Page 1

A Middleby Company

44 Lakeside Avenue, Burlington, VT 05401 USA

Telephone: (802) 860-3700

FAX (802) 864-0813

Website www.blodgett.com

INSTALLATION & OPERATION MANUAL

PHOENIX SERIES SUPER HEAVY DUTY RANGE LINE

MODEL SERIES BP, BPE, BPM, BPP, BPSB, BPCM, BPSHI & BPBB

P/N 3000012219 REV. A

Please read this manual completely before attempting to install or operate

this equipment. Notify carrier of damage. Inspect all components immediately.

RETAIN THIS MANUAL FOR FUTURE REFERENCE.

Page 1

Page 2

IMPORTANT FOR YOUR SAFETY

THE INSTALLATION INSTRUCTIONS CONTAINED HEREIN ARE FOR THE USE OF QUALIFIED

INSTALLATION AND SERVICE PERSONNEL ONLY. INSTALLATION OR SERVICE BY OTHER

THAN QUALIFIED PERSONNEL MAY RESULT IN DAMAGE TO THE UNIT AND/OR INJURY TO THE

OPERATOR. Qualified installation personnel are individuals, a firm, corporation, or company which either

in person or through a representative are engaged in and are responsible for:

A. The installation or replacement of gas piping or the connection, installation, repair or servicing of

equipment, who is experienced in such work familiar with all precautions required and have complied

with all requirements of state or local authorities having jurisdiction. Reference: National Fuel Gas

Code, ANSI Z223.1, section 1.4, latest addendum. Or National Gas – Profane Installation Code CSA

B149.1 as applicable.

B. The installation of electrical wiring from the electric meter, main control box or service outlet to the

electric appliance. Qualified installation personnel must be experienced in such work, be familiar with

all precautions required and have complied with all requirements of state and local authorities having

jurisdiction. Reference: National Electric Code, ANSI/NFPA No. 70, latest addendum.

BLODGETT PHOENIX SERIES RANGES MUST BE INSTALLED IN ACCORDANCE WITH LOCAL

CODES, OR IN THE ABSENCE OF LOCAL CODES, WITH THE NATIONAL FUEL GAS CODE, ANSI

Z223.1, LATEST ADDENDUM, INCLUDING:

The appliance and its individual shutoff valve must be disconnected from the gas supply piping system

during and pressure testing of that system at test pressures in excess of ½ psig (14"WC /3.45 kPa).

The appliance must be isolated from the gas supply piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply piping system at test pressures equal to or greater

than ½ psig (14" WC/3.45 kPa).

POST IN A PROMINENT LOCATION THE INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THE

SMELL OF GAS IS DETECTED. THIS INFORMATION CAN BE OBTAINED FROM THE LOCAL GAS

SUPPLIER.

WARNING

IN THE EVENT OF POWER FAILURE, DO NOT ATTEMPT TO OPERATE THIS DEVICE

IMPORTANT

IN THE EVENT A GAS ODOR IS DETECTED, SHUT DOWN UNITS AT MAIN SHUT OFF

VALVE AND CONTACT THE LOCAL GAS COMPANY OR GAS SUPPLIER FOR SERVICE.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMABLE VAPORS OR LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE.

WARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH. READ THE INSTALLATION,

OPRATING AND MAINTENANCE INSTRUCTIONS THOUROUGHLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT

P/N 3000012219 REV. A

Page 2

.

Page 3

INTRODUCTION

Unpacking / Initial inspection

This appliance was inspected before leaving the factory. After unpacking, inspect the

unit for any damage that may have occurred during shipping. **The transportation

company assumes all responsibility for safe delivery. If the appliance is found to be

damaged, save all packaging materials and contact the carrier within 7 days of delivery.

Move the appliance as close as possible to installation location. Remove all boxes and

packaging material from inside of oven. Remove all shipping banding from pallet and top

of range. Remove all tops and oven components from their boxes.

General

Blodgett Phoenix ranges are manufactured for use with natural or propane gas. The gas

type for each range and the BTU rate is listed on the name plate. Verify the unit is for the

correct gas type before installing it, by reading specifications on appliance rating plate.

Please read the installation instructions carefully. Proper installation is essential for safe

and trouble free operation of this appliance.

Rating Plate Location

Remove the kick plate. The data plate is located to the right of center (behind the kick

plate) beneath the oven door. If gas orifices or regulator types (gas or propane) are

changed in the field, the rating plate must be changed to reflect the new orifice or gas

type. All work should be performed by a licensed and qualified professional.

Figure 1: Rating Plate

Location

Locate appliance in an area that will make it easy to load and unload the oven and will

facilitate the movement of food orders. Read Ventilation Requirements in the Installation

portion of this manual before locating the appliance.

WARNING

THE EQUIPMENT AREA MUST BE KEPT FREE AND CLEAR OF COMBUSTIBLE

MATERIALS.

