Page 1

C70

CONVECTION MICROWAVE OVEN

INSTALLATION -- OPERATION -- MAINTENANCE

BLODGETT OVEN COMPANY

www.blodgettcorp.com

50 Lakeside Avenue, Box 586, Burlington, Vermont 05402 USA Telephone (800) 331-5842, (802) 860-3700 Fax: (802)864-0183

PN T0354 Rev G (3/01)

E 2000 --- G.S. Blodgett Corporation

Page 2

IMPORTANT

WARNING: IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, INJU RY OR DEATH. READ THE INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

FORYOURSAFETY

Do not store or use gasoline or other flammable vapors or

liquids in the vicinity of this or any other appliance.

The information contained in this manual is important for the proper

installation, use, and maintenance of this oven. Adherence to these

procedures and instructionswill result in satisfactory baking results

and long, trouble free service. Please read this manual carefully and

retain it for future reference.

Errors: Descriptive, typographic or pictorial errors are subject to correc-

tion. Specifications are subject to change without notice.

Page 3

Your Service Agency’s Address:

Model:

Serial Number:

Your oven was installed by:

Your oven’s installation was checked by:

Page 4

Table of Contents

Important Safety Instructions i..........................................

Precautions to Avoid Possible

Exposure to Excessive Microwave Energy ii.............................

Grounding Instructions iii...............................................

RF Interference Considerations iv.......................................

Introduction

Oven Description and Specifications 1................................

Installation

Installation Instructions 2............................................

Delivery and Location 3.............................................

Leg Attachment and Double Stacking 4...............................

Optional Stand/Cart Assembly 5.....................................

Oven Assembly 6..................................................

Operation

Glossary of Common Terms 7.......................................

Control Panel 8....................................................

Registration and Power-Up 9........................................

Menu Selection 10..................................................

Cooking Instructions 11..............................................

Programming 12....................................................

Operating Tips 14...................................................

Maintenance

Cleaning 15........................................................

Cleaning Supplies and Equipment 15...............................

Cleaning Tips 15.................................................

Cleaning Procedure 16..............................................

Oven Cavity Filter Cleaning 17........................................

Troubleshooting 18..................................................

Catalytic Converter 19...............................................

Page 5

IMPORTANT SAFETY INSTRUCTIONS

WHEN USING ELECTRICAL APPLIANCES, THE FOLLOWING

BASIC SAFETY PRECAUTIONS SHOULD BE STRICTLY ADHERED TO:

WARNING!!

To reduce the risk of burns, electric shock, fire, injury to persons or exposure to excessive

microwave energy:

1. Read all instructions before using the appliance.

2. Readandfollow the specificPRECAUTIONS TOAVOID POSSIBLE EXPOSURE TOEXCESSIVE

MICROWAVE ENERGY found on the following pages.

3. This appliance must be grounded. Connect only to properlygroundedoutlet. See GROUNDING

INSTRUCTIONS found on page iv.

4. Install or locate this appliance only in accordance with the provided installation instructions.

5. Some products such as whole eggs and sealed containers -- - for example, closed glass jars --- may

explode and SHOULD NOT be heated in this oven.

6. Use this appliance only for its intended use as described in the manual. DO NOT use corrosive

chemicals or vapors in this appliance. This type of oven is specifically designed to heat, cook, or

dry food. It is NOT designed for industrial or laboratory use.

7. Children SHOULD NOT use this appliance.

8. DO NOT operate this appliance if it has a damaged cord or plug, if it is not working properly, or if it

has been damaged or dropped. See POWER SUPPLY CORD REPLACEMENT found on page iv .

9. This appliance should be serviced only by qualified service personnel. Contact the nearest authorized service facility for examination, repair or adjustment.

10. DO NOT cover or block any openings on the appliance.

11. DO NOT store this appliance outdoors. DO NOTuse this product near water --- for example, near

a kitchen sink, in a wet basement, or near a swimming pool.

12. DO NOT immersecordorpluginwater.

13. Keep cord away; from heated surfaces.

14. DO NOT letcordhangoveredgeoftableorcounter.

15. DO NOT useawaterjetforcleaning.

16. See the Maintenance section of this manual.

17. To reduce the risk of fire in the oven cavity:

a.) DONOTovercookfood.Carefully attendappliance ifpaper,plastic,orothercombustiblemate-

rials are placed inside the oven to facilitate cooking.

b.) Removewiretwist---tiesfrompaperorplasticbaginoven.

c.) Ifmaterialsinsidethe ovens hould ignite,keep oven door closed,turn oven off,and disconnect

thepowercord,orshutoffpoweratthefuseorcircuitbreakerpanel.

d.) DONOT usethe cavityforstoragepurposes. DONOTleave paper products, cooking utensils,

or food in the cavity when not in use.

e.) If smoke is observed, switch off or unplug the appliance and keep the door closed in order to

stifle the flames.

SAVE THESE INSTRUCTIONS

i

Page 6

PRECAUTIONS TO AVOID POSSIBLE

EXPOSURE TO EXCESSIVE MICROWAVE ENERGY

WARNING!!

Toreducetheriskofexposuretoexcessivemicrowaveenergy:

1. DO NOT attempt to operate this oven with the door open since open---door operation can result

inharmfulexposuretomicrowaveenergy.Itisimportantnotto defeatortamperw ith thesafetyinterlocks.

2. DONOT place any object between the oven front face and the door orallow soilor cleaner residue

to accumulate on the sealing surfaces.

3. DONOToperate the oven if itis damaged. It isparticularlyimportant that the oven door closeproperly and that there is no damage to the:

a.) Door (bent).

b.) Hinges and latches (broken or loosened).

c.) Door seals and sealing surfaces.

