.

4. Replacement of items subject to normal wear, to include

such items as knobs and light bulbs. Normal maintenance

functions including adjustment of thermostats, microswitches,

and replacement of fuses and indicating lights are not

covered under warranty.

5. All problems due to inadequate water supply, such as

fluctuating, or high or low water pressure.

6. All problems due to mineral/calcium deposits, or

contamination from chlorides/chlorines. De-liming is

considered a preventative maintenance function and is

not covered by warranty.

7. Full use, care and maintenance instructions are supplied

with each machine. Those miscellaneous adjustments

noted are customer responsibility. Proper attention will

prolong the life of the machine.

8. Travel mileage is limited to sixty (60) miles from an

authorized Service Agency or one of its sub-agencies.

9. All labor shall be performed during normal working hours.

Overtime premium shall be charged to the customer.

10. All genuine Bloomfield replacement parts are warranted

for ninety (90) days from date of purchase on non warranted equipment. Any use of non-genuine

Bloomfield parts completely voids any warranty.

11. Installation, labor and job check-out are not considered

warranty.

12. Charges incurred by delays, waiting time or operating

restrictions that hinder the service technicians ability

to perform services are not covered by warranty.

This includes institutional and correctional facilities.

Service Parts Department

Wells Bloomfield, LLC

P.O. Box 280

Verdi, NV 89439

601 75815 Owners Manual Integrity Decanter Brewers

SHIPPING DAMAGE CLAIMS PROCEDURE

NOTE: For your protection, please note that equipment in

this shipment was carefully inspected and packaged by

skilled personnel before leaving the factory.

Upon acceptance of this shipment, the transportation

company assumes full responsibility for its safe delivery.

IF SHIPMENT ARRIVES DAMAGED:

1. VISIBLE LOSS OR DAMAGE: Be certain that any

visible loss or damage is noted on the freight bill

or express receipt, and that the note of loss or damage

is signed by the delivery person.

2. FILE CLAIM FOR DAMAGE IMMEDIATELY:

Regardless of the extent of the damage.

3. CONCEALED LOSS OR DAMAGE: if damage is

unnoticed until the merchandise is unpacked, notify the

transportation company or carrier immediately, and file

“CONCEALED DAMAGE” claim with them. This

must be done within fifteen (15) days from the date the

delivery was made to you. Be sure to retain the

container for inspection.

Wells Bloomfield cannot assume liability for damage or loss

incurred in transit. We will, however, at your request, supply

you with the necessary documents to support your claim.

xi

Page 3

TABLE OF CONTENTS

WARRANTY STATEMENT xi

SPECIFICATIONS 1

FEATURES & OPERATING CONTROLS 2

PRECAUTIONS & GENERAL INFORMATION 3

AGENCY APPROVAL INFORMATION 3

INSTALLATION INSTRUCTIONS 4

OPERATION 6

BREWING COFFEE 8

CLEANING INSTRUCTIONS 9

TROUBLESHOOTING SUGGESTIONS 10

SERVICING INSTRUCTIONS 11

Deliming Instructions 16

EXPLODED VIEWS & PARTS LISTS 18

WIRING DIAGRAMS 22

SPECIFICATIONS

MODEL STYLE VOLTS WATTS

Thank You for purchasing this

Wells Bloomfield appliance.

Proper installation, professional

operation and consistent

maintenance of this appliance will

ensure that it gives you the very

best performance and a long,

economical service life.

This manual contains the

information needed to properly

install this appliance, and to use,

care for and maintain or repair the

appliance in a manner which will

ensure its optimum performance.

AMPS

1ø

POWER SUPPLY

CORD

9010 3W IN-LINE, FAUCET 120 2300 19 NEMA 5-20P

9012 3W IN-LINE, FAUCET 120 1800 15 NEMA 5-15P

k9012CA

9016 3W IN-LINE, FAUCET 120/240 3800 17 NOT PROVIDED

9016EX 3W IN-LINE, FAUCET 220-240 3800 16.5 NOT PROVIDED

k 120V Canadian units are 1500 watts maximum.

601 75815 Owners Manual Integrity Decanter Brewers

3W IN-LINE, FAUCET 120 1500 12.5 NEMA 5-15P

1

Page 4

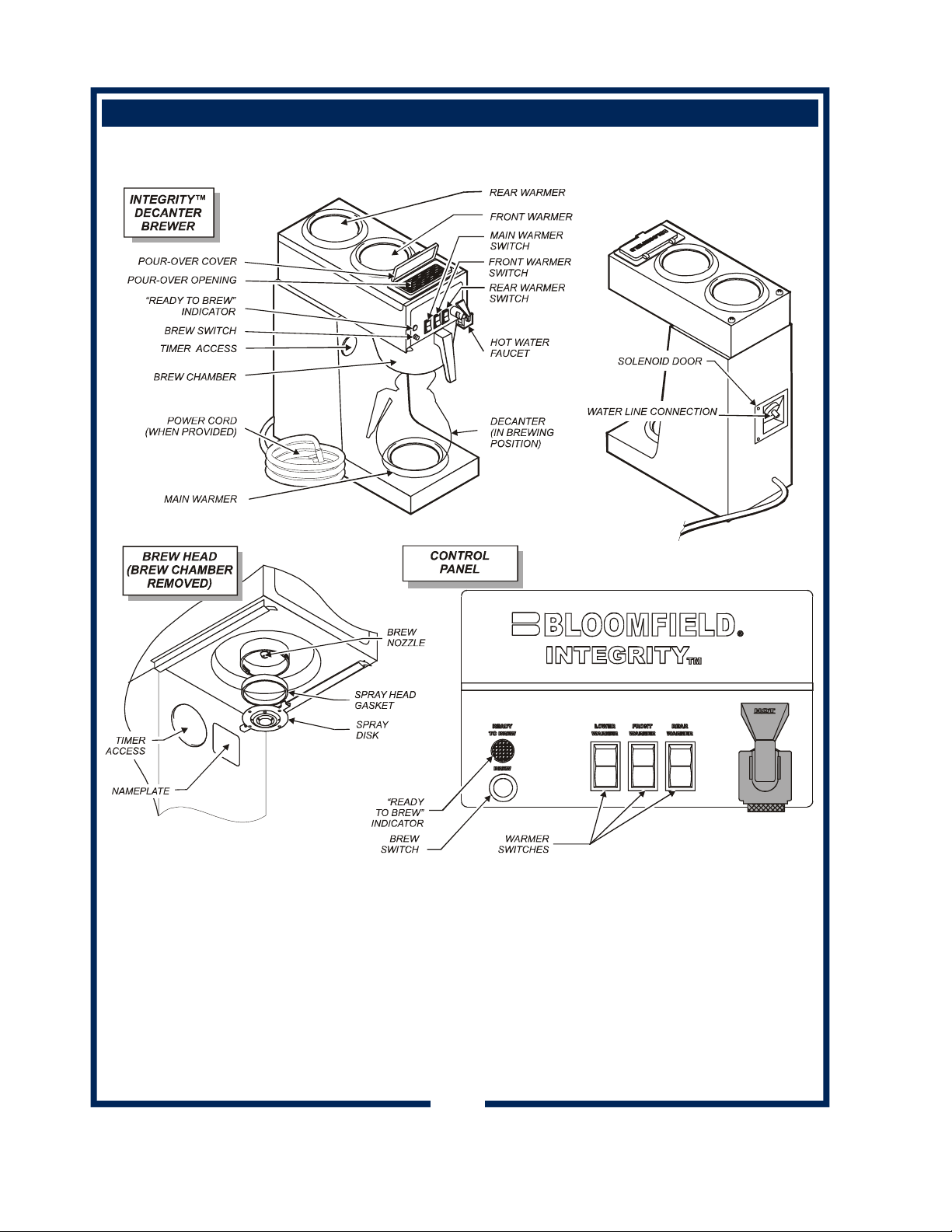

FEATURES AND OPERATING CONTROLS

Fig. 1 Features & Operating Controls

601 75815 Owners Manual Integrity Decanter Brewers

2

Page 5

PRECAUTIONS AND GENERAL INFORMATION

3

WARNING: ELECTRIC SHOCK HAZARD

All servicing requiring access to non-insulated components must be performed by qualified

service personnel. Do not open any access panels which require the use of tools. Failure to

heed this warning can result in electrical shock.

