Page 1

BC -20G

COMBINATION OVEN STEAMER

INSTALLATION -- OPERATION -- MAINTENANCE

BC -20G

COMBI-FOUR/ÉTUVE À VAPEUR

MANUEL D’INSTALLATION -- FONCTIONNEMENT -- ENTRETIEN

BLODGETT COMBI

www.blodgett.com

44 Lakeside Avenue, Burlington, Vermont 05401 USA Telephone (800) 331-5842, (802) 860-3700 Fax: (802)864-0183

PN R10869 Rev D (5/06)

E 2003 --- Blodgett Combi

Page 2

A PERSONAL WORD FROM BLODGETT COMBI

QUELQUES MOTS DE BLODGETT COMBI

Congratulations on your purchase of a BLODGETT Combi appliance. We

firmly believe that your choice has been a wise one, and trust you will receive many years of excellent service from your new Combi.

You will find that cooking with Combi appliances saves time, labor and

extensive cleaning of both the kitchen and the unit.

With Combi appliances the quality, taste, consistency, and look of your

food are improved, thus endorsing the policy to which we’ve always adhered: “For Better Cooking!”

Once you’ve had a chance to use your Combi, please tell us, your dealer

and colleagues about any creative a nd interesting applications you have

discovered; exchange ideas with other users. Be s ure to advise us or

your dealer immediately should a ny mechanical or technical problems

be encountered (...we’re here to help!) and above all “Enjoy Cooking the

BLODGETT Combi Way!

For information on cooking, please refer to our separate cooking guide.

Toutes nos félicitations sur votre achat d’appareil de Blodgett Combi.

Nous croyons fermement que votre choix est un choix raisonnable et

nous sommes certains que vous obtiendrez de nombreuses années

d’excellent service de votre nouveau four multi-usages.

Vous allez découvrir que la cuisson dans les appareils Combi économise

le temps, le travail et le degré de nettoyage de l’appareil aussi bien que

de la cuisine.

Avec les appareil de Combi, la qualité, le goût, la consistence et l’apparence des aliments sont améliorés, s ’accordant, de ce fait, avec notre

politique ”Pour une meilleure cuisson !”

Une fois que vous aurez eu la chance d’utiliser notre Combi, informez

nous, votre concessionnaire et vos collègues, de toutes les applications

nouvelles et intéressantes que vous avez découvertes ; échangez vos

idées avec d’autres utilisateurs. N’hésitez pas à nous prévenir, ou votre

concessionnaire, de tout problème mécanique ou technique que vous

pourriez rencontrer (... nous sommes ici pour vous aider) et par-dessus

tout “Régalez-vous à cuisiner à la façon BLODGETT Combi!

Pour obtenir de plus amples informations sur l’art culinaire, veuillez consulter notre livre de cuisine séparé.

Page 3

IMPORTANT

WARNING: IMPROPER INSTALLA TION, ADJUSTMENT, ALTERATION, SERVICE OR

MAINTENAN C E CAN CAUSE PROPERTY DAMAGE, INJURY OR DEA TH.READ THE

INSTALLA TION, OPERATING AND MAINTENANCE INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR SERVICING THIS EQUIPMENT

AVERTISS EMENT: UNE INS TALLATION, UN AJUSTEMENT, UNE ALTÉRATIO N, UN

SERVICE OU UN ENTRETIEN NON CONFORME AUX NORMES PEUT CAUSER DES

DOMMAGESÀ LA PROPRIÉTE,DES BLESSURES OU LA MORT. LISEZ ATTENTIV EMENT LES DIRECTIVES D’INST A L LATION, D’OPÉRATION ET D’ENTRETIEN AVANT

DE FAIRE L’IN S TALLATION OU L’ENTRETIEN DE CET ÉQUIPEMENT.

INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THE USER SMELLS GAS

MUST BE POSTED IN A PROMINENT LOCATION. THIS INFORMATION MAY BE

OBTAINED BY CONTACTING YOUR LOCAL GAS SUPPLIER.

LES INSTRUCTIONS À RESPECTER AU CAS OÙ L’UTILISATEUR PERÇOIT UNE

ODEUR DE GAZ DOIVENT ÊTRE AFFICHÉES DANS UN ENDROIT BIEN VISIBLE.

VOUS POUVEZ VOUS LES PROCURER AUPRÈS DE VOTRE FOURNISSEUR DE

GAZ LOCAL.

FORYOURSAFETY

Do not store or use gasoline or other flammable v apors or liquids in the vicinity

of this or any other appliance.

AVERTISSEMENT

Ne pas entreposer ni utiliser de l’essence ni d’autres vapeurs ou liquides inflammables dans le voisinage de cet appariel, ni de tout autre appareil.

The information contained in this manual is important for the proper installation,

use, and maintenance of this oven. Adherence to these procedures and instructions will result in satisfactory baking results and long, trouble free service.

Please read this manual carefully and retain it for future reference.

Les informatio n s données dans le présent manuel sont importantes pour installer,

utiliser et entret enir correctement ce four. Le respect de ces inst r u ctions et procédures permettra d’obtenir de bonsrésultats de cuisson et une longue durée de service sans problèmes. Veuillez lire le présent manuel et le conserver pour pouvoir

vous y reporter à l’avenir.

Errors: Descriptive, typographic or pictorial errors are subject to correction. Specifica-

tions are subject to change without notice.

Erreurs:Les erreurs de description, de typographie ou d’illustration font l’objet de

corrections. Les caractéristiques sont sujettes à modifications sans préavis.

Page 4

Your Service Agency’s Address:

Adressedevotreagencedeservice:

Model/Modèl:

Serial Number/Numéro de série:

Your oven w a s installed by/

Installateur de votre four:

Your oven’s installation was checked by/

Contrôleur de l’installation de votre four:

Page 5

Table of Contents/Table des Matières

Introduction

The Blodgett Combi-Oven/Steamer 2.....

Description of the Combi-Oven/Steamer 3.

Oven Features 4.......................

Installation

Owner’s Responsibilities 5...............

Location and Ventilation 6...............

Agency Approvals 7....................

Plumbing Connections 8................

Electrical Connections 9................

Gas Connections 10.....................

Final Check and Adjustments 12..........

Final Check Lists 13.....................

Operation

Safety Information for Gas Units 15........

Gas Controls 16.........................

Standard Controls 17....................

Optional Cook & Hold 19.................

Optional Meat Probe 23..................

Maintenance

Spray Bottle Operating Procedure 24......

Cleaning and Preventive Maintenance 25...

Deliming 26.............................

Communication 29......................

Introduction

Le four-étuveur Combi de Blodgett 32......

Descriptiondelefour-étuveur

Combi de Blodgett 33....................

Caractéristiques 34......................

Installation

Responsabilités du propriétaire 35.........

Placement et Ventilation 37..............

Normes et Codes 38.....................

Raccordement d e la plomberie 39.........

Raccordement à l’électricité 40............

Raccordement au gaz 41.................

Vérification finale et derniers réglages 43...

Vérifications Finales 44...................

Fonctionnement

Renseignements sur la sécurité

des appareils au gaz 46..................

Commandes du gaz 47..................

Commandes standard 48................

Cuisson et Pause en Option 50...........

Sonde thermique optionnelle 55...........

Entretien

Procédure de fonctionnement du

pulvérisateur 56.........................

Nettoyage et entretien préventif 57........

Détartrage 58...........................

Communications 61.....................

Page 6

Introduction

The Blodgett Combi-Oven/Steamer

The Blodgett Combi-Oven/Steamer offers a completely new method of cooking. With the Oven/

Steamer you have the choice of two cooking pro-

cesses: Steam and Hot Air, either...

D Separately

D Combined, or

D In Sequence

And for easy operation you can choose from three

modes:

Steam Hot Air

Combi

Steam &

Hot Air

In the Steam mode you can:

steam reheat reconstitute

stew thaw simmer

blanch preserve braise

poach

In the Hot Air mode you can:

roast bake

grill gratinate

broil

In the Combination Steam and Hot Air mode you

can:

defrost roast rethermalize

reheat bake forced steaming

You can also use two or three functions in sequence during one cooking process. We call this:

D combi-steaming

D combi-roasting

D combi-baking

The combination of circulating hot air and steam

in the space saving, high performance CombiOven/Steamer leads to improvements in the following areas:

D increased productivity in the kitchen

D a reduction in capital expenditures for multiple

equipment replacement

D a wider range of menu choices

D a simplified cleaning process

The work process is simplified since products are

prepared on or in steam table pans and trays.

Food can be cooked, stored, and transported with

the same pans. Small amounts of product can be

processed efficiently; pre-cooked and convenience foods can be reheated within minutes.

Many frozen foods can be processed without prethawing. This flexibility in preparation reduces the

need for kettles and steam tables since t here is no

need for large amounts of food to be kept warm for

long periods of time.

Today the improvement of food quality is more important than ever. Vegetables are cooked in the

Blodgett Combi-Oven/Steamer without water at

the optimal temperature of just under 100_C

(212_F), maintaining valuable vitamins, minerals,

nutrients and trace elements. Cooking meat in the

Combi results in less shrinkage and a firmer,juicier

product. The Blodgett Combi-Oven/Steamer is

being used more and more for baking. Steam and

Hot Air modes make it a general purpose baking

appliance.

2

Page 7

Introduction

Description of the Combi-Oven/Steamer

ABOUT THE OVEN/STEAMER

Blodgett Combi-Oven/Steamers are quality produced using high-grade stainless steel with first

class workmanship.

The two speed fan, which is guarded against accidental finger contact, is driven by a quiet and powerful motor. The condenser draws out excess

steam from t he appliance. Condensation and

waste water, which result during steaming and

cleaning, are continuously drained.

The use of high quality insulation impedes excessive heat radiation and saves energy.

The high performance fresh steam generator with

its control system makes it possible to enjoy all of

the advantages of a high quality steamer at the

flick of a switch. Fresh steam enters the oven cavity without pressure and is circulated at high

speed. This process enables quick and gentle

cooking and ensures high quality food while providing convenient working methods. The steam

generator is completely automatic and protected

from running dry.

OVEN/STEAMER OPERATION

The practical oven door, with a viewing window,

has a wide swing radius and handle which can be

operated easily, even with wet or greasy hands.

Ease of operation is guaranteed through the simple arrangement of the controls. Graphic symbols

make the appliance easy for even inexperienced

kitchen staff to operate. Steam, Hot Air and Combi

modes can be selected with one switch. The

Steam On Demand feature allows the operator to

add steam at any time for up to 8 minutes while operating in either the hot air or Combi modes. This

feature is excellent for baking as well a s roasting

operations. A fourth function on the mode selection switch, the Cool Down mode, allows the oven

cavity to cool down rapidly with the door opened.

The steam on demand function allows the operator the ability to introduce steam into the cooking

process at any time.

Cleaning is kept to a minimum. The interior is

sprayed with a self-acting cleaning solution which

interacts with steam to easily remove crusts and

stains. The oven is designed for easy care and is

welded water tight so that the internal cooking

cavity may be rinsed with a hose after the steam

cleaning process.