P/N 3000012219 REV. A

Page 3

Page 4

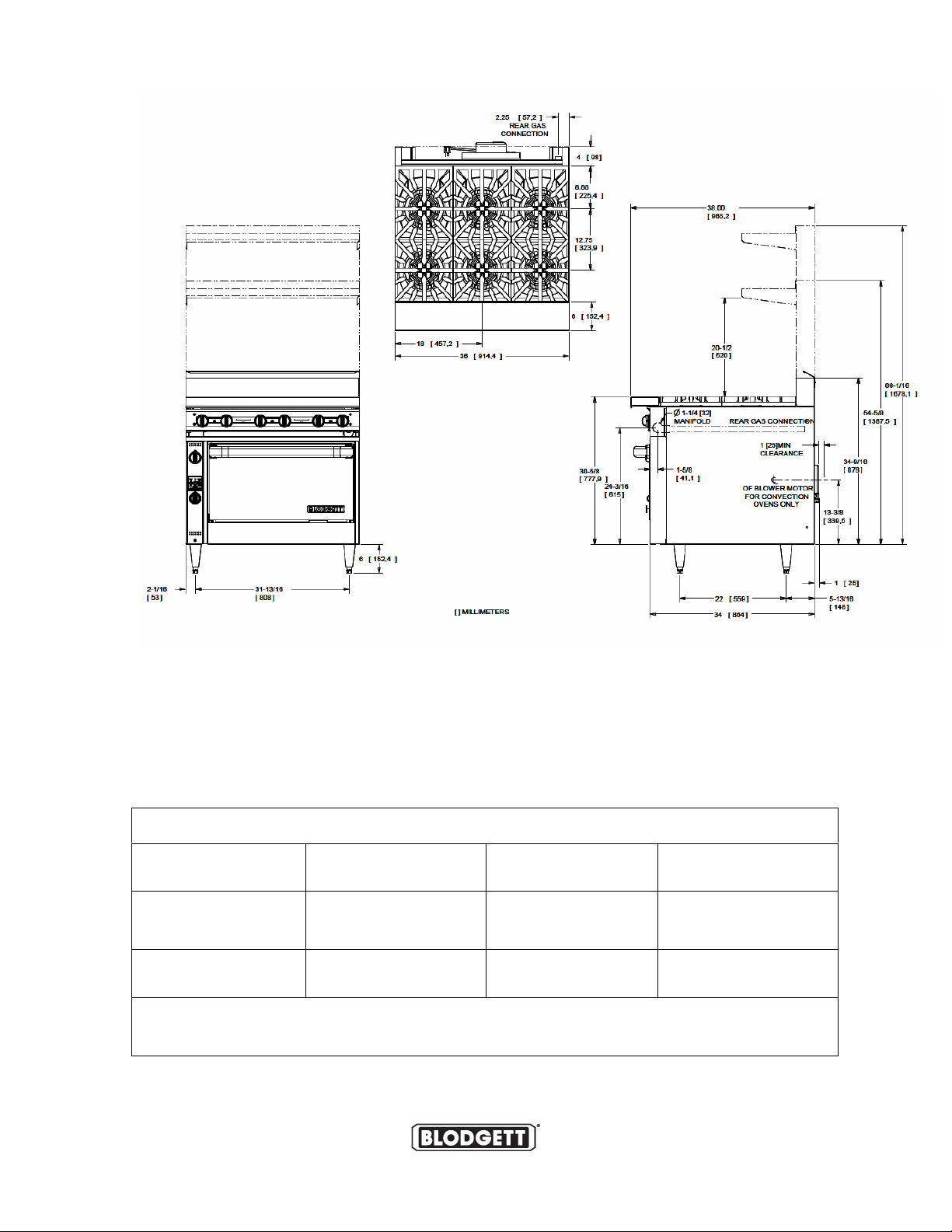

GENERAL RANGE SPECIFICATIONS

Model Width Height Depth

Standard Oven

Convection Oven

Convection ovens are provided with 1/4 HP 115 Volt 60HZ 1-Phase Blower Motor

PHOENIX Oven Specifications

28-1/4"

(71.75 cm)

28"

(71.12 cm)

(35.56 cm)

13-3/4"

(34.92)

14"

27-3/4"

(70.48 cm)

24-1/2"

(62.23 cm)

