Page 1

Owner’s Manual

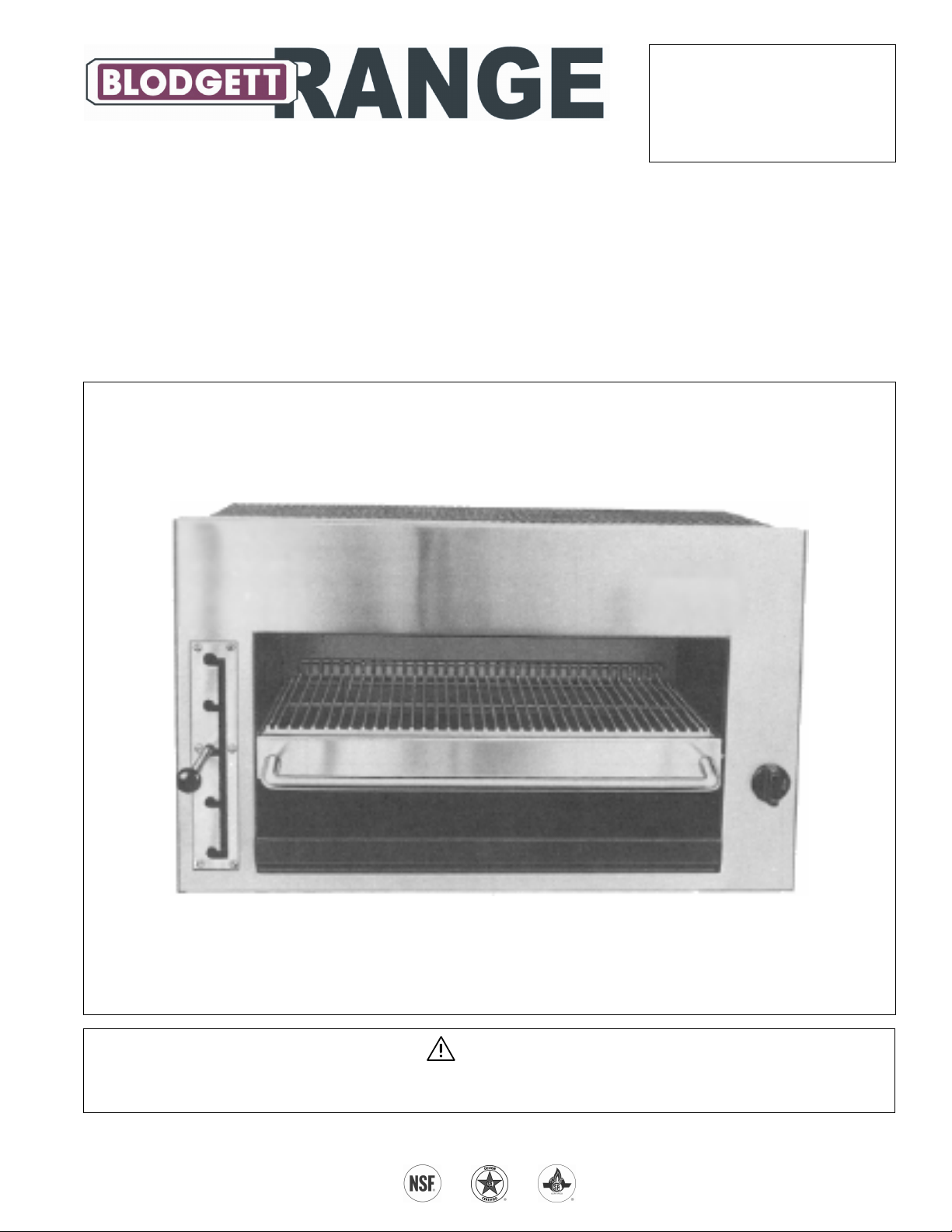

Infrared Salamander Broiler

Model BMRA-32 (mounts over sectional range)

Model BMRA-32W (mounts on wall)

Model BMRA-32C (has legs for countertop use)

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain

this manual for the life of the equipment:

Model #: __________________________

Serial #: __________________________

Date Purchased: ___________________

WARNING

Improper installation, adjustment, alteration, service, or maintenance can cause property damage, injury, or death.

Read installation, operation, and maintenance instructions thoroughly before installing or servicing this equipment.

1100 Old Honeycutt Road, Fuquay-Varina, NC 27526 USA • www.blodgettrange.com

MANUAL 1184962

$18.00

INFRARED SALAMANDER BROILER

MANUAL SECTION SR

Page 2

SAFETY PRECAUTIONS INFRARED SALAMANDER BROILER

SAFETY PRECAUTIONS

Before installing and operating this equipment, be sure everyone involved in its operation is fully trained and aware of

precautions. Accidents and problems can be caused by failure to follow fundamental rules and precautions.

The following symbols, found throughout this manual, alert you to potentially dangerous conditions to the operator,

service personnel, or to the equipment.

DANGER

WARNING

CAUTION

NOTICE

This symbol warns of immediate hazards that will result in severe injury or death.

This symbol refers to a potential hazard or unsafe practice that could result in injury or

death.

This symbol refers to a potential hazard or unsafe practice that could result in injury,

product damage, or property damage.

This symbol refers to information that needs special attention or must be fully understood,

even though not dangerous.

WARNING

FIRE HAZARD

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of cooking appliances.

Keep area around cooking appliances free and clear of combustibles.

Purchaser of equipment must post in a prominent location detailed instructions to be followed in the event the

operator smells gas. Obtain the instructions from the local gas supplier.

WARNING

BURN HAZARD

Contact with hot surfaces will cause severe burns. Always use caution when operating cooking appliances.

WARNING

EXPLOSION AND ASPHYXIATION HAZARD

In the event a gas odor is detected, shut down equipment at the main gas shut-off valve and immediately call

the emergency phone number of your gas supplier.

Improper ventilation can result in headaches, drowsiness, nausea, and could result in death. Do not obstruct the

flow of combustion and ventilation air to and from cooking appliances.

WARNING

ELECTRIC SHOCK HAZARD

For appliances that use electric power, disconnect the power to the appliance before cleaning. Do not remove

panels that require tools to remove.

NOTICE

Blodgett Range appliances are intended for commercial use only. Not for household use.

Warranty will be void if service work is performed by other than a qualified technician, or if other than genuine

Blodgett Range replacement parts are installed.

Give this Owner’s Manual and important papers to the proper authority to retain for future reference.

Copyright © 2002 by Blodgett Range. All rights reserved. Published in the United States of America.

PAGE 2 OF 24 OWNER'S MANUAL 1184962

Page 3

INFRARED SALAMANDER BROILER INTRODUCTION

INTRODUCTION

Congratulations! You have purchased one of the finest pieces of heavy-duty commercial cooking equipment on the

market.

You will find that your new equipment, like all Blodgett Range equipment, has been designed and manufactured to

meet the toughest standards in the industry. Each piece of Blodgett Range equipment is carefully engineered and

designs are verified through laboratory tests and field installations. With proper care and field maintenance, you will

experience years of reliable, trouble-free operation. For best results, read this manual carefully.

RETAIN THIS MANUAL FOR FUTURE REFERENCE.

This manual is for the Blodgett Range Infrared Salamander Broiler models BMRA-32 (mounts over 36" sectional

range), BMRA-32W (mounts on wall), and BMRA-32C (has legs for countertop use).