4. The oven SHOULD NOT be adjusted or repaired by anyoneexcept properlyqualified servicepersonnel.

SAVE THESE INSTRUCTIONS

ii

Page 7

GROUNDING INSTRUCTIONS

This appliance MUST BE grounded. In the event of an electrical short circuit, grounding reduces the

risk of electric shock by providing an escape wire for the electric current. This appliance is equipped

with a cord having a grounding wire w ith a grounding plug. The plug must be plugged into an outlet

that is properly installed and grounded.

WARNING!!

Improper use of the grounding can result in a risk of electric shock.

Consult a qualified electrician or serviceman if the grounding instructions are not completely understood, or if doubt exists as to whether the appliance is properly grounded.

DO NOT use an extension cord. If the power supply cord is too short, have a qualified electrician or

serviceman install an outlet near the appliance.

POWER SUPPLY CORD REPLACEMENT

If the power supply cord is damaged, it MUST BE replaced by the manufacturer or its service agent

or a similarly qualified person in order to avoid a hazard.

SAVE THESE INSTRUCTIONS

iii

Page 8

RF INTERFERENCE CONSIDERATIONS

This oven generates radio frequency signals. This device has been tested and determined to be in

compliance with applicable part of FCC part 18 requirements and to the protection requirements of

CouncilDirective89/336/EECon theapproximationofthelaws ofthe MemberStates relatingto electromagneticcompatibilityat thetime of manufacture. However, someother equipmentmayexhibit sensitivity to signals below these limits resulting in interference with that equipment.

If your equipment experiences interference, the following steps should be considered:

1. Increase the physical separation between this oven and the sensitive equipment.

2. If th e sensitive device can be grounded, do so following accepted grounding practices.

3. If battery powered microphones are being affected, insure that the batteries are fully charged.

4. Keep sensitive equipment on electrically separate circuits, if possible.

5. DO NOT route intercom wires, microphone wires, or speaker cables near oven.

SAVE THESE INSTRUCTIONS

iv

Page 9

Introduction

Oven Description and Specifications

Cooking in an Accellis oven is different and exciting. Accellis combines intense microwave energy

with high velocity hot air impingement to cook

much faster than conventionalovens withoutsacrificingproduct quality. Thistechnologyallowsyou

to cook a combination of different products at the

same time. The closed loop convectiveheat contains a catalytic converter that eliminates flavor

transfer between foods and reduces airborne

grease in the oven. Rapid response heaters pro-

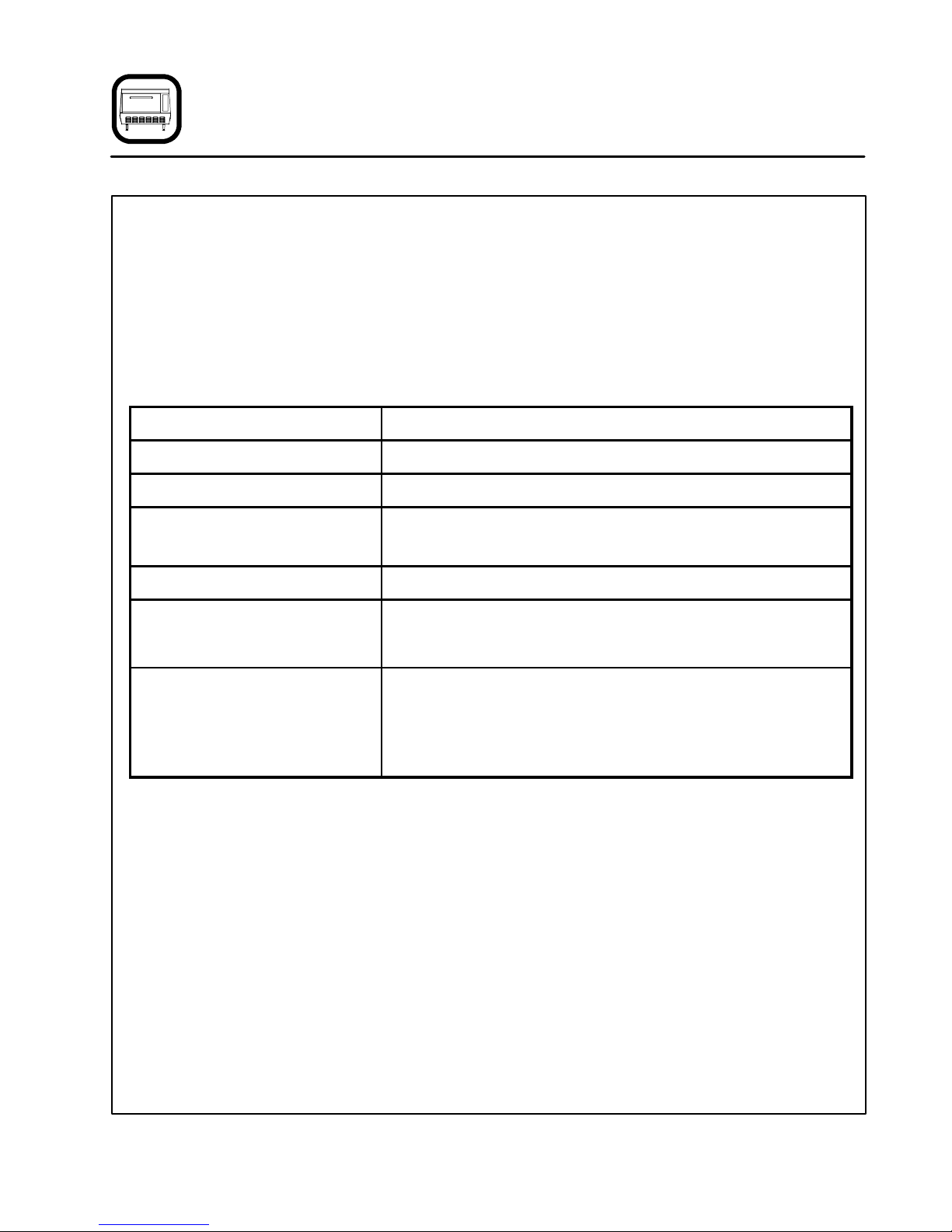

SPECIFICATIONS

Dimensions (single unit) 29” W x 21.5” H x 32.25” D (74.9 cm x 54.6 cm x 81.9 cm)

Maximum Input 8.0 KW/Hr.

