Page 1

DoPLnoInduction

Touch Control

Domino Induktion

Sensorstaten

MIS 3200 X

,QVWUXFWLRQV0DQXDOV

*HEUDXFKVDQOHLWXQJ

*% FR DE

PT FL

DA

Page 2

Page 3

ENGLISH

DOMINO INDUCTION

TOUCH CONTROL

OPERATING INSTRUCTIONS BOOK

GB

Page 4

Page 5

CONTENTS

1. WARNINGS……………………………………………………… 3

1.1 For installation……………………………………………….. 3

1.2 For cooking…………………………………………………… 3

2. INSTALLATION……………… ………… ………… ………… …. 5

2.1 Instruction for the installer…………………………………… 5

2.2 Instruction for the user……………………………………..... 6

2.3 Key panels…………………………………………………..... 8

3. FUNCTIONS

……………………………………………………... 9

3.1 ON/OFF switching of cooking zone …………………...…... 9

3.2 Cooking levels ……………………………………………..…10

3.3 Residual heat indication ………………………………….… 10

3.4 Key lock………………….………………………………….….10

3.5 Break indication …………………………………………….…10

3.6

Timer function ……………………………………………….11

3.7 Lo Temp – function (presently only for induction)………… 11

3.8 Booster……………………………………..………………..... 11

3.9 General errors …………………………………….………… 12

4. TECHNICAL DATA……………………………………………. 14

1

Page 6

2

Page 7

1.WARNINGS

Read these instructions for use carefully. This is the only way to use the hob correctly

and safely.

Keep the assembly instructions, the instructions for use and the technical data sheet

for the appliance in a safe place.

Check the hob immediately after unpacking it. If any damage has been caused during

transport, do not connect the appliance.

1.1 Important for installation

Connections must only be made by authorized and qualified personnel. If there

is any damage due to incorrect connections, any type of guarantee will no

longer be valid.

The electrical system must be equipped with an appropriate earth connection

system.

The material and glues used for the kitchen unit must resist a temperature of

min.100°C.

WARNING

Before any operation:

Disconnect the hob from the electrical mains.

Make sure that the hob is cold.

Do not try to repair the hob on your own, contact a qualified service centre.

1.2 For cooking

This appliance has been specifically designed for domestic use. The hob must only

be used for preparing food dishes.

Do not touch cooking zones that are overheated. BURN HAZARD!!! Keep out of

children’s reach. The afterheat indicator warns if zones are overheated.

Never place inflammable objects on the hob. FIRE HAZARD!!!

The power supply cable for electrical appliances must never touch hot cooking zones.

Cable insulation and the hob might get damaged.

The cooking zone and pan bottom must always be dry.

3

Page 8

If there are breaks, cracks or splits in the ceramic glass, there is a risk of shortcircuiting. Immediately switch off the appliance. Contact the technical assistance

service.

If the hob switches off by itself and it cannot be used, it is necessary to disconnect it

immediately from the electrical system and contact the technical assistance service.

Any repair operations carried out incorrectly are a high risk. Risk of electric

shocks!!! Repairs must only be carried out by qualified and specialized technical

personnel.

Rough surfaces on pans and frying pans scratch ceramic glass. Check pans.

For special pans, follow the manufacturer’s instructions.

Never place hot pans or frying pans on the control panel, on the display area or the

frame. This might cause damage!!!

Salt, sugar and sand scratch ceramic glass. Do not use the hob as a work surface or

for placing anything.

Hard or pointed objects accidentally falling on the hob may cause damage. Do not

place these objects on the hob.

Sugar and other food with high sugar content will damage the hob. Any spilt food

must be removed immediately with a scraper for glass.

Warning!!! The scraper

for glass has a sharp blade. (OPTIONAL fig. 6 )

The following damage will not affect the correct functioning or the stability of

the ceramic glass.

• The formation of gelatinous residues due to melted sugar or food with a high

sugar content.

• Scratches due to salt, sugar or sand grains or rough pan bottoms.

• Metal colour from pan use or after using unsuitable detergents.

• Opaque decoration after using unsuitable detergents.

Only use warm water with an alkaline product. Do not use corrosive or abrasive

products, as they might cause the formation of opaque areas.

4

Page 9

2.INSTALLATION

All operations relative to installation ( electric connection ) should be carried out by

personnel in conformity with the rules in force,

As for the specific instructions, see part pertaining to the installer,

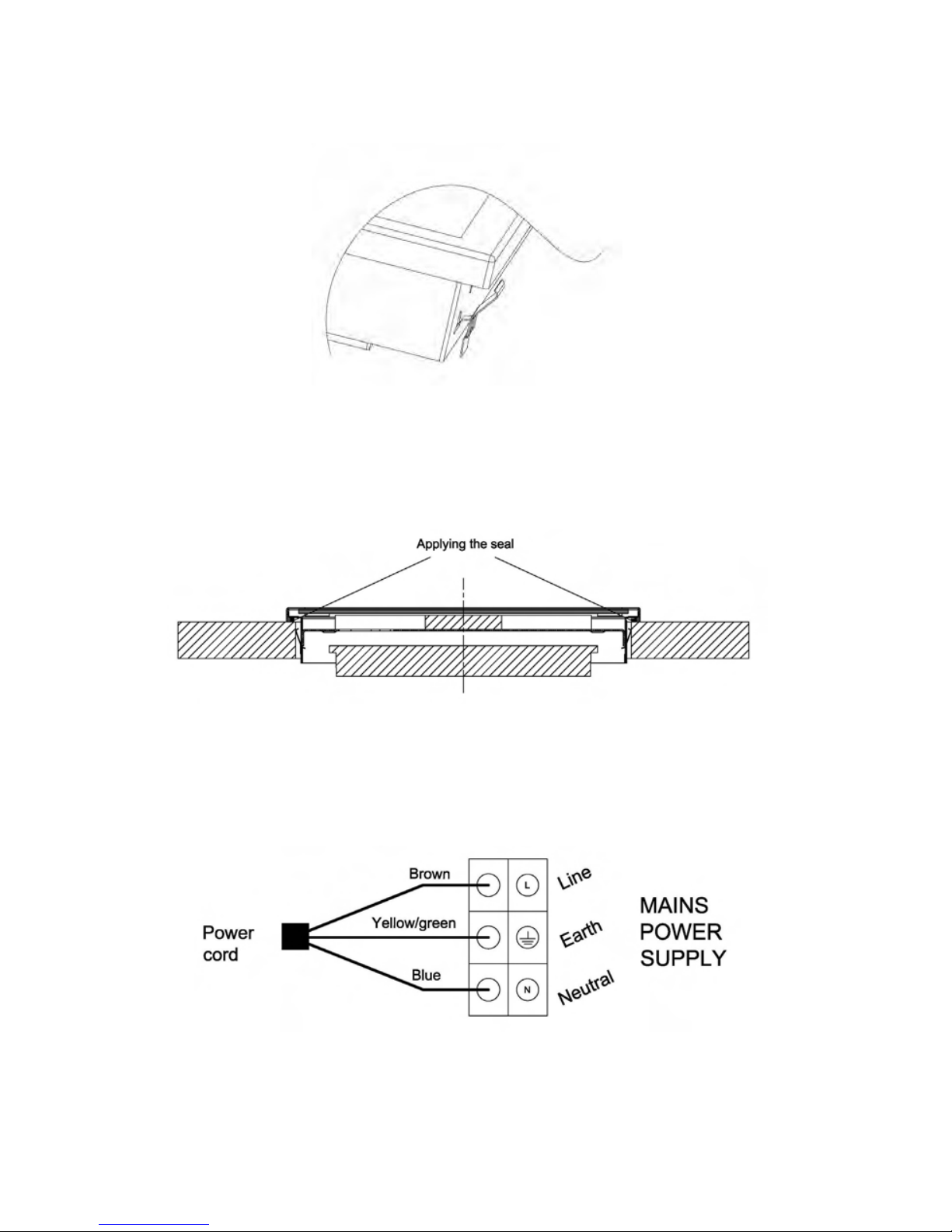

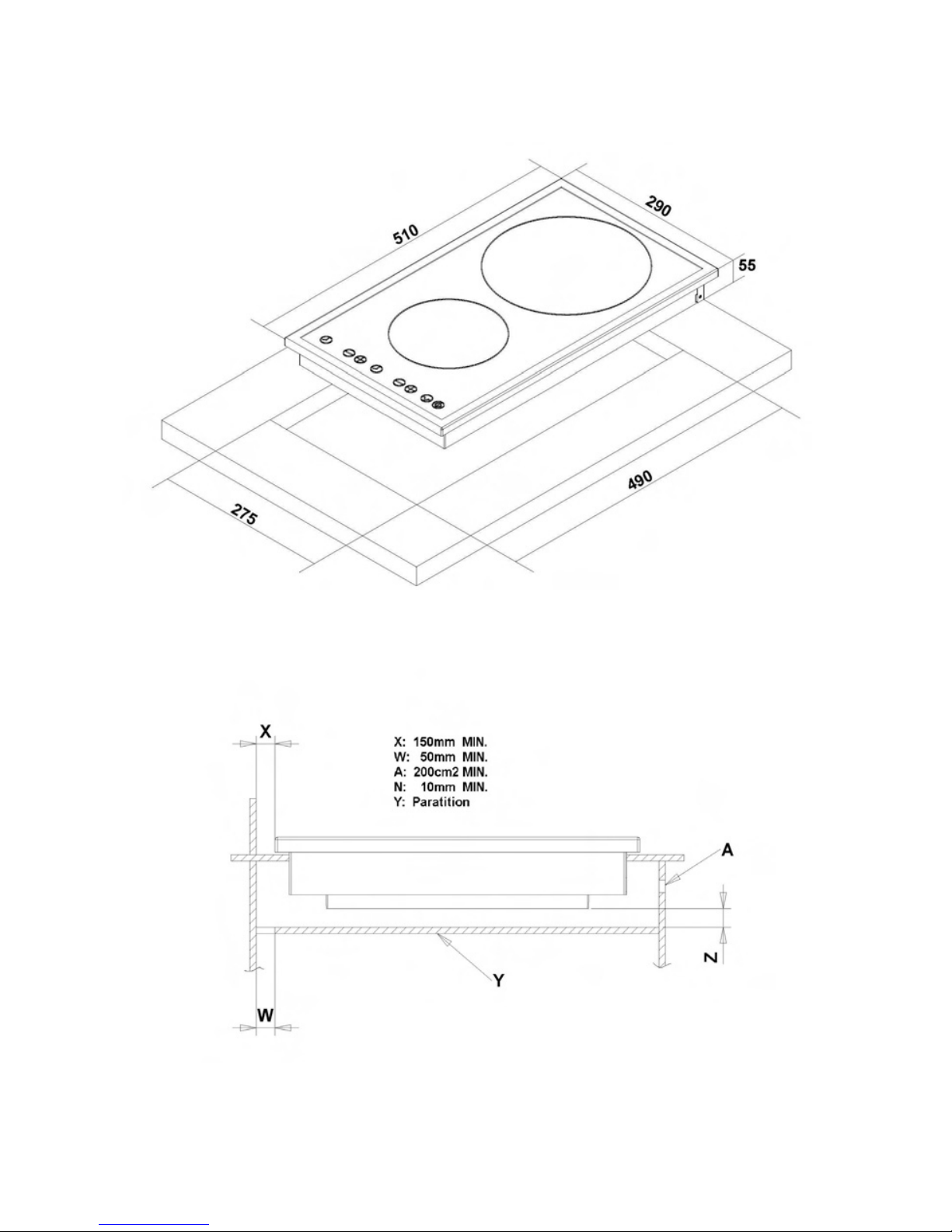

2.1 Instructions for the installer ( fig. 4 )

The present instructions are turned to the skilled installer as a guide to installation,

regulation and maintenance in compliance with the laws and the rules in force.

Should a build-in oven or any other appliance producing heat be fitted directly

under a glass ceramic cook-top with TOUCH CONTROL, THE APPLIANCE

(oven) AND THE GLASS CERAMIC COOK.TOP MUST BE PROPERLY

INSULATED, so that the heat produced by the oven, measured on the right side

of the bottom of the cook-top, is lower than 60°c. Disregard of the precaution

could cause the working of the TOUCH CONTROL system.

The appliance is provided to be built in a work-top as shown the relative figure

4. When there is accessible cupboard space underneath the cook top, a

partition made of insulating material (wood or the like) must be inserted

between the cook top and the space below. This partition must be at least 10

mm from the underside of the cook top tray.

Positioning

Spread the sealing agent all the perimeter. (for cut dimensions, see fig. 2)

Lock the appliance on the work-top with brackets, taking into consideration the

thickness of the work-top (fig. 1).

Electrical connections ( fig. 3 )

Before carrying out any electrical connection, be sure that;

- the characteristics of the electrical system meet the specifications of the plate

located at the bottom of the work-top;

- the electrical system is provided with effective ground in compliance with the

rules and the provisions of the law in force.

The ground is binding according to the law.

If you wish a direct connection to the line, it is necessary to interpose a single-pole

switch, with a minimum opening between the contacts of 3mm, suitable for the load

indicated in the plate and in conformity with the rules in force ( the yellow/green

ground cable should not be interrupted by the switch).

The single-pole switch should be easily accessible with appliance installed.

Note: The manufacturer declines all responsibility if the above and the usual

safety rules are not followed.