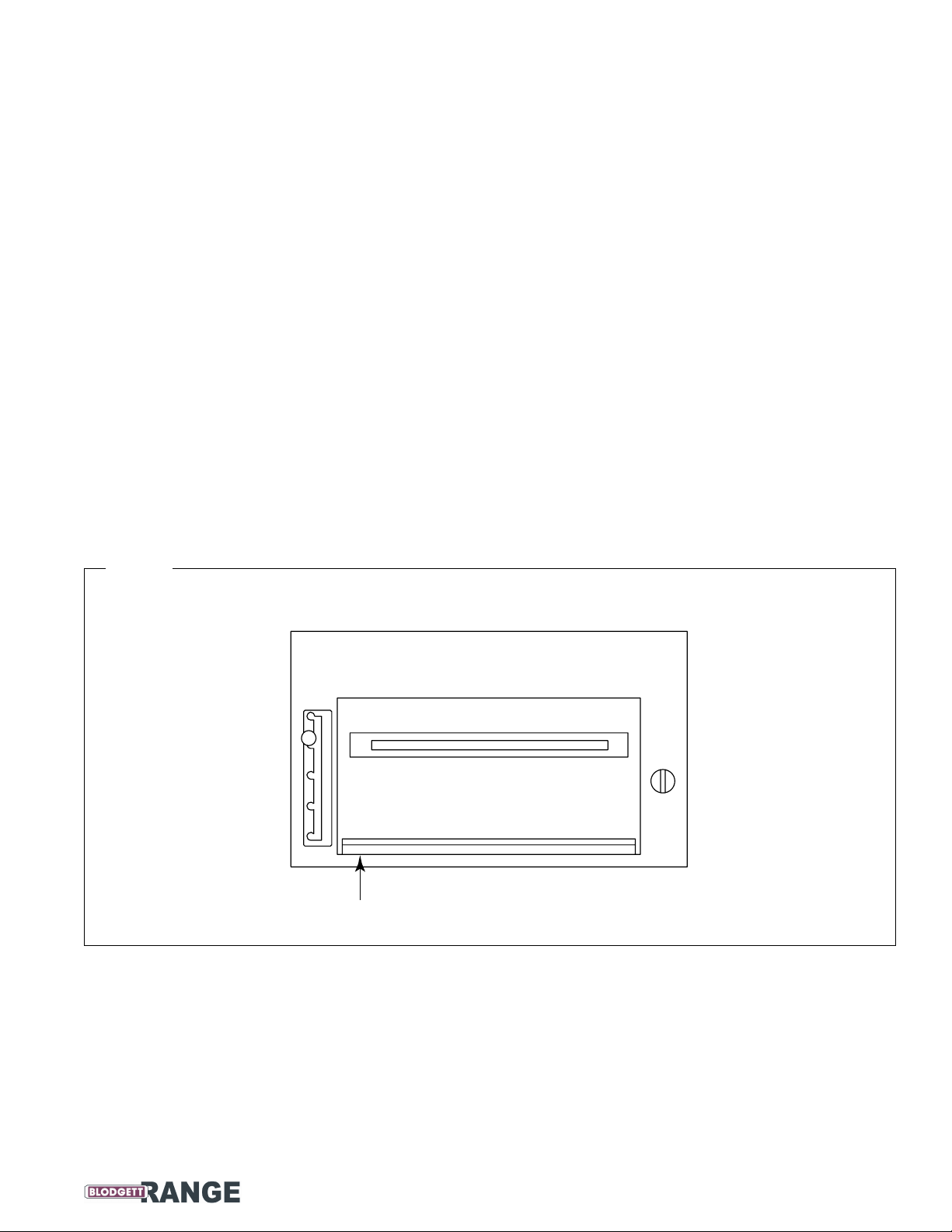

The serial plate is located under the broiler drippings pan at the front, toward the left (see Figure 1 below).

Read these instructions carefully before attempting installation. Installation and initial startup should be performed by

a qualified installer. Unless the installation instructions for this product are followed by a qualified service technician (a

person experienced in and knowledgeable with the installation of commercial gas and/or electric cooking equipment)

then the terms and conditions on the Manufacturer’s Limited Warranty will be rendered void and no warranty of any

kind shall apply.

In the event you have questions concerning the installation, use, care, or service of the product, write to:

Blodgett Range

1100 Old Honeycutt Road

Fuquay-Varina, North Carolina 27526 USA

Figure 1

Location of Serial Plate

SERIAL PLATE is located under the drippings pan at the front, toward the left.

OWNER'S MANUAL 1184962 PAGE 3 OF 24

Page 4

SPECIFICATIONS INFRARED SALAMANDER BROILER

SPECIFICATIONS

NOTICE

Local codes regarding installation vary greatly from one area to another. The National Fire Protection Association,

Inc. states in its NFPA 96 latest edition that local codes are the “authority having jurisdiction” when it comes to

installation requirements for equipment. Therefore, installations should comply with all local codes.

Blodgett Range reserves the right to change specifications and product design without notice. Such revisions do

not entitle the buyer to corresponding changes, additions, or replacements for previously purchased equipment.

This product is intended for commercial use only, not for household use.

The installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas Code,

ANSI Z223.1, Natural Gas Installation Code, CAN/CGA-B149.1, or the Propane Installation Code CAN/CGA-

B149.2, as applicable, including:

1. The appliance and its individual shutoff valve must be disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in excess of 1/2 psi (3.45 kPa).

2. The appliance must be isolated from the gas supply piping system by closing its individual manual shutoff valve

during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psi (3.45

kPa).

CLEARANCES

There must be adequate clearance between the broiler and adjacent construction due to the heat generated by the

broiler. Clearance must also be provided for servicing and for operation.

The minimum clearance from non-combustible construction is zero on the sides and 1" on rear (to permit combustion

air to enter the rear of the broiler). Also, all models require at least 6” accessibility-clearance on the right side for the

servicing of internal components.

Adequate clearance must be provided in front of the broiler for operation and cleaning.

The high-temperature flue products from the broiler burners flow out through a grill on the top of the broiler.

Installation under a vented hood is recommended.

WARNING

MINIMUM CLEARANCES FROM COMBUSTIBLE CONSTRUCTION

The countertop model (BRMA-32C) requires a minimum clearance from combustible surfaces of 1" on the sides

and rear.

The wall-mount model (BRMA-32W) requires a minimum clearance from combustible surfaces of 1" on the sides

and 3-3/4" on the rear (which is provided by the wall-mounting bracket).

The sectional-range-mount model (BRMA-32) requires a minimum clearance from combustible surfaces of 6" on

the sides and rear.

