Page 1

KLT-40GS

SHORT HEIGHT GAS TILTING KETTLE

INSTALLATION - OPERATION - MAINTENANCE

44 Lakeside Avenue, Burlington, Vermont 05401 USA

Telephone: (802) 658-6600 Fax: (802) 864-0183

www.blodgett PN S00157 Rev A (4/15

© 2015 - G.S. Blodgett Corporation

Page 2

Your Service Agency’s Address:

Model

Serial number

Kettle installed by

Installation checked by

Page 3

IMPORTANT

TABLE OF CONTENTS

WARNING: Improper installation, adjustment, alternation,

service or maintenance can

cause property damage, injury

or death. Read the installation,

operation and maintenance instructions thoroughly before installing or servicing this equipment.

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THE

USER SMELLS GAS MUST BE

POSTED IN A PROMINENT LOCATION. This information may be

obtained by contacting your local

gas supplier.

FOR YOUR SAFETY

Do not store or use gasoline or

other ammable vapors or liquids

in the vicinity of this or any other

appliance.

Do not obstruct the ow of combustion and ventilation air. Keep

the appliance area free and clear

from combustibles. Adequate

clearances must be maintained for

servicing and proper operation.

INSTALLATION

Service Connections ...................................................2

Installation Information .................................................3

Installation Codes and Standards ....................................3

Exhaust Fans and Canopies ........................................3

All Exhaust Fan ....................................................3

Clearances ........................................................3

Kettle Installation & Utility Connection ....................................4

Kettle Installation ...................................................4

Gas Connection ....................................................4

Water Connection ..................................................5

Electrical Connection ...............................................5

Performance Check ................................................5

OPERATION

Safety & Gas Control Information ........................................6

Kettle Controls .........................................................7

Kettle Operation .......................................................8

MAINTENANCE

Cleaning Instructions ...................................................9

Kettle Cleaning .....................................................9

Draw Off Valve Cleaning ............................................9

What to do if Surface Rust Appears ................................ 10

Stainless Steel .................................................. 10

Control Panel .................................................... 10

Preventative Maintenance .............................................11

The information contained in this

manual is important for the proper installation, use, and maintenance of this kettle. Adherence to

these procedures and instructions

will result in satisfactory baking

results and long, trouble free

service. Please read this manual

carefully and retain it for future reference.

ERRORS: Descriptive, typographic or pictorial errors are subject to

correction. Specications are subject to change without notice.