WARNING: INJURY HAZARD

All installation procedures must be performed by qualified personnel with full knowledge of all

applicable electrical and plumbing codes. Failure could result in property damage and

personal injury.

WARNING: ELECTRIC SHOCK HAZARD

Brewer must be properly grounded to prevent possible shock hazard. DO NOT assume a

plumbing line will provide such a ground. Electrical shock will cause death or se rious Injury.

WARNING: BURN HAZARD

This appliance dispenses very hot liquid. Serious bodily injury from scalding can occur from

contact with dispensed liquids.

This appliance is intended for commercial use only.

This appliance is intended for use to brew beverage products for

human consumption. No other use is recommended or

authorized by the manufacturer or its agents.

This appliance is intended for use in commercial establishments,

where all operators are familiar with the appliance use,

limitations and associated hazards. Operating instructions and

warnings must be read and understood by all operators and

users.

Except as noted, this piece of equipment is made in the USA

and has American sizes on hardware. All metric conversions

are approximate and can vary in size.

The following trouble shooting, component views and parts lists

are included for general reference, and are intended for use by

qualified service personnel.

This manual should be considered a permanent part of this

appliance. The manual must remain with the appliance if it is

sold or moved to another location.

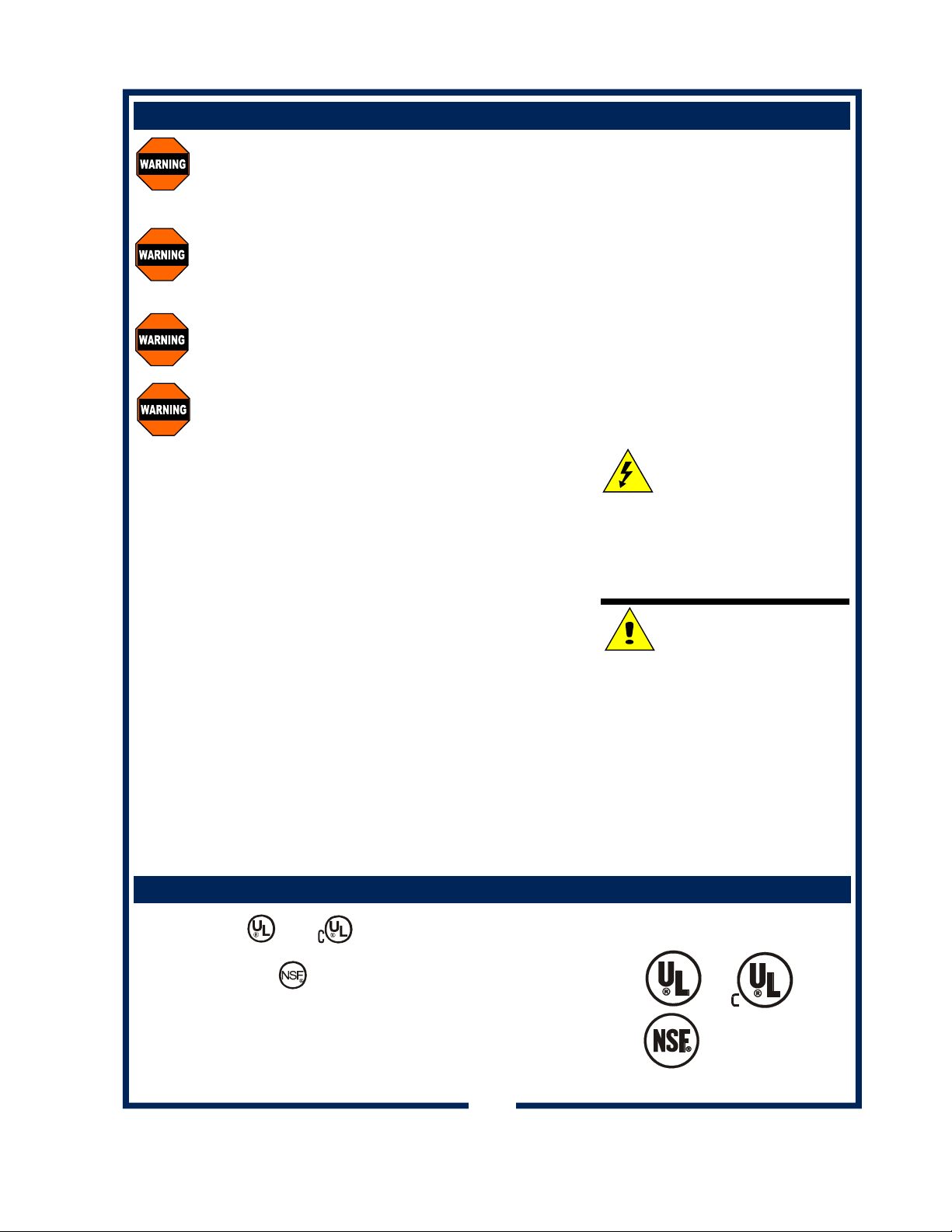

AGENCY APPROVAL INFORMATION

This brewer is and

This brewer meets

operated and maintained in accordance with the enclosed

601 75815 Owners Manual Integrity Decanter Brewers

listed under UL file E9253.

Standard 4 only when installed,

instructions.

CAUTION:

EQUIPMENT DAMAGE

DO NOT plug in or energize this

appliance until all Installation

Instructions are read and followed.

Damage to the Brewer will occur if

these instructions are not followed.

CAUTION:

BURN HAZARD

Exposed surfaces of the

appliance, brew chamber and

decanter may be HOT to the

touch, and can cause serious

burns.

E9253

E925

STD 4

3

Page 6

INSTALLATION INSTRUCTIONS

READ THIS CAREFULLY BEFORE STARTING THE INSTALLATION

IMPORTANT:

To enable the installer to make a

quality installation and to minimize installation time, the following suggestions and tests should

be done before the actual unit

installation is started:

CAUTION:

EQUIPMENT DAMAGE

DO NOT plug in or energize this

appliance until all Installation

Instructions are read and

followed.

Damage to the Brewer will occur

if these instructions are not

followed.

CAUTION:

UNSTABLE

It is very important for safety and

for proper operation that the

brewer is level and stable when

standing in its final operating position. Provided adjustable, nonskid legs must be installed at

each corner of the unit. Failure

to do so will result in movement

of the brewer which can cause

personal Injury and/or damage to

brewer.

NOTE: Water supply inlet line

must meet certain minimum

criteria to insure successful

operation of the brewer.

Bloomfield recommends 1/4" copper tubing for installation of less

than 12 feet and 3/8" for more

than 12 feet from a 1/2" water

supply line.

EQUIPMENT HAZARD

Unpack the unit. Inspect all components for completeness and

condition. Ensure that all packing materials have been removed

from the unit.

Verify that the Spray Head Gasket and Spray Disk are properly

installed.

LEVELING THE UNIT

Verify that an adjustable leg is installed at each corner of the

brewer.

Set brewer in its operating location. Level the brewer. A spirit

level should be placed on the top of the unit, at the edge, as a

guide when making level adjustments.

Level the unit from left to right and front to back by turning the

adjustable feet. Be sure all four feet touch the counter to prevent

tipping.

