Page 1

Cooker hood

Dunstabzugshaube

DKC 5030

Instruction Manual

Bedienungsanleitung

Page 2

EN

Instructions Manual

INDEX

RECOMMENDATIONS AND SUGGESTIONS .....................................................................................................................7

CHARACTERISTICS............................................................................................................................................................. 8

INSTALLATION...................................................................................................................................................................... 9

USE......................................................................................................................................................................................12

MAINTENANCE................................................................................................................................................................... 13

2

2

Page 3

FR

Manuel d’Instructions

SOMMAIRE

CONSEILS ET SUGGESTIONS..........................................................................................................................................15

CARACTERISTIQUES......................................................................................................................................................... 16

INSTALLATION.................................................................................................................................................................... 17

UTILISATION.......................................................................................................................................................................20

ENTRETIEN.........................................................................................................................................................................21

3

3

Page 4

DE

Bedienungsanleitung

INHALTSVERZEICHNIS

EMPFEHLUNGEN UND HINWEISE................................................................................................................................... 23

CHARAKTERISTIKEN.........................................................................................................................................................24

MONTAGE...........................................................................................................................................................................25

BEDIENUNG........................................................................................................................................................................28

WARTUNG........................................................................................................................................................................... 29

4

4

Page 5

NL

Gebruiksaanwijzing

INHOUDSOPGAVE

ADVIEZEN EN SUGGESTIES.............................................................................................................................................31

EIGENSCHAPPEN.............................................................................................................................................................. 32

INSTALLATIE....................................................................................................................................................................... 33

GEBRUIK .............................................................................................................................................................................36

ONDERHOUD...................................................................................................................................................................... 37

5

5

Page 6

DK

Brugsvejledning

INDHOLD

RÅD OG ANVISNINGER.....................................................................................................................................................39

APPARATBESKRIVELSE.................................................................................................................................................... 40

INSTALLATION.................................................................................................................................................................... 41

BRUG...................................................................................................................................................................................44

VEDLIGEHOLDELSE ..........................................................................................................................................................45

6

6

Page 7

EN

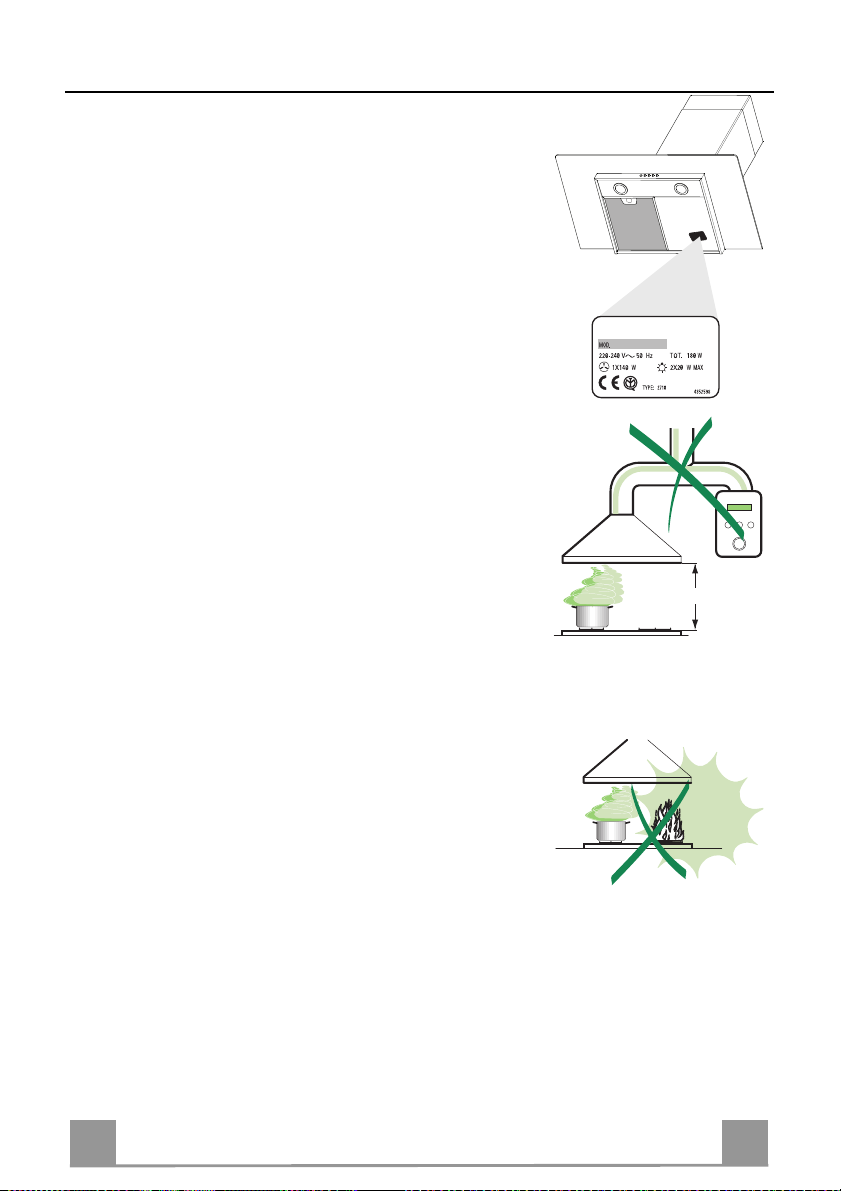

RECOMMENDATIONS AND SUGGESTIONS

650 mm min.

INSTALLATION

• The manufacturer will not be held liable for any damages resulting

from incorrect or improper installation.

• The minimum safety distance between the cooker top and the extractor hood is 650 mm.

• Check that the mains voltage corresponds to that indicated on the

rating plate fixed to the inside of the hood.

• For Class I appliances, check that the domestic power supply guarantees adequate earthing.

Connect the extractor to the exhaust flue through a pipe of minimum

diameter 120 mm. The route of the flue must be as short as possible.

• Do not connect the extractor hood to exhaust ducts carrying combustion fumes (boilers, fireplaces, etc.).

• If the extractor is used in conjunction with non-electrical appliances

(e.g. gas burning appliances), a sufficient degree of aeration must be

guaranteed in the room in order to prevent the backflow of exhaust

gas. The kitchen must have an opening communicating directly with

the open air in order to guarantee the entry of clean air.

USE

• The extractor hood has been designed exclusively for domestic use to

eliminate kitchen smells.

• Never use the hood for purposes other than for which it has ben designed.

• Never leave high naked flames under the hood when it is in operation.

• Adjust the flame intensity to direct it onto the bottom of the pan only,

making sure that it does not engulf the sides.

• Deep fat fryers must be continuously monitored during use: overheated oil can burst into flames.

• The hood should not be used by children or persons not instructed in

its correct use.

MAINTENANCE

• Switch off or unplug the appliance from the mains supply before carrying out any maintenance work.

• Clean and/or replace the Filters after the specified time period.

• Clean the hood using a damp cloth and a neutral liquid detergent.

7

7

Page 8

EN

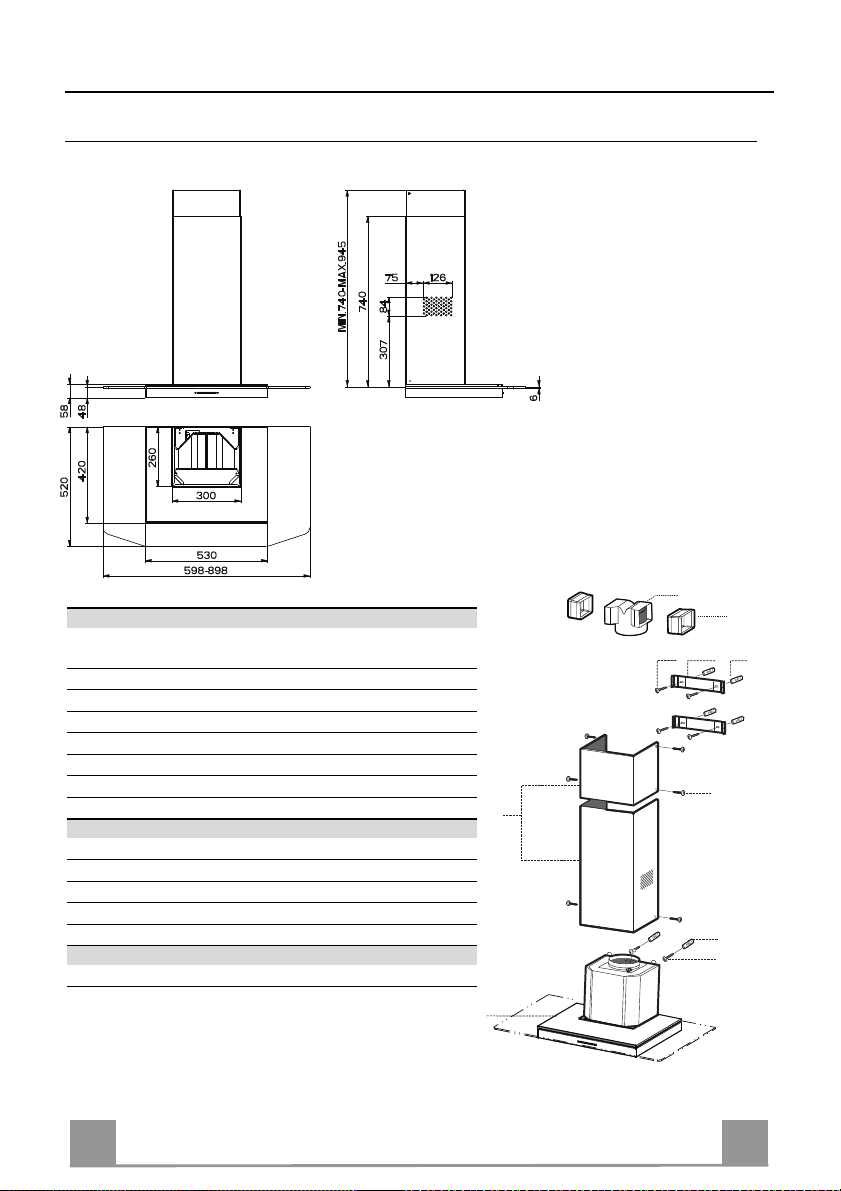

CHARACTERISTICS

11

12a

2.1

2.2

2

12c

12a

7.2.1 11

14.1

15

1

Components

Ref. Q.ty Product Components

1 1 Hood Body, complete with: Controls, Light, Blower,

2 1 Telescopic Chimney comprising:

2.1 1 Upper Section

2.2 1 Lower Section

9 1 Reducer Flange ø 150-120 mm

14.1 2 Air Outlet Connection Extension

15 1 Air Outlet Connection

Ref. Q.ty Installation Components

7.2.1 2 Upper Chimney Section Fixing Brackets

11 6 Wall Plugs

12a 6 Screws 4,2 x 44,4

12c 6 Screws 2,9 x 9,5

Q.ty Documentation

1 Instruction Manual

Filters

Dimensions

8

8

Page 9

EN

INSTALLATION

11

12a

306

X

116

1÷2

116

650 min.

7.2.1

Wall drilling and bracket fixing

Wall marking:

• Draw a vertical line on the supporting wall up to the ceiling, or as high as practical, at the

centre of the area in which the hood will be installed.

• Draw a horizontal line at 650 mm above the hob. Place bracket 7.2.1 on the wall as shown

about 1-2 mm from the ceiling or upper limit aligning the centre (notch) with the vertical

reference line.

• Mark the wall at the centres of the holes in the bracket.

• Place bracket 7.2.1 on the wall as shown at X mm below the first bracket (X = height of the

upper

chimney section supplied), aligning the centre (notch) with the vertical line.

• Mark the wall at the centres of the holes in the bracket.

• Mark a reference point as indicated at 116 mm from the vertical reference line and 306 mm

above the horizontal reference line.

• Repeat this operation on the other side.

• Drill ø 8 mm holes at all the centre points marked.

• Insert the wall plugs 11 in the holes.

• Fix the brackets using the 12a (4,2 x 44,4) screws supplied.

• Insert the two screws 12a (4,2 x 44,4) supplied in the hood body fixing holes, leaving a gap

of 5-6 mm between the wall and the head of the screw.

9

9

Page 10

EN

1

Mounting the hood body

12a

Vr

9

ø 120ø 150

14.115

• Before attaching the hood body, tighten the two

screws Vr located on the hood body mounting points.

• Hook the hood body onto the screws 12a.

• Fully tighten support screws 12a.

• Adjust screws Vr to level the hood body.

Connections

DUCTED VERSION AIR EXHAUST SYSTEM

When installing the ducted version, connect the hood to

the chimney using either a flexible or rigid pipe ø 150

or 120 mm, the choice of which is left to the installer.

• To install a ø 120 mm air exhaust connection, insert

the reducer flange 9 on the hood body outlet.

• Fix the pipe in position using sufficient pipe clamps

(not supplied).

• Remove any activated charcoal filters.

RECIRCULATION VERSION AIR OUTLET

• Push fit connection 15 onto the hood body outlet.

• Insert the connection extension pieces laterally 14.1

in connection 15.

• Make sure that the outlet of the extension pieces 14.1

is horizontally and vertically aligned with the chimney outlets. If this is not the case, adjust the position

by either reversing the connection extension pieces

14.1 and then reassemble as described previously.

• Ensure that the activated charcoal filters have been

inserted.

10

Page 11

EN

1

ELECTRICAL CONNECTION

12c

2.1

2.2

2

7.2.1

12c

• Connect the hood to the mains through a two-pole switch having a contact gap of at least 3 mm.

• Remove the grease filters (see paragraph Maintenance) being

sure that the connector of the feeding cable is correctly inserted

in the socket placed on the side of the fan.

Flue assembly

Upper exhaust flue

• Slightly widen the two sides of the upper flue and hook them

behind the brackets 7.2.1, making sure that they are well

seated.

• Secure the sides to the brackets using the 4 screws 12c (2,9 x

9,5) supplied.

Lower exhaust flue

• Slightly widen the two sides of the flue and hook them between the upper flue and the wall, making sure that they are

well seated.

• Fix the lower part laterally to the hood body using the 2 screws

12c (2,9 x 9,5) supplied.

11

Page 12

EN

1

USE

T2 T3 T4

S1

L T1

Control Panel

The hood can be switched on pushing directly onto the requested speed without firstly having

to select 0/1 button.

KEY LED FUNCTIONS

L 0/1 Light Turns lighting on and off.

T1 0/1 Motor on First speed.

T2 Speed on Second speed.

T3 Speed on Third speed.

T4 Speed Fixed Max. speed

Flashing Intensive speed.

Suitable for the strongest cooking vapours and odours.

S1 Led Fixed Indicates that the Metal grease filters saturation alarm has

Flashing indicates that the activated charcoal odour filter satura-

When pressed for about 1 seconds the motor is switched off.

The function becomes active when the button is pushed

for about 2 seconds. After 10 minutes of functioning it

turns off automatically. This function can be interrupted

by means of pressing any of the buttons.

been triggered, and the filters need to be washed. The

alarm is triggered after 100 working hours. (Reset; check

the Maintenance-paragraph)

tion alarm has been triggered, and the filter has to be replaced; the metal grease filters must also be washed. The

activated charcoal odour filter is triggered after 200

working hours. (Activation and Reset; check the Mainte-

nance-paragraph))

12

Page 13

EN

1

MAINTENANCE

REMOTE CONTROL (OPTIONAL)

The appliance can be controlled using a remote control powered

by a 1.5 V carbon-zinc alkaline batteries of the standard LR03AAA type.

• Do not place the remote control near to heat sources.

• Used batteries must be disposed of in the proper manner.

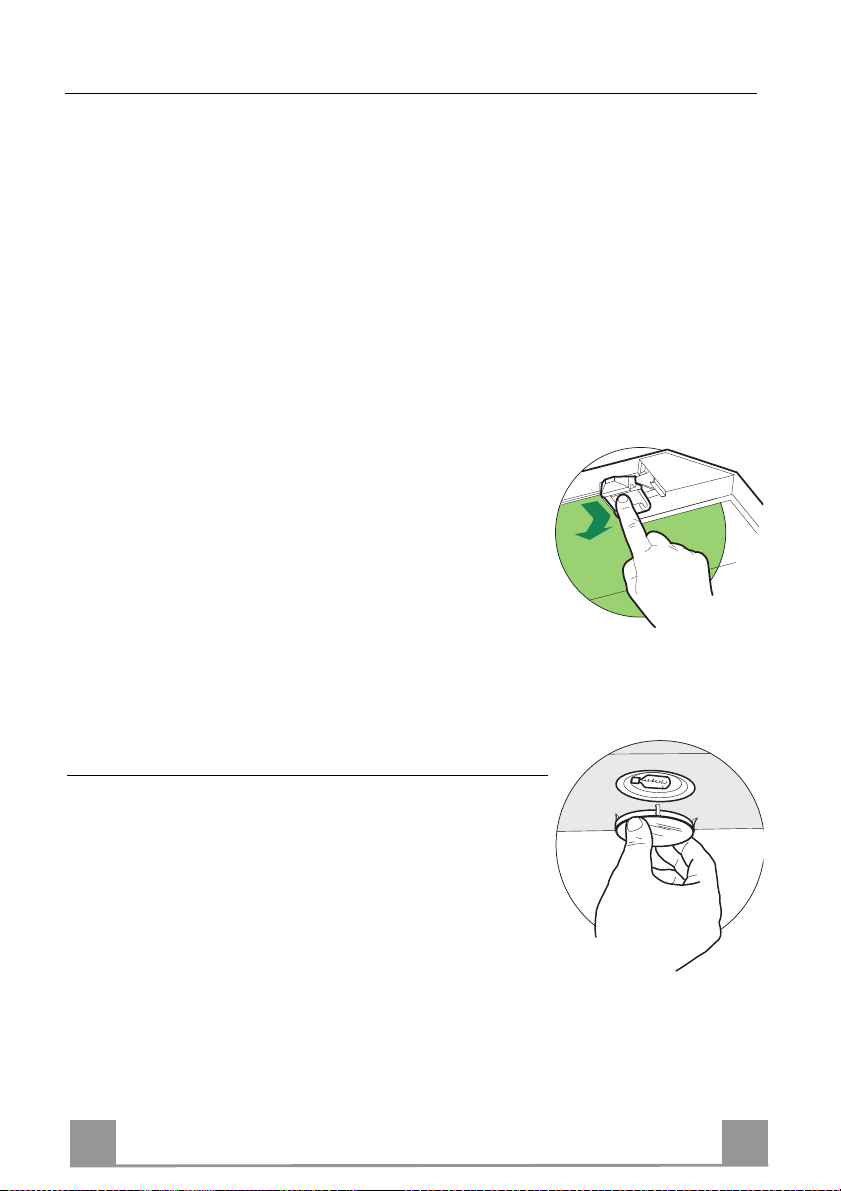

Grease filters

CLEANING METAL SELF- SUPPORTING GREASE FILTERS

Alarm signal reset

• Switch off the lights and extractor motor.