5

Page 10

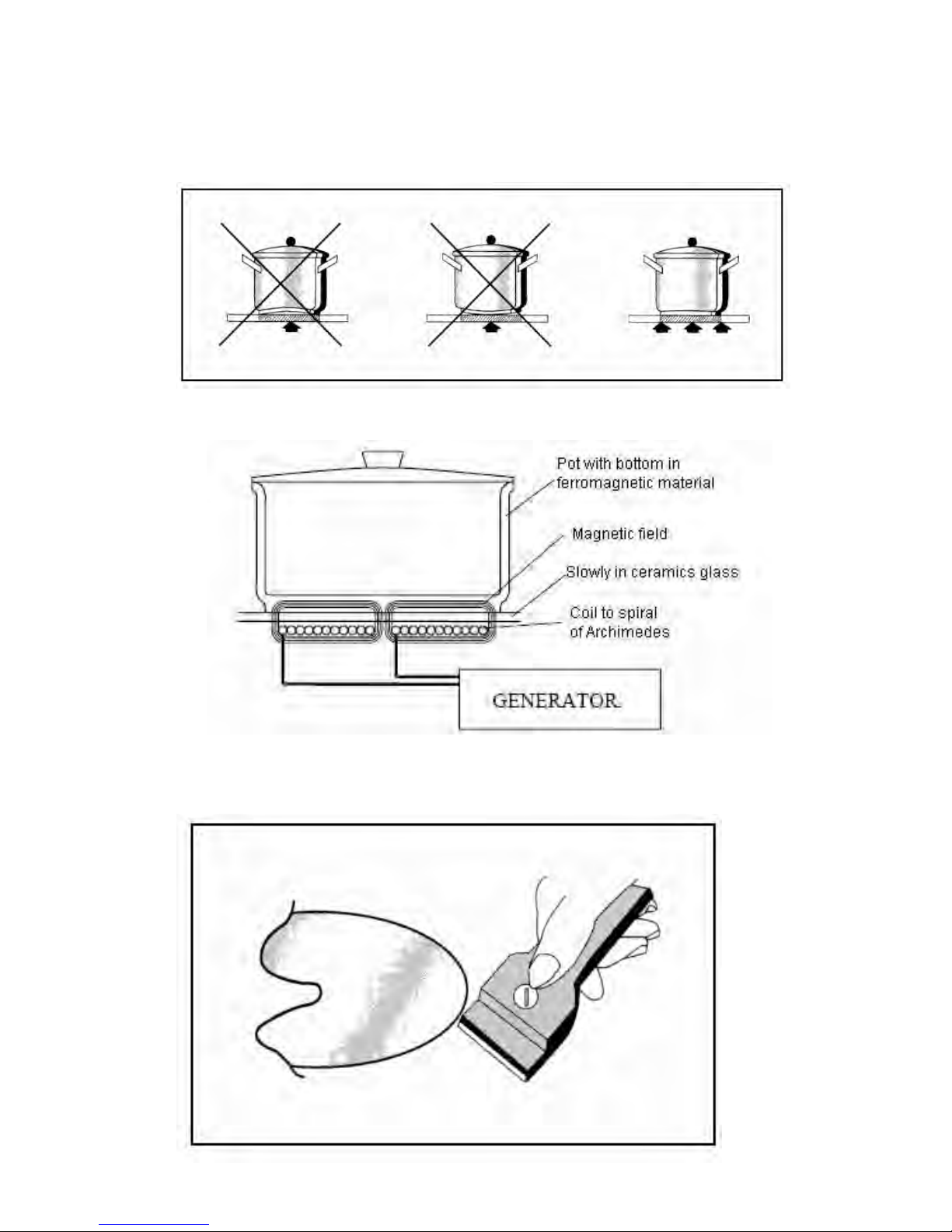

2.2 Instructions for the user

Receptables ( fig. 5)

We suggest receptacles with a flat bottom, having same or slightly higher diameter

than the one of the heating area.

Receptacles should not have rough bottoms in order to avoid scratches on the

heating surface.

Use only saucepans and frying pans with a sturdy, preferably thick bottom. This is

particularly important when preparing food requiring high cooking temperatures, such

as fried foods. If the bottom of the pan is not perfectly flat, the food takes loger to

cook and uses up more energy. The best heat transfer is obtained when the

saucepan and burner are the same size.

The induction cooking method rapidly transfers the energy needed for cooking directly

to the pan, so the cook top surface remains cold but the pan heats up. The result is a

fast, cost-effective and accurate cooking method. This type of cook top can be used

with enamelled steel or stainless steel pans; it is not suitable for use with glass,

ceramic or aluminium pans( unless a special magnetic base plate is used.

Limits of pot detection function

The following table shows the limits of the pot detection as they are tested

with cast iron

Nominal diameter of coil Limit of pot detection

(switches ON)

Ø 145 mm

Ø 90 mm

Ø 210 mm

Ø 135 mm

Integrated pot detection

Each one the cooking zones is equipped with a pot detection function. The pot

detection prevents a cooking zone from turning on without a pot being put on it. And

the cooking zone turns off as soon as the pot is taken away from it. The cooking zone

is turned off automatically after a certain time when a cooking level is set but there is

no pot put on it.

The pot needs to be made of magnetisable material. The pot detection of the

induction module depends on the pot and the material it is made of.

6

Page 11

IMPORTANT

Ƈ Avoid overflows of liquid, therefore when to boil or heat liquid, reduce the

heating supply;

Ƈ at the end of cooking, take again the cooking surface, disconnect the electric

power supply immediately.

If you find even a slight break on the cooking surface, disconnect the electric power

supply immediately.

Manteinance

First of all remove leftovers and grease from the cooking surface with the special

scraper ( optional, fig. 5).

After that clean the heating area as best as possible with a paper towel and SIDOL,

STAHLFIX or other similar products, then rinse again with water and dry with a clean

cloth.

Pieces of aluminium paper and plastic material which have unintentionally melted,

sugar or highly sacchariferous leftovers must be removed immediately from the

cooking area with the special scraper (optional, fig. 5) to avoid any possible damage

to the surface of the cook-top.

Never use abrasive sponges or irritating chemical detergents such as oven sprays or

spot removers.

Protection against excess temperature

The generator as well as the coils have integrated functions protecting against excess

temperature.

Inside the power board a temperature sensor controls the temperature of the heat

sink to protect the devices.

Soiling on the glass ceramic surface

Soiling, normally food stuffs and/or water can – however, not necessarily –

be mistaken as a key touch. Also, dampness in thin layers (film, streaks) may

cause this effect. Especially with larger quantities there is a chance that

none, one, several or all keys can, thus, be mistaken as touched briefly or

permanently. In this respect, soiling can, for a short period, lead to alterations

of settings which can just as well be generated by an operator. In case of

such an alteration e. g. activation of a cooking zone, the entire Touch Control

is disconnected after max. 10 sec (due to permanent operation detection).

This implies that the „activating“ effect on the sensors

caused by the soiling remains basically unchanged for as long as 10 sec.

7

Page 12

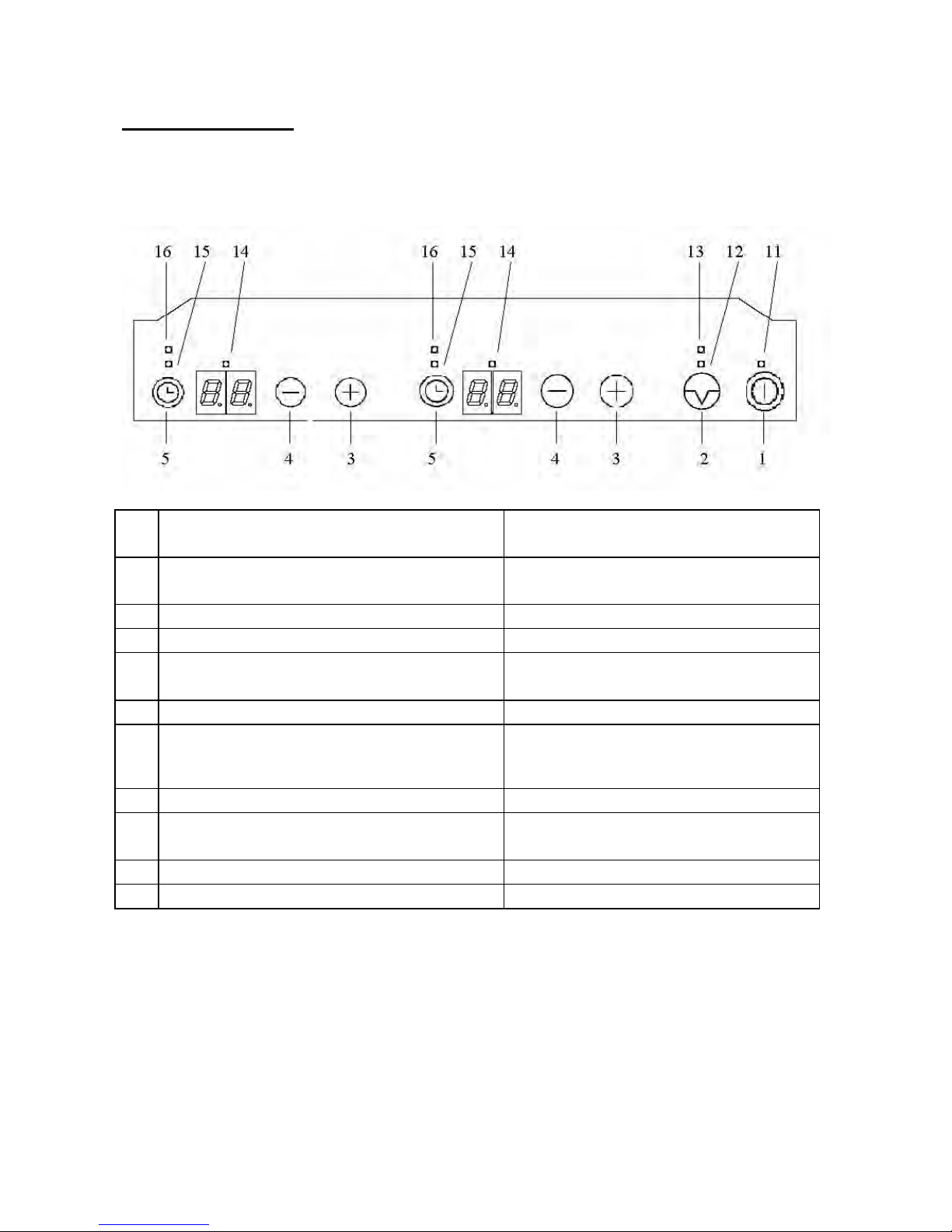

2.3 KEY PANEL:

Overview and description

Picture 1: Touch Domino incl. all keys, displays and LEDs

1 ON/OFF switch press for 1sec to switch control

unit ON/OFF

2 Multi-circuit / Special key e.g. key lock, break, dual-circuit,

triple-circuit

3 Plus increase cooking level

4 Minus reduce cooking level

5 Timer / Cooking zone special

function

Timer, dual-circuit, triple-circuit (if

no timer available)

11 Power LED

12 LED general special function 1 Cooking zone locked, dual-circuit

13 LED general special function 2 Triple-circuit

14 Timer LED Programming timer or cooking

level

15 LED Cooking zone special fct. 1 Cooking zone locked, dual-circuit

16 LED Cooking zone special fct. 2 Triple-circuit

8

Page 13

3.FUNCTIONS

3.1 ON/OFF switching of cooking zone

By pressing the ON/OFF key for 1 sec (key no. 1) the Touch Control changes

from OFF mode into standby mode emitting a short buzzing signal as well as

a visible „0“ on the cooking zone display. Instead of „0“ the cooking zone

display can also show an „H“ meaning „hot cooking surface” or, alternatively,

an „E“ meaning “error”. If no key is touched within the 10 sec after activating

the standby mode, the Touch Control unit changes back into OFF mode.

While activated or in standby mode the electronics may be reset, at any time,

into OFF mode by simply touching the ON/OFF key. During operation, the

OFF function always has priority , i. e. even if several keys are touched

simultaneously, the control unit would switch off. The Touch Control unit can

still be switched off, even though the Key-Lock function (see 2.10) had been

activated.

ON/OFF switching of a cooking zone

ON switching

A cooking zone can be directly activated via the corresponding plus / minus

keys while in standby or active mode, unless the cooking zone had not been

set by the optional timer programming (see 2.13).

Starting position: Cooking zone is in OFF mode. Display: „0“: If starting

out with the „+“ key, the cooking stage display moves from „0“ up to „5“. If

starting out with the „-“ key, the cooking stage display moves from „0“ up

to „9“ (i. e. the highest configurated cooking stage available).

While pressing the „+“ or „-“ key, the cooking stage is increased /

reduced automatically. The time difference occurring during changing

from one stage to another is about 0.5 sec. The buzzer only emits an

audible signal at the first change of cooking stages. Once the highest or

lowest stage is reached, the cooking stage remains there (limit stop).

Only releasing the key and touching again results in skipping this limit

stop. („0“ Å „9“ or „9“ Å „A“). Even if no automatic heat-up function or

booster function is available for the relevant cooking zone, changing from

9 to 0 is not possible.

OFF switching

A cooking zone can be switched off in the following way:

by pressing the „+“ and the „-“ keys of the desired cooking zone

simultaneously

by selecting cooking zone „0“ for the desired cooking zone by pressing

the „-“ key.