Page 4

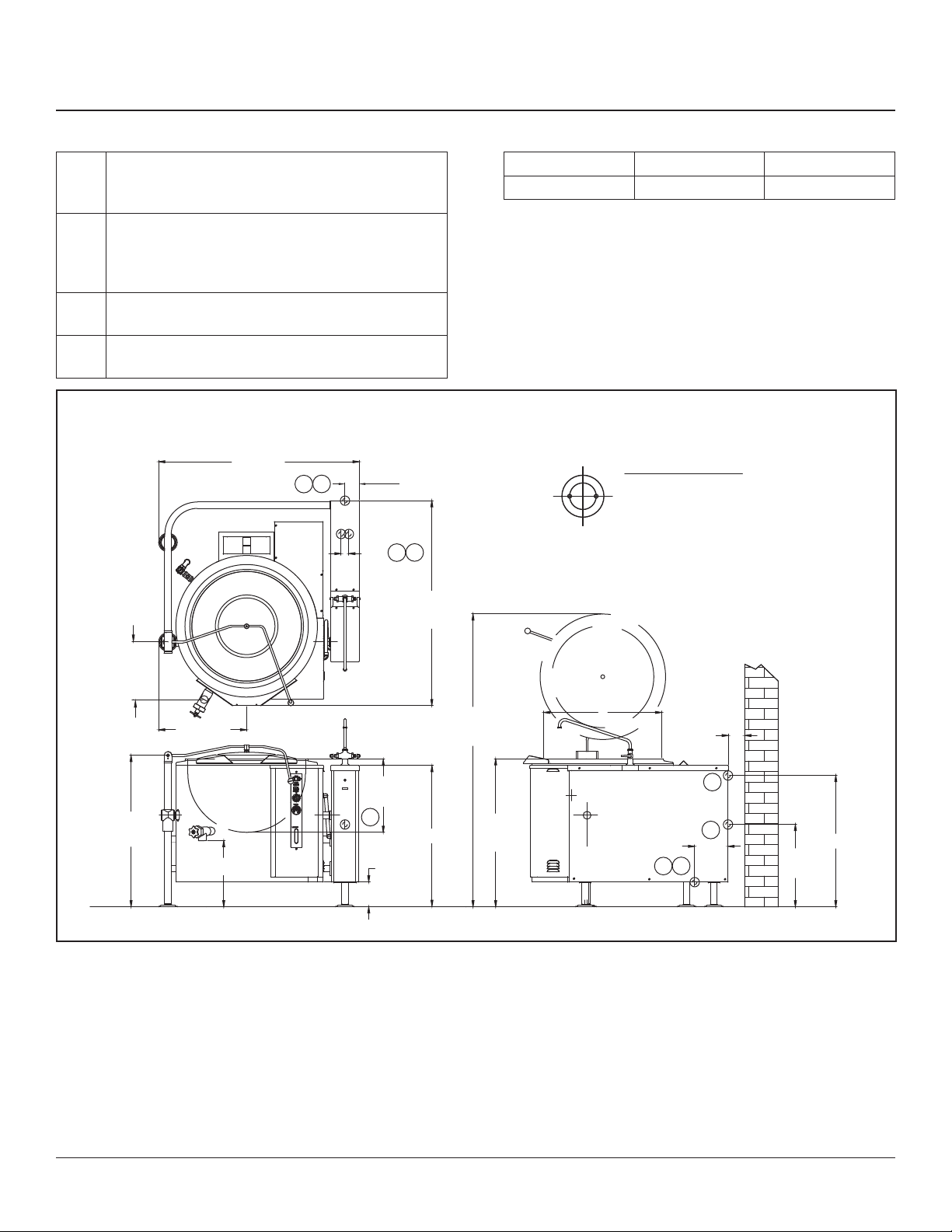

Service Connections

SERVICE CONNECTIONS

G Gas Connection - Supply gas through 3/4” pipe . A gas

shut-off valve must be installed in supply piping convenient

and adjacent to appliance.

EC Electrical Connection - Unless other wise specied,

Field Wire Electrical Connection to be 120 Volts, 60 Hertz

single phase with grounding wire. Unit furnished with 8’

cord and 3 prong plug. Total max. amps 4.0.

HW Hot Water Connection - 3/8” tubing to faucet (OP-

TIONAL)

CW Hot Water Connection - 3/8” tubing to faucet (OP-

TIONAL)

DIMENSIONS ARE IN INCHES [MM]

51 [1295]

2 [51]

3.63 [92]

H

EC

G

INSTALLATION CLEARANCE

Left Side Right Side Rear

0” [0mm] 0” [0mm] 4” [102mm]

BTU/Hour: 125,000

kW/Hour: 36.63

Gas Supply (Supply Pipe Pressure W.C.)

Natural 6”-14” (152-356mm)

Propane 11”-14” (279-356mm)

REAR FLANGED FOOT DETAIL

2 EQUALLY SPACED

Ø7/16" [11mm] HOLES

ON 2.5" [63mm] B.C.

C

* Use on non-combustible floors only.

* Shown with option faucet, cover and draw-off.

14.75

[375]

38.5

[978]

22.5 [572]

17.25 [438]

52.25

[1327]

74.5

[1892]

A

4 [102]

MINIMUM

POWER

ON

COOKING

LOW WATER

COOK TEMP.