P/N 3000012219 REV. A

Page 4

Page 5

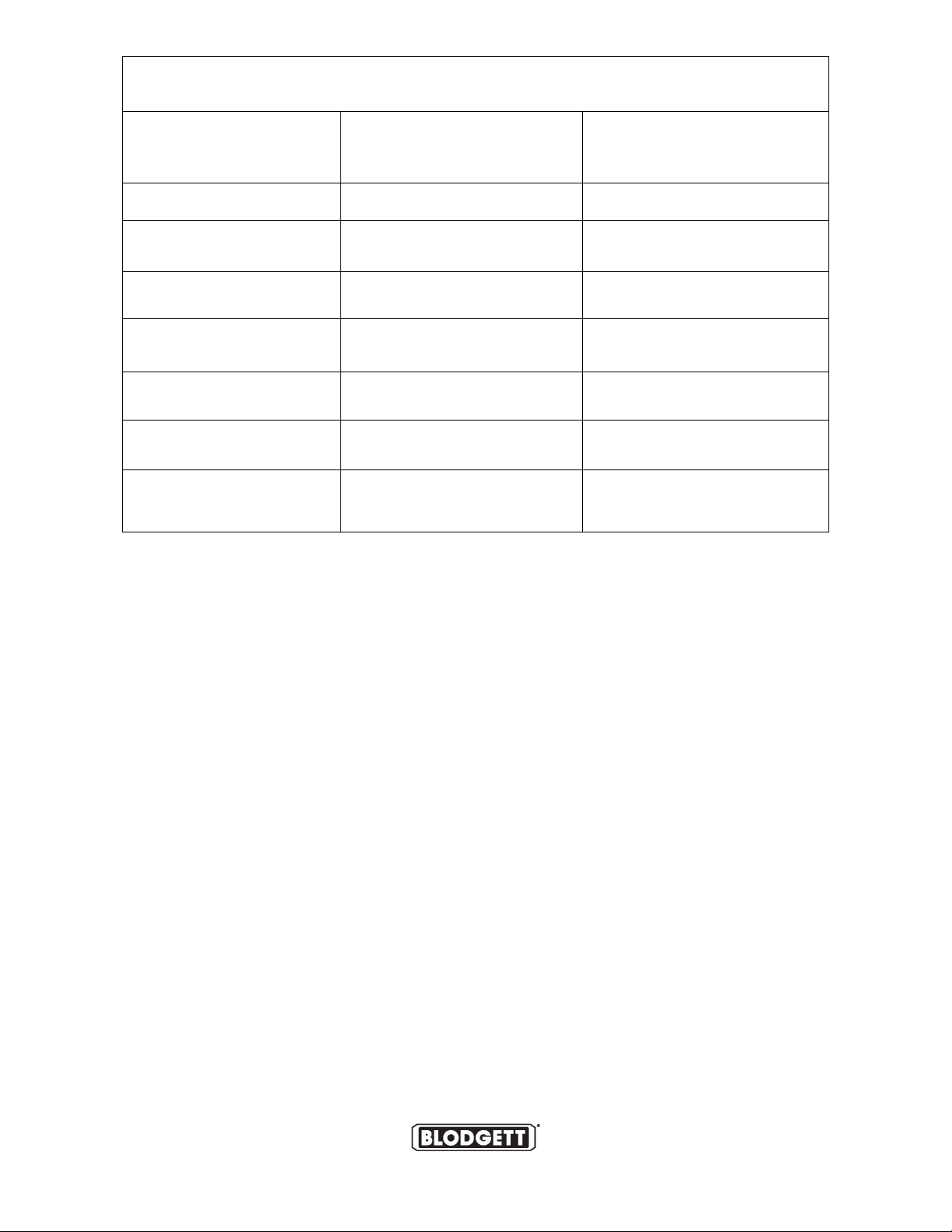

GAS BURNER BTU SPECIFICATIONS

MODEL/Feature BTU NOTES

Open burners 35,000 BTU per burner Lift-Off octagon type

Manual griddle

T’stat controlled griddle

Hot top

30,000 BTU per burner

25,000 BTU per burner

20,000 BTU per burner

25,000 BTU per burner

1 Every 12" of Griddle

width

12” wide full front to rear

18” wide full front to rear

Robata/Satay 35,000 BTU per burner 2 IR burners per grid

section

French Top Range 30,000 BTU per burner One for each top section

Charbroilers 15,000 BTU per burner

One Every 6" of Broiler

width

Standard oven

Convection Oven

35,000 BTU per burner

30,000 BTU per burner

Thermostat Adjustable from

150°F to 550°F

Gas Connections

Blodgett Phoenix ranges are supplied with a 1-1/4" front manifold and a 1" rear tailpipe.

For rear connection, remove cap. Ranges are supplied with 3/4" gas pressure regulator.

Operating pressure is 5.0" W.C. for natural gas or 10.0" W.C. for propane gas.

** Maximum incoming pressure is 14.0" W.C. (1/2 psi [3.45 kPa])

NOTE: Gas Pressure Regulator must be installed in an accessible “cool zone” protected

from grease and debris.

NOTE: Use a pipe joint compound that has been approved for use with liquefied

petroleum gases.

P/N 3000012219 REV. A

Page 5

Page 6

INSTALLATION

HOOD AND VENTILLATION REQUIREMENTS

Combustion Air

This appliance should be installed in an environment capable of providing adequate

combustion air for the range. Phoenix range model features and the BTU ratings are

listed under GAS BURNER BTU SPECIFICATIONS table shown prior to this section.

Locate the particular model/features being installed and note the BTU output of the

features of each appliance, then add the BTU rate for all burners operating at once. IT IS

IMPORTANT THAT ADEQUATE COMBUSTION AIR BE PROVIDED FOR THE TOTAL

BTU CALCULATED. Avoid locating the appliance in a tightly confined area that is

incapable of providing sufficient combustion air. Clear space MUST be provided in front

of the appliance to allow for entry of combustion air.

Ventilation

An exhaust hood with code-approved fire controls and sufficient CFM exhaust must be

provided to remove excess heat/steam/grease, etc. from cooking. The hood canopy

must extend beyond all sides of the appliance. Refer to Standard NFPA No. 96 (latest

edition) for the removal of smoke and grease laden vapors from commercial cooking

equipment. Use the BTU listings under GAS BURNER BTU SPECIFICATIONS chart at

the beginning of this manual to calculate the total BTU, and then furnish exhaust air

CFM required. Room ventilation (make-up air) must be provided to compensate for air

being removed by exhaust system. Excessive negative room air pressure will result if

this is not done. Lack of exhaust and/or excessive negative pressure will interfere with

oven and pilot light operation and result in pilot outage, improper combustion, and poor

overall performance.

BATTERY INSTALLATION REQUIREMENTS

Ranges that are installed in a battery (two or more) must be aligned, leveled, with

manifolds leveled and connected to each other.

Care must be exercised in leveling all appliances to the same plane. This is important so

that the 1-1/4" gas manifolds located at the front of each appliance can be connected via

plumbing unions. Failure to level all appliances to the same plane will prevent the proper

interconnection of gas manifolds. If the manifolds do not line up from one appliance to

another, re-check the level and correct so that appliances are leveled to the same plane.

Install the first appliance in the position it will occupy in the battery. Align and level the

second appliance to it and connect gas manifolds together. Continue until all appliances

are installed.

CAUTION: Provisions for gas and electrical shut offs must be incorporated in the design

of the “battery” and accessible in the event the appliance is to be serviced.

CAUTION: All gas manifolds must align correctly to each other. Failure to provide proper

alignment can damage gas manifolds, pilots and gas valves.

P/N 3000012219 REV. A

Page 6

Page 7

Adequate air supply must be provided for combustion air. Provide a minimum of 36" of

free space in front of all appliances. Provide adequate clearance for all air openings into

combustion chamber on all appliances.

Provide a gas regulator sufficient to supply adequate gas flow for the total BTU

requirement of all appliances that have connecting manifolds. Set gas regulators for 5.0"

W.C. for natural gas regulators and 10.0" W.C. for propane gas regulators.

Plate shelves and high shelves are adjustable and can be locked together with standard

3/8" bolts.

When installed and individually connected to the gas supply, each appliance must have

its own shutoff valve for servicing of the appliance.

ADJUSTABLE LEGS INSTALLATION

Raise the appliance above the floor. In the bottom plate of the appliance, locate the 5/8"

nuts that are welded into the bottom plate. Thread each of the legs into these nuts

tightly. Check that leg height adjustment operates freely.

OPTIONAL CASTERS INSTALLATION

Raise the appliance above floor. If legs are installed, remove them. Install casters by

threading caster bolts tightly into nuts that are welded into the bottom plate of the

appliance. If supplied, locking caster should be on the front side.

Locking

Lever

Figure 2: Caster Installation

CAUTION: Caster height is fixed and can’t be adjusted. If the floor is more than 1/4"

out of level over the span of a single appliance, 5/8” washers may be added in between

caster and bottom panel to level unit.