Power Supply 208 VAC, 50/60 Hz, 1Ô, 39 amp,3 wire including ground

240 VAC, 50/60 Hz, 1Ô, 36 amp,3 wire including ground

Microwave Frequency 2.45 GHz

Connections including ground The unit is supplied with a 6’ power cord with an approved

plug. The outlet box, receptacle and wall plate are to be fur-

nished by the installing contractor.

vide fast heating to control product temperatures

andmoisturewhileensuringnolagtime topreheat

or cool down between products with different

cooking temperatures.

Accellis ovens represent the latest advancement

in energy efficiency, reliability, and ease of opera tion: resulting in substantial reductions in energy

consumption and a cooler kitchen environment.

C70/AA

Maximum Power Usage

Convection Oven

Microwave Oven

5Kw

2Kw

1

Page 10

TheAccellisovenismanufacturedtocomplywith

applicable CE, NSF (pending), UL, Canadian,

FDA, and FCCrequirements. Allequipment is designed and certified for safe operation when

installed in accordance with local and or national

codes. Many local codes exist, and it is the responsibility of the owner and installer to comply

with these codes.

In no event shall the manufacturer assume any liabilityfordamagesor injuryresultingfrominstallationswhich are not in compliancewith the instructionsandcodeslistedabove.

Installation

Installation Instructions

WARNING!!

DEATH, INJURY, AND EQUIPMENT DAM-

AGEcouldresultfrom improperinstallati on

of this oven or inst allation of a unit which

has been damaged during shi pment or

storage. Eith e r of these conditions could

void the equipment warranty.

DO NOT INSTALL an oven suspected of

damage.

INSTALL this oven according to the policies and procedures outlined in this

manual.

2

Page 11

Installation

Delivery and Location

DELIVERY AND INSPECTION

WARNING!!

Uncrate the oven as describedbelow.DO

NOT use the oven handle to lift the oven

out of the crate. This can damage the

door’s microwave seal.

AllAccellisovensare shipped incontainers toprevent damage. Upon delivery of your new oven:

1. Inspect the shipping container for external

damage. Any evidence of damage should be

noted on the delivery receipt which must be

signed by the driver.

2. Uncrate the oven as follows:

a.) Open the shipping crate.

b.) Open the oven door.

c.) Grabthe inside of the oven cavity to lift the

oven out of the crate just enough to remove the lower access panel below the

door .

d.) Removetheloweraccesspanel.

e.) Grabbingtheframeoftheoveninsideof

the front access area, lift the oven out of

the shipping crate.

3. Check for internal damage. Carriers will accept claims for concealed damage if notified

withinfifteen daysof deliveryandt he shipping

container is retained for inspection.

The manufacturer cannot assume responsibility for loss or damage suffered in transit. The

carrier assumed full responsibility for delivery

in good order when the shipment was accepted. We are, however, prepared to assist

you if filing a claim is necessary.

OVEN LOCATION

The well planned and proper placement of your

oven will result in long term operator convenience

and satisfactory performance.

Be sure to place the oven in an area which is accessible for proper operation and servicing.

The countertop or work surface must be able to

support the weight of 275 pounds. The manufacturer shallnotassume liabilityfordamage or injury

resulting from improper installation of equipment

including temporary or unstable work stations or

countertops.

Theremust be 2”(5. 08 cm) between the top ofthe

unit a nd any shelf or other surface.

The oven must be installed level front to back and

side to side. The oven legs may be bolted to the

counter top if desired.

3

Page 12

Installation

Leg Attachment and Double Stacking

4” (10CM) LEG ATTACHMENT

1. Tilt the oven.

2. Screw one leg into each of the corner nuts.

Figure 1

DOUBLE STACKING

1. Stack and align the ovens.

2. Remove the exhaust cover from the back of

the bottom oven. Pull the cover straight away

from the oven to remove.

3. Removeandsave the bottomfivescrews from

the back of the top oven.

Remove and save the top fivescrews and the

drip strip from the back of the bottom oven.

4. Attach the stacking rail to the ovens using the

screws removedin step 3. Tighten the fiveupper screws. DO NOTfullytightenthefivelower

screws.

5. Align the three slots on the drip strip with the

three leftmost lower screws. Slide the drip

strip up and under the stacking rail.

6. Tightenthelowerfivescrews.

7. Reinstallthe exhaust cover on the lower oven.

Stacking

Rail

Exhaust

Cover

Drip Strip

Figure 2

4

Page 13

Installation

Optional Stand/Cart Assembly

NOTE: Unitswithcastersarecarts.Unitswithlegs

are stands.

1. Install an end cap into the mountingbrackets

on each leg assembly.

2. Attach the leg asssemblies to the stand/cart

top with flat washers, lock washers and hex

nuts. DO NOT tighten the hex nuts.

3. Attach the shelf assembly to the legs with the

bolts,hexnuts, flatwashers andlocknuts provided. DO NOT tighten the hex nuts. See

Figure 3.