OFF

10

9

1

8

2

7

3

6

4

5

PRESSURE

40

60

20

300

200

400

316 SS

TUBE AND CONNECTION

100

500

80

600

0

VENT AIR

kPa

psi

100

WATER LEVEL

18.75

[476]

G

36 [914]

37.75

[959]

8.5 [216]

6.38

[162]

EC

G

C

H

33.5 [891]

21

[533]

Figure 1

INSTALLATION

2

Page 5

Installation Information

INSTALLATION CODES AND STANDARDS

Installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas Code,

ANSI Z223.1/NFPA 54, or the Natural Gas and Propane

Installation Code, CSA B149.1, as applicable.

1. The appliance and its individual shut off valve must

be disconnected from the gas supply piping system

during any pressure testing of that system at pressures in excess of ½ psi (3.5 kPa).

2. The appliance must be isolated from the gas supply

piping system by closing its individual manual shut off

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than

½ psi (3.5 kPa).

Electrical grounding must be provided in accordance with

local codes, or in the absence of local codes, with the

National Electrical Code, ANSI/NFPA 70, or the Canadian

Electrical Code, CSA C22.2, as applicable.

The electrical diagram is located on the inside of side

panel of left hand console.

EXHAUST FANS AND CANOPIES

Canopies are set over ranges, ovens and kettles for ventilation purposes. It is recommended that a canopy extend

6 inches past appliance and be located 7.5 feet from the

oor. Filters should be installed at an angle of 45 degrees

or more with the horizontal. This position prevents dripping of grease and facilitates collecting the run-off grease

in a drip pan, usually installed with the lter. A strong exhaust fan tends to create a vacuum in the room and may

interfere with burner performance or may extinguish pilot

ames. Makeup air openings approximately equal to the

fan area will relieve such vacuum. In case of unsatisfactory performance on any appliance, check operation with

exhaust fan in the “OFF” position.

CLEARANCES

Adequate clearance must be provided in aisle and at the

side and back. Adequate clearances for air openings into

the combustion chamber must be provided, as well as for

serviceability.

• Sides - 0 inches

• Back - 4 inches at ue box

• Floors - Non-combustible

All units must be installed in such a manner that the ow

of combustion and ventilation air are not obstructed. Pro-

visions for an adequate air supply must also be provided.

Do not obstruct side of the unit, as combustion air enters

through this area.

Information on the construction and installation of ventilating hoods may be obtained from the standard for “Vapor

Removal from Cooking Equipment”, NFPA No. 96 (latest

edition), available from the National Fire Protection Association, Batterymarch Park, Quincy, MA, USA, 02269.

ALL EXHAUST FAN

he exhaust fan should be installed at least two feet above

the vent opening at the top of the unit.

3

INSTALLATION

Page 6

Kettle Installation & Utility Connection

KETTLE INSTALLATION

1. Uncrate carefully. Report any hidden freight damage

to the freight company immediately.

2. The pressure relief valve is located at the right rear of

the unit. This area should be kept clear and should

not be in an area where operators will normally stand.

The elbow on the relief valve should be turned toward

the oor. A maximum 3 foot, 3/4” diameter pipe may

be used to extend to the oor, but must not be piped

directly to a drain. It must vent to the atmosphere.

3. Set the unit in place. Be certain to maintain minimum

clearances as stated above.

4. To level the unit use a spirit level in all directions on

the top of the kettle (lid up). Adjust the bottom foot on

each leg to overcome an uneven oor.

5. Mark hole locations on oor through anchoring holes

provided in anged adjustable feet.

6. Remove appliance and drill holes in locations marked

on oor and insert proper anchoring devices.

7. Set unit back in position and re-level left to right and

front to back.

An adequate gas supply is imperative. Undersized or low

pressure lines will restrict the volume of gas required for

satisfactory performance. A steady pressure, minimum 6”

W.C. for natural gas and minimum 11” W.C. for propane

gas, is recommended. With all units operating simultaneously, the manifold pressure on all units should not show

any appreciable drop. Fluctuations of more than 25%

on natural gas, and 10% on propane gas, will create pilot problems and affect burner operating characteristics.

Contact your gas company for correct supply line sizes.

