Blodgett DFG-50, Mark V, DFG-100, KCO-25E, AC-500 Zephaire Installation And Operation Manual

...Page 1

DFG-50, DFG-100, AC-500

Zephaire, Mark V, CTB,

KCO-25E

44 Lakeside Avenue, Burlington, Vermont 05401 USA Telephone (800) 331-5842, (802) 860-3700 Fax: (802)864-0183

BLODGETT OVEN COMPANY

www.blodgett.com

PN 34133 Rev E (6/01)

E 2000 --- G.S. Blodgett Corporation

Page 2

Page 3

Installation and Operation Manual for Export Series Gas and Electric Convection Ovens

Installation 3..........................................................................

Operation 11...........................................................................

Maintenance 20........................................................................

Installations-og Betjeningsvejledning til Gas-og El-konvektorovne Eksportmodeller

Installering 23..........................................................................

Betjening 31...........................................................................

Vedligeholdelse 40......................................................................

Installatie-en Gebruikshandleiding voor Gas en Elektrische Convectieovens Exportserie

Installatie 43...........................................................................

Bediening 51...........................................................................

Onderhoud 60..........................................................................

Manuel d’Installation et d’Utilisation pour la Serie Export des Fours a Convection a Gaz ou

Electriques

Installation 63..........................................................................

Utilisation 71...........................................................................

Entretien 80............................................................................

Handbuch für den Einbau und den Betrieb von Gasbetriebenen und Elektrischen Umluftöfen

der Exportserie

Einbau 83..............................................................................

Betrieb 91.............................................................................

Wartung 100............................................................................

Manuale d’Uso e di Installazione per Forni Termoventilati a Gas ed Elettrici Serie Export

Installazione 103.........................................................................

Funzionamento 111......................................................................

Manutenzione 120.......................................................................

Manual de Instalação e Operação para Fornos de Convecção Elétricos e a Gás da Série Export

Instalação 123...........................................................................

Operação 131...........................................................................

Manutenção 140.........................................................................

ManualdeOperacioneInstalacionparalaSeriedeExportaciondelosHornosdeConveccion

Electricos y a Gas

Instalacion 143..........................................................................

Funcionamiento 151......................................................................

Mantenimiento 160.......................................................................

Handledning för Installation och Drift Exportserien Gas och Elektriska Konvektionsugnar

Installation 163..........................................................................

Drift 171................................................................................

Underhåll 180...........................................................................

Bιβλιο Οδηγιων Εγκαταστασησ και Χειρισµου για τη Σειρα Εξαγοµενων Φουρνων

Ηλεκτρικου και Γκαζιου

Εγκατάσταση 183........................................................................

Χειρισµός 191...........................................................................

Συντήρηση 200..........................................................................

Page 4

Page 5

Installation and Operation Manual

for

Export Series

Gas and Electric Convection Ovens

2

Page 6

Installation

Delivery and Location

DELIVERY AND INSPECTION

All Blodgett ovens are shipped in containers to

prevent damage. Upon delivery of your new oven:

D

Inspect the shipping container for external damage. Any evidence of damage should be noted

on the delivery receipt which must be signed by

the driver.

D

Uncrate the oven and check for internal damage. Carriers will accept claims for concealed

damage if notified within fifteen days of delivery

and the shipping container is retained for inspection.

The Blodgett Oven Company cannot assume

responsibility for loss or damage suffered in

transit. The carrier assumed full responsibility

for del ivery in good order when the shipment

was accepted. We are, however, prepared to

assist you if filing a claim is necessary.

OVEN LOCATION

The well planned and proper placement of your

oven will result in long term operator convenience

and satisfactory performance.

D

Place the oven at least 15.2 cm from the rear

wall and 15.2 cm from the side wall.

D

Place the oven in a properly ventilated area.

D

Place the oven under an exhaust hood, according to Localand NationalInstallationStandards.

D

Position the oven so the supply plug is accessible.

D

Place the oven in an area that is free of drafts.

D

Keepthe oven area free and clear of all combustiblessuch as paper, cardboard, and flammable

liquids and solvents.

D

Do not place the oven on a curb base or seal to

a wall. This will restrict the flow of air and prevent

proper ventilation.

D

For gas models the location must provide adequate clearance for the air opening into the

combustion chamber.

Before making any utility connections to this oven,

check the rating plate to be sure the oven specifications are compatible with the gas (if applicable)

and electrical services supplied for the oven.

3

Page 7

Installation

Oven Assembly

NOTE: This appliance shall be installed in accor-

dance with current regulations and used

only in a well-ventilatedspace. Refer to the

instructions before installing and using

this appliance.

NOTE: Installation must be performed by a quali -

fied installer only.

