Page 1

BLT-E

BLODGETT OVEN COMPANY

ELECTRIC FLOOR MODEL BRAISING PAN WITH

MANUAL TIL T

INSTALLATION – OPERATION – MAINTENANCE

44 Lakeside Avenue, Burlington, Vermont 05401 USA Telephone: (802) 658-6600 Fax: (802) 864-0183

www.blodgett.com

S00070 Rev B (12/12)

1

Page 2

symbol to avoid possible injury or death.

thoroughly before installing, operating or servicing this equipment.

IMPORTANT NOTES FOR INSTALLATION AND OPERATION

It is recommended that this manual be read thoroughly and that all instructions be

followed carefully. This manual should be retained for future reference.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

WARNING: Improper installation, operation, adjustment, alteration,

service or maintenance can cause property damage, injury or death.

Read the installation, operating and maintenance instructions

ADEQUATE CLEARANCES MUST BE MAINTAINED FOR SAFE AND PROPER OPERATION.

THIS MANUAL SHOULD BE RETAINED FOR FUTURE REFERENCE.

INTENDED FOR COMMERCIAL USE ONLY. NOT FOR HOUSEHOLD USE.

2

Page 3

TABLE OF CONTENTS

DESCRIPTION PAGE

Service Connections ..................................................................................................... 4

Installation and Service Connections ............................................................................. 5

1.0 Installation Instructions ........................................................................................... 5

2.0 Operation ............................................................................................................... 6

3.0 Cooking Guidelines ................................................................................................ 7

4.0 Cleaning Instructions ............................................................................................ 11

5.0 Troubleshooting .................................................................................................... 12