Purge the supply line to clean out any dust, dirt, or other

foreign matter before connecting the line to the unit. It is

recommended that an individual manual shut off valve be

installed in the gas supply line to the unit. Use pipe joint

compound which is suitable for use with LP gas on all

threaded connections. Test pipe connections thoroughly

for gas leaks.

WARNING

All connections must be checked for leaks,

after the unit has been put in operation. Use

soapy water only for testing on all gases.

Never use an open ame to check for gas

leaks.

8. Bolt and anchor appliances securely to the oor.

9. Seal bolts and anged feet with silastic or equivalent

compound.

10. Appliance location must allow air supply to unit and

obstruction free clearance for air opening into the

combustion chamber.

11. Make service connections as indicated.

12. Check the pressure gauge on the front panel before

operating. If the pressure gauge does not indicate

green vacuum zone (below 0 psi), see “Re-establishing Vacuum” section under SERVICE, after completing installation instructions.

GAS CONNECTION

The serial plate on the lower right side of the unit indicates

the type of gas your unit is equipped to burn. Do NOT

connect to any other gas type.

A 3/4” NPT line is provided at the rear for the connection.

Each unit is equipped with an internal pressure regulator

which is set for 3.5” W.C. manifold pressure for natural

gas and 4.0” W.C. for propane gas. Use 1/8” pipe tap on

the downstream side of the combination valve for checking pressure.

NOTICE

If applicable, the vent line from the gas appliance pressure regulator shall be installed to

the outdoors in accordance with local codes

or, in the absence of local codes, with the National Fuel Gas Code, ANSI Z223.1/NFPA 54, or

the Natural Gas and Propane Installation Code

CSA B149.1, as applicable.

NOTICE

If this equipment is being installed at over

2,000 feet altitude and was not so specied on

order, contact service department. Failure to

install with proper orice sizing may void the

warranty.

INSTALLATION

4

Page 7

Kettle Installation & Utility Connection

WATER CONNECTION

On units equipped with an optional water ll valve connect

a water line (minimum 1/4”) to the valve with a 1/4” NPT

female tting. Units with dual (hot and cold) valves must

have the hot water line connected to side with the hot water valve (red) and cold water line to the cold water valve

(blue). Plastic or rubber hose is not recommended, as it

may melt against the hot kettle side.

ELECTRICAL CONNECTION

WARNING

Do not connect the kettle to the electrical supply until after the gas connection has been

made.

1. 120 VAC - 60 Hz - Single Phase

WARNING

ELECTRICAL GROUNDING INSTRUCTIONS

This appliance is equipped with a three-prong

(grounding) plug for your protection against

shock hazard and should be plugged directly

into a properly grounded three-prong receptacle. Do not cut or remove the grounding

prong from this plug. (120V units only).

Units with this electrical rating are factory supplied with a

three-wired cord and three-prong plug which ts any standard 120V, three-prong grounded receptacle. A separate

15 amp supply is needed for each unit.

PERFORMANCE CHECK

The following items should be checked before or within

the rst 30 days of operation by a qualied service technician.

1. Verify correct gas type against rating plate on unit.

2. Verify correct voltage, cycle and phase against rating

plate on unit.

3. Gas pressure.

4. Internal gas connections.

5. Internal electrical connections.

6. Burners - adjustment and ignition.

7. Thermostat - cycle for operation check.

8. Gas supply valve - check for operation.

9. Check hinge and lid assembly.

10. Draw-off valve - check operation.

11. Advise user on cleaning procedure.

2. 208/240 VAC - 60 Hz - Single and Three Phase

Units with this electrical rating are factory equipped with

a transformer. To connect supply wires, remove cover

from right console. Route supply wires and ground wire

through the hole in the console with a strain relief tting. Connect wires to the terminal block in the rear of

the right console. Connect ground wire to lug. Replace

cover. Three-phase units are wired as above, using only

two supply wires. The third supply wire is not connected

and must be properly terminated.

3. 220 VAC - 50 Hz - Single Phase

Units equipped with this voltage ratings should be wired

exactly as in (2.) above.