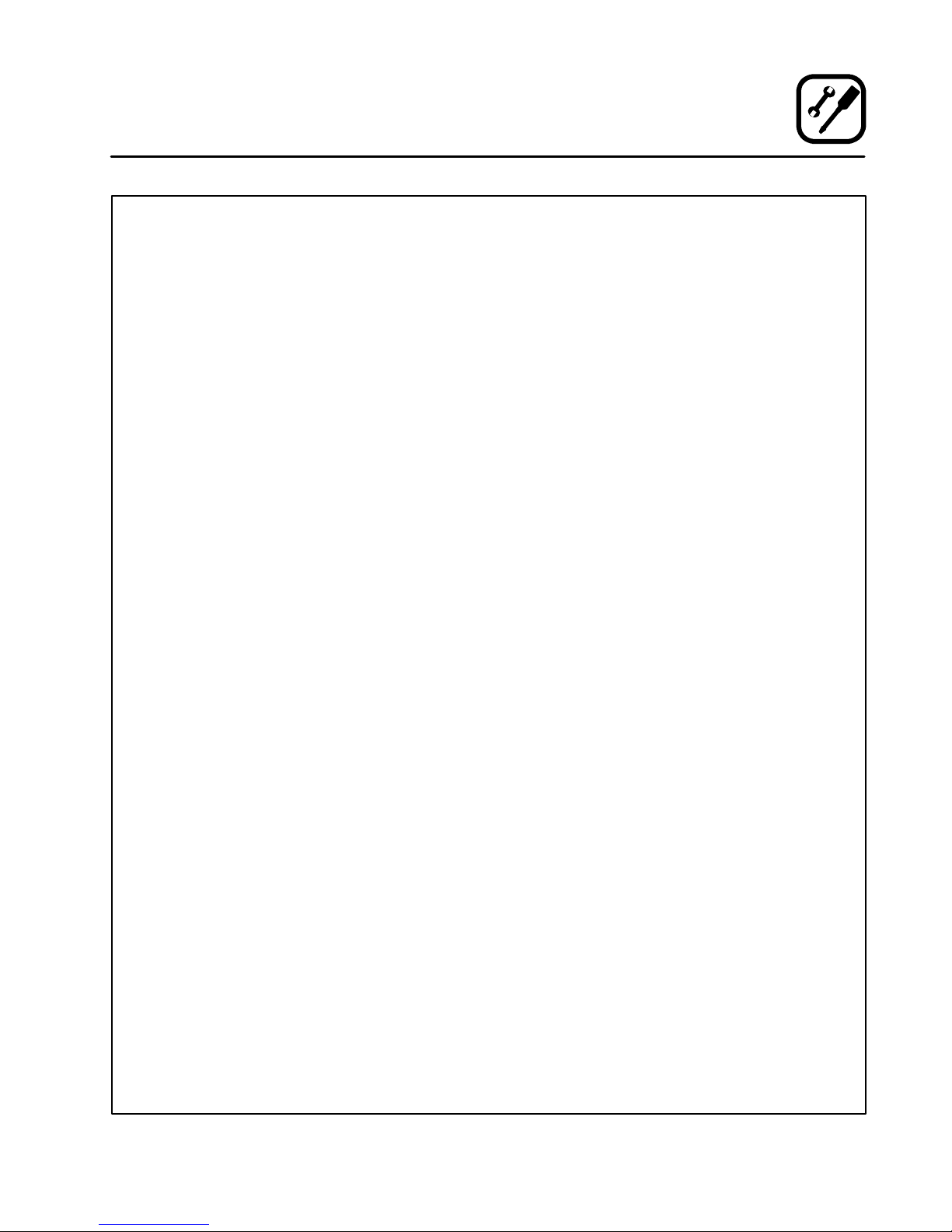

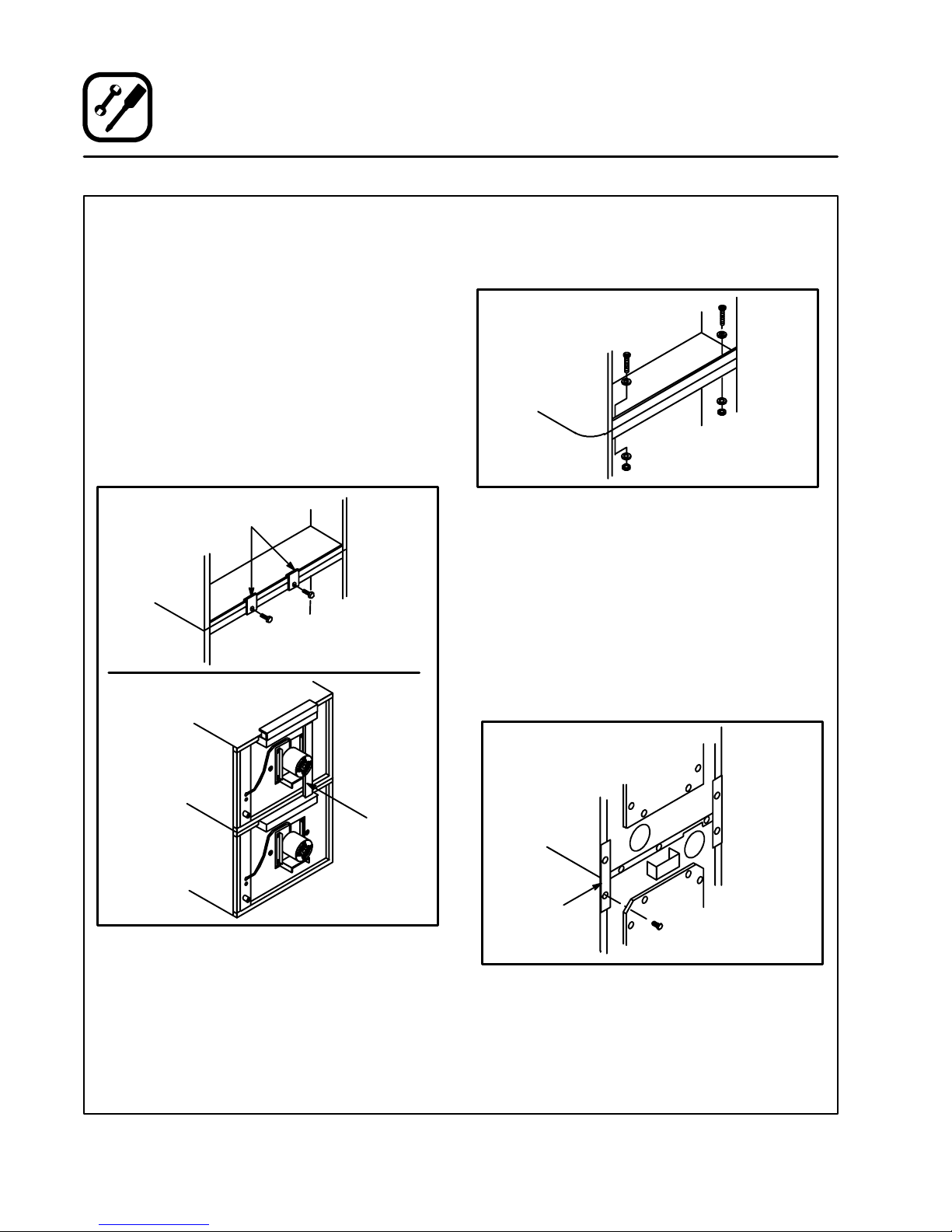

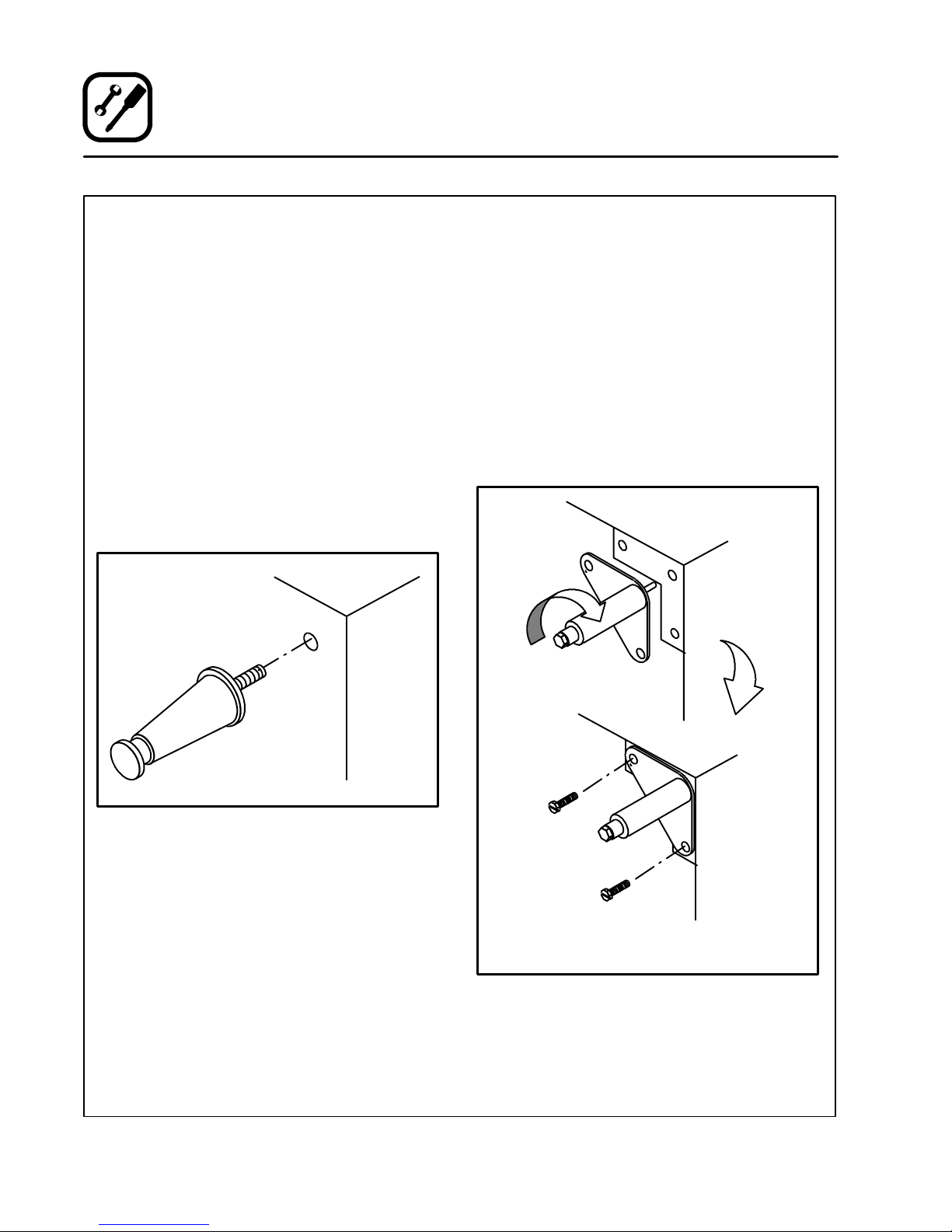

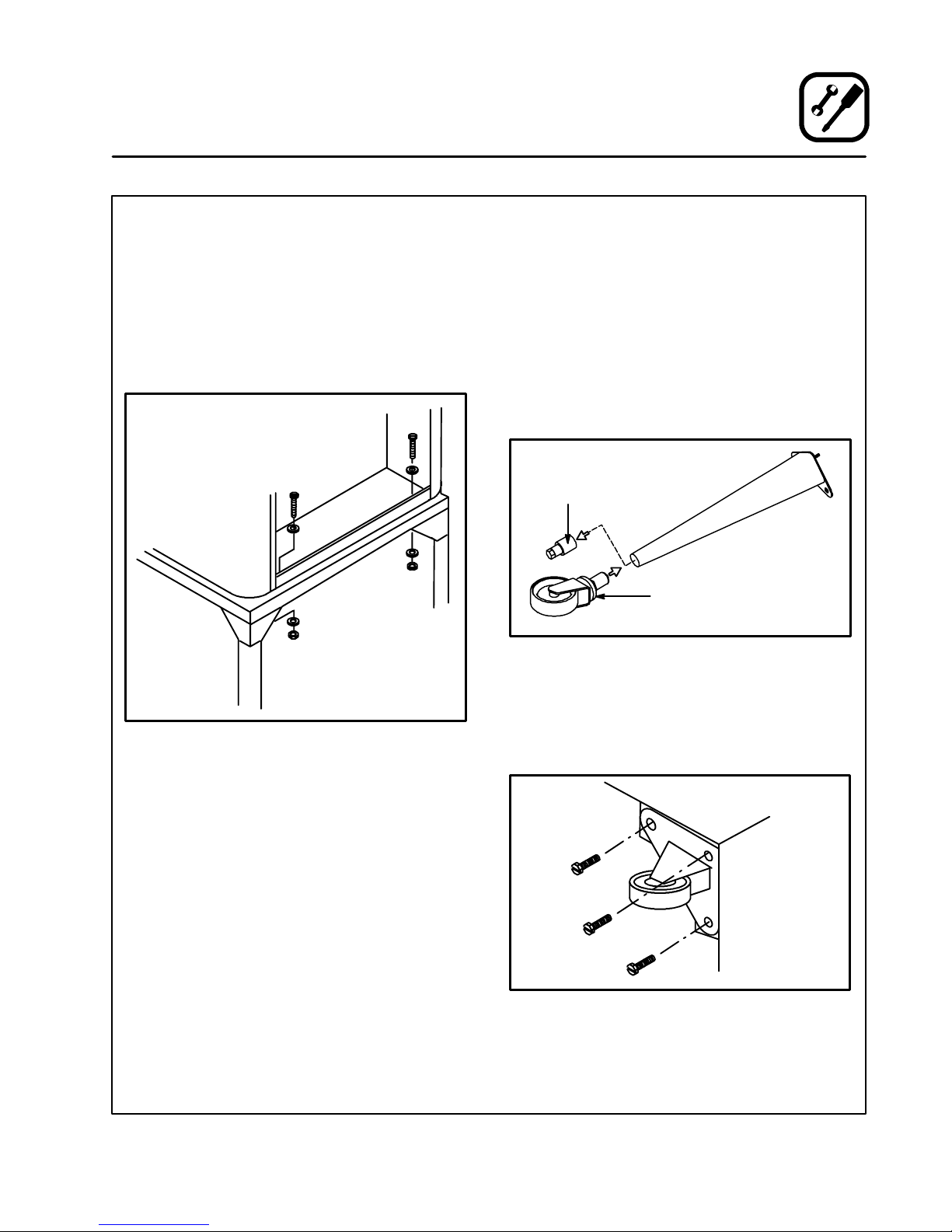

LEG ATTACHMENT

10 cm legs

1. Lay the oven on its back.

2. Screw the legs into the holes in the oven corners. Tighten the hex nut at the top of each leg

3. Tip the oven up on the legs.

4. Turn the adjustable leg feet to level the oven.

15 cm, 18 cm and 64 cm legs

1. Lay the oven on its back.

2. Align the threaded stud in each leg with the

nut inside each bottom corner. Turn the legs

clockwise to tighten.

3. Alignthe holes in each leg plate with the holes

in the oven frame. Secure each leg with two

1/2” bolts.

NOTE: See Caster Installation if applicable.

4. Tip the oven up on the legs.

5. Turn the adjustable leg feet (or casters) to level

the oven.

Figure 1

15 cm Adjustable Legs

Figure 2

4

Page 8

Installation

Oven Assembly

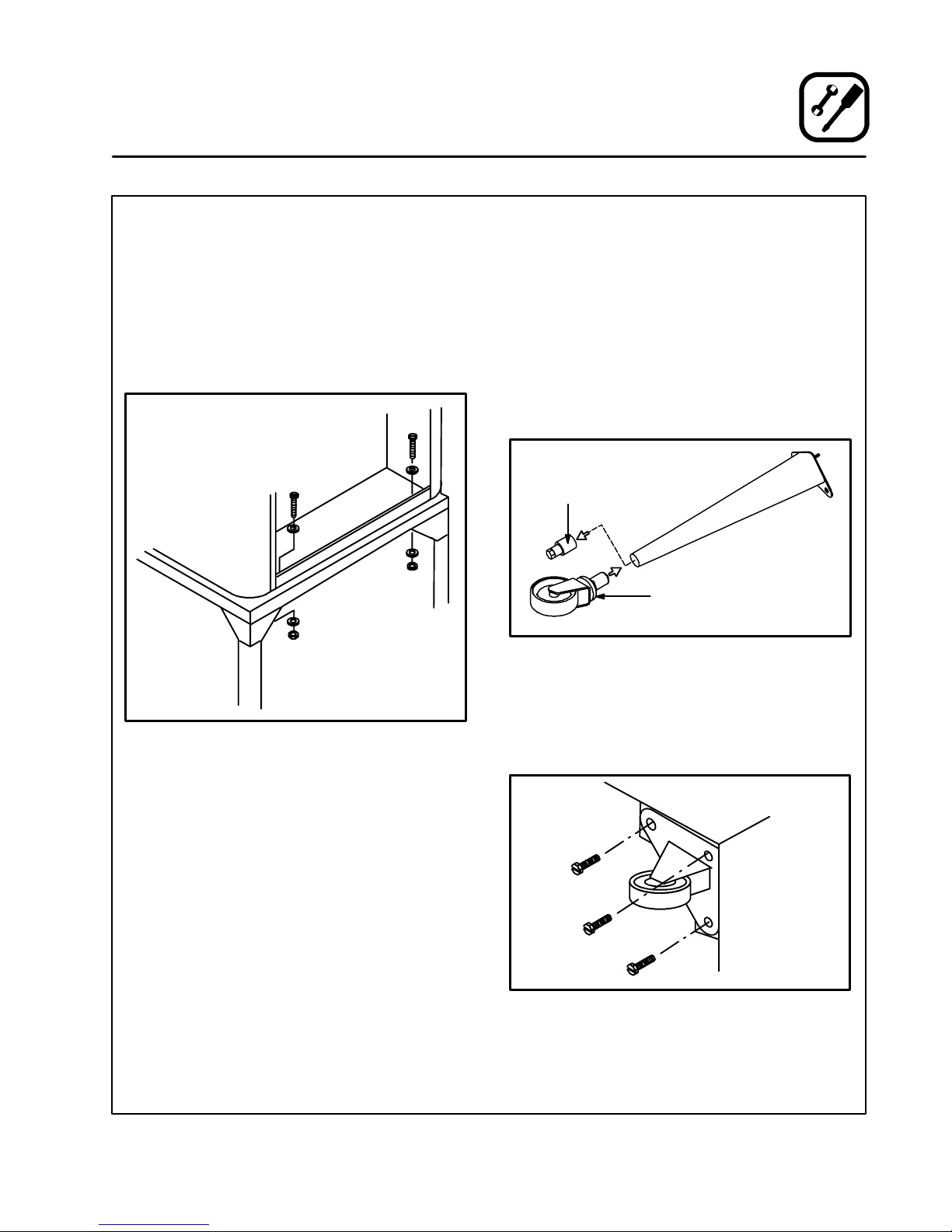

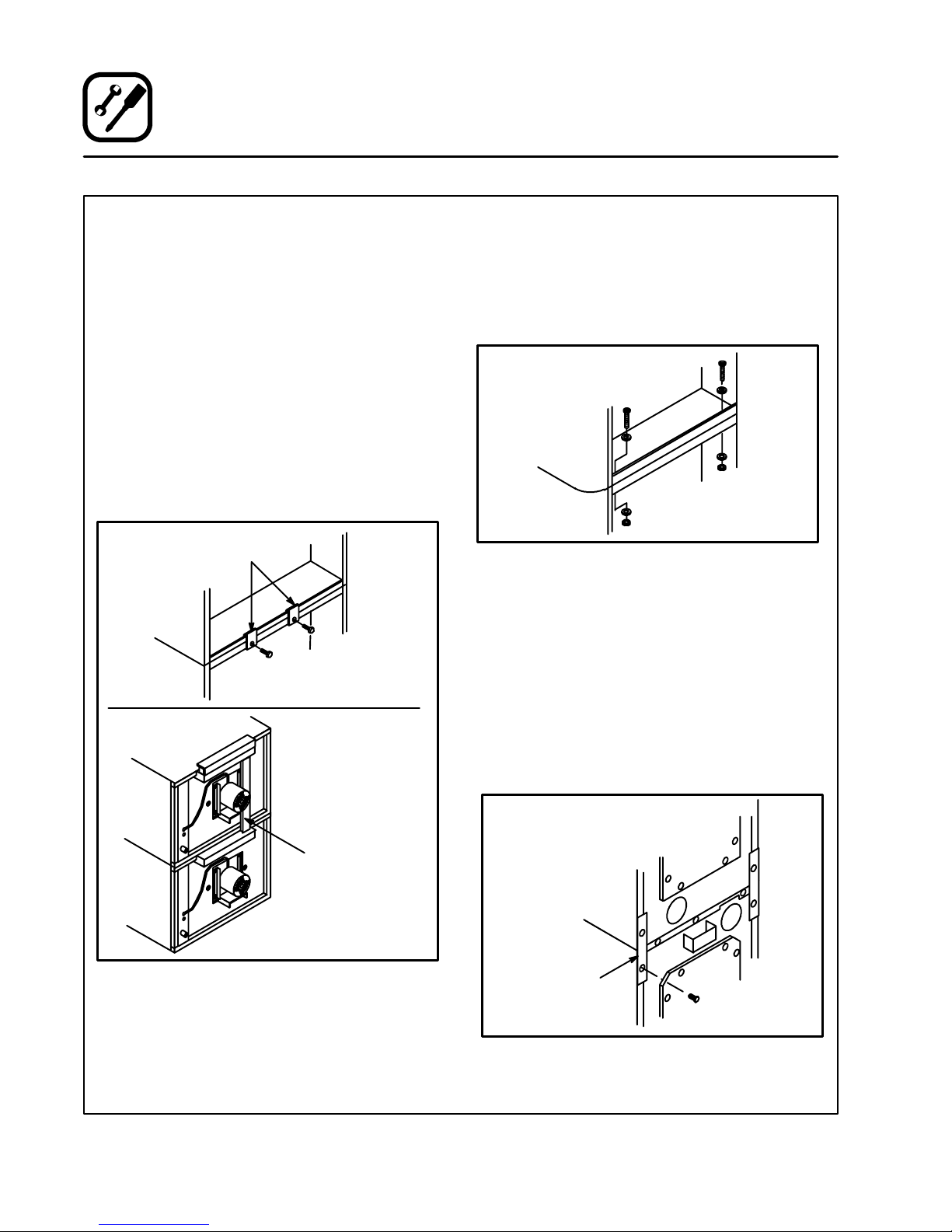

ATTACHMENT TO STAND

1. Set the oven on the stand. Center it to the

frame.

2. Remove the oven’s right side panel.

3. Align t he holes in the oven bottom with the

holes in the stand.

4. Attachwith bolts, washers and nuts as shown.

5. Replace the side panel

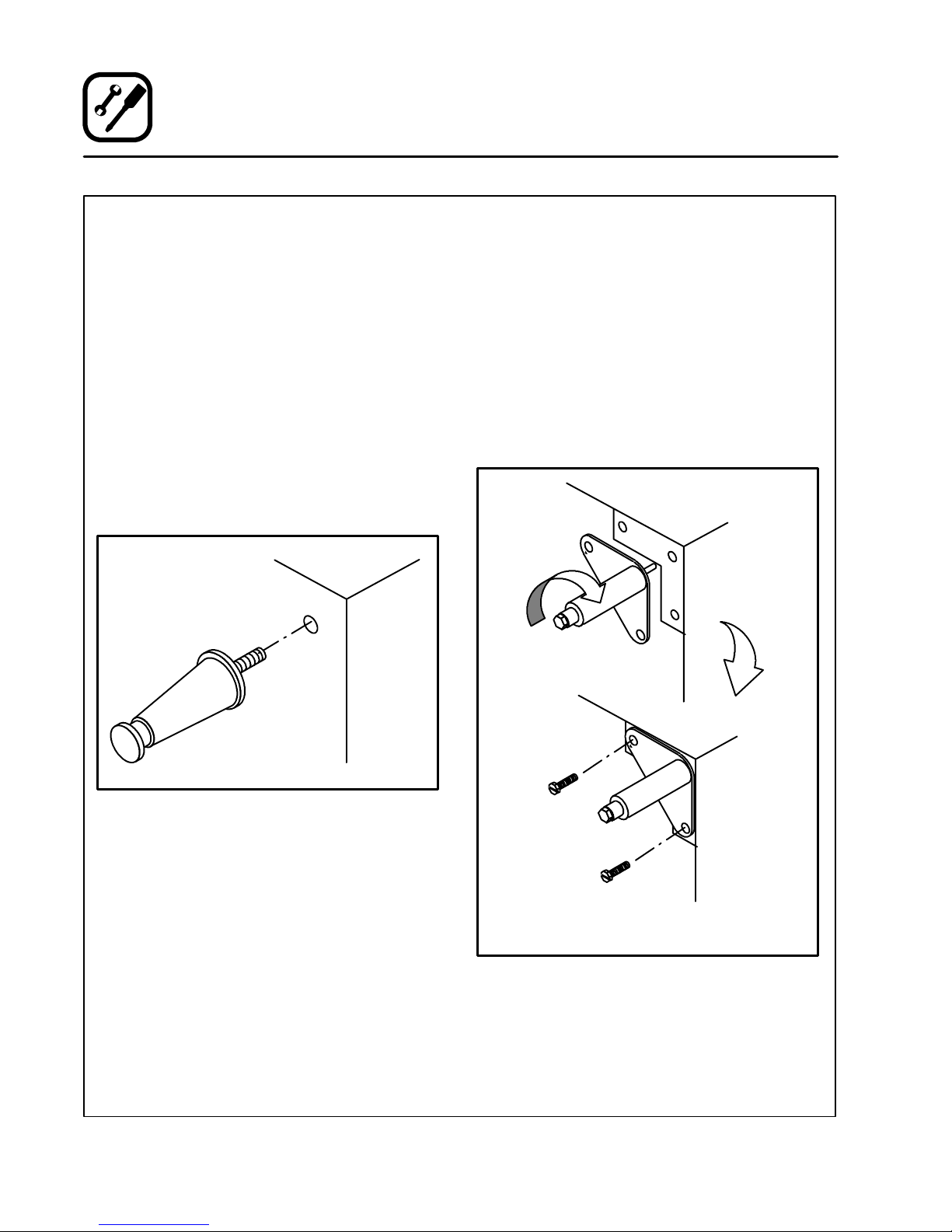

CASTER INSTALLATION

NOTE: Install casters with locking devices on the

front. Install non-locking casters on the

rear.