3

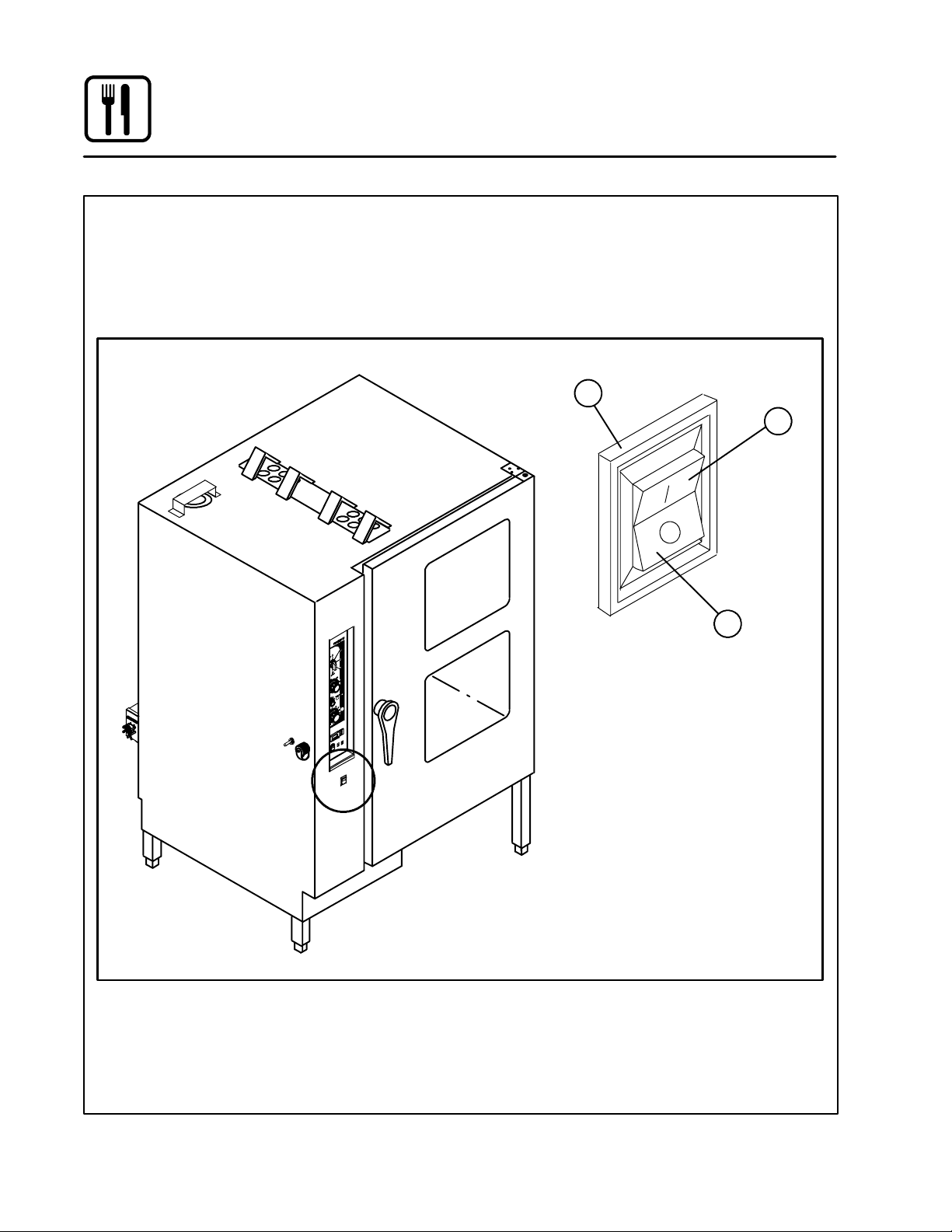

Page 8

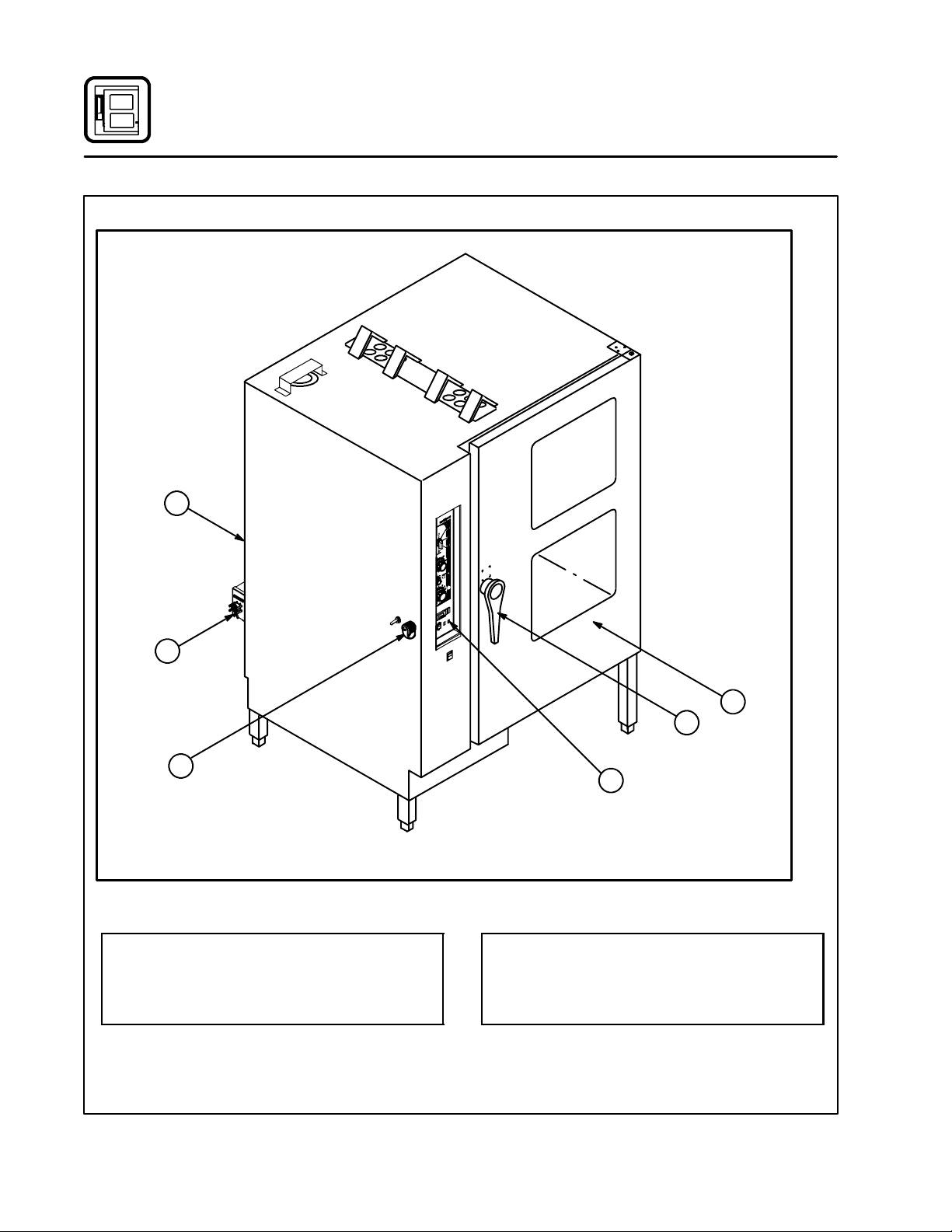

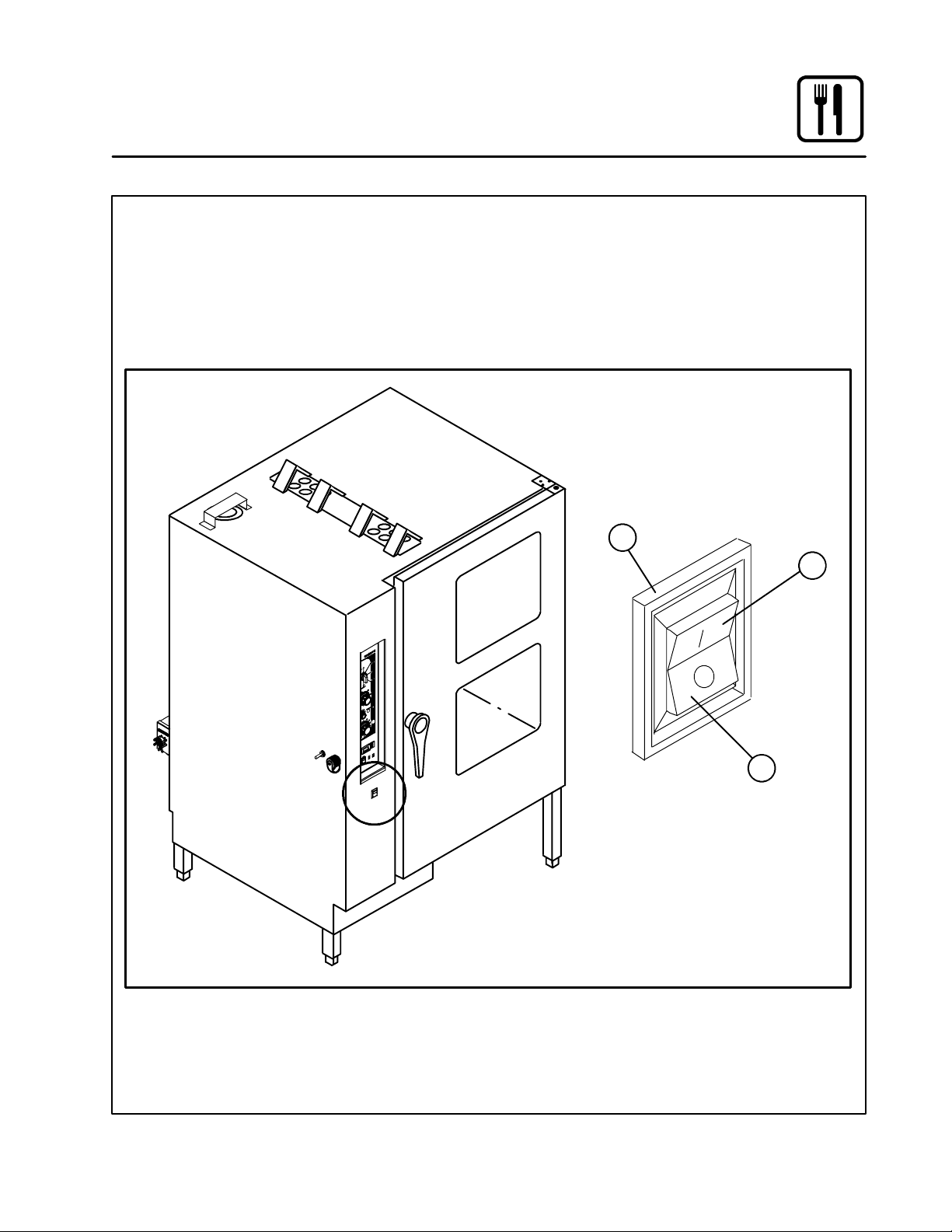

Introduction

Oven Features

4

6

5

1

Control Panel

2 Oven Door

3 Door Handle

2

3

1

Figure 1

4 Vent (not shown)

5 Manual Delimng Inlet

6 Semi -A ut oma t ic D eliming Pu mp

4

Page 9

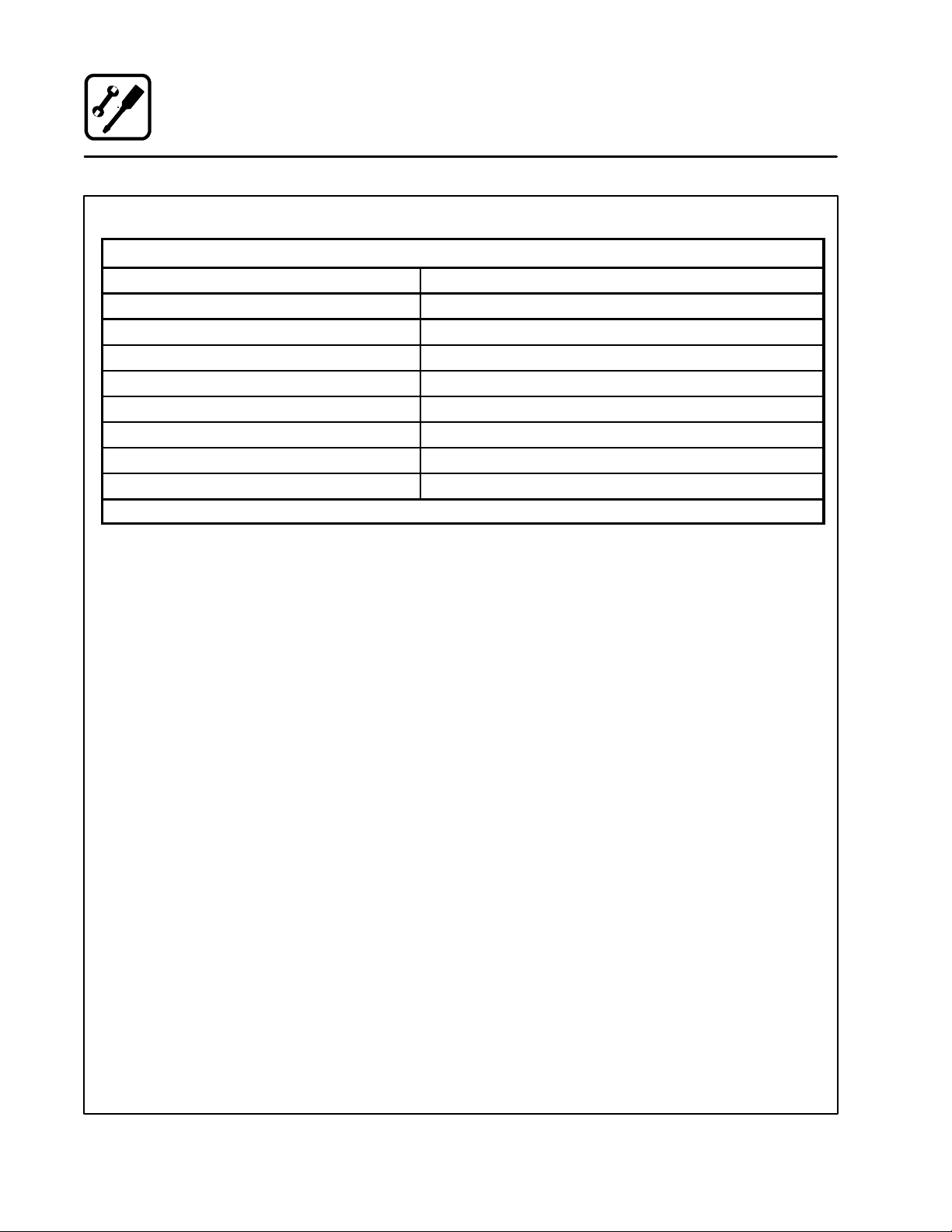

1. Oven(s) are uncrated and put in place.

2. The owner/operator must have the following

plumbing, gas and electrical requirements

met and installed.

NOTE: Refer to the Utility Connection infor-

mation provided.

ELECTRICAL -- BC-20G

115V --- 15 amp Nema 5-15 receptacle

208/240V --- 20 amp Nema 6-20 receptacle

PLUMBING -- BC-20G

Water

Water Pressure (min/max) 40 PSI min/50 PSI max

Water Connection 3/4” Hose Fitting, 3/8” ID hose minimum

Pressure Regulator Setting 35 PSI Preset

Minimum Requirements TDS --- less than 100 parts per million

Total Hardness --- 80-120 pa rts per million

Chlorine ---less than 30 parts per million

pH Factor --- 7.0-8.0

Drainage Atmospheric Vented Drain

Drain Connection 2” NPT

Avg Water Drain Temp. 122_F(50_C)

WARNING!!

Improper installation, adjustment, alteration service or maintenance can cause

property damage, injury or death. Read

the installation, operation and maintenance instruction thoroughly before installing or servicing this equipment.

Installation

Owner’s Responsibilities

GAS PRESSURE -- BC-20G

Gas Input

Steam 90,000 BTU/HR

Hot Air 125,000 BTU/HR

Inlet Pressure to the Unit

Natural Gas 5---14” WC (1.24 --- 3.48 kPa)

Propane 11---14” WC (2.73 --- 3.48 kPa)

Pressure at the Manifold

Natural Gas 3.5” WC (.87 kPa)

Propane 10” WC (2.49 kPa)

1” FNPT connector for all US and Canadian installations

5

Page 10

Installation

Location and Ventilation

LOCATION

The well planned and proper placement of your

appliance will result in long term operator convenience and satisfactory performance.

The following clearances must be maintained between the unit and any combustible or non-combustible construction.

BC-20G

D Right side of unit --- 6” (15 cm)

D Left side of unit --- 6” (15 cm)

D Back of unit --- 6” (15 cm)

The following clearances are recommended, but

not required, for servicing.

D Left side of unit --- 12” (30 cm)

D Back of unit --- 12” (30 cm)

Place the unit in an area which is free of drafts and

accessible for proper operation and servicing.

Keep the operating area free and clear of all combustibles such as paper, cardboard, and flammable liquids and solvents.

DO NOT place the unit on a curb base or seal to

the wall; either condition will prevent proper ventilation to the blower motors. Slight unevenness can

be corrected with the adjustable legs.

All motor bearings are permanently lubricated by

the manufacturer; there is no need for additional

lubrication during the operational lifetime of the

motors.

VENTILATION

The necessity for a properly designed and installed ventilation system cannot be over emphasized. The ventilation system will allow the unit to

function properly while removing unwanted vapors and products of combustion from the operating area.

The appliance must be vented with a properly designed mechanically driven exhaust hood. The

hood should be sized to completely cover the

equipment plus an overhang of at least 6” (15 cm)

on all sides not adjacent to a wall. The capacity of

the hood should be sized appropriately and provisions made for adequate makeup air.

WARNING!!

Failure to properly vent the oven can be

hazardous to the health of the operator;

and will result in operational problems,

unsatisfactory baking, and possible damage to the equipment. Damage sustained

as a direct result of improper ventilation

will not be covered by the Manufacturer’s

warranty.

U.S. and Canadian Installations

Refer to your local ventilation codes. In the absence of local codes, refer to the National ventilation code titled, “Standard for the Installation of

Equipment for the Removal of Smoke and Grease

Laden Vapors from Commercial Cooking Equipment”, NFPA-96- Latest Edition.

General Export Installations

Installation must conform with Local and National

installation standards. Local installation codes

and/or requirements may vary. If you have any

questions regarding the proper installation and/or

operation of your unit, please contact your local

distributor. If you do not have a local distributor,

please call Blodgett Combi at 0011-802-860-3700.

6

Page 11

Installation

Agency Approvals

THE INSTALLATION INSTRUCTIONS CONTAINED HEREIN ARE FOR THE USE OF QUALIFIED INSTALLATION AND SERVICE PERSONNEL

ONLY. INSTALLATION OR SERVICE BY OTHER

THAN QUALIFIED PERSONNEL MAY RESULT IN

DAMAGE TO THE OVEN AND/OR INJURY TO

THE OPERATOR.

Qualified installation personnel are individuals, a

firm, a corporation, or a company which either in

person or through a representative are engaged

in, and are responsible for:

D The installation or replacement of gas piping.

The connection, installation, repair or servicing

of equipment.

D The installation of electrical wiring from the elec-

tric meter, main control box or service outlet to

the electric appliance.

Qualified installation personnel must be experiencedinsuchwork,befamiliarwithallprecautions required and have complied with all requirements of state or local authorities having

jurisdiction.

U.S. and Canadian Installations

Installation must conform with local codes, or in

the absence of local codes, with the National Fuel

Gas Code, NFPA54/ANSI Z223.1 ---Latest Edition,

the Natural Gas and Propane Installation Code

CAN/CSA-B149.1.

Reference: National Electrical Code, ANSI/NFPA

70--- Latest Edition and/or Canadian Electrical

Code CSA C22.1 as applicable.

This equipment is to be installed in compliance

with the Basic Plumbing Code of the Building Offi-

cials and Code Administrators International Inc.

(BOCA) and the Food Service Sanitation Manual of

the Food and Drug Administration (FDA).

General Export Installations

Installation must conform with Local and National

installation standards. Local installation codes

and/or requirements may vary. If you have any

questions regarding the proper installation and/or

operation of your unit, please contact your local

distributor. If you do not have a local distributor,

please call Blodgett Combi at 0011-802-860-3700.