NOTE: Thestandisnot square.Theend ofthe

top with the three holes goes in the

front. The end of the shelf with the

notch in the underside lip goes in the

front. Be sure to line up the sides correctly.

4. Pull the leg flanges tightly into the corners of

the frame. Tighten the the hex nuts to fasten

the legs to the stand top.

Front of S tand

5. Tighten the hex nuts to fasten the legs to the

shelf. DO NOT overtighten.

6. For Carts with Casters:

NOTE: The casters with brakes must go on

the front of the stand.

a.) Slide the casters into the bottom of the

legs.The rubberstem should fit snuglyinside the leg.

b.) To adjust, hold the knurled nut and turn

the round pad at the base of the stem.

c.) Tighten the round pad to secure the cast-

er to the leg.

For Stands with Feet:

a.) Pusha footintothe bottomof each legas-

sembly.

7. Place the oven(s) on the stand/cart. Align the

four threaded holes in the bottom of the oven

withthe four holes inthe top of the stand/cart.

Attach the oven to the stand/cart with the

bolts,flatwashersand lockwashersprovided.

Front of Cart

Stand with Legs

Cart with Casters

Figure 3

5

Page 14

Installation

Oven Assembly

1. Carefully remove the pack ing material from

the ceramic cooking platter.

2. Open the cooking chamber door.

3. Placethewaveguidecapontopofthewaveguide. The waveguide is locatedin t he center

of the cook chamber floor.

4. Slidethe cooking platteron the side rails in the

cook chamber.

Cook Platter

Figure 4

6

Waveguide

Cap

Page 15

Operation

Glossary of Common Terms

OVEN OPERATING COMPONENTS

Display --- Primary interface to relay messages t o

the operator.

Keypad --- Primary interface for the operator to

control the oven.

Cook Chamber --- Cavity in which the food prod-

ucts are cooked.

PRODUCT RECIPES

Recipe --- The food product recipe programming.

It consists of time, percentage of hot air flow (AIR)

required and microwave (MW) level required.

Cook Cycle --- Time of operation for a recipe.

CookEvent– Segment of a recipe, up to 6events

can be used for each recipe.

Duration --- Time, in seconds, of a single cook

event.

Air --- Percent of convection air flow during a cook

event.

MW --- Percent of microwave used during a cook

event.

Cook Temperature Set Point --- Temperature

should be a constant parameter. The same cook

temperature should be used by all cook recipes.

MODES

Mode – The software environment which allows

certain operations to occur. There are several

modes, STANDBY, COOK, WARM UP and COOL

DOWN in which the oven can operate.

Standby Mode --- The s tandby mode is similar to

oven off. In standby there is no power to the oven.

There is power to the control, however, the oven

will not operate in standby mode.

Cook Mode --- Mode used to perform the normal

oven operations,such as,monitor the key pad for

requests to cook or change mode, and maintain

the oven at the cook temperature set point.

Warm-Up Mode --- Mode to bring the oven up to

the cook temperature set point.

Cool-Down Mode --- Turns off a ll oven components except the cooling fan and circulation blower.

7

Page 16

Operation

Control Panel

DESCRIPTION

1. DISPLAY WINDOW --- Displays operationand

1

L1

L2

2

L3

L4

3

4

R1

R2

2

R3

R4

3

programming information.

2. SOFT KEYS --- Eight round keys are used for

different functions depending on what is displayed.

NOTE: The names shown in Figure 5 (R1-4

and L1-4) are used for key identificationinthismanual.Theydonotappear

on the oven.

3. ARROWKEYS---Usetomovewithinmenu

selections and between screens.

4. STOP KEY --- Press to stop cook cycles.

5. NUMERIC KEYPAD --- Used to enter data in

the programming mode.

6. BACK KEY --- Used to move to a previous

screen in operation and programming mode.

7. ENTERKEY --- Use tosave programmedinformation.

8. SPACEKEY --- Usedas a spacekeyinthe programming mode. Also used to enter the numeral 0.

5

6

8

Figure 5

7

8

Page 17

Operation

Registration and Power-Up

REGISTRATION

You may be required to obtain a registration number from the Blodgett Service Department before

the unitcan be operated. Use the followingprocedure for control registration:

1. Registrationisrequired ifafter applyingpower

to the oven for the first time the display requests a registration code. See Figure 6.

2. Note the serial number of the oven, the oven

location and phone number. Call Blodgett at

the number shown on the display to obtain

your registration.

3. Use the NUMERIC KEYPAD (5) to enter the

registration number for your unit. Press the

ENTER key (7) to save the registration code.

4. The display advances to the standby screen.

L1

CALL

1-888-992-6624

S/N XXXXXXXXXXXX

L2

ENTER REG CODE

___

L3

L4

Registration Screen

NOTE: The R1-4 and L1-4 are used for key identification

in this manual. They do not appear on the oven.

R1

R2

R3

R4

Figure 6

TO POWER UP THE OVEN

The AccellisC70 ovenis equipped with astandby

mode. The standby mode is similarto oven off. In

standby there is no power to the oven. There is

powertothecontrol,however,the ovenwillnot operate in standby mode.

NOTE: After 1 hour in standby mode the display

goes blank to prevent burn in.

To turn on power to the oven (exit standby):

1. If the display is blank, press any key .

2. The display reads:

OVEN OFF

OVEN ON appears in the lowerright corner of

the display.

3. P ress the R4 SOFT KEY (2) to turn the oven on.

4. The display reads:

SET TEMP XXX

PRESS ENTER

OVENOFFappears in the lowerright corner of

the display.

5. Usethe ARROW keys (3) to select thedesired

setpoint temperature from 350---525_F

(175---275_C) in 25_ increments.

Press the ENTER key (7) to set the cook temperature.