9

Page 14

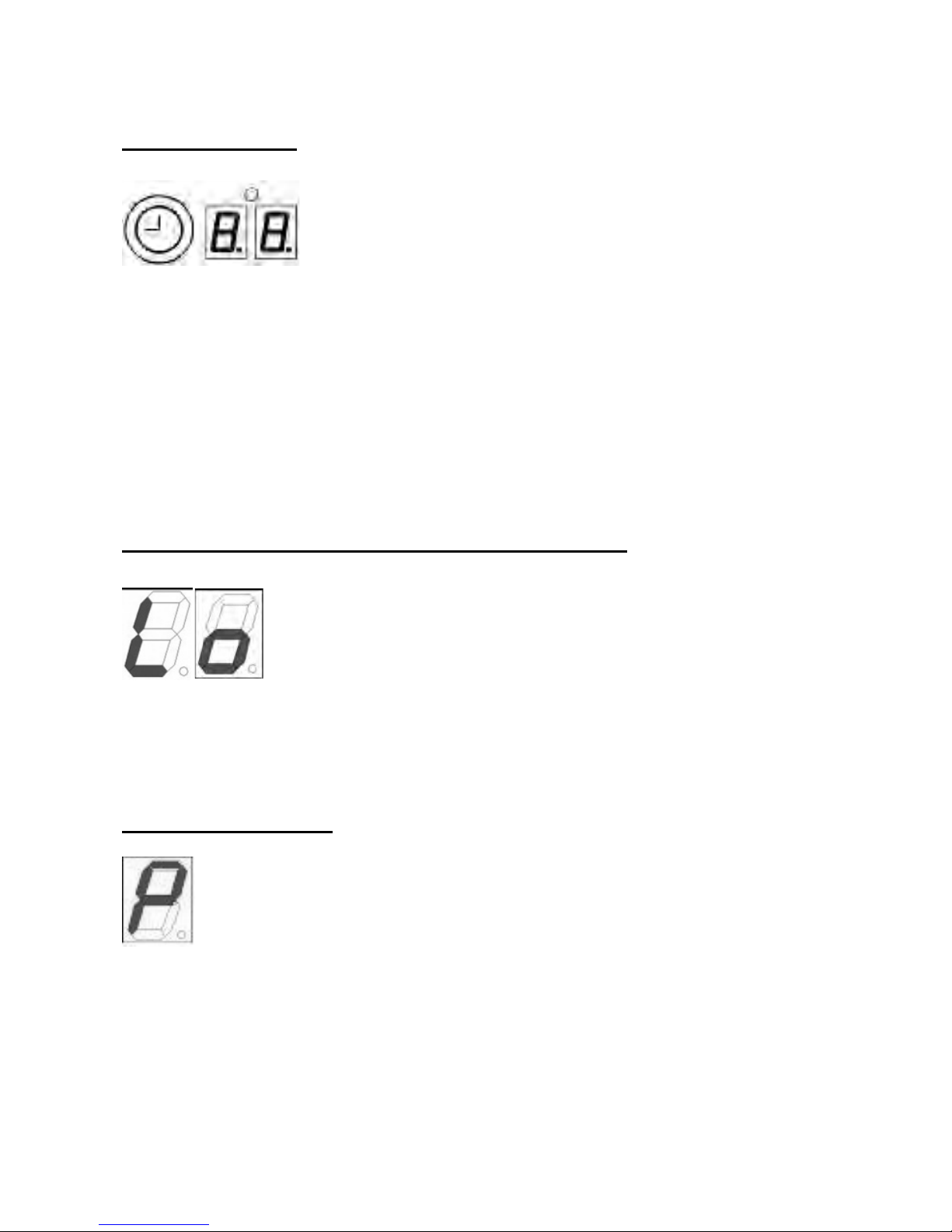

3.2 Cooking levels

As a standard, there are 9 cooking levels with the digits „1“ to „9“ on the

display.

„A“ for automatic heat-up function, „P“ for booster or the symbol for „no pot”

are only displayed on the right or on the single display serving a cooking

zone

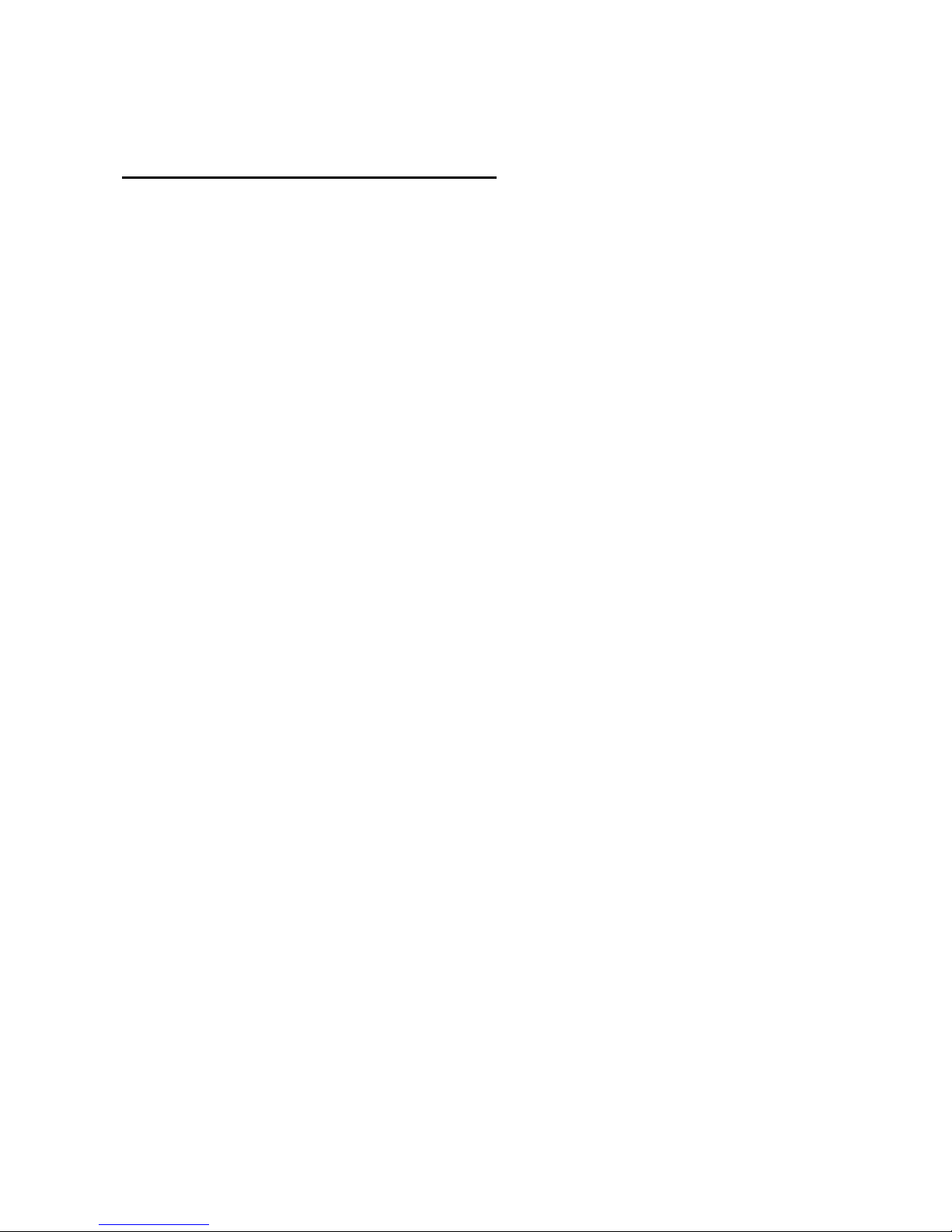

3.3 Residual heat indication

A hot cooking zone is indicated by an „H“

Overheat control for induction cooking zones

In principle, the induction works intrinsically safe.

The induction electronics provide temperature sensors at each cooking zone

being located

below the glass ceramic surface to monitor temperatures. Further

temperature sensors along

the heat sink protect the electronics itself against overheating.

This causes the „P“ symbol to flash on the relevant display indicating that the

booster request cannot be dealt with currently.

3.4 Key-lock function

LED 12 serves as display of the key-lock status. In this case locking and

unlocking can be done by pressing the minus key and the special function

key (key no.2 ) of a cooking zone at the same time. This also works for

locking at one cooking zone and unlocking at another and vice versa.

Switching OFF via the ON/OFF key is also possible in locked conditions.

3.5 Break indication

While at least one cooking zone is working, the cooking zones can

be switched off by touching the general special key (key no. 2) for

more than 1 sec.

The break mode can last for max. 10 min.

10

Page 15

3.6 Timer function

The timer function module provides a timer for each of

both cooking zones of a Touch Control.

All timers are countdown timers. The optional setting range is between 1 and

99 minutes. After the timer is set, it counts backwards in minute steps down

to 0. Then, a visible and audible alarm signal is emitted.

As for a cooking zone related mode, the corresponding cooking zone is

disconnected automatically upon expiry of the timer.

Before operating a timer, the Touch Control is to be switched into at least

standby mode via the ON/OFF key. Switching off the Touch Control disables

the cooking zone related timer, programmed egg timers continue running.

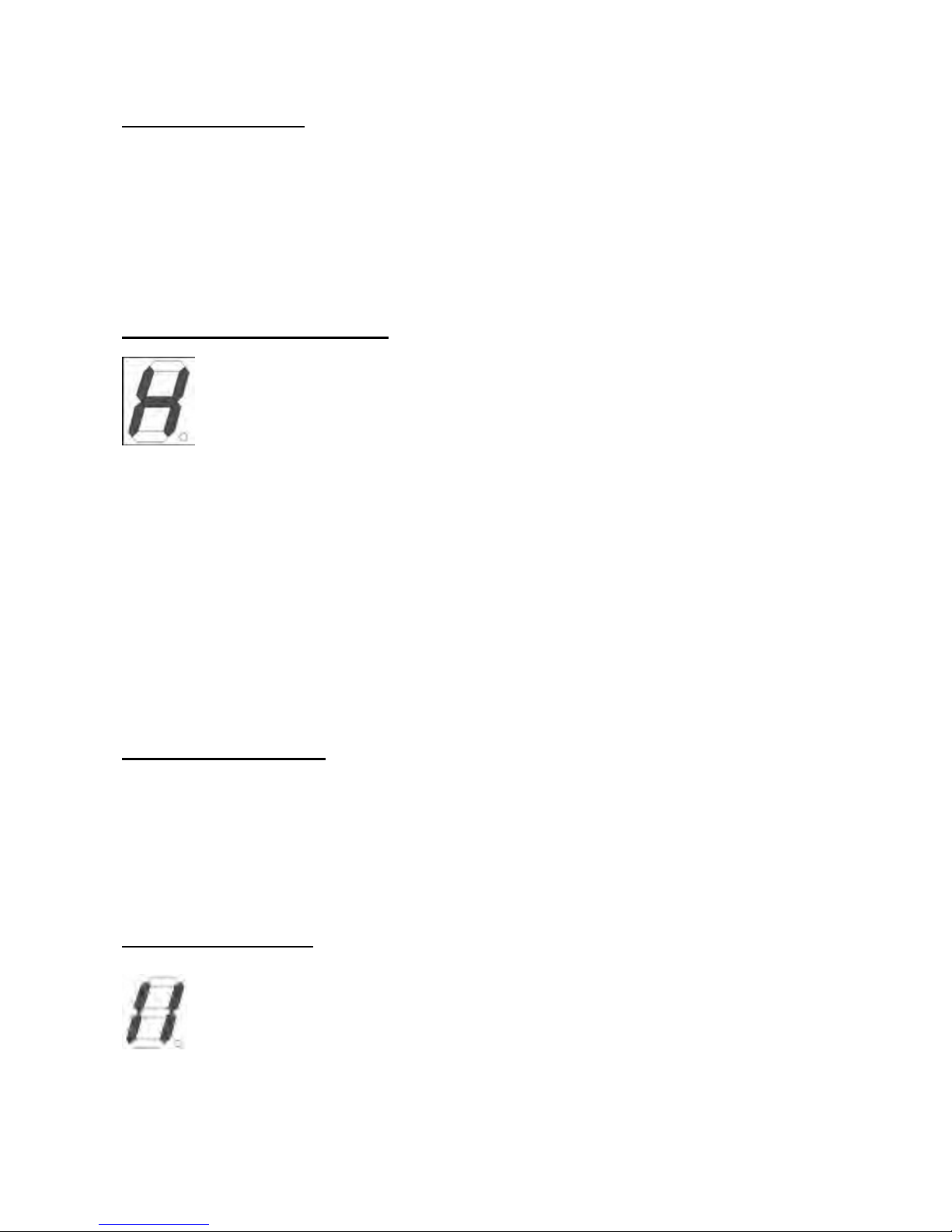

3.7 Lo Temp – function (presently only for induction)

The Lo Temp function is supposed to keep cooked meals

warm on top of a cooking zone.

The operator can activate it by selecting a cooking stage

between 0 and 1 resulting in both cooking zone displays to show the symbol

„Lo“ (see above). If the cooking stages are reduced by holding the minus

key, the Low-temp cooking stage is stopped. Another touch would be

necessary to switch to stage 0.

3.8 Booster activation

All induction cooking zones have a booster function.

The booster allows a particularly speedy heating of the food stuffs,

thus, helping the operator to save time.

No booster key available in the system:

Cooking zone must be set to the highest possible level :

Release of „+“ or „-“ key. Another touch on the „+“ key activates the booster

function. The corresponding cooking stage display shows a static „P“ symbol.

11

Page 16

For safety reasons the booster function of each cooking zone is only

available for a limited period of 10 min.

Pressing the minus key while the booster function is activated results in

disconnecting the same. Pressing the „+“ key has no effect on it.

The max. permissible output per induction power board is 3700 W.

