Page 1

BP-50 AND BP-100

PROOFER

INSTALLATION -- OPERATION -- MAINTENANCE

BLODGETT OVEN COMPANY

www.blodgett.com

44 Lakeside Avenue, Burlington, Vermont 05401 USA Telephone (800) 331-5842, (802) 860-3700 Fax: (802)864-0183

PN 23053 Rev D (6/01)

E 2000 --- G.S. Blodgett Corporation

Page 2

IMPORTANT

WARNING: IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJURY OR DEATH. READ THE INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR

SERVICING THIS EQUIPM ENT

FORYOURSAFETY

Do not store or use gasoline or other flammable vapors or

liquids in the vicinity of this or any other appliance.

The information contained in this manual is i mportant for the proper

installation, use, and maintenance of this oven. Adhere nce to these

procedures and instructionswill result in satisfactorybaking results

and long, trouble free service. Please read this manual carefully and

retain it for future reference.

Errors: Descriptive, typographic or pictorial errors are subject to correc-

tion. Specifications are subject to change without notice.

Page 3

THE REPUTATION YOU CAN COUNT ON

Forover acentury and a half,The BlodgettOven Companyhas been building

ovensand nothing but ovens. We’veset the industry’s qualitystandard forall

kinds of ovens for every foodservice operation regardless of size, application

or budget. In fact, noone offers more models, sizes, and oven applications

than Blodgett;gas andelectric,full-size, half-size,countertop and deck, convection, Cook’n Hold, Combi-Ovens and the industry’s highest quality Pizza

Oven line. For more information on the fullline of Blodgett ovens contact your

Blodgett representative.

Page 4

Your Service Agency’s Address:

Model:

Serial Number:

Your oven was installed by:

Your oven’s installation was checked by:

Page 5

Table of Contents

Introduction

Proofer Description and Specifications 2..............................

Installation

Delivery and Location 3.............................................

Proofer Assembly 4................................................

Packaging 4....................................................

Caster Assembly 4..............................................

Leg Attachment 4...............................................

Double Section Assembly 5......................................

Utility Connections --- Standards and Codes 6.........................

Electrical Connection and Initial Startup 7.............................

Operation

Safety Information 8................................................

Electro-Mechanical Thermostat and Humidity Controller 9...............

Solid State with Infinite Setting & Electro-Mechanical Humidity Controller 10

Solid State with Infinite Setting & Solid State Humidity Controller 11.......

Maintenance

Cleaning and Preventative Maintenance 12.............................