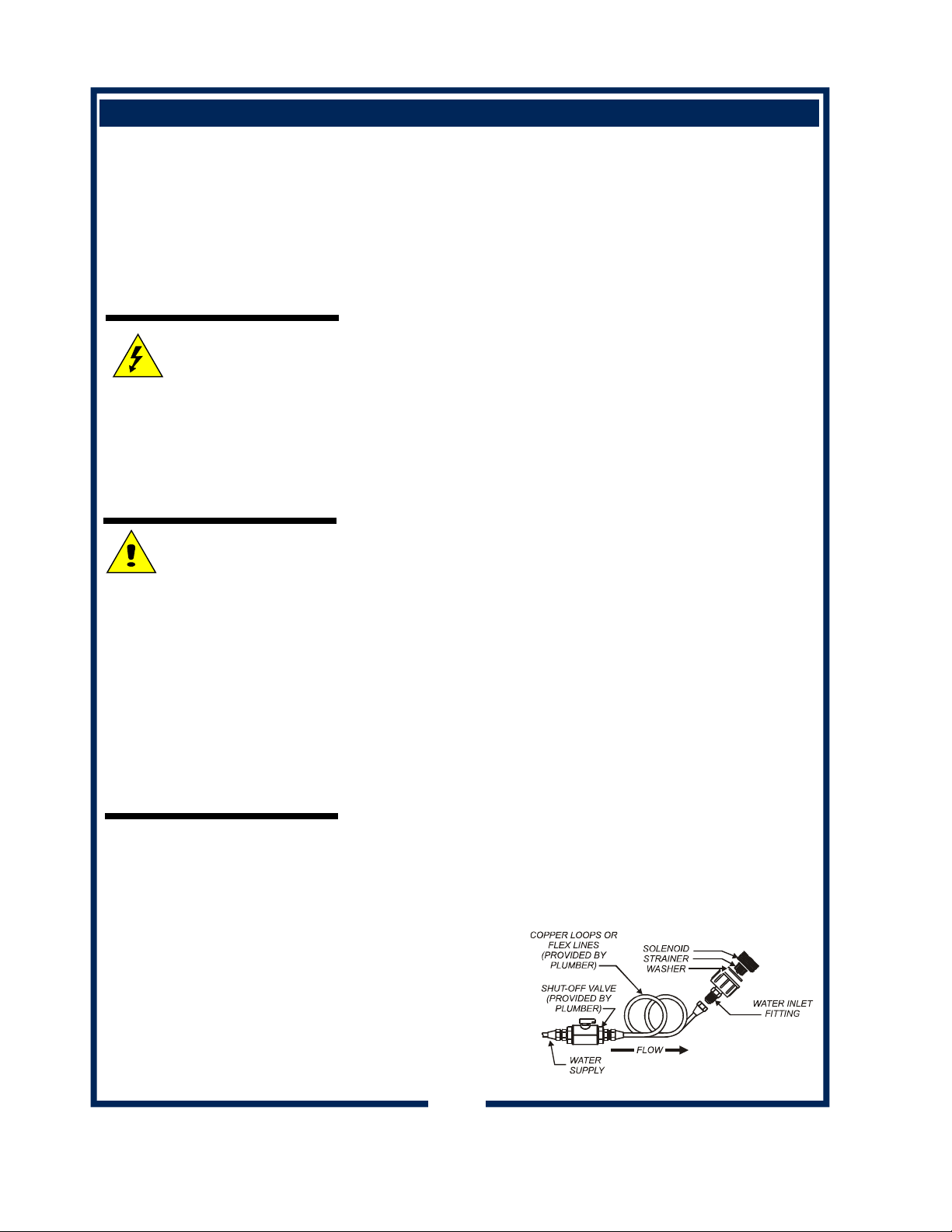

PLUMBER’S INSTALLATION INSTRUCTIONS

Brewer should be connected to a POTABLE WATER, COLD

WATER line. Flush water line before connecting to brewer.

DO NOT use a saddle valve with a self-piercing tap for the water

line connection. Such a tap can become restricted by waterline

debris. For systems that must use a saddle tap, shut off the main

water supply and drill a 3/16” (minimum) tap for the saddle

connection, in order to insure an ample water supply. Remember

to flush the line prior to installing the saddle.

The brewer must be installed on a water line with average

pressure between 20 PSI and 90 PSI. If your water pressure

exceeds 90 PSI at anytime, a pressure regulator must be

installed in the water supply line to limit the pressure to not more

than 90 PSI in order to avoid damage to lines and solenoid.

A water shut-off valve should be installed on the incoming water

line in a convenient location (Use a low restriction type valve,

such as a 1/4-turn ball valve, to avoid loss of water flow thru the

valve.

NSF requires that the brewer be able to be moved for cleaning

underneath. A flex line or loops of copper tubing will satisfy this

requirement. See Figure 2 below.

Fig. 2 Water Supply

Installation

601 75815 Owners Manual Integrity Decanter Brewers

4

Page 7

INSTALLATION INSTRUCTIONS (continued)

In some areas, local codes require a backflow preventer (check

valve) to be installed on the inlet water line. If a backflow

preventer is used, you must install a water hammer arrester in

the incoming line, between the backflow preventer and the

brewer inlet, as far away from the brewer as space will allow.

This will relieve the excessive back pressures that can cause

faucet leaks and solenoid malfunctions.

ELECTRICIAN’S INSTALLATION INSTRUCTIONS

REFER TO ELECTRICAL SPECIFICATIONS - Page 1

Check the nameplate to determine correct electrical service

required for the brewer to be installed.

IMPORTANT: Before connecting to electricity, make sure

automatic brewers are connected to the water supply.

Models 9010 & 9012 are equipped with a cord and plug. They

require a 115 - 125 volt 20 amp circuit (50/60 Hz, 2 wire plus

ground, with NEMA 5-15R or 5-20R Receptacle).

IMPORTANT: The ground prong of the plug is part of a system

designed to protect you from electrical shock in the event of

internal damage. Never cut off the ground prong nor twist a

blade to fit an existing receptacle. Contact a licensed electrician

to install the proper circuit and receptacle.

Models 9016 must be wired by an electrician, and require a

115/230V 20A circuit (50/60 Hz, 2 hot legs / 1 neutral leg, plus

ground). Remove front panel to gain access to terminal block.

Green terminal must be connected to a suitable building ground.

Circuit must be capable of 3800 Watts. See figure 3 at right.

IMPORTANT: Wiring must be installed in approved solid or

flexible conduit, and must be secured to the brewer with a strain

relief (to be provided by the installer).

Models 9016EX must be wired by an electrician, and require

a 220-240V 20A circuit (50/60 Hz, 2 hot legs plus ground).

Remove front panel to gain access to terminal block. Green

terminal must be connected to a suitable building ground.

Circuit must be capable of 3800 Watts. Refer to 9016EX wiring

diagram on page 23.

IMPORTANT: Wiring must be installed in accordance with local

codes and ordinances.

NOTE: This equipment must be

installed to comply with

applicable federal, state and

local plumbing codes and

ordinances.

WARNING:

SHOCK HAZARD

Brewer must be properly

grounded to prevent possible

shock hazard. DO NOT

assume a plumbing line will

provide such a ground.

Electrical shock will cause death

or serious injury.

IMPORTANT: Do not connect

brewer to electrical power until

the tank is filled with water.

Pour water into the pour-over

opening until water flows from

the brew head.

IMPORTANT:

Supply power must match

nameplate for voltage and

phase. Connecting to the

wrong voltage will damage the

brewer or result in decreased

performance. Such damage is

not covered by warranty.