3.9 General errors

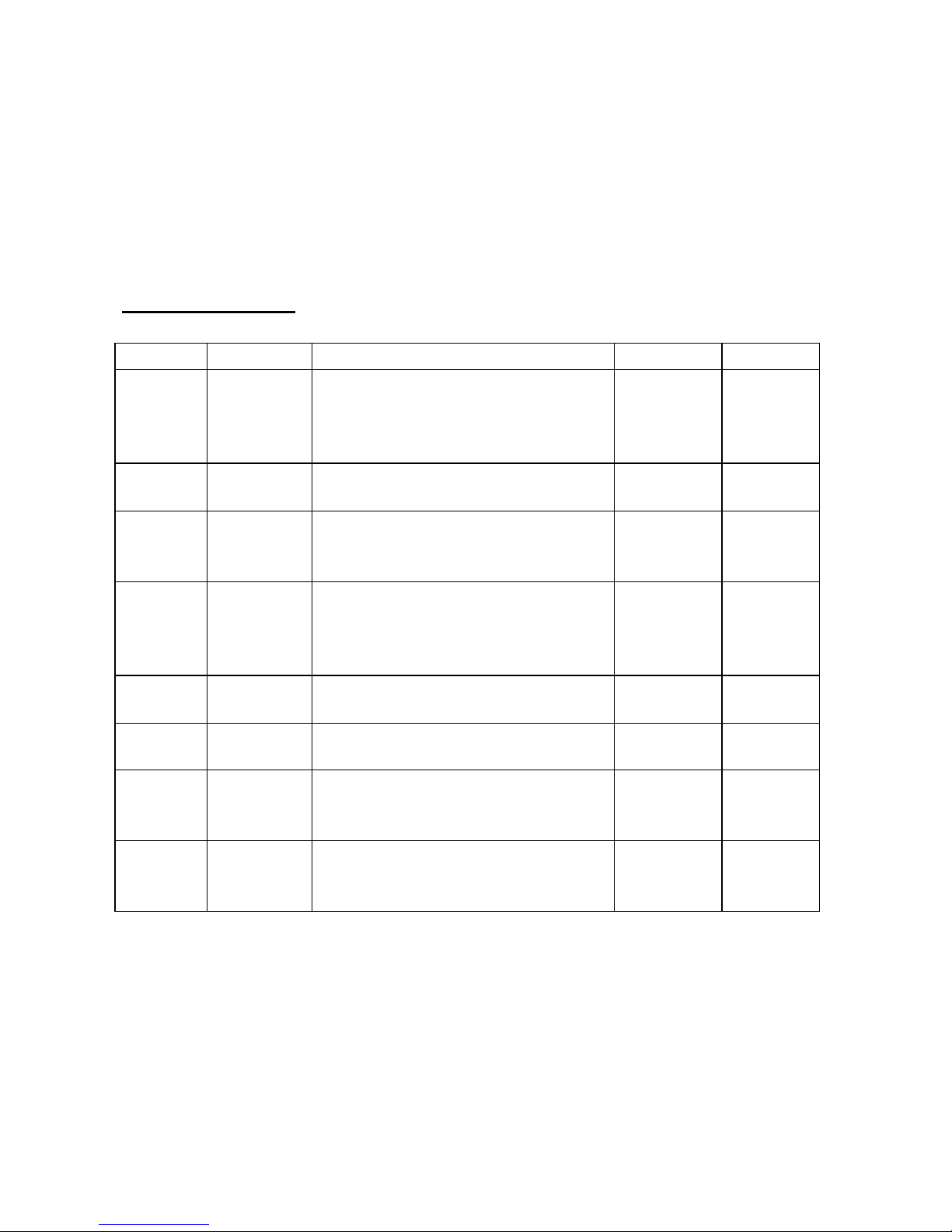

Priority Display Description Lag-time System

1 U400 Blind connection of control.

Directly located at radiant

heating element or reported via

LIN (induction)

1 sec all

2 Er31 Invalid or no configuration

available

1 sec induction

3 Er47 Interference on LIN Bus. A

necessary participant

does not respond

1 sec induction

4 Er36 Short-circuit of temperature

sensor of TC(all) or of

power board (only rad. heat.

element)

10 sec all

5 Er39 Wrong programming options

(fuses, lockbits)

1 sec all

6 Er20 Defective controller flash.

Checking total incorrect

1 sec all

7 Er37 Faulty feedback of shift register

signals to the

segment or relay activation

1 sec all

8 Er22 Faulty keyboard: at least one

key has invalid

level

10 sec all

12

Page 17

Cooking zone specific errors

Priority Display Description System

1 E5 LIN Bus communication error. Most

probably diagnosed by the Touch

Control unit and indicated as Er47

Induction

2 E5 Defective controller flash. Incorrect

checking total

Induction

3 E5 Wrong programming options Induction

4 E5 Incorrect EEPROM checking total Induction

5 E5 Unclear EEPROM data Induction

6 U400 Overvoltage 400V (becomes general error

with Touch Control as

soon as indicated by at least one induction

cooking zone)

Induction

7 E5 Error mains voltage signal Induction

8 E7 Sub LIN error between filter and power

board

Induction

9 E6 5V short circuit with power board Induction

10 E6 12V too low for power board Induction

11 E6 Defective temperature sensor on cooling

element

Induction

12 E6 Faulty mains hold pulse Induction

13 E9 Defective coil detector Induction

14 E2 Overheated coil detector (diagnosed by

induction)

Induction

15 „Blitz“ Permanent operation (minim. 10 sec) upon

switching a cooking zone

off

all

16 „Blitz“ Permanent operation (minim. 10 sec)

without switching a

cooking zone off

all

13

Page 18

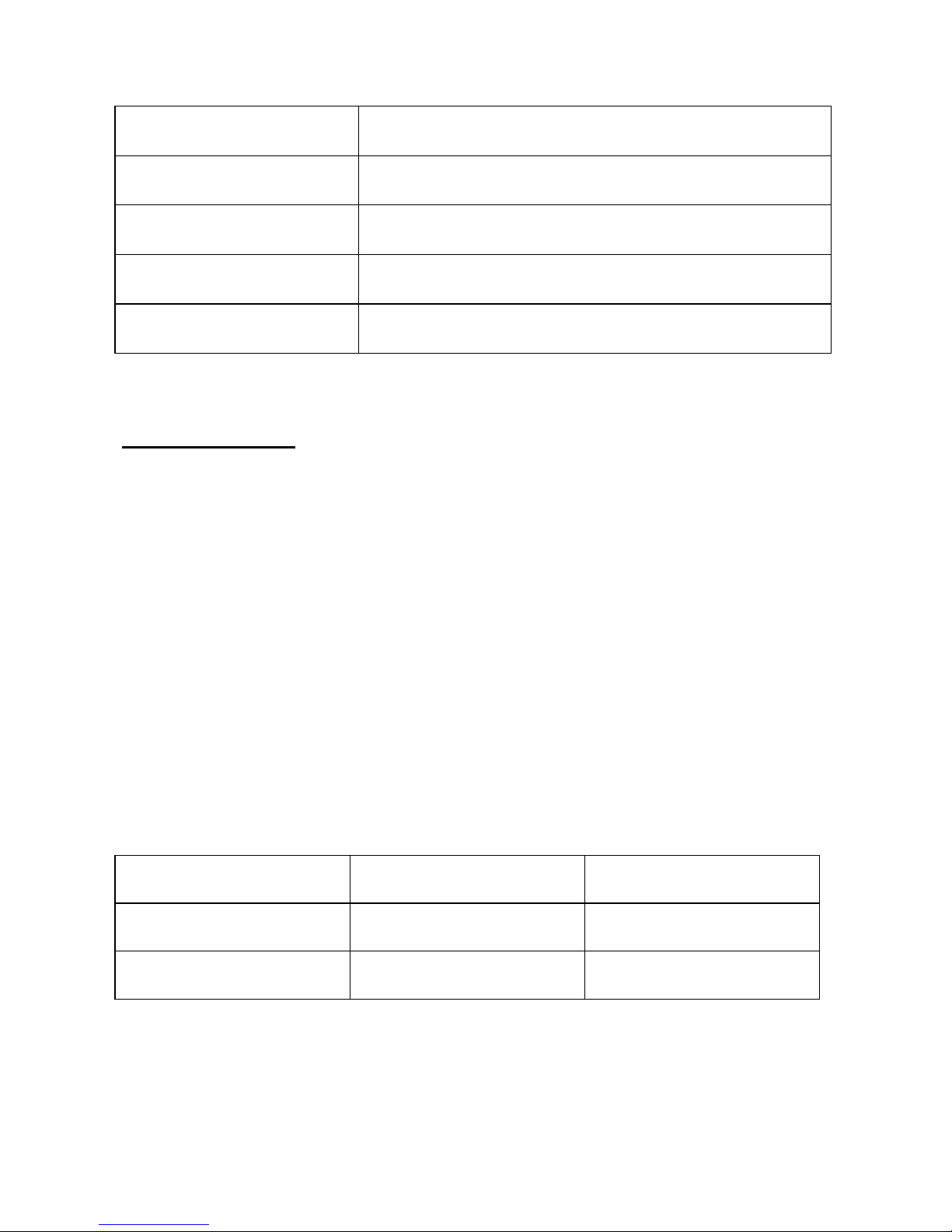

E2 Overheating

E5 Exchange filter board

E6 Exchange power board

E7 Unknown error, cannot be clearly identified

E9 Exchange temperature sensor

4 Technical data

Rated voltage and current

nominal voltage: 220-240 V

nominal frequency: 50-60 Hz

The power of a power board is limited to 3700 W.

Use only rubber cable type H05VV-F; the cross-setion on the wires must be

3x1.5mm.

Stand-by consumption of the generator

Max. 0,6 W (not including user interface).

Nominal power and diameters of coils

Diameter Nominal power Boost power

Ø 145 mm

1400 W 1800 W

Ø 210 mm

2300 W 3200 W

diameter nominal power boost power

14

Page 19

Fan control

Integrated cooling of the generator

The cooling is integrated within the plastic housing of the generator. The

operation of the fan is controlled by the temperature which is measured at

the heat sink. Then fan switches on, when a certain temperature is reached

and switches to a higher speed when the second temperature limit is

reached.

Start lower speed 45°C

Start higher speed 55°C

Temperature control of cooking zones

The residual heat indicator contributes to the protection of the user. The

residual heat indication switches on with an „H“ as soon as a certain

temperature underneath the glass ceramic is reached.

And it switches off again as soon as the temperature decreases under a

certain level.

Threshold „ON“ residual heat indicator 65°C + 5K

Threshold „OFF“ residual heat indicator 60°C – 5K

15

Page 20

Fig.1

Fig.2

Fig.3

16

Page 21

Fig.4

17

Page 22

Fig.5

Fig.6

18

Page 23

FRANÇAIS

DOMINO INDUCTION

COMMANDE SENSITIVE

MANUEL D’UTILISATION

F

R

Page 24

Page 25

TABLE DES MATIÈRES

1. AVERTISSEMENTS……………………………………………………… 23

1.1 Pour l’installation……………………………………………….. 23

1.2 Pour la cuisson…………………………………………………… 23

2. INSTALLATION…………………………………………………... 25

2.1Instructions pour l'installateur…………………………………… 25

2.2Instructions pour l’utilisateur…………………………………… 26

2.3Bandeau de commande……………………………………………..... 29

3. FONCTIONS……………………………………………….……... 30

3.1Commande Marche/Arrêt de la zone de cuisson ………………...... 30

3.2 Niveaux de cuisson …………………………………………….......… 31

3.3 Indication de chaleur résiduelle …………………………………..… 31

3.4 Verrouillage des touches………………….………………………..…. 31

3.5 Indication de pause ………………………………....................….… 32

3.6

Fonction minuterie ………………………………………….....……. 32

3.7 Fonction Basse temp. (disponible uniquement pour l'induction).... 32

3.8Fonction d’appoint……………………………………......................... 33

3.9 Erreurs générales …………………………………….…………........ 33

4. DONNÉES TECHNIQUES…………………………………………….... 36

21

Page 26

22

Page 27

1.AVERTISSEMENTS

Veuillez lire ces instructions d’utilisation attentivement. Il s’agit de la seule façon

d’utiliser la table de cuisson correctement et en toute sécurité.

Conserver soigneusement les instructions de montage, les instructions d’utilisation et

la fiche technique de l'appareil.

Inspecter la table de cuisson immédiatement après l'avoir déballée. Si des

dommages ont été occasionnés durant le transport, ne pas connecter l’appareil.

1.1 Important pour l’installation

Les raccordements doivent uniquement être effectués par le personnel agréé et

qualifié. En cas de dommages dus à des raccordements inadaptés, tout type de

garantie ne sera plus valable.

Le système électrique doit être muni d’un système d’installation électrique

adapté de mise à la terre.

Les matériaux et colles utilisées pour l’élément de cuisine doivent résister à

une température minimale de 100 °C.

AVERTISSEMENT

Avant toute utilisation :

Déconnecter la table de cuisson du réseau d'alimentation électrique.

S’assurer que la table de cuisson est froide.

Ne pas essayer de réparer la table de cuisson par vous-même ; contacter un

centre de service qualifié.

1.2 Pour la cuisson

Cet appareil a été conçu spécifiquement pour l'usage domestique. La table de

cuisson doit uniquement servir à préparer des denrées alimentaires.

Ne pas toucher les zones de cuisson surchauffées. RISQUE DE BRÛLURE !!! Tenir

hors de la portée des enfants. L’indicateur de chaleur résiduelle indique si les zones

sont surchauffées.

Ne jamais poser d’objets inflammables sur la table de cuisson. RISQUE D’INCENDIE

!!!

23

Page 28

Le câble d’alimentation des appareils électriques ne doit jamais entrer en contact

avec les zones de cuisson chaudes. L’isolation du câble et la table de cuisson

pourraient être abîmés.

La zone de cuisson et le bas des récipients doivent toujours être secs.

Si vous observez des cassures, fêlures ou fissures sur la surface vitrocéramique, il y

a un risque de court-circuit. Éteindre l’appareil immédiatement. Contacter le service

d’assistance technique.

Si la table de cuisson s'éteint par elle-même et ne peut être utilisée, il convient de la

déconnecter du système électrique immédiatement et de contacter le service

d’assistance technique.

Toutes réparations réalisées incorrectement présentent un risque important. Risque

de décharges électriques !!! Les réparations sont réservées au personnel technique

qualifié et spécialisé.

Les surfaces rugueuses sur les casseroles et poêles rayent la surface céramique.

Inspecter les récipients.

Pour les récipients spéciaux, suivre les instructions du fabricant.

Ne jamais poser de casseroles ou poêles chaudes sur le bandeau de commande, la

zone d'affichage ou le cadre. Ceci pourrait occasionner des dommages !!!

Le sel, le sucre et le sable rayent la surface céramique. Ne pas utiliser la table de

cuisson comme surface de travail ou de rangement.

Les objets durs ou pointus qui pourraient tomber sur la table de cuisson par accident

pourraient occasionner des dommages. Ne jamais poser de tels objets sur la table de

cuisson.

Le sucre et autres aliments à forte teneur en sucre abîmeront la table de cuisson.

Tout déversement de nourriture doit être nettoyé immédiatement à l’aide d'un grattoir

pour verre.

Avertissement !!! Le grattoir pour verre est muni d’une lame

affûtée. (EN OPTION fig. 6)

Les dommages suivants n’auront aucun effet sur le bon fonctionnement ou la

stabilité de la surface vitrocéramique.

• La formation de résidus gélatineux due à du sucre fondu ou des aliments à

forte teneur en sucre.

• Rayures dues aux grains de sel, sucre ou sable ou aux fonds rugueux des

récipients.

• Couleur métallique due à l’utilisation de récipients ou suite à l’emploi de

détergents inadaptés.

• Décoloration opaque suite à l'utilisation de détergents inadaptés.