5

INSTALLATION

Page 8

Safety & Gas Control Information

SAFETY INFORMATION

Contact the factory, the factory representative or a local

service company to perform maintenance and repairs

should the appliance malfunction.

CAUTION

If you smell gas during the lighting procedure,

immediately shut off the gas supply until the

leak has been corrected.

WARNING

In the event of main burner ignition failure, a

5 minute purge period must be observed prior

to re-establishing ignition source.

WARNING

In the event you smell gas, shut down equipment at the main shut off valve and contact

the local gas company or gas supplier for

service.

GAS CONTROL INSTRUCTIONS

The units do not require “lighting” the pilot with a match.

Lighting

NOTE: Unit is shipped with gas combination valve turned

“on”.

1. Open manual gas shut off valve.

Daily Shutdown

1. Turn power switch “OFF.”

2. Turn thermostat “OFF.”

Complete Shutdown

1. Turn power switch “OFF.”

2. Turn thermostat “OFF”.

3. Turn power supply to unit “OFF”.

4. Remove front access panel on left side and turn dial

on combination valve to “OFF”.

5. Close manual gas shut off valve.

2. Set thermostat to OFF, and kettle in fully upright position, turn power switch ON.

3. Set thermostat to maximum, initiating a 30 second

pre-purge. Red “COOKING” pilot will come on, and

after 30 seconds, the green “IGNITION” pilot will

come on, lighting the main burners.

If after 36 seconds the burner fails to ignite or the

“ignition light goes out, the system goes into Safety

Lockout. De-energize the system by setting the ther-

mostat to “OFF” for ve minutes and try again.

4. Set the thermostat to desired temperature setting.

When temperature setting has been reached, the “IGNITION” pilot will go off, turning off the burner. The

unit will then cycle on and off to maintain set temperature.

NOTE: When the kettle is tilted a safety switch will au-

tomatically turn off gas supply. The kettle will not

operate once it has been tilted.

OPERATION

6

Page 9

Kettle Controls

POWER SWITCH

This switch turns the main power to the unit on and off. It

must be turned on to heat the kettle. It should be turned

off when the kettle will not be in use for long periods.

(GREED) IGNITION LIGHT

This light is on whenever the main burner gas is on.

(RED) COOKING LIGHT

This light is on when the thermostat is calling for heat.

(AMBER) LOW WATER LIGHT

All kettles are supplied with sufcient distilled water in

pressurized jacket. If at any time the water level falls be-

low that required for proper operation, the kettle will not

heat and this light will come on. See “Adding Water” in

Service section.

THERMOSTAT

The thermostat selects the desired internal kettle operating temperature. The thermostat must be set at a desired

setting in order for the burner to ignite.

For Reference:

PRESSURE GAUGE

The pressure gauge indicates the internal operating pressure of the kettle. When cold, the gauge should point to

the green vacuum zone. If it does not, refer to “Re-establishing Vacuum” section. Under normal operation with the

kettle empty (thermostat set at 10 or 275°F) the pressure

should reach 30 psi. When loaded the pressure may be

considerably less.

SIGHT GLASS

The sight glass indicates the minimum and maximum water level within the kettle. If water level falls below minimum level more distilled water should be added. See

“Adding Water” in Service section.

PRESSURE RELIEF VALVE

The pressure relief valve is a safety device which prevents the internal kettle pressure from exceeding 50 psi.

It should never be tampered with.

DIAL SETTING °C °F

1 15 60

2 27 81

3 40 104

4 53 127

5 67 153

6 81 178

7 95 203

8 108 226

9 122 252

10 135 275

7

MAINTENANCE

Page 10

Kettle Operation

DAILY OPERATION

Daily operation should consist of turning on the power

switch and setting thermostat for the desired temperature.

It is recommended the kettle be preheated prior to use.

Milk or egg based products should be placed in the kettle

before heating however, to prevent sticking. The kettle is

preheated when the cooking light goes off the rst time.

At the end of the day, or if the kettle will not be used for

some time, shut the unit down by turning the power switch

to “OFF”.

Clean as required or on a daily basis. See “CLEANING

INSTRUCTIONS” section.