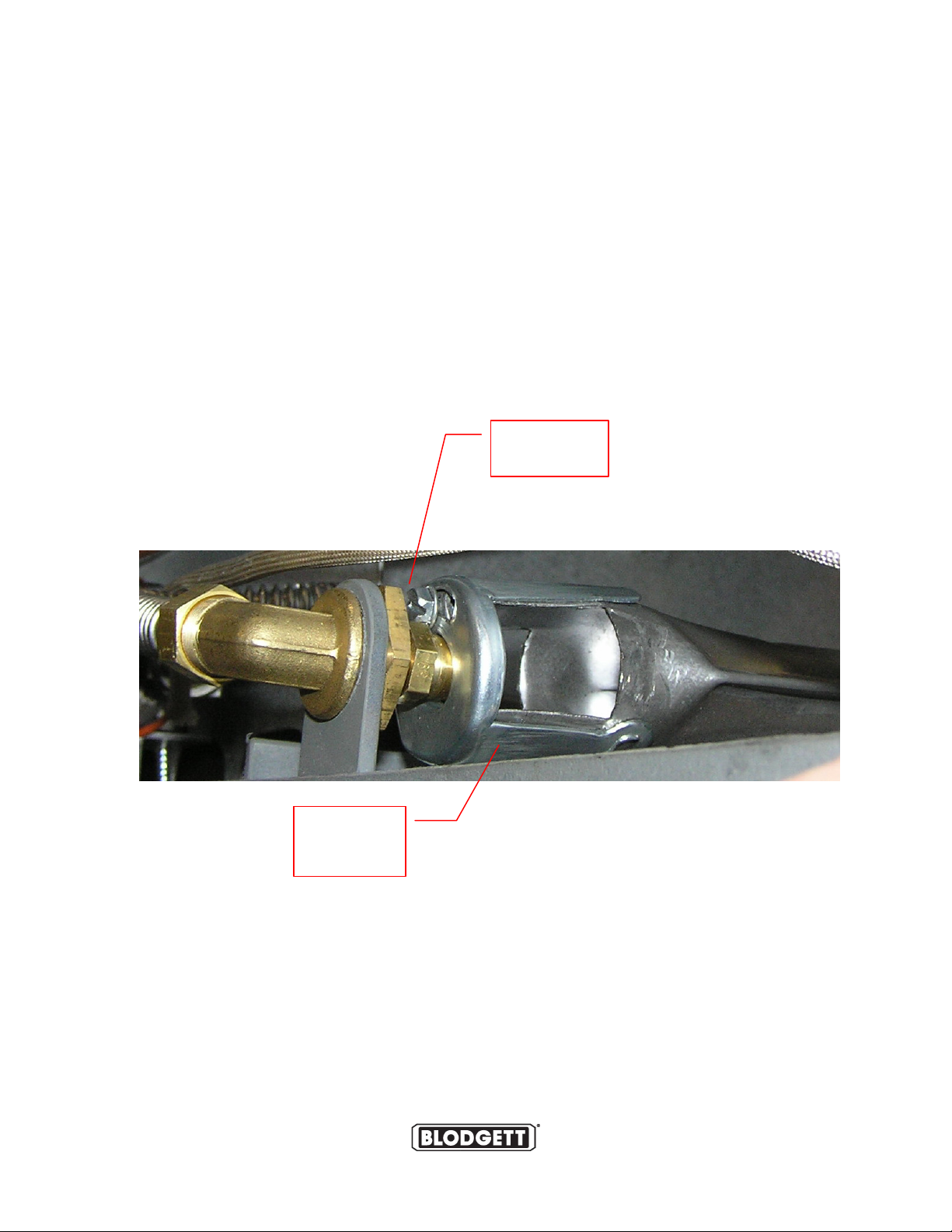

NOTE: When the appliance is to be installed with casters, gas connection must be made

with approved connectors for movable gas appliances (ANSIZ21.69-1987 and

addendum Z21.69189) with a quick-disconnect device approved for gas fuel.

(ANSIZ21.41-1989) In addition, a secure method of limiting the movement of the

appliance must be provided to protect the connector, gas line or any associated gas

piping from excess tension or being pulled from its connection. See Figure 3.

P/N 3000012219 REV. A

Page 7

Page 8

CAUTION: This restraining device must always be in place when the appliance is in use.

If it is to be removed for cleaning purposes or to service the appliance, it must be reinstalled before the appliance is put back into service. Per ANSI regulations Z-21.69

(connectors), Z-83.11 (commercial gas ranges), Z-21.41 (quick-disconnect devices), with

latest revisions.