Casters for Single and Double Stacked Ovens

1. Attach the legs.

2. Loosen the lock nut on each adjustable leg

foot. Remove the foot assemblies.

3. Insert one caster into each leg as shown.

Tighten the lock nuts to secure the casters.

Adjustable

Leg Foot

Caster Assembly

64 cm Legs Shown

Figure 4

Figure 3

Low Profile Casters for Double Stacked Ovens

1. Align the three holes in each caster assembly

plate with those in the oven bottom. Attach

with three 1/2” bolts.

Figure 5

5

Page 9

Installation

Oven Assembly

DOUBLE SECTION ASSEMBLY

NOTE: Be sure to remove the single oven flue

boxes prior to attaching the flue connector.

AC-500, DFG-100/200, CTB, Mark V, and

Zephaire E&G

1. Secure the short legs to the bottom sections.

2. Stack t he ovens.

3. Place the clips over the edge of the oven

frames.

4. Bolt the clips together with 3/8” bolts and nuts

provided.

5. Attach the flue connector.

Stacking

Clips

4. Attachwith bolts, washers and nuts as shown.

5. Replace the combustion compartment cover

and side panel.

Figure 7

KCO-25E

1. Secure the short legs to the bottom sections.

2. Stack t he ovens.

3. Remove the bottom left and right screws from

the upper section. Remove the top left a nd

right s crews from the lower section.

4. Attach the two stacking angles. Use the

screws removed.

5. Attach the flue connector.

Figure 6

DFG-50

1. Stack the ovens

2. Remove the combustion compartment cover

and side panel.

3. Align the holes in the front a nd rear corners of

the ovens.

Flue

Connector

Stacking

Angle

Figure 8

6

Page 10

Installation

Oven Assembly

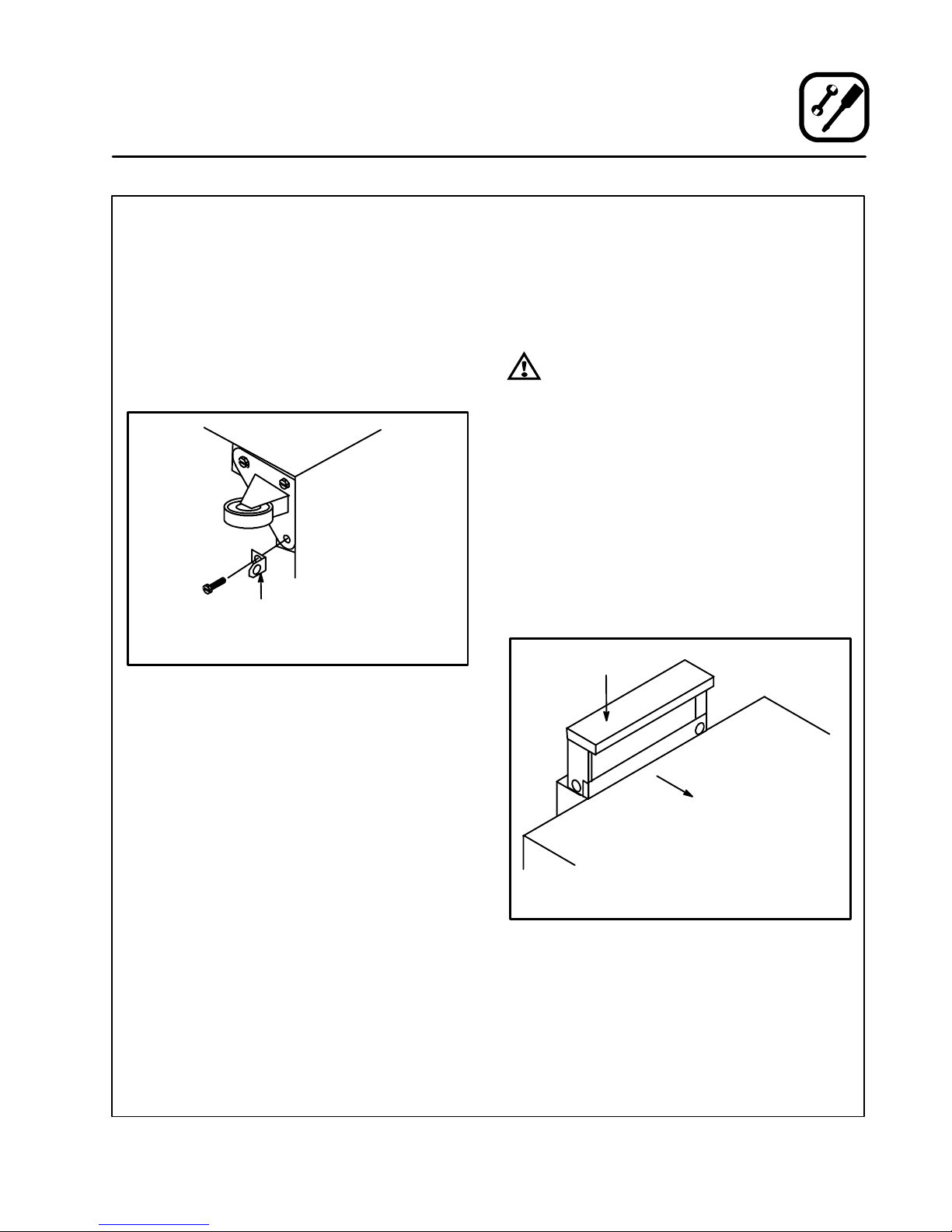

GAS HOSE RESTRAINT ( gas model s)

If the oven is mounted on casters, a commercial

flexible connector with a minimum of 1.9 cm inside

diameter must be used along with a quick connect

device.

1. Mount the supplied bracket to the leg bolt just

below the gas inlet.

2. Attach the clip on restraining cable to the

mounting bracket.

Back of Oven

Restraint Cable

Bracket

Double stacked unit shown.

Figure 9

VENTILATION (gas models)

A mechanically driven, canopy type exhaust hood

is required. The hood should completely cover the

oven with an overhang of at least 15 cm on all

sides not adjacent to a wall. The distance from the

floor to the lower edge of the hood should not exceed 2.1m.

WARNING:

Failure to properly vent the oven can be

hazardous to the health of the operator

and may result in operational problems,

unsatisfactory baking and possible damage to the equipment.

Damage sustained as a direct result of improper ventilation will not be covered by

the manufacturer’s warranty.

Ovens ordered for hood venting are supplied with

a draft diverter. Install the draft diverter as follows:

1. Place the diverter over the flue connector with

the open area facing the front of the oven.

2. Secure with the sheet metal screws provided.

Draft Diverter

Front of

Oven

Full Size Oven Shown

Figure 10

7

Page 11

Installation

Utility Connection

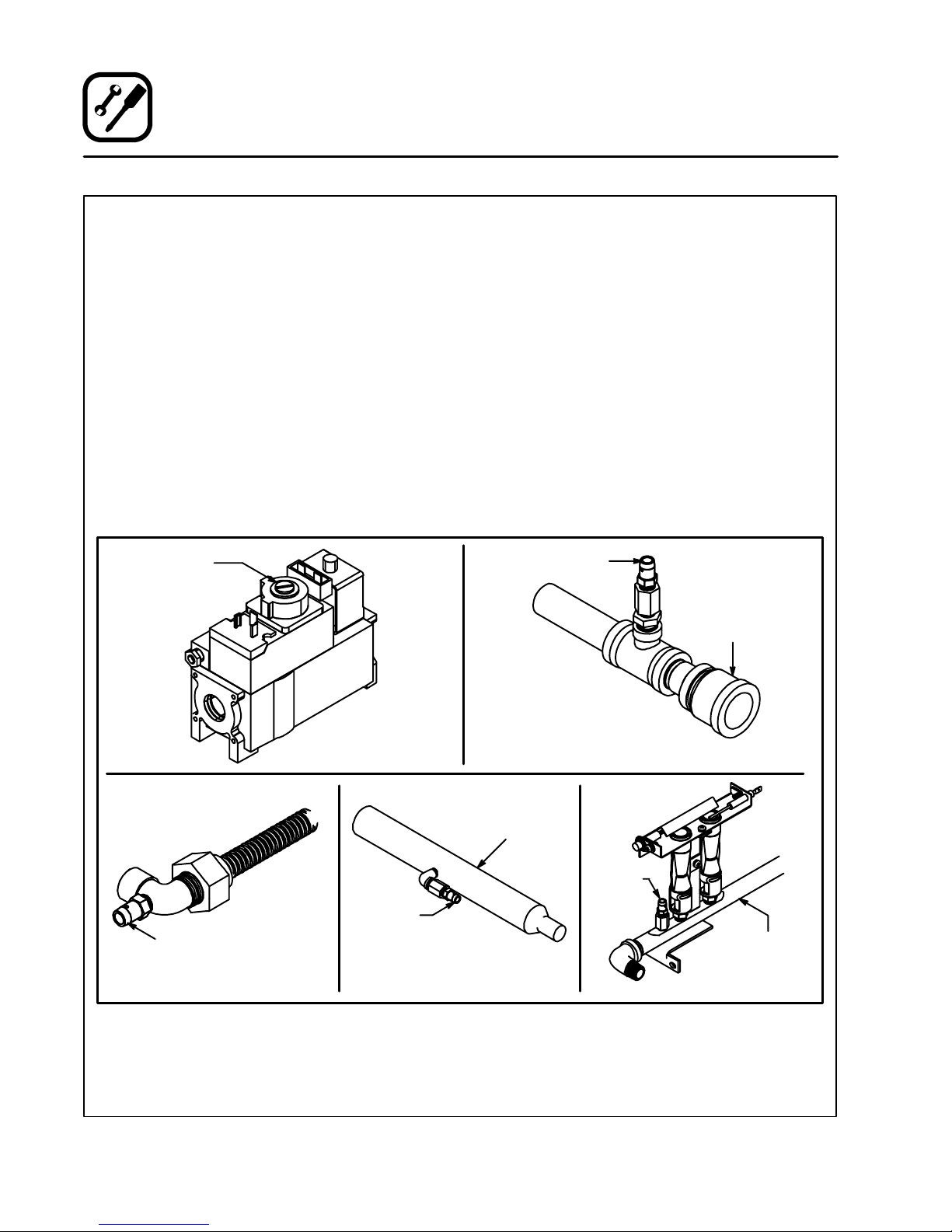

GAS CONNECTION (if applicable)

Connect the oven to the gas line with the proper

type of gas according to Local and National Installation Standards.

Setting Equipment for Other Types of G as

1. Shut off the gas valve and turn off the operating switch.

2. Dismantle the gas block by means of couplings.

3. Dismantle the burner and replace the injectors.

4. Install the burner and gas block.

5. Check for leakage and possible loose electrical connections.

6. Adjust gas pressure if necessary, See figure.

Gas Pressure

Adjustment

INLET PRESSURE TAP

NOTE: Zephaire-G/DFG-50 units only. See figure

for pressure tap location.

1. Removethebluepipecapfromthegasinlet

pipe.

2. Apply thread sealer to the male pipe threads.

3. Thread the inlet pressure tap assembly onto

the gas pipe and tighten.