6.0 Periodic Maintenance ........................................................................................... 12

3

Page 4

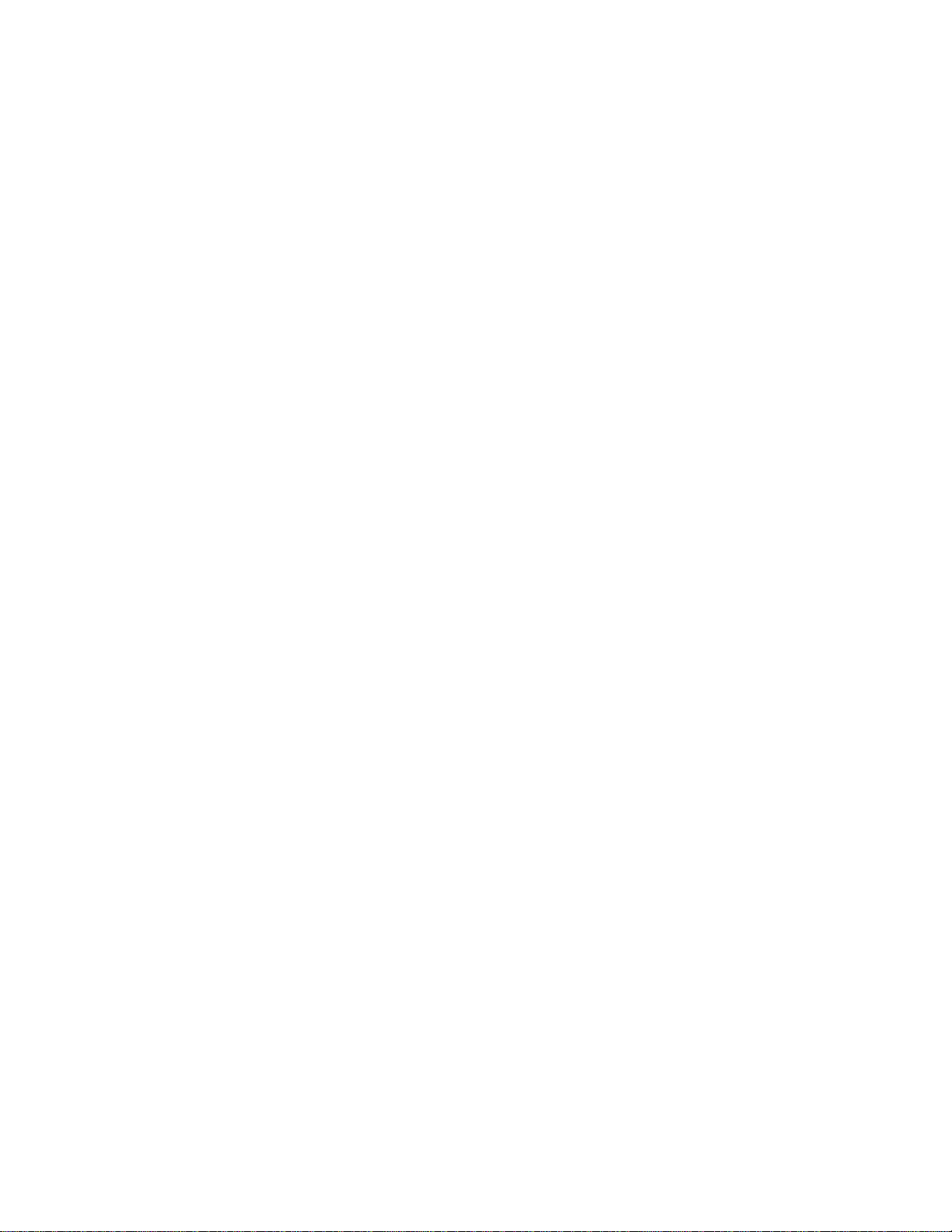

ELECTRICAL CHARACTERISTICS

Available kW

MODEL STD. OPT.

BLT-30E

BLT-40E

18 12

27 18

Min. Clearance

SIDES

BACK

6 [152]

6 [152]

Amps Per Line

12

18

27

1

1

3

3

3

kW PHASE 208V 220V 240V 380V 415V 480V

57.7

33.3

86.5

50.0

75.0

54.5

31.5

81.8

47.2

70.9

50.0

28.9

75.0

43.3

65.0

N/A N/A N/A

N/A N/A N/A

18.2 16.7 14.4

27.3

41.0

25.0

37.6

21.7

32.5

DIMENSIONS

Model Shipping Wt. Capacity Units A B C D E F

G H

2

2

3

3

BLT-30E

BLT-40E

501 lbs [228 kg]

547 lbs [248 kg]

30 gallons

[114 litres]

40 gallons

[152 litres]

inches

[mm]

49.75

[1264]

inches

[mm]59[1499]

32.88

[835]

42.88

[1089]

23.50

[597]

23

[584]

43.13

[1095]

52.50

[1334]

9.25

[235]

9.25

[235]

67.63

[1718]

67.5

[1715]

39

[991]

38.75

[984]

43.5

[1105]

43.25

[1099]

1063

[270]

10.25

[260]

11.13

[283]

10.75

[273]

A

3.25 [83]

G

2.63 [67]

C

H

B

9.75 [248]

36.63 [930]

OPTIONAL

DRAW-OFF

VALVE

OPTIONAL

FAUCET

E

18.5 [470]

D

34 [684]

36.50 [927]

F

21 [533]

21.13 [537]

SERVICE CONNECTIONS

4

Page 5

INSTALLATION AND SERVICE CONNECTIONS

1.0 INSTALLATION INSTRUCTIONS

Set braising pan in place, level appliance using spirit level. Mark hole locations on floor

through anchoring holes provided in flanged adjustable feet.

Remove appliance and drill holes in locations marked on floor and insert proper

anchoring devices.

Re-level the appliance, leveling the unit left to right and front to back.

Bolt and anchor appliance securely to the floor. Seal bolts and flanged feet with Silastic

or equivalent compound.

SERVICE CONNECTIONS

All internal wiring for the skillet is complete.

Make service connections as indicated on page 4.

This must be a waterproof connection from incoming lines.

Ground skillet to terminal provided in control housing. A wiring diagram is provided and

is located inside the control cover panel.

If faucet is provided connect water supply and check for proper operation.

5

Page 6

2.0 OPERATION

Ensure the power supply is connected to unit and that circuit breakers are on.

Tilt braising pan to ascertain that it moves easily. Turn handle as far as it will go and

return to upright position.

Turn power switch “ON”. Preheat braising pan and allow it to cycle thus equalizing heat

across entire pan surface. Cooking should be done at various temperature settings on

the dial as determined by the user. Cooking will occur faster with the cover down.

At the end of cooking turn thermostat to “OFF”, turn power switch “OFF”, remove

product.

WARNING: Never tilt pan with cover down

CAUTION: The appliance and its parts are hot. Use care when

operating, cleaning and servicing the appliance.

6

Page 7

BLT-30E PER LOAD

BLT-40E PER LOAD

3.0 COOKING GUIDELINES

The guidelines given below are suggested quantities, temperature settings, and

estimated numbers of orders per load and per hour. When two temperatures are given,

the first is to start the product, and the second to finish the product.