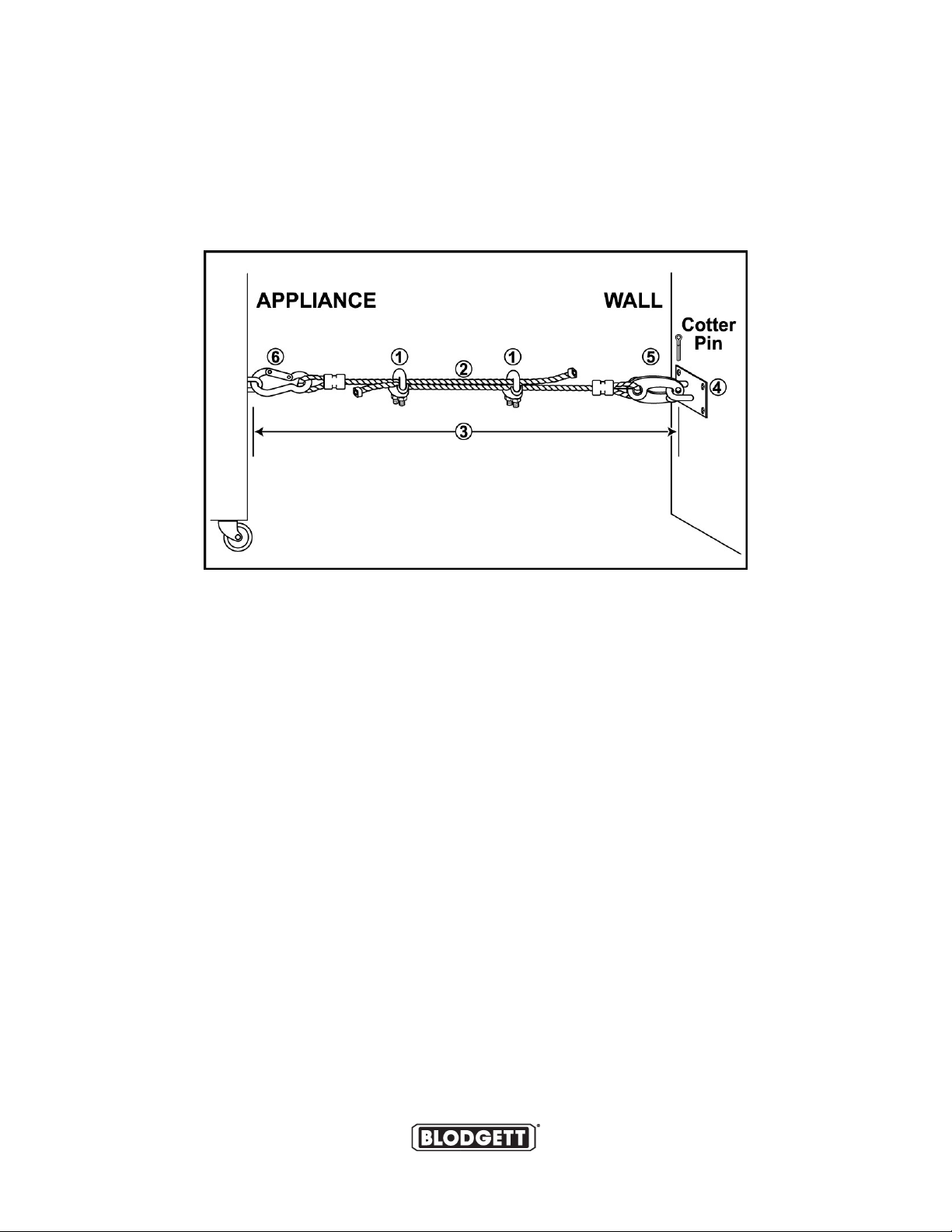

RESTRAINING DEVICE INSTALLATION

Figure 3: Restraining Device

(Must be installed when casters are used)

INSTRUCTIONS

This is a separate cable and should be less than 6" away from the gas connector in a

parallel orientation.

1. Adjust cable clamps (1) so that cable length is 3" to 6" shorter than the

length of the gas connector including fittings.

2. Secure eyelet plate to structurally sound attachment such as wall stud or

other solid attachment point.

3. Attach the scissor hook to the staple and secure with cotter pin.

4. Attach the spring hook to the gas appliance.

5. ** Check to make certain that the overall length of the restraining device is 3"

to 6" shorter than the overall length of the gas connector.

WARNING: Eyelet cable and all connections to wall and appliance must be

strong and secure enough to prevent appliance movement from pulling on gas

fitting in any way when the appliance is moved.

P/N 3000012219 REV. A

Page 8

Page 9

HI-SHELF /RISER INSTALLATION

1. Remove the existing riser from the unit.

2. Slide the riser support assembly into the back of the appliance as shown in

the illustration below.

3. Slide the riser support assembly toward the front of the range.

4. Install the bolts through the slots with washers as shown.

5. Tighten all bolts securely.

6. Slide the stainless steel shroud over the riser support.

7. Install rear panel and tighten securely.

8. Install the flue diverter.

Assembly riser using

¼-20 Bolts and washers

Figure 4: Installing Hi-Shelf/Riser

MOUNTING SALAMANDER or CHEESEMELTER

CAUTION: Salamander (BP-SB model) and Cheesemelter (BP-CM model) models

require a “reinforced” riser for range mounting.

For the installation of a salamander or cheesemelter on the riser of a Phoenix range,

please refer to the Installation and Operation manual provided with the accessory unit.

Order the range mount and interconnect gas line kit (optional) to install these units.

P/N 3000012219 REV. A

Page 9

Page 10

INSTALLATION CODES and STANDARDS

Installation of Phoenix series appliances must comply with all local and national building

codes for gas and electrical installations. Refer to standards ANSI Z233.1-1988 and

ANSI/NFPA 70-1990 or later for specifications. All installation or service work should be

performed by qualified personnel. (See explanation of qualified personnel at the

beginning of this manual).

ELECTRICAL INSTALLATION (convection models only)

WARNING: Electrical and grounding connections must comply with applicable

portions of the NATIONAL ELECTRICAL CODE ANSI/NFPA-70 (latest edition) and

local code requirements.

WARNING: The range must be electrically grounded in accordance with the

NATIONAL ELECTRICAL CODE and local code requirements.

For convection ovens, provide an electrical outlet capable of supplying 115 volts 60HZ 1

Phase for 1/4 HP blower motor. Blower motor amp draw is 4.4 amps/8 amp surge.

WARNING: This appliance is equipped with a three prong (grounding) plug for

user protection against shock hazard and should be plugged directly into a

properly grounded three prong receptacle. Do not cut or remove the grounding

prong from the plug.

CLEARANCES FROM COMBUSTABLE MATERIALS

Side Rear Floor

With 6" legs or 5" caters installed

Without 6" legs or 5" casters installed

4"

(10.16 cm)

4"

(10.16 cm)

2"

(5.08 cm)

2"

(5.08 cm)

6"

(15.24 cm)

0"

( 0 cm)

CAUTION: When appliance is installed without legs or casters, it must be set on a noncombustible curb or platform with a minimum front projection of 4 1/2" over the curb or

platform. Leveling bolts (5/8-11) can be used in the bottom frame of the range. If

plumbing and electrical connections allow, standard oven units can be installed flush to a

NON-COMBUSTABLE rear wall.

NOTE: Convection models are NOT recommended for curb or platform installations.

These models also require minimum 2” clearance at rear of unit

P/N 3000012219 REV. A

Page 10

Page 11

Leveling

Appliances can be leveled with provided 6" high adjustable legs or in curb or platform

installations (with the legs/casters removed) using 5/8-11 leveling bolts. Attachment

points are located inside the body of the unit at the front and rear of the control box area

and inside the combustion area bottom on the right side of the inner body.

Adjust leveling legs or leveling bolts in base plate until the appliance is level left to right

and front to back. Re-check and re-level in both directions until the appliance is level in

all directions.

Gas Line and Regulator Installation

A gas pressure regulator is required for all installations. For single appliance

installations, a 3/4" regulator is supplied. Other size regulators are available as options

for larger pipe diameters. In all cases, the feed line should never be smaller than the

inlet pipe of the unit. For proper operation, the gas regulator should be installed

horizontally, in a accessible cool zone and protected from grease and debris. Install the

gas line with an individual shutoff valve for servicing and code requirements.

NOTE: In battery installations where a main gas feed is branched to multiple

appliances, pipe size and gas regulator should be calculated to provide a flow rate

sufficient for all burners on all appliances to operate simultaneously.

CAUTION: Do not use domestic flexible gas lines to install this product!

NOTE: Use a pipe joint compound that has been approved for use with liquefied

petroleum gases.

Gas Line Pressure Testing

If the gas system is pressure tested at any pressure equal to or greater than ½ psig (14"

WC/ 3.45 kPa), the appliance must be isolated from the system by closing the gas

shutoff valve. In Battery or Waldorf installations, each appliance must have its shutoff

valve closed.