4. Check for leaks.

Pressure Tap

Gas

Connection

Pressure Tap

DFG-50

Pressure

Tap

DFG-100 and Zephaire-G

Figure 11

8

Back of Oven All Units

Manifold

Pressure

Tap

Manifold

AC-500

Page 12

Installation

G20/G2520/25TotallyScrewedi

n

2,10182x0,3816NaturalGa

s

G20/G2520/25TotallyScrewedi

n

2,1092x0.388NaturalGa

s

G20/G2520/25TotallyScrewedi

n

2,10182x0.3817,6NaturalGa

s

G20/G2520/25TotallyScrewedi

n

1,7516N/A20,5NaturalGas

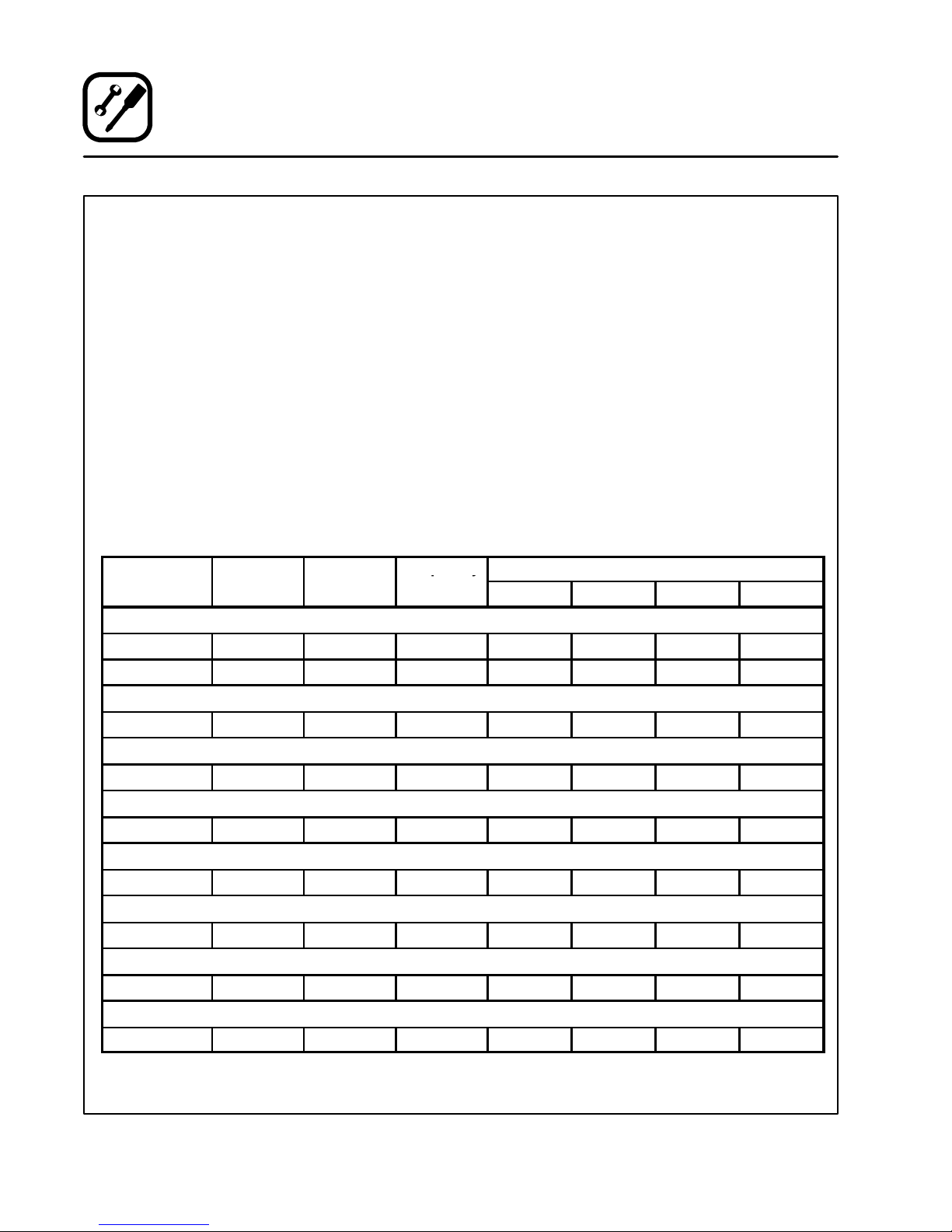

Utility Connection

Type of

Gas

DFG-100-3

G25 25 12 2,60 18 2 x 0,38 16 Natural Gas

G20 20 8 2,60 18 2 x 0,38 16 Natural Gas

G20/G25 20/25 Totally Screwed in 2,10 18 2 x 0,38 16 Natural Gas

G30 30/50 17 1,60 10 2 x 0,20 16 Butane

G31 30/37/50 24 1,60 10 2 x 0,20 16 Propane

DFG-50

G25 25 12 2,50 9 2 x 0.38 8 Natural Gas

G20 20 8 2,50 9 2 x 0.38 8 Natural Gas

G20/G25 20/25 Totally Screwed in 2,10 9 2 x 0.38 8 Natural Gas

G30 30/50 17 1,60 9 2 x 0,20 8Butane

G31 30/37/50 24 1,60 9 2 x 0,20 8Propane

Zephaire-G-L

G25 25 12 2,70 18 2 x 0.38 17,6 Natural Gas

G20 20 8 2,70 18 2 x 0.38 17,6 Natural Gas

G20/G25 20/25 Totally Screwed in 2,10 18 2 x 0.38 17,6 Natural Gas

Inlet

Pressure

mbars

Burner

Pressure

mbars

Pressure Regulator

Pressure Regulator

Pressure Regulator

Injector

Diameter

mm

Air

Opening

mm

Pilot

Injector

mm

Standard

Delivery

Value kW (H

)

i

G30 30/50 17 1,60 10 2 x 0,20 17,6 Butane

G31 30/37/50 24 1,60 10 2 x 0,20 17,6 Propane

AC-500

G25 25 12 2,10 16 N/A 20,5 Natural Gas

G20 20 8 2,10 16 N/A 20,5 Natural Gas

G20/G25 20/25 Totally Screwed in 1,75 16 N/A 20,5 Natural Gas

Pressure Regulator

G30 30/50 17 1,32 16 N/A 20,5 Butane

G31 30/37/50 24 1,32 16 N/A 20,5 Propane

9

Page 13

Installation

V

q

y

Utility Connection

ELECTRICAL CONNECTION

NOTE: Electrical connection must be performed

by a qualified installer only.

NOTE: The electrical connection must comply

with National and Local codes.

A strain relief for the supply cord is required. The

installer must provide a supply cord bushing that

meets all Local and National Installation Standards.

For Gas Models:

NOTE: Gas models havea phase sensitiveburner

control unit. If the phase and neutral are

switched the control locks out.

Connect phase + neutral + ground.

Frequency

KW/Section

CTB/CTBR

5,6 400 3N 50 9 8 8 1

8,0 400 3N 50 13 11 11 2

oltage Phase

(Hz)

For Electric Models:

Connect the oven to a separate group with rigid

connectionand circuit breaker.The circuit breaker

should disconnect all poles, including neutral with

a contact separation of at least 3 mm.

For 1 Phase --- Connect phase + neutral +

ground.

For 3 Phase --- Connect L1 + L2 + L3 + neutral +

ground.

INITIAL STARTUP

1. Set the THERMOSTAT to 260_Candoperate

for 2 hours prior to loading product. This procedure produces smoke.

2. Clean the oven after the initial burn-in process.

See page 20 for proper cleaning instructions.