• Press button T3 for at least 3 seconds, until the leds start to

flash.

Cleaning the filters

• The filters are washable and must be cleaned when the LED S1

lights up or at least every 2 months of operation, or more frequently for particularly heavy usage.

• Remove the filters one at a time by pushing them towards the

back of the group and pulling down at the same time.

• Wash the filters, taking care not to bend them. Allow them to

dry before refitting.

• When refitting the filters, make sure that the handle is visible

on the outside.

13

Page 14

EN

1

Activated charcoal filter (Recirculation version)

• The filter is not washable and cannot be regenerated. It must be replaced when led S1

flashes or at least every 4 months. The alarm signal will only light up when the extractor

motor is switched on.

Alarm signal activation

• In Recirculation version Hoods, the Filter saturation alarm can be enabled on installation or

at a later date. Turn the Lights and the suction Motor off.

• Disconnect the Hood using the Main switch or the double-pole switch on the mains power

supply.

• Restore the connection by pressing and holding T1.

• Release the button. All five LEDs are turned on

• Within 3 seconds press T1 until LEDs T1 and T4 flash in confirmation:

LED flashes twice - Activated charcoal filter saturation alarm ENABLED

LED flashes once - Activated charcoal filter saturation alarm DISABLED

Replacing the activated charcoal filter

Alarm signal reset

• Switch off the lights and extractor motor.

• Press button T3 for at least 3 seconds, until the leds start to

flash.

Replacing the Filter

• Remove the metal grease filters

• Remove the saturated activated carbon filter by releasing the

fixing hooks

• Fit the new filter by hooking it into its seating

• Replace the metal grease filters.

Lighting

LIGHT REPLACEMENT

20 W halogen light.

• Remove the snap-on lamp cover by levering it from under the

metal ring, supporting it with one hand.

• Remove the halogen lamp from the lamp holder by pulling

gently.

• Replace the lamp with a new one of the same type, making

sure that you insert the two pins properly into the housings on

the lamp holder.

• Replace the snap-on lamp cover.

14

Page 15

FR

1

CONSEILS ET SUGGESTIONS

INSTALLATION

650 mm min.

• Le fabricant décline toute responsabilité en cas de dommage dû à

une installation non correcte ou non conforme aux règles de l’art.

• La distance minimale de sécurité entre le plan de cuisson et la hotte

doit être de 650 mm au moins.

• Vérifier que la tension du secteur correspond à la valeur qui figure sur

la plaquette apposée à l’intérieur de la hotte.

• Pour les Appareils appartenant à la Ière Classe, veiller à ce que la

mise à la terre de l’installation électrique domestique ait été effectuée

conformément aux normes en vigueur.

• Connecter la hotte à la sortie d’air aspiré à l’aide d’une tuyauterie

d’un diamètre égal ou supérieur à 120 mm. Le parcours de la

tuyauterie doit être le plus court possible.

• Eviter de connecter la hotte à des conduites d’évacuation de fumées

issues d’une combustion tel que (Chaudière, cheminée, etc…).

• Si vous utilisez des appareils qui ne fonctionnent pas à l’électricité

dans la pièce ou est installée la hotte (par exemple: des appareils

fonctionnant au gaz), vous devez prévoir une aération suffisante du

milieu. Si la cuisine en est dépourvue, pratiquez une ouverture qui

communique avec l’extérieur pour garantir l’infiltration de l’air pur.

UTILISATION

• La hotte a été conçue exclusivement pour l’usage domestique, dans

le but d’éliminer les odeurs de la cuisine.

• Ne jamais utiliser abusivement la hotte.

• Ne pas laisser les flammes libres à forte intensité quand la hotte est

en service.

• Toujours régler les flammes de manière à éviter toute sortie latérale

de ces dernières par rapport au fond des marmites.

• Contrôler les friteuses lors de l’utilisation car l’huile surchauffée

pourrait s’enflammer.

• La hotte ne doit pas être utilisée par des enfants ou des personnes ne

pouvant pas assurer une utilisation correcte.

ENTRETIEN

• Avant de procéder à toute opération d’entretien, retirer la hotte en

retirant la fiche ou en actionnant l’interrupteur général.

• Effectuer un entretien scrupuleux et en temps dû des Filtres, à la

cadence conseillée.

• Pour le nettoyage des surfaces de la hotte, il suffit d’utiliser un

chiffon humide et détersif liquide neutre.

15

Page 16

FR

1

CARACTERISTIQUES

11

12a

2.1

2.2

2

12c

12a

7.2.1 11

14.1

15

1

Composants

Réf. Q.té Composants de Produit

1 1 Corps Hotte équipé de:Comandes,

Lumière,Groupe Ventilateur,Filtres

2 1 Cheminée Télescopique formée de :

2.1 1 Cheminée Supérieure

2.2 1 Cheminée Inférieure

9 1 Flasque de Réduction ø 150-120 mm

14.1 1 Rallonge Raccord Sortie Air

15 1 Raccord Sortie Air

Réf. Q.té Composants pour l ’installation

7.2.1 2 Brides Fixation Cheminée Supérieure

11 6 Chevilles

12a 6 Vis 4,2 x 44,4

12c 6 Vis 2,9 x 9,5

Q.té Documentation

1 Manuel d’instructions

Encombrement

16

Page 17

FR

1

INSTALLATION

11

12a

306

X

116

1÷2

116

650 min.

7.2.1

Perçage Paroi et Fixation Brides

Tracer sur la paroi:

• une ligne verticale allant jusqu’au plafond ou à la limite supérieure, au centre de la zone

prévue pour le montage de la hotte;

• une ligne horizontale à 650 mm min. au-dessus du plan de cuisson.

• Poser comme indiqué une bride 7.2.1 sur la paroi à 1-2 mm du plafond ou de la limite supérieure, en alignant son centre (découpes) sur la ligne verticale de repère.

• Marquer les centres des trous rainurés de la bride.

• Poser comme indiqué la bride 7.2.1 à X mm sous la première bride (X = hauteur cheminée

supérieure fournie), en alignant son centre (découpes) sur la ligne verticale de repère.

• Marquer les centres des trous rainurés de la bride.

• Marquer comme indiqué, un point de référence à 116 mm de la ligne verticale de repère, et

306 mm au-dessus de la ligne horizontale de repère.

• Répéter cette opération sur le côté opposé.

• Percer de ø 8 mm tous les points marqués.

• Insérer les chevilles 11 dans les trous.

• Fixer les brides en utilisant les vis 12a (4,2 x 44,4) fournies.

• Visser les 2 vis 12a (4,2 x 44,4) fournies dans les trous de fixation du corps hotte, en laissant

un espace de 5-6 mm entre le mur et la tête de la vis.

17

Page 18

FR

1

Montage Corps Hotte

12a

Vr

9

ø 120ø 150

14.115

• Avant d’accrocher le corps hotte, serrer les deux vis

Vr situées sur les points d’accrochage du corps hotte.

• Accrocher le corps hotte aux vis 12a prévues à cet

effet.

• Serrer définitivement les vis 12a de support.

• Agir sur les vis Vr pour niveler le corps hotte.

Branchements

SORTIE AIR VERSION ASPIRANTE

En cas d’installation en version aspirante, brancher la

hotte à la tuyauterie de sortie via un tube ri-gide ou

flexible de ø 150 ou 120 mm, au choix de l’installateur.

• En cas de branchement avec un tube de ø120 mm,

insérer le flasque de réduction 9 sur la sortie du corps

de la hotte.

• Fixer le tube par des colliers appropriés. Le matériau

nécessaire n’est pas fourni.

• Retirer les éventuels filtres anti-odeur au charbon

actif.

SORTIE AIR VERSION FILTRANTE

• Insérer sous pression le raccord 15 sur la rallonge

corps hotte 14.

• Insérer latéralement les rallonges raccord 14.1 sur le

raccord 15.

• S’assurer que la sortie des rallonges raccord 14.1 se

trouve au niveau des bouches de la cheminée aussi

bien en horizontal qu’en vertical. Si tel n’est pas le

cas, ajuster la position en inversant les rallonges raccord 14.1 et remonter les pièces comme décrit au préalable.

• S’assurer de la présence des filtres anti-odeur au

charbon actif.

18

Page 19

FR

1

BRANCHEMENT ELECTRIQUE

12c

2.1

2.2

2

7.2.1

12c

• Brancher la hotte sur le secteur en interposant un interrupteur

bipolaire avec ouverture des contacts d’au moins 3 mm.

• Enlever les filtres à graisse (voir § "Entretien") et s'assurer que

le connecteur du câble d'alimentation soit bien branché dans la

prise du diffuseur.

Montage Cheminée

Cheminée supérieure

• Elargir légèrement les deux bords latériaux, et les accrocher

derrières les brides 7.2.1; refermer jusqu’à la butée.

• Fixer latéralement aux brides à l’aide des 4 vis 12c fournies.

Cheminée inférieure

• Elargir légèrement les deux bords latériaux de la Cheminée et

les accrocher entre la Cheminée supérieure et la paroi; refermer

jusqu’à la butée.

• Fixer latéralement la partie inférieure au corps hotte, à l’aide

des deux 2 vis 12c fournies.

19

Page 20

FR

2

UTILISATION

T2 T3 T4

S1

L T1

Tableau des commandes

Il est possible d’allumer la hotte directement à la vitesse demandée en pressant la touche sans devoir

d’abord utiliser la touche 0/1

.