Page 6

Introduction

Proofer Description and Specifications

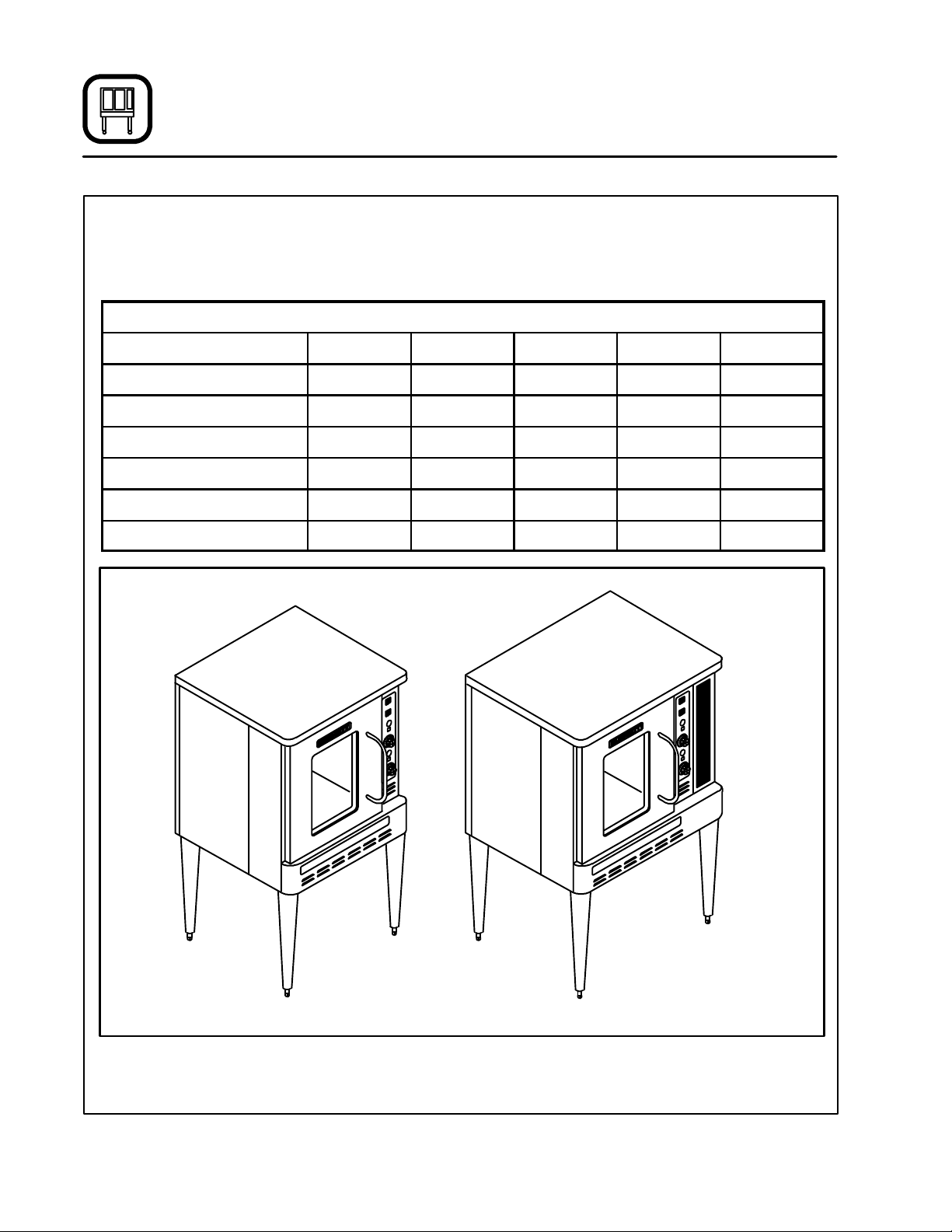

The B P Series proofers are available in two (2)

sizes. The BP-50 models are designed to fit under

theBlodgettlineof half sizeconvection ovens. The

ELECTRICAL SPECIFICATIONS (per section)

Model Watts Hz Volts Phase Amps

BP-50 1425 60 120 1 11.9

BP-50 1425 50 220 1 6.5

BP-50 1425 50 240 1 5.9

BP-100 1675 60 120 1 14.0

BP-100 1675 50 220 1 7.6

BP-100 1675 50 240 1 7.0

BP-100 models are designed to fit under the

Blodgett line of full size convection ovens.

BP-50 PROOFER BP-100 PROOFER

Figure 1

2

Page 7

Installation

Delivery and Location

DELIVERY AND INSPECTION

All Blodgett proofers are shipped in containers to

prevent damage. Upon delivery ofyournewproofer:

D

Inspecttheshippingcontainerforexternaldamage. Any evidenceof damage should be noted

onthe deliveryreceipt which mustbe signed by

the driver.

D

Uncratethe prooferand check for internaldamage. Carriers will accept claims for concealed

damage if notified within fifteendays of delivery

and the shipping container is retained for inspection.

The Blodgett Oven Company cannot assume

responsibility for loss or da m age suffered in

transit. The carrier assumed full responsibility

for delivery in good order when the shipment

was accepted. We are, however, prepared to

assist you if filing a claim is necessary.

PROOFER LOCATION

The well planned and proper placement of your

proofer will result in long term operator convenience and satisfactory performance.

D

Placethe proofer inan area whichis accessible

forproperoperationandservicing.

D

DO NOT place the proofer on a curb base or

seal to a wall. Either condition will restrict the

proper flow of ventilation air , resulting in damage to the unit.

3

Page 8

Installation

Proofer Assembly

PACKAGING

Before beginning assembly of the proofer, verify

that all the components necessary for the correct

configuration have been received. In addition to

the proofer other accessories may be required.