Max Load

L1 L2 L3 N

KCO-25E

3,0 230 1N 50 13 --- --- 13

Mark V-III

11,0 400 3N 50 18 15 15 3

Zephaire-E

11,0 400 3N 50 18 15 15 3

DFG-100-3

0,7 230 1N 50 3 --- --- 3

DFG-50

0,7 230 1N 50 3 --- --- 3

Zephaire-G-L

0,7 230 1N 50 3 --- --- 3

AC-500

1,3 230 1N 50 6 --- --- 6

10

Page 14

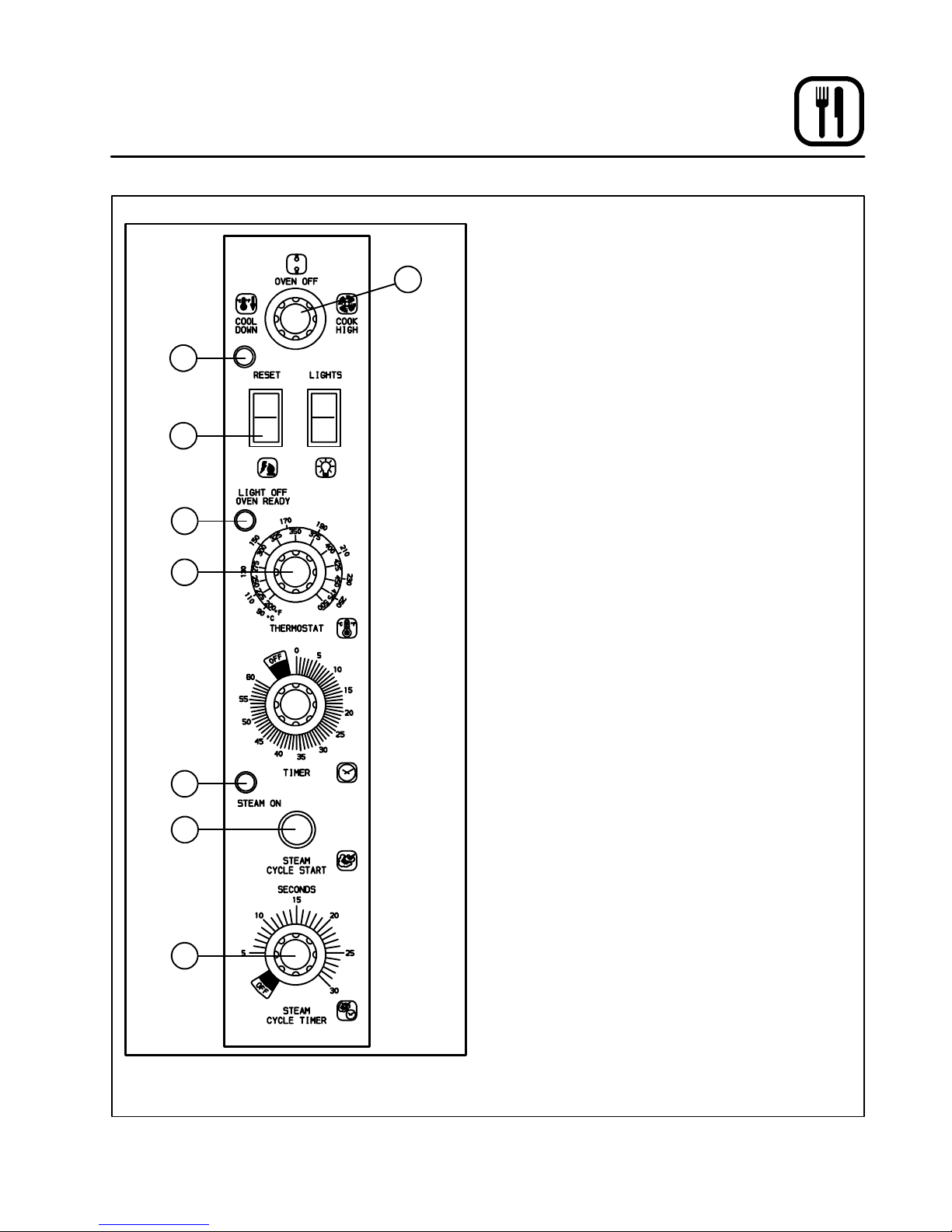

2

Gas Models

Only

3

4

5

6

7

8

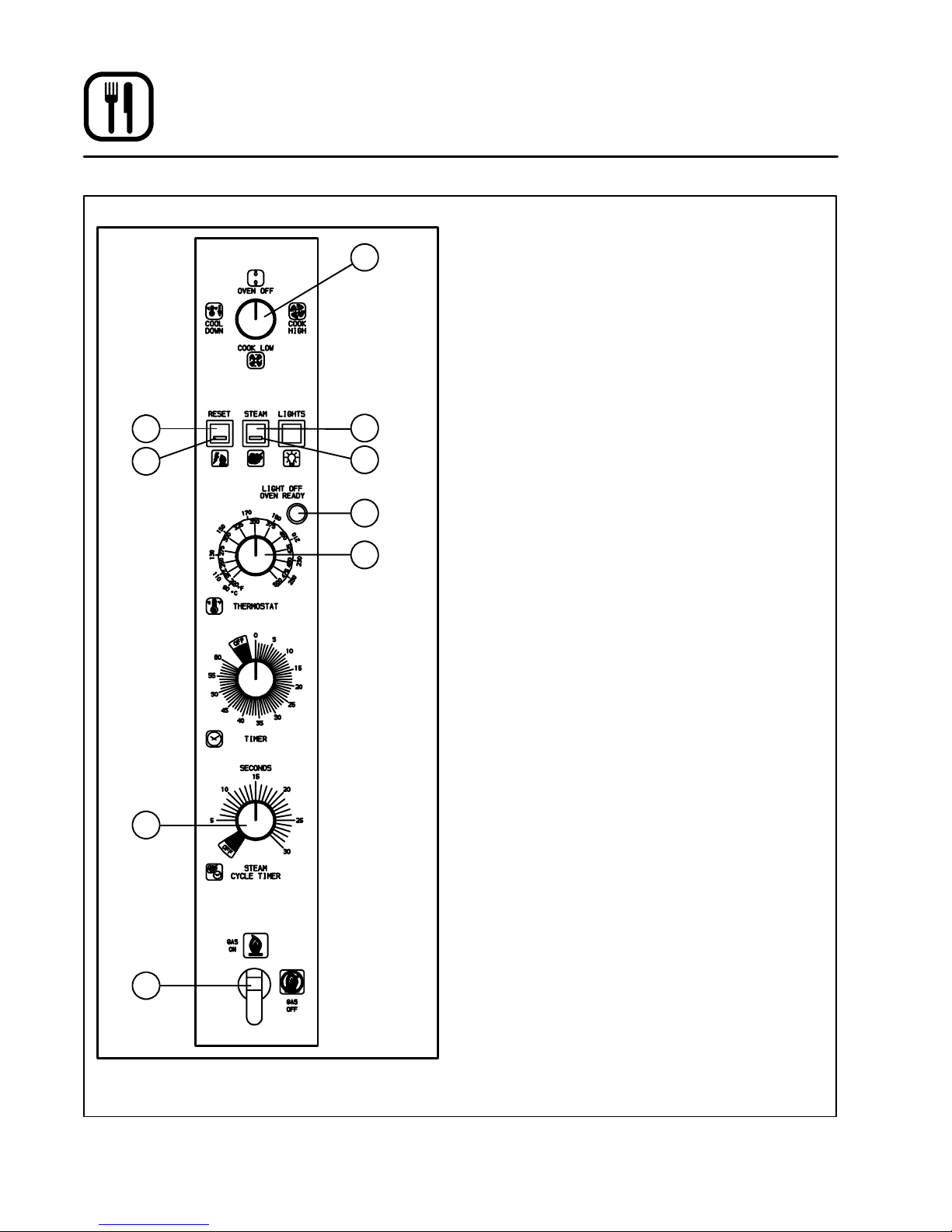

Operation

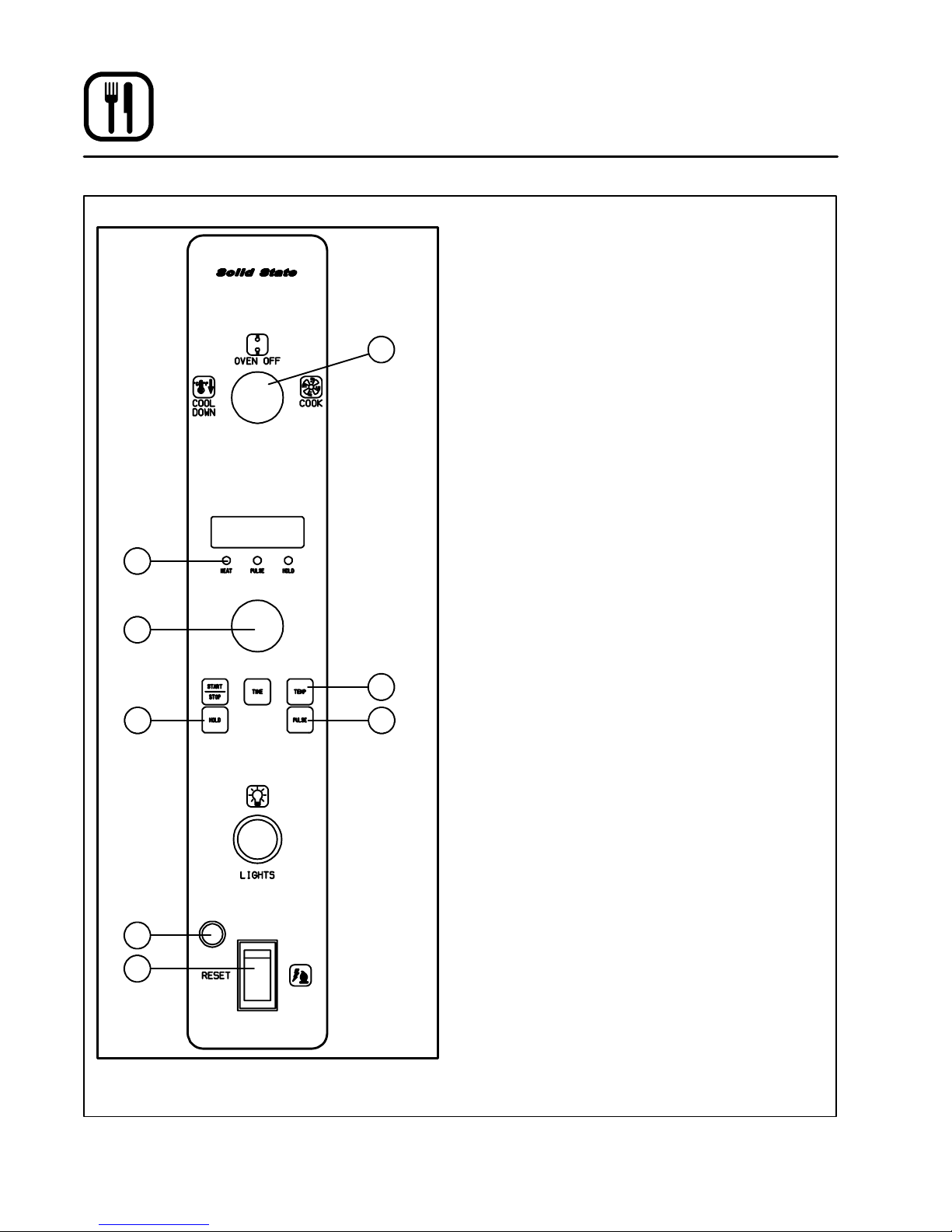

Solid State Controls

OPERATION

NOTE: Operationis restrictedto qualifiedperson-

1

1. Turn on the gas valve. (Gas models only.)

2. Close the oven door.

3. Turn the SELECTOR Switch (1) to the desired

4. Set THERMOSTAT (5) to the desired tempera-

NOTE: If the oven will not start after several at-

For the HUMIDAIRE control option:

1. When steam is desired, set the STEAM

2. Momentarily press and release the STEAM

Cool Down

1. Open oven door.

2. Turn the SELECTOR Switch (1) to COOL

Shut Down

1. Turn the SELECTOR Switch (1) to OFF.

2. Shut off the gas valve. (Gas models only.)

nel.

cook position.

The fan will start to turn and the temperature

controlwillgoon.

ture.

The burner will ignite or the elements willcome

on. The OVEN READY light (4) on the control

panelwillilluminate.

For gas models if in starting, the burner does

not ignite within a few seconds, the RESET

alarm light (2) will go on. Press the RESET

switch (3) to restart the burner.

The LIGHT OFF OVEN READY light (4) will go

out when the oven has reached temperature.

tempts contact a qualified installer.

CYCLE TIMER (8) to the required injection

time.

CYCLE START button (7). The STEAM indicator (6) will light as water is injected into the

baking compartment.

DOWN.

Figure 12

11

Page 15

Operation

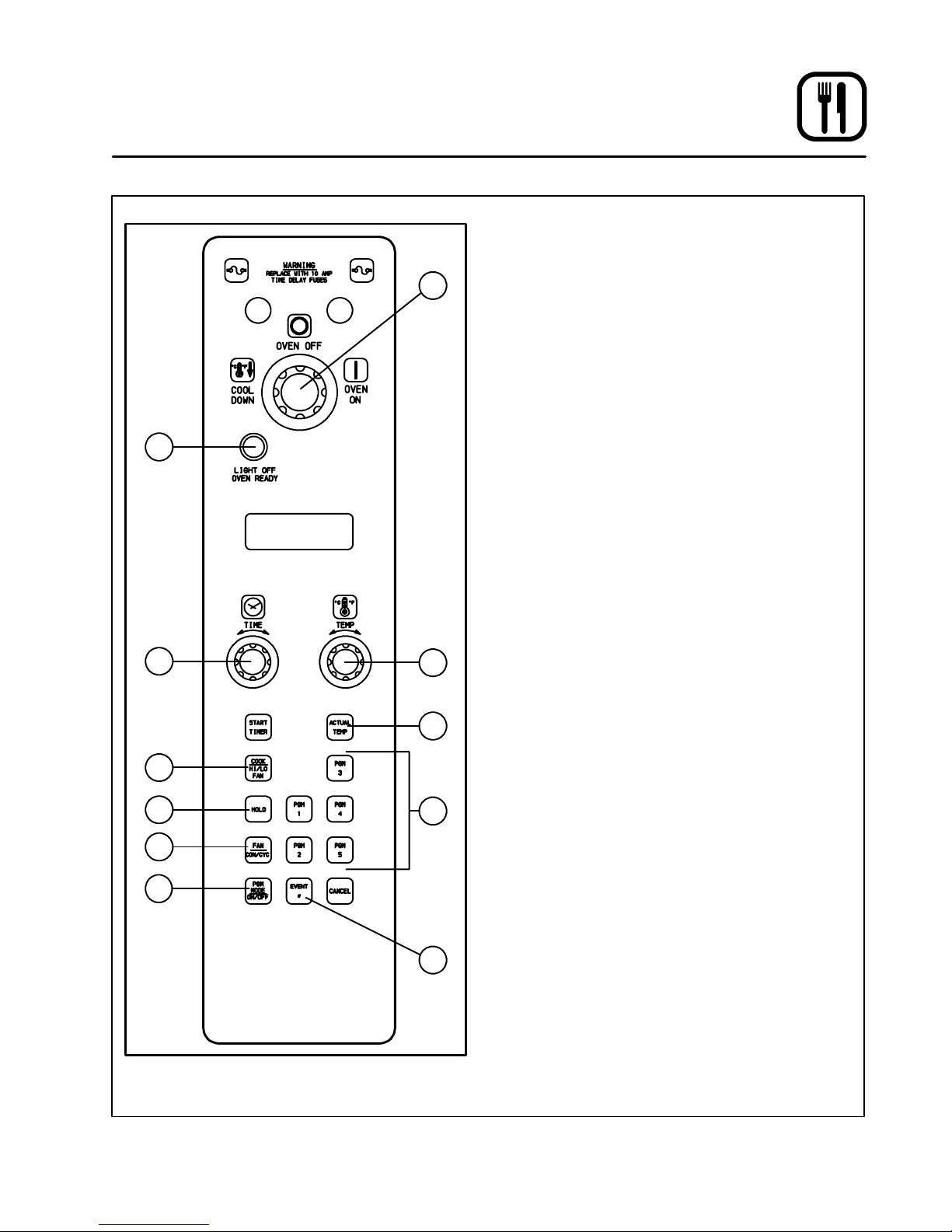

AC-500 Solid State Controls

2

3

8

OPERATION

1

4

5

6

7

NOTE: Operationis restrictedto qualifiedperson-

nel.

1. Turn on the gas valve (9).

2. Close the oven door.

3. Turn the SELECTOR Switch (1) to the desired

cook position.

The fan will start to turn and the temperature

controlwillgoon.

4. Set THERMOSTAT (7) to the desired temperature.

Theelementswillcomeon.TheOVENREADY

light (6) on the control panel will illuminate.

If in starting, the burner does not ignite within

a few seconds, the RESET alarm light (3) will

go on. Press the RESET switch (2) to restart

the burner.

The LIGHT OFF OVEN READY light (6) will go

out when the oven has reached temperature.

NOTE: If the oven will not start after several at-

tempts contact a qualified installer.

For the HUMIDAIRE control option:

1. When steam is desired, set the STEAM

CYCLE TIMER (8) to the required injection

time.

2. Momentarily press and release the STEAM

CYCLE START button (4). The STEAM indicator (5) will light as water is injected into the

baking compartment.

Shut Down

1. Turn the SELECTOR Switch (1) to OFF.

2. Shut off the gas valve (9).

9

Figure 13

12

Page 16

1

2

3

4

Gas

Models

Only

5

ON

OFF

ON

OFF

MAN

AUTO

Operation

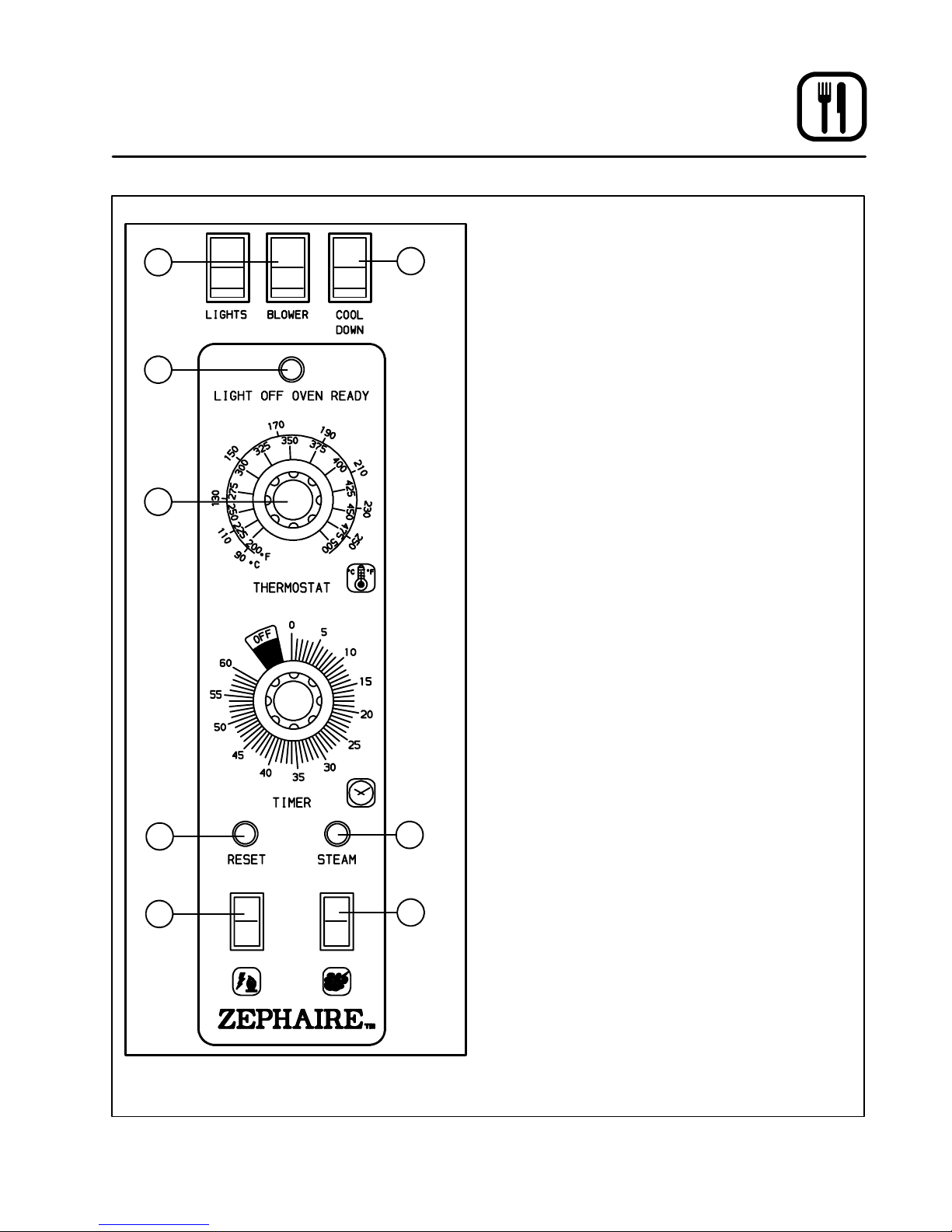

Zephaire Controls

OPERATION

8

6

7

NOTE: Operationis restrictedto qualifiedperson-

nel.

1. Turn on the gas valve. (Gas models only.)

2. Close the oven door.

3. Turn the BLOWER Switch (1) on the front panel

to ON. Set the COOL DOWN Switch (8) to

AUTO.

The fan will start to turn and the temperature

controlwillgoon.

4. Set THERMOSTAT (3) to the desired tempera-

ture.

The burner will ignite or the elements willcome

on. The OVEN READY light (2) on the control

panelwillilluminate.

For gas models if in starting, the burner does

not ignite within a few seconds, the RESET

alarm light (4) will go on. Press the RESET

switch (5) to restart the burner.

The LIGHT OFF OVEN READY light (2) will go

out when the oven has reached temperature.

NOTE: If the oven will not start after several at-

tempts contact a qualified installer.

For the HUMIDAIRE control option:

1. Momentarily press and release the STEAM

CYCLE START button (7). The STEAM indicator (6) will light as water is injected into the

baking compartment.

