Bloomfield 1222 Owner's Manual

10 Sunnen Drive

St. Louis, MO 63143

telephone: 314-678-6336

fax: 314-781-2714

www.wellsbloomfield.com

712

OWNERS MANUAL

for

HOT WATER

DISPENSER

2 GALLON MODELS:

1222

1222CA

5 GALLON MODELS:

1225

1226

Includes:

Installation

Operation

Use & Care

Servicing Instructions

Model 1222 Dispenser

2M-76580 Rev. I M712 110215

NOTE: For your protection, please note that equipment in

this shipment was carefully inspected and packaged by skilled

personnel before leaving the factory.

Upon acceptance of this shipment, the transportation

company assumes full responsibility for its safe delivery.

IF SHIPMENT ARRIVES DAMAGED:

1. VISIBLE LOSS OR DAMAGE: Be certain that any

visible loss or damage is noted on the freight bill

or express receipt, and that the note of loss or damage

is signed by the delivery person.

2. FILE CLAIM FOR DAMAGE IMMEDIATELY:

Regardless of the extent of the damage.

3. CONCEALED LOSS OR DAMAGE: if damage is

unnoticed until the merchandise is unpacked, notify the

transportation company or carrier immediately, and

le “CONCEALED DAMAGE” claim with them. This

must be done within fteen (15) days from the date

the delivery was made to you. Be sure to retain the

container for inspection.

Wells Bloomeld cannot assume liability for damage or loss

incurred in transit. We will, however, at your request, supply

you with the necessary documents to support your claim.

WARRANTY STATEMENT

SERVICE POLICY AND PROCEDURE GUIDE

ADDITIONAL WARRANTY EXCLUSIONS

SHIPPING DAMAGE CLAIMS PROCEDURE

1. Resetting of safety thermostats, circuit breakers,

overload protectors, or fuse replacements unless

warranted conditions are the cause.

2. All problems due to operation at voltages other than

specied on equipment nameplates; conversion to

correct voltage must be the customer’s responsibility.

3. All problems due to electrical connections not made in

accordance with electrical code requirements and

wiring diagrams supplied with the equipment.

4. Replacement of items subject to normal wear, to

include such items as knobs and light bulbs. Normal

maintenance functions including adjustment of

thermostats, microswitches, and replacement of fuses

and indicating lights are not covered under warranty.

5. All problems due to inadequate water supply, such as

uctuating, or high or low water pressure.

6. All problems due to mineral/calcium deposits, or

contamination from chlorides/chlorines. De-liming is

considered a preventative maintenance function and is

not covered by warranty.

All electrical equipment manufactured by WELLS

BLOOMFIELD, LLC is warranted against defects in materials

and workmanship for a period of one year from the date of

original installation or eighteen (18) months from the date of

shipment from our factory, whichever comes rst, and is for

the benet of the original purchaser, except that:

a. airpots carry a 30 day parts warranty only.

b. dispensers; i.e., tea and coffee carry a 90 days parts

warranty only, excludes decanters.

THE FOREGOING OBLIGATION IS EXPRESSLY GIVEN

IN LIEU OF ANY OTHER WARRANTIES, EXPRESSED

OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE, WHICH ARE HEREBY EXCLUDED.

WELLS BLOOMFIELD, LLC SHALL NOT BE LIABLE FOR

INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES

OR LOSSES FROM ANY CAUSE WHATSOEVER.

This warranty is void if it is determined that upon inspection

by an Authorized Service Agency that the equipment has

been modied, misused, misapplied, improperly installed, or

damaged in transit or by re, ood or act of God.

It also does not apply if the serial nameplate has been

removed or unauthorized service personnel perform service.

The prices charged by Bloomeld Industries for its products

are based upon the limitations in this warranty. Seller’s

obligation under this warranty is limited to the repair of

defects without charge by a Bloomeld Authorized Service

Agency or one of its sub-agencies. This service will be

provided on customer’s premises for non-portable models.

Portable models (a device with a cord and plug) must be

taken or shipped to the closest Authorized Service Agency,

transportation charges prepaid, for services.