The following temperatures should be used:

Temperature (ΕF)

Simmering 200 Maximum

Sautéing 225 - 275

Searing 300 - 350

Frying 325 - 375

Grilling 350 - 450

ITEM

BREAKFAST FOODS

Bacon 3 slices 350 12 2 lbs. 10 3 lbs. 15

Eggs

- Boiled-Hard 1 egg 225 5 50 eggs 50 75 eggs 75

- Boiled-Soft 1 egg 225 8 50 eggs 50 75 eggs 75

- Fried 1 egg 400 4 30 eggs 30 45 eggs 45

- Poached 1 egg 225 5 36 eggs 36 60 eggs 60

PORTION TEMP (F) BATCH/HR

QTY PORTIONS

QTY PORTIONS

- Scrambled 1-1/2 eggs 300-200 1 18 gal. 720 28 gal. 1100

French Toast 3 slices 450 7 35 slices 12 50 slices 17

Regular

Oatmeal

Pancakes 2 each 400 10 30 ea. 15 50 ea. 25

Clams 1 pt. 400 10 10 qts. 20 15 qts. 30

Fish Cakes 2 - 3 oz. 400 5 70 - 3 oz. 35 110 - 3 oz. 55

Haddock Fillet 4 oz. 400 4 60 - 4 oz. 60 90 - 4 oz. 90

Halibut Steak 5 oz. 450 3 60 - 4 oz. 60 90 - 4 oz. 90

Lobster 1 - 1 lb. 350 4 20 - 1 lb. 20 30 - 1 lb. 30

Swordfish 5 oz. 450 3 50 - 5 oz. 50 75 - 5 oz. 75

½ cup 250 2 20 lbs.

(100 cups)

FISH

500 40 lbs. (200

cups)