6. The display reads either:

WARMING UP

or

COOLING DOWN

7. When the oven has reached operating temperature the display reads:

READY TO COOK

An audible alarm sounds for approximately

threeseconds. Thedisplaychangesto theselect group screen.

9

Page 18

Operation

Menu Selection

NOTE: Press the BACK button at any time during

menu selection to return to the previous

screen.

1. The select group screen is displayed with

eight menu groups (A---H).

NOTE: See Programming on page 13 to as-

sign new names to the menu groups.

2. Press the SOFT KEY (2) corresponding tothe

desired menu group. The oven advances to

the Menu Item screen.

3. The Menu Item screen displays the selected

menugroupnamefollowedbyITE MS 1 ---8.

NOTE: See Programming on page 13 to as-

sign new names to the menu items.

L1

L2

GROUPAGROUP

E

GROUPBGROUP

F

R1

R2

4. Press the SOFT KEY (2) corresponding to the

desiredmenuitem.Theovenadvancestothe

Cooking screen if a cook setting is stored for

the menu item selected. Otherwise, the display momentarily reads:

NO COOK SETTING

and returns to the Menu Group screen.

To change the current cook temperature:

1. PresstheBACKkey (6)repeatedlyuntiltheset

temp screen is displayed.

2. Use the ARROW keys (3) to change the cook

temperature.

3. Pressthe ENTERkey (7)to savethe newcook

temperature.

L1

L2

ITEM

1

ITEM

2

GROUP A

ITEM

5

ITEM

6

R1

R2

L3

L4

NOTE: The R1-4 and L1-4 are used for key identification in this manual. They do not appear on the oven.

GROUPCGROUP

G

GROUPDGROUP

H

Select Group Screen

R3

R4

L3

L4

ITEM

3

ITEM

4

Menu Item Screen

Figure 7

ITEM

7

ITEM

8

R3

R4

10

Page 19

Operation

Cooking Instructions

COOK

1. Use either of the following methods to initiate

the cook mode:

a.) Selectamenu itemwith astored cookset-

ting. The cook screen displays the name

of the menu group and menu item.

b.) Test cook settingson the Edit screen. See

page 13. The cook screen displays the

name of the menu groupand menu item.

2. The total cook time is displayed at the top of

the screen and counts down as the product

cooks.

Pressthe STOP key (4) at anytimeto immediately stop t he cook cycle

If the door is opened during the cook cycle, the

display reads PAUSE. When the door is closed,

a RESUME button appears. Press the corresponding SOFT KEY (1) to continue cooking.

If a fault condition is detected during the cook

cycle, th e cook is terminated and a message

indicating the source of the fault is displayed.

3. When the cook time expires or the STOP key

(4) is pressed, an alarm sounds and the display reads:

DONE

PLEASE REMOVE FOOD

FROM OVEN

4. Open the door to remove the product. The

Cook More function is displayed.

NOTE: The COOK MORE function is used to

improve browning and/or add more

heat to the food.

If no button is pressed, after one minute the

ovenautomaticallyreturns tothe Menu Group

screen.

5. If you do not want touse the Cook More function,press the BACK key (6) toreturn immediately to the group screen.

COOK MORE

1. At the conclusionof thecooktime the display

offersthe option ofusing the Cook More function. Press the R4 SOFT key (2)to advance to

the Cook More screen.

2. The cook more time displayed is 25% of the

originalcook time unless limits are exceeded.

a.) Use the UP ARROW key (3) to increase

the cook more time in twenty second incrementstoa maximum timeof 9 minutes

55 seconds.

b.) Use the DOWN ARROW key (3) to de-

crease the cook more time in twenty sec ond increments to a minimum of 10 seconds.

3. There are three different cook more methods.

Press the corresponding SOFT key (2) to select the desired method.

a.) COOKMORE is used to add more heat to

the food.

b.) BROWNMOREis used todarken the out-

side of the food.

c.) COOK & BROWN combine the two.

4. When the cook time expires or the STOP key

(4) is pressed, an alarm sounds and the display reads:

DONE

PLEASE REMOVE FOOD

FROM OVEN

5. Openthedoorto removethe product.The Cook

More function is displayed. Repeat steps 1---3

to use the Cook More function again.

If no button is pressed, after one minute the

ovenautomaticallyreturns tothe Menu Group

screen.

6. If you do not want touse the Cook More function again, press the BACK key (6) to return

immediately to the group screen.

OVEN OFF (STANDBY MODE)

1. Press the BACK key (6) repeatedly until the

Set Temp screen is displayed.

2. Thedisplayreads OVEN OFF in the lower right

corner. Press thecorresponding SOFTkey (2)

--- R4 --- t o enter the sta ndby mode.

11

Page 20

Operation

Programming

TO ENTER PROGRAMMING MODE

1. From the standby mode, press and hold both

ARROWkeys(3) simultaneouslyforthreeseconds.

2. The display reads:

ENTERPIN____

3. Use the NUMERIC keypad (5) t o enter thefollowing access code:

9

4. Press the ENTER key (7).

RECIPE PROGRAMMING

1. The edit group screen is displayed with eight

menu groups (A --- H).

2. Press the SOFT KEY (2) corresponding tothe

desired menu group. The oven advances to

the Menu Item screen.

3. The Menu Item screen displays the selected

menugroupnamefollowedbyITE MS 1 ---8.

4. Press the SOFT KEY (2) corresponding tothe

desiredmenuitem.Theovenadvancestothe

Item Edit screen.

5. Thecontroldisplaysthe Item Editscreen. This

screenincludes thecook settemperature and

the programming information for each cooking event of the item r ecipe. Each recipe can

contain up to six cooking events. Each event

consists of time, % Air (hot air) and % Microwave.