PAGE 4 OF 24 OWNER'S MANUAL 1184962

Page 5

INFRARED SALAMANDER BROILER SPECIFICATIONS

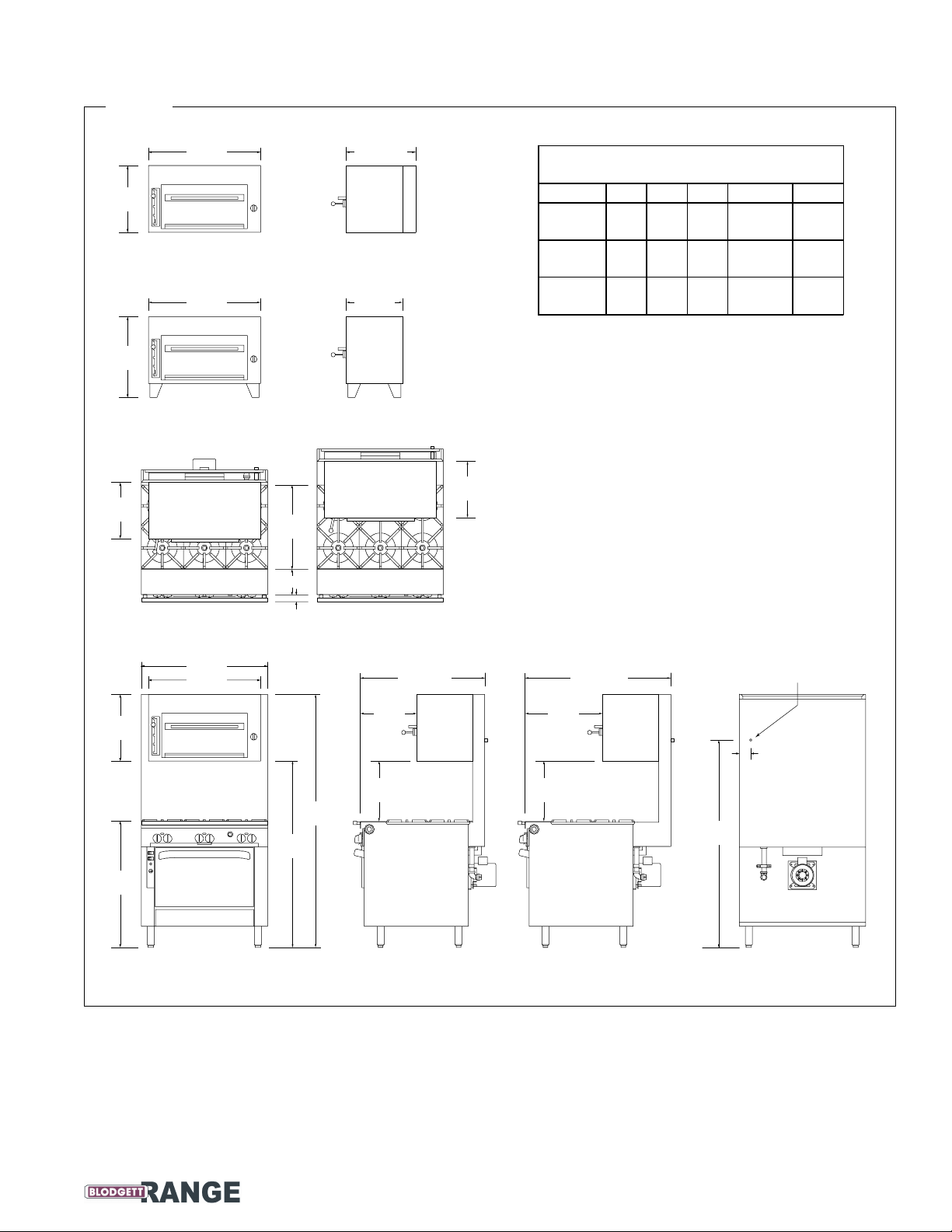

DIMENSIONS

Figure 2

32" (813)

19"

(483)

FRONT VIEW of Wall-Mount Model

32" (813)

23"

(584)

FRONT VIEW of Countertop Model

showing 4" (102 mm) legs

16"

(406)

SIDE VIEW of Wall-Mount Model

showing 3-3/4" (95 mm) deep

stand-off mounting bracket

SIDE VIEW of Countertop Model

showing 4" (102 mm) legs

24"

(610)

7" (178)

19-3/4" (502)

16" (406)

16"

(406)

SHIPP ING CRATE DIMENSIONS & WEIGHT

(Door-entry clearanc e whe n uncrated is 20" )

Model Width Height Depth Volume Weight

BMRA-32

BMRA-32W

BMRA-32C

(914)

36.0

(914)

36.0

(914)

(686)

27.0

(686)

27.0

(686)

(584)

23.0

(584)

23.0

(584)

12.9cuft

(0.37cum)

12.9cuft

(0.37cum)

12.9cuft

(0.37cum)

255 lb s

(116 k g)

255 lb s

(116 k g)

255 lb s

(116 k g)

36.0

27.0

23.0

Dimensions are in inches and millimeters.

The broiler and flue-riser assembly is shown here mounted on

a six-burner open-top range-top with a convection oven base.

Two removable broiler grids rest in a roll-out rack. The total grid

cooking area is 23-3/4" (603 mm) wide and 14-1/2" (368 mm)

deep, with the front 3" (76 mm) a lower-temperature holding area.

The five grid-height positions are 2-1/2", 3-3/4", 5", 6-1/4", and

7-1/2" (64, 95, 127, 159, and 190 mm) from the surface of the

infrared cermaics.

(Standard-Depth Flue Riser)

19"

(483)

36"

(914)

TOP VIEW

36" (914)

32" (813)

FRONT VIEW

2" (51)

53"

(1346)

(Deep-Depth Flue Riser)

72"

(1829)

TOP VIEW

35-3/4" (908)

16"

(406)

17"

(432)

SIDE VIEW

(Standard-Depth Flue Riser)

41-3/4" (1060)

22"

(559)

17"

(432)

SIDE VIEW

(Deep-Depth Flue Riser)

(internal piping to front manifold is an option)

59"

(1499)

Gas Connection

3-1/4" (83)

REAR VIEW

OWNER'S MANUAL 1184962 PAGE 5 OF 24

Page 6

SPECIFICATIONS INFRARED SALAMANDER BROILER

VENTILATION

WARNING

Improper ventilation can result in personal injury or death. Ventilation which fails to properly remove flue products

can cause headaches, drowsiness, nausea, or could result in death.

All broilers must be installed in such a manner that the flow of combustion and ventilation air is not obstructed.

Provisions for adequate air supply must be provided.

NOTICE

Proper ventilation is the owner’s responsibility. Any problem due to improper ventilation will not be covered by the

warranty.

Do not obstruct the front of the broiler since combustion air enters through this area. Be sure to inspect and clean

the ventilation system according to the ventilation equipment manufacturer’s instructions.

If a ventilation canopy is used, it is recommended that the canopy extend 6" past the broiler and that the bottom edge

be located 6'6" from the floor. Filters should be installed at an angle of 45° or more from the horizontal. This position

prevents dripping grease, and facilitates collecting the run-off grease in a drip pan under the filter.

A strong exhaust fan tends to create a vacuum in the room and may interfere with burner performance or may

extinguish pilot flames. Fresh air openings approximately equal to the fan area will relieve such a vacuum. The

exhaust fan should be installed at least 2" above the vent opening on the top of the broiler.

If the broiler is connected directly to an outside flue, a CSA design certified down draft diverter must be installed.

In case of unsatisfactory performance by any gas appliance, check the appliance with the exhaust fan turned OFF. Do

this only long enough to check whether doing so corrects any problems with equipment performance. Then turn the

exhaust fan back on and let it run to remove any exhaust that may have accumulated during the test.

GAS SUPPLY

The broiler is design-certified for operation on natural or propane gases. The broiler is shipped configured and

adjusted for the type of gas specified by the purchaser, which is indicated on the serial plate (see Figure 1 on page 3).

Connect the broiler ONLY to the type of gas for which it is configured and adjusted.

Gas Type Total BTU/hour Burner Orifice Pilot Orifice Min. Supply Pressure Manifold Pressure

Natural Gas 32,000 No. 53 (P/N 1008753) 0.0240 (P/N 1161263) 7" W.C. 4" W.C.

Propane 32,000 No. 63 (P/N 1008763) 0.0145 (P/N 1176664) 11" W.C. 10" W.C.

A model BMRA-32 mounts on the flue riser of a sectional range, and either will have a 3/8" rear gas connection (with

a 3/8" male NPT connector) extending through the rear of the flue riser (see Figure 2 on page 5), or will have the

optional internal-piping to the front-manifold of the sectional range (and so will not require a separate gas connection).

For models BMRA-32W (wall-mount) and BMRA-32C (countertop), the gas supply is connected to the inlet of the

internal pressure regulator (which has a 3/8" female NPT connector). The gas connection can extend directly out the

rear of the broiler (near the bottom right-rear corner), or out the top of the broiler (near the top right-rear corner), or out

the bottom of the broiler (near the bottom right-rear corner, wall-mount model only).

Minimum supply pressure is 7" W.C. for natural gas, 11" W.C. for propane. An internal pressure regulator and shut off

valve are provided. If using a flexible-hose gas connection, the I.D. of the hose must not be smaller than the

connector on the broiler, and must comply with ANSI Z21.69. Provide an adequate means of restraint to prevent

undue strain on the gas connection. Test pressure should not exceed 14" W.C.

If applicable, the vent line from the gas appliance pressure regulator shall be installed to the outdoors in accordance

with local codes, or in the absence of local codes, with the National Fuel Gas Code, ANSI Z223.1, Natural Gas

Installation Code, CAN/CGA-B149.1, or the Propane Installation Code CAN/CGA-B149.2, as applicable.

An adequate gas supply is imperative. Undersized or low pressure lines will restrict the volume of gas required for

satisfactory performance. Fluctuations of more than 25% on natural gas or 10% on propane gas will create problems

and affect burner operating characteristics. A 1/8" pressure tap is located on the manifold to measure the manifold

pressure. The supply line to the broiler should be no smaller than the inside diameter of the pipe on the broiler to

which it is connected.