GAS LEAK TEST

WARNING: Test all pipe joints for leaks before operating this appliance. This

includes all gas connections that may have loosened during shipment. Do not use

the appliance if any leaks are detected.

After gas connections are compete and tightened, use an approved liquid leak detector

or combination of liquid soap and water in a spray bottle to test all installed fittings.

Check for the smallest bubbles that can indicate a leak. Correct all leaks before

operation of the appliance.

WARNING! RISK OF FIRE, EXPLOSION, BODILY HARM, OR DEATH. Do not use an

open flame to check for leaks!

P/N 3000012219 REV. A

Page 11

Page 12

BURNER FLAME ADJUSTMENTS

NOTE: All burner flames have been adjusted at the factory, occasionally onsite fine-

tuning may be necessary, see below for proper burner flame adjustment.

Flame Characteristics for a Properly Adjusted Burner

A correctly adjusted burner produces a flame that makes contact with the burner and

makes the same contact all along or around the burner. It should be sitting on the burner

and should be dark blue at the bottom and light blue at the top. It should be steady, not

dancing or jumping (indication of too much primary air). This is true for both natural gas

fig. (7A) and LP gas. LP gas may exhibit light yellow tips fig. (7B). There are several

problems that can happen if the air and fuel mixture is not delivered to the burner

correctly fig. (7C).

Figure 7: Burner Flame Characteristics

Top Burner Pilot Adjustment

Locate the pilot adjustment screw as shown on the illustration below. Adjust the screw

until the pilot intersects the gas jets on burners.

P/N 3000012219 REV. A

Figure 8: Top Burner Pilot Light Adjustment

Page 12

Page 13

Top Burner Adjustment

1. Remove top burner control knobs.

2. Remove front manifold cover plate

3. Loosen the screw on the air shutter.

4. Light the burners and observe the quality of the flame. Flame should be

sharp, well defined, two-tone blue as shown in Figure 7 (A).

5. Adjust the air shutter as required.

6. Tighten screw on the air shutter.

7. Repeat procedure for all remaining burners.

8. Replace burner knob

9. Replace front manifold cover plate

NOTE: When using LP (liquid petroleum/propane) the flame may have a slight yellow tip,

however the yellow tip should be no greater than 10% the overall flame size as shown in

Figure 7 (B).

Figure 9: Top Burner Air Shutter Adjustment

P/N 3000012219 REV. A

Page 13

Page 14

Oven, Griddle and Hot Top Burner Adjustment (Tubular Type Burners)

1. Remove kick plate (For oven). Remove front manifold cover (For Griddle/Hot

Tops

2. Loosen the screw on the air shutter.

3. Light the burner and observe the quality of the flame. Flame should be sharp,

well defined, two-tone blue as shown in Figure 7 (A).

4. Adjust the air shutter as required.

5. Tighten the screw on the air shutter, replace covers, knobs, panels as

required.

NOTE: When using LP (liquid petroleum/propane) the flame may have a slight yellow tip,

however the yellow tip should be no greater than 10% the overall flame size as shown in

Figure 7 (B).

Adjustment

Screw

Sleeve type

air shutter

P/N 3000012219 REV. A

Figure 10: Tubular Burner Air Shutter Adjustment

Page 14

Page 15

Top Burner Controls

To include, but not limited to:

• Open Burners

• Hot Top Burners

• French Top Burners

• Manual Griddle Burners

•

Char Broiler Burners

OPERATION

Figure 9 (a): Conventional Top Controls

Figure 9 (b): Thermostatic Top Controls

Range Top Controls

1. Check that pilot lights are lit.

2. Turn valve to ON position. (Burner will light)

3. Adjust flame to desired height. (See Figure 7)

4. To turn off, move control to the OFF position.

P/N 3000012219 REV. A

Page 15

Page 16

Broiler Top Controls

1. Check that pilot lights are lit.

2. Turn valve to ON position. (Burner will light)

3. Adjust flame to desired height. (See Figure 7)

4. To turn off, move control to the OFF position.

Griddle Top Controls (Conventional Controls)

1. Check that pilot lights are lit.

2. Turn valve to ON position. (Burner will light)

3. Adjust to desired heat. (See Figure 7)

4. To turn off, move control to the OFF position.

Griddle Top Controls (Thermostatic Control Option)

NOTE: Titan appliances with thermostatic griddle controls require special attention at

time of original set up.

1. Check that pilot lights are lit.

2. Turn valve to ON position. (Burner will light)

3. Adjust to desired temperature; allow 10-15 minutes for temperature to stabilize.

Temperature should be +/- 25 degrees of dial setting.

4. To turn off, move control to the OFF position.

Hot Top Range Controls

1. Check that pilot lights are lit.

2. Turn valve to ON position. (Burner will light)

3. Adjust to desired temperature.

4. To turn off, move control to the OFF position.

French Top Range Controls

1. Check that pilot lights are lit.

2. Turn valve to ON position. (Burner will light)

3. Adjust flame to desired height. (See Figure 7)

4. To turn off, move control to the OFF position.

P/N 3000012219 REV. A

Page 16

Page 17

LIGHTING OVEN PILOT LIGHT

Standard Oven:

BEFORE LIGHTING PILOT LIGHT FOR OVEN LIGHT ALL PILOTS FOR TOP

BURNERS

1. Remove the oven kick plate.

2. Turn the oven gas valve to OFF.

Figure 16: Standard Oven Gas Valve Location

3. Turn the oven thermostat to OFF.

4. Push and hold down the red button on the pilot valve to light the pilot light.

Continue to hold down the red button for 30 seconds until the pilot light

remains on when the red button is released.

5. If the pilot light goes out, repeat step 4. (In a new range installation this

procedure may have to be repeated several times until air is purged from gas

line.)

6. Be sure oven door is closed.

7. Turn the oven thermostat to desired temperature setting and turn the oven

gas valve to ON. Oven will light.

8. Verify that the pilot light is still on.

9. Turn oven gas valve to OFF.

10. Reinstall the kick plate.

P/N 3000012219 REV. A

Page 17

Page 18

Convection Oven

BEFORE LIGHTING PILOT LIGHT FOR OVEN LIGHT ALL PILOTS FOR TOP

BURNERS

1. Remove the oven kick plate.

2. Turn the master power switch to ON. (The light between the toggle switches

will glow indicating that the re-igniter is ON.)