% AIR --- is the percentage of the blower

speed.

% WAV --- is the percentage of microwave

power, the power level

NOTE: The Set Temp is given for test cook

purposes only. Cook temperatures

arenot associated with therecipeprogramming. Change the set temp only

when testing a recipe for evaluation.

6. Use the following procedure to program the

recipe event parameters:

a.) Press the DOWN ARROW key (3) twice to

move to SET TEMP. The display reads:

DEC SET TEMP INC

Use L1 or R1 to set the desired temperature. Press L1 todecrease thetemperature.

Press R1 to increase the temperature.

b.) Press the DOWN ARROW key (3) to move

to TIME. Use the NUMERIC KEYP AD(5) to

enter a cook time for the first cook event of

the recipe. The maximum allowable time is

59:59.

c.) Press the DOWNARROWkey (3) to move

to %AIR. Use the NUMERIC KEYPAD (5)

to enter the desired blower speed. The

blowerspeed willbe roundeddown to the

nearest 10%.

d.) Press the DOWNARROWkey (3) to move

to %WAV. Use the NUMERIC KEYPAD (5)

toenter the desiredmicrowave power level. The microwave power level will be

rounded down to the nearest 10%.

e.) Repeat steps a---d for each desired event.

7. When all events have been programmed,

press the R4 SOFT KEY (2) to save the programming.

L1

L2

L3

L4

GROUP A

ITEM 1

SET TEMP XXX

TIME %AIR %WAV

1 00:00 0 0

2 00:00 0 0

3 00:00 0 0

4 00:00 0 0

5 00:00 0 0

6 00:00 0 0

TEST

SAVE

R1

R2

R3

R4

NOTE: The R1-4 and L1-4 are used for key identification

Edit Item Screen

in this manual. They do not appear on the oven.

Figure 8

12

Page 21

Operation

Programming

TO TEST A POTENTIAL RECIPE

NOTE: Besurethereistestproductintheoven

and that the oven door is closed.

1. PresstheDOWN ARROWkey (3) twice tomove

to SET TEMP. The display reads:

DEC SET TEMP INC

Use L1 or R1 to set the desired temperature.

Press L1 to decrease the temperature. Press

R1 to increase the temperature. The display

reads either:

WARMING UP

or

COOLING DOWN

The unit has reached temperature when the

display clears.

2. Press the DOWN ARROW key (3) to move to

TIME. Use the NUMERIC KEYPAD (5) toenter

a cook time for the first cook event of the recipe. The maximum allowable time is 59:59.

3. Press the DOWN ARROW k ey (3) to move to

%AIR.Usethe NUMERIC KEYPAD(5)to enter

the desired blower speed. The blower speed

will be rounded down to the nearest 10%.

4. Press the DOWN ARROW k ey (3) to move to

%WAV. Use the NUMERIC KEYPAD (5) to enterthedesiredmicrowavepowerlevel.Themicrowave power level will be rounded down to

the nearest 10%.

5. Repeat steps a---d for each desired event.

6. When all events have been programmed,

press the L4 SOFT KEY (2) to test the recipe.

7. The oven will cook the product according to

the test recipe program.

8. Upon completion of the cook cycle, the controlwillautomaticallyreturn to the Edit Recipe

screen for further programming.

Iftherecipeisacceptable,presstheR4SOFT

KEY (2) to save the new recipe.

TO EXIT PROGRAMMING MODE

1. Pressthe BACK key (6) repeatedly to exit programming mode.

TO CHANGE THE PIN NUMBER

1. Press and hold the ARROW keys (3) simultaneously for approximately 3 seconds.Thedisplay reads:

ENTERPIN____

2. Use the NUMBERIC KEYPAD (5) to enter

2237. The display reads:

ENTERNEWPIN____

3. Use the NUMERIC KEYPAD (5) to enter up to

four digits.

4. Press the ENTER key (7) to accept the newPIN.

The display moves to the edit group screen

TO RENAME GROUPS AND ITEMS

1. The edit group screen is displayed with eight

menu groups (A---H). Press the SOFT KEY (2)

corresponding to the desired menu group.

The oven advances to t he Menu Item screen.

2. The Menu Item screen displays the selected

menugroupnamefollowedbyITE MS 1 ---8.

3. Press the SOFT KEY (2) corresponding tothe

desiredmenuitem.Theovenadvancestothe

Item Edit screen.

4. Usethe ARROWkeys (3) to move thecurserto

thenametobeedited,eitherGROUPorITEM.

5. A right and left arrow key appear atthe top of

thedisplay.Thesearrowsare tonavigatewith in the text.

a.) Use the L1 SOFT KEY (2) to move the

curser to the left.

b.)UsetheR1SOFTKEY(2)tomovethe

curser to the right.

6. Use the NUMERIC KEYPAD(5) to changethe

digits as follows:

a.) Press the key onceto enter the first letter.

b.) Press the key twice to enter the second letter .

c.) Press the key three times to enter the third

letter.

d.) Pressthe key fourtimestoenterthefourth

letter if applicable or to enter the number.

e.) Press the key fivetimes to enter the num-

ber if applicable.

7. After the name has been changed, press the

ENTER KEY (7) to store the new name.

8. To rename other parameters repeat steps 4---7.

13

Page 22

Operation

Operating Tips

HOW TO DEVELOP COOK SETTINGS

Accellisovensuse both hot airand microwave energy to cook food. If you have experience with either a convection oven or microwave oven you will

see similarities and significant differences. The

key to creating good cooksettings foryour food is

to understand the following rules:

D

Accellisovens use a movingshroud ofhot air to

surroundthe food. This locks inthefood’smoisture.