PAGE 6 OF 24 OWNER'S MANUAL 1184962

Page 7

INFRARED SALAMANDER BROILER OPERATION

OPERATION

DANGER

EXPLOSION HAZARD

In the event a gas odor is detected, shut down equipment at the main shut off valve. Immediately call the

emergency phone number of your gas supplier.

CAUTION

If the broiler pilots should go out the flow of gas to the broiler burners is NOT interrupted. Consequently, it is the

responsibility of the operator to check the ignition of the burners immediately EVERY TIME the broiler is turned on.

Should ignition fail after 10 seconds, turn off burners, wait 5 minutes, and then try again.

NOTICE

Blodgett Range infrared broilers cook food in about half the time of conventional broilers, so adjust cooking times.

Blodgett Range Infrared Broilers are unique in design. They incorporate our exclusive Schwank ceramic tile burners,

which generate infrared rays that provide better quality products in about one-half the usual broiling time, and with

less gas input than ordinary broilers. Very little energy is wasted in heating secondary surfaces, which is necessary for

conventional-type broilers.

Since the surface of the ceramic tiles becomes red hot in less than one-half minute, the broiler is ready to start broiling

with a very short preheat time, thereby saving time, labor and energy. These glowing surfaces emit intense infrared

rays, which are transmitted directly onto the product, thereby yielding better tasting broiled food in less time.

The broiler design supplies 100% clean primary air to the burners, which ensures efficient combustion and maintains

full production capacity and maximum recovery, even in the most severe conditions of grease vapors and smoke

atmospheres, which are created during any broiling process.

Blodgett Range Infrared Broilers provide such rapid speed and recovery that broiling techniques may require

some modification in order to take full advantage of their productive capabilities.

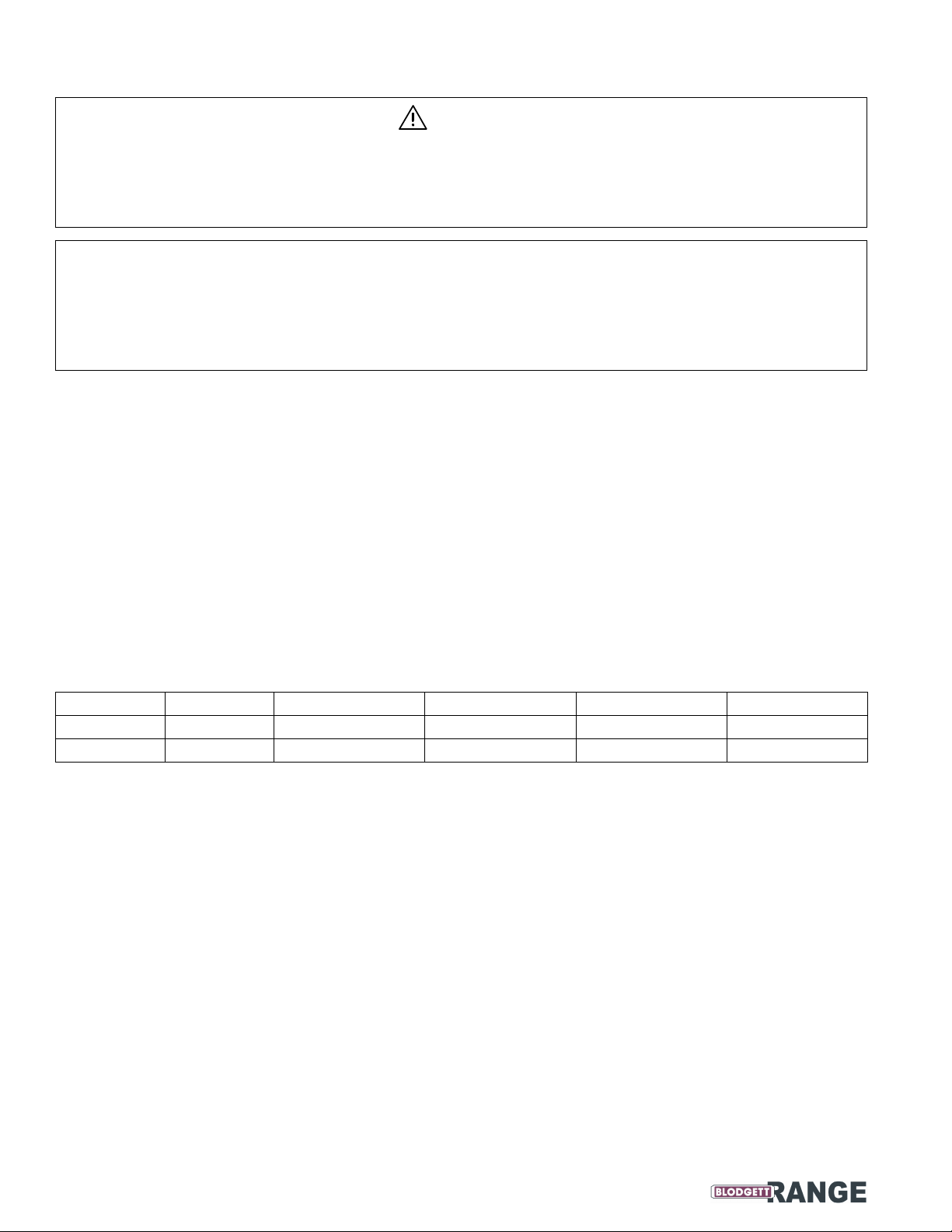

The location of the broiler controls and other components are shown in Figure 3 below.

Figure 3

Broiler Operation

Broiler Rack Height

Adjustment Lever

3"

Front 3" of broiler

is a reduced-heat

holding area.

Keep the drippings pan in place when broiling. Without it in place, excessive air is

pulled past the burners, reducing temperature and cooking efficiency.

OWNER'S MANUAL 1184962 PAGE 7 OF 24

Broiler Rack

(rolls out)

Broiler Burner Control

(OFF-HIGH-LOW)

Broiler Drippings

Collection Pan

Page 8

OPERATION INFRARED SALAMANDER BROILER

LIGHTING AFTER GAS HAS BEEN SHUT OFF

When turning on the main gas supply to an appliance or a group of appliances, do the following:

1. Make sure that all the control valves and power switches of all the appliances are in the OFF position.

2. Turn on the main gas supply valve.

3. Light the standing pilots of each connected appliance.

4. For broilers that are mounted over a sectional range and which receive their gas from the front-manifold of the

sectional range, light the ovens of the sectional range first, then wait six minutes before lighting the broilers. This

enables all air to be purged from the sectional-range gas piping.

OPERATION OF INFRARED BROILER

Blodgett Range infrared broilers broil in half the time of ordinary broilers. The burners reach operating temperature in

just 90 seconds, and their intense infrared energy quickly heats the food, not the surrounding air. The broiling rack

adjusts to five heights, and rolls out for easy access.

The broiler grid (the cooking area) is 23-3/4" (603 mm) wide by 14-1/2" (368 mm) deep. The front 3" (76 mm) of the

grid receives less heat, and so can be used as a lower-temperature holding area. As food cooks, drippings drain into

a collection tray on the bottom of the broiler cavity. To operate the broiler, do the following:

1. Light the constant-burning pilots located near the front of the broiler burners (unless the pilots are already lit).

2. If necessary, pull out and empty the drippings pan. (Always keep the drippings tray in place while broiling. Without

it in place, excessive air will be pulled past the burners, reducing the cooking temperature and efficiency.)

3. Turn the burner control to HIGH and visually check that the burners have ignited. When the burners ignite, a blue

haze-type flame will cover the surface of the ceramics, but will gradually disappear within two minutes. When the

burner control is set to HIGH, the ceramics will glow red and the flame on the surface of the ceramics should be

barely visible, with little or no blue haze. When the burner control is set to LOW, the surface of the ceramics will

glow very dull red and the flame will have a blue-haze color. (If the flame flutters or “pops” the broiler requires

adjustment by a service technician.)