3. Turn the oven gas valve to OFF.

Figure 17: Convection Oven Gas Valve Location

4. Turn the oven thermostat to OFF.

5. Push and hold down the red button on the pilot valve, the electronic ignition

will light the pilot light. Continue to hold down the red button for 30 seconds

until the pilot light remains on when the red button is released.

6. Be sure that oven door is closed.

7. Set rocker switch to AUTO.

8. Turn the thermostat to the desired temperature setting. Turn oven gas valve

to ON. The oven will light and the convection fan will run.

9. Turn the oven gas valve to OFF.

10. Verify that pilot light is still on.

11. Reinstall the oven kick plate.

P/N 3000012219 REV. A

Page 18

Page 19

Convection Oven Re-Igniter (electronic ignition)

CONTROL

SWITCH

NOTE: In order for the re-Igniter to operate, the master (power) switch located at the top

of the oven panel must be in the ON position.

If the pilot light is extinguished by drafts or temporary loss of gas pressure from air in

lines, the re-igniter will immediately attempt to re-light the pilot.

If the pilot fails to light, the thermocouple will cool (usually within 30 seconds) and shut

the gas off to the burner. This will require that the pilot light be re-lit manually.

Turn the oven gas valve to the OFF position. Wait 5 minutes. Then repeat steps 1-10

above to re-light pilot.

CONVECTION OVEN OPERATION

WARNING: The oven and its parts are hot. Use care when operating, cleaning, or

servicing the appliance.

1. Turn on the master power switch.

2. Turn the oven gas valve to ON.

3. Set thermostat to the desired temperature.

4. Turn fan switch to AUTO. (This will turn on the fan.)

5. Allow oven to pre-heat to the desired temperature. (12-16 minutes.)

6. Open oven door. (Fan will automatically stop.)

7. Place product into oven leaving space all around for even heating.

8. Close oven door. (Fan will turn on and oven will begin baking.)

NOTE: Placing the fan switch to MANUAL will allow the fan to run when the oven door is

opened to rapidly lower the oven temperature.

Convection Oven Controls

OVEN GAS

POWER ON

LIGHT

BLOWER

POWER

AUTO-MANUAL

SWITCH

P/N 3000012219 REV. A

OVEN

THERMOSTAT

Page 19

Page 20

Power Switch

Master power switch for the convection oven.

Power ON Light

Light will illuminate when the oven is operating.

Blower Auto/Manual Switch

Toggle switch controls the mode for the blower.

AUTO – Normal mode. Allows for automatic operation of the blower. (Fan

shuts off when door is opened)

OFF – Turns the blower off. Used for limited cooking setting.

MANUAL – Used to rapidly cool the oven to accommodate cooking of

another product at a lower temperature setting. Or in the event of a door

switch failure fan will still operate but fan will stay on with door open

Oven Thermostat

This control is used to set the desired cooking temperature for the oven.

WARNING: The range parts are hot. Use care when operating, cleaning, or

servicing the range.

Lowering/Changing Oven Temperature:

In order to rapidly lower the oven temperature to accommodate another product, adjust

the thermostat to the new temperature, open the oven door and set the blower toggle

switch to MANUAL. The blower will operate and cool the oven very quickly, usually in a

few seconds.

When the oven has cooled, place the product into the oven, close the door and set the

blower toggle switch to the AUTO position.

Use of Oven without Blower Fan

It may be desirable for certain products (milk products, meringues, etc.) to turn off the

blower in order to allow the product to set. In these cases, the blower should not be

turned off for more than 2 or 3 minutes at a time.

NOTE: Use of the convection oven without the blower will not immediately damage the

oven but will reduce the lifespan of the blower motor, the efficiency of the oven, change

cooking times and create uneven heat distribution. It is recommended that the blower

be used whenever the oven is on.

WARNING: Do not operate the convection oven in the event of a power failure.

Control valves require electrical connection to operate.

P/N 3000012219 REV. A

Page 20

Page 21

Care and Cleaning

The complete range should be given a periodic general cleaning. Lint and grease

suspended in the air will tend to collect in passages. Therefore, all flue ways, air

passages, and openings, burner ports, primary air openings, air shutters, etc. should be

periodically cleaned to prevent clogging.

WARNING: Range parts are hot. Use care when cleaning or servicing range top

and oven surfaces and burners.

Stainless Steel Surface

To remove dirt, grease or product residue from stainless steel, use an ordinary soap

solution. Dry thoroughly with a soft cloth.

To remove grease, food splatter and condensed vapors that have baked on the

appliance, apply cleanser to a damp cloth or sponge. NEVER RUB WITH A CIRCULAR

MOTION. To avoid marring the stainless steel finish, rub as gently as possible in the

direction of the grain lines of the stainless steel surface. Stubborn soil and burned-on

deposits can usually be removed with a Scotch-Brite ™ pad or stainless steel scouring

pad.

NOTE: Do not use ordinary steel wool, which will leave particles that will rust on the

stainless steel surface and further spoil the appearance of the finish.

CAUTION: Never use any metal tools including a wire brush, scouring pad (excluding

stainless steel), scrapper or file, which will permanently mar the stainless steel surface.

A marred stainless steel surface collects dirt more rapidly, is more difficult to clean and

increases the possibility of corrosion.

Darkened areas, called heat tint, may appear on stainless steel surfaces exposed to

excessive heat. Heat tint is caused by thickening of the protective surface of the

stainless steel and is not harmful. Heat tint can usually be removed by normal cleaning

procedures, but tint, which does not respond, requires vigorous scouring. Use a ScotchBrite™ pad or stainless scouring pad along with a powdered cleanser. Rub in the

direction of the stainless steel grain lines. Heat tint can be reduced by limiting exposure

of equipment to excessive heat during slack periods.

Oven Interior Cleaning

Frequent cleaning is required. Spills should be cleaned as soon as possible to prevent a

burned on condition called carbonizing. Allow the oven to cool before cleaning. A soap

or detergent solution is usually strong enough to remove any grease residue. Use a

mildly abrasive nylon cleaning pad for stubborn, stuck-on spills and stains. Use a noncaustic commercial oven cleaner when necessary, but do not allow it to come in contact

with the temperature probe. **Be sure to follow directions of the cleaning product being

used and wipe off all oven cleaner residues.