Cool Down

1. Open oven door

2. Set the BLOWER Switch to ON.

3. Set COOL DOWN Switch (8) to MANUAL.

Shut Down

1. Turn the BLOWER Switch (1) to OFF.

2. Turn the THERMOSTAT (3) to OFF.

3. Shut off the gas valve. (Gas models only.)

Figure 14

13

Page 17

Operation

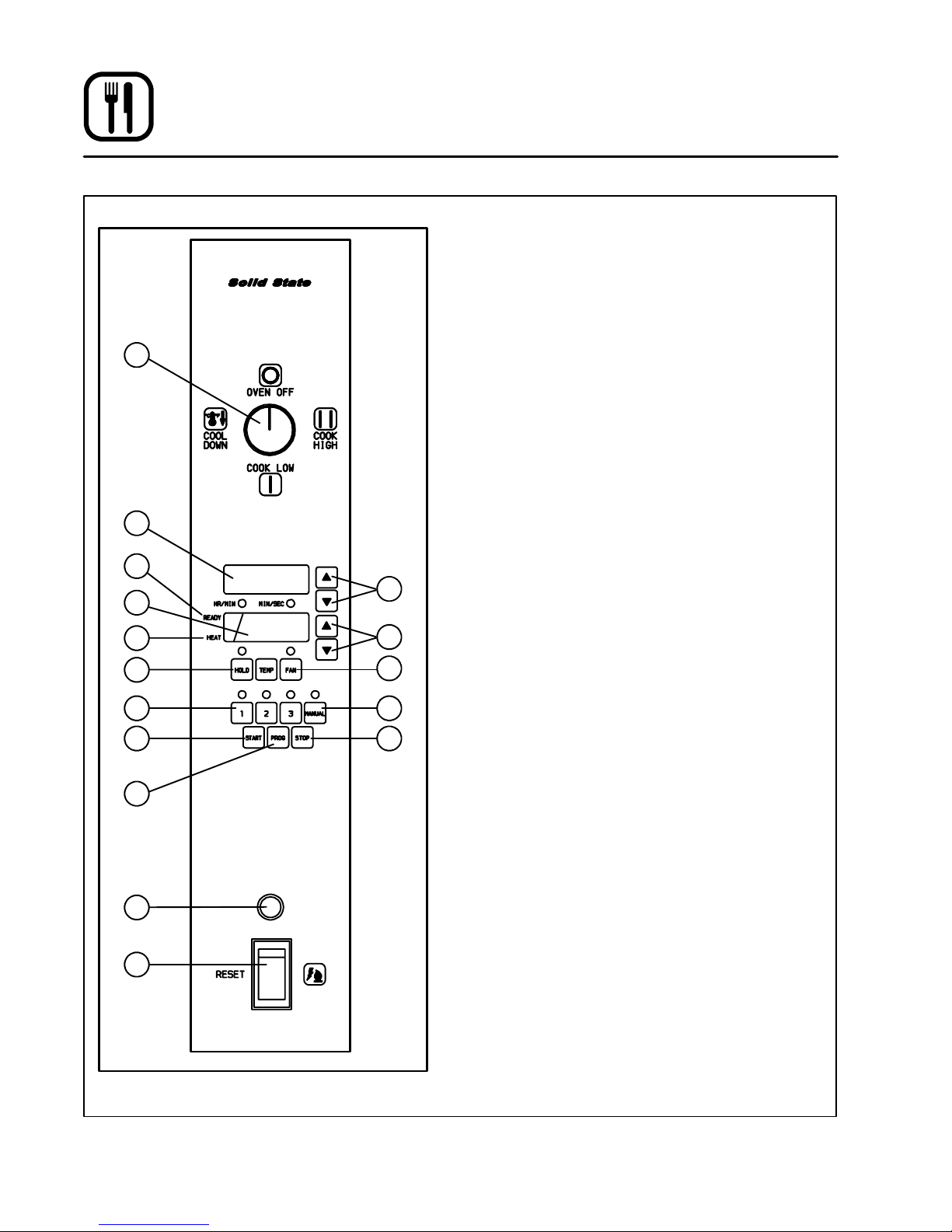

CH-Pro3 (Solid State Programmable Digital Control)

NOTE: Operationis restrictedto qualifiedperson-

nel.

OPERATION

Oven Startup:

1. Turn the SELECTOR SWITCH (1) to the de-

1

2

sired cook position. The burners ignite or the

elements come on. The HEAT INDICATOR (7)

lights.

On gas models, if the burner does not ignite

within a few seconds, the RESET ALARM

LIGHT(15)comeson.PresstheRESET

SWITCH (16) to restart the burner.

NOTE: If the oven will not start after several at-

tempts contact a qualified installer.

Manual Operation:

4

5

7

8

10

12

13

15

16

Gas Models

Only

Figure 15

3

6

9

11

14

NOTE: Press the arrow keys to change the cook

time and temperature at any point during

manual operation.

1. Press the MANUAL PRODUCT KE Y (11). The

manual and fan key LEDs light.

2. Press the TIME ARROW KEYS (3) to enter the

cook time.

For Cook with Pulse --- P r e s s th e FA N K E Y

(9). Use the TIME ARROW KEYS (3) to enter

the pulse time. The fan key LED flashes.

3. Press the TEMPERATURE ARROW KEYS (6)

to enter the cook temperature.

4. For Cook and Hold --- Press and hold the

HOLDKEY (8). At the same time, use the TEMPERATURE ARROW KEYS (6) to enter the

hold temperature. The hold key LED lights.

5. The READY INDICATOR (4) lights when the

oven has reached the cook temperature.

6. Press the START KEY (12). The TIME DISPLAY

(2) counts down. The manual key LED flashes.

7. When the cook time expires the LEDs and displays flash and an alarm sounds. Press the

STOP KEY (14) to silence the alarm.

NOTE: In Cook and Hold the alarm self can-

cels. The oven cools to the hold temperature. The time display counts up.

Press the HOLD KEY (8) to turn off hold

mode.

14

Page 18

Operation

CH-Pro3 (Solid State Programmable Digital Control)

Product Key Operation:

1. Press the desired PRODUCT KEY (10). The

applicable LEDs light.

2. The READY INDICATOR (4) lights when the

oven has reached the cook temperature.

3. Press the START KEY (12). The TIME DISPLAY

(2) counts down. The product key LED flashes.

NOTE: InCookwithPulsethefanLEDflashes.

4. When the cook or pulse time expires the applicable LEDs and both displays flash and an audible alarm sounds.

5. Press the STOP KEY (14) to silence the alarm.

NOTE: In Cook and Hold the alarm self can-

cels. The oven cools to the hold temperature. The time display counts up.

Press the HOLD KEY (8) to turn off hold

mode.

Oven Shut Down:

1. T urn the SELECTOR SWITCH (1) to OVEN OFF.

PROGRAMMING THE PRODUCT KEYS

NOTE: This procedure is also used to program

the default settings for the manual key.

1. Turn the SELECTOR SWITCH (1) to the desired cook position.

2. Press the desired PRODUCT KEY (10). The

product and fan key LEDs light.

3. Press a nd hold the PROGRAM KEY (13) for

approximately five seconds until the product

key LED flashes.

4. Press the TIME ARROW KEYS (3) to enter the

cook time.

For Cook with Pulse --- P r e s s th e FA N K E Y

(9). Use the TIME ARROW KEYS (3) to enter

the pulse time.

5. Press the TEMPERATURE ARROW KEYS (6)

to enter the cook temperature.

6. For Cook and Hold --- Press and hold the

HOLD KEY (8). At the same time use the TEMPERATURE ARROW KEYS (6) to enter the

hold temperature.

7. Pressthe PROGRAM KEY (13) to save the program settings.

15

Page 19

Operation

Solid State Digital Control

2

3

OPERATION

NOTE: Operationis restrictedto qualifiedperson-

nel.

1. Turn on the gas valve. (Gas models only.)

2. Close the oven door.

1

4

65

3. Turn the SELECTOR Switch (1) to the desired

cook position.

The fan will start to turn and the temperature

controlwillgoon.

4. Press the TEMP key (4) and rotate the dial to

enter the desired temperature.

The burner will ignite or the elements willcome

on. The HEAT light (2) on the control panel will

illuminate.

For gas models if in starting, the burner does

not ignite within a few seconds, the RESET

alarm light (7) will go on. Press the RESET

switch (8) to restart the burner.

TheHEATlight(2)willgooutwhentheoven

has reached temperature.

NOTE: If the oven will not start after several at-

tempts contact a qualified installer.

For Cook with Pulse:

NOTE: Set the pulse time before loading the prod-

uct.

1. Press the PULSE KEY (6).

2. Rotate the DIAL (3) to enter the pulse time.

Pulsetimeisaportionofthecooktime.

For Cook and Hold:

7

8

Gas Models

Only

Figure 16

NOTE: Settheholdtimebeforeloadingtheprod-

uct.

1. Press the HOLD KEY (5).

2. Rotate the DIAL (3) to enter the hold time.

Cool Down

1. Open oven door.

2. Turn the SELECTOR Switch (1) to COOL

DOWN.

Shut Down

1. Turn the SELECTOR Switch (1) to OFF.

2. Shut off the gas valve. (Gas models only.)

16

Page 20

Operation

Intelliplus

OPERATION

NOTE: Operationis restrictedto qualifiedperson-

1

NOTE: Electric models only.

1. Close the oven door.

2. Turn the SELECTOR Switch (1) to OVEN ON.

3. Rotate the TEMPERATURE DIAL (4) to the de-

4. Press the COOK HI/LO FAN key (6) to select

2

5. Press the FAN CON/CYC k ey (9) to select the

6. To display the temperature within the oven,

NOTE: If the oven will not start after several at-

For Cook and Hold:

nel.

sired cooking temperature.

The LIGHT OFF OVEN READY (2) will light.

the fan speed.

fan mode.

press and hold the ACTUAL TEMP key (5).

The oven has reached temperature when the

LIGHT OFF OVEN READY (2) light goes out.

tempts contact a qualified installer.

10

3

6

7

9

Figure 17

4

5

8

11

NOTE: Settheholdtimebeforeloadingtheprod-

uct.

1. Press the HOLD KEY (7).

2. Rotate the DIAL (3) to enter the hold time.

Chain Event Programming:

1. Press PGM MODE ON/OFF (10).

2. Press the desired PGM# (8) key to program.

3. Set the temperature, fan speed, fan mode and

cook time. See above.

4. Press the EV ENT # (11) key to advance to the

next event.

5. When all events have been programmed

press PGM MODE ON/OFF (10).

To use programming:

1. Load the product.

2. Press desired PGM # (8) key.

Shut Down

1. Turn the SELECTOR SWITCH (1) to OVEN

OFF.

17

Page 21

Operation

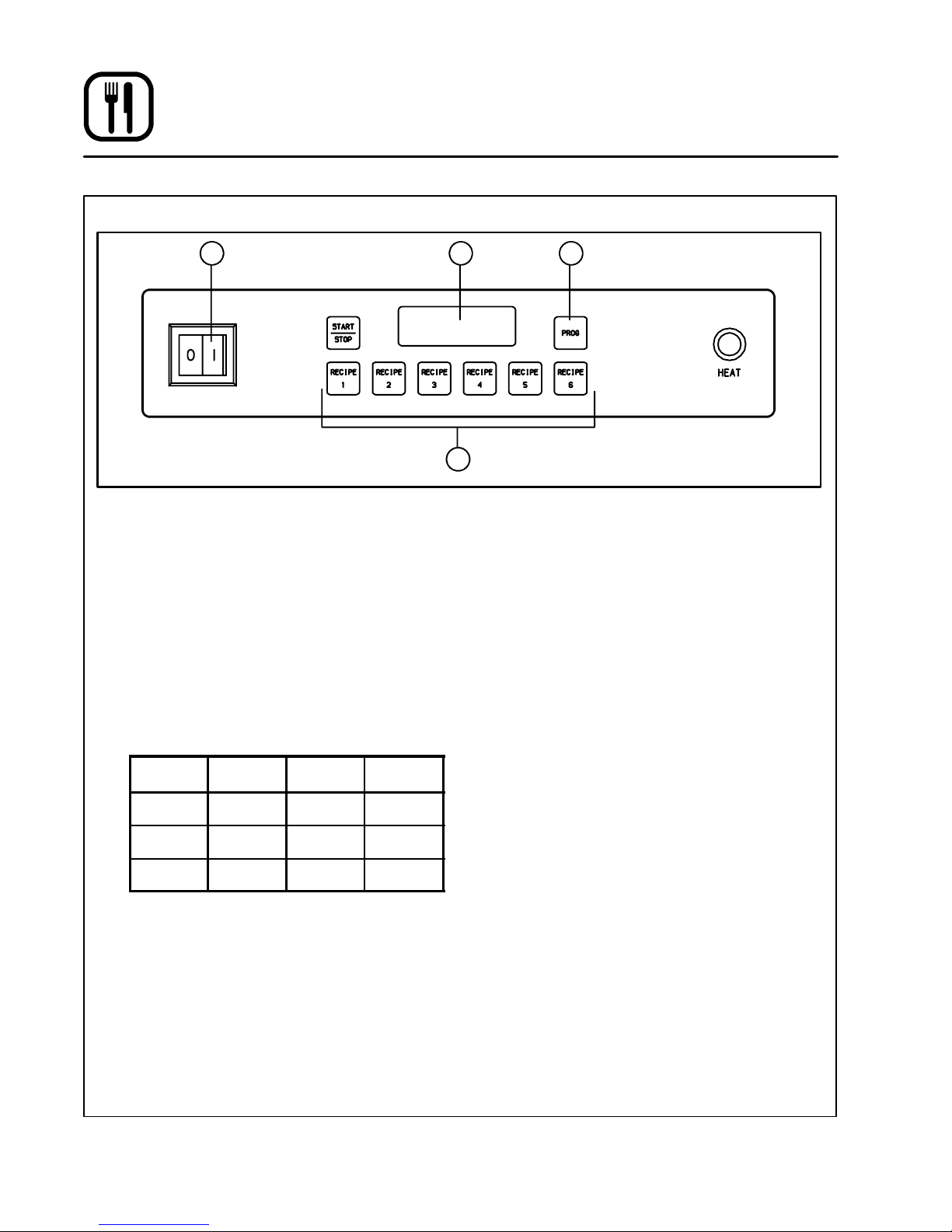

KCO-25E Solid Stage Digital

1 2 3

4

Figure 18

OPERATION

NOTE: Operationis restrictedto qualifiedperson-

nel.

1. Toggle the POWER SWITCH (1) to the ON

position.

2. Select one of the programmed PRODUCT

KEYS (4).

NOTE: Press once for one pan, twice for two

pans, etc.

The product keys have been programmed at

the factory as follows:

Recipe

1 149_C 4 191_C

2 163_C 5 205_C

3 177_C 6 219_C

3. When the DISPLAY (2) flashes PROD and 1

the unit is at the programmed temperature.

NOTE: If the oven will not start after several at-

tempts contact a qualified installer.

Shut Down

1. Toggle the POWER SWITCH (1) to the OFF

position.

Tem p. Recipe Tem p

PROGRAMMING

1. Press the PROGRAM (3) key.

2. When the display reads CODE,usetheproduct keys to enter 1 1 1 1. Press the PROGRAM

(3) key.

3. Press the desired product key. The display

reads TE # and the current cook temperature.

Use the product keys to enter the new cook

temperature. Press t he PROGRAM (3) key.

4. The display reads TI # and the current cook

time for one pan. Use the product keys to enter the new cook time. Press the PROGRAM

(3) key.

5. Repeatstep 4 for up to three pans. The display

reads PROG.