24

Page 29

Utiliser uniquement de l’eau chaude avec un produit alcalin. Ne pas utiliser de

produits corrosifs ou abrasifs car ils pourraient entraîner la formation de zones

opaques.

2.INSTALLATION

Toutes les opérations relatives à l’installation (raccordement électrique) doivent être

effectuées par le personnel conformément aux réglementations en vigueur.

En ce qui concerne les instructions spécifiques, voir la section destinée à

l’installateur.

2.1 Instructions pour l’installateur (fig. 4)

Les instructions ci-dessous sont adressées à l’installateur qualifié en tant que guide à

l’installation, la réglementation et la maintenance conformément aux lois et normes

en vigueur.

S’il est prévu qu’un four intégré ou un autre appareil générant de la chaleur soit

installé directement sous la plaque de cuisson vitrocéramique à COMMANDE

SENSITIVE, L'APPAREIL (four) ET LA PLAQUE DE CUISSON

VITROCÉRAMIQUE DOIVENT ÊTRE ISOLÉS CORRECTEMENT de manière à ce

que la chaleur émanant du four, mesurée sur le côté droit du dessous de la

plaque de cuisson soit inférieure à 60 °C. La négligence de cette précaution

pourrait affecter le fonctionnement du système de COMMANDE SENSITIVE.

L’appareil est conçu pour être intégré dans une plaque de cuisson comme

l’indique la figure relative numéro 4. S’il y a de l’espace dans le placard situé en

dessous de la plaque de cuisson, une cloison de matière isolante (bois ou

similaire) doit être insérée entre la plaque de cuisson et l'espace situé en

dessous. Cette cloison doit se trouver au moins 10 mm en dessous du support

de la plaque de cuisson.

Positionnement

Étaler l'agent d'étanchéité tout autour du périmètre. (pour les dimensions de découpe,

voir fig. 2)

Fixer l’appareil à la plaque de cuisson à l’aide d'attaches, en prenant l’épaisseur de la

plaque de cuisson en considération (fig. 1).

Raccordements électriques (fig. 3)

Avant d’exécuter tout raccordement électrique, s’assurer que :

25

Page 30

- les paramètres du système électrique satisfont les spécifications du support situé

en dessous de la plaque de cuisson ;

- le système électrique est fourni avec un dispositif de mise à la terre efficace

conformément aux réglementations et dispositions prévues

par la loi en

vigueur.

La mise à la terre a force obligatoire selon la loi.

Si vous souhaitez établir un raccordement direct à la ligne, il est nécessaire

d’interposer un interrupteur unipolaire avec une ouverture minimale entre les contacts

de 3 mm, adapté pour la charge indiquée sur la plaque et conforme aux

réglementations en vigueur (le câble jaune/vert de mise à la terre ne doit pas être

interrompu par l'interrupteur).

L’interrupteur unipolaire doit être facilement accessible une fois l’appareil installé.

Remarque : Le fabricant décline toute responsabilité si les instructions cidessus ainsi que les règles de sécurité conventionnelles ne sont pas

respectées.

2.2 Instructions pour l’utilisateur

Récipients (fig. 5)

Nous conseillons des récipients au fond plat dont le diamètre est identique ou

légèrement supérieur à celui de la zone chauffante.

Le fond des récipients ne doit pas être rugueux afin d'éviter de rayer la surface

chauffante.

Utiliser uniquement des casseroles et poêles dont le fond est solide et épais de

préférence. Ceci est particulièrement important lors de la préparation de denrées

nécessitant des températures de cuisson élevées, telles que les aliments frits. Si le

fond du récipient n'est pas parfaitement plat, la nourriture est plus longue à cuire et

utilise plus d'énergie. Le transfert optimal de chaleur est obtenu lorsque la casserole

et le brûleur sont de la même taille.

La méthode de cuisson par induction transfère rapidement l’énergie nécessaire à la

cuisson directement au récipient si bien que la surface de la plaque de cuisson reste

froide mais le récipient chauffe. On obtient ainsi une méthode de cuisson rapide,

rentable et précise. Ce type de plaque de cuisson est adapté à des récipients en

acier émaillé ou en inox ; il ne convient pas pour les casseroles en verre, en

céramique ou en aluminium (à moins d’utiliser un socle magnétique spécial).

Limites de la fonction de détection des récipients

Le tableau suivant indique les limites de détection des récipients lorsqu'ils

sont testés avec des ustensiles en fonte.

26

Page 31

Diamètre nominal de la bobine Limite de détection des récipients

(interrupteurs activés)

Ø 145 mm

Ø 90 mm

Ø 210 mm

Ø 135 mm

Détection intégrée des récipients

Chaque zone de cuisson est munie d’une fonction de détection des récipients. La

détection des récipients évite qu’une zone de cuisson ne se mette en marche sans

qu’un récipient soit posé dessus. De même, la zone de cuisson s’éteint dès que le

récipient est retiré. La zone de cuisson est éteinte automatiquement au bout d’un

certain temps si un niveau de cuisson est défini mais qu'il n'y a pas de récipient posé

dessus.

Le récipient doit être composé de matériaux magnétisables. La détection des

récipients du module à induction dépend du récipient et de sa matière.

IMPORTANT

Ƈ Éviter les déversements de liquides ; réduire la chaleur livrée lorsque vous

souhaitez faire bouillir ou chauffer un liquide.

Ƈ En fin de cuisson, si vous observez la moindre fissure sur la surface de

cuisson, déconnecter l’alimentation électrique immédiatement.

Entretien

Commencer par nettoyer les résidus et la graisse de la surface de cuisson à l’aide

d'un grattoir spécial (en option, fig. 5).

Ensuite, bien nettoyer la surface de cuisson avec un essuie-main en papier et du

SIDOL, STAHLFIX ou d'autres produits similaires, puis rincer à nouveau à l'eau et

sécher avec un chiffon propre.

Les morceaux de papier d’aluminium et les matières plastiques ayant été fondus

involontairement, le sucre ou les résidus saccharifères doivent être nettoyés de la

zone de cuisson immédiatement à l’aide du grattoir spécial (en option, fig. 5) afin

d’éviter tout dommage éventuel de la surface de la plaque de cuisson.

Ne jamais utiliser d’éponges abrasives ni de détergents chimiques irritants tels que

des produits de nettoyage pour les fours ou des détachants.

Protection contre les températures excessives

Le générateur ainsi que les bobines sont équipés de fonctions intégrées contre les

températures excessives.

27

Page 32

À l’intérieur de la platine d’alimentation se trouve un capteur de température qui

commande la température du dissipateur de chaleur en vue de protéger les

dispositifs.

Salissures sur la surface vitrocéramique

Les salissures, habituellement des résidus alimentaires et/ou de l’eau,

peuvent éventuellement être confondues avec une commande sensitive.

Aussi, l'humidité en couches fines (film, traînées) pourrait produire cet effet.

Pour de grandes quantités en particulier, il se peut qu'aucune, une, plusieurs

ou toutes les touches puissent donc être confondues et activées brièvement

ou de manière permanente. À cet égard, les salissures peuvent entraîner

des modifications à court terme des réglages qui pourraient aussi bien être

définis par un opérateur. Dans le cas d'une modification telle que l'activation

d'une zone de cuisson, toute la Commande sensitive est déconnectée au

bout de 10 sec au maximum (en raison de la détection permanente de

fonctionnement). Ceci implique que l’effet « d’activation » sur les capteurs

dû

aux salissures demeure fondamentalement inchangé pendant 10 secondes.

28

Page 33

2.3 BANDEAU DE COMMANDE :

Aperçu et description

Image 1 : Domino sensitif comprenant toutes les touches, écrans et voyants lumineux.

1 Interrupteur Marche/Arrêt appuyer pendant 1 sec pour

allumer ou éteindre l’unité de

commande

2 Touche multi-circuit / spéciale par ex. verrouillage des touches,

pause, double circuit, triple circuit

3 Plus augmente le niveau de cuisson

4 Moins réduit le niveau de cuisson

5 Fonction Minuterie / Zone de cuisson

spéciale

Minuterie, double circuit, triple

circuit (s'il n’y a pas de minuterie)

11 Voyant lumineux de puissance

12 Voyant lumineux, fonction spéciale

générale 1

Zone de cuisson verrouillée,

double circuit

13 Voyant lumineux, fonction spéciale

générale 2

triple circuit

14 Voyant lumineux de la minuterie Minuterie de programmation ou

niveau de cuisson

15 Voyant lumineux, fonction spéciale

zone de la cuisson spéciale 1

Zone de cuisson verrouillée,

double circuit

16 Voyant lumineux, fonction spéciale

zone de la cuisson spéciale 2

Triple circuit

29

Page 34

3. FONCTIONS

3.1 Commande Marche/Arrêt de la zone de cuisson

En appuyant sur la touche Marche/Arrêt pendant 1 sec (touche numéro 1), la

Commande sensitive passe du mode Arrêt au mode stand-by, émet un bref

bruit sourd et affiche un « 0 » sur l'écran de la zone de cuisson. Au lieu du

« 0 », la zone de cuisson peut également afficher un « H » qui signifie

« surface de cuisson chaude » ou bien un « E » pour « erreur ». Si aucune

touche n’est enfoncée au cours des 10 sec suivant l'activation du mode

stand-by, l'unité de commande sensitive passe à nouveau en mode Arrêt.

Le système électronique, lorsqu'il est activé ou en mode stand-by, peut être

réinitialisé à tout moment en passant en mode Arrêt en appuyant simplement

sur la touche Marche/Arrêt.

En cours de fonctionnement, la fonction Arrêt est toujours prioritaire, même

si plusieurs touches sont activées simultanément, et l'unité de commande

s'éteindra.

L’unité de Commande sensitive peut toujours être éteinte, même si la

fonction Verrouillage des touches (voir 2.10) a été activée.

Commande Marche/Arrêt d’une zone de cuisson

Mettre en marche

Une zone de cuisson peut être activée directement par les touches

plus/moins correspondantes en mode stand-by ou actif sauf si la zone de

cuisson n’avait pas été définie dans la programmation optionnelle de la

minuterie (voir 2.13).

Position de départ : La zone de cuisson est en mode Arrêt. Affichage :

« 0 » : En commençant par la touche « + », l'écran indiquant la phase de

cuisson va de « 0 » à « 5 ». En commençant par la touche « - », l'écran

indiquant la phase de cuisson va de « 0 » à « 9 » (c’est-à-dire la phase

de cuisson configurée la plus élevée disponible).

En appuyant sur la touche « + » ou « - », la phase de cuisson est

augmentée/diminuée automatiquement. La différence de temps entre les

passages d'une phase à une autre est d'environ 0,5 sec. La sonnerie

n’émet qu’un signal audible au premier changement de phase de

cuisson. Une fois que le niveau le plus haut ou le plus bas est atteint, la

phase de cuisson reste la même (limite atteinte). Il n’est possible de

dépasser la limite qu’en relâchant la touche puis en appuyant dessus à

nouveau. (« 0 » à « 9 » ou « 9 » à « A »). Même la zone de cuisson en

question n'est pas munie d'une fonction mise en marche automatique ou

d'appoint, il n’est pas possible de passer de 9 à 0.

30

Page 35

Éteindre

Une zone de cuisson peut être éteinte de la manière suivante :

en appuyant simultanément sur les touches « + » et « - » de la zone de

cuisson souhaitée.

en sélectionnant le niveau « 0 » pour la zone de cuisson souhaitée en

appuyant sur la touche « - ».

3.2 Niveaux de cuisson

Selon la norme, il y a 9 niveaux de cuisson numérotés de « 1 » à « 9 » à

l’écran.

Les symboles « A » pour la fonction de mise en marche automatique, « P »

pour la fonction d'appoint ou le symbole pour « pas de récipient » sont

uniquement affichés sur la droite ou sur l'écran unique correspondant à une

zone de cuisson.

3.3 Indication de chaleur résiduelle

Une zone de cuisson chaude est indiquée par un « H ».

Commande de surchauffe pour les zones de cuisson à induction

En principe, l'induction est une méthode de sécurité intrasèque.

Le système électronique comprend des capteurs de température pour

chaque zone de cuisson située

en dessous de la surface vitrocéramique afin de surveiller les températures.

D’autres capteurs de température le long

du dissipateur de chaleur protègent les composants électroniques contre la

surchauffe.

Ceci fait clignoter le symbole « P » sur l'écran correspondant et indique que

la demande d’appoint ne peut être satisfaite actuellement.

3.4 Fonction de verrouillage des touches

Le voyant 12 indique le statut du verrouillage des touches. Ainsi, le

verrouillage et déverrouillage peuvent être effectués en appuyant sur la

touche moins et la touche de fonction spéciale (touche numéro 2) d'une zone

de cuisson à la fois. La même méthode s'applique si vous souhaitez

verrouiller une zone de cuisson et en déverrouiller une autre et vice versa.

31

Page 36

Vous pouvez également éteindre au moyen de la touche Marche/Arrêt

lorsque le système est verrouillé.

3.5 Indication de pause

Pendant l’utilisation d'au moins une zone de cuisson, toutes les

zones peuvent être éteintes en activant la touche spéciale générale

(touche numéro 2) pendant plus d'une seconde.

Le mode pause peut durer 10 min maximum.

3.6 Fonction minuterie

La fonction minuterie fournit une minuterie pour

chacune des deux zones de cuisson à Commande

sensitive.

Toutes les minuteries sont des minuteries à rebours. L'intervalle de définition

optionnelle se situe entre 1 et 99 minutes. Une fois la minuterie réglée, elle

compte à rebours en minutes jusqu’à 0. Ensuite un signal visible et audible

sera émis.

En ce qui concerne le mode lié à une zone de cuisson, la zone

correspondante est automatiquement déconnectée à l'expiration de la

minuterie.

Avant d’utiliser une minuterie, il convient de faire passer la Commande

sensitive au moins en mode stand-by au moyen de la touche Marche/Arrêt.

Le fait d'éteindre la Commande sensitive désactive la minuterie liée à la zone

de cuisson, les minuteurs programmés continuant à fonctionner.