4. If searing the food to mark it with grid marks is desired, before placing food on the grid move the broiler rack to its

highest position and allow the burners to operate on HIGH for five minutes.

5. Turn the burner control to HIGH, LOW, or somewhere in between (as appropriate for the food to be cooked).

6. Raise or lower the broiler rack to the height appropriate for the food to be cooked. To raise or lower the rack,

move the lever arm to the right, raise or lower it, then move it to the left into a notch.

7. Pull out the rack, place food on the grid, and slide the rack back into the broiler. Remember that the front 3" of the

grid receives less heat so it can be used as a holding area. This holding area is marked by a 1/8" diameter rod.

8. Cook the food for the appropriate time, turning it when appropriate. Periodically check the broiler drippings tray

and empty it when necessary.

9. When done broiling, turn the burner control to OFF. (To keep the broiler grid hot in order to mark food with sear

marks without preheating, turn the burner controls to LOW and move the broiler rack to its highest position.)

LIGHTING BROILER PILOTS

The pilots should burn continuously unless the broiler is to be completely shut down. The broiler cavity has two pilots,

each near the front of a pair of burners. If the pilots are extinguished, the pilot gas supply is NOT automatically

interrupted. To light the pilots, do the following:

1. Turn the control valve on the front of the broiler to OFF.

2. Turn on the gas supply to the broiler (if not already on).

3. Light the pilots.

SHUTDOWN OF BROILER

To place the broiler in a standby state (ready for use), turn the burner control valve to OFF. The pilots will remain lit.

To completely shut down the broiler for an extended period (or prior to disconnecting the gas supply), turn OFF the

manual shut-off valves of all gas supply connections. (This will extinguish all pilots.)

PAGE 8 OF 24 OWNER'S MANUAL 1184962

Page 9

INFRARED SALAMANDER BROILER CLEANING & MAINTENANCE

CLEANING & MAINTENANCE

WARNING

Shut off the gas supply to the appliance before cleaning or performing maintenance on any gas appliance.

The appliance may be equipped with a restraint device to limit its movement in order to prevent damage to the

gas connection. If disconnection of this restraint is necessary to move the appliance for cleaning or

maintenance, reconnect the restraint when the appliance is moved back to its original installed position.

Blodgett Range equipment is sturdily constructed of the best materials and is designed to provide durable service

when treated with ordinary care. To expect the best performance, your equipment must be maintained in good

condition and cleaned daily. Naturally, the periods for this care and cleaning depend on the amount and degree of

usage.

Following daily and periodic maintenance procedures will enhance long life for your equipment. Climatic conditions

(such as salt air) may require more thorough and frequent cleaning or the life of the equipment could be adversely

affected.

Keep exposed, cleanable areas of broiler clean at all times. (See next page for instructions on cleaning stainless

steel and baked-enamel surfaces.)

DAILY CLEANING AND MAINTENANCE

To prevent excess smoking, the broiler grid, drippings pan, and the other broiler components must be kept clean of

food remnants. Use a wire brush or similar scraping utensil. DO NOT use steel wool or similar scrub pad that will

leave small particles, which can get into food. The daily cleaning procedure is as follows:

1. Move the broiling rack to the low position. Pull out the rolling broiler rack.

2. Lift out the broiler grids and clean them with a wire brush or non-toxic solvent.

3. With rolling rack pulled-out to its “stop,” raise front handle so rack's rollers will come through the notches in the

raising and lowering frame. Clean all parts where residue can collect.

4. Remove the drippings pan and clean it.

5. Clean all parts of the raising and lowering frame.

6. Lubricate bearings with cooking oil.

7. Reassemble broiling rack mechanism.

8. Check that nothing has been placed on top of the broiler (which will block the escape of combustion exhaust).

9. Check that the air-intake openings on the rear of the broiler are not obstructed.

MONTHLY CLEANING AND MAINTENANCE

The following tasks should be performed monthly:

1. Clean around burner air mixers and orifices if lint has accumulated in these areas.

2. Check for proper pilot operation. The flame on each pilot should be just large enough to extend along the flame

carrier to the burner surface. If adjustment is necessary, call for service.

3. Check for proper burner operation. When the burner control is set to HIGH, the ceramics should glow red and the

flame on the surface of the ceramics should be barely visible, with little or no blue haze. When the burner control

is set to LOW, the surface of the ceramics should glow very dull red and the flame should have a blue-haze color.

The flame should not flutter or “pop”. If adjustment is necessary, call for service.

SEMIANNUAL CLEANING AND MAINTENANCE

At least twice a year the venting system should be examined and cleaned.

OWNER'S MANUAL 1184962 PAGE 9 OF 24

Page 10

CLEANING & MAINTENANCE INFRARED SALAMANDER BROILER

STAINLESS-STEEL SURFACES

To remove normal dirt, grease and product residue from stainless steel surfaces that operate at LOW temperature,

use ordinary soap and water (with or without detergent) applied with a sponge or cloth. Dry thoroughly with a clean

cloth.

To remove BAKED-ON grease and food splatter, or condensed vapors; apply cleanser to a damp cloth or sponge and

rub cleanser on the metal in the direction of the polishing lines on the metal. Rubbing cleanser, as gently as possible,

in the direction of the polished lines will not mar the finish of the stainless steel. NEVER RUB WITH A CIRCULAR

MOTION. Soil and burnt deposits which do not respond to the above procedure can usually be removed by rubbing

the surface with SCOTCH-BRITE scouring pads or STAINLESS scouring pads. DO NOT USE ORDINARY STEEL

WOOL as any particles left on the surface will rust and further spoil the appearance of the finish. NEVER USE A

WIRE BRUSH, STEEL SCOURING PADS (EXCEPT STAINLESS), SCRAPER, FILE OR OTHER STEEL TOOLS.

Surfaces which are marred collect dirt more rapidly and become more difficult to clean. Marring also increases the

possibility of corrosive attack. Refinishing may then be required.

“Heat tint” is darkened areas that sometimes appear on stainless steel surfaces where the area has been subjected to

excessive heat. These darkened areas are caused by thickening of the protective surface of the stainless steel and

are not harmful. Heat tint can normally be removed by the foregoing, but tint which does not respond to this procedure

calls for a vigorous scouring in the direction of the polish lines using SCOTCH-BRITE scouring pads or a STAINLESS

scouring pad in combination with a powered cleanser. Heat tint may be lessened by reducing heat to equipment

during slack periods.

BLACK BAKED-ENAMEL SURFACES

Allow appliance to cool somewhat after use and wash black baked-enamel surfaces with a hot, mild detergent or soap

solution. In particular, clean off all grease deposits. Dry thoroughly with a dry cloth.

PAGE 10 OF 24 OWNER'S MANUAL 1184962

Page 11

INFRARED SALAMANDER BROILER INSTALLATION

INSTALLATION

NOTICE

These installation procedures must be followed by qualified personnel or warranty will be void.

Local codes regarding installation vary greatly from one area to another. The National Fire Protection Association,

Inc. states in its NFPA 96 latest edition that local codes are the “authority having jurisdiction” when it comes to

installation requirements for equipment. Therefore, installations should comply with all local codes.

The installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas Code,

ANSI Z223.1, Natural Gas Installation Code, CAN/CGA-B149.1, or the Propane Installation Code CAN/CGAB149.2, as applicable, including:

1. The appliance and its individual shutoff valve must be disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in excess of 1/2 psi (3.45 kPa).

2. The appliance must be isolated from the gas supply piping system by closing its individual manual shutoff valve

during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psi (3.45

kPa).

The following installation procedure is for the free-standing models. For the sectional-match models, follow the

installation instructions in the Blodgett Range Saffire Sectional Ranges Owner's Manual (1184743) to install the

sectional range, incorporating the following steps into that procedure.

STEP 1: UNPACKING

IMMEDIATELY INSPECT FOR SHIPPING DAMAGE

All containers should be examined for damage before and during unloading. The freight carrier has assumed

responsibility for its safe transit and delivery. If damaged equipment is received, either apparent or concealed, a

claim must be made with the delivering carrier.