7

Page 12

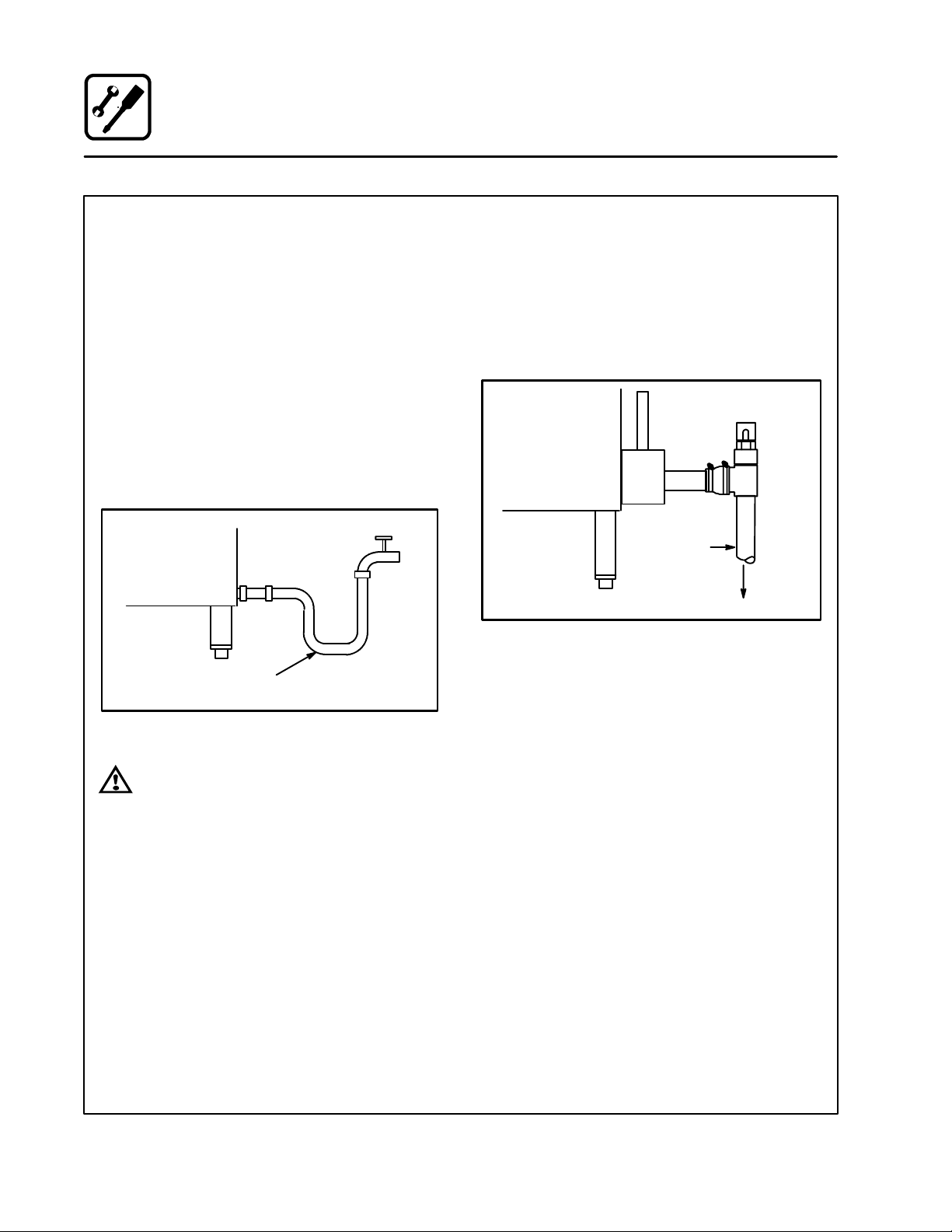

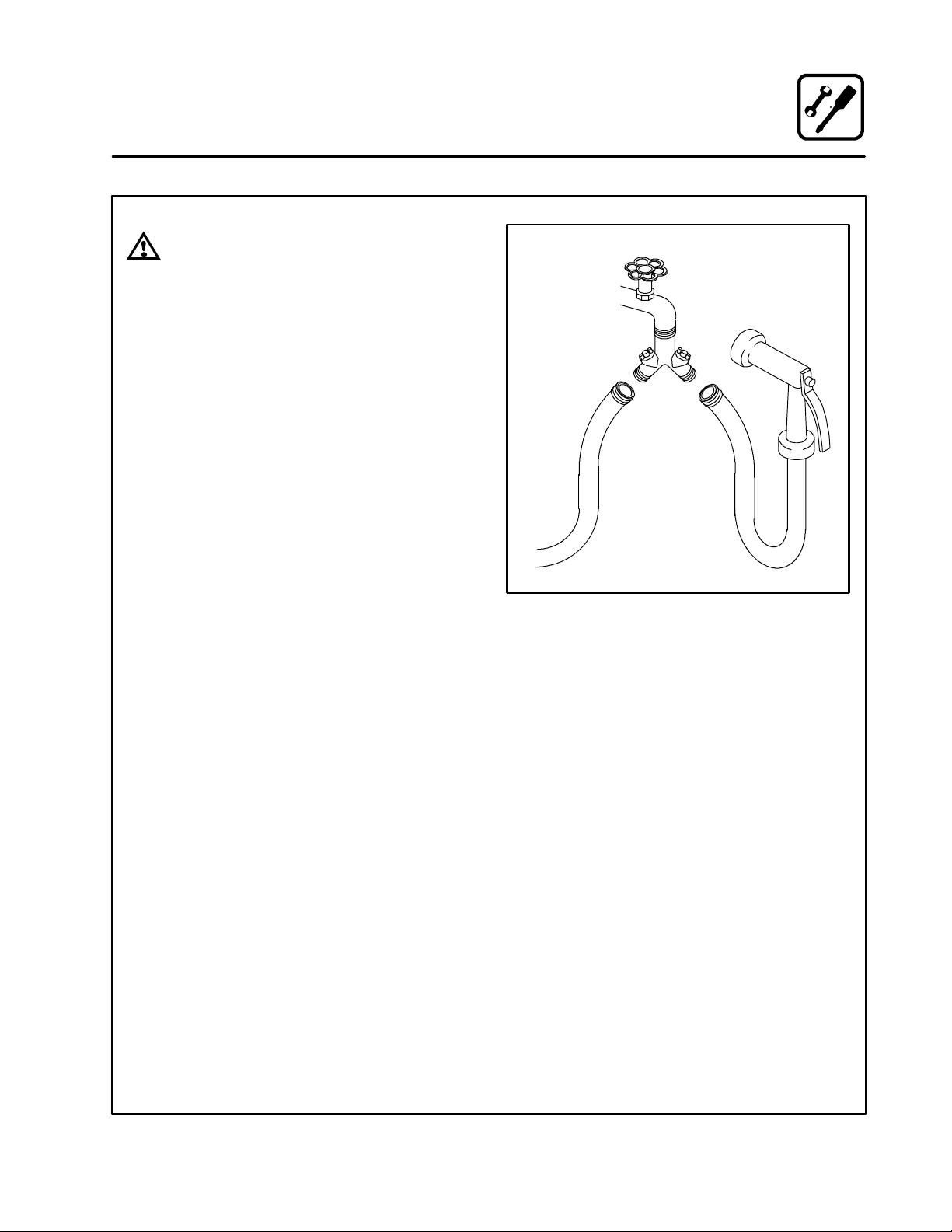

Installation

Plumbing Connections

WATER CONNECTION

NOTE: Hot water maximizes steam production

but is not required. Cold water may be

supplied to both inlets if hot water is not

available.

BC-20G -- - Connect the appliance to quality cold

water via a pressure hose with 3/4” (1/9 cm) couplings. Cold water is connected to the left solenoi d/

pressure regulator as viewed from the rear of the

oven. Hot water connection, right solenoid/pressure

regulator, to the boiler is recommended. A shut off

valvemustbeprovidedadjacenttotheoven.

NOTE: Hot water must not be applied to the cold

water inlet.

1/2” Appliance Hose

With 3/4” Hose Fittings

Figure 2

WARNING!!

The use of poor quality water will invalidate your warranty.

DRAIN CONNECTION

A 2” (5 cm) copper pipe with standard drain pitch

mustberuntoanopendrainorconnectedtoa

standpipe equipped with a vent.

NOTE: Thewastewatercanalsobedirectedtoa

nearby floor drain. Flexible hose which allows trapped water to accumulate in

sagged runs must be avoided.

1. Find the drain connection on the lower rear of

the unit.

2. Loosen the coupling clamps. Attach a 2” (5

cm) copper drain pipe to the drain connection.

Retighten the coupling clamps.

NOTE: The open end of the drain should be in-

stalled facing the floor. Copper line, used

for installation to an open drain or floor

sink, must be supplied by the installer. Use

of a trap inline will cause drain backup.

Oven

Drain

2” Drain

Customer

Supplied

To Dr a i n

Figure 3

Specific water/drain connection for City of Los

Angeles

1. Each drai n line from the appliance shall be

routedwithoutdipsorsagstoterminateabove

the flood level rim of an approved indirect waste

receptor.

2. The appliance shall be installed in accordance

with the manufacturer’ s printed instructions

and the LAPC and LAMC, 1999 editions.

3. A backflow protection device may be required

by local codes. If so, install on the potable water

system directly ahead of the appliance. The

backflow protection device shall be any of the

following: an approved pressure type vacuum

breaker install ed at least 12” above the highest

point of use, a double check valve backflow preventer or a reduced pressure principal backflow

preventer.

8

Page 13

Installation

Electrical Connections

Before making any electrical connections to these

units, check that the power supply is adequate for

the voltage, amperage, and phase requirements

stated on the rating name plate mounted on the

right side of the unit.

Wiring diagrams are located on the inside of the

removablesidepanel.

NOTE: DISCONNECT THE POWER SUPPLY TO

THE UNIT BEFORE SERVICING!

U.S. and Canadian installation

All units, when installed, must be electrically

grounded in accordance with local codes or in the

absence of local codes, with the National Electrical

Code, ANSI/NFPA 70 ---Latest Edition and/or Canadian Electrical Code CSA C22.1 as applicable.

General Export Installations

Installation must conform with Local and National

installation standards. Local installation codes

and/or requirements may vary. If you have any

questions regarding the proper installation and/or

operation of your unit, please contact your local

distributor. If you do not have a local distributor,

please call Blodgett Combi at 0011-802-860-3700.

Gas Models

U.S. and Canadian Installations

A power cord (115V or 230V) is supplied with a

plug attached. Plug the power cord into the desired receptacle.

WARNING!!

If the supply cord is damaged, it must be

replaced by a special cord or assembly

available from the manufacturer or its service agent.

WARNING!!

Improper electrical installation will invalidate your warranty.

9

Page 14

Installation

L

t

h

p

g

Gas Connections

GAS PIPING

A properly sized gas s upply system is essential for

maximum oven performance. Piping should be

sized to provide a supply of gas sufficient to meet

the maximum demand of all appliances on the line

without loss of pressure at the equipment.

Example:

NOTE: BTU values in the following example are

for natural gas.

You purchase a BC-20G to add to your existing

cook line.

1. Add the BTU rating of your current appliances.

Pitco Fryer 120,000 BTU

6 Burner Range 60,000 BTU

Deck Oven 50,000 BTU

Total 230,000 BTU

2. Add the BTU rating of the new oven to the total.

Previous Total 230,000 BTU

BC-20G (for hot air) 125,000 BTU

New Total 355,000 BTU

3. Measure the distance from the gas meter to

the cook line. This is the pipe length. Let’s say

thepipelengthis20’(6m)andthepipesize

is 1” (2.54 cm).

4. Use the appropriate table to determine the total capacity of your current gas piping.

The total capacity for this example is 465,000

BTU. Since the total required gas pressure,

355,000 BTU is less than 465,000 BTU, the

current gas piping will not have to be increased.

NOTE: The BTU capacities given in the tables are

for straight pipe lengths only. Any elbows

or other fittings will decrease pipe capacities. For example: a schedule 40-1/2” elbow fitting has an equivalent cpapacity of

4.2” (10.2 cm) of straight pipe. Contact

your local gas supplier if you have any

questions.

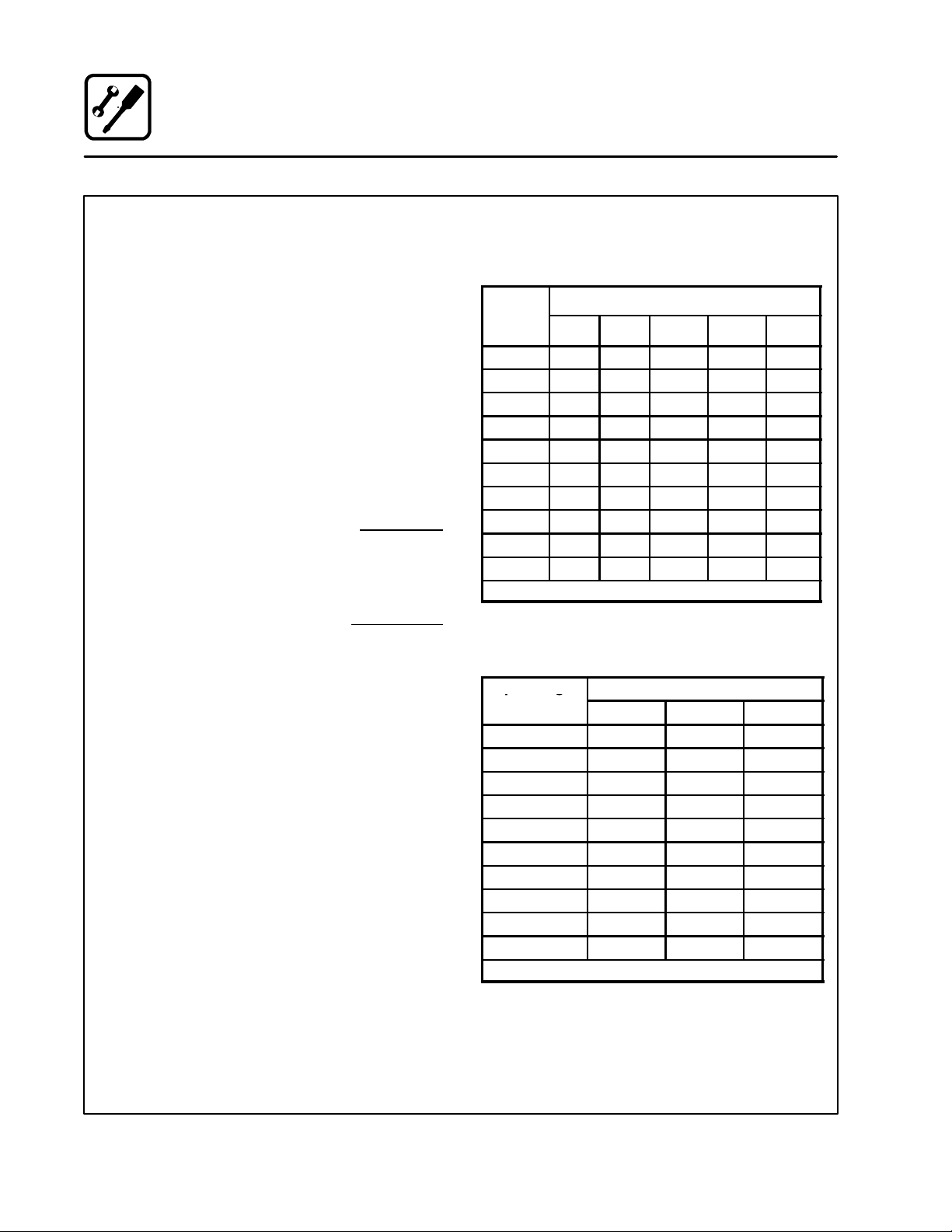

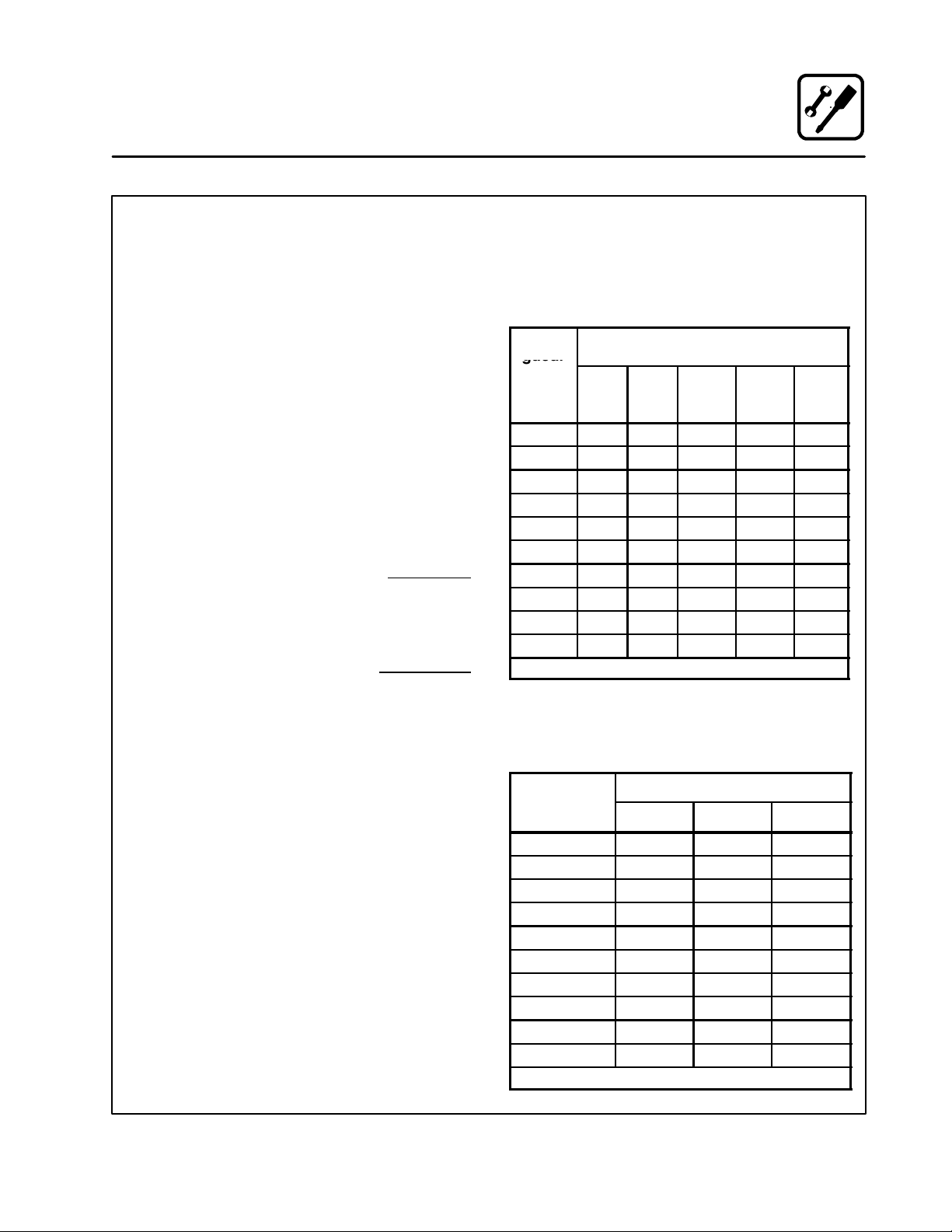

Maximum Capacity of Iron Pipe in Cubic Feet

of Natural Gas Per Hour

(Pressure drop of 0.5 Inch W.C.)