Single Sections:

The 25” (63.5 cm) legs and the optional regular

casters are packaged in the proofer cabinet.

Double Sections:

Thelowprofilecastersarepackagedinthelower

proofer section.

Accessories:

Proofer racks, rack guides and guide stops a re

packaged within the proofer cabinet.

CASTER ASSEMBLY

NOTE: Install the locking casters on the front of

theproofer. Install the non-locking casters

on the back of the proofer.

NOTE: If your proofer does not include casters,

proceed to the leg attachment section on

page 4.

Casters with 25” (63.5 cm) Legs

1. Insert the stem of a caster into the 1-1/2” I.D.

leg tubing. The caster shouldfit snugly. If not,

removethe castera ssembly and adjust as follows:

Hold the large hex nut. Tighten the knurled

washerto expandtherubber sleevea nd allow

the caster assembly to fit snugly into the leg

tubing. Make sure the caster fits completely

inside the leg tubing.

2. Tightenthe largehexnutas muchas possible.

This will further expand the rubber sleeve

against the leg tubing wall. If the rubber

sleeves turn inside the leg tubing, removethe

caster and repeat the caster adjustment procedure in 1.

Low Profile Casters

1. Carefully tip the proofer on it’s side.

2. Align the low profilecasters with the boltholes

in the corners on the bottom of the proofer.

3. Securethe casterstotheprooferwiththebolts

provided.

Figure 2

Figure 3

25” (63.5 CM) LEG ATTACHMENT

NOTE: If casters are used, remember to install the

legs with the locking casters in the front of

the proofer. Thenon-lo c kingcasters should

beinstalledonthe rearlegs. Besure thatthe

locksaresetonthefrontcasters.

1. Raisethe prooferatleast 30” (76 cm)off ofthe

ground using a lift.

2. Alignthe threaded studs of the front legs with

the bolt holes located in the corners of the

proofer’s bottom.

3. Turn the legs clockwise and tighten to the

nearest full turn.

4. Align the leg plate holes with the remaining

bolt holes. Secure the legs with the four (4)

1/2” x 3/4” bolts provided.

4

Page 9

Installation

Proofer Assembly

NOTE: If casters are used, ensure that the

locks are set on the casters.

Repeat Steps 1---4 for the rear legs.

The proofer should be leveled after being moved

to the operating location. Except for units with

casters, level the proofer by screwing the adjustable feet in or out as necessary.

Half Size Convection Oven on a BP-50

NOTE: The following instructions are for half size

convection ovens with LH doors.

1. On gas ovens, remove the combustion

compartment cover. On electric ovens, open

the control compartment cover.

2. Remove the access panel from the oven.

3. Remove the rear panel from the proofer.

4. Remove the control cover from the proofer .

5. Locate and align the front and rear bolt holes

with the bolt holes in the proofer frame.

6. Place a round washer and a hex nut on the

bottomendof eachbolt.Tightensecurelywith

a wrench.

7. Replace the combustion cover or close the

control compartment cover on the oven.

8. Replace the access panel on the oven.

9. Replace the rear panel on the proofer.

10. Replace the control cover on the proofer.

The proofer should be leveled after being as-

sembledand moved to theoperating location.Except for units with casters, adjust the feet located

on the bottom of each leg to level the unit.

Figure 4

DOUBLE SECTION ASSEMBLY

Full Size Convection Oven on a BP-100

1. Securethe lowprofilecastersto theprooferas

described.

2. Place the oven section on top of the proofer

section.

3. Remove the rear panel from the proofer.

4. Alignthe two rear bolt holes oftheproofersectionwith the two threaded holes in the bottom

of the oven section.

5. Insert a bolt from the bottom up through each

of the two holes and tighten securely.

6. Reinstall the rear panel on the proofer.

DOUBLE SECTION ASSEMBLY

(BP-100shown with panels removed for clarity)

Figure 5

5

Page 10

Installation

Utility Connections --- Standards and Codes

THE INSTALLATION INSTRUCTIONS CONTAINED HEREIN ARE FOR THE USE OF QUALIFIEDINSTALLATIONAND SERVICEPERSONNEL

ONLY. INSTALLATION OR SERVICE BY OTHER

THAN QUALIFIED PERSONNEL MAY RESULT IN

DAMAGE TO THE proofer AND/OR INJURY TO

THE OPERATOR.