6. Press the PROGRAM (3) key to exit program ming.

18

Page 22

Operation

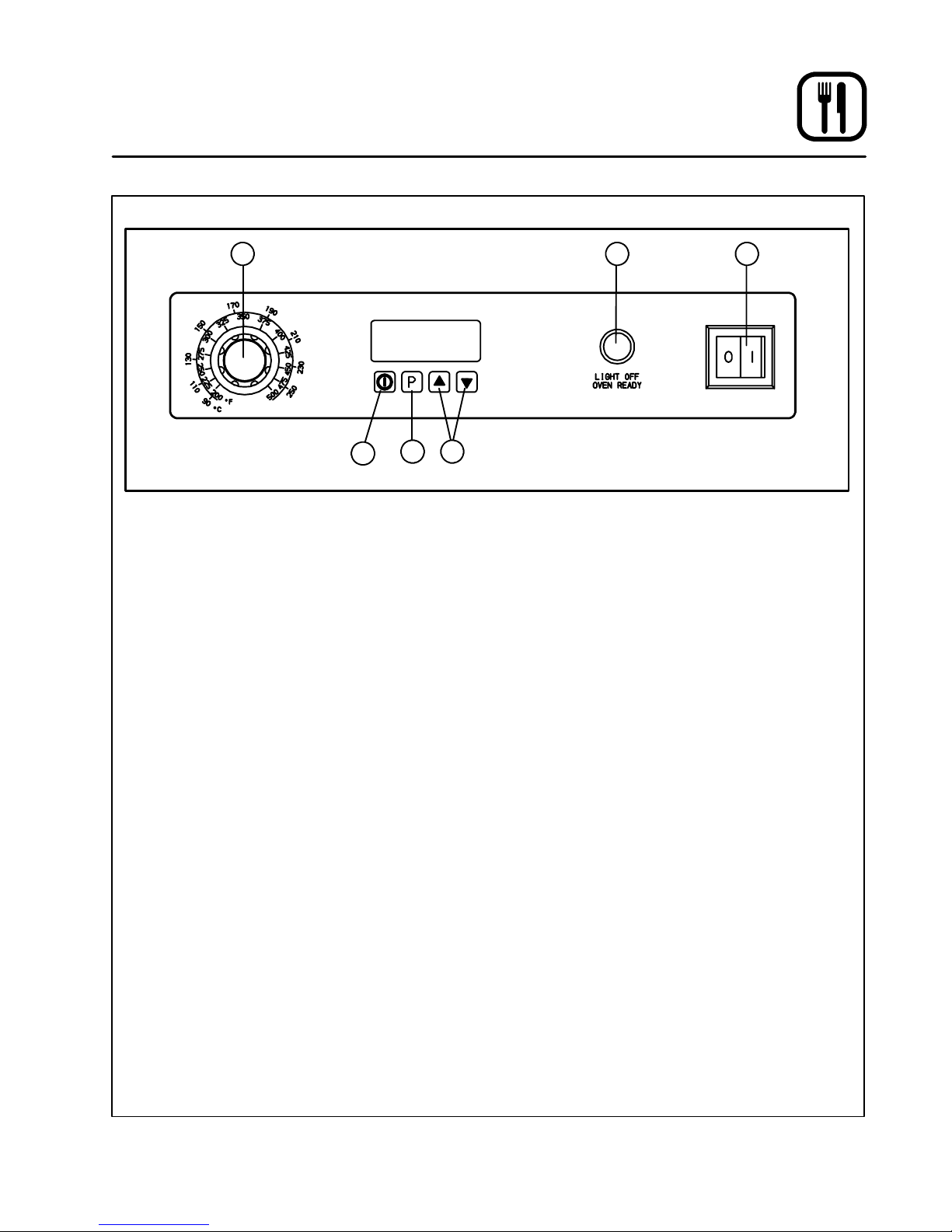

KCO-25E Infinite Control

31 2

6

OPERATION

NOTE: Operationis restrictedto qualifiedperson-

nel.

1. Toggle the POWER SWITCH (3) to the ON

position.

2. Set the THERMOSTAT (1) to the desired setting. The oven has reached temperature when

the LIGHT OFF OVEN READY (2) light goes

out.

NOTE: If the oven will not start after several at-

tempts contact a qualified installer.

Using the Timer (8 Presets)

1. Press UP and D OWN ARROW (5) keys to

scroll to desired preset.

2. Press the START/STOP key (6) to start timer

countdown.

Shut Down

1. Toggle the POWER SWITCH (3) to the OFF

position.

4 5

Figure 19

TIMER PROGRAMMING:

1. Press and hold the TIMER PROGRAM KEY (4).

2. Press UP or DOWN ARROW (5) keys t o scroll

to the desired cook time.

3. Pressthe TIMER PROGRAM KEY (4) to exitthe

program mode.

19

Page 23

Maintenance

Cleaning

WARNING!!

DO NOT spray the oven with a water jet.

DAILY

1. Saturate a cloth w ith light oil. W ipe the oven

exterior when it is cold. Dry the oven with a

clean cloth.

2. Clean stainless surfaces with a non-toxic industrial stainless steel cleaner. Apply the

cleaner when the oven is cold, and always rub

with the grain of the metal.

3. Clean the porcelain interior with a non-toxicin dustrial porcelain cleaner.

WEEKLY

1. Remove the racks and rack support. Soak

them in a solution of ammonia and water.

EVERY 12 MONTHS

For all oven models:

1. Check the main electrical connection.

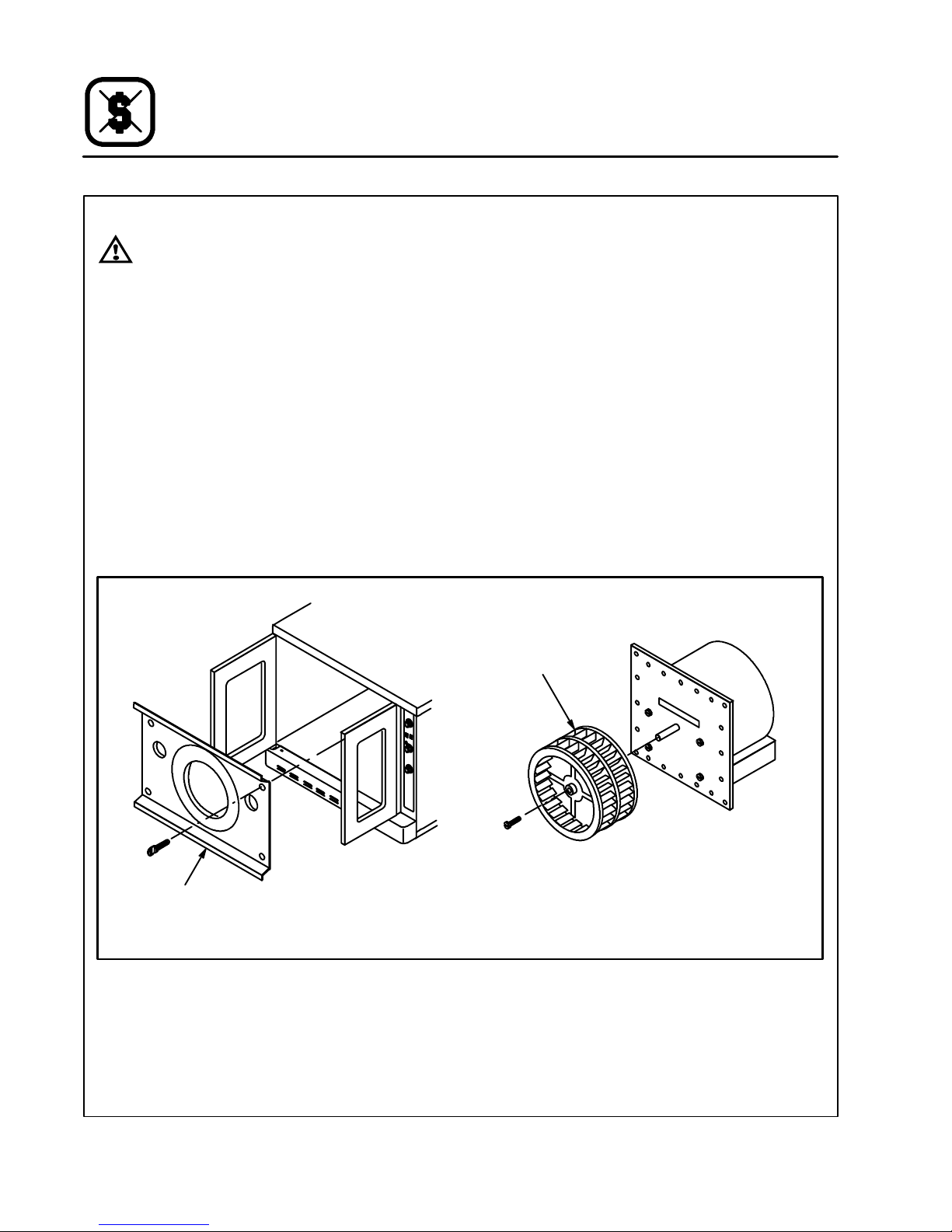

2. Remove the blower wheel. Soak in a solution

of ammonia and water.

For gas models only:

1. Check the venting system for possible deterioration resulting from moisture and corrosive

flue products.

2. Check and adjust the gas setting.

Blower Wheel

Cover

Blower Wheel

DFG-100-3 Shown

Figure 20

20

Page 24

Maintenance

Replacement of Parts

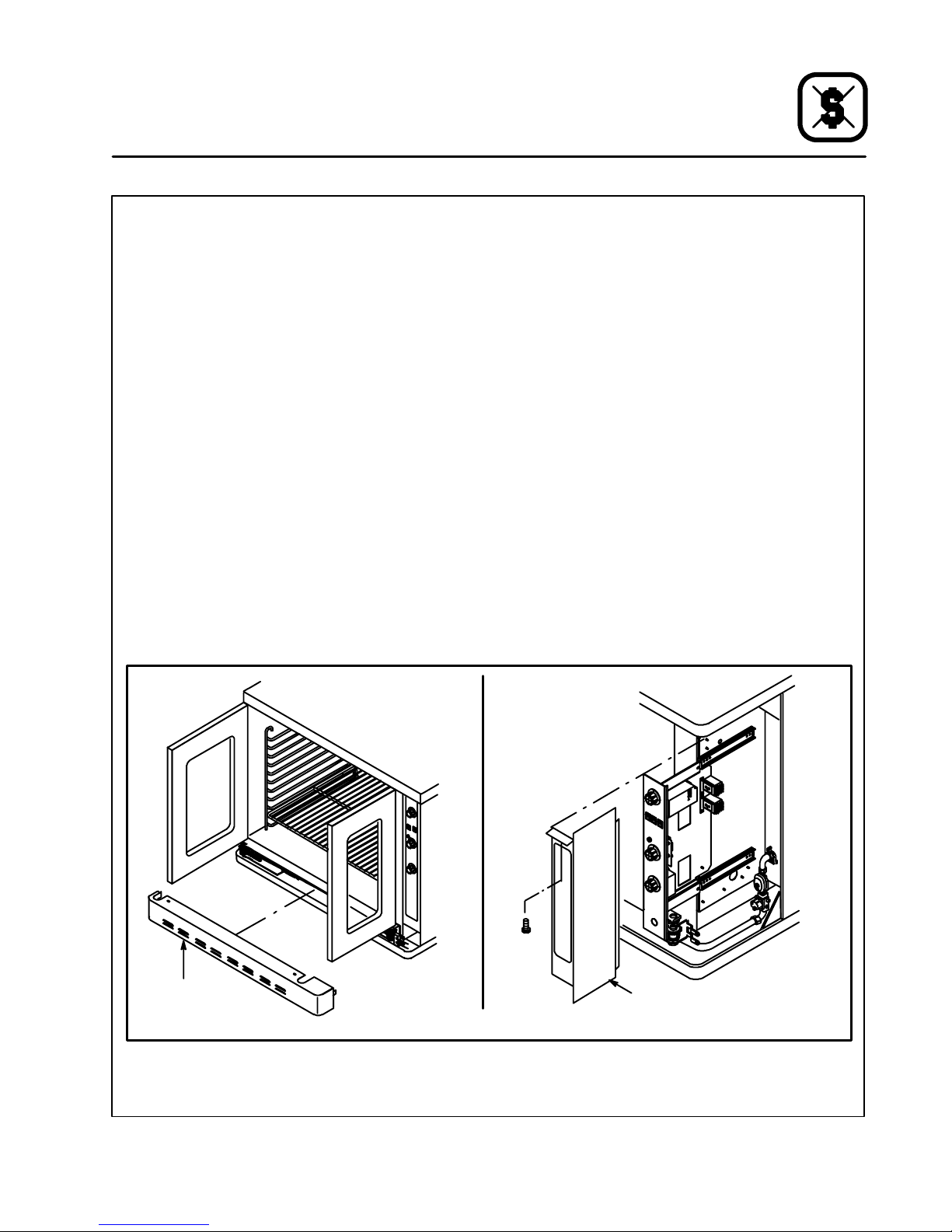

ELECTRICAL COMPONENTS

1. Turn off the main electrical connection to the

oven.

2. Remove the components from the panel and

set the wiring aside.

3. Reinstall the components.

GAS CONTROL COMBINATION

NOTE: Gas models only.

1. Shut off the gas and turn off the power to the

oven.

2. Remove the electrical connection.

3. Remove the gas connection in front of and behind the control combination.

4. Remove the pilot line, replace, reinstall, and

adjust. Check for gas leaks.

REMOVAL OF BURNER

NOTE: Gas models only.

1. Shut off the gas and turn off the power.

2. Remove the combustion cover.

3. Remove the gas connection, etc.

4. Remove the screw s from the burner mounting

bracket.

5. Remove the burner from t he combustion

chamber.

6. Replace pilot burner if necessary. Install the

burner.

CONTROL COMPARTMENT COMPONENTS

1. Switch power off.

2. Remove the combustion cover.

3. Remove the control compartment cover.

4. Slide the control panel out.

5. Replace and repair the respective component.

6. Install the panel, the control compartment

cover and combustion cover.

Combustion

Cover

Control Cover

DFG-100-3 Shown

Figure 21

21

Page 25

Installations-og Betjeningsvejledning

til Gas-og El-konvektorovne

Eksportmodeller

22

Page 26

Installering

Levering og Placering

LEVERING OG INSPICERING

Alle Blodgett ovne er emballeret i kasse til forsendelse. Ved modtagelsen skal man:

D

Inspicere kassen med ovnen for ydre skader;

dersom skade konstateres, skal dette noteres

på fragtbrevet, der skal underskrives af fragtmanden.

D

Tag ovnen ud af emballagen, og se den efter for

intern skade. Fragtlinien anerkender anmeldelse af intern forsendelsesskade, hvis man gør

det inden for 15 dage efter modtagelsen og

gemmer emballagen til inspektion.

Blodgett Oven Company påtager sig intet ansvar for tab eller skade under forsendelsen.

Fragtlinien har ansvar for levering i god stand,

da forsendelsen blev modtaget. Men vi kan assistere, dersom der er behov for at indgive

klage.

OVNENS PLACERING

Ovnen vil få let betjening og tilfredsstillende ydelse

i det lange løb ved velgennemtænkt og korrekt

placering.

D

Ovnen skal anbringes således, at der er mindst

15,2 cm til væggen bag den og ligeledes 15,2

cm til vægge på siderne.

D

Ovnen skal anbringes et velventileret sted.

D

Ovnen skal anbringes under en emhætte iht.

gældende lokal--- og landsregulativ.

D

Anbring ovnen sådan, at den ikke blokerer stikkontakten.

D

Placér ovnen, hvor det ikke trækker.