3.7 Fonction Basse temp. (disponible uniquement pour l'induction)

La fonction Basse temp. est sensée tenir les plats cuisinés

au chaud sur une zone de cuisson.

L’opérateur peut l'activer en sélectionnant une phase de

cuisson entre 0 et 1, de telle sorte que les deux écrans des zones de cuisson

afficheront le symbole « Lo » (voir ci-dessus). Si les phases de cuisson sont

32

Page 37

réduites en maintenant la touche moins enfoncée, la phase de cuisson

Basse temp. sera interrompue. Il faudrait activer une autre commande pour

passer à la phase 0.

3.8 Activation de la fonction d’appoint

Toutes les zones de cuisson à induction disposent d’une fonction

d’appoint.

Cette dernière permet de faire chauffer les denrées alimentaires

particulièrement vite, ce qui aide l'opérateur à gagner du temps.

Aucune touche d’appoint n’est disponible sur le système :

La zone de cuisson doit être réglée au niveau le plus haut possible :

relâcher la touche « + » ou « - ». Le fait d'appuyer à nouveau sur la touche

« + » active la fonction d'appoint. L’écran de la phase de cuisson

correspondant indique un symbole statique « P » .

Pour des raisons de sécurité, la fonction d'appoint de chaque zone de

cuisson n'est disponible que pendant 10 min.

Le fait d’appuyer sur la touche moins alors que la fonction d’appoint est

activée entraîne sa désactivation. Le fait d’appuyer sur la touche « + » n’a

aucun effet ici.

La puissance de sortie maximale acceptable pour une platine d’alimentation

à induction est de 3700 W.

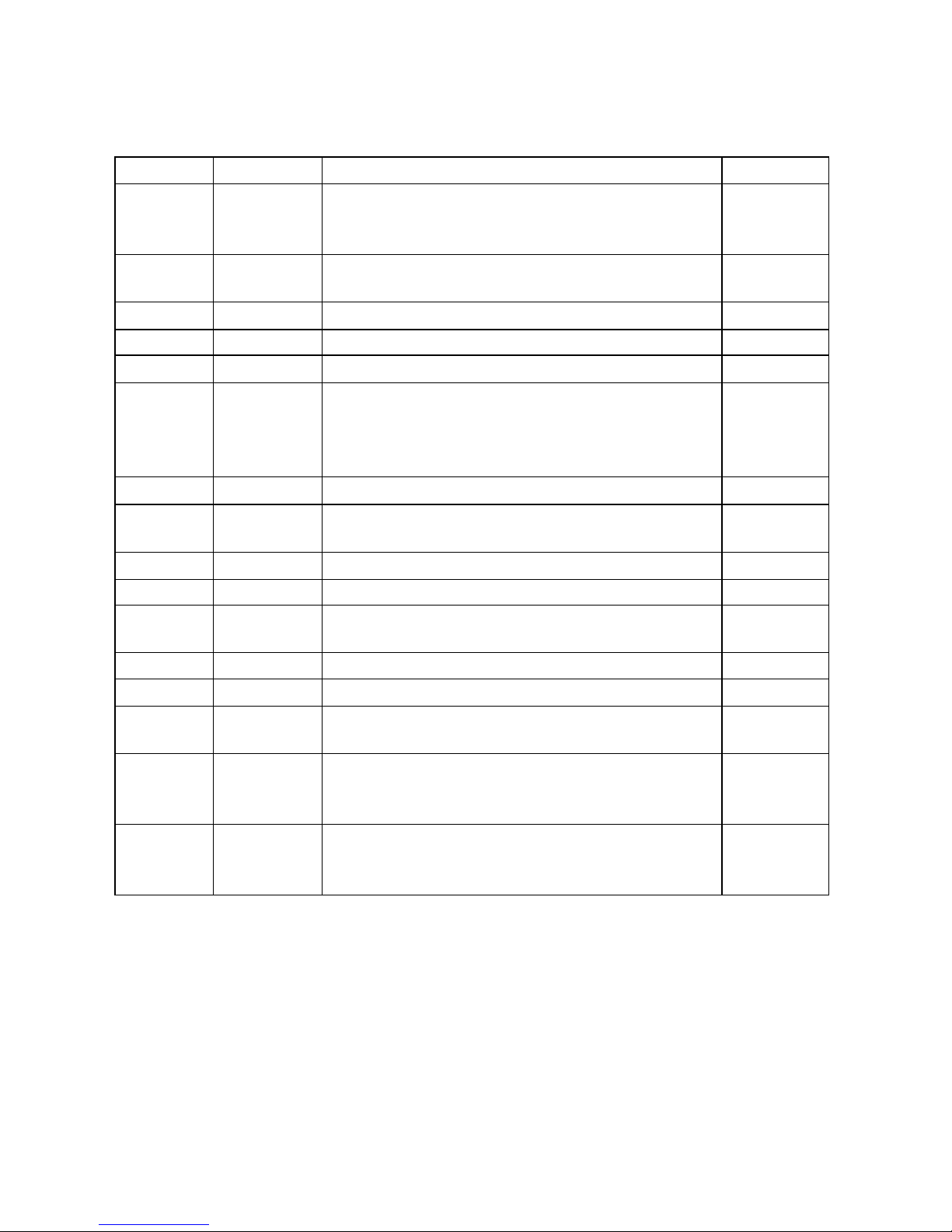

3.9 Erreurs générales

Priorité Affichage Description temps de

décalage

Système

1 U400 Raccordement aveugle de la

commande. Situé directement

au niveau de

l’élément radiant

ou rapporté via LIN (induction)

1 sec tous

2 Er31 Configuration invalide ou non

disponible

1 sec induction

3 Er47 Interférence sur le Bus LIN. Un

participant nécessaire ne répond

pas

1 sec induction

33

Page 38

4 Er36 Court-circuit du capteur de

température de CS (tous) ou de

la platine d'alimentation (élément

radiant seulement)

10 sec tous

5 Er39 Mauvaises options de

programmation (fusibles,

lockbits)

1 sec tous

6 Er20 Indications lumineuses

défectueuses du dispositif de

commande Total de vérification

incorrect

1 sec tous

7 Er37 Rétroaction défectueuse des

signaux de mémoire temporisée

en raison de l’activation de

segments ou de relais

1 sec tous

8 Er22 Clavier défectueux : au moins

une des touches n’est pas au

bon niveau

10 sec tous

Erreurs spécifiques aux zones de cuisson

Priorité Affichage Description Système

1 E5 Erreur de communication du Bus LIN. Très

probablement diagnostiquée par l'unité

de commande sensitive et indiquée par

Er47

Induction

2 E5 Indications lumineuses défectueuses du

dispositif de commande Total de

vérification incorrect

Induction

3 E5 Mauvaises options de programmation Induction

4 E5 Vérification incorrecte du total EEPROM Induction

5 E5 Données EEPROM vagues Induction

6 U400 Surtension 400 V (devient une erreur

générale avec la Commande sensitive dès

qu'elle est signalée par une zone de

cuisson à induction)

Induction

7 E5 Erreur de signal du réseau d’alimentation

électrique

Induction

34

Page 39

8 E7 Erreur Sub LIN entre le filtre et la platine

d’alimentation

Induction

9 E6 Court-circuit de 5 V avec la platine

d'alimentation

Induction

10 E6 12 V trop bas pour la platine d’alimentation Induction

11 E6 Capteur de température de l’élément de

refroidissement défectueux

Induction

12 E6 Maintien défectueux de l’impulsion du

réseau d’alimentation

Induction

13 E9 Détecteur à bobine défectueux Induction

14 E2 Détecteur à bobine surchauffé

(diagnostiquée par induction)

Induction

15 „Blitz“ Fonctionnement continu (min. 10 sec) en

éteignant une zone de cuisson

tous

16 „Blitz“ Fonctionnement continu (min. 10 sec)

sans éteindre de zone de cuisson

tous

E2

Surchauffe

E5 Changer la platine de filtre

E6 Changer la platine d’alimentation

E7 Erreur inconnue, impossible à identifier avec

précision

E9 Changer le capteur de température

35

Page 40

4 Données techniques

Tension et courant nominaux

tension nominale : 220-240 V

fréquence nominale : 50-60 Hz

La puissance d’une platine d'alimentation est limitée à 3700 W.

Utiliser uniquement un câble en caoutchouc de type H05VV-F ; la section

transversale des fils doit être de 3x1,5 mm.

Consommation du générateur en stand-by

0,6 W max. (interface utilisateur exclue).

Puissance nominale et diamètres des bobines

Diamètre Puissance nominale Puissance d’appoint

Ø 145 mm

1400 W 1800 W

Ø 210 mm

2300 W 3200 W

diameter nominal power boost power

Commande du ventilateur

Refroidissement intégré du générateur

Le refroidissement est intégré au boîtier plastique du générateur. Le

fonctionnement du ventilateur est commandé par la température qui est

mesurée au niveau du dissipateur de chaleur. Ensuite, le ventilateur se met

en marche si une certaine température est atteinte et passe à une vitesse

supérieure lorsque la deuxième limite de vitesse est atteinte.

Vitesse basse de démarrage 45 °C

Vitesse haute de démarrage 55 °C

36

Page 41

Commande de température des zones de cuisson

L’indicateur de chaleur résiduelle contribue à la protection de l’utilisateur.

L’indication de chaleur résiduelle affiche un H lorsqu'une certaine

température est atteinte sur la surface vitrocéramique.

Elle s'éteint de nouveau dès que la température descend en dessous d'un

certain niveau.

Seuil « Marche » indicateur de chaleur résiduelle 65 °C + 5 K

Seuil « Arrêt » indicateur de chaleur résiduelle 60 °C - 5 K

37

Page 42

Fig.1

Fig.2

Fig.3

Pose du joint

Marron

Jaune/vert

Bleu

Ligne

Terre

Neutre

RÉSEAU D’ALIMENTATION

ÉLECTRIQUE

Cordon

d’alimentation

38

Page 43

Fig.4

X: 150mm MIN.

W: 50mm MIN.

A: 200cm

2

MIN.

Y: Cloison

39

Page 44

Fig.5

Fig.6

GÉNÉRATEUR

Récipient dont le fond est en

matériau ferromagnétique

Champ magnétique

Doucement dans la vitre

céramique

Bobine en spirale d’Archimède

40

Page 45

DEUTSCH

DOMINO INDUKTION

SENSORTASTEN

BEDIENUNGSANLEITUNG

DE

Page 46

Page 47

INHALT

1. WARNHINWEISE 45

1.1 Installation 45

1.2 Bedienung 45

2. INSTALLATION 47

2.1Hinweise für den Installateur 47

2.2Hinweise für den Benutzer 48

2.3Bedienfeld 50

3. FUNKTIONEN 51

3.1Kochzone ein- und ausschalten 51

3.2Kochstufen 52

3.3Restwärmeanzeige 52

3.4Tastensperre 52

3.5Pause 53

3.6Timer 53

3.7Warmhalten (nur bei Induktion) 53

3.8Schnellkochen 54

3.9 Allgemeine Fehler 54

4. TECHNISCHE DATEN 56

43

Page 48

44

Page 49

1. WARNHINWEISE

Lesen Sie diese Bedienungsanweisung aufmerksam durch. Nur so können Sie Ihr

Kochfeld richtig und sicher bedienen.

Bewahren Sie die Montageanleitung, die Bedienungsanleitung und das technische

Datenblatt zum Gerät an einem sicheren Ort auf.

Überprüfen Sie das Kochfeld gleich nach dem Auspacken. Falls das Gerät beim

Transport Schaden genommen haben sollte, schließen Sie es nicht an.

1.1 Wichtige Hinweise zur Installation

Elektrogeräte dürfen nur von autorisierten und qualifizierten Personen

angeschlossen werden. Falls Schäden durch falschen Anschluss verursacht

werden, erlöschen sämtliche Garantien.

Das elektrische System muss ordnungsgemäß geerdet sein.

Sämtliche verwendeten Materialien und Klebeverbindungen müssen einer

Temperatur von mindestens 100 °C standhalten.

WARNUNG

Vor der Ausführung jedweder Arbeiten:

Trennen Sie das Kochfeld von der Stromversorgung.

Vergewissern Sie sich, dass das Kochfeld abgekühlt ist.

Versuchen Sie nicht, das Kochfeld selbst zu reparieren. Wenden Sie sich an ein

qualifiziertes Servicecenter.

1.2 Hinweise zum Kochen

Dieses Gerät wurde speziell für den Einsatz zuhause konzipiert. Das Kochfeld darf

nur zum Zubereiten von Speisen eingesetzt werden.

Berühren Sie keine stark aufgeheizten auch Zonen. VERBRENNUNGSGEFAHR!!!

Halten Sie Kinder von dem Gerät fern. Die Restwärmeanzeige warnt vor stark

aufgeheizten Kochzonen.

Stellen Sie niemals brennbare Gegenstände auf das Kochfeld. BRANDGEFAHR!!!

Netzkabel von Elektrogeräten dürfen niemals in Kontakt mit heißen Kochzonen

geraten. Die Kabelisolierung und das Kochfeld können beschädigt werden.

45

Page 50

Kochzonen und Böden von Kochgeschirr müssen grundsätzlich trocken sein.

Falls Brüche, Spalte oder Risse in der Glaskeramik auftreten, besteht

Kurzschlussgefahr. Schalten Sie das Gerät sofort aus. Wenden Sie sich an den

technischen Kundendienst.

Falls sich das Kochfeld von selbst ausschaltet und nicht wieder benutzt werden kann,

muss es sofort von der Stromversorgung getrennt und der technische Kundendienst

gerufen werden.

Sämtliche nicht ordnungsgemäß ausgeführten Reparaturen stellen ein hohes

Sicherheitsrisiko dar. Stromschlaggefahr!!! Reparaturen dürfen nur von

qualifizierten und spezialisierten Technikern ausgeführt werden.

Raue Böden von Töpfen und Pfannen können die Glaskeramik verkratzten. Schauen

Sie sich Ihr Kochgeschirr vorher genau an.

Bei speziellem Kochgeschirr halten Sie sich an die Anweisungen des Herstellers.

Stellen Sie niemals Kochgeschirr auf das Bedienfeld, den Anzeigebereich oder den

Rahmen. Dies kann zu Beschädigungen führen!!!