Qualified installation personnel are individuals, a

firm, a corporation, or a company which either in

person or through a representative are engaged

in, and responsible for:

D

the installationofelectrical wiring from the electric meter, main control box or service outlet to

the electric appliance.

Qualified installation personnel must be experienced in such work, familiar with all precautions

required,and havecompliedwith allrequirements

of state or local authorities having jurisdiction.

U.S. and Canadian installations

All proofers, when installed, must be electrically

groundedinaccordancewith localcodes,orinthe

absenceoflocalcodes, withtheNationalElectrical

Code, ANSI/NFPA70---Latest Edition and/or Canadian National Electric Code C22.2 as applicable.

General export installations

Installationmust conform with Local and National

installation standards. Local installation codes

and/or requirements may vary. If you have any

questionsregarding the proper installationand/or

operation of your Blodgett proofer, please contact

yourlocaldistributor. If youdonot have alocaldistributor,please calltheBlodgettOven Companyat

0011-802-860-3700.

6

Page 11

Installation

Electrical Connection and Initial Startup

ELECTRICAL CONNECTION

This appliance is rated UL and CSA approved for

operation on 120VAC, 60 Hz, single phase,

grounded circuits, International 220 and 240VAC,

50 Hz versions are also available. Before making

anyconnection to this appliance, check the rating

plate attached to the underside of the front top

trim, directly above the control panel.

NOTE: Be sure that the proofer is connected to

the proper electrical supply.

The supply cord is connected to the junction box

in the rear of the proofer.

Wiring diagrams are located on the inside of the

control compartment, as well as the rear of the

proofer.

WARNING!!

Always disconnect the power supply to

theappliancebeforeservicingtheunit.

NOTE: There is no power to the heating element

without the rear blower operating. This is

to prevent damage to the element.

INITIAL STARTUP

Each proofer, and its component parts, have

been thoroughly tested and inspected prior to

shipment.However,it is often necessary to further test or adjust the proofer as part of a normaland proper installa tion. Theseadjustments

are the responsibility of the installer, or dealer.

Since these adjustments are not considered

defects in material or workmanship, they are

notcovered by the Original Equipment Warranty.Theyinclude,butarenotlimitedto:

DDDD

calibration of the thermostat

DDDD

adjustment of the doors

DDDD

leveling

DDDD

tightening of fasteners.

No installationshouldbe consideredcomplete

without proper inspection, and if necessary,

adjustment by qualified installation or service

personnel.

The following is a check-listto be completed by

qualified personnel prior to turning on the

applianceforthefirsttime.

j

Verify that the proofer has been properly

installed with the preceding installation instructions. If so, proceed to the operation

instructions. Allow the proofer to operate

forabouttwo (2) hoursprior tousing for the

first time.

7

Page 12

Operation

Safety Information

THE INFORMATION CONTAINED IN THIS SECTIONISPROVIDEDFORTHEUSE OFQUALIFIED

OPERATINGPERSONNEL. QUALIFIED OPERATING PERSONNEL ARE THOSE WHO HAVE

CAREFULLY READ THE INFORMATION CONTAINED IN THIS MANUAL, ARE FAMILIAR WITH

THE FUNCTIONS OF THE OVEN AND/OR HAVE

HAD PREVIOUS EXPERIENCE WITH THE OPERATIONOFTHE EQUIPMENTDESCRIBED.ADHERENCE TO THE PROCEDURES RECOMMENDED HEREIN WILL ASSURE THE

ACHIEVEMENT OF OPTIMUM PERFORMANCE

AND LONG, TROUBLE-FREE SERVICE.

Please take the time to read the following safety

andoperatinginstructions. Theyare the keyto the

successful operation of your Blodgett conveyor

oven.

SAFETY TIPS

For your safety read before operating

General safety tips:

D

DONOT remove the control panel coverunless

the oven is unplugged.