END USE TIPS

• For easier cleaning add cold water to the kettle immediately after removing contents.

• When preparing foods containing vinegar or tomatoes, or those which have a high salt content, clean

the kettle immediately after using to prevent pitting.

• Do not use salt to clean the kettle. This will scratch

the surface.

GAS SAVING TIPS

Use these reminders to help develop energy-saving procedures and habits. Using less natural or propane gas

saves energy as well as money.

1. Turn off when not in use.

2. Limit preheat times.

3. Use lid when possible.

4. Maintain equipment.

• If using salt water to cook shellsh, be sure to rinse

and wash the kettle thoroughly after use.

• Bring milk and egg products slowly up to temperature in a cold kettle to prevent product from adhering

to the sides. When preparing milk-based products

do not preheat the kettle.

• When planning actual cooking capacity, allow room

at top for stirring without spilling.

• When preparing puddings from a mix, place the

powder in a cold kettle, add a small amount of liquid,

and stir to form a thin paste. Turn on the kettle and

add the remainder of the liquid. Continue as per

recipe instructions.

• When browning meat, bring the kettle up to temperature before adding. This will seal the juices in the

meat.

OPERATION

8

Page 11

Cleaning Instructions

KETTLE CLEANING

WARNING

Disconnect the power supply to the appliance

before cleaning or servicing.

WARNING

Never spray water into electric controls or

components!

CAUTION

The equipment and its parts are hot. Use care

when operating, cleaning and servicing.

CAUTION

Do not use cleaning agents that are corrosive.

Your kettle should be cleaned immediately after each use

or when cooking a different product. Before cleaning,

check that the kettle has cooled enough to touch it.

1. Rinse the inside of the kettle thoroughly and drain to

remove any food particles.

2. Using a nylon brush, clean the kettle with a mild detergent and water. Never use steel wool or scouring

powder as it will scratch stainless steel. Plain steel

wool can leave small pieces of steel which can rust.

3. Rinse the inside of the kettle thoroughly with clean

water. Drain the kettle by tilting or the tangent drawoff valve, depending on model, to allow the detergent

and water solution to drain.

4. Wipe the exterior of the kettle with a clean, damp

cloth.

DRAW OFF VALVE CLEANING

1. If equipped with a tangent draw-off valve, turn the

large hex nut on the draw-off valve counterclockwise

until it is completely disengaged from the threads.

Grasp the valve knob and slowly pull out the valve

stem and disk. Do not allow the disk to come in contact with hard surfaces as it can be damaged and

cause valve leakage. Wash the valve stem, disk and

handle. Insert a nylon brush, wet with detergent and

water, into the valve body and tangent draw-off tube.

Brush vigorously.

2. Replace the valve stem assembly and turn the hex

nut until snug. Rinse the kettle with clean warm water.

3. Leave the draw-off valve open when the kettle is not

in use.

Dairy Draw Off Valve Cleaning

1. Remove the plug by rst removing the handle, then

turn the plug to line up with the pin and pull with both

hands. It is important to use both hands because the

plug is heavy.

2. Put the plug in a plastic pail that contains a mild soap

solution. A plastic pail works best, as it reduces the

possibility of nicking or scratching the plug. If the plug

gets scratched it may not seal correctly and could

leak.

3. Use a soft cloth or soft brush and clean all surfaces.

4. Using both hands remove the valve from the soap

and rinse well in another plastic pail that contains

fresh water.

5. Wash out the kettle as normal.

WARNING

If you are cleaning a valve that is assembled

to a kettle, be sure the kettle is completely

empty of any product.

6. Once the kettle is washed out, return the plug into the

body. Be sure the plug is inserted into the notch and

turned. Ensure the plug is tight and secure before

letting go of it.

If you are cleaning a body and plug assembly, remove

the plug and follow the above procedures. When nished

with the plug, follow the same instructions for washing the

body. Always use both hands when handling the plugs.

Reassemble the plug into the body and use as normal.

NOTICE

Draw-off valve has a vulcanized rubber coated

stem for better sealing. Do not over tighten.