1000

7

Page 8

BLT-30E PER LOAD

BLT-40E PER LOAD

ITEM

SAUCES, GRAVIES, SOUPS

Brown Gravy 1 oz. 350 - 200 2 18 gal. 2300 35 gal. 4500

Cream Sauce 2 oz. 250 - 175 1 18 gal. 1150 35 gal. 2250

Cream Soup 6 oz. 200 1 18 gal. 375 35 gal. 725

French Onion

Soup

Meat Sauce 4 oz. 350 - 200 1 18 gal. 575 35 gal. 1100

VEGETABLES

CANNED

FRESH

Beans, Wax,

Green

Beets 3 oz. 400 1 30 lbs. 125 60 lbs. 300

Broccoli 3 oz. 400 3 25 lbs. 125 40 lbs. 200

Cabbage 3 oz. 400 5 20 lbs. 80 30 lbs. 125

Carrots 3 oz. 400 2 35 lbs. 150 70 lbs. 300

PORTION TEMP (F) BATCH/HR

6 oz. 225 1 18 gal. 350 35 gal. 700

3 oz. 400 6 30 lbs. 125 45 lbs. 200

3 oz. 400 3 25 lbs. 125 50 lbs. 250

QTY PORTIONS

QTY PORTIONS

Cauliflower 3 oz. 250 5 15 lbs. 75 25 lbs. 125

Corn 1 ear 400 8 50 ears 50 75 ears 75

Potatoes 3 oz. 400 2 40 lbs. 200 60 lbs. 300

Spinach 4 oz. 250 10 6 lbs. 25 9 lbs. 35

Turnips 4 oz. 400 2 20 lbs. 100 30 lbs. 150

FROZEN

Beans, French

Green

Lima Beans 3 oz. 250 4 15 lbs. 60 22-1/2 lbs. 90

Broccoli 3 oz. 400 8 12 lbs. 50 18 lbs. 75

Sliced Carrots 3 oz. 250 6 15 lbs. 60 22-1/2 lbs. 90

Small Whole

Carrots

Corn 3 oz. 250 18 15 lbs. 50 22-1/2 lbs. 90

Small Whole

Onions

Peas 3 oz. 400 10 15 lbs. 75 22-1/2 lbs. 110

Spinach 3 oz. 400 3 15 lbs. 75 22-1/2 lbs. 110

3 oz. 400 6 15 lbs. 60 22-1/2 lbs. 90

3 oz. 250 3 15 lbs. 50 22-1/2 lbs. 90

3 oz. 250 7 15 lbs. 50 22-1/2 lbs. 90

8

Page 9

BLT-30E PER LOAD

BLT-40E PER LOAD

ITEM

DESSERTS, PUDDINGS, SWEET SAUCES

Butterscotch

Sauce

Cherry Cobbler 3 oz. 200 1 18 gal. 750 35 gal. 1500

Chocolate

Sauce

Cornstarch

Pudding

Fruit Gelatin 3 oz. 250 2 18 gal. 750 35 gal. 1500

MEAT-POULTRY

Bacon 3 slices 350 12 2 lbs. 10 3 lbs. 15

BEEF

Amer. Chop

Suey

Beef Stew 8 oz. 300 - 18 gal. 280 35 gal. 560

Corned Beef

Hash

PORTION

1 oz. 200 1 18 gal. 2300 35 gal. 4500

1 oz. 200 1 18 gal. 2300 35 gal. 4500

4 oz. 200 1 18 gal. 575 35 gal. 1100

6 oz. 400 - 225 2 18 gal. 350 35 gal. 700

5 oz. 400 5 16 lbs. 50 25 lbs. 75

TEMP (F) BATCH/HR

QTY PORTIONS

QTY PORTIONS

Cheeseburger 3 oz. 300 12 7 lbs. 35 10 lbs. 50

Hamburger 3 oz. 300 15 7 lbs. 35 10 lbs. 50

Meatballs 1 oz. 400-225 3 12-1/2 lbs. 65 18 lbs. 100

Pot Roast 2 oz. 350-200 120 lbs. 500 180 lbs. 750

Salisbury Steak 5 oz. 400 3 16 lbs. 50 24 lbs. 75

Sirloin Steak 6 oz. 400 5 15 lbs. 40 22-1/2 lbs. 60

Swiss Steak 4 oz. 300-200 1 25 lbs. 110 40 lbs. 160

CHICKEN

Pan Fried 2-1/4's 350 3 50 pieces 25 80 pieces 40

Whole 2 oz. 350-200 16 - 5 lbs. 200 24-5 lbs. 265

FRANKFURTERS

Grilled 2 oz. 300 8 22 lbs. 176 33 lbs. 264

Boiled 2 oz. 250 12 16 lbs. 128 25 lbs. 200

PORK

Ham Steak 3 oz. 400 8 10 lbs. 50 15 lbs. 75

Sausage Links 3 links 350 7 30 lbs. 120 45 lbs. 180

Pork Chops 5 oz. 350 4 15 lbs. 50 25 lbs. 75

9

Page 10

BLT-30E PER LOAD

BLT-40E PER LOAD

ITEM

MEAT-POULTRY (continued)

TURKEY

Off Carcass 2 oz. 400-200 – 3 26-30 lbs. 200 4 26-30 lbs. 275

On Carcass 2 oz. 400-200 – 4 16-20 lbs. 175 6 16-20 lbs. 265

MISCELLANEOUS

Grilled Cheese

Sandwich

Macaroni &

Cheese

Rice 4 oz. 350-225 1 20 lbs. raw 320 40 lbs. raw 650

Spaghetti 4 oz. 350-225 2 8 lbs. raw 200 12 lbs. raw 300

PORTION TEMP (F) BATCH/HR

1 sandwich 400 8 35

8 oz. 200 2 18 gal. 300 35 gal. 525

QTY PORTIONS

35 50 sand. 50

sandwiches

QTY PORTIONS

10

Page 11

4.0 CLEANING INSTRUCTIONS

WARNING: Disconnect the power supply to the appliance before cleaning

or servicing.

The electric tilting braising pan should be cleansed after each use.

Soak cooking surface with water and a mild soap to remove any food stuck to surface.

Wash entire unit surface with mild detergent and water. Rinse entire unit and dry.

WARNING: Never spray water into electrical controls or components.

Check that pour spout, strainer, cover and sides of unit are cleansed as well as cooking

surface.

11

Page 12

5.0 TROUBLESHOOTING

Unit will not operate:

1. Power supply not “ON”.

2. Pan not in down position.

3. Defective thermostat or elements.

Pan difficult to tilt:

1. Unit not level.

2. Thrust bearings worn out.

3. Dirt in bearings causing it to bind.

4. Shaft bent.

6.0 PERIODIC MAINTENANCE

1. Grease pivot bearings via lubricating nipple as required. Use Petro-Canada type 0G2 or equivalent.

2. Check that screws in element terminals are not loose. Loose connections may

cause arcing and burn off connection causing element failure.

12

Loading...

Loading...