Apparent damage or loss must be noted on the freight bill at the time of delivery. The freight bill must then be

signed by the carrier representative (Driver). If the bill is not signed, the carrier may refuse the claim. The carrier

can supply the necessary forms.

A request for inspection must be made to the carrier within 15 days if there is concealed damage or loss that is not

apparent until after the equipment is uncrated. The carrier should arrange an inspection. Be certain to hold all

contents plus all packing material.

1. Cut the banding straps and remove the corrugated cardboard surrounding the broiler. Do not remove any of the

attached tags or labels until the broiler is installed and working properly.

2. Cut the banding strap holding the broiler to the wooden skid.

3. Do NOT remove (yet) the six screws at the ends of the burners that hold the burners in place during shipping.

4. If installing a model BMRA-32 (which mounts over a sectional range), go to Step 2a.

If installing a model BMRA-32W (which mounts on a wall, go to Step 2b.

If installing a model BMRA-32C (which has legs for countertop use), go to Step 2c.

OWNER'S MANUAL 1184962 PAGE 11 OF 24

Page 12

INSTALLATION INFRARED SALAMANDER BROILER

STEP 2A: MOUNT ON FLUE RISER OF SECTIONAL RANGE

A Model BMRA-32 mounts over a sectional range. A special flue riser with a cut-out opening will have been shipped

with the broiler and sectional range. Depending on the shipping requirements, the broiler, flue-riser, and sectionalrange base may already be partially or completely assembled.

1. Check that the shipping-screws that hold the burners in place during shipping have NOT yet been removed.

2. Attach the flue riser to the rear of the sectional range using the installation procedure included in the sectionalrange manual, but do not attach the wall shield (the back of the flue riser) yet.

3. Attach the broiler hook (item “A” in Figure 4 below) to the rear of the broiler (item “B”) using the three provided

sheet-metal screws.

4. Lift the broiler (using two people is recommended) and hook the broiler-hook over the top-front edge of the flue

riser. If necessary, move the broiler left or right so that the holes in the top of the broiler hook line-up with the

holes in the top of the flue riser, then secure the broiler-hook to the flue riser using three sheet-metal screws.

5. Secure the bottom rear corners of the broiler to the flue riser with two provided sheet-metal screws. The holes are

accessible from the bottom since the bottom cover (or sloped-enclosure) has not yet been installed.

6. If the optional internal piping from the broiler to the sectional range was ordered, connect the gas line now (as

described in Step 3), before attaching the wall shield.

7. Attach the wall shield, which forms the rear of the flue riser. The gas supply pipe extending out from the rear of

the broiler should extend through the corresponding hole on the back of the flue riser.

8. Go on to Step 3.

Figure 4

Mounting of Model BMRA-32 on Flue-Riser

PAGE 12 OF 24 OWNER'S MANUAL 1184962

Page 13

INFRARED SALAMANDER BROILER INSTALLATION

STEP 2B: MOUNT ON WALL

The model BMRA-32W broiler is installed by first attaching a mounting bracket to the wall, then attaching the broiler to

the bracket.

1. Check that the shipping-screws that hold the burners in place during shipping have NOT yet been removed.

2. Attach the wall-mount assembly to the wall using the six screws and six washers provided (see Figure 5). Make

sure that the screws hit wall studs since the broiler weighs about 150 pounds (68 kilograms).

3. Check that the wall-mount is level (both side-to-side and front-to-back).

Figure 5

Installation of Wall Bracket for Model BMRA-32W

4. Attach the broiler hook (item “A” in Figure 6 on next page) to the rear of the broiler using the three provided sheet-

metal screws.

5. It may be more convenient to prepare the gas supply line before the broiler is mounted on the wall bracket. If so,

install the supply line and connector now (but do not yet attach it to the broiler).

6. Lift the broiler (using two people is recommended) and hook the broiler-hook over the top of the front of the wall

bracket. If necessary, move the broiler left or right so that the holes in the top of the broiler hook line-up with the

holes in the wall bracket, then secure the broiler-hook to the wall-mount bracket using three sheet-metal screws.

7. Secure the bottom rear corners of the broiler to the wall-mount bracket with the two provided sheet-metal screws.

The holes are accessible from the bottom before the bottom cover has been installed.

8. Go on to Step 3.

OWNER'S MANUAL 1184962 PAGE 13 OF 24

Page 14

INSTALLATION INFRARED SALAMANDER BROILER

Figure 6

Attachment of Model BMRA-32W to Wall-Mount Bracket

STEP 2C: ATTACH COUNTERTOP LEGS AND SPACERS

A Model BMRA-32C has legs to support the broiler on a non-combustible countertop, and spacers that extend from

the rear to help ensure that there is adequate clearance to permit air to enter the rear of the broiler. These parts and

hardware connectors are shipped in a bag inside the broiler cavity.

1. Check that the shipping-screws that hold the burners in place during shipping have NOT yet been removed, then

carefully lay the broiler on its back (see Figure 7).

2. Install each leg (labeled “L” in Figure 7) using eight flat washers and four #10x1/2" sheet-metal screws inserted

into the pre-drilled holes on the bottom of the broiler.

3. Stand the broiler on its legs and install two shoulder bolts (labeled “B” in Figure 7) in the pre-drilled holes on the

back of the broiler (near the bottom corners). Use the provided flat washer, locknut, and hex-nut provided. When

installed, the bolts extend rearward to prevent the broiler from being positioned flush against a wall (which would

block the flow of air for the burners into the rear of the broiler).

PAGE 14 OF 24 OWNER'S MANUAL 1184962

Page 15

INFRARED SALAMANDER BROILER INSTALLATION

Figure 7

Attaching Legs and Spacers to Model BMRA-32C

STEP 3: CONNECT GAS SUPPLY

If this equipment is being installed at over 2,000 feet altitude and that information was not specified when ordered,

contact the appropriate authorized Blodgett Range Service Representative or the Blodgett Range Service

Department. Failure to install with proper orifice sizing will result in poor performance and may void the warranty.

The broiler is design-certified for operation on natural or propane gases. The broiler is shipped configured and

adjusted for the type of gas specified by the purchaser, which is indicated on the serial plate (see Figure 1 on page 3).

Connect the broiler ONLY to the type of gas for which it is configured and adjusted.

A model BMRA-32 mounts on the flue riser of a sectional range, and either will have a 3/8" rear gas connection (with

a 3/8" male NPT connector) extending through the rear of the flue riser (see Figure 2 on page 5), or will have the

optional internal-piping to the front-manifold of the sectional range.

For models BMRA-32W (wall-mount) and BMRA-32C (countertop), the gas supply is connected to the inlet of the

internal pressure regulator (which has a 3/8" female NPT connector). The gas connection can extend directly out the

rear of the broiler (near the bottom-right-rear corner), or (using an elbow) out the top of the broiler near the top-rightrear corner, or (using an elbow) out the bottom of the broiler near the bottom-right-rear corner.

Minimum supply pressure is 7" W.C. for natural gas, 11" W.C. for propane. An internal pressure regulator and shut off

valve are provided. If using a flexible-hose gas connection, the I.D. of the hose must not be smaller than the

connector on the broiler, and must comply with ANSI Z21.69. Provide an adequate means of restraint to prevent

undue strain on the gas connection.

If applicable, the vent line from the gas appliance pressure regulator shall be installed to the outdoors in accordance

with local codes, or in the absence of local codes, with the National Fuel Gas Code, ANSI Z223.1, Natural Gas

Installation Code, CAN/CGA-B149.1, or the Propane Installation Code CAN/CGA-B149.2, as applicable.

An adequate gas supply is imperative. Undersized or low pressure lines will restrict the volume of gas required for

satisfactory performance. Fluctuations of more than 25% on natural gas or 10% on propane gas will create problems

and affect burner operating characteristics. A 1/8" pressure tap is located on the manifold to measure the manifold

pressure. The supply line to the broiler should be no smaller than the inside diameter of the pipe on the broiler to

which it is connected.

CAUTION

ALL PIPE JOINTS AND CONNECTIONS MUST BE TESTED THOROUGHLY FOR GAS LEAKS. USE ONLY

SOAPY WATER FOR TESTING ON ALL GASES. NEVER USE AN OPEN FLAME TO CHECK FOR GAS LEAKS.