601 75815 Owners Manual Integrity Decanter Brewers

Fig. 3 115/240 Volt Terminal Block

5

Page 8

OPERATION

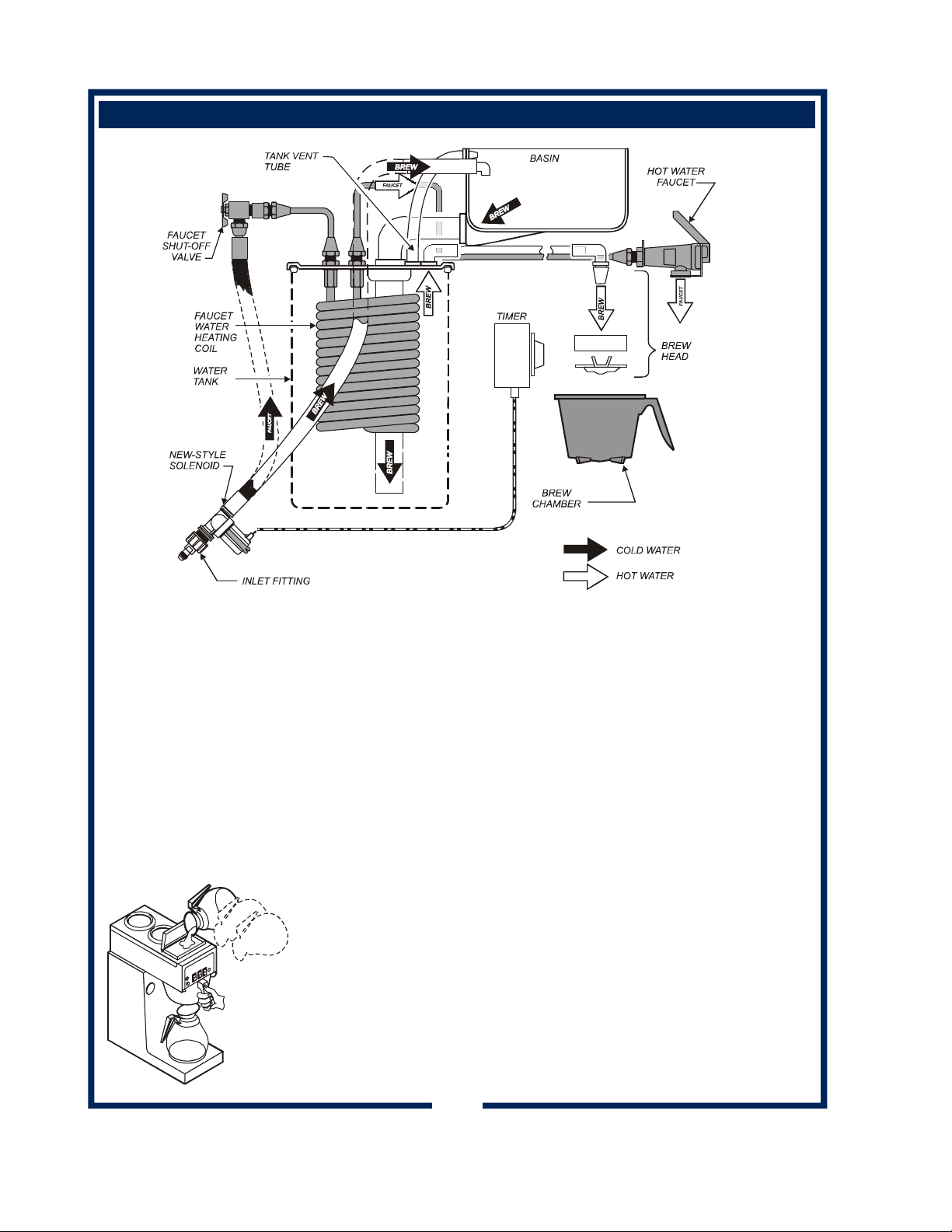

Fig. 4 Brewer Operation Diagram

IMPORTANT:

Tank must be full of water

before connecting brewer

to electrical power.

Heating elements will be

damaged if allowed to

operate without being fully

submerged in water.

Damage caused by

operating the brewer

without water in the tank

is NOT COVERED BY

WARRANTY.

A. START-UP

For initial start-up, or if the brewer has not been used for an

extended period of time:

♦ Be sure spray disk and brew gasket are properly installed in the

brew head.

♦ Be sure the water supply is properly connected and the water

supply valve is turned ON.

♦ Be sure the WATER TANK IS FILLED

BEFORE plugging the brewer into a receptacle, or otherwise

connecting brewer to electrical power THE WATER TANK MUST

BE FILLED. Place an empty decanter under the brew head. Lift

the pour-over cover then pour warm tap water into the pour-over

opening until water flows from the brew head. When water stops

dripping from the brew head, empty the container.

Once the tank is full of water, connect the brewer to electrical

power. The heating elements will begin heating the water in the

tank. When the water has reached the proper temperature, the

“HEAT” light will go out.

601 75815 Owners Manual Integrity Decanter Brewers

6

Page 9

WATER HEATER

Water temperature is sensed by a

thermobulb inserted into the water tank. This

temperature signal is fed to the thermostat,

which controls line power to the heating

element.

The setpoint temperature is adjustable at the

thermostat.

The element is protected from overtemperature by a hi-limit thermostat.

WATER FLOW

POUR-OVER FEATURE

Pouring any amount of cold water into the

pour-over opening and into the basin pan

forces an identical amount of hot water out

of the tank and through the spray head into

the brew chamber.

AUTOMATIC OPERATION

Pressing BREW button energizes the

solenoid valve, allowing water from an

external water supply to flow into the basin

pan and then into the hot water tank. This

forces an identical amount of hot water out

of the tank and through the spray head into

the brew chamber

The solenoid uses a flow control device so

that flow is consistent between 20 p.s.i. and

90 p.s.i.

Length of time the solenoid is open is

controlled by the timer.

HOT WATER FAUCET

The faucet water coil is submerged in the hot

water tank and draws heat from the brew

water. Water going to the water coil is not

controlled by the solenoid valve.

The faucet is at supply water pressure any

time the faucet shut-off valve is OPEN.

601 75815 Owners Manual Integrity Decanter Brewers

OPERATION (continued)

Fig. 5 Heat Control Diagram

Fig. 6 Water Flow Diagram

7

Page 10

BREWING COFFEE

CAUTION:

BURN HAZARD

Exposed surfaces of the

brewer, brew chamber and

decanter may be HOT to

the touch, and can cause

serious burns.

CAUTION:

BURN HAZARD

To avoid splashing or overflowing hot liquids,

ALWAYS place an empty

decanter under the brew

chamber before starting

the brew cycle. Failure to

comply can cause serious

burns.

CAUTION:

BURN HAZARD

After a brew cycle, brew

chamber contents are

HOT. Remove the brew

chamber and dispose of

used grounds with care.

Failure to comply can

cause serious burns.

NOTE: Water for the hot

water faucet is heated in a

coil inside of the water

tank. Use of the faucet will

not affect the volume of

water delivered for a brew.

However, overuse of the

faucet during a brew may

lower the temperature of

the brew water.

B. PREPARATION

Place one (1) genuine Bloomfield

paper filter in the brew chamber.

Add a pre-measured amount of

fresh coffee grounds.

Gently shake the brew chamber to

level the bed of grounds. Slide the

brew chamber into place under the

brew head.

Fig. 7 Brew Chamber

C. POUR-OVER OPERATION

NOTE: Any Integrity™ brewer can be used in the pour-over mode.

BE sure “READY TO BREW” light is lit.

Place the appropriate EMPTY decanter in place under the brew

chamber.

Fill a decanter with tap water. Lift the pour-over cover and pour the

entire contents of the decanter into the pour-over opening, which

will fill the basin.

Water from the basin will displace a like amount of heated water

from the tank. The hot water will be forced into the brew head

where it will spray over the bed of grounds. Freshly brewed coffee

will begin to fill the container under the brew chamber. When the

flow and all dripping stops, the coffee is ready to serve.

Discard the contents of the brew chamber. Rinse the brew

chamber in a sink. When the ”HEAT” light goes out, the brewer is

ready for another brew cycle.

C. AUTOMATIC OPERATION

BE sure “READY TO BREW” light is lit.

Place an EMPTY decanter in place under the brew chamber.

Press the “BREW” switch. The solenoid will open for an amount of

time determined by the timer setting, admitting a measured quantity

of water into the basin.

Water from the basin will displace a like amount of heated water

from the tank. The hot water will be forced into the brew head

where it will spray over the bed of grounds. Freshly brewed coffee

will begin to fill the decanter under the brew chamber. At the end

of the brew cycle, plus an amount of time set to allow all water to

drip out of the brew chamber, two beeps will sound. When the

flow and all dripping stops, the coffee is ready to serve.

Discard the contents of the brew chamber and rinse it in a sink.

When the ”READY TO BREW” light comes on, the brewer is ready

for another brew cycle.

601 75815 Owners Manual Integrity Decanter Brewers

8

Page 11

CLEANING INSTRUCTIONS

PROCEDURE: Clean Coffee Brewer

PRECAUTIONS: Disconnect brewer from electric power.

Allow brewer to cool.

FREQUENCY: Daily

TOOLS: Mild Detergent, Clean Soft Cloth or Sponge

Bristle Brush.

1. Disconnect brewer from electric power.

Allow brewer to cool before cleaning.