Pipe

eng

(ft)

10 360 680 1400 2100 3950

20 250 465 950 1460 2750

30 200 375 770 1180 2200

40 170 320 660 990 1900

50 151 285 580 900 1680

60 138 260 530 810 1520

70 125 240 490 750 1400

80 118 220 460 690 1300

90 110 205 430 650 1220

100 103 195 400 620 1150

From the National Fuel Gas Code Part 10 Table 10-2

Maximum Capacity of Pipe in Thousands of

BTU/hr of Undiluted P.P. Gas at 11” W.C.

Pipe Length

From the National Fuel Gas Code Part 10 Table 10-15

3/4” 1” 1-1/4” 1-1/2” 2”

(Pressure drop of 0.5 Inch W.C.)

(ft)

10 608 1146 3525

20 418 788 2423

30 336 632 1946

40 287 541 1665

50 255 480 1476

60 231 435 1337

70 215 404 1241

80 198 372 1144

90 187 351 1079

100 175 330 1014

Nominal Size, Inches

Inside Diameter, Inches

3/4” 1” 1-1/2”

10

Page 15

Installation

Gas Connections

PRESSURE REGULATION AND TESTING

The gas pressure to the appliance must be rated

for each appliance while the burners are on. A sufficientgaspressuremustbepresentattheinletto

satisfy these conditions. Refer to the table below

for correct gas pressure.

Each appliance has been adjusted at the factory

to operate with the type of gas specified on the rating plate attached to the right side of the appliance.

Each oven is supplied with a regulator to maintain

the proper gas pressure. The regulator is essen-

tial to the proper operation of the oven and

should not be removed.

DO NOT INSTALL AN ADDITIONAL REGULATOR

WHERE THE UNIT CONNECTS TO THE GAS

SUPPL Y UNLESS THE INLET PRESSURE IS

GREATER THAN 14” W.C. (1/2 PSI) (37mbar).

The oven and its individual shutoff valve must be

disconnected from the gas supply piping system

during any pressure testing of that system at test

pressuresinexcessof1/2psig(3.45kPa).

The oven must be isolated from the gas supply

piping system by closing its individual manual

shutoff valve during any pressure testing of the

gas piping system at test pressures equal or less

than 1/2 psig (3.45kPa).

Prior to connecting the appliance, gas lines

should be thoroughly purged of all metal filings,

shavings, pipe dope, and other debris. After connection, the appliance must be checked for cor rect gas pressure.

U.S. and Canadian Installations

Installation must conform with local codes, or in

the absence of local codes, with the National Fuel

Gas Code, NFPA54/ANSI Z223.1 ---Latest Edition,

the Natural Gas and Propane Installation Code

CAN/CSA-B149.1.

General Export Installations

Installation must conform with Local and National

installation standards. Local install atio n codes and/

or requirements may vary. If you have any questions

regarding the proper installation and/or operation of

your appliance, please contact your local distributor.

If you do not have a local distributor, please call

Blodgett Combi at 0011-802-860-3700.

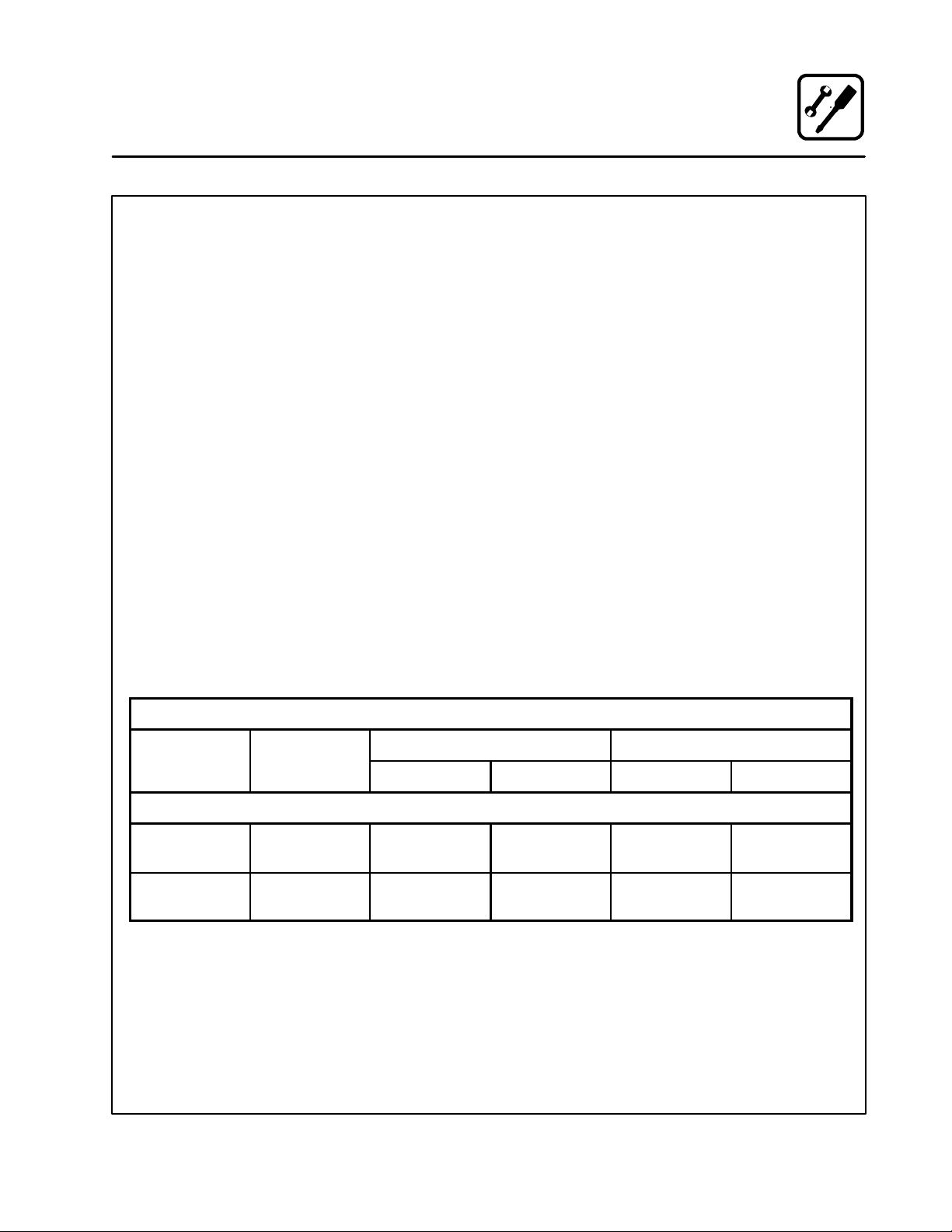

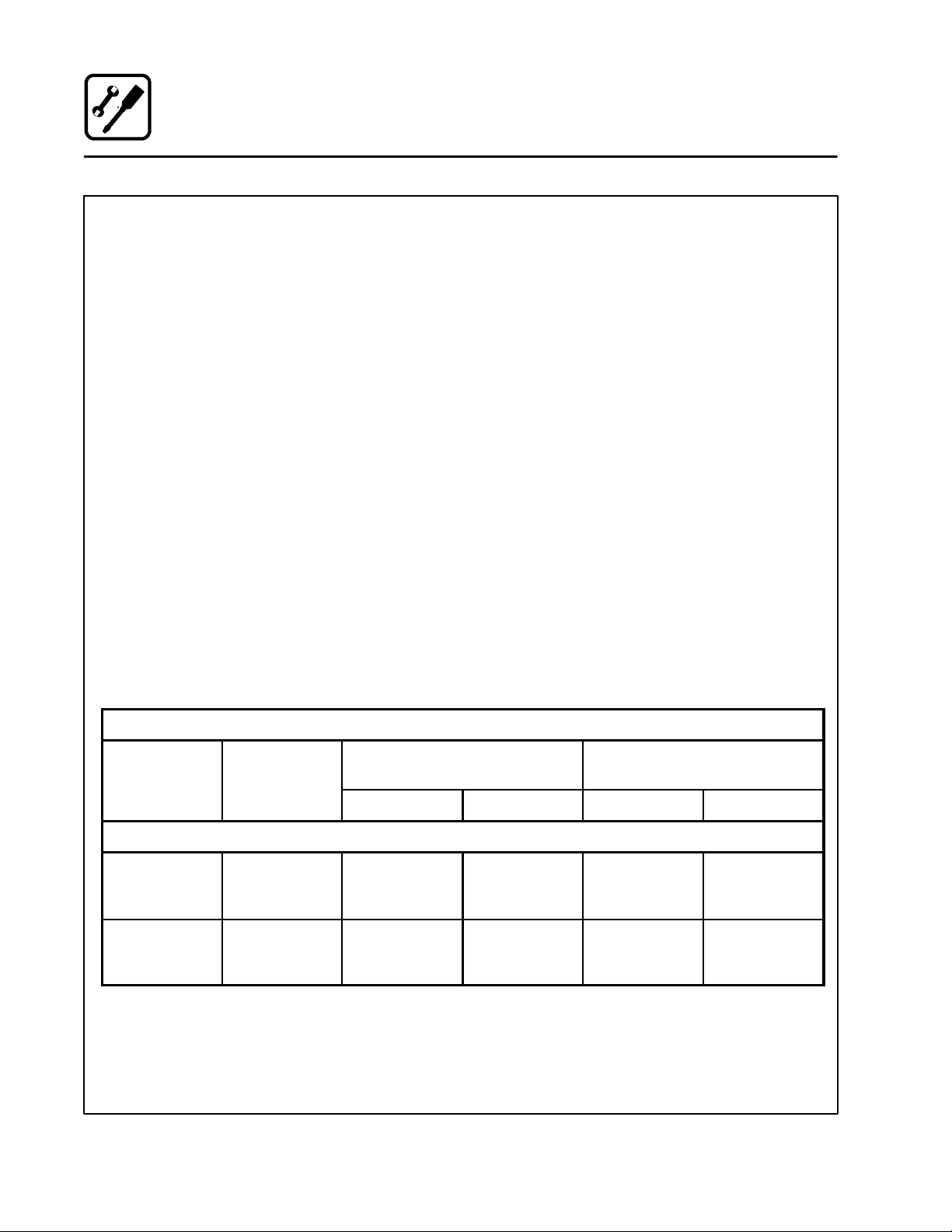

GAS PRESSURE

Gas

Typ e Pressure

U. S. and Canadian Installati ons

Natural 5 --- 1 4” W. C . 1/16”

Propane 11- --14” W .C. #62

Inlet

Orifice Size at Sea Level Manifold Pressure

Hot Air Steam Hot Air Steam

.0625” dia

.0380” dia

#58

.042” dia

#70

.0280” dia

3.5” W .C. 3.5” W .C.

10” W.C. 10” W.C.

11

Page 16

Installation

Final Check and Adjustments

BEFORE SWITCHING THE APPLIANCE ON

Before applying power to the unit for the first time,

check for the following conditions:

j The unit is level.

j All electrical safety provisions have been ad-

hered to and the electrical connections are

correct.

j Water is connected, turned on and all of the

connections are water tight.

j Grease filters are in their proper positions

j The transport cart is inserted into the cooking

cavity. When the cart is not inserted into the unit,

water can spill onto the floor causing it to become slippery. If the door will not close properly ,

use the follo wing adjustment procedure.

j Check gas fittings with leak detection solution.

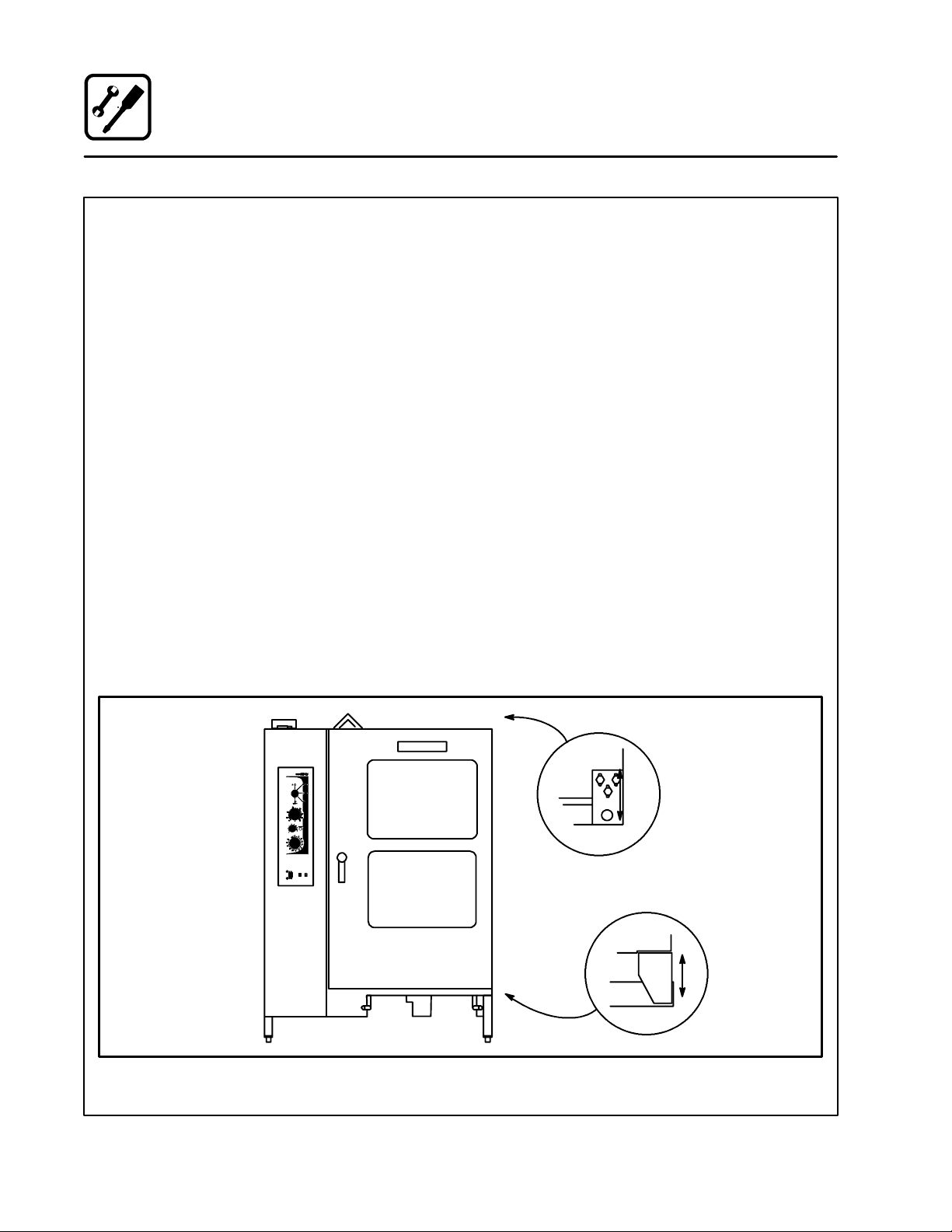

DOOR ADJUSTMENT

The hinges may be adjusted using t he following

procedure:

1. Adjust the top hinge plate by loosening the

three mounting bolts on the top right corner of

the unit.

2. Adjust the bottom hinge pin by loosening the

mounting bolt located under the bottom hinge

plate on the lower right corner of the oven.

3. Adjust the hinges so that t he door back and

the unit face are parallel.

4. Tighten the bolts so that there is no further

movement.

5. The adjustment is correct when the door closes

firmly and no steam leaks from the gasket.

The hinges can also be adjusted as follows:

1. Adjust the door catch by loosening the four

mounting screw s located on the inside surface of the oven door.

2. The adjustment is correct w h en no steam

leaks from the gasket. DO NOT over compress the door gasket. When closed the door

should slightly compress the door gasket.

Figure 4

12

Oven

Door

Oven

Door

Page 17

Installation

Final Check Lists

WARNING!!

Final check list must be performed b y a

qualified installer only.

ELECTRICAL CONTROL COMPARTMENT

j Voltage to appliance matches rating plate

PLUMBING FINAL CHECK

j Incoming water pressure within appliance

specification.

j Atmospheric vented drain in place.

j Water solenoid properly bracketed and not

leaking.

j Water feed lines intact without leaks.

j Optional Spray Hose connected properly.

Connect the optional spray hose to the fill solenoid as shown.

Cold Water Supply

Hose and Spray

Option

To

Oven Fill

Manifold

Figure 5

13

Page 18

Installation

Final Check Lists

OVEN OPERATIONAL TESTS

NOTE: Checkstobemadebycustomerorautho-

rized service agent.

Cool Down Mode

j Check that the fan runs with the door open.