TOUCHE LED FUNCTIONS

L 0/1 éclairage Allume et éteint l'éclairage.

T1 0/1 Moteur Allumé Première vitesse.

Cette touche permet d’éteindre la hotte en y pressant pour

environ 1 secondes.

T2 Vitesse Allumé Deuxième vitesse.

T3 Vitesse Allumé Troisième vitesse.

T4 Vitesse Fixe Vitesse maximum.

Clignotement Vitesse turbo.

S1 Led Fixe

Clignotement

Cette vitesse est conseillée pour de grandes émissions de vapeurs de cuisson. Elle peut être insérée en pressant pour 2 secondes environ la touche. Elle s’éteint en automatique après 10

minutes de fonctionnement. On peut l’éteindre manuellement en

pressant n’importe quelle touche.

Signale la saturation des filtres métalliques et la nécessité de les

laver. L'alarme se met en marche après 100 heures de fonctionnement effectif de la hotte. (Reset. Voir paragraphe Entretien)

Signale, lorsqu' il est activé, la saturation des filtres à charbon et

la nécessité de les remplacer et de laver les filtres métalliques.

L'alarme saturation des filtres à charbon se déclenche après 200

heures de fonctionnement effectif de la hotte. (Mise en activité et

Reset. Voir paragraphe Entretien)

20

Page 21

FR

2

ENTRETIEN

TELECOMMANDE (FOURNIE SUR DEMANDE)

Il est possible de commander cet appareil au moyen d’une télécommande, alimentée avec des piles alcalines zinc-charbon 1,5 V

du type standard LR03-AAA.

• Ne pas ranger la télécommande à proximité de sources de chaleur.

• Ne pas jeter les piles; il faut les déposer dans les récipients de

récolte spécialement prévus à cet effet.

Filtres anti-graisse

NETTOYAGE FILTRES ANTI-GRAISSE METALLIQUES AUTOPOR-

TEURS

Remise à l’état initial du signal d’alarme

• Éteindre les Lumières et le Moteur d’aspiration.

• Appuyer sur la touche T1 pendant 3 secondes au moins, jusqu’au clignotement de confirmation des dels.

Nettoyage Filtres

• Ils peuvent être lavés au lave-vaisselle et nécessitent d’être nettoyés lorsque la Led S1 s'allume ou, au moins, environ tous les

2 mois d’emploi ou plus fréquemment en cas d’emploi particulièrement intense.

• Retirer les filtres l’un aprés l’autre, en les poussant vers la partie arrière du groupe et en tirant simultanément vers le bas.

• Laver les filtres en évitant de les plier et les laisser sécher avant

de les remonter.

• Remonter les filtres en veillant à ce que la poignée reste vers la

partie visible externe.

21

Page 22

FR

2

Filtre anti-odeur (Version filtrante)

• Il n’est pas lavable ni régénérable, il faut le remplacer lorsque la del S1 clignote ou tous les

4 mois au moins. La signalisation d’Alarme a lieu uniquement lorsque le Moteur

d’aspiration est actionné.

Activation du signal d’alarme

• Pour les Hottes dans la Version Filtrante, la signalisation d'Alarme de saturation Filtres doit être

activée au moment de l'installation ou par la suite. Éteindre l'Éclairage et le Moteur d'aspiration.

• Déconnecter la Hotte en actionnant l'Interrupteur bipolaire interposé sur l'alimentation du Réseau

ou en intervenant sur l'Interrupteur général.

• Rétablir la connexion, en maintenant appuyée la touche T1.

• Relâcher la touche, les cinq dels sont allumées en position fixe.

• Dans un délai de 3 secondes, appuyer sur la Touche T1 jusqu'au clignotement de confirmation des

Dels T1 et T4:

2 clignotements Del - Alarme de saturation Filtre anti-odeur au Charbon actif ACTIVÉE.

1 clignotement Del - Alarme de saturation Filtre anti-odeur au Charbon actif DÉSACTIVÉE.

Remplacement filtre au charbon actif

Remise à l’état initial du signal d’alarme

• Éteindre les Lumières et le Moteur d’aspiration.

• Appuyer sur la touche T3 pendant 3 secondes au moins, jusqu’au clignotement de confirmation des dels.

Remplacement Filtre

• Retirer les filtres anti-graisse métalliques.

• Retirer le filtre anti-odeur au charbon actif colmaté, en agissant

sur les crochets prévus à cet effet.

• Monter le nouveau filtre anti-odeur au charbon actif.

• Remonter le filtres anti-graisse métalliques.

Eclairage

REMPLACEMENT LAMPES

Lampe halogène de 20 W.

• Enlever le dispositif métallique de blocage du verre par encliquetage en exerçant une pression sous l’embout en le soutenant

d’une main.

• Extraire la lampe du support

• Remplacer la lampe par une nouvelle ayant le mêmes caractéristiques, en prenant soin d'insérer correctement les deux fiches

dans le support.

• Remonter le dispositif de blocage du verre par encliquetage.

22

Page 23

DE

2

EMPFEHLUNGEN UND HINWEISE

650 mm min.

MONTAGE

• Der Hersteller haftet nicht für Schäden, die auf eine fehlerhafte und

unsachgemäße Montage zurückzuführen sind.

• Der minimale Sicherheitsabstand zwischen Kochmulde und Haube

muss 650 mm betragen.

• Prüfen, ob die Netzspannung mit dem Wert auf dem im Haubeninneren angebrachten Schild übereinstimmt.

• Bei Geräten der Klasse I ist sicherzustellen, dass die elektrische Anlage des Wohnhauses über eine vorschriftsmäßige Erdung verfügt.

• Das Anschlussrohr der Haube zur Luftaustrittsöffnung muss einen

Durchmesser von 120 mm oder darüber aufweisen. Der Rohrverlauf

muss so kurz wie möglich sein.

• Die Haube darf an keine Entlüftungsschächte angeschlossen werden,

in die Verbrennungsgase (Heizkessel, Kamine usw.) geleitet werden.

• Werden im Raum außer der Dunstabzugshaube andere, nicht elektrisch betriebene (z.B. gasbetriebene) Geräte verwendet, muss für eine ausreichende Belüftung gesorgt werden. Sollte die Küche diesbezüglich nicht entsprechen, ist an einer Aussenwand eine Öffnung anzubringen, die Frischluftzufuhr gewährleistet.

BEDIENUNG

• Die Dunstabzugshaube ist ausschließlich zum Einsatz im privaten

Haushalt und zur Beseitigung von Küchengerüchen vorgesehen.

• Unsachgemäßer Einsatz der Haube ist zu unterlassen.

• Große Flammen bei eingeschalteter Haube niemals unbedeckt lassen.

• Die Intensivität der Flamme ist so zu regulieren, dass sie den Topfboden nicht überragt.

• Frittiergeräte müssen während des Gebrauchs stets beaufsichtigt

werden: überhitztes Öl kann sich entzünden.

• Die Dunstabzugshaube darf von Kindern oder Personen, die hinsichtlich der Bedienung nicht unterwiesen wurden, keinesfalls verwendet

werden.

WARTUNG

• Bevor Wartungsarbeiten durchgeführt werden, muss die Stromzufuhr

zur Haube unterbrochen werden, indem der Stecker gezogen oder

der Hauptschalter abgeschaltet wird.

• Bei der Filterwartung müssen die vom Hersteller empfohlenen Zeiträume zum Austauschen der Filter genauestens eingehalten werden.

• Zur Reinigung der Haubenflächen Wir empfehlen ein feuchtes Tuch

und ein mildes Flüssigreinigungsmittel.

23

Page 24

DE

2

CHARAKTERISTIKEN

11

12a

2.1

2.2

2

12c

12a

7.2.1 11

14.1

15

1

Komponenten

Pos. St. Produktkomponenten

1 1 Haubenkörper mit Schaltern,Beleuchtung,

Gebläsegruppe,Filter

2 1 Teleskopkamin bestehend aus:

2.1 1 oberer Kaminteil

2.2 1 unterer Kaminteil

9 1 Reduzierflansch ø 150-120 mm

14.1 2 Verlängerung Luftaustritt-Anschlussstück

15 1 Luftaustritt-Anschlussstück

Pos. St. Montagekomponenten

7.2.1 2 Befestigungsbügel oberer Kaminteil

11 6 Bügel

12a 6 Schrauben 4,2 x 44,4

12c 6 Schrauben 2,9 x 9,5

St. Dokumentation

1 Bedienungsanleitung

Platzbedarf

24

Page 25

DE

2

MONTAGE

11

12a

306

X

116

1÷2

116

650 min.

7.2.1

Bohren der Befestigungslöcher und Fixieren der Befestigungsbügel

Nachstehende Linien an die Wand zeichnen:

• eine vertikale Linie bis zur Decke oder oberen Begrenzung, und zwar in der Mitte des Bereiches, in dem die Haube montiert werden soll;

• eine horizontale Linie mit einem minimalen Abstand von 650 mm zur Kochfläche.

• Einen Bügel 7.2.1 zirka 1-2 mm unter der Decke oder oberen Begrenzung an die Wand legen und seinen Mittelpunkt (Einschnitte) auf die vertikale Bezugslinie ausrichten.

• Die Mitte der beiden Bügellöcher an der Wand markieren.

• Den zweiten Bügel 7.2.1 an die Wand legen, wobei ein Abstand X mm vom oberen Bügel

einzuhalten ist (X = Höhe des jeweiligen oberen Kaminteils); den Mittelpunkt (Einschnitte)

auf die vertikale Bezugslinie ausrichten.