ALL CONNECTIONS MUST BE CHECKED FOR LEAKS AFTER THE APPLIANCE HAS BEEN PUT INTO

OPERATION. TEST PRESSURE SHOULD NOT EXCEED 14" W.C.

OWNER'S MANUAL 1184962 PAGE 15 OF 24

Page 16

INSTALLATION INFRARED SALAMANDER BROILER

1. Check that the control valve on the broiler is in the OFF position.

2. Purge the gas supply line to clean out dust, dirt, or other foreign matter before

connecting the line to the broiler.

3. For wall-mount and countertop models, connect the gas supply to the inlet on the pressure regulator. A

connection extending out the rear can be made directly to the inlet on the pressure regulator. A connection

extending out the top can be made by attaching an elbow to the inlet and running the gas line up though a

knockout hole in the top partition and through a hole in the expanded metal top (which must be drilled). A

connection extending out the bottom can be made by attaching an elbow to the inlet and running the gas line

down through a knockout hole in the bottom partition and a knockout hole in the bottom cover (which has not yet

been installed).

CAUTION

HOLD THE PRESSURE REGULATOR WITH A WRENCH WHEN TIGHTENING THE CONNECTION TO THE

SUPPLY PIPE TO AVOID DAMAGE TO THE REGULATOR, VALVE, AND OTHER COMPONENTS.

4. For the flue-riser-mounted model, either attach the gas supply to the gas pipe extending out of a hole on the rear

of the flue riser; or (if the optional internal piping was ordered) connect the gas pipe extending from the rear of the

broiler to the corresponding gas pipe extending from the rear of the sectional range below the broiler, then attach

the wall-shield (the rear of the flue riser).

5. Turn on the gas and check for leaks using soapy water.

6. Remove the six screws (one at each end of the three burners) that held the burners in place during

shipping.

STEP 4: INSTALL BOTTOM COVER (OR SLOPED ENCLOSURE)

A model BMRA-32W (wall-mount) has a flat bottom cover, while a model BMRA-32 (flue-riser mount) has either a flat

bottom cover or a sloped enclosure. (A bottom cover is shipped with countertop model BMRA-32C, but it is not used.)

To install a flat bottom cover (item “C” in Figure 8), first temporarily remove the body-side-retainers (item “F”). Then

place the bottom cover into position (note that the flanges on the bottom cover go inside the broiler housing). Finally,

reattach the two body-side retainers. (If the optional sloped enclosure was ordered, install it at this time.)

Figure 8

Installation of Flat Bottom Cover

PAGE 16 OF 24 OWNER'S MANUAL 1184962

Page 17

INFRARED SALAMANDER BROILER INSTALLATION

STEP 5: CHECK THE INSTALLATION

1. Check that all screws and bolts are tightened.

2. Check that gas connection has been made correctly.

3. Check that the six screws (one at each end of the three burners) that held the burners in place during shipping

have been removed.

4. Move the broiler into the final position at which it will be operated.

5. Check that the broiler is level.

6. Check that the appropriate minimum clearances are satisfied (see page 4), including adequate clearance for

combustion air to enter the rear of the broiler.

7. Check that there is sufficient clearance to pull-out the broiler rack and drippings pan.

8. Check that adequate ventilation (fresh air supply and hood exhaust) is available to the room in which the

appliance will operate.

9. Wipe clean all surfaces.

STEP 6: CHECK BROILER OPERATION

1. Turn gas supply on. Immediately check all gas connections for leaks using soapy water.

2. Light the pilots (see the appropriate Operation section elsewhere in this manual). Check that the pilot flames are

large enough to extend along the flame carrier to the burner surface. If not, adjust the pilots (see page 19).

3. Turn on the broiler burners and check for correct flame appearance and height at both the HIGH and LOW

settings. When the burners ignite, a blue haze-type flame will cover the surface of the ceramics, but will gradually

disappear within two minutes. When the burner control is set to HIGH, the ceramics should glow red and the

flame on the surface of the ceramics should be barely visible, with little or no blue haze. When the burner control

is set to LOW, the surface of the ceramics should glow very dull red and the flame should have a blue-haze color.

The flame should not flutter or “pop”. If necessary, adjust the burners (see page 20) and/or LOW setting (see

page 19).

4. Check that gas supply is adequate by simultaneously turning on all burners of all appliances connected to the

same gas supply to their highest setting, then again checking that the broiler's pilot and burner flames have

correct appearance and height.

5. Turn-off all burners and allow the broiler to cool.

STEP 7: WIPE-CLEAN AND SHUT-DOWN APPLIANCE

1. Wipe clean all surfaces.

2. Unless the broiler is to be placed in service immediately, shut off the gas supply.

3. Make sure that a copy of this manual will be available to the people who will operate and maintain the broiler.

OWNER'S MANUAL 1184962 PAGE 17 OF 24

Page 18

SERVICE INFRARED SALAMANDER BROILER

SERVICE

WARNING

ADJUSTMENTS AND SERVICE WORK MAY BE PERFORMED ONLY BY A QUALIFIED TECHNICIAN WHO IS

EXPERIENCED IN, AND KNOWLEDGEABLE WITH, THE OPERATION OF COMMERCIAL COOKING

EQUIPMENT. TO ASSURE YOUR CONFIDENCE, CONTACT YOUR AUTHORIZED SERVICE AGENCY FOR

RELIABLE SERVICE, DEPENDABLE ADVICE OR OTHER ASSISTANCE, AND FOR GENUINE FACTORY

PARTS.

NOTICE

INSTALLATION OF OTHER THAN GENUINE BLODGETT RANGE PARTS WILL VOID THE WARRANTY ON

THIS EQUIPMENT.

The serial plate is located under the broiler drippings pan at the front, toward the left (see Figure 1 on page 3).

Replacement parts (including parts not listed in this manual) may be ordered either through a Blodgett Range

Authorized Parts Distributor or a Blodgett Range Authorized Service Agency.

When ordering parts, please supply the Model Number, Serial Number, Part Number, and Part Description.

TROUBLESHOOTING

Problem Look for -

Not enough heat – Low pressure in gas supply

– Restriction in gas piping and/or valves

– Misalignment of burner orifice tube

– Clogged burner orifice

– Incorrect burner orifice

Too much heat – Incorrect orifices

– Defective or incorrectly set pressure regulator

Burner flame has excessive blue haze – Obstruction of combustion-air intake on rear of broiler

– Exhaust gases blocked by objects sitting on top of broiler

– Low pressure in gas supply

– Misalignment of orifice tube

Burner flame fluttering – LOW setting of burner valve out of adjustment

Burner flame popping – Cracked or loose ceramic

Slow burner ignition – Pilot flame out of adjustment

– Pilot alignment out of adjustment

Pilot outage – Pilot flame out of adjustment

– Draft condition

– Pilot orifice clogged

– Incorrect pilot orifice

PAGE 18 OF 24 OWNER'S MANUAL 1184962

Page 19

INFRARED SALAMANDER BROILER SERVICE

ACCESS TO SERVICEABLE PARTS

Some serviceable parts are only accessible by removing a body side panel and/or the front panel.

Each body side panel (labeled “B” in Figure 9) is fastened with two sheet-metal screws (labeled “S1” and “F1” or “F2”).

To remove a body side, remove the screws and slide the body side rearward and up. (It is not necessary to remove

the front panel in order to remove a side panel provided that the installation provides enough clearance to slide the

side panels.)

The main front panel (labeled “M” in Figure 9) is fastened with six sheet-metal screws (labeled “F1”, “F2”, “F3”, “F4”,

“F5”, and “F6”). To remove the front panel, remove these screws, as well as the burner-control-valve knob and the

rack-height-position-lever knob. The main front panel can then be pulled forward and removed.

Figure 9

Access to Serviceable Parts

If necessary (or convenient), wall-mounted and flue-riser-mounted models can be un-mounted for servicing or repairs.