Steam Mode

Turn on STEAM mode and set thermostat to

steam. Verify the following:

j Heat demand lamp is on.

j Heat demand lamp shuts off at approximately

212_F (100_C).

j Check timer operation in all three positions

a.) Set timer to “OFF” position, buzzer should

sound.

b.) Set timer in position other than “OFF” or

“STAY ON”, timer should count down.

c.) Set timer in “STA Y ON” position, oven

should operate continuously without timer .

j Run light (power light) turns on.

j Unit produces steam, window fogs, door seal

does not leak.

Hot Air Mode

Turn to HOT AIR mode and set thermostat to

400_F (204_C) and verify:

j Heat demand lamp is on.

j Oven is heating.

j Heat demand lamp shuts off at 400_F (204_C)

and oven maintains 400_F (204_C).

j Fan shuts off with door open.

Steam On Demand Mode

Turn the oven to Hot Air mode. Set Steam On Demand for 1 minute. Press the Steam On Demand

button and verify:

j Steam demand lamp is on.

j Steam demand lamp shuts off after approxi-

mately 1 minute.

Combi Mode

Turn to COMBI mode, set thermostat to 350_F

(177_C) and verify:

j Heat demand lamp is on.

j Oven is heating.

j Heat demand lamp shuts off at 350_F (177_C)

and oven maintains 350_F (177_C).

j Fan shuts off with door open.

14

Page 19

Operation

Safety Information for Gas Units

THE INFORMATION CONTAINED IN THIS SECTION IS PROVIDED FOR THE USE OF QUALIFIED

OPERATING PERSONNEL. QUALIFIED OPERATING PERSONNEL ARE THOSE WHO HAVE

CAREFULLY READ THE INFORMATION CONTAINED IN THIS MANUAL, ARE FAMILIAR WITH

THE FUNCTIONS OF THE OVEN AND/OR HAVE

HAD PREVIOUS EXPERIENCE WITH THE OPERATIONOF THE EQUIPMENT DESCRIBED. ADHERENCE TO THE PROCEDURES RECOMMENDED HEREIN WILL ASSURE THE

ACHIEVEMENT OF OPTIMUM PERFORMANCE

AND LONG, TROUBLE-FREE SERVICE.

Please take the time to read the following safety

and operating instructions. They are the key to the

successful operation of your Blodgett Combi appliance.

SAFETY TIPS

For your safety read before operating

What to do if you smell gas:

D DO NOT try to light any appliance.

D DO NOT touch any electrical switches.

D Use an exterior phone to call your gas supplier

immediately.

D If you cannot reach your gas supplier, call the

fire department.

What to do in the event of a power failure:

D Tur n a ll swi t ch es to of f.

D DO NOT attempt to operate the appliance until

the power is restored.

NOTE: In the event of a shut-down of any kind, al-

low a five (5) minute shut off period before

attempting to restart the oven.

General safety tips:

D DO NOT use tools to turn off the gas control. If

the gas cannot be turned off manually do not try

to repair it. Call a qualified service technician.

D If the oven needs to be moved for any reason,

the gas must be turned off and disconnected

fromtheappliancebeforeremovingtherestraint cable. Reconnect the restraint after the

oven has been returned to its original location.

D DO NOT remove the control panel cover unless

the oven is unplugged.

15

Page 20

Operation

Gas Controls

CONTROLS IDENTIFICATION

1. GAS CONTROL SWITCH --- Used to turn gas

on or off.

2. GAS ON POSITION --- Press the switch into

the I position.

3. GAS OFF POSITION --- Press the switch into

the O position.

1

2

See View A

3

Figure 6

16

Page 21

Operation

Standard Controls

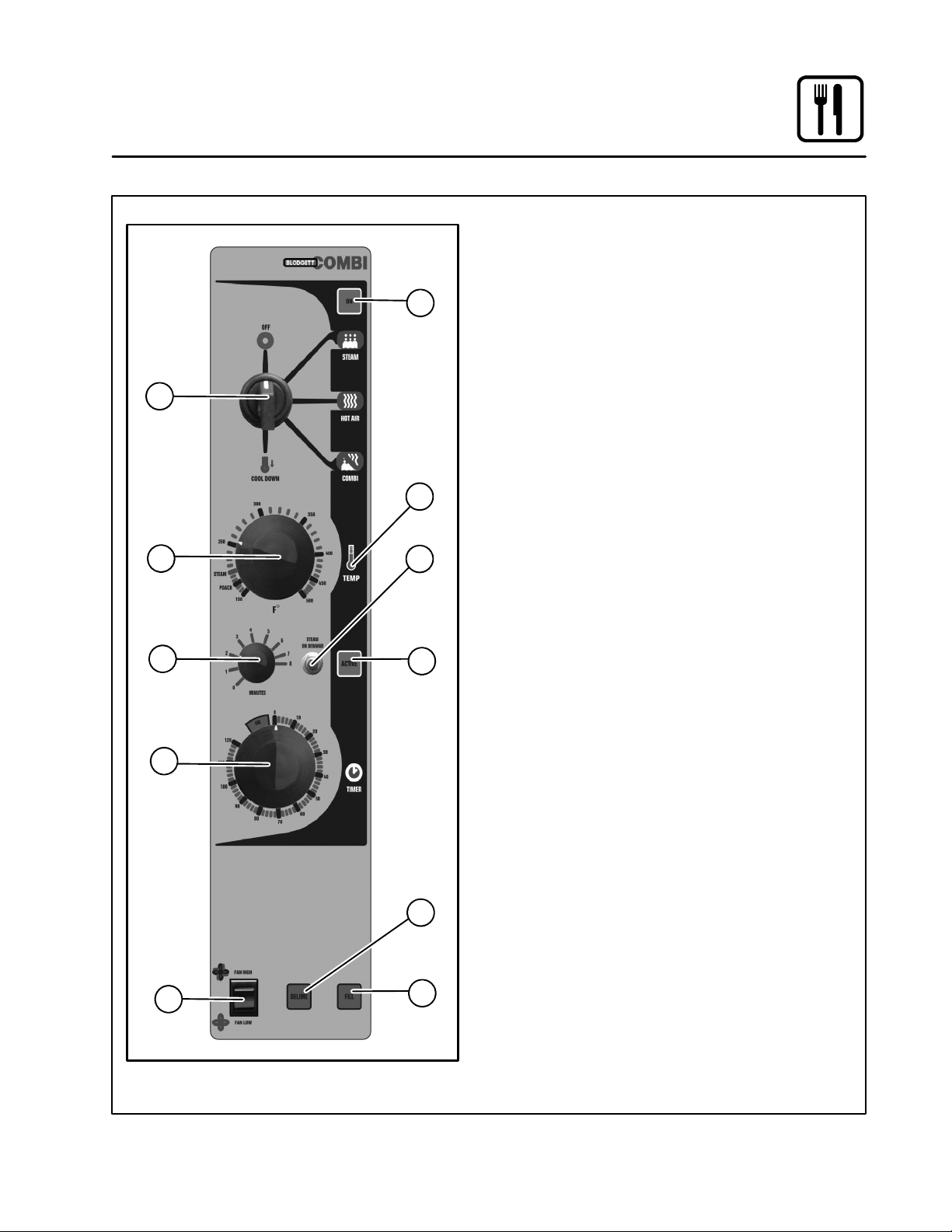

CONTROLS IDENTIFICATION

1. POWER ON LAMP --- when lit indicates power

to the unit is turned on.

1

2

4

3

5

8

6

7

2. MODE SELECTOR SWITCH --- t u r n s p o w e r

to the oven on or off. Allows selection of

Steam, Hot Air, Combi or Cool Down Modes.

3. TEMPERATURE DIAL --- used to set desired

cooking temperature.

4. HEAT ON LIGHT --- When lit indicates that the

unit is heating. The light goes off when the unit

has reached the set temperature.

5. STEAM ON DEMAND TIMER --- u s e d t o s e t

steam time

6. STEAM ON DEMAND SWITCH --- u s e d t o i n i -

tiate steam injection cycle

7. STEAM ON DEMAND LAMP --- i l l u m i n a t e d

when steam on demand is activated.

8. TIMER DIAL --- used to set desired cook time.

9. FAN SPEED SWITCH --- used to select low or

high speed.

10. DELIME LAMP --- Flasheswhen steam gener-

ator deliming is needed. Remains steady

when deliming process is active.

NOTE: BC14DS does not have a delime

lamp.

11. FILL LAMP --- illuminated until the steam gen-

erator is filled with water

NOTE: BC14DS, the direct steam unit, does

not have a fill lamp.

10

9

Figure 7

11

17

Page 22

Operation

Standard Controls

OPERATION

1. Turn the MODE SELECTOR Switch (2) to the

desired function.

2. Set the TIMER (8) to ON.

3. For the HOT AIR and COMBI modes, set the

TEMPERATURE Dial (3) to the desired cook

temperature.

NOTE: The optimum temperature for Combi

mode is 300-350

ForSTEAM mode set the TEMPERATURE Dial

(3) no higher than 212_F (100_C).

NOTE: For steaming use 212

poaching turn the temperature dial to

the POACH position, 180

4. Once the oven is preheated, place the food inside and close the door.

5. Set the TIMER (8) for the desired cook time.

6. The selected mode operates automatically.

Thetemperature,timeandmodecanbealtered at any time during the cooking process.

The operation can be stopped by the use of

the Mode Selector Switch or by opening the

door .

7. At the end of the specified time period, the

buzzer sounds and the appliance will s hut off

automatically. Turn the TIMER (8) to the ON

position to stop the buzzer and restart the appliance in a continuous on mode. Or, simply

turn the mode switch to the off position.

8. To cool down the oven cavity, switch the

MODE SELECTOR Switch (2) to COOL DOWN.

In the Cool Down mode neither the temperature dial or the timer will be operational.

NOTE: The unit can be cooled down rapidly

for steaming, cleaning, etc. Open the

dor wide and select the cool down

mode. The oven will cool from

350---212

mately two minutes.

9. The mode selector switch is also the main

power switch. In the OFF position the appliance is not operational.

_

_

F (149-177_C).

_

F (100_C). For

_

F(82_C).

F (177 ---100_C) in approxi-

Steam on Demand

How to set the Steam On Demand mode:

While in the Hot A ir or Combi mode, the unit can

be set to steam for a timed period. At the end of the

timed cycle the unit reverts back to the original setting. Steam On Demand can be used at any time

during t h e cook cycle.

NOTE: Steam On Demand is not available in

steam mode.

1. Set the desired “steam on” time with the

STEAM ON DEMAND TIMER (5).

2. Press the STEAM ON DEMAND SWITCH (6).

This feature is useful in many ways. A few are listed

below. Most of the ideas came from our creative

customers. Experiment with this feature on your

own and let us know of any new uses.

D Add a minute or two at the beginning when bak-

ing bread for a shiny crust.

D Kick start large loads such as 20 or more chick-

ens. By starting large loads with 5 to 8 minutes

of steam you help the oven recover and cut the

cooking time by more than 10%.

D Bake bagels without boiling. By starting raw ba-

gels with 1 to 2 minutes of steam you can

achieve a beautiful crust.

D Cream caramel is great at 230_F to 250_Finthe

Combi mode using 2 minutes of on demand

steam.

D When cooking chicken wings, try setting the

oven in the Combi mode at 375_F and use 3

minutes of Steam On Demand. This method will

stop the tips from burning. T otal cooking time is

approximately 12 minutes.

D Pork ribs tend to pull off the bone better when

using 5--- 8 minutes of Steam On Demand. Try

ribs in the Combi mode at 350_F.

18

Page 23

1

2

3

5

6

8

9 10

11 12

13 14

16

19

4

7

15

18

17

20

21

Operation

Optional Cook & Hold

CONTROLS IDENTIFICATION

1. POWER ON LIGHT --- when lit indicates pow-

er to the unit is turned on.

2. MODE SELECTOR SWITCH --- c o n t r o l s p o w e r

to the oven and selectio n of steam, hot air and

combi modes. The convection fan runs with the

switch in steam, hot air , combi or cool down.

3. TIME DISPLAY --- indicates cook time.

4. TIME ARROW KEYS --- press to enter cook

time from 00:00 to 99:59.

5. TEMPERATURE DISPLAY --- g i v e s c o o k t e m -

perature.

6. HEAT LIGHT --- when lit indicates hot air or

steam is in operation.

7. TEMPERATURE ARROW KEYS --- p r e s s to

enter cook temperature from 120 --- 212_F

( 4 8 --- 1 0 0 _C) for steam and 140 ---500_F

( 6 0 --- 2 6 0 _C) for hot air/combi.

8. STAGE ONE LED --- when lit indicates opera-

tion or programming of stage one for the current product. Cook cycles may contain one or

two different stages.

9. ACTUALTEMP KEY --- press to display actual

oven/steamer temperature

10. STAGE TWO KEY --- press to enter stage two

cook time and t emperature.

11. PRODUCT KEYS --- three programmable keys.

12. MANUAL PRODUCT KEY --- default product

key used for manual and programmed cooking.

13. START KEY --- press to begin a timer count

down.

14. STOP KEY --- press to silence audible alarms

and pause or cancel cook cycles.

15. PROGRAM KEY --- press to enter program-

ming mode and save programmed settings.

16. STEAM ON DEMAND TIMER --- u s e d t o s e t

steam time

17. STEAM ON DEMAND SWITCH --- u s e d t o i n i -

tiate steam injection cycle

18. STEAM ON DEMAND LAMP --- i l l u m i n a t e d

when steam on demand is activated.

19. FAN SPEED SWITCH --- used to select low or

high speed.

Figure 8

19

Page 24

Operation

Optional Cook & Hold

20. DELIMELAMP --- Flashes when steam gener-

ator deliming is needed. Remains steady

when deliming process is active.

NOTE: BC14DS does not have a delime

lamp.

21. FILL LAMP --- illuminated until the steam gen-

erator is filled with water

NOTE: BC14DS, the direct steam unit, does

not have a fill lamp.

MANUAL OPERATION

1. Turn the SELECTOR SWITCH (2) to the desired mode. The LED above the manual key

lights.

2. Press the TEMPERATURE ARROW KEYS (7)

to set the stage one cook temperature.

3. Press the TIME ARROW KEYS (4) to set the

stage one cook time.

4. Press the STAGE TWO KEY (10).

NOTE: Stage two can be used for either a

hold mode or a second cook temperature. Example: Cook meats or poultry

at a low temperature for maximum

moisture retention, then set the second stage for browning. To use the

second stage for holding, you must

set an appropriate hold time for the

unit to count down from.

NOTE: If stage two is not required enter a

cook time of 00:00.

5. Press the TEMPERATURE ARROW KEYS (7)

to set the stage two cook temperature.

6. Press the TIME ARROW KEYS (4) to set the

stage two cook time.

7. Press the START KEY (13) to begin the cook

cycle. The STAGE ONE LED (8) lights. The

TIME DISPLAY (3) counts down the stage one

cook time.

If stage two is selected an alarm sounds at the

end of stage one. The time display counts

down the stage two cook time.

8. When all cook stages are complete the TIME

DISPLAY (3) flashes 00:00, the TEMPERATURE DISPLAY (5) flashes 0 and an a udible

alarm sounds. Press the STOP KEY (14) to silence the alarm. The control maintains the

stage one cook temperature.

9. Turn the SELECTOR SWITCH (2) to OFF to

shut down the oven/steamer.

NOTE: Time and temperature settings may be

changed at any time during manual operation. Press the time arrow keys to change

the cook time. Press the temperature arrow keys to change the cook temperature.

PROGRAMMED OPERATION

NOTE: See page 22 for programming instruc t io ns.

1. Turn the SELECTOR SWITCH (2) to the desired mode.

2. Press the desired PRODUCT KEY (11). The

LED a bove the selected key lights.

3. Press the START KEY (13) to begin the cook

cycle. The STAGE ONE LED (8) lights. The

TIME DISPLAY (3) counts down the stage one

cook time.

NOTE: Press the STOP KEY (14) once to pause

an active stage one cycle. Press the

START KEY (13) to resume.

NOTE: Press the STOP KEY (14) twice to can-

cel an active stage one cycle.

4. An alarm sounds at the end of stage one The

time display counts down the stage two cook

time.

NOTE: Press the STOP KEY (14) once to can-

cel an active stage two cycle. Stage

two cycles cannot be paused.

5. When all cook stages are complete, the TIME

DISPLAY (3) flashes 00:00, the TEMPERATURE DISPLAY (5) flashes 0 and an a udible

alarm sounds. Press the STOP KEY (14) to silence the alarm. The control maintains the

stage one cook temperature.

20

Page 25

STEAM ON DEMAND

How to set the Steam On Demand mode:

While in the Hot A ir or Combi mode, the unit can

be set to steam for a timed period. At the end of the

timed cycle the unit reverts back to the original setting. Steam On Demand can be used at any time

during t h e cook cycle.

NOTE: Steam On Demand is not available in

steam mode.