• Die Mitte der Bügellöcher an der Wand markieren.

• Wie beschrieben einen Bezugspunkt 116 mm von der vertikalen Bezugslinie und 306 mm

oberhalb der horizontalen Bezugslinie kennzeichnen.

• Gleichermaßen an der gegenüberliegenden Seite vorgehen.

• Mit einem Bohrer ø 8 mm die markierten Punkte bohren.

• Die Dübel 11 in die Bohrungen einfügen.

• Die Bügel mit den mitgelieferten Schrauben 12a (4,2 x 44,4) fixieren.

• 2 der mitgelieferten Schrauben 12a (4,2 x 44,4) bei den Befestigungslöchern des Haubenkörpers einschrauben, wobei zwischen Wand und Schraubenkopf ein Freiraum von 5-6 mm

zu belassen ist.

25

Page 26

DE

2

Montage des Haubenkörpers

12a

Vr

9

ø 120ø 150

14.115

• Bevor der Haubenkörper eingehakt wird, die 2

Schrauben Vr bei den Haubenkörper-Anhakpunkten

festziehen.

• Den Haubenkörper bei den Schrauben 12a einhängen.

• Die Halteschrauben 12a definitiv festziehen.

• Den Haubenkörper mit Hilfe der Schrauben Vr ausrichten.

Anschlüss in abluftversion

Bei Abluftbetrieb kann die Haube vom Installateur

wahlweise mittels Rohr oder Schlauch (ø 150 oder 120

mm) an die Außenrohrleitung angeschlossen werden.

• Bei Verwendung eines Anschlussrohres ø 120 den

Reduzierflansch 9 am Haubenaustritt anbringen.

• Das Rohr mit geeigneten Rohrschellen fixieren. Das

hierzu erforderliche Material wird nicht mitgeliefert.

• Eventuell vorhandene Aktivkohlefilter entnehmen.

ANSCHLUSS IN UMLUFTVERSION

• Den Anschluss 15 beim Luftaustritt des Haubenkörpers eindrücken.

• Die Verlängerungen 14.1 beim Anschluss 15 seitlich

einfügen.

• Überprüfen, ob die Verlängerungen 14.1 mit den entsprechenden Kaminstutzen sowohl horizontal wie

auch vertikal übereinstimmen. Sollte dies nicht der

Fall sein, müssen die Verlängerungen 14.1 miteinander vertauscht und wie zuvor beschrieben wieder zusammengebaut werden.

• Kontrollieren, ob der Aktivkohle-Geruchsfilter vorhanden ist.

26

Page 27

DE

2

ELEKTROANSCHLUSS

12c

2.1

2.2

2

7.2.1

12c

• Bei Anschluss der Haube an das Stromnetz muss ein zweipoliger Schalter mit einem Öffnungsweg von mindestens 3 mm

zwischengeschaltet werden.

• Entfernen Sie die Fettfilter (s. Abschnitt „Wartung“) und versichern Sie sich, daß die Kabelverbindung in die Steckdose des

Gebläses einwandfrei eingesteckt wird.

Kaminmontage

Oberer Kaminteil

• Die beiden seitlichen Schenkel leicht auseinanderbiegen, hinter

den Bügeln 7.2.1 einhängen und bis zum Anschlag wieder

schließen.

• Bei den Bügeln mit Hilfe der 4 mitgelieferten Schrauben 12c

fixieren.

Unterer Kaminteil

• Die beiden seitlichen Schenkel des Kaminteils leicht auseinanderbiegen, zwischen dem oberen Kaminteil und der Wand einhängen und bis zum Anschlag wieder schließen.

• Den unteren Teil seitlich am Haubenkörper mit 2 der mitgelieferten Schrauben 12c fixieren.

27

Page 28

DE

2

BEDIENUNG

T2 T3 T4

S1

L T1

Die Haube kann direkt auf die gewünschte Stufe eingeschaltet werden ohne daß man vorher auf die Gebläsetaste 0/1 drückt.

TASTE LED FUNKTION

L 0/1

T1 0/1 Motor

Schaltet die Haube aus wenn die Taste für ungefähr 1’’ gedrückt

T2

Geschwindig- Eingeschaltet Zweite Geschwindigkeitsstufe.

keitsstufe

T3

Geschwindig- Eingeschaltet Dritte Geschwindigkeitsstufe.

keitsstufe

T4

Geschwindig- Ständiges Höchste Geschwindigkeitsstufe.

keitsstufe Aufleuchten

Blinklicht Intensivstufe.

Bei sehr starker Kochdunstentwicklung geeignet. Wird durch

S1

Led Ständiges signalisiert die Sättigung der Metallfettfilter und dass Aufleuch-

Beleuchtung

Eingeschaltet Erste Geschwindigkeitsstufe.

Ein- und Ausschalten der Beleuchtung.

wird

2’’ langes Drücken auf diese Taste aktiviert. Nach 10 Minuten

schaltet sich das Gebläse automatisch auf die vorher gewählte

Stufe zurück. Kann auch manuell unterbrochen werden indem

man einfach auf eine andere Taste drückt.

ten eine Reinigung erforderlich ist. Dieser Alarm wird nach 100

effektiven Arbeitsstunden der Haube aktiviert. (Für Reset siehe

Abschnitt Wartung)

Blinklicht signalisiert die Sättigung des Aktivkohle-Geruchsfilters,

der ausgetauscht werden muss; die Metallfettfilter müssen ebenfalls gewaschen werden. Die Sättigungsanzeige

des Aktivkohle-Geruchsfilters wird nach 200 effektiven

Arbeitsstunden der Haube aktiviert.(Für Aktivierung und

Reset siehe Abschnitt Wartung)

Bedienfeld

28

Page 29

DE

2

WARTUNG

FERNBEDIENUNG (OPTION)

Dieses Gerät kann mit einer Fernbedienung gesteuert werden,

welche mit alkalischen Zink-Kohle-Batterien 1,5 V des Standardtyps LR03-AAA versorgt wird.

• Die Fernbedienung nicht in die Nähe von Hitzequellen legen.

• Batterien müssen vorschriftsmäßig entsorgt werden.

Fettfilter

SELBSTTRAGENDER METALLFETTFILTER REINIGUNG

Rücksetzen der Sättigungsanzeige

• Licht und Gebläsemotor abschalten.

• Mindestens 3 Sekunden lang die Taste T3 drücken, bis die

Leds zur Bestätigung zu blinken beginnen.

Filterreinigung

• Die Filter können im Geschirrspüler gewaschen werden und

sind dann zu reinigen, wenn die Led S1 zu sich einschalten beginnt bzw. zumindest nach 2-monatigem Betrieb oder bei starkem Einsatz auch häufiger.

• Die Filter nacheinander aushaken, indem sie auf die Rückseite

der Haube geschoben und gleichzeitig nach unten gezogen

werden.

• Die Filter reinigen (darauf achten, sie nicht zu verbiegen) und

vor der Remontage trocknen lassen.

• Bei der Remontage ist darauf zu achten, dass sich der Griff auf

der sichtbaren Außenseite befindet.

29

Page 30

DE

3

Geruchsfilter (Umluftversion)

Dieser Filter kann weder gewaschen noch wiederverwendet werden und ist bei Blinken der

Led S1 oder zumindest alle 4 Monate auszutauschen. Die Sättigungsanzeige erfolgt nur bei

laufendem Gebläsemotor.

Aktivierung der Sättigungsanzeige

• Bei Hauben mit Umluftbetrieb erfolgt die Aktivierung der Sättigungsanzeige bei der Installation oder später.

• Die Beleuchtung und den Gebläsemotor abschalten. Die Haube vom Stromnetz trennen, indem der zwischengeschaltete zweipolige Schalter oder der Hauptschalter betätigt wird.

• Den Anschluss wieder herstellen, indem die Taste T1 gedrückt gehalten wird.

• Die Taste loslassen; alle fünf Leds leuchten pausenlos auf.

• Innerhalb von 3 Sekunden die Taste T1 solange drücken, bis die Leds T1 und T4 zur Bestätigung zu blinken beginnen:

2-maliges Blinken der Leds - Sättigungsanzeige Aktivkohle-Geruchsfilter AKTIVIERT

1-maliges Blinken der Leds - Sättigungsanzeige Aktivkohle-Geruchsfilter DEAKTIVIERT

Austauschen der Aktivkohle Filter

Rücksetzen der Sättigungsanzeige

• Licht und Gebläsemotor abschalten.

• Mindestens 3 Sekunden lang die Taste T3 drük-ken, bis die

Leds zur Bestätigung zu blinken beginnen.

Austauschen der Filter

• Die Metallfettfilter entfernen.

• Den gesättigten Aktivkohle-Geruchsfilter aushaken.

• Den neuen Filter in seinem Sitz einhaken.

• Die Metallfettfilter wieder montieren.

Beleuchtung

AUSWECHSELN DER LAMPEN

Halogenlampe 20 W

• Die mittels Eindrücken befestigte Glashalterung aus Metall

durch Anheben der Zwinge entfernen und die Halterung dabei

mit einer Hand stützen.

• Die Lampe aus der Halterung nehmen.

• Die Lampe durch eine gleichwertige ersetzen und bei der Remontage darauf achten, daß die beiden Steckerstifte vorschriftsmäßig in die Lampenfassung eingeführt werden.

• Die Glashalterung wieder eindrücken.

30

Page 31

NL

3

ADVIEZEN EN SUGGESTIES

650 mm min.

INSTALLATIE

• De fabrikant aanvaardt geen enkele aansprakelijkheid voor schade

die voortkomt uit onjuiste of niet overeenkomstig de regels der kunst

uitgevoerde installaties.