D

The hot air provides most of the heating and

browning of foods. The higher the air velocity,

the fasterheatenergyis transferred to the food.

D

The microwave provides heat to the center of

the food. Don’t try to do all the cooking with microwave!

D

The weight of food determines the total time requiredto cook. The more weight,the longer the

time required. (Most mediumthick crust pizzas

cook in about 100 seconds.)

D

Thick and dense foods may need to be flipped

half way through the cooking cycle.

D

Microwave seems to work best in the early

stages of cooking, then use hot air to finish the

cooking.

D

Colorseems to developmostlyat the end ofthe

cooking cycle. Higher velocity air in the later

stages ofcookingwillstronglycontrolthefood’s

color.

Don’t be afraid to experiment! Write down your

current cook settings and then start testing. You

can always go back to the old cook settings in a

few seconds. Enjoy the power and flexibility of

your Accellis oven.

OPERATING TIPS

DO – Wait one to two minutes after removing

product from the oven before checking the

core temperature.

DO – Cook frozen product directly from the freezer.

DO – Storechilledproductinthe refrigeratorprior

tocooking.Ifchilledproduct was previously

frozen, it shouldbecompletelythawed and

stored in the refrigerator prior to cooking.

DO – Make sure all products are completely to

spec (weight, thickness, temperature, etc.)

DO – Remove product from the oven as soon as

it is cooked.

DO – Remove multi-cookproducts from the Pres-

sware plates as soon as they are taken out

of the oven.

DO – Besurethe oveniskeptclean.Carbonbuild

up will eventually reduce the efficiency of

the unit.

DO – Be careful when handling beverages that

have been heated with with microwaves.

Delayed eruptive boiling can occur.

DO – Keep bottles and jars open when heating

feeding bottles and baby food. To avoid

burns after heating the contents must be

stirred or shaken and the temperature

checked before consumption.

DO – Checkthat allutensils aresuitable forusein

microwave ovens.

DO – Becarefulusingmetal tongsthat couldchip

orbreak thecookplatter.A paddleispreferable.

DO NOT – Place foil or metal objects in the oven.

DO NOT – Slam the door.

DO NOT – Operate the oven without food or a

suitable microwave load in the cook

chamber.

DO NOT – Keep products tobe cooked in an am-

bient temperature unless otherwise

specified.

DO NOT – Store products in the oven prior to

cooking.

DO NOT – Cook items wrapped in plastic.

DO NOT – Frequently open and close the door to

check the product.

DO NOT – Cook mostproducts directlyon thece-

ramic deck. The ceramic deck is intended for pizza and bread products.

Other types of food may be cooked in

pans or containers.

14

Page 23

Cleaning

Maintenance

Carbon and grease build-up will adversely affect

the cooking performance and life expectancy of

certain components of the Accellis oven. It is the

operator’s responsibility to properly maintain this

unit. Failure to maintain this unit in a clean condition will void the warranty.

WARNING!!

Never use a NaOH (Lye) based chemicalto

clean the Accellis oven. Use of NaOH (Lye)

based chemicals can damage critical components and will void the warranty.

CLEANING SUPPLIES AND EQUIPMENT

Supplies:

D

Non-Lye Non-Caustic Oven Cleaner

D

Non-Lye Non-Caustic Degreaser

D

All Purpose Cleaner

D

Oven Coating (optional) To more easily maintaina cleanoven(especiallythe back wallofthe

cookingchamber),greaseshield ovencoatings

maybeappliedaftertheovenhas beencleaned

NOTE: For a specific listing of non-caustic, non-

lye cleaning products, call your local Authorized Service Provider.

Equipment:

D

Nylon 3x5 green scrub pads

D

Dry, clean towels

D

Firm bristle brush (6---8 inch handle with 2x2x1

bristles) DO NOT use a nylon bristle brush, nylon is subject to melting.

D

Protective rubber gloves, optional

CLEANING TIPS

DO – Keep the oven clean. Daily cleaning is rec-

ommended.

DO – Be careful when cleaning the oven. Sur-

faces stay hot for a long time.

DO – Thoroughly wipe all surfaces that come in

contact with oven cleaner w ith a damp

sponge or cloth.

DO – Cleanceramic platter with anon Lye based

cleaner then rinse off and dry.

DO – Clean ceramic wave guide cap with a non

Lye based cleaner then rinse off and dry.

DO – Empty a nd clean grease tray daily.

DO NOT – Place hot ceramics on cold surfaces.

DO NOT – Allow ceramics to soak inany liquid for

any period of time.

DO NOT – Remove any panels fromthe oven (ex-

cept lower access panel).

DO NOT – Allow water to be forced up into the air

louvers in the panels of the oven.

DO NOT – Allow build up of grease or carbon on

any surface in the oven.

DO NOT – Spray LYE BASED oven cleaners into

the oven

DO NOT – Use metal objects to clean the oven.

DO NOT – Spray non-caustic oven cleaners, de-

greasers, and grease shield products

orany otherliquidontothewaveguide

seal.

DO NOT – Scrub the wave guide seal.

DO NOT – Spray grease shield products on t he

catalytic converter.

DO NOT – Clean the ceramic cook platter or wa-

veguide cap in the dishwasher.

DO NOT – Soakthe ceramiccookplatterorwave -

guide cap in water.

15

Page 24

Maintenance

Cleaning Procedure

PREPARING OVEN FOR CLEANING

1. Place the oven in standby mode as follows:

a.) Press the BACK key (6) repeatedly until

the Set Temp screen is displayed.

b.) Thedisplay reads OVEN OFF in the lower

right corner. Press the corresponding

SOFT key (2) --- R4 --- to enter the st andby

mode.