2. Remove and empty decanters.

3. Remove and empty brew chamber.

4. Remove the spray disk from the brew head (See figure 8):

Press up on the spray disk ears, then turn the disk to the left

to unlatch. Remove the gasket from inside the brew head.

5. Wipe inside of brew head and area around the brew head

with a soft clean cloth or sponge moistened with clean water.

6. Wash the spray disk in a sink using warm water and a mild

detergent. A bristle brush may be used to clear clogged

spray holes. Rinse the spray disk with clean water and allow

to air dry.

7. Wash the brew chamber in a sink using warm water and a

mild detergent. A bristle brush may be used to clean the

inside. Rinse with clean water and allow to air dry. For

stainless steel brew chambers, be sure the wire ra ck is

properly reinstalled.

8. Wipe the exterior of the brewer with a soft clean cloth or

sponge moistened with clean water.

10. Reinstall the gasket INSIDE the brew head, then reinstall the

spray disk.

11. Reinstall the brew chamber.

12. Decanters may be washed in a dishwasher or sink.

Procedure is complete

CAUTION:

BURN HAZARD

Brewing and serving

temperatures of coffee are

extremely hot.

Hot coffee will cause

serious skin burns.

CAUTION:

SHOCK HAZARD

Do not submerge or immerse

brewer in water.

IMPORTANT:

DO NOT use steel wool, sharp

objects, or caustic, abrasive or

chlorinated cleansers to clean

the brewer.

Fig. 8 Cleaning

601 75815 Owners Manual Integrity Decanter Brewers

9

Page 12

TROUBLESHOOTING SUGGESTIONS

SYMPTOM

Water won’t heat

Trips hi-limit safety at start-up

Coffee level low (pour-over)

Coffee level too high or low

(automatic)

Brew chamber overflows

Sprays water from brew head

incorrectly

No brew (automatic)

No flow from hot water faucet

Poor coffee quality

POSSIBLE CAUSE

Brewer unplugged or circuit

breaker tripped

Thermostat set too low

Hi-Limit thermostat tripped

Damaged internal component or

wiring

No water or too little water

added at start-up

Not enough water poured in

Too much coffee grounds

Timer out of adjustment

Too many filter papers or wrong

filter paper

Brew chamber dispense hole

plugged

Too much coffee or too fine a

grind

Spray gasket missing or

improperly installed

Spray disk plugged

Water supply OFF

Water line strainer plugged

Water filter (if used) plugged

Bad BREW switch

Damaged internal component or

wiring

Faucet valve turned OFF

Faucet plugged

Water not hot enough

SUGGESTED REMEDY

Check power supply cord

Check / reset circuit breaker

Set for desired temperature

Allow to cool

Reset hi-limit (8786, 8788)

Examine wiring & connectors,

thermostat and heating element

Repair/replace as needed

Be sure to add sufficient water

prior to energizing

Increase water amount

Adjust amount of grounds

Adjust timer

Use one (1) genuine Bloomfield

filter per brew

Thoroughly clean brew chamber

Adjust coffee amount and grind

Check/reinstall gasket on

INSIDE of brew head

Clean spray disk

Turn water supply ON

Clean strainer

Replace filter element

Replace switch

Examine wiring & connectors,

brew switch and solenoid

Repair/replace as needed

Turn faucet valve ON

Disassemble faucet, clean

Adjust water temp 195-205ºF

601 75815 Owners Manual Integrity Decanter Brewers

Also:

Keep brewer, airpots and servers clean.

Install a taste and odor filter in water supply, and replace

cartridges regularly.

Use a quality coffee with a consistent roast. Use proper grind and

amount of coffee per brew.

10

Page 13

SERVICING INSTRUCTIONS

ACCESS PANELS

Each warmer plate has a center stud which screws into a

bracket. Warmer plates on Canadian brewers are secured with a

nut. Remove button plug on bottom of brewer to access nut on

main warmer. Remove top panel to access nuts on top warmers.

Remove warmer plates by turning counter-clockwise.

Solenoid door is held by two screws and a retaining lip.

IN-LINE BREWERS:

Top panel is held by two screws at the rear and a retaining lip at

the front. Disconnect wires from the upper warmers.

Top front panel is held by two screws at the bottom and a

retaining lip at the top.

Bottom front panel is held by two clips under the warmer plate.

CAUTION:

SHOCK HAZARD

Opening access panels or

removing warmer plates on this

brew may expose uninsulated

electrical components.

Disconnect brewer from

electrical power before

removing any panel or warmer

plate.

601 75815 Owners Manual Integrity Decanter Brewers

Fig. 9 Access Panels

11

Page 14

SERVICING INSTRUCTIONS (continued)

CAUTION:

SHOCK HAZARD

These procedures involve

exposed electrical circuits.

These procedures are to be

performed by qualified

technical personnel only.

NOTE:

Optimum brewing temperature

range is 195ºF to 205ºF (90ºC

to 96ºC).

IMPORTANT:

A mechanical thermostat will

maintain temperature within

±5ºF. To prevent boiling water

in the brewer, thermostat should

be adjusted to a maximum

temperature equal to the local

boiling temperature minus 5ºF.

NOTE: 1/8 turn = approximately

10ºF (5.6ºC).

TEMPERATURE ADJUSTMENT

Unplug power cord or turn circuit breaker OFF. Remove top

panel.

Pull vent tube out of tank lid and insert a thermometer of known

accuracy in vent hole. Reconnect brewer to electrical power.

Fig. 10 Checking and Adjusting Brew Temperature

Place an empty decanter under brew chamber. Energize brewer

and pour one decanter (64 oz.) of cold water into pour-over

opening. When READY TO BREW light comes on, read

temperature displayed on thermometer.

Adjust thermostat by turning shaft; clockwise increases

temperature. 1/8 turn = approximately 10ºF.

Refer to Table 1 below for proper brewing temperature based on

altitude.

BOILING

POINT OF

WATER

IDEAL

BREWING

TEMPERATURE

MAXIMUM

TEMPERATURE

0

SETTING

0

0

5

,

6

)

F

º

(

.

P

M

E

T

210

205

200

195

190

0

0

0

0

5

0

0

5

0

,

,

1

1

0

0

0

0

0

,

2

0

0

0

5

0

,

,

2

3

0

0

0

0

0

0

5

0

5

,

,

,

4

4

3

0

0

0

0

0

0

5

0

,

,

,

6

5

5

ELEVATION (feet above seal level)

601 75815 Owners Manual Integrity Decanter Brewers

Fig. 11 Adjust Thermostat

0

0

5

9

.

1

BOILING

POINT OF

WATER

IDEAL

BREWING

TEMPERATURE

RANGE

MAXIMUM

TEMPERATURE

SETTING

)

C

º

(

.

P

M

E

T

100

97

94

88

91

0

0

0

0

5

3

1

0

0

0

5

6

4

0

0

0

5

9

7

0

0

0

5

2

0

.

.

1

1

0

0

5

3

.

1

0

0

5

0

8

6

5

.

.

.

1

1

1

ELEVATION (meters above seal level)

Table 1 Boiling Temperature by Altitude

Upon completion, remove thermometer and reinstall vent tube.

12

Page 15

SERVICING INSTRUCTIONS (continued)

TIMER ADJUSTMENT

The amount of water dispensed automatically during a brew cycle

is controlled by the timer.

Place empty decanter under brew chamber. Press BREW

button. Brewer should dispense one decanter of water. To

adjust amount:

Remove brew chamber and button plug. Adjust knob on timer;

clockwise increases time. Run several cycles to check amount

of water delivered. Replace button plug.

REMOVE TANK LID ASSEMBLY

Unplug brewer or turn circuit breaker OFF. Turn OFF water

supply. Remove top panel. Pull vent tube and inlet elbow out of

basin pan.

Pull water inlet tube out of basin pan. Remove basin pan.

On models with faucet, disconnect inlet pipe at faucet shut-off

valve and outlet pipe at faucet.

Disconnect all wiring from thermostat, hi-limit, and heating

element.

Loosen center screw on tank hold-down bracket. Remove

hold-down bracket by sliding short slotted end off of locking stud

and lifting it off. Remove cover assembly by lifting it straight up.

Reassemble in reverse order.