• De minimale veiligheidsafstand tussen de kookplaat en de wasemkap

bedraagt 650 mm.

• Controleer of de netspanning correspondeert met de spanning die

aangegeven is op het plaatje aan de binnenkant van de wasemkap.

• Voor apparaten van klasse I dient u zich ervan te verzekeren dat het

elektriciteitsnet in uw huis over een goede aarding beschikt.

• Verbind de wasemkap met de luchtuitlaat door middel van een leiding

met een diameter van 120 mm of groter. De leiding moet een zo kort

mogelijke route afleggen.

• Sluit de wasemkap niet aan op afvoerpijpen van rook die geproduceerd is door verbranding (verwarmingsketels, open haarden etc.).

• Als er in het vertrek zowel de wasemkap als apparaten die niet op

elektriciteit werken (bijvoorbeeld gasapparaten) worden gebruikt,

moet ervoor worden gezorgd dat het vertrek voldoende geventileerd

wordt. Indien de keuken geen gat in de buitenmuur heeft om de aanvoer van schone lucht te garanderen, dient dit gemaakt te worden.

GEBRUIK

• De wasemkap is uitsluitend ontworpen voor huishoudelijk gebruik,

voor het elimineren van kookgeuren. Gebruik de kap nooit op oneigenlijke wijze.

• Laat geen hoog brandende branders onbedekt onder de wasemkap

terwijl deze in werking is.

• Regel de vlammen altijd zo dat ze niet langs de pannen omhoogkomen.

• Controleer frituurpannen tijdens het gebruik: de oververhitte olie zou

vlam kunnen vatten.

• De wasemkap mag niet gebruikt worden door kinderen of door personen die niet in staat zijn de kap correct te gebruiken.

ONDERHOUD

• Alvorens onderhoudswerkzaamheden uit te voeren, moet de wasemkap uitgeschakeld worden door de stekker uit het stopcontact te halen

of de hoofdschakelaar om te zetten.

• Voer het onderhoud van de filters altijd tijdig en nauwgezet uit,volgens

de aanbevolen intervallen.

• Om de oppervlakken van de kap schoon te maken is het voldoende

een vochtige doek en een neutraal reinigingsmiddel te gebruiken.

31

Page 32

NL

3

11

12a

2.1

2.2

2

12c

12a

7.2.1 11

14.1

15

1

EIGENSCHAPPEN

Onderdelen

Ref. Productonderdelen

1 1 Wasemkap compleet met:Bedieningen,

Licht,Ventilatorgroep,Filters

2 1 Telescopische Schouw Bestaande uit:

2.1 1 Bovenstuk

2.2 1 Onderstuk

9 1 Reductieflens ø 150-120 mm

14.1 2 Verlengstuk Verbindingsstuk Luchtuitlaat

15 1 Verbindingsstuk Luchtuitlaat

Ref. Installatieonderdelen

7.2.1 2 Bevestigingsbeugels Bovenstuk van de

Schouw

11 6 Pluggen

12a 6 Schroeven 4,2 x 44,4

12c 6 Schroeven 2,9 x 9,5

Documentatie

1 Gebruiksaanwijzing

Buitenafmetingen

32

Page 33

NL

3

INSTALLATIE

11

12a

306

X

116

1÷2

116

650 min.

7.2.1

Boren van gaten in de wand en bevestiging van de draagbeugels

Trek de volgende lijnen op de wand:

• een verticale lijn tot aan het plafond of tot aan de bovenlimiet, in het midden van de zone

waar u de wasemkap wilt installeren;

• een horizontale lijn op 650 mm min. boven de kookplaat.

• Plaats, zoals aangegeven, de beugel 7.2.1 op 1-2 mm van het plafond of van de bovenlimiet,

en lijn het midden ervan (inkepingen) uit op de verticale referentielijn.

• Teken de middelpunten van de gaten in de beugel af.

• Plaats, zoals aangegeven, de beugel 7.2.1 op X mm onder de eerste beugel (X = hoogte bijgeleverde bovenstuk van de schouw), en lijn het midden ervan (inkepingen) uit op de verticale referentielijn.

• Teken de middelpunten van de gaten in de beugel af.

• Teken, zoals aangegeven, een referentiepunt af op 116 mm van de verticale referentielijn en

op 306 mm boven de horizontale referentielijn.

• Herhaal deze handeling aan de andere kant.

• Boor op de afgetekende punten gaten van ø 8 mm.

• Schuif de pluggen 11 in de gaten.

• Bevestig de beugels met behulp van de bijgeleverde schroeven 12a (4,2 x 44,4).

• Schroef 2 van de bijgeleverde schroeven 12a (4,2 x 44,4) in de gaten voor bevestiging van

de wasemkap en laat hierbij een ruimte van 5-6 mm tussen de wand en de kop van de

schroef.

33

Page 34

NL

3

Montage van de Wasemkap

12a

Vr

9

ø 120ø 150

14.115

• Alvorens de wasemkap vast te haken, de 2 schroeven

Vr, die zich op de bevestigingspunten van de wasemkap bevinden, aanhalen.

• Haak de wasemkap vast aan de schroeven 12a.

• De dragende schroeven 12a definitief aanhalen.

• Draai aan de schroeven Vr om de wasemkap recht te

hangen.

Aansluitingen

LUCHTUITLAAT AFZUIGVERSIE

Bij installatie in afzuigversie, moet u de wasemkap met

de uitlaatleiding verbinden door middel van een starre

of buigzame leiding van ø 150 of 120 mm, naar keuze

van de installateur.

• Voor verbinding met een leiding van ø120 mm, moet

de reductieflens 9 op de uitlaat van de wasemkap

worden aangebracht.

• Zet de leiding vast met geschikt leidingklemmen. Het

benodigde materiaal wordt niet bij de wasemkap geleverd.

• Verwijder de eventuele geurfilters met actieve koolstof.

LUCHTUITLAAT FILTERVERSIE

• Breng verbindingsstuk 15 op de luchtuitgang aan

door het vast te drukken’.

• Plaats de verlengstukken 14.1 op de zijkant van verbindingsstuk 15.

• Controleer of de uitlaat van het verlengstuk 14.1

overeenstemt met de gaten van de schouw, en dit

zowel horizontaal als vertikaal. Als dit niet het geval

is, dan moet U de compositie aanpassen door de verlengstukken 14.1 .

• Controleer of er een geurfilter met actieve koolstof

aanwezig is.

34

Page 35

NL

3

ELEKTRISCHE AANSLUITING

12c

2.1

2.2

2

7.2.1

12c

• Sluit de wasemkap aan op de netspanning met een tweepolige

schakelaar ertussen met een opening tussen de contacten van

tenminste 3 mm.

• Verwijder de vetfilters (zie par. "Onderhoud") en verzeker u

ervan dat de stekker van de voedingskabel goed in de contactdoos van de afzuigkap is gestoken.

Montage van de schouw

Bovenstuk van de schouw

• De twee zijplaten enigszins openen, ze vasthaken achter de

beugels 7.2.1 en ze weer zo ver mogelijk sluiten.

• Aan de zijkant aan de beugel bevestigen met de 4 bijgeleverde

schroeven 12c.

Onderstuk van de schouw

• De twee zijplaten van de schouw enigszins openen, ze vasthaken tussen het bovenstuk van de schouw en de wand en ze

weer zo ver mogelijk sluiten.

• Bevestig het onderstuk aan de zijkanten aan de wasemkap met

2 van de bijgeleverde schroeven 12c.

35

Page 36

NL

3

GEBRUIK

Ó ingedrukt te houden.

T2 T3 T4

S1

L T1

Bedieningspaneel

De wasemkap kan rechtstreeks ingeschakeld worden op de gewenste snelheid, door de desbetreffende toets

in te drukken zonder eerst de toets 0/1 motor te bedienen.

TOETS LED FUNCTIES

L 0/1 Licht Schakelt de verlichting aan en uit.

T1 0/1 Motor brandt Eerste snelheid.

T2 Snelheid brandt Tweede snelheid.

T3 Snelheid brandt Derde snelheid.

T4 Snelheid permanent Maximum snelheid.

knipperend Intensieve snelheid.

S1 Led permanent

knipperend

Schakelt de wasemkap uit als hij ongeveer 2” ingedrukt wordt.

Geschikt om de sterkste kookdampen af te voeren. Wordt

geactiveerd door de toets ongeveer 2

Wordt 10 minuten nadat hij in werking getreden is automatisch uitgeschakeld. Kan met de hand worden uitgeschakeld

door een willekeurige andere toets in te drukken.

Signaleert het alarm Verzadiging metalen vetfilters, hetgeen

wil zeggen dat deze moeten worden afgewassen. Het alarm

wordt na 100 effectieve bedrijfsuren van de wasemkap geactiveerd. (Reset zie parag. Onderhoud)

Signaleert, wanneer hij geactiveerd wordt, het alarm Verzadiging actief koolstoffilter, hetgeen wil zeggen dat het moet

worden vervangen; ook moeten de metalen vetfilters worden

afgewassen. Het alarm Verzadiging actief koolstoffilter

wordt na 200 effectieve bedrijfsuren van de wasemkap geactiveerd. (Activering en Reset zie parag. Onderhoud)

36

Page 37

NL

3

ONDERHOUD

AFSTANDSBEDIENING (OPTIE)

Dit apparaat kan met behulp van een afstandsbediening worden

bestuurd. Deze werkt op alkaline zinkkoolstof batterijen van 1,5

V van het standaardtype LR03-AAA.