2. Open the oven door.

3. Allow the oven to cool before cleaning.

DAILY CLEANING

1. Carefully remove the cooking platter and ceramic wave-guide cap. Handle carefully to

avoidbreakage. Take the dirty parts to a well

ventilated area for cleaning.

Spray both pieces generously with non-lye

non-caustic oven cleaner or non-lye noncaustic degreaser and set aside to allow the

cleaner to penetrate. DO NOT soak the Ce-

ramicCookPlatterorWaveguideCapin

water.

2. Clean the ceramic cooking platter, and wave

guide cap using brushes and scrub pads.

Rinse to remove all cleaner a nd debris. Inspect for damage and replace as required.

3. Reinstall the clean wave-guidecap into the

oven. This will protect the wave-guide seal

whilethecookchamberiscleaned.

4. Thoroughly scrub and wipe the inside of oven

door, front ledge, top, side and back walls of

cook chamber using non-caustic degreaser

(non-lye based), and a scrub pad (green

mesh). Take care not to rip the door gasket.

5. Install the clean cooking platter.

6. Close the oven door.

7. Remove the lower access panel.

8. Removethegreasecollectionpan.Empty,

clean and reinstall t he pan.

9. Brush the louvers on the front and side of the

oven.

10. Wipe down exterior of oven with a damp cloth

and all-purposecleaner.Stainless steelpolish

may be used on the exterior only.

MONTHLY CLEANING

1. Remove the exhaust cover from the back of

the oven.

2. Clean the fan guard.

3. Reinstall the exhaust cover.

Cook Platter

Exhaust

Cover

Waveguide

Cap

Figure 9

16

Grease

Tray

Lower Access

Panel

Page 25

Maintenance

Oven Cavity Filter Cleaning

Filtershould be cleaned once a week, depending

on food product and unit run time.

1. Turn the C70 off and disconnect power tothe

unit.

2. Allowthe unit to coolbefore cleaning the filter.

3. Open the oven door.

4. Carefully remove the ceramic platter.

5. The oven cavity filter is located in the bottom

left corner.

6. Remove the two screws.

7. Pull the two tabs on the filter to remove it.

8. Clean the filter with soap and warm water.

Filter

Tab

Screws

Screws

Tab

9. Clean the oven filter cavity.

DO NOT reach into the air return more than

six inches.

10. Reinstall the filter and secure with the two

screws.

DO NOT over tighten the screws.

WARNING!!

DO NOT operate the unit without the oven

filterinstalled.Failure to doso may result

inprematurefailureofthe heaterelement.

Tabs

Filter

Figure 10

17

Page 26

POSSIBLE CAUSE(S) SUGGESTED REMEDY

SYMPTOM: No power to oven

S

Oven is in standby

S

Oven not plugged in.

S

Circuit breaker tripped.

S

Ifyouhavetried allofthe abovewithoutsuccess.

SYMPTOM: Oven does not warm up

S

Oven is in standby.

S

Door is not closed.

SYMPTOM: Oven does not cook properly

Maintenance

Troubleshooting

S

Press the OVEN ON key.

S

Plug in oven.

S

Reset circuit breaker.

S

Contact a qualifiedservice agency to determine

the root problem.

S

Press the OVEN ON key.

S

Verify that the cook chamber and filter doors are

completely closed.

S

Air flow is restricted.

SYMPTOM: OVEN DOOR OPEN message will not go off display screen and alarm sounds

S

Cook chamber door open.

S

Ifyouhavetried allofthe abovewithoutsuccess.

S

Verify air filters are clean.

S

Open and close the cook chamber door.

S

Contact a qualifiedservice agency to determine

the root problem.

18

Page 27

Maintenance

Catalytic Converter

The catalytic converter, P/N T0185, is installed in

the return air duct behind the heater assembly.

The installation of the catalytic converterrequires

a catalytic converter inner frame, part # T0260, to

properlypositionit inthe air path. The aboveparts

may be ordered in kit form, Kit # T0355.

Due to the nature of most foods and the physics

governing the operation of the Accellis Oven,

greasebuildupdownstreamof the cookingchamber is inevitable. Strict cleaning regiments can

solve a majority of the problems, however, recirculation of undiluted grease saturated air is the

main cause of downstream grease accumulation

and any associated residual flavors.

Theairbornegreasetendstocollectandbake

onto the oven surface downstream of the cooking

chamber. This grease, due to the high operating

temperatures of the oven, will start to rapidly decompose into derivative organic compounds.

Thesedecompositionalderivativesgenerallyhave

positive and negative effects on cooking; the

shorter chain derivatives add favorable flavor

characteristics to t he food, while the higher order

carbon chains lend unpleasant flavor characteristics, such as bitter tarry tastes.

Theinstallationofthe catalyticconvertergreatlyeffectst he grease handling and any residualflavors

which might build up over time. A properlyoperating catalytic converter causes the conversion of

airborne grease into water, carbon dioxide and

small amounts of nitrogen and oxygen. The catalytic converter acts as a combustion chamber for

theairbornegrease.Thecatalystspresentonthe

filter lowers the ignition temperature of the airborne grease from approximately 700_F (371_C)

to 450-550_F (232-288_C), allowing combustion

tooccur. Theoperatingtemperature ofthe ovendirectly determines the percentage of airborne

grease conversion.A single pass oftheairstream

yields a 20-30% improvement in air quality.

A problemwiththe catalyticconverter is indicated

by a decrease in the effectiveness of browning

(caused by a reduction in airflow) or by flavor

transfer from one food group to another.

If you experience a problem with your catalytic

converter contact your Blodgett qualified service

agency.

19

Page 28

CUSTOMER

INSERT

WIRING DIAGRAM

HERE

Loading...

Loading...