P/N 3000012219 REV. A

Page 21

Page 22

Convection models

Grease should not be allowed to build-up on fan blower, also the vent openings of the

motor (located in the rear) must be kept clean using a stiff bristle brush and/or vacuum

Open Top Section

DAILY: Allow surfaces to cool and wipe top with burlap or other grease absorbing

material to remove spills and grease before they burn on.

WEEKLY: Allow surfaces to cool and wash open top section with a solution of washing

soda and water. Remove and wash drip pan under burners. Brush burner head with a

stiff wire brush. Clean clogged ports with a stiff wire or ice pick. Remove excessive

grease build up from burners by soaking in a solution of washing soda. Dry burners by

inverting them on an oven rack at a low temperature.

NOTE: Make sure the air shutters remain intact and in the same position as when the

burners were removed from the appliance.

Hot Top / French Top Section

DAILY: Allow surfaces to cool and wipe top with heavy burlap or steel wool and rub

briskly until clean. In order to clean all flanges and under lid, lift rings and plates.

WARNING: Never pour water on a HOT French Top/Hot Top section as water can

splash and/or intense steam can cause severe burns.

Griddle Section

DAILY: During use, scrape surface with the flat edge of spatula or metal scraper to

remove encrusted material. Wipe frequently with heavy absorbent cloth. Allow surface to

cool and polish with soft griddle stone or a high-grade grill pad. The griddle may be

washed with a cleanser and warm water, which will not crack the steel plate.

WARNING: Never pour water on a HOT griddle as water can splash and/or intense

steam can cause severe burns.

To oil the griddle, use a hydrogenated shortening. Never use salad oils, margarine or

butter, which cannot withstand temperatures greater than 300ºF.

Service

When service is required, contact your local Blodgett Authorized service company. To

find a Blodgett Authorized service company, go to www.blodgett.com and click on

service locator. You may also contact your dealer or the factory to perform mechanical

maintenance and repair. All mechanical maintenance procedures can be found in the

P/N 3000012219 REV. A

Page 22

Page 23

Service Manual and must be performed only by Authorized service personnel. The

appliance should be inspected on an annual basis by an authorized service technician.

Any replacement of parts especially, gas control parts such as main burner valve or

thermostat should be an OEM factory part only.

Service/Maintenance Intervals

In order to provide maximum performance and longevity, this appliance must be

serviced regularly. Frequency of service largely depends on usage see below:

HOURS IN SERVICE NUMBER OF DAYS *RECOMMENDED INTERVAL

18-24 hours a day 7 days a week Every 30 days

12-18 hours a day 7 days a week Every 60 days

8-10 hours a day 5 days a week Every 120 days

4-6 hours a day 5 days a week Every 180 days

NOTE: All commercial appliances must be serviced at least once a year.

* -

This schedule is not meant to imply that a service company needs to be hired at the

recommended intervals. Someone with basic mechanical knowledge (supervisor or

manager) should check and/or inspect the following:

• Knobs/Dials – Make sure that they turn easily and are not seized.

• Verify the burners are clean and light/burn properly

• Check that moving parts operate freely

• Look for grease, oil or debris buildup

• Check thermostats for correct temperature

• Verify that the racks, panels, guides are covers are installed and operating

properly.

If any of these items are found to be incorrect, malfunctioning or in need of attention,

contact an authorized servicer to repair or correct the issue (See SERVICE section to

locate a Blodgett Authorized service company).

In order to provide maximum performance, proper operation and to insure the safety of

the operator, all commercial appliances must be serviced at least once a year by an

authorized servicer. If for any reason the appliance has NOT been in use or has been

in storage, it is imperative that the appliance be inspected by a Blodgett Authorized

servicer prior to re-installation and/or operation.

NOTE: Most Blodgett Authorized servicers offer a scheduled maintenance program that

can be customized to the particular operation. Contact the servicer nearest you for

details.

P/N 3000012219 REV. A

Page 23

Page 24

WARNING

If not installed, operated and maintained in accordance with the manufacturer’s

instructions, this product could expose you to fuel or fuel combustion substances,

which can cause death or serious illness and which are known to the State of California

to cause cancer, birth defects or other reproductive harm

.

The State of California enacted the California Safe Drinking Water and Toxic Enforcement Act

of 1986, (Prop. 65), which “prohibits any person in the course of doing business from knowingly

and intentionally exposing any individual to a chemical known to the State of California to cause

cancer or reproductive toxicity without first giving clear and reasonable warning to such

individuals.” The Governor’s Scientific Advisory Panel added carbon monoxide to the list of

hazardous chemicals known to cause reproductive harm.

In order to establish full compliance with Proposition 65, a yellow warning label has been

attached to each gas-fired unit manufactured by Blodgett.

Carbon monoxide would not be present in concentrations that would pose a “significant risk” to

the consumer when the equipment is installed, operated and maintained as follows:

1. Installed in accordance with all local codes, or in the absence of local codes, with the

current National Fuel Gas Code ANSI Z223.1 Latest Addenda.

2. Installed under a properly designed and operating exhaust hood.

3. Connected to the type of gas for which the unit is equipped.

4. Proper appliance pressure regulator installed on the gas supply line and adjusted for the

manifold pressure marked on the rating plate.

5. Adequate air supply to the unit.

6. The equipment is operated in the manner intended and using the proper utensil for that

type of appliance.

7. Keep the equipment clean and have it checked periodically.

8. Burner air adjustments, mechanical maintenance and repairs must be performed by

qualified service personnel.

WARNING:

with the above requirements, concentrations of carbon monoxide in excess of the

established limits could be present in the kitchen environment.

If the equipment is not installed, operated and maintained in accordance

**

ALL PERSONNEL IN THE WORKPLACE WHO MAY BE SUBJECT TO ANY

EXPOSURE OF CARBON MONOXIDE MUST BE WARNED OF SUCH POSSIBLE

EXPOSURE. THIS WARNING SHOULD BE CONVEYED IN A MANNER SO THAT IT

IS CLEARLY UNDERSTOOD BY THE EMPLOYEE. THE EMPLOYEE MUST BE

ASKED IF IN FACT HE OR SHE UNDERSTANDS THE CORRECT METHOD OF

OPERATION OF THE EQUIPMENT AND THAT A RISK OF EXPOSURE EXISTS IF

THE EQUIPMENT IS OPERATED IMPROPERLY.

P/N 3000012219 REV. A

Page 24

Loading...

Loading...