Salz, Zucker und Sand verkratzten die Glaskeramik. Missbrauchen Sie das Kochfeld

nicht als Arbeitsplatte oder zum Abstellen von Gegenständen.

Harte und spitze Gegenstände können das Kochfeld schwer beschädigen, wenn sie

darauf fallen. Halten Sie solche Gegenstände vom Kochfeld fern.

Zucker und Lebensmittel mit hohem Zuckeranteil können das Kochfeld beschädigen.

Verschüttete Lebensmittel müssen sofort mit einem Glaskratzer entfernt werden.

Warnung!!! Der Glaskratzer ist extrem scharf. (optional, Abbildung 6)

Folgende Dinge beeinflussen Funktionalität und Stabilität der Glaskeramik

nicht:

• Bildung von gallertartigen Rückständen durch geschmolzenen Zucker oder

durch Lebensmittel mit einem hohen Zuckeranteil.

• Durch Salz, Zucker, Sandkörner oder raue Geschirrböden verursachte

Kratzer.

• Metallische Verfärbungen durch Geschirrböden oder nicht geeignete

Reinigungsmittel.

• Verfärbungen durch ungeeignete Reinigungsmittel.

Zum Reinigen verwenden Sie lediglich warmes Wasser mit geringen Mengen

eines leicht alkalischen Reinigungsmittels. Verwenden Sie keine ätzende

Reinigungsmittel oder Scheuermittel; diese können zu Verfärbungen führen.

46

Page 51

2. INSTALLATION

Sämtliche Installationstätigkeiten (elektrischer Anschluss) sollten von Personen

ausgeführt werden, die über die entsprechenden Bestimmungen informiert sind.

Spezielle Hinweise finden Sie im folgenden Abschnitt für den Installateur.

2.1 Hinweise für den Installateur (Abbildung 4)

Die nachstehenden Hinweise richten sich an den erfahrenen Installateur und

informieren über Installation, Einstellung und Wartung. Sämtliche Arbeiten müssen in

Übereinstimmung mit den gültigen Vorschriften und Normen ausgeführt werden.

Wenn ein Einbauofen oder ein anderes Wärme erzeugendes Gerät direkt unter

einem glaskeramischen Kochfeld mit Sensortasten eingebaut wird, muss das

Gerät (Ofen) und das glaskeramische Kochfeld ordnungsgemäß so isoliert

werden, dass die durch den Ofen hervorgerufene Erwärmung (gemessen an der

rechten Seite an der Unterseite des Kochfeldes) 60 °C nicht übersteigt. Bei

Nichteinhaltung kann es zu Fehlfunktionen der Sensortasten kommen.

Das Gerät ist zum Einbau in eine Arbeitsplatte vorgesehen; siehe Abbildung 4.

Falls sich ein Schrank oder eine sonstige Ablagemöglichkeit unterhalb des

Kochfeldes befindet, muss das Kochfeld durch eine isolierende Schicht aus

einem geeigneten Material (z. B. Holz) vom Stauraum darunter getrennt werden.

Zwischen Stauraum und Unterkante des Kochfeldes muss ein Abstand von

mindestens 10 mm eingehalten werden.

Platzierung

Verteilen Sie das Dichtungsmittel auf der gesamten Fläche. (Ausschnittmaße finden

Sie in Abbildung 2)

Fixieren Sie das Gerät mit Klammern an der Arbeitsplatte, beachten Sie dabei die

Stärke der Arbeitsplatte (Abbildung 1).

Elektrische Anschlüsse (Abbildung 3)

Bevor Sie elektrische Verbindungen herstellen, sorgen Sie für Folgendes:

- Die Charakteristiken des elektrischen Systems stimmen mit den Angaben

auf dem Typenschild am Boden des Kochfeldes überein.

- Das elektrische System ist in Übereinstimmung mit den gültigen

gesetzlichen Bestimmungen und Normen geerdet.

Die ordnungsgemäße Erdung ist gesetzlich vorgeschrieben.

Sofern Sie das Gerät direkt mit der Stromversorgung verbinden möchten, müssen Sie

einen einpoligen Schalter mit einem minimalen Kontaktabstand von 3 mm

zwischenschalten. Dieser Schalter muss den auf dem Typenschild angegebenen

Lastwerten sowie den gültigen Vorschriften entsprechen (das gelb-grüne

Erdungskabel sollte nicht vom Schalter unterbrochen werden).

Der einpolige Schalter sollte bei installiertem Gerät leicht erreichbar sein.

47

Page 52

Hinweis: Der Hersteller haftet nicht bei Nichteinhaltung der obigen und

üblichen Sicherheitsvorschriften.

2.2 Hinweise für den Benutzer

Kochgeschirr (Abbildung 5)

Wir empfehlen Kochgeschirr mit einem flachen Boden, das denselben oder einen

etwas größeren Durchmesser als die jeweilige Kochzone aufweist.

Vermeiden Sie Kochgeschirr mit rauen Böden, damit die Glaskeramik nicht verkratzt.

Verwenden Sie ausschließlich Kochgeschirr mit einem stabilen, vorzugsweise dicken

Boden. Dies ist besonders bei der Zubereitung von Nahrungsmitteln wichtig, bei

denen es auf hohe Temperaturen ankommt - zum Beispiel beim Braten und Frittieren.

Falls der Boden des Kochgeschirrs nicht absolut eben ist, braucht die Zubereitung

länger, der Energieverbrauch steigt. Die beste Wärmeübertragung erreichen Sie,

wenn Geschirr und Kochzone denselben Durchmesser aufweisen.

Beim Induktionskochen wird die nötige Energie direkt in das Kochgeschirr übertragen.

Dabei bleibt die Oberfläche des Kochfeldes kühl, weil sich lediglich das Kochgeschirr

aufheizt. Das Ergebnis ist eine schnelle, kostengünstige und saubere Zubereitung.

Sie können Ihr Kochfeld mit emailliertem Stahl- oder Edelstahlgeschirr verwenden.

Kochgeschirr aus Glas, Keramik oder Aluminium ist nicht geeignet, sofern es nicht

über eine spezielle, magnetische Bodenplatte verfügt.

Grenzen der Geschirrerkennung

Die folgende Tabelle zeigt die Grenzen der Geschirrerkennung. Geprüft

wurde mit Gusseisen.

Nenndurchmesser der Spule Grenze der Geschirrerkennung

(eingeschaltet)

Ø 145 mm

Ø 90 mm

Ø 210 mm

Ø 135 mm

Integrierte Geschirrerkennung

Jede einzelne Kochzone ist mit einer Geschirrerkennungsfunktion ausgestattet. Die

Geschirrerkennung vermeidet das Einschalten einer Kochzone, wenn kein Geschirr

darauf steht. Zusätzlich schaltet sich die Kochzone automatisch ab, sobald das

Geschirr herunter genommen wird. Die Kochzone schaltet sich nach einer

bestimmten Zeit automatisch ab, wenn eine Kochstufe vorgewählt, jedoch kein

Geschirr darauf gestellt wurde.

Das Geschirr muss aus magnetisierbarem Material bestehen. Die Geschirrerkennung

des Induktionsmoduls hängt von Geschirrtyp und Geschirrmaterial ab.

48

Page 53

WICHTIG

Ƈ Vermeiden Sie ein Überlaufen von Flüssigkeiten beim Kochen oder

Erhitzen; verwenden Sie eine geringere Temperatureinstellung.

Ƈ Nach Beendigung des Kochens schalten Sie das Gerät ab.

Falls Sie auch nur kleinste Beschädigungen der Kochfeldoberfläche feststellen

sollten, schalten Sie den Strom sofort ab.

Wartung und Pflege

Zunächst entfernen Sie mit dem speziellen Kratzer (optional, Abbildung 5) sämtliche

Rückstände von der Oberfläche des Kochfeldes.

Anschließend reinigen Sie die Kochfeldoberfläche so gut wie möglich mit einem

Papiertuch, SIDOL, STAHLFIX oder einem ähnlichen Produkt. Danach spülen Sie mit

klarem Wasser nach und trocknen die Oberfläche mit einem sauberen Tuch.

Aluminiumfolie, geschmolzene Kunststoffe, Zucker oder stark zuckerhaltige

Rückstände müssen unverzüglich mit dem speziellen Kratzer (optional, Abbildung 5)

entfernt werden, damit es nicht zu Beschädigungen des Kochfeldes kommt.

Benutzen Sie niemals Scheuerschwämme oder aggressive Chemikalien wie

Ofensprays oder Fleckentferner.

Schutz gegen übermäßige Erwärmung

Sowohl Generator als auch Spulen verfügen über integrierte Schutzschaltungen

gegen übermäßige Erwärmung.

Im Inneren des Gerätes befindet sich ein Temperatursensor, der das Gerät vor

Überhitzung schützen.

Verschmutzungen der glaskeramischen Oberfläche

Verschmutzungen durch Lebensmittel und/oder Wasser können in

Ausnahmefällen ungewollte Tastenbetätigungen auslösen. Dieser

unerwünschte Effekt kann auch durch Feuchtigkeit ausgelöst werden.

Gerade bei großflächigen Verschmutzungen besteht die Möglichkeit, dass

ein bis mehrere Tasten versehentlich ausgelöst und kurz oder dauerhaft

betätigt werden. Daher können Verschmutzungen kurzzeitig zu

Veränderungen der Einstellungen führen: Das Gerät kann nicht zwischen

ungewollten und gewollten Betätigungen unterscheiden. Wenn das Gerät

eine permanente Tastenbetätigung (zum Beispiel das Einschalten einer

Kochzone) feststellt, werden die Sensortasten nach maximal 10 Sekunden

automatisch deaktiviert. Dies setzt jedoch voraus, dass die Aktivierung der

Sensortasten durch Verschmutzungen mindestens 10 Sekunden lang erfolgt.

49

Page 54

2.3 BEDIENFELD:

Überblick und Beschreibung

Bild 1: Touch Domino mit sämtlichen Tasten, Anzeigen und LEDs

1 Ein-/Ausschalter Zum Ein- und Ausschalten 1

Sekunde lang gedrückt halten

2 Multizone-/Spezialtaste z. B. Tastensperre, Pause,

Doppelzone, Dreifachzone

3 Plus Kochstufe erhöhen

4 Minus Kochstufe vermindern

5 Timer/Kochzone-Spezialfunktion Timer, Doppelzone, Dreifachzone

(wenn kein Timer verfügbar)

11 Betrieb-LED

12 Spezialfunktion-LED 1

Kochzonensperre,

Doppelzone

13 Spezialfunktion-LED 2 Dreifachzone

14 Timer-LED Programmtimer oder Kochstufe

15 Spezialfunktion-LED 1 Kochzonensperre, Doppelzone

16 Spezialfunktion-LED 2 Dreifachzone

50

Page 55

3. FUNKTIONEN

3.1 Kochzone ein- und ausschalten

Wenn Sie die Ein-/Austaste (Taste Nummer 1) eine Sekunde lang gedrückt

halten, werden die Sensortasten aktiviert und ein kurzes Tonsignal ist zu

hören. Gleichzeitig wird eine „0“ im Display der Kochzone angezeigt. An

Stelle der „0“ kann im Display der Kochzone auch ein „H“ für „heiß“ angezeigt

werden. Außerdem kann auch ein „E“ erscheinen, das „Fehler“ (Englisch:

Error) bedeutet. Falls Sie innerhalb von 10 Sekunden nach dem Aktivieren

der Sensortasten keine weiteren Tasten betätigen, schalten sich die

Sensortasten wieder ab.

Über die Ein-/Austaste können Sie die Sensortasten jederzeit zurücksetzen

und abschalten - egal, ob diese aktiviert sind oder sich im

Bereitschaftsmodus befinden. Im Betrieb genießt das Ausschalten

grundsätzlich höchste Priorität. Das bedeutet, dass sich das Gerät sofort

ausschaltet, auch wenn mehrere Tasten gleichzeitig berührt werden. Die

Sensortasten lassen sich grundsätzlich auch dann ausschalten, wenn die

Tastensperre (siehe 2.10) aktiviert wurde.

Kochzone ein- und ausschalten

Einschalten

Eine Kochzone kann direkt über die entsprechenden Plus-/Minustasten

eingeschaltet werden (bei aktiven Sensortasten oder im Standbymodus),

sofern die jeweilige Kochzone nicht über die Timerprogrammierung (optional,

siehe 2.13) belegt wurde.

Ausgangsposition: Die Kochzone ist ausgeschaltet. Anzeige: „0“:

Wenn Sie nun die „+“-Taste berühren, werden die Kochstufen von

„0“ bis „5“ durchgeschaltet. Wenn Sie zuerst die „-“-Taste berühren,

werden die Kochstufen von „0“ bis „9“ (also bis zur höchsten

Kochstufe) durchgeschaltet.

Wenn Sie die Tasten „+“ oder „-“ gedrückt halten, werden die

Kochstufen automatisch erhöht oder vermindert. Der Sprung zur

nächsten Stufe erfolgt nach jeweils einer halben Sekunde. Allerdings

wird nur bei der ersten Kochstufenänderung ein Tonsignal

ausgegeben. Sobald die höchste oder niedrigste Stufe erreicht ist,

bleibt die Kochstufe unverändert. Diese Sperre lässt sich nur

überwinden, indem Sie die Taste loslassen und danach erneut

berühren. („0“ Å „9“ oder „9“ Å „A“). Auch wenn eine Kochzone keine

automatische Aufheiz- oder Schnellkochfunktion ermöglicht, ist es

nicht möglich, von Stufe 9 auf Stufe 0 zu springen.

51

Page 56

Ausschalten

Sie können eine Kochzone auf folgende Weisen ausschalten:

Durch gleichzeitiges Drücken der Tasten „+“ und „-“ der jeweiligen

Kochzone.

Indem Sie die Kochstufe der gewünschten Kochzone durch Drücken

der „-“-Taste auf „0“ einstellen.

3.2 Kochstufen

Grundsätzlich verfügt Ihr Kochfeld über neun Kochstufen, die mit den Ziffern

„1“ bis „9“ im Display angezeigt werden.

