Page 1

Document Number 469420

r

®

BR series Counterweight Adjustments

Installation, Operation, and Maintenance Instructions

This manual is the property of the owner, and is required for future maintenance. Please leave it with the

owner when the job is complete.

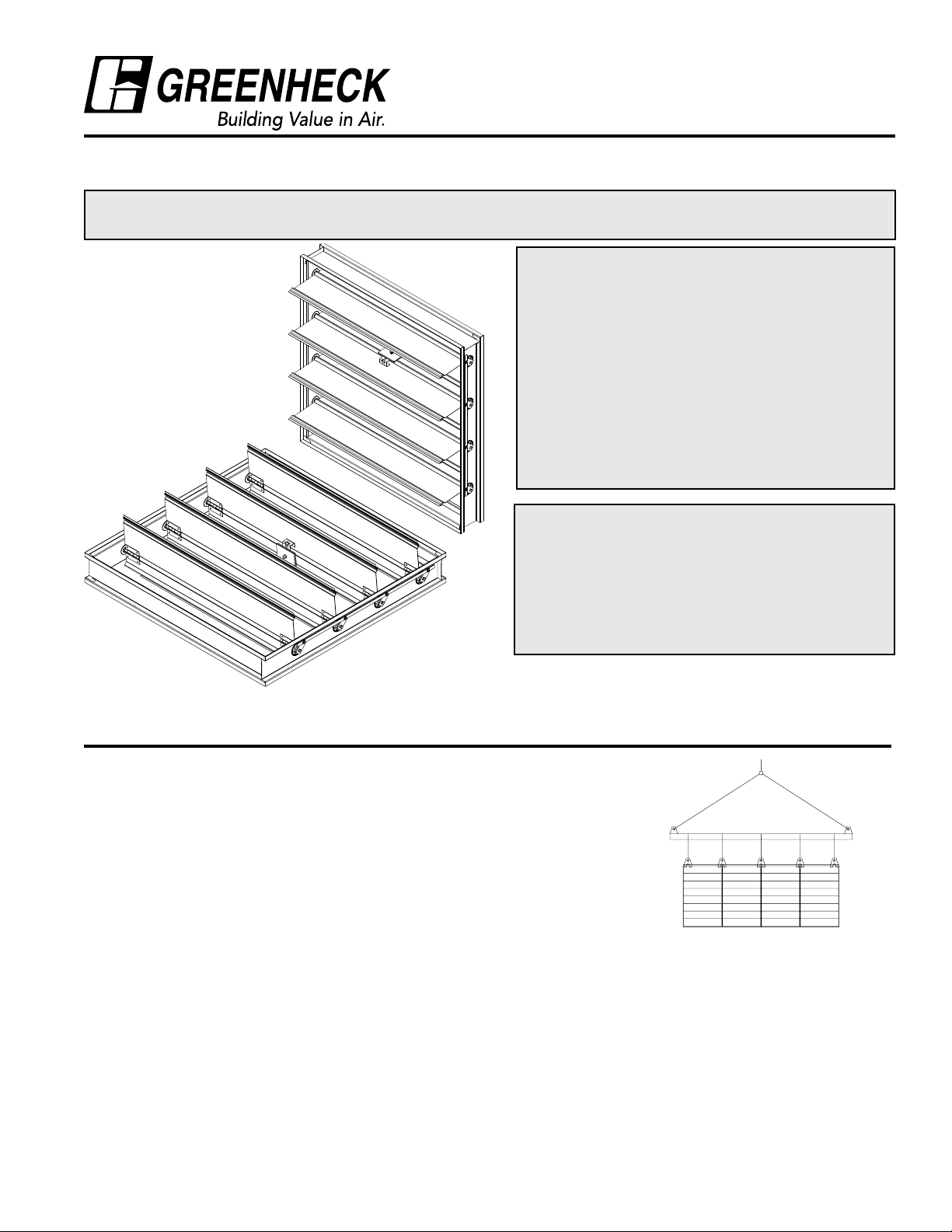

RECEIVING AND HANDLING

Upon receiving dampers, check for both obvious

and hidden damage. If damage is found, record all

necessary information on the bill of lading and file

a claim with the final carrier. Check to be sure that

all parts of the shipment, including accessories,

are accounted for.

Dampers must be kept dry and clean. Indoor

storage and protection from dirt, dust and the

weather is highly recommended. Do not store at

temperatures in excess of 100°F (37ºC).

SAFETY WARNING:

Improper installation, adjustment, alteration,

service or maintenance can cause property

damage, injury or death. Read the installation,

operating, and maintenance instructions

thoroughly before installing or servicing this

equipment.