1. Set the desired “steam on” time with the

STEAM ON DEMAND TIMER (16).

2. Press the STEAM ON DEMAND SWITCH (17).

Operation

Optional Cook & Hold

This feature is useful in many ways. A few are listed

below. Most of the ideas came from our creative

customers. Experiment with this feature on your

own and let us know of any new uses.

D Add a minute or two at the beginning when bak-

ing bread for a shiny crust.

D Kick start large loads such as 20 or more chick-

ens. By starting large loads with 5 to 8 minutes

of steam you help the oven recover and cut the

cooking time by more than 10%.

D Bake bagels without boiling. By starting raw ba-

gels with 1 to 2 minutes of steam you can

achieve a beautiful crust.

D Cream caramel is great at 230_F to 250_Finthe

Combi mode using 2 minutes of on demand

steam.

D When cooking chicken wings, try setting the

oven in the Combi mode at 375_F and use 3

minutes of Steam On Demand. This method will

stop the tips from burning. T otal cooking time is

approximately 12 minutes.

D Pork ribs tend to pull off the bone better when

using 5--- 8 minutes of Steam On Demand. Try

ribs in the Combi mode at 350_F.

21

Page 26

Operation

Optional Cook & Hold

PROGRAMMING THE PRODUCT KEYS

NOTE: Each product key can hold two programs:

one for steam and one for hot air/combi. Hot

air programs can be used in combi.

1. Turn the SELECTOR SWITCH (2) to the desired mode.

2. Press the desired PRODUCT KEY (11).

3. Press and hold the PROGRAM KEY (15) for

five seconds. The control beeps. The product

key LED and STAGE ONE LED (8) light.

4. Press the TEMPERATURE ARROW KEYS (7)

to set the stage one cook temperature.

5. Press the TIME ARROW KEYS (4) to set the

stage one cook time.

6. Press the STAGE TWO KEY (10).

NOTE: Stage two can be used for either a

hold mode or a second cook temperature. Example: Cook meats or poultry

at a low temperature for maximum

moisture retention, then set the second stage for browning. To use the

second stage for holding, you must

set an appropriate hold time for the

unit to count down from.

NOTE: If stage two is not required enter a

cook time of 00:00.

7. Press the TEMPERATURE ARROW KEYS (7)

to set the stage two cook temperature.

8. Press the TIME ARROW KEYS (4) to set the

stage two cook time.

9. Press and hold the PROGRAM KEY (15) to

save the program settings.

PROGRAMMING THE MANUAL KEY

NOTE: The manual key may be used for manual

cooking and programmed for two products, one for steam and one for hot air/combi. Hot air programs can be used in combi.

1. Turn the SELECTOR SWITCH (2) to the desired mode.

2. Press the MANUAL KEY (12). The LED above

the manual key lights.

3. Press the TEMPERATURE ARROW KEYS (7)

to set the stage one cook temperature.

4. Press the TIME ARROW KEYS (4) to set the

stage one cook time.

5. Press the STAGE TWO KEY (10).

NOTE: Stage two can be used for either a

hold mode or a second cook temperature. Example: Cook meats or poultry

at a low temperature for maximum

moisture retention, then set the second stage for browning. To use the

second stage for holding, you must

set an appropriate hold time for the

unit to count down from.

NOTE: If stage two is not required enter a

cook time of 00:00.

6. Press the TEMPERATURE ARROW KEYS (7)

to set the stage two cook temperature.

7. Press the TIME ARROW KEYS (4) to set the

stage two cook time.

8. Press and hold the PROGRAM KEY (15) to

save the program settings.

NOTE: Time and temperature settings may be

changed at any time during operation of a

programmed manual key. Press the time

arrow keys to change the cook time. Press

the temperature arrow keys to change the

cook temperature.

22

Page 27

Operation

Optional Meat Probe

CONTROLS IDENTIFICATION

1. MEAT PROBE SWITCH --- c o n t r o l s p o w e r t o

the meat probe.

2. MEATPROBE CONTROL --- u s e t o s e t t h e d e -

sired probe temperature. Indicates the actual

temperature of the product

3. MEAT PROBE CONNECTOR --- re c e p t a c l e

for the plug in meat probe.

NOTE: For sanitation purposes it is recom-

mended that the meat probe remain

plugged into the front panel receptacle at all times.

OPERATION

Measuring the product core temperatures during

long roasting periods is very practical. It is especially important for products such as Roast Beef to

reach a specific internal temperture.

Place the probe through to the middle of the product’s thickest section. B e sure the probe does not

touch any bone and the tip is not in a fat pocket.

These conditions can ca use inaccurate readings.

1. Set the MODE SELECTOR Switch to the de-

sired function.

2. Turn the MEAT PROBE Switch (1) to ON.

3. To set the desired core temperature press and

hold the * BUTTON (4) on the MEAT PROBE

CONTROL (2).

Use the up arrow key (6) to increase the setpoint temperature. Use the down arrow key

(5) to decrease the setpoint temperature.

4. Set the TIMER to STAY ON. The cooking pro-

cess runs automatically.

When the selected core temperature is

reached, the buzzer will sound and the appliance shuts off automatically.

The temperature and mode can by changed

at any time during the process.

NOTE: The Steam On Demand feature may be

used with the meat probe.

5. Shut the appliance off by setting all switches

to OFF.

NOTE: When setting the internal temperature, be

sure to allow for carry-over cooking after

the roast is removed from the oven

3

1

2

4 5 6

Figure 9

23

Page 28

Maintenance

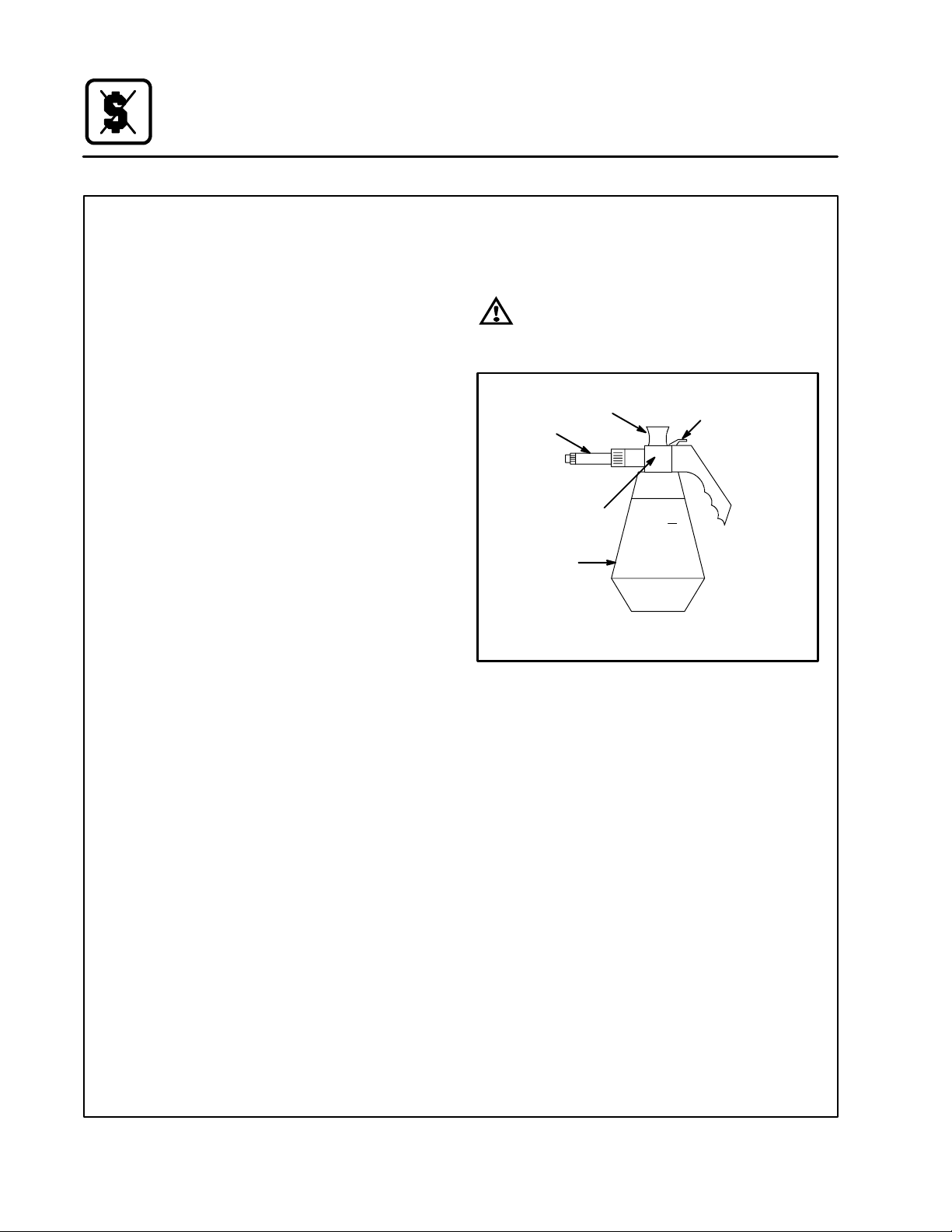

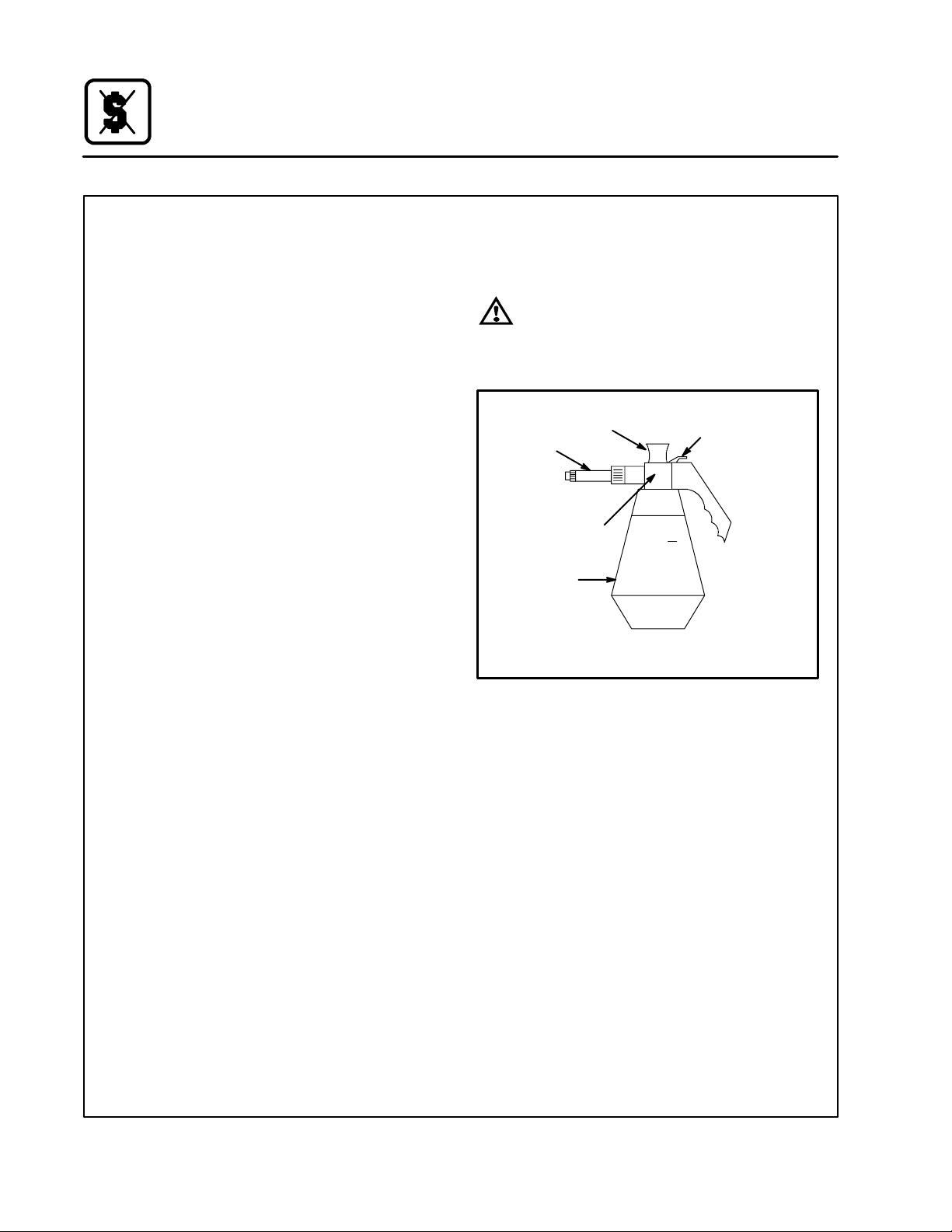

Spray Bottle Operating Procedure

NOTE: Only use a commercial oven cleaner/de-

greaser with the spray bottle. DO NOT use

chemicalsthatarenotintendedasoven

cleaners. See chemical manufacturer’s information for intended use.

1. Unscrew the sprayer head and fill the container to the MAX mark. Screw the head assembly

on firmly to ensure an airtight seal. The liquid

must be clean and free from foreign matter. Do

not overfill - space must be left for compressing air.

2. Tobuilduppressure,pumpapproximately20

full strokes when the container is filled with liquid. The higher the pressure, the finer the

spray. If the container is only partially filled,

then more pumping is required to compress

the additional air space.

3. To spray, depress the trigger with your thumb.

4. Adjust spray nozzle for a w ide spray pattern.

5. After a period of spraying, the pressure will

drop. Restore the pressure by operating the

air pump.

6. Release pressure after use by inverting the

spray head and depressing the trigger or by

slowly unscrewing the spray head assembly

which will allow air to escape from around the

filling aperture.

7. After use, rinse the spray bottle w ith clean water and check that the hole in the nozzle is perfectly clean and clear. Warm water (not hot)

used with a household detergent is a useful

cleaning agent for this purpose.

NOTE: Further information can be found in the in-

struction leaflet supplied with your spray

bottle.

WARNING!!

Protective clothing and eyewear should

be worn while using cleaning agents.

Spray

Head

Pressure

Vessel

Clean the pump 2 or 3 times per week with warm water

Pressure Pump

Pump

MAX

Spray Trigger

Figure 10

Complete Spray Bottle --- P/N R0006

Spray Head Repair Kit --- P/N R6332

24

Page 29

Maintenance

Cleaning and Preventive Maintenance

CLEANING THE INTERIOR

Daily cleaning of the appliance is essential for sanitation, and to ensure against operational difficulties. Use an oven cleaning detergent in conjunction with the supplied spray bottle.

For difficult cleaning, allow the spray-on oven

cleaner to work longer before rinsing.

1. Cool the appliance down to 140_F(60_C) or,

if the oven has been idle, t urn the steam mode

on for 3 to 4 minutes in order to warm the cavity surfaces.

2. Fillthe spray bottle and pump air into the con-

tainer w ith the pressure pump.

3. Spray the interior of the oven with a cleaning

solution.

NOTE: Never spray water into the appliance

when the temperature is above 212_F

(100_C).

4. Let the cleaner work the time recommended

by the cleaning solution manufacturer. For difficult, baked on grease, etc. allow to work over

night.

5. Set the timer for 15 to 20 minutes.

6. Set the mode selector switch to Steam. This

will soften all burned on residue.

7. Rinsethe applianceinteriorwith water(a hose

is supplied, but take care that only the interior

cavity is sprayed with water).

On stainless interiors, deposits of baked on splatter, oil, grease or light discoloration may be removed with a good non toxic industrial stainless

steel cleaner. Apply cleaners when the oven is

cold and always rub with the grain of the metal.

The racks, rack supports and the blower wheel

maybecleanedintheovenorbyremovingthem

from the oven and soaking them in a solution of

ammonia and water.

NOTE: DO NOT use corrosive cleaners on the

Oven/Steamer.

CLEANING THE EXTERIOR

The exterior of the appliance may be cleaned and

kept in good condition with a light oil. Saturate a

cloth and wipe the appliance when it is cold; wipe

drywithacleancloth.

WARNING!!

DO NOT spray the outside of the appliance

with water or clean with a water jet.

PREVENTIVE MAINTENANCE

The best preventive maintenance measures are

the proper initial installation of the equipment and

a program for cleaning and deliming the a ppliance

routinely. The Oven/Steamer requires no lubrication. Contact the factory, the factory representative or a local Blodgett Combi service company to

perform maintenance and repairs should they be

required.

25

Page 30

Deliming

Maintenance

WARNING!!

Deliming solutions are hazardous and

can cause burns to the skin and eyes.

Wear protective clothing and eyewear

when decalcifying your appliance.

Deliming of the steam generator is the single most

important preventative maintenance task. Lime

will build up inside the steam generator, reducing

efficiency and causing damage to the level control

system.

WARNING!!

Problems caused by insufficient deliming

are not covered by the warranty.