In addition to restrictions contained in this warranty, specic

limitations are shown below (Additional Warranty Exclusions).

Bloomeld Industries Authorized Service Agencies are located

in principal cities.

This warranty is valid in the United States and void elsewhere.

Please consult your classied telephone directory or your food

service equipment dealer; or, for information and other details

concerning warranty, write to:

Service Parts Department

Wells Bloomeld, LLC

10 Sunnen Drive, St. Louis, MO 63143

Phone: (314) 678-6336... Fax: (314) 781-2714

7. Full use, care and maintenance instructions are supplied

with each machine. Those miscellaneous adjustments

noted are customer responsibility. Proper attention will

prolong the life of the machine.

8. Travel mileage is limited to sixty (60) miles from an

authorized Service Agency or one of its sub-agencies.

9. All labor shall be performed during normal working hours.

Overtime premium shall be charged to the customer.

10. All genuine Bloomeld replacement parts are warranted

for ninety (90) days from date of purchase on non-

warranted equipment. Any use of non-genuine

Bloomeld parts completely voids any warranty.

11. Installation, labor and job check-out are not considered

warranty.

12. Charges incurred by delays, waiting time or operating

restrictions that hinder the service technicians ability

to perform services are not covered by warranty.

This includes institutional and correctional facilities.

xi

712 p/n 2M-76580 1222_1225_1226 Owmers Manual

TABLE OF CONTENTS

WARRANTY STATEMENT xi

SPECIFICATIONS 1

FEATURES & OPERATING CONTROLS 2

PRECAUTIONS & GENERAL INFORMATION 3

AGENCY LISTING INFORMATION 3

INSTALLATION INSTRUCTIONS 4

OPERATION 6

CLEANING INSTRUCTIONS 7

TROUBLESHOOTING SUGGESTIONS 8

SERVICING INSTRUCTIONS 9

Deliming Instructions 12

EXPLODED VIEW & PARTS LIST 13

WIRING DIAGRAMS 16

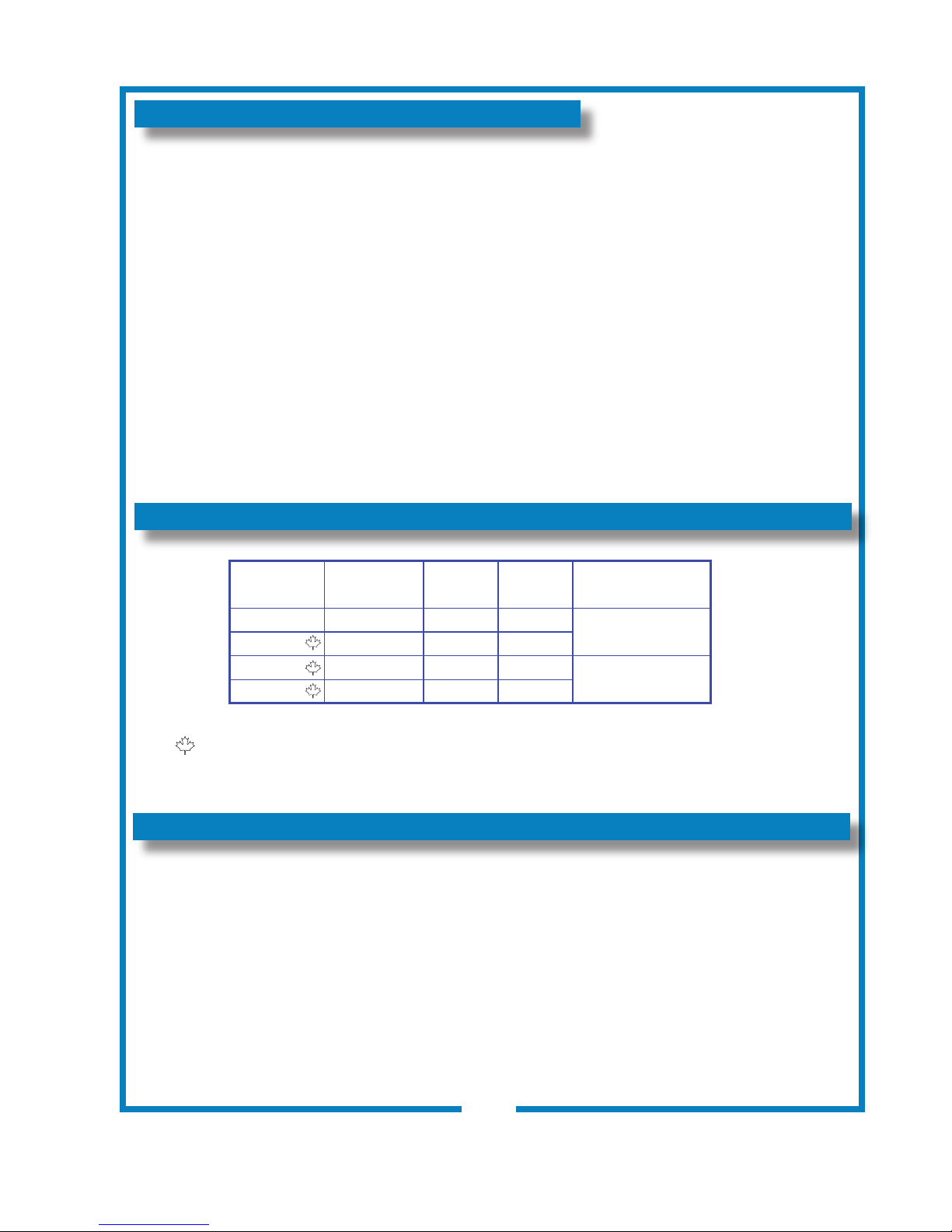

SPECIFICATIONS

MODEL

1222 120 1800 15

1222CA 120 1500 12.8

1225 208 4000 19

1226 240 4000 16.5

VOLTS

1ø 50/60Hz 1ø

WATTS

AMPS

Thank You for purchasing this

Wells Bloomeld appliance.

Proper installation, professional

operation and consistent

maintenance of this appliance will

ensure that it gives you the very

best performance and a long,

economical service life.

This manual contains the

information needed to properly

install this appliance, and to use,

care for and maintain or repair the

appliance in a manner which will

ensure its optimum performance.

POWER SUPPLY

CORD

NEMA 5-15P

NEMA 6-30P

Meets Canadian standards

APPLICABILITY

This manual applies to the following Wells Bloomeld products:

1222 2-Gallon Hot Water Dispenser

1222CA 2-Gallon Hot Water Dispenser

1225 5-Gallon Hot Water Dispenser

1226 5-Gallon Hot Water Dispenser

712 p/n 2M-76580 1222_1225_1226 Owmers Manual

1

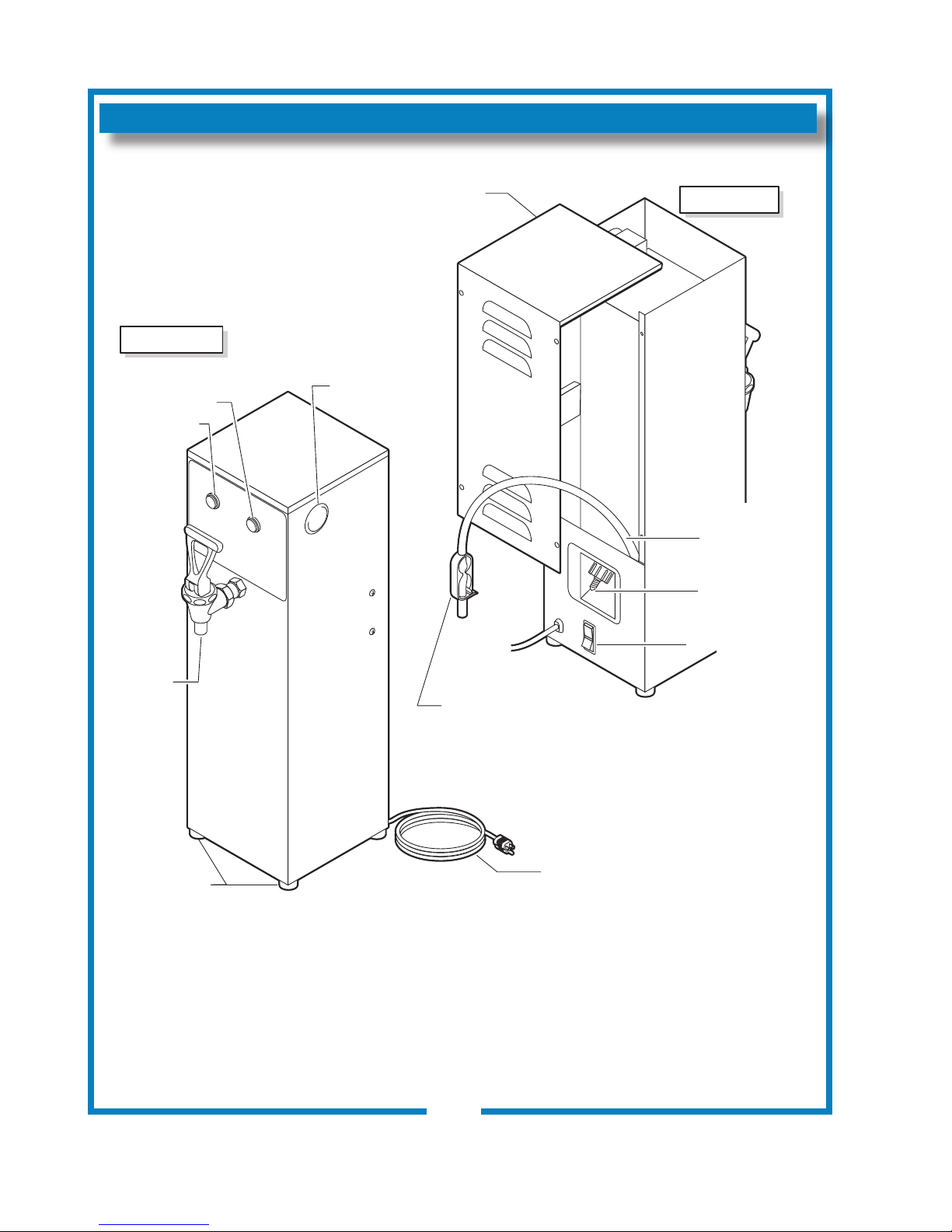

FEATURES AND OPERATING CONTROLS

HOT

WATER

REAR COVER

FLEXIBLE

DRAIN LINE

WATER SUPPLY

CONNECTION

TANK HEATER

SWITCH

POWER LITE

READY LITE

DISPENSE

FAUCET

RUBBER

GRIP FEET

POWER CORD

THERMOSTAT

ACCESS

FRONT VIEW

REAR VIEW

DRAIN LINE

TUBING CLAMP

IL2081

2

712 p/n 2M-76580 1222_1225_1226 Owmers Manual

PRECAUTIONS AND GENERAL INFORMATION

E9253

E9253

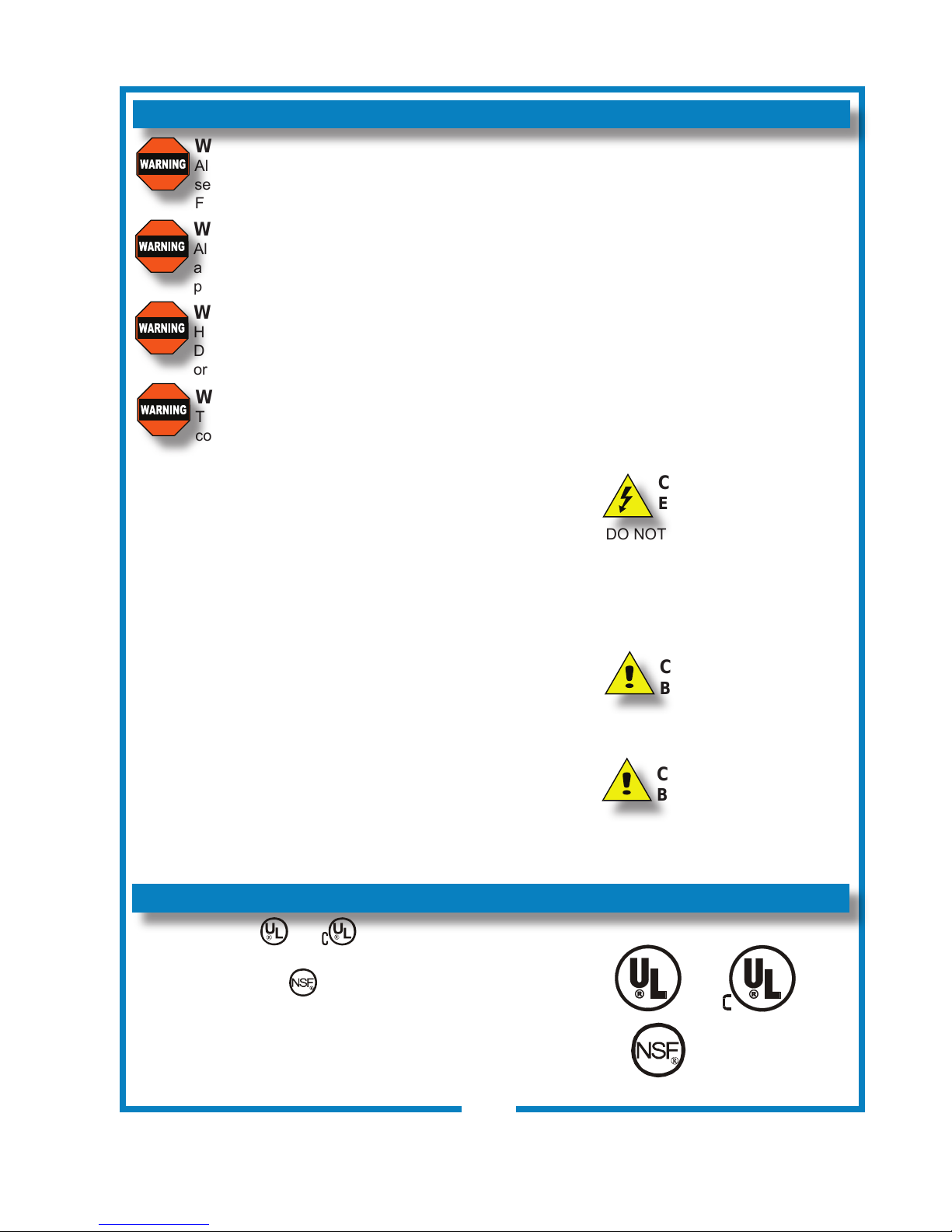

WARNING: ELECTRIC SHOCK HAZARD

All servicing requiring access to non-insulated components must be performed by qualied

service personnel. Do not open any access panels which require the use of tools.

Failure to heed this warning can result in electrical shock.

WARNING: INJURY HAZARD

All installation procedures must be performed by qualied personnel with full knowledge of all

applicable electrical and plumbing codes. Failure could result in property damage and

personal injury.

WARNING: ELECTRIC SHOCK HAZARD

Hot Water Dispenser must be properly grounded to prevent possible shock hazard.

DO NOT assume a plumbing line will provide such a ground. Electrical shock will cause death

or serious Injury.

WARNING: BURN HAZARD

This appliance dispenses very hot liquid. Serious bodily injury from scalding can occur from

contact with dispensed liquids.

This appliance is intended for commercial use only.

This appliance is intended for use to dispense heated

water. No other use is recommended or authorized by the

manufacturer or its agents.

This appliance is intended for use in commercial establishments,

where all operators are familiar with the appliance use,

limitations and associated hazards. Operating instructions and

warnings must be read and understood by all operators and

users.