This may cause the rubber to pull away from

stem and permanently damage it. This is not

covered under warranty.

9

MAINTENANCE

Page 12

Cleaning Instructions

WHAT TO DO IF SURFACE RUST APPEARS

Metal utensils should never be used as they will scratch

the surface of the equipment and rust may begin to form.

To remove surface accumulation of rust from the inadvertent use of such utensils, the following procedure may be

used.

CAUTION

Improper use of this procedure may damage

your appliance!

1. Use undiluted white vinegar with a non-abrasive

scouring pad (plastic) or cloth on the affected area to

remove the rust stain. The appliance should not be

heated and remain at room temperature during the

entire cleaning process.

2. If the stain resists removal, additional exposure time

with vinegar may be required, to a maximum of one

hour.

3. Thoroughly wash all of the vinegar away with fresh

clear water. Dry the surface completely and allow one

hour before using the appliance to cook.

Following daily and period maintenance procedures will

prolong the life for your equipment. Climatic conditions salt air - may require more thorough and frequent cleaning

or the life of the equipment could be adversely affected.

STAINLESS STEEL

To remove normal dirt, grease or product residue from

stainless steel, use ordinary soap and water (with or without detergent) applied with a sponge or cloth. Dry thoroughly with a clean cloth. Never use vinegar or any other

corrosive cleaner.

To remove grease and food splatters or condensed va-

pours that have baked on the equipment, apply cleanser

to a damp cloth or sponge and rub cleanser on the metal

in the direction of the polishing lines. Rubbing cleanser

as gently as possible in the direction of the polished lines

will not mar the nish of the stainless steel. NEVER RUB

WITH A CIRCULAR MOTION.

Soil and burn deposits which do not respond to the above

procedure can usually be removed by rubbing the surface

with SCOTCH-BRITE™ scouring pads or STAINLESS

scouring pads. DO NOT USE ORDINARY STEEL WOOL

as any particles left on the surface will rust and further

spoil the appearance of the nish. NEVER USE A WIRE

BRUSH, STEEL SCOURING PADS (EXCEPT STAINLESS), SCRAPER, FILE OR OTHER STEEL TOOLS.

Surfaces which are marred collect dirt more rapidly and

become more difcult to clean. Marring also increases

the possibility of corrosive attack. Renishing may then

be required.

To remove heat tint: Darkened areas sometimes appear on stainless steel surfaces where the area has been

subjected to excessive heat. These darkened areas are

caused by thickening of the protective surface of the

stainless steel and is not harmful. Heat tint can normally

be removed by the foregoing, but tint which does not respond to this procedure calls for a vigorous scouring in

the direction of the polish lines using SCOTCH-BRITE™

scouring pads or a STAINLESS scouring pad in combination with a powdered cleanser. Heat tint action may be

lessened by not applying or by reducing heat to equipment during slack periods.

All food contact surfaces must be thoroughly drained and

ushed prior to cooking in the kettle.

CONTROL PANEL

The textured control panel should be cleaned with warm

water and mild soap. Never use an abrasive cloth or steel

wool. Never use cleaning solvents with a hydrocarbon

base.

MAINTENANCE

10

Page 13

Contact the factory, the factory representative or a local

service company to perform maintenance and repairs.

WARNING

Disconnect the power supply to the appliance

before cleaning or servicing.

Daily:

1. Wash exposed cleanable areas.

Monthly:

1. Blower wheel inlet and motor air vent should be

cleansed if an accumulation of dust or lint is obvious.

Twice a Year: (minimum)

1. Have an authorized service person clean and adjust

the unit for maximum performance.

2. The unit venting system should be examined and

cleaned.

3. Grease the screw jack tilt mechanism via the lubricating nipple. Use Petro-Canada type OG-2 or equivalent.

Preventative Maintenance

Annually:

1. Have an authorized service person inspect the screw

jack assembly for wear. The screw must be replaced

immediately if the end play has reached 0.019”

[0.5mm].

11

MAINTENANCE

Loading...

Loading...