8

Page 13

Operation

Electro-Mechanical Thermostat and Humidity Controller

COMPONENT DESCRIPTION

1. POWER SWITCH --- controls power to the

proofer for ON/OFF operation.

ON

1

OFF

2

LOW WATER

3

TEMPERATURE

OFF

4

5

HUMIDITY

OFF

LOW

HIGH

2. LOWWATERINDICATORLIGHT --- whenlitindicates need to add water.

3. AIR HEATER PI LOT LIGHT --- wh en lit, indicates air heater ON operation.

4. THERMOSTAT --- allows for temperature

selection from 60-125_F(16-52_C).

5. WATER HEATER PILOT LIGHT --- when lit, indicates water heater ON operation.

6. HUMIDITY CONTROLLER --- allows humidity

selection from LOW to HIGH.

CONTROL OPERATION

1. Visually check the level in the water pan. Add

water as necessary.DO NOT overfill the res-

ervoir.

NOTE: The water level monitoring system will

sound a buzzer, located behind the

control panel, and illuminate a front

panel indicator light when the water

falls below the factory set level. Add

three (3) quarts (96 fl. oz.) of water to

restore the fluid to the correct level.

2. Set the THERMOSTAT (4) to the desired temperature.

3. Set the HUMIDITY CONTROLLER (6) to the

desired humidity level.

4. Set the POWER SWITCH (1) to the ON position. Allow the cavity temperature and humiditytoreach the correct levelbeforeloadingthe

product.

5. Remove the product when ready.

6. Toggle the POWER SWITCH (1) to OFF.

6

Figure 6

9

Page 14

Operation

Solid State with Infinite Setting & Electro-Mechanical Humidity Controller

CONTROLS

1. POWER SWITCH --- controls power to the

proofer for ON/OFF operation.

ON

1

OFF

2

LOW WATER

3

TEMPERATURE

4

5

HUMIDITY

OFF

LOW

HIGH

2. LOWWATERINDICATORLIGHT --- whenlitindicates need to add water.

3. AIR HEATER PI LOT LIGHT --- wh en lit, indicates air heater ON operation.

4. SOLID STATE TEMPERATURE CONTROLLER

--- allows an infinite number of temperature

settings from 80-125_F(27-52_C).

5. WATER HEATER PILOT LIGHT --- when lit, indicates water heater ON operation.

6. HUMIDITY CONTROLLER --- allows humidity

selection from LOW to HIGH.

OPERATION

1. Visually check the level in the water pan. Add

water as necessary.DO NOT overfill the res-

ervoir.

NOTE: The water level monitoring system will

sound a buzzer, located behind the

control panel, and illuminate a front

panel indicator light when the water

falls below the factory set level. Add

three (3) quarts (96 fl. oz.) of water to

restore the fluid to the correct level.

2. Set the SOLID STATE TEMPERATURE CONTROLLER (4) to the desired temperature.

3. Set the HUMIDITY CONTROLLER (6) to the

desired humidity level.

4. Set t he POWER SWITCH (1) to ON and allow

the cavity temperature and humidity to reach

the correct level before loading the product.

5. Remove the product when ready.

6. Toggle the POWER SWITCH (1) to OFF.

6

Figure 7

10

Page 15

Operation

Solid State with Infinite Setting & Solid State Humidity Controller

CONTROLS

1. POWER SWITCH --- controls power to the

proofer for ON/OFF operation.

ON

1

OFF

2

LOW WATER

2. LOWWATERINDICATORLIGHT --- whenlitin-

dicates need to add water.

3. AIR HEATER PI LOT LIGHT --- wh en lit, indi-

cates air heater ON operation.

4. SOLID STATE TEMPERATURE CONTROLLER

--- allows an infinite number of temperature

settings from 80---125_F (27---52_C).

5. WATER HEATER PILOT LIGHT --- when lit, in-

dicates water heater ON operation.

6. SOLID STATEHUMIDITYCONTROLLER --- Al-

lows an infiniteselection of humidity levels between 70% and 99% RH. (relative humidity).

3

TEMPERATURE

1. Visually check the level in the water pan. Add

water as necessary.DO NOT overfill the res-

ervoir.