Due to continuing research, Greenheck reserves the right to change specifications without notice.

Pre-Installation Guidelines

The basic intent of a proper installation is to secure the damper into the opening in such

a manner as to prevent distortion and disruption of damper operation. The following

items will aid in completing the damper installation in a timely and effective manner.

1) Check the schedules for proper damper locations within the building. Visually inspect

the damper for damage.

2) Lift or handle damper using sleeve or frame. Do not lift damper using blades or

linkage. When handling multiple sections assemblies, use sufficient support to evenly

lift at each section mullion (see Figure 1). Do not drag, step on, apply excessive

bending, twisting, or racking.

3) Do not install screws in damper frame that will interfere with damper blades and

prevent them from opening and/or closing.

4) Damper must be installed into duct or opening square and free of twist or other

misalignment. Damper must not be squeezed or stretched into duct or opening. Out

of square, racked, twisted or misaligned installations can cause excessive leakage

and/or prevent free operation.

5) Damper must be kept clean, dry and protected from dirt, dust and other foreign materials prior to and after installation.

Examples of such foreign materials include but are not limited to:

a) Drywall/mortar dust

b) Firesafing materials

6) Damper should be sufficiently covered as to prevent overspray if wall texturing or spray painting will be performed

within 5 feet (1.50m) of the damper.

c) Wall texture

d) Paint overspray

Figure 1- supports for lifting a

multi-section damper

Multi section dampers

Spreader Ba

Attachments

Page 2

Pre-Installation Guidelines continued....

Assembly

7) ACCESS: Suitable access must be provided for damper inspection and servicing. Where it is not possible to achieve

sufficient size access, it will be necessary to install a removable section of duct.