• Bewaar de afstandsbediening niet in de buurt van warmtebronnen.

• De batterijen mogen na gebruik niet in het milieu terechtkomen, gooi ze in de hiervoor bestemde afvalbakken.

Vetfilters

REINIGING VAN DE ZELFDRAGENDE METALEN VETFILTERS

Reset van het alarmsignaal

• Schakel de verlichting en de afzuigmotor uit.

• Houd de toets T3 tenminste 3 seconden ingedrukt, tot de led’s

gaan knipperen ter bevestiging van de reset.

Schoonmaken filters

• De filters kunnen in de afwasmachine gewassen worden en

moeten gereinigd worden wanneer de led S1 gaat branden of

hooguit eens in de 2 maanden dat het filter gebruikt wordt.

• Verwijder de filters één voor één door ze naar de achterkant

van de groep te duwen en ze tegelijkertijd omlaag te trekken.

• Was de filters en vermijd hierbij ze te buigen, en laat ze drogen

alvorens ze terug te plaatsen.

• Plaats de vetfilters terug en let er hierbij op dat de handgreep

zichtbaar blijft.

37

Page 38

NL

3

Geurfilter (filterversie)

• Het filter kan niet gewassen en niet geregenereerd worden en moet worden vervangen wanneer de led S1 knippert o f minstens eenmaal in de 4 maanden. De alarmsignalering is alleen

actief wanneer de afzuigmotor wordt gebruikt.

Activering van het alarmsignaal

• Bij de afzuigkappen met luchtcirculatie moet het alarmsignaal ten teken dat de filters verzadigd zijn geactiveerd worden op het moment van de installatie of daarna.Schakel de lampen

en de zuigmotor uit.

• Sluit de afzuigkap van het elektriciteitsnet af door de 2-polige schakelaar tussen de netvoeding met behulp van de hoofdschakelaar uit te schakelen.

• Sluit de afzuigkap weer aan door de toets T1 ingedrukt te houden.

• Laat de toets los. Alle vijf leds branden nu voortdurend.

• Druk binnen 3 seconden op de toets T1 totdat de leds T1 en T4 gaan branden ter bevestiging:

2 maal knipperen Led - Alarm actief koolstof-geurfilter verzadigd GEACTIVEERD

1 maal knipperen Led - Alarm actief koolstof-geurfilter verzadigd GEDEACTIVEERD

Vervanging filter met actieve koolstof

Reset van het alarmsignaal

• Schakel de verlichting en de afzuigmotor uit.

• Houd de toets T3 tenminste 3 seconden ingedrukt, tot de led’s

gaan knipperen ter bevestiging van de reset.

Vervanging Filter

• Verwijder de metalen vetfilters.

• Verwijder het verzadigde geurfilter met actieve koolstof door

de bevestigingen los te maken.

• Monteer het nieuwe filter door het op zijn plaats vast te drukken.

• Plaats de metalen vetfilters terug.

Beleuchtung

AUSWECHSELN DER LAMPEN

Halogenlampe 20 W

• Die mittels Eindrücken befestigte Glashalterung aus Metall

durch Anheben der Zwinge entfernen und die Halterung dabei

mit einer Hand stützen.

• Die Lampe aus der Halterung nehmen.

• Die Lampe durch eine gleichwertige ersetzen und bei der Remontage darauf achten, daß die beiden Steckerstifte vorschriftsmäßig in die Lampenfassung eingeführt werden.

• Die Glashalterung wieder eindrücken.

38

Page 39

DK

3

RÅD OG ANVISNINGER

650 mm min.

INSTALLATION

• Producenten kan ikke holdes ansvarlig for eventuelle skader, der

skyldes ukorrekt eller forkert installation.

• Den mindst tilladelige sikkerhedsafstand mellem komfurets top og

emhættens underside er 650 mm.

• Kontrollér, at lysnetspændingen er den samme som den spænding,

der er angivet mærkepladen, der sidder på inde i emhætten.

• For Klasse I apparater skal det også kontrolleres, at elforsyningen er

forsynet med jord.

• Emhætten kobles til aftrækskanalen ved hjælp af et rør med en min.diameter på 120 mm. Afstanden fra emhætten til kanalen skal være

så kort som mulig.

• Emhætten må ikke tilsluttes en kanal, der fører forbrændingsgasser

ud i det fri (oliefyr, brændeovne etc.).

• Hvis emhætten skal anvendes i forbindelse med ikke-elektriske apparater (f.eks. gaskomfur, gaskogeblus), skal det sikres, at lufttilgangen

til rummet er tilstrækkelig, så aftræksgasserne ikke slår tilbage. Køkkenet skal have en åbning, der har direkte forbindelse til det fri, så der

er sikret en tilstrækkelig mængde ren luft.

ANVENDELSE

• Emhætten er udelukkende beregnet til at fjerne em og lugte i køkkener i private husholdninger.

• Emhætten må kun anvendes til det formål, hvortil den er konstrueret.

• Der må ikke forekomme høj åben ild under emhætten, mens den anvendes.

• Justér brænderen, så flammerne er rettet direkte mod bunden af panden/gryden – de må ikke nå ud over kanten af bunden.

• Frituregryder skal under brug holdes under konstant opsyn: kogende

varm olie kan sprøjte ind i flammerne.

• Emhætten må ikke anvendes af børn og personer, som ikke ved,

hvordan den betjenes.

• Apparatet er ikke beregnet til at skulle anvendes af mindre børn eller

svækkede personer uden opsyn.

• Mindre børn skal holdes under opsyn for at sikre, at de ikke leger med

apparatet.

VEDLIGEHOLDELSE

• Inden apparatet skal vedligeholdes eller rengøres, skal der slukkes for

det eller stikket skal tages ud af stikkontakten.

• Rengør og/eller udskift filtrene iht. det angivne tidinterval.

• Rengør emhætten ved hjælp af en fugtig klud og et neutralt flydende

rengøringsmiddel.

39

Page 40

DK

4

11

12a

2.1

2.2

2

12c

12a

7.2.1 11

14.1

15

1

APPARATBESKRIVELSE

Komponenter

Ref. Kvantum Produktkomponenter

1 1 Emhætte, komplet med Styring, lys, blæser, filtre

2 1 Teleskopisk skorsten indeholdende:

2.1 1 Øverste sektion

2.2 1 Nederste sektion

9 1 Reduktionsflange ø 150-120 mm

14.1 2 Tilslutningsforlænger til luftudtag

15 1 Tilslutning til luftudtag

Ref. Kvantum Installationskomponenter

7.2.1 2 Fastgørelsesbøjler til øverste skorstenssektion

11 6 Vægstikkonttakter

12a 6 Skruer 4,2 x 44,4

12c 6 Skruer 2,9 x 9,5

Kvantum Dokumentation

1 Brugsanvisning

Dimensioner

40

Page 41

DK

4

INSTALLATION

11

12a

306

X

116

1÷2

116

650 min.

7.2.1

Gennemboring af væg og fastspænding af beslag

Optegn på væggen:

• en lodret linie helt op til loftet eller op til øverste kant fra midten af zonen, hvor emhætten

skal monteres, samt

• en vandret linie i mindst 650 mm’s højde over komfuret.

• Anbring, som vist på tegningen, beslaget 7.2.1 i en afstand af 1-2 mm fra loftet eller den

øverste kant, idet dets midte (hak) anbringes på den lodrette referencelinie.

• Afmærk midten af beslagets huller.

• Anbring, som vist, beslaget 7.2.1 i en afstand af X mm under det første beslag (X = højden

af den medleverede øvre skorsten), idet dets midte (hak) anbringes på den lodrette referencelinie.

• Afmærk midten af beslagets huller.

• Lav, som vist på tegningen, et referencepunkt 116 mm fra den lodrette referencelinie og 306

mm over den vandrette referencelinie.

• Gentag denne operation på den modsatte side.

• Bor 8 mm huller i de angivne punkter.

• Anbring rawlplugs 11 i hullerne.

• Spænd beslagene fast med de medleverede skruer 12a (4,2 x 44,4).

• Skru de to medleverede skruer 12a (4,2 x 44,4) i ophængningshullerne til emhætten, idet

man lader en afstand på 5-6 mm være mellem væggen og skruehovederne.

41

Page 42

DK

4

Montering af emhætte

12a

Vr

9

ø 120ø 150

14.115

• Inden man hænger emhætten op, skal man stramme

de to skruer Vr, som sidder i hættens ophængningspunkter.

• Hæng emhætten op på de forberedte skruer 12a.

• Stram ophængningsskruerne 12a helt til.

• Ved at dreje på skruerne Vr nivelleres emhætten.

Tilslutninger

AFSKÆRMET UDGAVE LUFTAFTRÆKSYSTEM

Når den afskærmede version installeres, skal emhætten

tilsluttes skorstenen ved hjælp af enten et flex- eller et

stift rør ø 150 eller 120 mm. Det beslutter installatøren

• For at installere en ø 120 mm tilslutning til luftaftræk

skal reduktionsflangen 9 sættes på emhættens udtræk.

• Fastgør røret på plads ved hjælp af tilstrækkeligt med

rørholdere (ikke medleveret).

• Fjern alle aktive kulfiltre.

RECIRKULATIONS VERSION LUFTAFTRÆK

• Skub pasforbindelsen 15 oven på emhættens udtag.

• Isæt forbindelses forlængerstykkerne fra siden 14.1 i

forbindelse 15.