Die Buchstaben „A“ (für automatisches Aufheizen) und „P“ (Schnellkochen)

sowie das Symbol für „kein Geschirr“ werden nur rechts oder im

Einzeldisplay einer Kochzone angezeigt.

3.3 Restwärmeanzeige

Eine heiße Kochzone wird durch ein „H“ gekennzeichnet.

Überhitzungsschutz für Induktionskochzonen

Im Prinzip arbeitet das Induktionsverfahren eigensicher.

Die Induktionselektronik überwacht jede Kochzone mit Hilfe von

Temperatursensoren, die sich unterhalb der Glaskeramik befinden. Weitere

Temperatursensoren an den Kühlblechen schützen die Elektronik vor

Überhitzung.

Bei Überhitzungsgefahr blinkt das Symbol „P“ in der zutreffenden Anzeige

und zeigt damit an, dass derzeit kein Schnellkochen möglich ist.

3.4 Tastensperre

Die LED 12 zeigt den Status der Tastensperre an. Sie können eine

Kochzone sperren oder freigeben, indem Sie die Minustaste und die

spezielle Funktionstaste (Taste Nummer 2) einer Kochzone gleichzeitig

betätigen. Auf diese Weise können Sie unterschiedliche Kochzonen sperren

oder freigeben.

Mit der Ein-/Austaste können Sie eine Kochzone auch dann ausschalten,

wenn diese gesperrt ist.

52

Page 57

Wenn mindestens eine Kochzone in Betrieb ist, können Sie die

Kochzonen vorübergehend abschalten, indem Sie die Spezialtasten

(Taste Nummer 2) länger als eine Sekunde gedrückt halten.

Diese Pause kann bis zu 10 Minuten dauern.

3.6 Timer

Die Timerfunktion bietet einen Timer für jede einzelne

Kochzone, die mit den Sensortasten bedient werden

kann.

Sämtliche Timer zählen von einer vorgegebenen Zeit bis auf Null zurück. Sie

können Zeiten zwischen 1 und 99 Minuten einstellen. Nachdem der Timer

gesetzt wurde, zählt er in Minutenschritten bis auf 0 herunter. Danach wird

ein optisches und akustisches Alarmsignal ausgegeben.

Wenn ein Timer für eine Kochzone eingestellt wurde, wird die jeweilige

Kochzone nach Ablauf des Timers automatisch ausgeschaltet.

Bevor Sie einen Timer einstellen können, müssen Sie die Sensortasten über

die Ein-/Austaste zumindest in den Standbymodus schalten. Beim

Abschalten der Sensortasten werden sämtliche Kochzonen-Timer

abgeschaltet; eventuell programmierte Eier-Timer laufen jedoch weiter.

3.7 Warmhalten (nur bei Induktion)

Mit der Warmhaltefunktion können Sie bereits gekochte

Speisen warm halten.

Dies erreichen Sie, indem Sie eine Kochstufe zwischen 0

und 1 auswählen: Dadurch wird im Display der Kochzone das Symbol „Lo“

(siehe oben) angezeigt. Wenn Sie die Kochstufe durch Gedrückthalten der

Minustaste weiter reduzieren, wird die Warmhaltefunktion aufgehoben. Um

auf Stufe 0 zu schalten, müssen Sie die Taste noch einmal berühren.

53

3.5 Pause

Page 58

Sämtliche Induktionskochzonen verfügen über eine

Schnellkochfunktion.

Die Schnellkochfunktion ermöglicht ein besonders schnelles

Erhitzen und spart dadurch Zeit.

Wenn keine spezielle Schnellkochtaste vorhanden ist:

Stellen Sie die Kochzone zunächst auf die höchstmögliche Stufe ein.

Lassen Sie die Tasten „+“ oder „-“ los. Ein weiterer Druck auf die „+“-Taste

aktiviert die Schnellkochfunktion. Als Kochstufe wird das Symbol „P“

angezeigt.

Aus Sicherheitsgründen kann die Schnellkochfunktion der einzelnen

Kochzonen maximal 10 Minuten lang genutzt werden.

Wenn Sie bei aktivierter Schnellkochfunktion die Minustaste drücken, wird

die Schnellkochfunktion abgeschaltet. Das Drücken der „+“-Taste hat keinen

Effekt.

Pro Induktionschaltung kann eine maximale Leistung von 3700 Watt erreicht

werden.

3.9 Allgemeine Fehler

Priorität Anzeige Beschreibung Verzögerungszeit System

1 U400 Falscher Anschluss der

Steuerung. Aktives

Heizelement oder per LIN

(Induktion).

1 Sek. alle

2 Er31 Falsche oder keine

Konfiguration

1 Sek. Induktion

3 Er47 Störung am LIN-Bus. Eine

erforderliche Komponente

reagiert nicht.

1 Sek. Induktion

4 Er36 Kurzschluss am TC-

Temperatursensor (alle)

oder an der

Leistungsplatine (nur

aktives Heizelement).

10 Sek. alle

5 Er39 Falsche

Programmierungsoptionen

1 Sek. alle

54

3.8 Schnellkochen

Page 59

(Sicherungen, Sperrbits).

6 Er20 Defekter Controller.

Prüfsummenfehler.

1 Sek. alle

7 Er37 Falsche Rückmeldung

oder verschobene

Registersignale

hinsichtlich Segment- oder

Relais-Aktivierung.

1 Sek. alle

8 Er22 Tastenfehler: Falscher

Pegel bei mindestens

einer Taste.

10 Sek. alle

Kochzonen-spezifische Fehler

Priorität Anzeige Beschreibung System

1 E5 LIN-BUS-Kommunikationsfehler.

Wahrscheinlich durch Sensortasteneinheit

erkannt und als Er47 angezeigt.

Induktion

2 E5 Defekter Controller. Prüfsummenfehler. Induktion

3 E5 Falsche Programmierungsoptionen. Induktion

4 E5 EEPROM-Prüfsummenfehler Induktion

5 E5 Unklare EEPROM-Daten Induktion

6 U400 400 Volt-Unterspannung (wird zu

allgemeinem Sensortasten-Fehler, wenn

durch mindestens eine

Induktionskochzone angezeigt).

Induktion

7 E5 Fehlerhaftes Netzspannungssignal Induktion

8 E7 Sub-LIN-Fehler zwischen Filter und

Leistungsplatine

Induktion

9 E6 5 Volt-Kurzschluss an Leistungsplatine Induktion

10 E6 12 V zu niedrig für Leistungsplatine Induktion

11 E6 Defekter Temperatursensor am Kühlkörper Induktion

12 E6 Fehlerhafter Netz-Haltepuls Induktion

13 E9 Defekte Spulenerkennung Induktion

55

Page 60

14 E2 Überhitzte Spulenerkennung (durch

Induktion erkannt)

Induktion

15 „Blitz“ Dauerbetätigung (mindestens 10

Sekunden) nach Abschalten einer

Kochzone

alle

16 „Blitz“ Dauerbetätigung (mindestens 10

Sekunden) ohne Abschalten einer

Kochzone

alle

E2 Überhitzung

E5 Filterplatine tauschen

E6 Leistungsplatine tauschen

E7 Unbekannter Fehler, kann nicht eindeutig

identifiziert werden

E9 Temperatursensor tauschen

4 Technische Daten

Nennspannung und Strom

Nennspannung: 220 - 240 V

Nennfrequenz: 50 - 60 Hz

Die maximale Leistung einer Leistungsplatine ist auf 3700 Watt beschränkt.

Ausschließlich Kautschukkabel vom Typ H05VV-F verwenden,

Leitungsquerschnitt 3 x 1,5 mm.

Generator-Stromverbrauch im Bereitschaftsmodus

Maximal 0,6 Watt (ausschließlich Bedienfeld).

56

Page 61

Nennleistung und Spulendurchmesser

Durchmesser Nennleistung Schnellkochleistung

Ø 145 mm

1400 W 1800 W

Ø 210 mm

2300 W 3200 W

Lüftersteuerung

Integrierte Generatorkühlung

Eine Kühlungsvorrichtung ist in das Kunststoffgehäuse des Generators

integriert. Der Lüfter wird durch einen Temperatursensor am Kühlkörper

gesteuert. Der Lüfter schaltet sich ein, wenn eine bestimmte Temperatur

erreicht wird und schaltet auf eine höhere Stufe, wenn eine zweite

Temperaturgrenze überschritten wird.

Schwellwert niedrige Geschwindigkeit: 45 °C

Schwellwert hohe Geschwindigkeit: 55 °C

Kochzonen-Temperatursteuerung

Die Restwärmeanzeige trägt zum Schutz des Benutzers bei. Die

Restwärmeanzeige schaltet sich ein und zeigt ein „H“ an, sobald unterhalb

der Glaskeramik eine bestimmte Temperatur erreicht wird.

Die Anzeige schaltete sich wieder aus, nachdem die Temperatur um einen

bestimmten Wert gefallen ist.

Einschalt-Schwellwert Restwärmeanzeige: 65 °C +5 K

Ausschalt-Schwellwert Restwärmeanzeige: 60 °C - 5 K

57

Page 62

Abbildung 1

Abbildung 2

Abbildung 3

Dichtung anbringen

Braun

Gelb/grün

Blau

Phase

Erde

Nullleiter

NETZSTROMVERSORGUNG

Netzkabel

58

Page 63

Abbildung 4

X: Mind. 150mm

W: Mind. 50mm

A: Mind. 200cm

2

Y: Teilung

59

Page 64

Abbildung 5

Abbildung 6

GENERATOR

Topf mit ferromagnetischem

Boden

Magnetfeld

Glaskeramik

Archimedes-Spule

60

Page 65

PORTUGUÊS

DOMINO INDUCTION

CONTROLO DIGITAL

MANUAL DE INSTRUÇÕES DE

FUNCIONAMENTO

PT

Page 66

Page 67

ÍNDICE

1. AVISOS……………………………………………………… 65

1.1 Para instalação…………………………………………….. 65

1.2 Para cozedura……………………………………………… 65

2. INSTALAÇÃO…………………………………………………. 67

2.1Instruções para o instalador………………………………… 67

2.2Instruções para o utilizador………………………………… 68

2.3Painéis das teclas…………………………………………..... 70

3. FUNÇÕES……………………………………………………... 71

3.1Comutação ON/OFF (LIGAR/DESLIGAR) da área de cozedura..... 71

3.2 Níveis de cozedura ……………………………………………72

3.3 Indicação do calor residual …………………………………. 72

3.4 Bloqueio………………….………………………………….….72

3.5 Indicação de interrupção ………………………………….… 73

3.6

Função temporizador …………………………………….....73

3.7Função Lo Temp (actualmente apenas para indução) ……73

3.8Aquecimento rápido…………………………………….…. 74

3.9 Erros gerais …………………………………….………… 74

4. DADOS TÉCNICOS……………………………………………. 77

63

Page 68

64

Page 69

1.AVISOS

Leia estas instruções para utilização cuidadosa. Este é o único modo de utilizar a

placa de maneira correcta e segura.

Guarde as instruções de montagem, as instruções de utilização e a folha de dados

técnicos do equipamento num local seguro.

Verifique imediatamente a placa, após desempacotá-la. Se ocorreu qualquer dano

durante o transporte, não ligue o equipamento.

1.1 Importante para a instalação

As ligações devem ser feitas apenas por pessoal autorizado e qualificado. Se

ocorrer algum dano por ligações incorrectas, ficará invalidado qualquer tipo de

garantia.

O sistema eléctrico deve ser equipado com um sistema de ligação à terra

adequado.

As colas e os materiais utilizados para a unidade de cozinha devem resistir a

temperaturas de no mínimo 100ºC.

AVISO

Antes de qualquer operação:

Desligue a placa das tomadas eléctricas.

Certifique-se que a placa esteja fria.

Não tente reparar a placa por conta própria, contacte o dentro de assistência a

clientes qualificado.

1.2 Para cozedura

Este equipamento foi concebido especificamente para uso doméstico. A placa deve

ser utilizada apenas na preparação de alimentos.

Não toque nas áreas de cozedura que estão sobreaquecidas. RISCO DE

QUEIMADURA!!! Mantenha fora do alcance das crianças. O indicador pósaquecimento avisa se as áreas estão sobreaquecidas.

Nunca pouse objectos inflamáveis sobre a placa. RISCO DE INCÊNDIO!!!

O cabo de alimentação para equipamentos eléctricos nunca devem tocar nas áreas

de cozedura quentes. O isolante do cabo e a placa podem ficar danificados.

65

Page 70

A área de cozedura e o fundo da panela devem estar sempre secos.

Se houver quebras, rachaduras ou fendas na vitrocerâmica, existe risco de curtocircuito. Desligue imediatamente o equipamento. Contacte o serviço de assistência

técnica.

Se a placa se desligar sozinha e não puder ser utilizada, é necessário desligá-la

imediatamente do sistema eléctrico e contactar o serviço de assistência técnica.

Qualquer reparação efectuada de modo incorrecto é de alto risco. Risco de

choques eléctricos!!! As reparações devem ser realizadas apenas por pessoal

técnico especializado e qualificado.

Superfícies ásperas nos tachos ou frigideiras riscam a vitrocerâmica. Verifique os

tachos.

No caso de tachos especiais, siga as instruções do fabricante.

Nunca coloque tachos ou frigideiras quentes no painel de controlo, na área do visor

ou na estrutura. Isto pode causar danos!!!

Sal, açúcar e areia riscam a vitrocerâmica. Não utilize a placa como uma superfície

de trabalho ou para colocar algo.

Objectos duros ou pontiagudos que caiam acidentalmente na placa podem causar

danos. Não pouse estes objectos sobre a placa.

O açúcar ou outros alimentos com alto teor de açúcar danificarão a placa. Qualquer

alimento derramado deve ser removido imediatamente com um raspador para vidro.

Aviso!!! O raspador para vidro possui uma lâmina afiada. (OPCIONAL

fig. 6)

Os seguintes danos não afectarão o funcionamento adequado ou a

estabilidade da vitrocerâmica.

• A formação de resíduos gelatinosos devido ao açúcar derretido ou de algum

alimento com alto teor de açúcar.