Except as noted, this piece of equipment is made in the USA

and has American sizes on hardware. All metric conversions are

approximate and can vary in size.

The following trouble shooting, component views and parts lists

are included for general reference, and are intended for use by

qualied service personnel.

This manual should be considered a permanent part of this

appliance. The manual must remain with the appliance if it is

sold or moved to another location.

AGENCY LISTING INFORMATION

CAUTION:

EQUIPMENT DAMAGE

DO NOT plug in or energize this

appliance until all Installation

Instructions are read and followed.

Damage to the dispenser will

occur if these instructions are not

followed.

CAUTION:

BURN HAZARD

Dispensed liquid is VERY HOT

and can cause burns.

CAUTION:

BURN HAZARD

Exposed surfaces of the

appliance may be HOT to the

touch and can cause burns.

This dispenser is and listed under le E9253.

This dispenser meets

operated and maintained in accordance with the enclosed

instructions.

712 p/n 2M-76580 1222_1225_1226 Owmers Manual

Standard 4 only when installed,

STANDARD 4

3

INSTALLATION

READ THIS CAREFULLY BEFORE STARTING THE INSTALLATION

IMPORTANT:

To enable the installer to make

a quality installation and to

minimize installation time, the

following suggestions and tests

should be done before the

actual unit installation is started:

CAUTION:

EQUIPMENT DAMAGE

DO NOT plug in or energize this

appliance until all Installation

Instructions are read and

followed. Damage to the

dispenser will occur if these

instructions are not followed.

CAUTION:

UNSTABLE

EQUIPMENT HAZARD

It is very important for safety

and for proper operation that

the dispenser is level and

stable when standing in its nal

operating position. Provided

adjustable, non-skid legs must

be installed at each corner

of the unit. Failure to do so

will result in movement of the

dispenser which can cause

personal Injury and/or damage

to appliance.

NOTE: Water supply inlet line

must meet certain minimum

criteria to insure successful

operation of the dispenser.

Bloomeld recommends 1/4”

copper tubing for installation of

less than 12 feet and 3/8” for

more than 12 feet from a 1/2”

water supply line.

REFER TO EXPLODED VIEWS PAGE 14 FOR COMPONENT

NAMES/NUMBERS.

Unpack the unit. Inspect all components for completeness and

condition. Ensure that all packing materials have been removed

from the unit.

LEVELING THE UNIT

Two Gallon Dispenser is NOT provided with adjustable legs. Be

sure dispenser is placed on a solid level surface with all four feet

touching the surface.

Five Gallon Dispenser is provided with adjustable legs. Verify

that an adjustable leg is installed at each corner of the brewer.

Set Brewer in its operating location. Level the Brewer. A spirit

level should be placed on the top of the unit, at the edge, as a

guide when making level adjustments. Level the unit from left to

right and front to back by turning the adjustable feet. Be sure all

four feet touch the counter to prevent tipping.

PLUMBER’S INSTALLATION INSTRUCTIONS

Dispenser should be connected to a POTABLE WATER, COLD

WATER line. Flush water line before connecting to appliance.

DO NOT use a saddle valve with a self-piercing tap for the water

line connection. Such a tap can become restricted by waterline

debris. For systems that must use a saddle tap,

main water supply and drill a 3/16” (minimum) tap for the saddle

connection, in order to insure an ample water supply. Remember

to ush the line prior to installing the saddle.

The dispenser must be installed on a water line with average

pressure between 20 PSI and 90 PSI. If your water pressure

exceeds 90 PSI at anytime, a pressure regulator must be

installed in the water supply line to limit the pressure to not more

than 90 PSI in order to avoid damage to lines and solenoid.

A water shut-off valve should be installed on the incoming water

line in a convenient location (Use a low restriction type valve,

such as a 1/4-turn ball valve, to avoid loss of water ow thru the

valve.

shut off the

4

712 p/n 2M-76580 1222_1225_1226 Owmers Manual

Loading...

Loading...