REPLACE THERMOSTAT

Unplug brewer or turn circuit breaker OFF. Turn OFF water

supply. Remove top panel.

Disconnect all wiring from thermostat only. Loosen and free

jam nut from pass-thru fitting securing temperature sensing bulb.

Remove two screws holding thermostat to bracket.

Lift out thermostat, sensing bulb and thermostat gasket.

Push sensing bulb into tank lid thermowell until fitting seats.

Tighten capillary lock nut only enough to ensure no water

leakage. Excessive tightening is not necessary.

Reassemble in reverse order.

IMPORTANT: Water pressure

must be between 20 p.s.i and

90 p.s.i. flowing pressure.

If water pressure exceeds this

value, or if water pressure

varies greatly, a pressure

regulator must be installed in

the water supply line.

IMPORTANT: Before setting

assembly into tank, make sure

tank lid gasket is properly

seated on flange of lid.

DO NOT OVER-TIGHTEN.

IMPORTANT:

If mounting thermostat

p/n 8512-51, be sure to place

a new seal washer below the

fitting on the capillary line.

If replacing gray-bodied thermo

with p/n 8512-51, be sure to

remove tube from thermowell.

601 75815 Owners Manual Integrity Decanter Brewers

13

Page 16

SERVICING INSTRUCTIONS (continued)

IMPORTANT: When replacing

heating element, also replace

seal gaskets.

Fig. 11 Remove Faucet

Supply from Solenoid

Fig. 12 Clean Strainer Screen

REPLACE HEATING ELEMENT

Remove tank lid assembly as described on page 13.

Remove two hex nuts holding element to cover. Pull element

from mounting holes.

Reassemble in reverse order.

REPLACE SOLENOID

Symptom: Automatic brewer will not flow water; or,

automatic brewer drips continuously from brew head.

NOTE: Wrench p/n 86660 is designed to allow easy removal of

the hoses from the plastic solenoid valve.

IMPORTANT: Shut-off water and electric supply to brewer

before removing hoses or wiring.

Remove water supply flare fitting:

a. Slide the 5/8" end of the wrench over the flats on the

inlet fitting of the valve.

b. Hold the wrench to prevent the inlet fitting from turning

while installing or removing the inlet water supply flare

nut.

Remove braided hose:

a. Slide the 7/16" end of the wrench between the valve

body and the white ring on the extreme end of the metal

hose fitting.

b. Pressure on the white ring toward the metal ferrule

releases the clinch ring, allowing the hose to be easily

slid off of the solenoid bypass outlet.

c. Install hose on new valve by pressing end of hose onto

bypass outlet until it is fully seated.

Disconnect wiring.

Remove two screws holding solenoid to access door.

Reassemble in reverse order.

CLEAN SOLENOID SCREEN

Symptom: Automatic brewer will not flow water.

Unplug power cord or turn circuit breaker OFF. Turn OFF and

disconnect water supply from brewer inlet fitting.

Unscrew water inlet fitting from solenoid.

Using needle-nose pliers, withdraw strainer screen from solenoid.

Clean screen under faucet. A stiff bristle brush may be used if

necessary.

Reinsert screen in solenoid. Be careful to maintain correct

orientation. (The OPEN END of the screen goes in FIRST.)

Reassemble in reverse order.

601 75815 Owners Manual Integrity Decanter Brewers

14

Page 17

SERVICING INSTRUCTIONS (continued)

REPLACE TIMER ASSEMBLY

Unplug power cord or turn circuit breaker OFF.

Remove front panel. Remove knob and three screws holding

timer to bracket. Disconnect wiring to timer.

Reassemble in reverse order.

Adjust timer as described on page 13

REPLACE HOT WATER FAUCET COIL

Symptom: Brewer drips continuously from brew head, except

when faucet valve is turned OFF.

Remove tank lid assembly per above.

Remove two hex nuts hot water coil to cover. Pull coil from

mounting holes.

Reassemble in reverse order.

REPAIR HOT WATER FAUCET

Remove top panel and turn faucet valve OFF.

Unscrew aerator cap from faucet and remove handle retaining

clip. Do not let faucet body turn.

Pull bonnet assembly from faucet body.

Examine the interior of the faucet body and the surface of the

seat cup. Clean out any debris in the faucet body, using a stiff

bristle brush if necessary.

Examine the aerator. Clean any debris from the screen or flow

straightener, using a stiff bristle brush if necessary.

Reassemble in reverse order.

REPLACE BREW READY LIGHT or BREW BUTTON

Unplug power cord or turn circuit breaker OFF.

Using Switch Removal Tool (p/n 83209) or a thin screwdriver, pry

light or switch from mounting hole. Disconnect leads.

Reassemble in reverse order.

IMPORTANT: When replacing

water faucet coil, also replace

seal gaskets.

NOTE: Any abrasion or

roughness on the flat end of the

seat cup will require replacing

the seat cup:

Work the seat cup out of the

bonnet and off of the end of the

stem.

Install a new seat cup, making

sure the knob on the stem is

fully inserted into the pocket of

the seat cup, and the skirt of the

seat cup is fully inserted into the

bonnet.

601 75815 Owners Manual Integrity Decanter Brewers

15

Page 18

SERVICING INSTRUCTIONS (continued)

CAUTION:

CHEMICAL BURN

HAZARD

Deliming chemicals may be

caustic. Wear appropriate

protective gloves and goggles

during this procedure.

Never siphon deliming

chemicals or solutions by

mouth.

This operation should only be

performed by qualified and

experienced service personnel.

IMPORTANT: DO NOT spill,

splash or pour water or deliming

solution into or over any internal

component other than the inside

of the water tank.

IMPORTANT: DO NOT allow

any internal components to

come into contact with the

deliming solution. Take care to

keep all internal components

dry.

NOTE: Repeat steps 4 thru 5

as required to remove all scale

and lime build-up.

PROCEDURE: Delime the Water Tank

PRECAUTIONS: Disconnect brewer from electric power.

Allow brewer to cool.

FREQUENCY: As required (Brewer slow to heat)

TOOLS: Deliming Solution

Protective Gloves, Goggles & Apron

Mild Detergent, Clean Soft Cloth or Sponge

Bristle Brush, Bottle Brush

Large Sink (or other appropriate work area)

1. Disconnect brewer from the electrical supply. Turn off the

water shut-off valve and disconnect the water supply line

from the brewer inlet fitting.

2. Remove the tank lid assembly as described on page 13.

3. Remove the water tank from the brewer body by lifting

straight up. Empty all water from the tank. Set the tank back

into the brewer.

4. Mix 2 quarts of deliming solution according to the

manufacturer’s directions. Carefully pour the deliming

solution into the water tank. Lower the lid assembly back

onto the tank. Allow to sit for 30 minutes, or as directed by

the manufacturer.

5. At end of soaking period, remove lid assembly from tank.

Thoroughly rinse internal components of lid assembly with

clear water. Using a stiff bristle brush, scrub the heating

element (and faucet water coil on automatic brewers) to

remove lime and calcium build-up. Rinse with clean water.

Store lid assembly in a safe location .

6. Remove the tank from the brewer and empty. Using a stiff

bristle brush, scrub the interior of the water tank to remove

lime and calcium build-up. Rinse with clean water.

601 75815 Owners Manual Integrity Decanter Brewers

16

Page 19

)

d

e

u

t

n

i

I

V

R

E

S

I

I

C

N

S

N

I

T

O

C

U

R

T

S

N

G

n

o

(

c

7. Set the tank back into the brewer. Reassemble the tank lid to

the water tank. Make sure the gasket is properly in place,

then reinstall the hold-down strap.

8. Reinstall wiring to heating element and thermostat. Reinstall

the hi-limit thermostat (if removed). For brewers with hot

water faucet, reassemble faucet piping. Verify that all internal

components are dry, then reinstall the top panel.

10. Reconnect brewer to electrical supply and, for automatic

brewers, reconnect water supply.

11. Install the brew chamber without filter paper or grounds.

Run at least three full brew cycles and discard all water

generated.

12. Brewer is ready to use.

NOTE: Normally, silicone

hoses do not need to be

delimed. Should deliming

hoses become necessary,

Bloomfield recommends

replacing the hoses.