This oven comes equipped with a Delime lamp to

indicate when the steam generator needs to be

delimed. The Delime lamp will flash when the

steam generator has been run for the preset interval. The flashing Delime lamp does not impede the

operation of the oven, as you can use the oven

normally when the lap is flashing. You may choose

the best time to start the deliming process.

NOTE: To further prevent buildup of scale, this

oven will automatically drain the steam

generator after 5 hours of being in the off

mode.

WARNING!!

Iftheovenishot,itmustbeplacedinthe

cool down mode for 1 minute with the

door open prior to starting the deliming

process. Once the process has been

started, the oven cannot be used until the

process is complete. The total process

time is approximately 45 minutes.

DELIMING WITH DELIMING PUMP

NOTE: The Delime lamp must be flashing to start

this process.

1. Be sure the container delivering the deliming

agent to the appliance is full.

2. Be sure the door is open.

3. Turn the oven into Cool Down mode. Press

and release the On Demand Steam button.

The Delime lamp will flash faster, acknowledging the action.

4. Turn the oven to the OFF mode.

5. The remainder of the procedure is automatic.

The Delime lamp will stay illuminated while the

process is active. When the process is completed, the Delime lamp will turn off indicating

theappliancecannowbeusednormally.

26

Page 31

DELIMING INTERVAL SETTING

Refer to Figure 11 to determine the correct deliming interval for your appliance. Find your location

and the corresponding potentiometer setting.

These values are general and are guidelines only.

Your specific water quality may be harder or softer.

Adjust the deliming interval to your specific water

quality.

Maintenance

Deliming

NOTE: If you have the oven connected to a filter

system, the water hardness may be reduced. Check with filter supplier for details.

Over 14 gpg

10 to 14 gpg Very Hard Setting B

7to10gpg Hard SettingB

3 to 7 gpg Moderately Hard Setting C

Less than 3 gpg Slightly Hard Setting C

Extremely Hard Setting A

Canadian Water Quality

Most of Canadian water contains 112 mg/L (8 gpg).

This would place Canada in the hard water catagory

and setting B should be used. If your water exceeds

196 mg/L (14 gpg), setting A should be used.

Figure 11

27

Page 32

Maintenance

Deliming

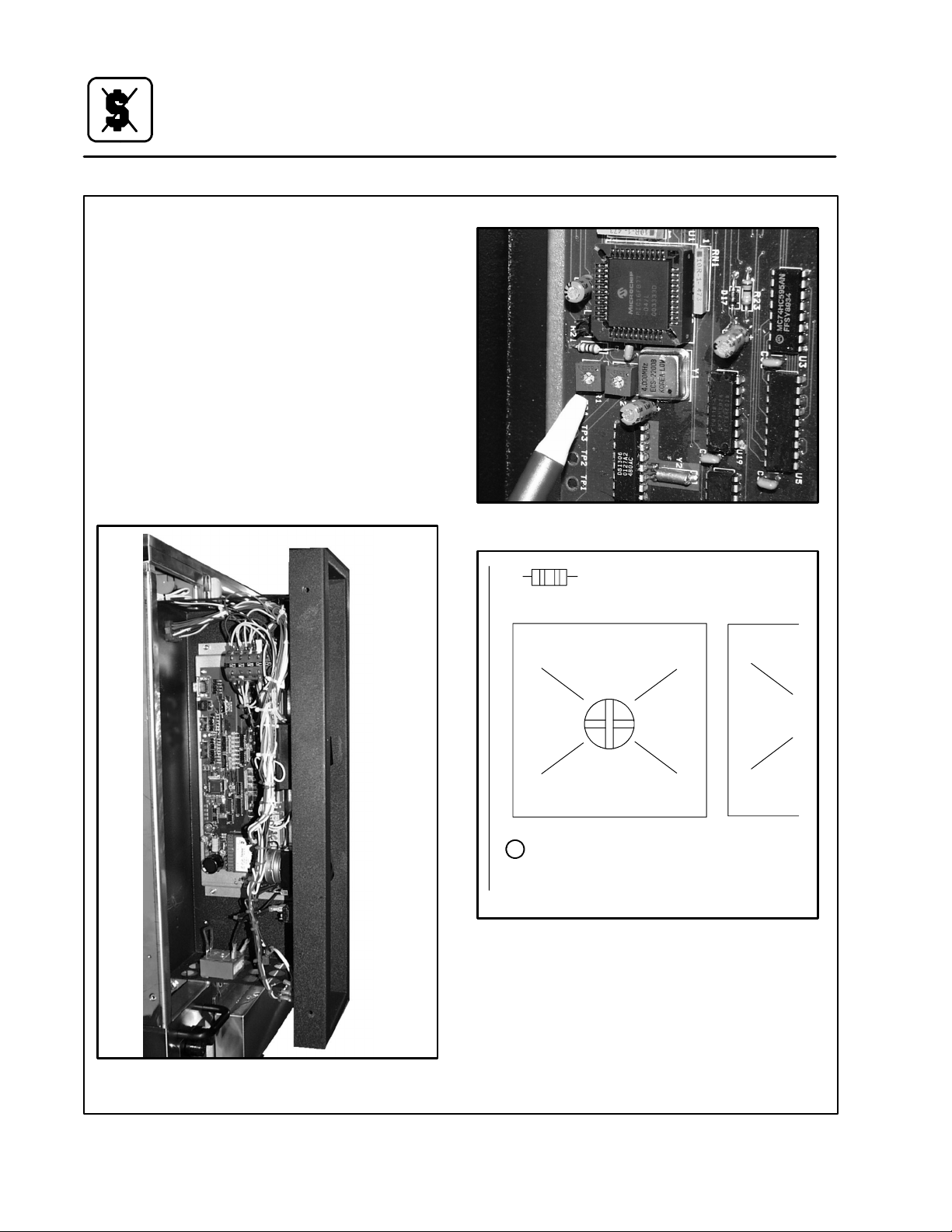

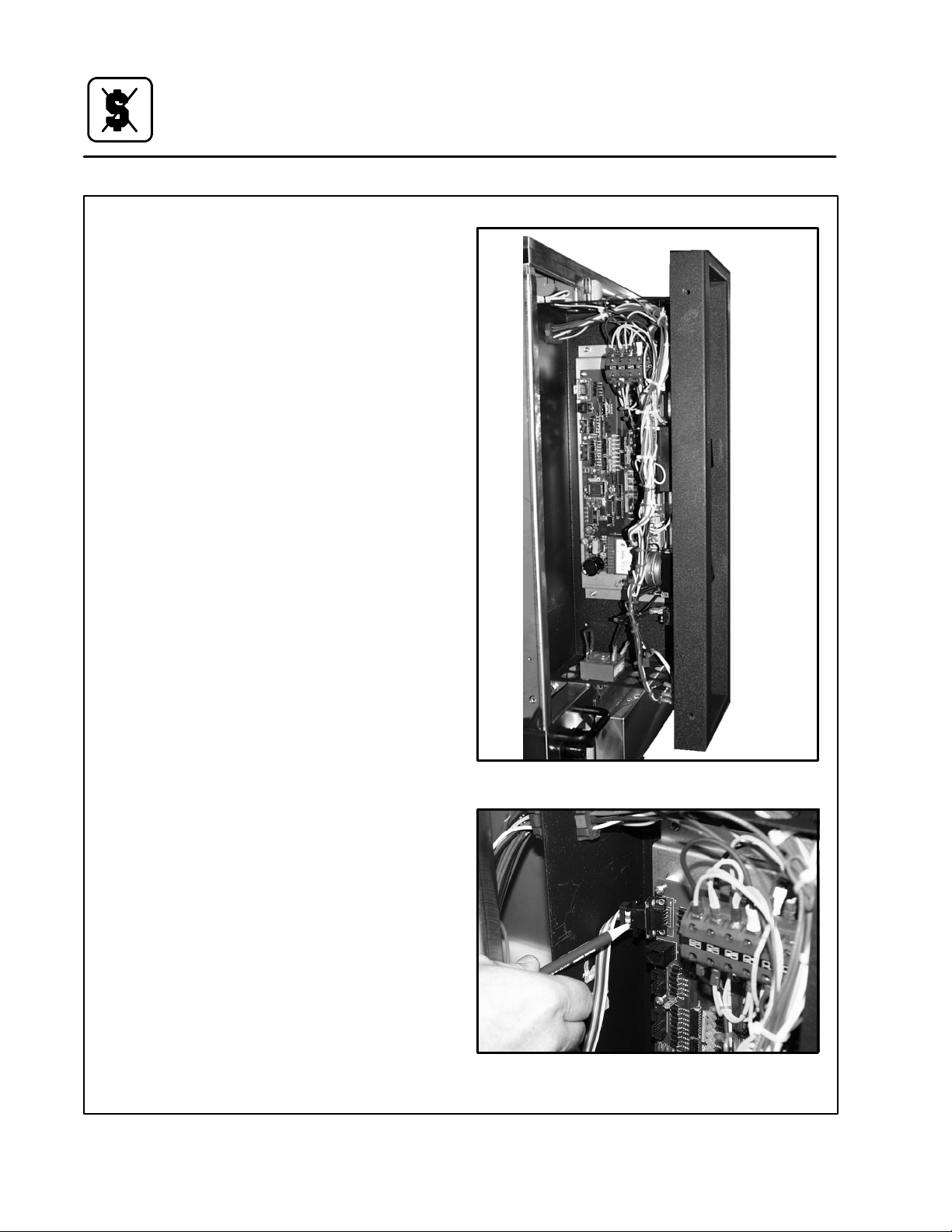

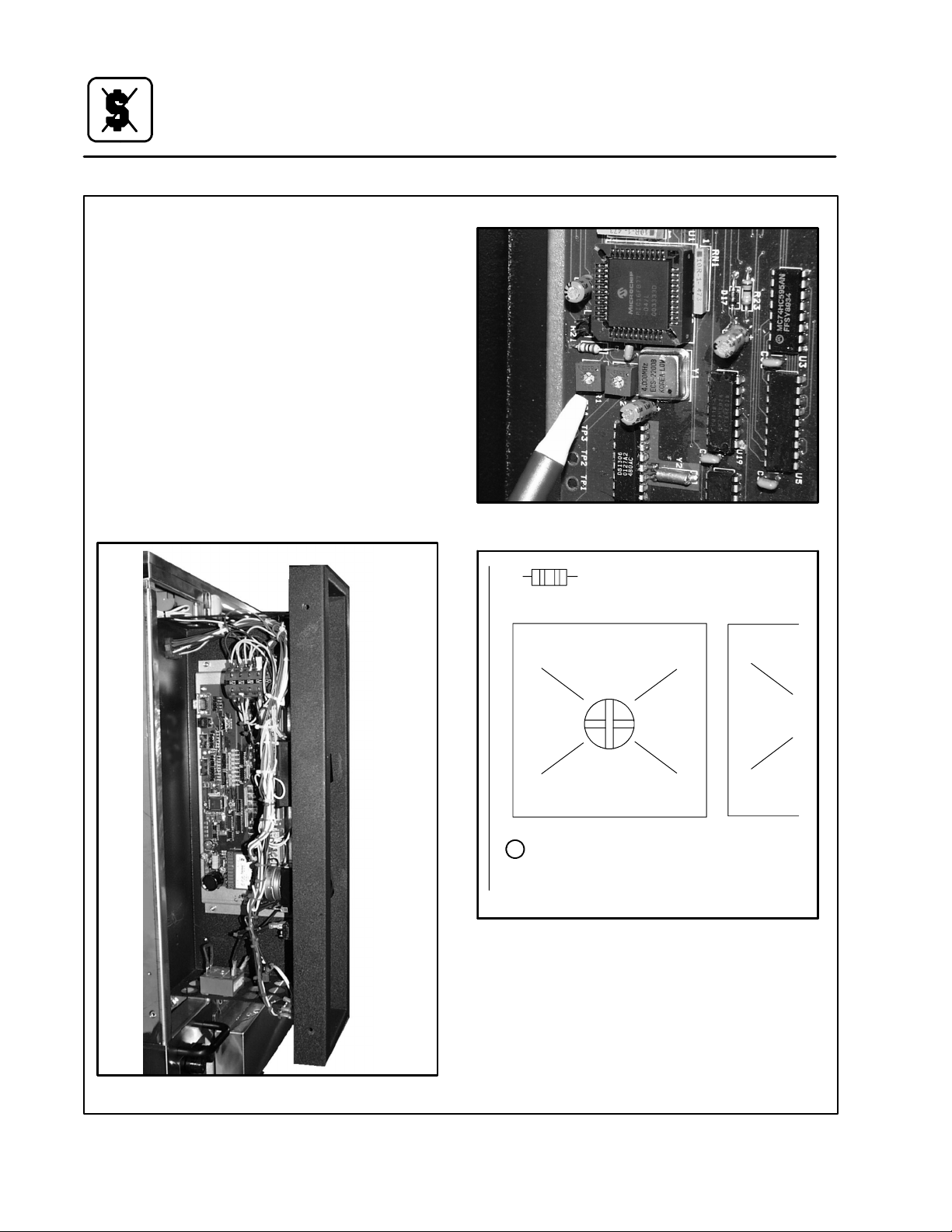

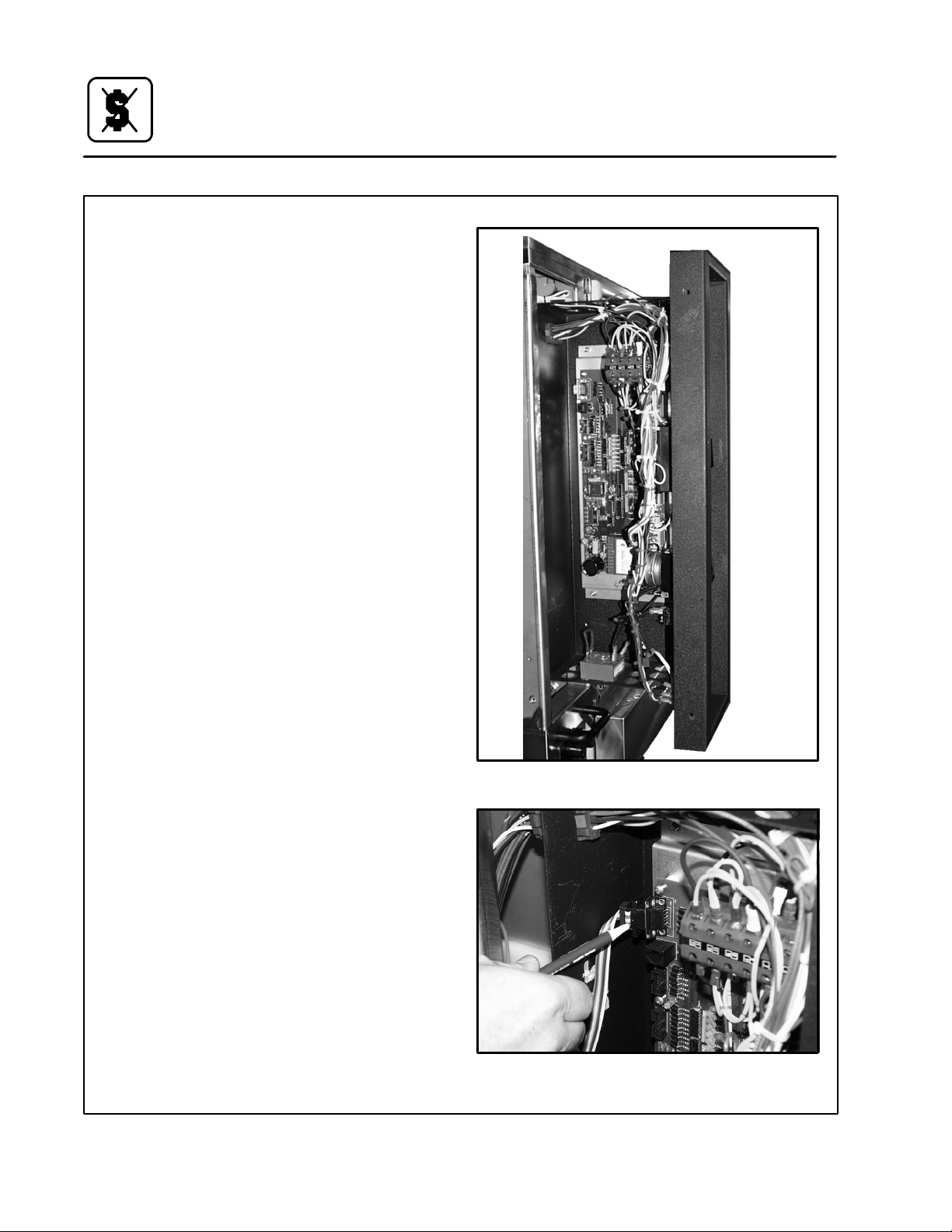

To se t th e de l im i n g i nt e r v al :

1. Remove power from the appliance.

2. Remove the two screws located on the side

panel. Slide the control module forward. See

Figure 12.

3. Turn the potentiometer to the required setting.

See Figure 13.