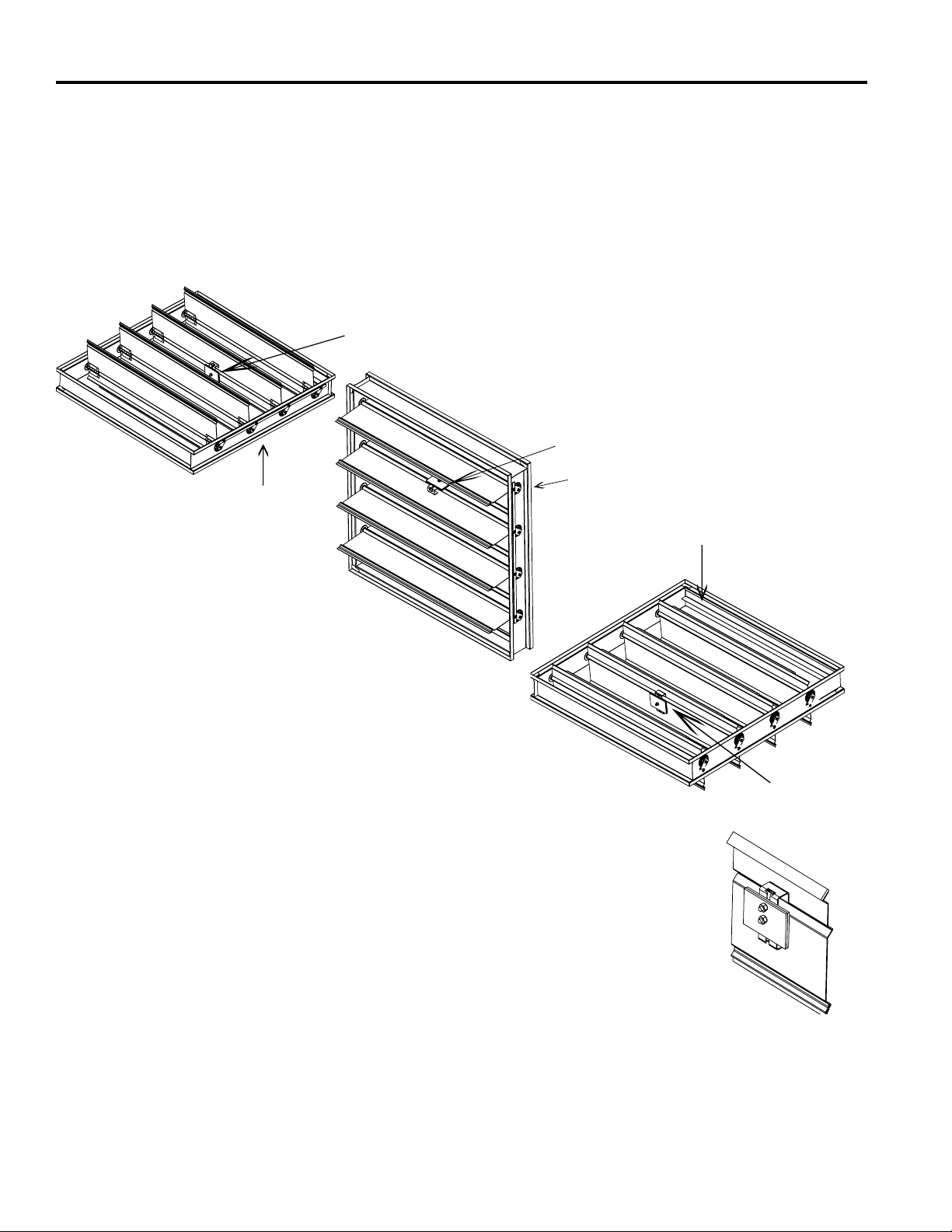

Counterweight Adjustment Procedure for BR Models

Dampers are shipped from the factory with frame flange location and flow direction as ordered. Location and size of both

counterbalances (blade edge, adjustable blade weights) are dependent upon flow direction and damper size. The damper

must be mounted square and plumb and must operate freely before any weight adjustments are performed. Contact

Greenheck for required modifications to change flow directions.

The following instructions should be followed when attempting to adjust counterweights on the BR series damper. Figure

1, 1A, & 1B shows the typical location of the adjustable counterweight assembly. Depending on the size of the damper and

specified start open pressure, the damper may have more than one counterweight assembly.

Adjustable

Counterweight

Assembly

Adjustable

Counterweight

Figure 1

BR-1x series

Airflow

Assembly

Airflow

Airflow

Figure 1A

BR-3x series

Figure 1B

BR-4x series

Adjustable

Counterweight

Counterbalance Adjustment for BR-1X Series: Horizontal mount - Vertical Up Airflow

Figures 2 & 3 show the components of a typical adjustable counterweight assembly. BR-1X series

damper with a short height may have a different style blade and a trimmed mounting bracket. The

adjustment procedure is the same for both styles of blades.

The blade edge counterweight (Figure 3) is factory set and not intended for field adjustment. For

vertical up airflow, all adjustments should be made in the adjustable counterweight assembly.

When adjusting the counterbalance weights, you will need to adjust the full open pressure and start

open pressure. Both steps will need to be done.

Adjusting Full Open Pressure and Closing Force

Adjusting the closing force will also affect the full open pressure. Figure 3 shows the blade in the full

open position. Additional weights can be added to increase the closing force. Removal or trimming

of weights will reduce the closing force. After adjustment, verify blades close under no airflow from

the full open position. Increase the closing force if the blades fail to close.

Adjusting Start Open Pressure

When the blades are in the closed position, the adjustable weights are used for the start open pressure of the damper.

Sliding the weights toward the blade seal will increase the start open pressure and sliding the weights toward the blade edge

counterweight will decrease pressure (Figure 4).

Figure 2 Adjustable

counterweight assembly

Page 3

Counterbalance Adjustment for BR-1X Series: Horizontal mount - Vertical Up Airflow

Damper

Increases Closing

Force

Decreases Closing

Force

Bottom of

Bracket

cont.......

Blade

Counterweight

Adjustment

Bracket

Increases Start

Open Pressure

Decreases Start

Open Pressure

Counterbalance

Weights

Figure 4: Counterweight adjustment for start open pressure. Blade is shown in

full close position

If sliding the weights to the furthest left position (toward the blade seal) does not provide a high

enough start open pressure, additional weights can be added. In this case, the closing force will

also increase.

Dampers are factory adjusted to the start open pressure, based upon your order, for the specified

flow direction. Typically, a minimum of one weight plate will be used to keep blades closed,

although only the mounting bracket may be sufficient for small damper sizes. Consult factory for

Blade Edge

Counterweight

Figure 3 - Adjustable

counterweight assembly

detail

plate quantity and sizing if an elevated start open pressure is required.

Final Adjustment Check

After adjusting the counterweights, verify that no interference occurs between the counterweights and the adjacent blades.

If any interference, adjust counterweights. Also verify that the damper blades close under no airflow from the full open, 1/2

open, and 1/4 open positions. If blades do not close, adjust weights as required.

Counterbalance Adjustment for BR-3X Series: Vertical mount - Horizontal Airflow

Figure 5 details the components of a typical adjustable counterweight assembly. Dampers

with a short height may have a different style blade and a trimmed mounting bracket. The

adjustment procedure is the same for both styles of blades.

The blade edge counterweight (Figure 5) is factory set and not intended for field adjustment.