601 75815 Owners Manual Integrity Decanter Brewers

17

Page 20

EXPLODED VIEW & PARTS LIST

HOT WATER TANK ASSEMBLY

60

61

14

59

68

55

62

50

52

13

54

63

66a

56

57

56

70

58

67

ITEM PART NO. DESCRIPTION USED ON

13 8043-5 HOLD-DOWN STRAP 9010, 9012(CA), 9016(EX)

14 83457 NUT, HEX 8-32 KEPS 9010, 9012(CA), 9016(EX)

8512-51

50

52 8512-41 SEAL WASHER, THERMO CAP TUBE (ONLY) 9010, 9012(CA), 9016(EX)

54 8043-12 TANK COVER GASKET 9010, 9012(CA), 9016(EX)

55 8043-28 NUT HEX 1/2-20 BRASS 9010, 9012(CA), 9016(EX)

56 8043-30 SEAL GASKET, ELEMENT OR WATER COIL 9010, 9012(CA), 9016(EX)

57 8941-21 NUT HEX 7/16-20 BRASS

58 8540-6 HOT WATER COIL 9010, 9012(CA), 9016(EX)

59 8043-8 TUBE, BASIN OUTLET/TANK INLET, SILICONE 9010, 9012(CA), 9016(EX)

60 8043-15 TUBE, VENT, SILICONE 9010, 9012(CA), 9016(EX)

61 8043-11 ELBOW, TANK OUTLET, SILICONE 9010, 9012(CA), 9016(EX)

62 8514-68 TAN COVER, PLATE ONLY, 8 HOLES 9010, 9012(CA), 9016(EX)

63

66 8043-24 WATER INLET TUBE 9010, 9012(CA), 9016(EX)

66a 8543-74 NUT, HEX 4-40 SS 9010, 9012(CA), 9016(EX)

66b 8543-73 SCREW 4-40 x 1 PAN HEAD 9010, 9012(CA), 9016(EX)

67

68 8043-10 TANK BODY 9010, 9012(CA), 9016(EX)

70 80625 BRACKET, HI LIMIT THERMOSTAT 9010, 9016 (EX)

86280

8043-83

8552-50

8043-93

8043-14

8716-1

TANK COVER ASSEMBLY

8541WF-

300

THERMOSTAT (BLACK BODY - INCL. SEAL & MOUNTING SCREWS)

THERMO (ALT) (GRAY BODY - INCL. TUBE & MOUNTING SCREWS)

THERMOSTAT, HI-LIMIT

THERMOSTAT, HI-LIMIT RESET

HEATING ELEMENT (120V, 1200W)

HEATING ELEMENT (120V, 1500W)

HEATING ELEMENT (240V, 3500W)

INCLUDES: MOUNTED THERMO, HI-LIMIT, 120V 1500W HEATING

ELEMENT & HOT WATER COIL)

66b

66

50

ALTERNATE

9010, 9012(CA), 9016(EX)

9012(CA)

9010, 9016(EX)

9012CA

9010, 9012

9016, 9016EX

601 75815 Owners Manual Integrity Decanter Brewers

18

Page 21

CABINET PLUMBING COMPONENTS

EXPLODED VIEW & PARTS LIST (continued)

11

10

61

9

60

59

18

29a

29b

29c

29d

19

12

43

24

45

TANK ASSY

see PAGE 18

ITEM PART NO. DESCRIPTION USED ON

8 8540-3 FORMED TUBE, FAUCET OUTLET ASSEMBLY 10-7/8" LONG 9010, 9012(CA), 9016(EX)

9 8540-4 FORMED TUBE, FAUCET COIL INLET ASSEMBLY 9010, 9012(CA), 9016(EX)

10 8551-30 ADAPTER, 1/4" MALE FLARE x 1/8" FPT BRASS 9010, 9012(CA), 9016(EX)

11 8514-26 VALVE, FAUCET SHUT OFF, NEEDLE SEAT 9010, 9012(CA), 9016(EX)

12 85681 BRAIDED TUBE, FAUCET INLET 6MM x 299MM (11-3/4") LONG 9010, 9012(CA), 9016(EX)

18 8540-30 ELBOW, BASIN INLET DIVERTER POLYPROPYLENE 9010, 9012(CA), 9016(EX)

24 8043-26 TUBE, BREW OUTLET, METAL 4-3/4" LONG 9010, 9012(CA), 9016(EX)

25 8043-13 ELBOW, SPRAYER, SILICONE 9010, 9012(CA), 9016(EX)

26 82680 LOCK NUT, HEX 7-16-20 9010, 9012(CA), 9016(EX)

27 8551-100B LOCK WASHER 7/16" EXT SEMS (FAUCET) 9010, 9012(CA), 9016(EX)

28 82681 WASHER, FLAT 15/32" x 1-1/8" x 1/16" SS 9010, 9012(CA), 9016(EX)

29 82556 FAUCET ASSEMBLY, PRESSURE 9010, 9012(CA), 9016(EX)

33 8543-42 GASKET, SPRAY HEAD 9010, 9012(CA), 9016(EX)

34 82727 SPRAY DISK, EMBOSSED 9010, 9012(CA), 9016(EX)

34a 8543-45 RETAINER, SPRAY HEAD (REQUIRES DRILL/RIVETS TO INSTALL) 9010, 9012(CA), 9016(EX)

43 8541-46 TUBE, BASIN INLET, SILICONE 13" 9010, 9012(CA), 9016(EX)

45

59 8043-8 TUBE, BASIN OUTLET/TANK INLET, SILICONE 9010, 9012(CA), 9016(EX)

60 8043-15 TUBE, VENT, SILICONE 9010, 9012(CA), 9016(EX)

61 8043-11 ELBOW, TANK OUTLET, SILICONE 9010, 9012(CA), 9016(EX)

108 8541-21 BASIN PAN 9010, 9012(CA), 9016(EX)

601 75815 Owners Manual Integrity Decanter Brewers

85685

84570

FAUCET REPAIR KITS

82573 HANDLE, FAUCET RED (29a)

82575 SEAT CUP (29c)

82576

82682 RETAINER CLIP (29b)

84804 AERATOR REPLACEMENT, INCL: O-RING (29e), DISK (29f) & CAP (29g)

84870 AERATOR REPAIR KIT, INCL: O-RING (29e) & DISK (29f)

SOLENOID W/BYPASS, 120V, .75 GPM

SOLENOID W/BYPASS, 220/240V, .75 GPM

FAUCET REPAIR KIT, INCL: HANDLE (29a), SEAT CUP (29c),

SPRING (29d), STEM (29h), PIN (29j) & BONNET (29k)

25

34a

33

34

8

26

27

28

29

29e

29f

29g

29j

29h

9010, 9012(CA)

9016(EX)

29k

19

Page 22

EXPLODED VIEW & PARTS LIST (continued)

ELECTRICAL COMPONENTS

120V

63

2

50

35

30

240V

63

43

32

31

ALT

2

45

36

37

ITEM PART NO. DESCRIPTION USED ON

8572-18

2

8533-32

6710-23

30

8563-110

8572-24

31

8707-55

8718-31

32

35

8738-2

8718-1

8738-1

36 6407-15 POWER CORD ASSEMBLY, 120V NEMA 5-15P 9010, 9012(CA)

37 35-210 STRAIN RELIEF 9010, 9012(CA)

43 8552-18 TERMINAL BLOCK, 4P 9016(EX)

45

50

63

85685

84570

8512-51

86280

8043-83

8552-50

8541-1

8043-14

67

8716-1

SOLENOID REPAIR KITS

84570 SOLENOID 220/240V W/BYPASS .75GPM, COMPLETE

85685 SOLENOID 120V W/BYPASS .75GPM, COMPLETE

85218

85219 INLET STRAINER ( 45d ONLY)

HEATING ELEMENT, WARMER 120V 100W

HEATING ELEMENT, WARMER 220V 85W / 240V 100W

SWITCH, WARMER ON/OFF 120V

SWITCH, WARMER ON/OFF 240V

SWITCH, MOMENTARY PUSH-BUTTON, BREW

SWITCH, MOMENTARY ROCKER, BREW

INDICATOR, 120V, READY-TO-BREW

INDICATOR, 240V, READY-TO-BREW

TIMER, 2-MINUTE (WITH DIAL & KNOB) 120V

TIMER, 2-MINUTE (WITH DIAL & KNOB) 240V

SOLENOID W/BYPASS, 120V, .75 GPM

SOLENOID W/BYPASS, 220/240V, .75 GPM

THERMOSTAT (BLACK BODY - INCL. SEAL & MOUNTING SCREWS)