NOTE: The water level monitoring system will

sound a buzzer, located behind the

control panel, and illuminate a front

panel indicator light when the water

OPERATION

4

falls below the factory set level. Add

three (3) quarts (96 fl. oz.) of water to

restore the fluid to the correct level.

2. Set the SOLID STATE TEMPERATURE CON-

TROLLER (4) to the desired temperature.

3. Set the SOLID STATE HUMIDITY CONTROL-

5

HUMIDITY

LER (6) to the desired humidity level.

4. Set t he POWER SWITCH (1) to ON and allow

the cavity temperature and humidity to reach

thecorrectlevelbeforeloadingtheproduct.

5. Remove the product when ready.

6. Toggle the POWER SWITCH (1) to OFF.

6

%R.H.

Figure 8

11

Page 16

Maintenance

Cleaning and Preventative Maintenance

CLEANING THE PROOFER

Painted and stainless steel proofers may be kept

clean and in good condition with a light oil. Saturate a cloth, and wipe the proofer when it is cold.

Dry the unit with a clean cloth. On the stainless

front or interiors, heat tint and heavy discoloration

or deposits of baked on splatter may be removed

with a good non-toxic industrial stainless steel

cleaner. Apply cleaners when the proofer is cold,

and always rub with the grain of the metal.

WARNING!!

Disconnect the unit from power supply

before servicing or cleaning.

PERIODIC CLEANING

Daily:

Clean residue from the unit with a small brush.

Weekly:

Brush out control area.

Every 6 Months:

Clean the ductwork system and water pan.

CLEANING THE DUCTWORK SYSTEM

1. Disconnect the power supply to the proofer.

2. Movethe unittoallowaccesstotheremovable

rear panel. Lift the panel up and pull the bottom out. Carefully lower the panel while pulling the line cord through the access hole.

3. Slide the rear duct up to disengage the duct

flanges from the offset guide track. Remove

the duct. Set it on the left side of the unit.

NOTE: Be careful not to damage the control

wires or the capillary tube.

4. Slide the top duct straight out of the track

through the rear of the unit.

5. Remove the two quick-disconnect plugs.

Slideoutthelowerductassembly.DONOT

damage the blower wheel or heating elements. The water pan assembly may be removedfromtheductforeasiercleaning.

6. Replace by reversing Steps 1---5 above. Be

sure to make proper electrical connections.

CLEANING THE WATER PAN

Visuallyinspectthew a ter panfor residualbuildup.

The water pan alone can be removed through the

front of the unit.

1. Disconnect the power supply to the proofer.

2. Removethet humbscrews fromthe lowercover. Grasp the cover by the sides. Pull out and

up toclear the three holding tabs mountedon

the inside bottom of the cover.

3. Remove the quick-disconnect plug from the

front of the water pan.

4. Pullup on the water pan todisengage thetab

from the front slot. Pull the pan forward.

NOTE: If the pan contains water , be careful

not to spill any inside of the unit.

5. Remove the pan from the proofer and clean

thoroughly .DO NOT immersethe pan inwa-

ter.

6. Replace by reversing Steps 1---5 above. Be

sure to line up the holes on the trim piece below the door with the lower cover. Lock the

tabs on the bottom inside of the cover.

OnBP-50unitsbe sure to insert the tab on the

right side of the lower cover into the slot in the

control panel cover.

7. Install the thumbscrews. Be sure to position

thelowertrimpiece underneaththe lowercover.Makesurethesealbetweenthedoorgasket and the lower door trim is tight.

PREVENTATIVE MAINTENANCE

The best preventativemaintenance measuresare

theproper installationof the equipmentand a program for routinely cleaning the proofer.

Every 6 Months:

Thefanassembly blower motor,located inthelower air duct assembly at the rear of the unit, should

beoiledwithanSAE20weightoil.

1. Disconnect the power supply to the unit. Applythe oiltothe twofillertubes locatedateach

end of the motor shaft.

The rest of the proofer needs no lubrication. If

maintenance or repairs are required, they

should be performed by qualified personnel

only.

12

Page 17

CUSTOMER

INSERT

WIRING DIAGRAM

HERE

Loading...

Loading...