• Sørg for at aftrækket på forlængerstykkerne 14.1 er

horisontalt og vertikalt ensrettet med skorstensaftrækkene. Hvis det ikke er tilfældet, skal du justere

placeringen ved enten at vende forbindelse forlængerstykkerne 14.1 og så samle dem igen som beskrevet tidligere.

• Sørg for at de aktive kulfiltre er blevet sat ind.

42

Page 43

DK

4

TILSLUTNING TIL STRØMFORSYNING

12c

2.1

2.2

2

7.2.1

12c

• Tilslut emhætten til elnettet, idet der indsættes en topolet afbryder med en kontaktafstand på mindst 3 mm.

• Fjern fedtfiltrene (se afsnittet ”Vedligeholdelse”) og kontroller,

at eltilslutningens kabelklemme er korrekt indsat i udsugningsgruppens stik.

Montering af aftræk

Øverste del af aftrækskanalen

• Udvid let de to sider på den øverste aftrækskanalen og hægt

dem bag ved bøjlerne 7.2.1, idet der sørges for, at de sidder

godt.

• Fastgør de to sider til bøjlerne ved hjælp af de 4 skruer 12c (2,9

x 9,5), der følger med.

Sænk aftrækskanalen

• Udvid let de to sider på aftrækket og hægt dem mellem det

øverste aftræk og væggen, idet der skal sørges for, at de sidder

godt.

• Fastgør den nederste del lateralt til emhætten ved hjælp af de 2

skruer 12c (2,9 x 9,5), der medfølger.

43

Page 44

DK

4

BRUG

T2 T3 T4

S1

L T1

Betjeningspanel

Emhætten kan tændes direkte på den ønskede hastighed ved at trykke på den relative knap,

uden at det er nødvendigt at trykke på motorknappen 0/1.

KNAP LAMPE FUNKTIONER

L 0/1 Lys Tænder og slukker for belysningen.

T1 0/1 Motor Tændt Første hastighed.

Slukker for emhætten, hvis den trykkes ind i ca. 1”.

T2 Hastighed Tændt Anden hastighed

T3 Hastighed Tændt Tredie hastighed

T4 Hastighed Konstant Højeste hastighed

lysende

Blinker Intensiv hastighed.

Velegnet ved meget kraftig mados og damp. Denne fun-

ktion aktiveres ved at trykke på knappen i ca. 2” og slukker automatisk efter 10 minutters forløb. Funktionen kan

inaktiveres manuelt ved tryk på en hvilken som helst

knap.

S1 Lampe Konstant Allarmsignal der angiver, at fedtfiltrene i metal er

lysende snavsede og skal rengøres. Allarmen træder i funktion

efter 100 effektive arbejdstimer af emhætten. (Reset, se

afsnittet ”Vedligeholdelse”).

Blinker Allarmsignal som, hvis aktiveret, angiver, at det lugtab-

sorberende kulfilter er opbrugt og skal udskiftes; fedtfiltrene i metal skal også rengøres. Allarmen for opbrugt

kulfilter træder i funktion efter 200 effektive arbejdstimer

af emhætten. (Aktivering og reset, se afsnittet ”Vedligeholdelse”).

44

Page 45

DK

4

VEDLIGEHOLDELSE

FJERNBETJENER (EKSTRAUDSTYR)

Denne emhætte kan styres ved hjælp af en fjernbetjener, der fungerer med 1,5V alkaliske carbon-zink batterier af standardtypen

LR03-AAA.

• Fjernbetjeneren må ikke anbringes i nærheden af varmekilder.

• Batterierne må ikke bortskaffes i naturen, men skal lægges i de

specielle beholdere.

Fedtfiltre

RENGØRING AF SELVBÆRENDE FEDTFILTRE AF METAL

Reset af alarmsignal

• Sluk for belysning og udsugningsmotor.

• Tryk på knappen T3 i mindst 3 sekunder, indtil lamperne begynder at blinke.

Rengøring af filtre

• Filtrene kan vaskes i opvaskemaskine og skal rengøres ca. hver

anden måned ved normalt brug eller oftere, hvis emhætten

bruges meget.

• Fjern filtrene ét af gangen ved at skubbe dem bagud, mens man

samtidig trækker nedad.

• Vask filtrene uden at bøje dem og lad dem tørre helt, inden de

monteres igen.

• Når filtrene monteres igen, skal man sørge for, at håndtaget

vender den synlige del fremad.

45

Page 46

DK

4

Lugtabsorberende filter (Recirkulation gennem filter)

Dette filter kan ikke vaskes og bruges igen, men skal udskiftes, når lampen S1 blinker eller

mindst hver 4. måned. Allarmsignalet træder kun i funktion, når udsugningsmotoren er aktiveret.

Aktivering af alarmsignalet

• For versionen af emhætter med recirkulation gennem filter kan alarmsignaleringen af opbrugte filtre aktiveres ved installationen eller senere.

• Sluk for belysning og udsugningsmotor.

• Slå emhætten fra strømforsyningen ved hjælp af den topolede afbryder på elnettet eller hovedafbryderen.

• Genopret eltilslutningen mens knappen T1 holdes trykket ind.

• Slip knappen og alle fem lamper tænder med konstant lys.

• Inden 3 sekunder skal man igen trykke på knap T1, indtil lamperne T1 og T4 begynder at

blinke:

- 2 blink - alarm for opbrugt lugtabsorberende kulfilter er AKTIVERET

- 1 blink - alarm for opbrugt lugtabsorberende kulfilter er INAKTIVERET

UDSKIFTNING AF LUGTABSORBERENDE KULFILTER

Reset af alarmsignal

• Sluk for belysning og udsugningsmotor.

• Tryk på knappen T3 i mindst 3 sekunder, indtil lamperne begynder at blinke.

Udskiftning af filter

• Fjern fedtfiltrene af metal.

• Tag det opbrugte lugtabsorberende kulfilter ud af de specielle

holdere.

• Montér det nye filter ved at sætte det fast i holderne.

• Montér derefter fedtfiltrene af metal.

Lys

UDSKIFTNING AF LYS

20 W halogenlys.

• Tag lampedækslet med snaplås af ved at løfte det fra neden

under metalringen, idet du støtter med en hånd.

• Tag halogenlampen af lampeholderen ved at trække forsigtigt.

• Udskift lampen med en ny af samme type, idet du sørger for, at

du isætter de to tappe korrekt i hylstrene på lampeholderen.

• Sæt lampedækslet med snaplås tilbage på plads.

46

Page 47

Page 48

73/23/CEE

Dir. 89/336/CEE

93/68/CEE

The symbol on the product or on its packaging indicates that this product may not be treated as household waste. Instead it shall

be handed over to the applicable collection point for the recycling of electrical and electronic equipment. By ensuring this product is

disposed of correctly, you will help prevent potential negative consequences for the environment and human health, which could otherwise be caused by inappropriate waste handling of this product. For more detailed information about recycling of this product, please

contact your local city office, your household waste disposal service or the shop where you purchased the product.

Le symbole sur le produit ou son emballage indique que ce produit ne peut être traité comme déchet ménager. Il doit plutôt être

remis au point de ramassage concerné, se chargeant du recyclage du matériel électrique et électronique. En vous assurant que ce

produit est éliminé correctement, vous favorisez la prévention des conséquences négatives pour l’environnement et la santé humaine

qui, sinon, seraient le résultat d’un traitement inapproprié des déchets de ce produit. Pour obtenir plus de détails sur le recyclage de ce

produit, veuillez prendre contact avec le bureau municipal de votre région, votre service d’élimination des déchets ménagers ou le

magasin où vous avez acheté le produit.

Das Symbol auf dem Produkt oder seiner Verpackung weist darauf hin, dass dieses Produkt nicht als normaler Haushaltsabfall

zu behandeln ist, sondern an einem Sammelpunkt für das Recycling von elektrischen und elektronischen Geräten abgegeben werden

muss. Durch Ihren Beitrag zum korrekten Entsorgen dieses Produkts schützen Sie die Umwelt und die Gesundheit Ihrer Mitmenschen.

Umwelt und Gesundheit werden durch falsches Entsorgen gefährdet. Weitere Informationen über das Recycling dieses Produkts

erhalten Sie von Ihrem Rathaus, Ihrer Müllabfuhr oder dem Geschäft, in dem Sie das Produkt gekauft haben.

Het symbool op het product of op de verpakking wijst erop dat dit product niet als huishoudafval mag worden behandeld. Het

moet echter naar een plaats worden gebracht waar elektrische en elektronische apparatuur wordt gerecycled. Als u ervoor zorgt dat dit

product op de correcte manier wordt verwijderd, voorkomt u mogelijk voor mens en milieu negatieve gevolgen die zich zouden kunnen

voordoen in geval van verkeerde afvalbehandeling. Voor meer details in verband met het recyclen van dit product, neemt u het best

contact op met de gemeentelijke instanties, het bedrijf of de dienst belast met de verwijdering van huishoudafval of de winkel waar u

het product hebt gekocht.

Symbolet på produktet eller på pakken angiver, at dette produkt ikke må behandles som husholdningsaffald. Det skal i stedet

overgives til en affaldsstation for behandling af elektrisk og elektronisk udstyr. Ved at sørge for at dette produkt bliver bortskaffet på

den rette måde, hjælper du med til at forebygge eventuelle negative påvirkninger af miljøet og af personers helbred, der ellers kunne

forårsages af forkert bortskaffelse af dette produkt. Kontakt det lokale kommunekontor, affaldsselskab eller den forretning, hvor produkt

er købt, for yderligere oplysninger om genanvendelse af dette produkt.

436002727_ver2

www.blomberginternational.com

Loading...

Loading...