THERMO (ALT) (GRAY BODY - INCL. TUBE & MOUNTING SCREWS)

THERMO, HI-LIMIT

THERMO, HI-LIMIT, RESET

HEATING ELEMENT, WATER TANK 120V 2000W

HEATING ELEMENT, WATER TANK 120V 1500W

HEATING ELEMENT, WATER TANK 240V 3500W

INLET FITTING KIT INCLUDES: CAP (45a), FITTING (45b),

GASKET (45c) & STRAINER (45d)

45c

ALL EXCEPT 9016(EX)

9016(EX)

ALL EXCEPT 9016(EX)

9016(EX)

9010, 9012(CA), 9016(EX)

ALL EXCEPT 9016(EX)

9016(EX)

ALL EXCEPT 9016(EX)

9016(EX)

9010, 9012(CA)

9016(EX)

9010, 9012(CA), 9016(EX)

9012(CA)

9010, 9016(EX)

9010, 9012(CA)

9012CA

9016(EX)

45d

50

ALTERNATE

120V

240V

67

67

601 75815 Owners Manual Integrity Decanter Brewers

20

45b

45a

Page 23

EXPLODED VIEW & PARTS LIST (continued)

CABINET COMPONENTS

ITEM PART NO. DESCRIPTION USED ON

3 8700-16 COVER PLATE, WARMER BLACK 9010, 9012(CA), 9016(EX)

33 8543-42 GASKET, SPRAY HEAD 9010, 9012(CA), 9016(EX)

34 82727 SPRAY DISK, EMBOSSED 9010, 9012(CA), 9016(EX)

34a 8543-45 RETAINER, SPRAY HEAD (REQUIRES DRILL/RIVETS TO INSTALL) 9010, 9012(CA), 9016(EX)

70 8706-75 BUTTON PLUG, 2", METAL 9010, 9012(CA), 9016(EX)

73 81732 LEG ASSEMBLY, LEVELLING 9010, 9012(CA), 9016(EX)

75 8543-69 BUSHING, HEYCO 9010, 9012(CA), 9016(EX)

104 85089 DOOR, SOLENOID ACCESS, PLASTIC 9010, 9012(CA), 9016(EX)

105 86666 POUR OVER ASSEMBLY, PLASTIC 9010, 9012(CA), 9016(EX)

107 9012-28 SPLASH GUARD, POUR-OVER 9010, 9012(CA), 9016(EX)

108 8541-21 BASIN PAN 9010, 9012(CA), 9016(EX)

9012-11

121

9016-211

122 9012-7 PANEL, UPPER FRONT 9010, 9012(CA), 9016(EX)

123 9012-6 PANEL, LOWER FRONT 9010, 9012(CA), 9016(EX)

124 9012-23 BOTTOM PLATE 9010, 9012(CA), 9016(EX)

125 8543-80 CLIP, MOUNTING 9010, 9012(CA), 9016(EX)

126 9012-10 BASIN COVER W/ 2 WARMER PLATE MOUNTS 9010, 9012(CA), 9016(EX)

8942-6B

200

201 POF FILTER PAPER, COFFEE (CASE OF 1000) 9010, 9012(CA), 9016(EX)

8942-6

8707-6

BODY & BASE ASSEMBLY

BODY & BASE ASSEMBLY, EXPORT

BREW CHAMBER, BLACK PLASTIC

BREW CHAMBER, BROWN PLASTIC (OPTIONAL limited to stock on hand)

BREW CHAMBER, STAINLESS W/ WIRE BASKET (OPTIONAL)

9010, 9012(CA), 9016

9016(EX)

9010, 9012(CA), 9016(EX)

601 75815 Owners Manual Integrity Decanter Brewers

21

Page 24

WIRING DIAGRAMS

HI-LIMIT

LINE 1

120V

LINE 2

NEUT.

GROUND

GREEN

TIMER

BROWN

SOLENOID

WHITE

WHITE

TOP

REAR

WARMER

BLUE

3

WARMER

SWITCH

THERMOSTAT

14ga

14ga

14ga

BLACK

BLACK

2

BLACK

BROWN

WHITE

WHITE

WHITE

WHITE

14ga

1

1

1

2

1

READY

LIGHT

MODEL 9010

p/n 75446

BLACK

ORANGE

ELEMENT

BREW

SWITCH

MAIN

WARMER

WHITE

ORANGE

123 123 123

WARMER

SWITCH

TOP

FRONT

WARMER

RED

WHITE

3

WHITE

3

BLACK

WARMER

SWITCH

LINE 1

120V

LINE 2

NEUT.

GROUND

GREEN

TIMER

BROWN

SOLENOID

WHITE

THERMOSTAT

BLACK

21

1

2

2

BLACK

ORANGE

1

BROWN

WHITE

READY

LIGHT

MODEL 9012

p/n 71725

22

BLACK

HI-LIMIT

BLACK

BLACK

WHITE

WHITE

WHITE WHITE

ELEMENT

BREW

SWITCH

MAIN

WARMER

1

WHITE

ORANGE

123 123 123

WARMER

SWITCH

TOP

FRONT

WARMER

RED

WHITE

33 3

WHITE

BLACK

WARMER

SWITCH

TOP

REAR

WARMER

BLUE

WARMER

SWITCH

601 75815 Owners Manual Integrity Decanter Brewers

Page 25

WIRING DIAGRAMS (continued)

LINE

NEUT

LINE

GND

LINE

LINE

GND

BROWN

BLACK

BLACK

WHITE

WHITE

RED 12 ga

GREEN

BROWN

GREEN

TIMER

WHITE

BROWN

TIMER

B2

BLACK

BLUE

ORANGE

HI-LIMIT

12 ga

SOLENOID

HI-LIMIT

ORANGE

BROWN 12 ga.

BROWN

BLUE 12 ga

BLUE

BLUE

BLUE

THERMOSTAT

A1

BLACK

12 ga

B3

B2

A4

ORANGE

B1

READY

LIGHT

MODEL 9016

p/n 72356

THERMOSTAT

BLACK

A4

BLACK

A1

12 ga

BROWN

BREW

SWITCH

BROWN 12 ga.

B3

ELEMENT

WHITE

WHITE

WHITE

ELEMENT

B1

TOP

FRONT

WARMER

RED

C3

WARMER

SWITCH

TOP

FRONT

WARMER

C1

RED

WHITE

C2

BLUE

MAIN

WARMER

WHITE

ORANGE

A2

WHITE

WHITE

BLACK

BLACK

123 123 123

WARMER

SWITCH

MAIN

WARMER

BLUE 12 ga

A3

C2

WHITE

TOP

REAR

WARMER

BLUE

C1

WARMER

SWITCH

TOP

REAR

WARMER

C3

WHITE

BROWN

BLUE

601 75815 Owners Manual Integrity Decanter Brewers

SOLENOID

READY

LIGHT

MODEL 9016EX

p/n 73652

BREW

SWITCH

23

123 123 123

WARMER

SWITCH

WARMER

SWITCH

WARMER

SWITCH

Page 26

Genuine Parts

Protect - YOU - All - Ways

SERVICE TRAINING - QUALITY SERVICE

CUSTOMER SATISFACTION

Commercial Food Equipment Service Association

Wells Bloomfield proudly supports CFESA

Commercial Food Equipment Service Association

SERVICE TRAINING - QUALITY SERVICE

CUSTOMER SATISFACTION

WELLS BLOOMFIELD, LLC

2 ERIK CIRCLE, P. O. Box 280 Verdi, NV 89439

telephone: 775-689-5707

fax: 775-689-5976

www.wellsbloomfield.com

PRINTED IN UNITED STATES OF AMERICA

Loading...

Loading...