4. Slide the control back in, replace the two

screws.

5. Apply power to the appliance.

A PC may be connected at power up of the appliance to verify the potentiometer setting. The “Deliming interval is x hour(s) of steam generator run

time.” Status line will show 30, 60 or 90. Refer to

Figure 15 on page 29.

Figure 13

Figure 12

Setting C

Setting B

Setting A

TP4

Potentiometer Settings

Figure 14

28

Page 33

Maintenance

Communication

The oven is equipped with a serial RS-232 communication port located inside the control panel.

A laptop computer can be used to view informa-

Software (c) 2002 Blodgett

Blodgett Combi BC --- 2 Control

ROM Saved Data

===========================

V e r s i o n --- > 3

M o d e l --- > 0

Startup Date --- > 25

Startup Month --- > 6

S t a r t u p Y e a r --- > 2

L o w V o l t --- > 3 7

H i g h V o l t --- > 8 0

Steam Time(sec) ---> 16384

S D T i m e ( s e c ) --- > 4 5 7

CNV Time(sec) --- > 239087

Combi Time(sec)---> 71870

Heat DMD events --- > 0378956

Current time --- > 11h : 22m : 10s

Currentdate --->26day6month2year

Total deliming events ---> 3

Steam has been run --- > 21 hour(s) 52 min(s) 8 sec(s) since last deliming.

Next deliming in approximately 3 hour(s) of Steam Generator run time.

Deliming interval is 24 hour(s) of Steam Generator run time.

Deliming History

=====================================

Last address 5 and state 0

Eventno.1on25day5month2year

Eventno.2on23day6month2year

Eventno.3on21day7month2year

Eventno.4on0day0month0year

Eventno.5on0day0month0year

tion regarding certain parameters of the appliance

including deliming history . A typical screen shot is

shown below.

Explanation of output

Version – Software version.

Model – 1=Gasoven,0=Electricoven.

Startup Date, Month, Year – Date oven was started up.

Low Volt,High Volt – Power supply fluctuations.

Steam Time --- Time in second’s oven has used Steam Mode.

SD Time --- Time in second’s oven has used in On Demand Steam mode.

CNV Time --- Time in second’s oven has used Hot Air Mode.

Combi Time --- Time in second’s oven has used in Combi Mode.

Heat DMD events – Total number of heat demand events.

Current time, Current date --- C u r r e n t d a t e a n d t i m e .

Total deliming events --- Total number of times oven has been delimed.

Steam has been run --- > --- How long steam generator has been run since last deliming.

Next deliming.. – Approximately next time steam generator will need a deliming.

Deliming interval ..– Hours the steam generator will run between deliming events.

Deliming History --- The last 52 events will be printed out. If an event has not occurred, a 0 will be

used. Last address and state are used to record the last deliming state in

case of power fail during the process. Normally, state should be 0.

Figure 15

29

Page 34

Maintenance

Communication

To connect to the oven using a Laptop computer (Microsoft Windows OS)

1. Disconnect the appliance from the power

source.

2. Remove (2) screws and slide the control panel

forward.SeeFigure16.

3. Boot up the computer.

4. Attach a standard serial cable to the laptop

computer’s serial port, and to the 9 pin s erial

port located on the PCB in the control area.

SeeFigure17.

5. Start a communcation program such as “Hyperterminal” by selecting Start --- >Prog r a m s --- > A c c e s s o r i e s --- > H y p e r t e r m i n a l --- > H y p e r Te r m i n a l .

6. Enter a name for the connection, and select an

icon, select OK.

7. Click on “Connect Using” and select the desired COM port used by the seriall cable. Select OK.

8. Set the following parameters, then click OK.

d.) Bits per second 9600

e.) Data bits 8

f.) Parity none

g.) Stop bits 1

h.) Flow Control None

To vi e w d a ta :

Toviewtheoutputdata,theappliancemustbedisconnected from the power source for 10 seconds,

then power must be re-applied. The data will then

be outputted t o the terminal window.Data is also

outputted during the deliming process. Each state

is written to the screen, with the amount of seconds left in the current state being counted down.

Figure 16

Figure 17

30

Page 35

BC-20G

Combi-Four/Étuve à Vapeur

Manuel D’Installation --- Fonctionnement --- Entretien

31

Page 36

Introduction

A

Le four-étuveur Combi de Blodgett

Le four-étuveur Combi de Blodgett propose une

toute nouvelle manière de cuire les aliments. Avec

le four-étuveur Combi, vous pouvez choisir entre

deux modes de cuisson :àlavapeur et à l’air

chaud, soit...

D séparément

D combiné, ou

D en séquence

En outre, trois modes de fonctionnement faciles

s’offrent à vous :

Vapeur

ir Chaud

Combinaison

Vapeau et

Air Chaud

En mode Steam (vapeur), vous pouvez :

étuver réchauffer reconstituer

bouillir décongeler mijoter

blanchir conserver braiser

pocher

En mode Hot Air (air chaud), vous pouvez :

rôtir cuire du pain et des gâteaux

griller gratiner

En mode Combi (combinaison de vapeur et d’air

chaud), vous pouvez :

décongeler rôtir réchauffer

étuver cuire du pain et des gâteaux

De plus, vous pouvez utiliser deux ou trois fonctions de manière séquentielle au cours d’une

même cuisson. Nous appelons cette méthode :

D étuvage combiné

D rôtissage combiné

D cuissondepaincombinée

La circulation de l’air chaud combinée avec la vapeur du four-étuveur Combi à haute performance

assurer des améliorations à plusieurs niveaux :

D productivité accrue dans la cuisine

D diminution des dépenses liées au remplace-

ment des appareils de cuisine

D un choix de menus plus vaste

D un nettoyage simplifié

Le travail est simplifié puisque les aliments sont

préparés sur des plateaux ou dans des récipients

de la table à vapeur. Vous pouvez cuire, stocker et

transporter les aliments dans ces mêmes récipients. Vous pouvez préparer avec efficacité de

petites quantités d’aliments de même que réchauffer les plats cuisinés et les aliments prêts-àservir en quelques minutes seulement. Il devient

possible aussi de préparer certains aliments surgelés sans même les décongeler. Cette souplesse

au niveau de la préparation réduit l’utilisation de

chaudrons et de tables à vapeur puisqu’il n’est

plus nécessaire de conserver au chaud de grandes quantités d’aliments pendant de longues périodes.

De nos jours, il devient de plus en plus important

d’améliorer la qualité des aliments. Avec le fourétuveur Combi de Blodgett, la cuisson des légumes se fait sans eau et à une température optimale légèrement inférieure à 100_C (212_F),

permettant ainsi de conserver les vitamines, les

minéraux, les éléments nutritifs et les oligo-éléments. La viande cuite dans le Combi perd moins

de sa masse et demeure plus ferme et plus juteuse. Vous utiliserez aussi le four-étuveur Combi davantage pour les produits de la boulangerie, car

les modes Steam (vapeur) et Hot Air (air chaud) du

four-étuveur Combi en font un appareil de cuisson

tout usage.

32

Page 37

Introduction

Description de le four-étuveur Combi de Blodgett

À PROPOS DU FOUR-ÉTUVEUR

Les fours-étuveurs Combi de Blodgett sont des

appareils haut de gamme fabriqués en acier

inoxydable de première qualité en faisant appel à

des procédés supérieurs.

Le ventilateur à deux vitesses est doté d’un dispo sitif de protection pour les doigts et alimenté par

un puissant moteur silencieux. Le condenseur aspire l’excès de vapeur de l’appareil. La condensation et les eaux usées générées par la vapeur et le

nettoyage sont continuellement évacuées.

L’isolant de haute qualité empêche un rayonnement thermique excessif et aide à conserver

l’énergie.

Le générateur de vapeur fraîche haute performan ce comporte un système de commande qui vous

permet de profiter de tous les avantages d’un étuveur de haute qualité au simple actionnement

d’un bouton. La vapeur fraîche entre dans la cavité

du four sans pression et y circule à haute vitesse.

Cette méthode simple et pratique favorise une

cuisson rapide et en douceur qui vous procure

des aliments de première qualité. Le générateur

de vapeur est complètement automatique et il est

doté d’un dispositif qui l’empêche de fonctionner

àsec.

FONCTIONNEMENT DU FOUR-ÉTUVEUR

COMBI

La porte pratique du four est dotée d’un hublot et

possède un grand rayon d’ouverture. La poignée

de la porte est facile à saisir, même avec des mains

mouillées ou grasses.

La disposition simple des commandes facilite l’utilisation de l’appareil. Même un cuisinier inexpérimenté peut facilement utiliser l’appareil grâce à un système de pictogrammes explicites. Un sélecteur

permet de passer facilement d’un mode de cuisson

à l’autre, soit Steam (vapeur), Hot Air (air chaud) ou

Combi (combinaison). La fonction de vapeur sur demande permet à l’opérateur d’injecter de la vapeur

pendant 8 minutes lorsque l’appareil se trouve dans

les modes d’air chaud ou de combinaison. Cette

fonction est très utile pour la cuisson de pains et de

gâteaux et le rôtissage. La quatrième fonction du sélecteur, le mode Cool Down (refroidissement), permet de refroidir rapidement la cavité du four lorsque

la porte est ouverte.

L’appareil exige un nettoyage minime. L’intérieur

est vaporisé d’une solution nettoyante à action instantanée qui réagit avec la vapeur pour éliminer

les croûtes et les taches. La conception du fourétuveur Combi assure un entretien facile. Les soudures sont étanches à l’eau, ce qui permet de rincerlacavitédufouraprèslenettoyageàlavapeur.

33

Page 38

Introduction

Caractéristiques

4

6

5

1

Panneau de Commande

2 Porte du four

3 Poignéedelaporte

2

3

1

Figure 1

4 Ventilation (pas montré)

5 Orifice de détartrage

6 Détartrage semi-automatique

34

Page 39

Installation

Responsabilités du propriétaire

1. Les fours sont déballés et mis en place.

2. Le propriétaire/utilisateur doit remplir les

conditions de plomberie, de gaz et d’électricité suivantes.

REMARQUE:Consultez les informations four-

nies dans la section Branchements utilitaires.

CARACTÉRISTIQUES ÉLECTRIQUES -- BC-20G

115Vca---Prisedecourantaveccontactdemiseàlaterrede15ampèresNemaL5-15

208/240 Vca --- Prise de courant avec contact de mise à la terre de 20 ampères Nema 6-20

CARACTÉRISTIQUES PL OMBERIE-- BC-20G

Eau

Pression de l’eau (min/max) 40 PSI min/50 PSI max

Provision pour eau Raccord de tuyau de 3/4 po, 3/8 po de diamètre

intérieur (d.i) min

Réglage du régulateur de pression 35 psi statique

Conditions requises minimum Total des solides en suspension (TDS) --- doit être

moins que 100 parties par million

Dureté totale de l’eau --- 80-120 parties par million

Chlorine --- doit être moins que 30 parties par million

Le pH de l’eau --- 7.0-8.0

Drainage Drain mis à l’air libre

Raccordement du drain 2poencuivre

Température moyenne de l’eau drainée A peu près 50_C (122_F)

AVERTISSEMENT!!

Unemauvaiseinstallation,unmauvaisré-

glage, l’apport de modifications inadéquatesouunmauvaisentretiendecetappareil

peuvent entraîner l’endommagement du

matériel ainsi que des blessures graves,

voire mortelles. Lisez soigneusement les

instructions d’installation, d’utilisation et

d’entretien avant d’installer ou de procéder

à l’entretien de ces appareils.

35

Page 40

Installation

Responsabilités du propriétaire

PRESSION DU GAZ -- BC-20G

Entrée de gaz

Vapeur 90,000 BTU/HR

Air chaud 125,000 BTU/HR

Pression d’entrée dans l’appareil

Gaz naturel 5 --- 1 4 p o W C (1 . 2 4 --- 3 . 4 8 k Pa )

Propane 11---14 po WC (2.73---3.48 kPa)

Pression dans la rampe à gaz

Gaz naturel 3.5poWC(.87kPa)

Propane 10 po WC (2.49 kPa)

Connecteur de 1 po FNPT pour toutes les installations canadiennes et américaines

36

Page 41

Installation

Placement et Ventilation

PLACEMENT

Un emplacement correct et soigneusement prévu

pour l’appareil aura pour résultat, à long terme, une

utilisation pratique et un rendement satisfaisant.

Les espaces de dégagement ci-dessous doivent

être prévus entre le four et toute constructioncombustible ou non.

BC-20G

D Côté droit du four --- 15 cm (6 po)

D Côté gauche du four --- 15 cm (6 po)

D Arrière du four --- 15 cm (6 po)

Les espaces de dégagement ci-dessous doivent

être possible pour permettre l’entretien.

D Côté gauche du four --- 30 cm

D Arrière du four --- 30 cm

Placer le four dans une zone sans courants d’air

et accessible pour permettre son fonctionnement

et son entretien.

Garder la zone du l’appareil libre et dégagée de

toutes matières combustibles, telles que papiers,

cartons, liquides inflammables et solvants.

NE PLACEZ PAS l’appareil sur un socle courbé, et

ne le fixez pas au mur. Dans ces deux cas, les moteurs à soufflerie ne pourraient pas être convenablement ventilés. Une petite dénivellation peut se

corriger avec les pieds réglables.

Tous les paliers de moteur sont lubrifiés en permanence à l’usine; ils ne nécessitent aucune lubrification supplémentaire pendant la durée de vie opérationnelle des moteurs.

VENTILATION

On ne saurait trop insister sur la nécessité de prévoir un système d’aération bien conçu. Un tel système permettra au four de bien fonctionner, tout

en évacuant les vapeurs et produits de combustion gênants de la zone d’utilisation.

L’extraction des fumées de combustion de l’appareil

doit se faire au moyen d’un groupe d’aspiration à

commande mécanique. Celui-ci doit être dimensionné de façon à ce qu’il recouvre entièrement l’appareil, tout en dépassant d’au moins 15 cm de tous

les côtés qui ne sont pas contigüs à un mur. Le groupe doit avoir la capacité qui convient et un appoint

d’air adéquat doit être prévu.

AVERTISSEMENT!!

Une mauvaise extraction des fumées de

combustion du four peut mettre en danger

la santé de l’opérateur. Elle aura également

pour résult at s des problèmes de fonctionnement, une cuisson laissant à désirer et

de possibles dégâts subis par le matér i el.

Les dégâts résultant directement d’une aération inadéquate ne seront pas couverts

par la garant ie offerte par le fabrican t.

Mises en service américaines et canadiennes

Se reporter aux codes locaux de la ventilation. En

l’absence de codes locaux, se reporter au code

national de la ventilation intitulé “Normes pour l’in-

stallation d’équipements pour l’enlèvement des fumées et vapeurs grasses provenant d’équipements commerciaux pour la cuisine”, NFPA-96Édition la plus récente.

Mise en service dans les autres pays

L’installation doit respecter les normes nationales et locales, qui varient selon le pays. Si vous avez des questions sur les méthodes d’installation acceptables ou

sur le fonctionnement de votre appareil, veuill ez communiquer avec votre détaillant. S’il n’y a aucun détaillant dans votre région, veuillez communiquer avec

Blodgett Combi au 0011-802-860-3700.

37

Page 42

Installation

Normes et Codes

LES CONSEILS D’INSTALLATION ET D’ENTRETIEN CONTENUS DANS CE MANUEL NE

S’ADRESSENT QU’Á UN PERSONNEL QUALIFIÉ. UN PERSONNEL NON QUALIFIE PEUT SE

BLES SER ET/OU ABÎMER LE FOUR LORS DE

SON INSTALLATION ET/OU SON ENTRETIEN.

Un personnel d’installation qualifié est représenté

soit par des personnes physiques, soit par un société, une usine, une corporation qui en personne

ou par l’intermédiaire d’un représentant s’engage

à et est responsable de:

D l’installation ou le remplacement de conduits de

gaz, ou le branchement, l’installation, la réparation ou l’entretien de l’équipement.

D l’installation du câblage électrique reliant le

compteur d’électricité, l’armoire électrique ou la

prise de courant à l’appareil électrique.

Le personnel d’installation qualifié doit être expérimentédanscetypedetravail,s’êtrefamiliarisé

avec toutes les précautions requises et respecter

tous les réglements promulgués par les autorités

provinciales ou locales compétentes.

Installations aux États-Unis et au Canada

La mise en service doit respecter les normes locales ou, en l’absence de tels normes, les règlements suivants : National Fuel Gas Code,

NFPA54/ANSI Z223.1 --- dernière édition, le Code

d’installation du gaz naturel et propane

CAN/CSA-B149.1.

Référence : National Electrical Code, ANSI/NFPA

70 --- dernière édition ou le Code canadien de

l’électricité C SA C22.1,selonlecas.

La mise en service de ce matériel doit respecter

lesnormessuivantes:BasicPlumbing Code of the

Building Officials and Code Administrators International Inc. (BOCA) et Food Service Sanitation