For horizontal airflow, all adjustments should be made in the adjustable counterweight

assembly.

When adjusting the counterbalance weights, you will need to adjust the full open pressure and

start open pressure. Both steps will need to be done.

Adjusting Start Open Pressure

Counterbalance

Weights

Counterweight

Adjustment bracket

When the blades are in the closed position (Figure 5), the adjustable weight are used for

the start open pressure of the damper. Additional weights can be added to increase start

open pressure and removal or trimming of weights will reduce start open pressure. After

adjustment, verify blades close under no airflow from the 1/4 open position. If the blades fail

Figure 5 - Adjustable

counterweight assembly detail

to close, additional weight is required.

Figure 6: Counterweight adjustment in the full open position

Adjusting Full Open Pressure and Closing Force

Adjusting the closing force will also affect the full open pressure. Figure 6 shows the blade in the full open position. If blades

hang open or more closing force is desired, slide weights toward the bottom of the bracket (Figure 6). If the blades close too

fast or less closing force is desired, move weights toward the top of the bracket (Figure 6).

Dampers are factory adjusted to the start open pressure, based upon your order, for the specified flow direction. Typically,

a minimum of one weight plate will be used to keep blades closed, although only the mounting bracket may be sufficient for

small damper sizes. Consult factory for plate quantity and sizing if an elevated start open pressure is required.

Final Adjustment Check

After adjusting the counterweights, verify that no interference occurs between the counterweights and the adjacent blades.

If any interference, adjust counterweights. Also verify that the damper blades close under no airflow from the full open, 1/2

open, and 1/4 open positions. If blades do not close, adjust weights as required.

Blade Edge

Counterweight

Damper Blade

Page 4

Counterbalance Adjustment for BR-4X Series: Horizontal mount - Vertical Down

Blade Edge

Blade Edge

Counterweight

Counterweight

Adjustment

Bracket

Airflow

Figure 7 details the components of a typical adjustable counterweight assembly. Dampers

with a short height may have a different style blade and a trimmed mounting bracket. The

Counterweight

Adjustment

Bracket

adjustment procedure is the same for both styles of blades.

The blade edge counterweight (Figure 7) is factory set for the specified start open pressure.

For vertical down airflow, minor adjustments can be made in the adjustable counterweight

assembly. If the desired change is greater than the capability of the adjustable

counterweight assembly, then changes to the blade edge weight would be required.

Consult factory for assistance in adjusting blade edge weight.

When adjusting the counterbalance weights, you will need to adjust the full open pressure

and start open pressure. Both steps will need to be done.

Counterbalance

Weights

Adjusting Full Open Pressure and Closing Force

Adjusting the closing force will also affect the full open pressure. Figure 7 shows the blade

in the full open position. Additional weights can be added to increase the closing force.

Removal or trimming of weights will reduce the closing force. After adjustment, verify

blades close under no airflow from the full open position. Increase the closing force if the

Figure 7 - Adjustable counterweight

assembly detail

blades fail to close.

Adjusting Start Open Pressure

When the blades are in the closed position, the adjustable weights are used for the start open pressure of the damper. Sliding

the weights toward the blade edge counterweight will increase the start open pressure and sliding the weights toward the

blade seal will decrease pressure (Figure 8).

Counterweight

Increases

Open Pressure

Figure 8: Counterweight adjustment for start open pressure.

Blade is shown in full close position.

Decreases

Open Pressure

If sliding the weights to the furthest left position (toward the blade edge counterweight) does not provide a high enough start

open pressure, additional weight to the blade edge counterweight would be required. Consult factory with desired start open

pressure.

Dampers are factory adjusted to the start open pressure, based upon your order, for the specified flow direction. Typically,

a minimum of one weight plate will be used to keep blades closed, although only the mounting bracket may be sufficient for

small damper sizes. Consult factory if an elevated start open pressure is required.

Final Adjustment Check

After adjusting the counterweights, verify that no interference occurs between the counterweights and the adjacent blades.

If any interference, adjust counterweights. Also verify that the damper blades close under no airflow from the full open, 1/2

open, and 1/4 open positions. If blades do not close, adjust weights as required.

Our Commitment

As a result of our commitment to continuous improvement, Greenheck reserves the right to change

specications without notice.

Specic Greenheck product warranties are located on greenheck.com within the product area tabs and in

the Library under Warranties.

®

Phone: (715) 359-6171 • Fax: (715) 355-2399 • E-mail: gfcinfo@greenheck.com • Website: www.greenheck.com

469420• BR Series Rev. 2, October 2012 Copyright 2012 © Greenheck Fan Corporation

Loading...

Loading...