Use two people since the broiler weighs about 150 pounds (68 kilograms). Refer to the installation procedure in the

previous section of this manual for guidance.

ADJUSTMENT OF BROILER PILOTS

The pilots are adjusted at the factory. If later the pilots are over-adjusted to the point where the flame is leaving its

port, or “blowing off,” the result is an unstable condition in which the pilot may extinguish. If necessary, adjust the

pilots using the following procedure:

1. If necessary, light the pilots.

2. Locate the pilot adjustment screw (which adjusts both pilots). It is a small slotted screw located on the pilot valve,

and is accessed though a hole in the front panel above the control-valve knob.

3. Turn the pilot adjustment screw to adjust the size of the pilot flames. The flame on each pilot should be large

enough to extend along the flame carrier to the burner surface.

ADJUSTMENT OF LOW SETTING

The minimum gas flow of the burner control valve (which occurs when the valve is in the LOW position) is adjusted by

a set screw in the hollow stem of the valve. Turn the set screw clockwise to reduce the gas flow, or counterclockwise

OWNER'S MANUAL 1184962 PAGE 19 OF 24

Page 20

SERVICE INFRARED SALAMANDER BROILER

to increase the gas flow. Adjust the screw so that when the broiler control knob is in the LOW position, the burner

flames do not flutter or “pop”, but rather burn with a dull red and a blue haze.

ADJUSTMENT OF BROILER BURNERS

The infra-red burners require no air adjustment after they have left the factory. If a major change in burner operation is

noticed, check for obstruction of air flow, including around the burner air mixer and orifice. Burner performance is

effected by (a) orifice size, (b) pressure, (c) injection, and (d) primary air flow. The burner orifice must be centered

within the air mixer opening.

ADJUSTMENT OF GAS PRESSURE REGULATOR

The pressure regulator is located in the right-hand interior compartment of the broiler. Accessing it may require

removing the right side panel of the broiler. The regulator is preset for 4" W.C. for natural gas, or 10" W.C. for propane

gas. If adjustment is necessary, do the following:

1. Turn broiler control knob to OFF.

2. Attach a pressure measuring device to the 1/8" NPT connector located on the rear of the burner manifold.

3. Turn the broiler control knob to HIGH and, with the burners lit, check the manifold pressure. The pressure should

be 4" W.C. (for natural gas) or 10" W.C. (for propane gas).

4. If necessary, adjust the pressure by unscrewing the top of the pressure regulator (use a screwdriver) to expose

the adjustment screw underneath. Rotating the adjustment screw clockwise increases the manifold pressure.

5. After the pressure has been adjusted, turn the broiler control knob to OFF, replace the top of the pressure

regulator, and disconnect the pressure measuring device (replacing the plug into the connector on the manifold).

PARTS

The following table and Figure 10 (on page 22) describe the serviceable parts.

Parts List

Part Number

1160486 1 1 1

1160515 1 1 1

1185007 1 1 1

1075105 1 1 1

1075106 1 1 1

1078600 1 1 1

1077500 1 1 1

1077200 1 1 1

1184689 1 1 1

1075001 1 1 1

1075099 1 1 1

1176014 1 1 1

1176015 1 1 1

P5239-3 1 1 1

1176664 1 1 1

1176665 1 1 1

1160622 1 1 1

1133301 1 1 1

1165704 1 1 1

1078401 1 1 1

1075496 1 1 1

1075400 1 1 1

P6016 4 4 4

1173562 1 1 1

1173874 2 2 2

Quantity*

32 32C 32W

Description

BROILER RACK

SS BODY FRONT FOR MRA

BLODGETT RANGE NAMEPLATE SMALL

LEFT BODY SIDE SS

RIGHT BODY SIDE SS

MAIN BOTTOM COVER

BLACK PERFERATED BODY TOP

RACK GREASE DRAWER

KNOB

LEFT BURNER REST

RIGHT BURNER REST

HI-LO VALVE - NATURAL GAS

HI-LO VALVE - LP GAS

PIPE UNION

PILOT ASSEMBLY - NATURAL GAS

PILOT ASSEMBLY - LP GAS

SUPPLY PIPE ASSEMBLY

PRESSURE REGULATOR - NATURAL GAS

PRESSURE REGULATOR - PROPANE GAS

MANIFOLD TUBE

MANIFOLD ASSEMBLY (with connectors and plug)

MANIFOLD PIPE

MALE CONNECTORS

TWIN PILOT ADJSUTMENT VALVE

PILOT SUPPLY TUBE

PAGE 20 OF 24 OWNER'S MANUAL 1184962

Page 21

INFRARED SALAMANDER BROILER SERVICE

Parts List

Part Number

1057519 3 3 3

1057520 3 3 3

1008753 3 3 3

1008763 3 3 3

1076200 1 1 1

12476 1 1 1

1160413 3 3 3

1160418 1 1 1

1160419 1 1 1

1173874 2 2 2

1160465 1 1 1

1160469 1 1 1

1160475 1 1 1

1160477 1 1 1

1160478 1 1 1

1160479 1 1 1

1160484 2 2 2

P1089 2 2 2

1160495 1 1 1

1160494 1 1 1

4440000 1 1 1

1160500 1 1 1

1160504 1 1 1

1160505 1 1 1

1160512 1 1 1

1160507 1 1 1

1160508 1 1 1

1160622 1 1 1

1168212 1 1 1

MRL-30 - 1 MRW30-7 - - 1

1161331 1 1 1

* Quantity of part used by each model: “32” = Model BMRA-32 (mounts over sectional range), “32C” = Model BMRA-32C (countertop), “32W” = Model

BMRA-32W (mounts on wall using bracket).

Quantity*

32 32C 32W

Description

BURNER ASSEMBLY CPL - NAT

BURNER ASSEMBLY CPL - LP

BURNER ORIFICE #53 - NAT GAS

BURNER ORIFICE #63 - LP GAS

BROILER HOOK

PLUG BUTTON

BEARING

MANIFOLD TUBE 3/8" O.D.

BURNER SUPPLY TUBE 3/8" O.D.

PILOT TUBING

SHAFT - LEFT ARM ASSEMBLY - UPPER

SHAFT - LEFT ARM ASSEMBLY - LOWER

RAISING-LOWERING KNOB

CRADLE ASSEMBLY (both)

LEFT CRADLE - SIDE ASSEMBLY

RIGHT CRADLE - SIDE ASSEMBLY

ROLLER BEARING

SPRING

INNER RACK FRAME

RACK FACE

RACK HANDLE

BACK DRIP SHIELD

SIDE DRIP SHIELD ASSEMBLY - RIGHT

SIDE DRIP SHIELD ASSEMBLY - LEFT

INDEX PLATE

SPRING MOUNTING BRACKET - RIGHT

SPRING MOUNTING BRACKET - LEFT

SUPPLY PIPE ASSEMBLY

PILOT SHIELD

LEGS FOR BMRA-32C (set of 4)

WALL MOUNT ASSEMBLY - SS

RACK DRIP PAN ASSEMBLY

OWNER'S MANUAL 1184962 PAGE 21 OF 24

Page 22

SERVICE INFRARED SALAMANDER BROILER

Figure 10

Gas Train Parts

SIDE VIEW FROM RIGHT

PAGE 22 OF 24 OWNER'S MANUAL 1184962

Page 23

INFRARED SALAMANDER BROILER

Notes:

OWNER'S MANUAL 1184962 PAGE 23 OF 24

Page 24

INFRARED SALAMANDER BROILER

INFRARED SALAMANDER BROILER

Flue-Riser Mount, Wall Mount, or Countertop

A product with the Blodgett Range name incorporates the best in durability and low maintenance. We all

recognize, however, that replacement parts and occasional professional service may be necessary to extend the

useful life of this appliance. When service is needed, contact a Blodgett Range Authorized Service Agency, or your

dealer. To avoid confusion, always refer to the model number, serial number, and type of your appliance.

Blodgett Range

1100 Old Honeycutt Road, Fuquay-Varina, NC 27526

www.blodgettrange.com

PAGE 24 OF 24 OWNER'S MANUAL 1184962

Loading...

Loading...