D

Hold området omkring ovnen fri for brandfarlige

materialer, såsom papir og pap, og for væsker

og opløsningsmidler.

D

Ovnen må ikke placeres på et lukket fodstykke

eller slutte tæt op af en væg, da lufttilgangen

derved spærres og forhindrer passende ventilering.

D

Gasovne skal placeres, så der er tilstrækkelig

frit til luftindtaget til brænderen.

Man skal selvfølgelig sikre sig, at ovnens specifikationer på mærkeskiltet svarer til henholdsvis

de n t y p e g a s --- e l l e r e l --- f o r s y n i n g , m a n h a r, i n d e n

den tilsluttes ledningerne.

23

Page 27

Installering

Ovnens Samling

NOTE: Denne ovn skal installeres i henhold til

gældende regulativer og må kun benyttes

i velventilerede rum. Læs installations--og betjeningsvejledningen, inden oven

installeres og tages i brug.

NOTE: Ovne skal installeres af en autoriseret

installatør.

MONTERING AF BEN

10 cm ben

1. Læg ovnen ned på bagsiden.

2. Skru benene i gevindhullerne i hjørnerne af

ovnen, og spænd møtrikken oven i benene.

3. Rejs ovnen op på benene.

4. Justér tæerne på benene, så ovnen står i vater.

15cm,18cmog64cmben

1. Læg ovnen om på bagsiden.

2. Styr gevindstudsene i benene til møtrikkerne

i stelhjørnerne, og spænd dem i.

3. Ret hullerne i toppladerne på benene og ovnrammen ind med hinanden, og spænd benene på med to 1/2” bolte.

NOTE: Der henvises endvidere til afsnittet

Monteringaf hjul, dersom man agter at

bruge dem.

4. Rejs oven op på benene.

5. Justér tæerne (eller hjulene) på benene, så

ovnen står i vater.

Figure 1

15 cm justerbare ben

Figure 2

24

Page 28

Installering

Ovnens Samling

MONTERING PÅ STATIV

1. Anbring ovnen midt på stativet.

2. Afmontér ovnpanelet i højre side.

3. Ret hullerne i bunden af ovnen og stativet ind

med hinanden.

4. Spænd ovnen på stativet med bolte, skiver og

møtrikker, som vist på Figure 3.

5. Sæt sidepanelet på igen.

MONTERING AF HJUL

NOTE: Montérhjulenemedlåsforpå,oghjul

uden lås bag på ovnen.

Montering af svirvelhjul på enkelt-- og do bbeltovne

1. Montér benene.

2. Løsn låsemøtrikken på de justerbare tæer, og

skru tæerne af.

3. Sæt et svirvelhjul på hver ben, som vist på fig.

4, og spænd dem fast med låsemøtrikkerne.

Justerbar tå

Svirvelhjul

Illustrationen viser 64 cm bentype

Figure 4

Figure 3

Lave svirvelhjul til dobbeltovne

1. Ret hullerne i hjulbeslagene og ovnbunden

ind med hinanden, og spænd hjulene på med

3 1/2” bolte pr. stk.

Figure 5

25

Page 29

Installering

Ovnens Samling

MONTERINGAFTOOVNEOVENPÅHINANDEN

NOTE: Trækkannalerne til enkeltovnsmontage

skal aftages, inden trækkombinationen

monteres.

Model AC--500, DFG--100 og 200, CTB, Ma rk

VogZephaireE&G

1. Montér et sæt korte ben på den ovn, der skal

stå underst.

2. Anbring den anden ovn oven på den.

3. Sæt beslagene på kanten af ovnstellene, jf.

Figure 6.

4. Spænd beslagene sammen med de 3/8” bolte

ogmøtrikker,derfulgtemed.

5. Montér trækkombinationen.

Samlebeslag

3. Ret hullerne i hjørnerne for og bag på ovnene

ind med hinanden.

4. Spænd ovnene sammen med bolte, skiver og

møtrikker, som illustreret på Figure 7.

5. Sæt brænderkammerdækslet og sidepanelet

på igen.

Figure 7

KCO-25E

1. Spænd et sæt k orte ben på den ovn, der skal

stå forneden.

2. Sæt den anden ovn oven på den.

3. Tag den nederste skrue a f i begge sider af den

øverste ovn, og de øverste skruer i begge sider af den nederste ovn af.

4. Montér de to vinkelbeslag, på model KCO-25E

meddefireskruer,derligeblevtagetud.

5. Montér trækkombinationen.

Trækkombination

Figure 6

DFG-50

1. Anbring den ene ovn oven på den anden.

2. Tag brænderkammerdækslet og sidepanelet af.

Vinkelbeslag

Figure 8

26

Page 30

Installering

Ovnens Samling

GASSLANGEHOLDER (gasmodeller)

Når ovne sættes på svirvelhjul, skal gasforbindelsen føres med fleksibel slange til forretningsbrug

(mindst 19 mm indvendig diameter) med en hurtigkobling på.

1. Montér det medfølgende beslag på hjulmonteringsbolten lige under gasstudsen.

2. Slangeholderen skal så spændes på beslaget.

Ovn, bagside

Slangeholderbeslag

Lave svirvelhjul til dobbeltovn illustreret

Figure 9

AFTRÆK (gasovne)

Der skal installeres en emhætte med blæser, og

hætten skal dække hele ovnens areal plus mindst

15 cm overhæng på de tre sider, der er fri af

væggen. Afstanden fra gulv til hættens underkant

må højst være 2, 1 m.

ADVARSEL!:

Dersom ovnen ikke ventileres korrekt,

udgør den en sundhedsfare for betjeningen, giver driftsproblemer, utilfredstillende bagning og evt. skade på udstyret

selv.

Skade, der forårsages af ukorrekt ventilering, dækkes ikke af fabriksgarantien.

Ovne, der bestilles til aftrækshætte, leveres med

trækfløj, der monteres på følgende måde:

1. Anbring fløjen over trækkombinationen med

åbningen vendt mod forsiden af ovnen.

2. Spænd den på med de selvskærende pladeskruer, der fulgte med.

Trækfløj

Forside af

ovn

Model til stor ovn illustreret

Figure 10

27

Page 31

Installering

Tilslutning

GASTILSLUTNING (gasmodeller)

Ovne skal tilsluttes den pågældende type gasledning iht. lokal--- og landsregulativetaf en autoriseret gas--- og vandmester.

Specifikation efter gastype

1. Luk gashanen, og sluk kontakten på ovnen.

2. Afmontér regulatorventil ved omløberne.

3. Afmontér brænderen, og skift dyserne.

4. Genmontér brænder og regulatorventil.

5. Gå apparaturet efter for læk og løse el--- forbindelser.

6. Indstil til korrekt gastryk, jf. illustration herunder.

Gastryksindstilling

MANOMETER PÅ GASINDGANG

NOTE: Følgende anvisning gælder kun model

Zephaire-G/DFG -50 ovne. Manometer studsens placering vises på tegningen.

1. Tagdenblåmuffeafstudsenpågasrøret.

2. Smør paksalve på studsgevindene.

3. Skru indgangsmanometret på, og spænd det.

4. Efterse for gaslæk.

Manometerstudse

Gastilslutning

Manometerstudse

DFG-50

Manometerstudse

DFG-100/Zephaire-G

Figure 11

Ovnens bagside - alle ovne

blandeblok

Manometerstudse

blandeblok

AC-500

28

Page 32

Installering

G20/G2520/25Trykregulator

2,10182x0,3816Naturga

s

G20/G2520/25Trykregulator

2,1092x0.388Naturga

s

G20/G2520/25Trykregulator

2,10182x0.3817,6Naturga

s

G20/G2520/25Trykregulator

1,751620,5Naturga

s

Tilslutning

Gastype Indgangs-

tryk

mbar

DFG-100-3

G25 25 12 2,60 18 2 x 0,38 16 Naturgas

G20 20 8 2,60 18 2 x 0,38 16 Naturgas

G20/G25 20/25 Trykregulator 2,10 18 2 x 0,38 16 Naturgas

G30 30/50 17 1,60 10 2 x 0,20 16 Butangas

G31 30/37/50 24 1,60 10 2 x 0,20 16 Propangas

DFG-50

G25 25 12 2,50 9 2 x 0.38 8Naturgas

G20 20 8 2,50 9 2 x 0.38 8Naturgas

G20/G25 20/25 Trykregulator 2,10 9 2 x 0.38 8Naturgas

G30 30/50 17 1,60 9 2 x 0,20 8Butangas

G31 30/37/50 24 1,60 9 2 x 0,20 8Propangas

Zephaire-G-L

G25 25 12 2,70 18 2 x 0.38 17,6 Nat urgas

G20 20 8 2,70 18 2 x 0.38 17,6 Naturgas

G20/G25 20/25 Trykregulator 2,10 18 2 x 0.38 17,6 Naturgas

Brændertryk

mbar

skruet helt i bund

skruet helt i bund

skruet helt i bund

DyseåbningmmLuftåbningmmVågekone

dyse

mm

Standard

ydelse

ikW(H

)

i

G30 30/50 17 1,60 10 2 x 0,20 17,6 Butangas

G31 30/37/50 24 1,60 10 2 x 0,20 17,6 Propangas

AC-500

G25 25 12 2,10 16 --- 20,5 Nat urgas

G20 20 8 2,10 16 --- 20,5 Naturgas

G20/G25 20/25 Trykregulator 1,75 16 --- 20,5 Naturgas

skruet helt i bund

G30 30/50 17 1,32 16 --- 20,5 Buta n gas

G31 30/37/50 24 1,32 16 --- 20,5 Propangas

29

Page 33

Installering

p

g

Tilslutning

EL-TILSLUTNING

NOTE: Elektrisk tilslutning skal udføres af en auto-

riseret el -installatør.

BEMÆRK:Elektrisk tilslutning skal ske i henhold til

gældende Nationale og Lokale bestemmelser.

Der skal monteres trækaflastning på ledningen;

installatøren skal levere ledningsbøsning iht.

gældende regulativ.

Gasovne:

NOTE: Brænderkontrollen på gasmodeller er fa-

sebestemt; dersom fase-og nulleder forbyttes, virker kontrollen ikke.

Forbind fase + nul + og jordledning.

kW

pr. sektion

CTB/CTBR

5,6 400 3N 50 9 8 8 1

8,0 400 3N 50 13 11 11 2

Spænding-

stype Faser (Hz)

Frekvens

El-ovne:

Ovnen skal tilsluttes en særskilt gruppe med fast

forbindelse og termosikring, hvilken sidste skal afbryde alle poler, herunder nulleder, med kontaktgab på mindst 3 mm.

Til enfaset: Tilslut fase + nul + og jordledning.

Til trefaset: Tilslut leder 1 + leder 2 + leder 3 +

nul--- og jordledning.

FØRSTE GANG OVNEN TÆNDES

1. Stil termostaten på 260_C, og lad ovnen være

tændt i 2 timer, inden der s ættes noget i den.

Ovnen ryger under denne tilbrændingsproces.

2. Ovnen skal gøres ren efter tilbrændingen. Der

henvises til rengøringsanvisning side 40 herunder.

Maks. belastning

L1 L2 L3 N

KCO-25E

3,0 230 1N 50 13 --- --- 13

Mark V-III

11,0 400 3N 50 18 15 15 3

Zephaire-E

11,0 400 3N 50 18 15 15 3

DFG-100-3

0,7 230 1N 50 3 --- --- 3

DFG-50

0,7 230 1N 50 3 --- --- 3

Zephaire-G-L

0,7 230 1N 50 3 --- --- 3

AC-500

1,3 230 1N 50 6 --- --- 6

30

Page 34

2

på

gasmodeller

3

4

5

Betjening

Betjeningspanel (elektronisk)

BETJENING

NOTE: Ovne må kun betjenes af kvalificeret per-

1

1. Luk op for gassen på gashanen (på gasmo-

2. Luk ovnen.

3. Sæt VALGKONTAKTEN (1) på den ønskede

4. Sæt THERMOSTAT (TERMOSTATEN) (5) på

NOTE: Dersom ovnen ikke tænder efter flere

sonale.

deller).

funktion.

Blæseren går i gang, og temperaturkontrollen

starter.

den ønskede temperatur.

På gasovne tændes brænderen, og på el---

ovne starter varmelegemerne. Indikatoren

LIGHT OFF OVEN READY (FORVARMNING)

(4) på betj eningspanelet tænder.

Dersom brænderen ikke tændes på gasmodeller inden for få sekunder, t ænder advarselslampen RESET (GENSTIL) (2). Man skal

så trykke på kontakten RESET (GENSTIL) (3)

for at starte brænderen igen.

Indikatoren LIGHT OFF OVEN READY (FORVARMNING) (4) går ud, når ovnen er kommet

op på temperaturen.

forsøg, bør man sende bud efter en autoriseret installatør.

På ovne med HUMIDAIRE dampkontrol:

6

7

8

Figure 12

1. Når man vil benytte damp, skal STEAM

CYCLE (DAMPPROGRAMMET) (8) stilles på

den ønskede indsprøjtningstid.

2. Tryk startknappene STEAM CYCLE START

(DAMPPROGRAM) (7) ind, og slip den. Indikatoren for STEAM (DAMP) (6) tænder, når der

sprøjtes vand ind i ovnen.

Afkøling

1. Luk ovnlågen op.

2. Stil SELECTOR (valgkontakten) (1) på COOL

DOWN (afkøling).

Slukning

1. Stil VALGKONTAKT (1) på OVEN OFF (SLUK -

KET).

2. Luk gashanen (på gasmodeller).

31

Page 35

Betjening

Model AC-500 Betjeningspanel (elektronisk)

BETJENING

1

2

3

4

5

6

7

NOTE: Ovne må kun betjenes af kvalificeret per-

1. Luk op for gassen på gashanen (9).

2. Luk ovnen.

3. Sæt VALGKONTAKTEN (1) på den ønskede

funktion.

Blæseren går i gang, og temperaturkontrollen

starter.

4. Indstil den ønskede temperatur på THERMOSTAT, 7 (TERMOSTATEN).

Varmelegemerne starter. Indikatoren for

LIGHT OFF OVEN READY, 6 (FORVARMNING) på betjeningspanelet tænder.

Dersom brænderen ikke tændes på gasmodeller inden for få sekunder, t ænder advarselslampen RESET (GENSTIL) (3). Man skal

så trykke på kontakten RESET, (2) (GENSTIL)

for at starte brænderen igen.

LIGHT OFF OVEN READY (FORVARMNING),

(6)---indikatoren går ud, når ovnen er kommet

op på temperaturen.

NOTE: Dersom ovnen ikke tænder efter flere

sonale.

forsøg, bør man sende bud efter en autoriseret installatør.

På ovne med HUMIDAIRE dampkontrol:

1. Når man vil benytte damp, skal STEAM

CYCLE TIMER, (8) (DAMPPROGRAMUR)

stilles på den ønskede indsprøjtningstid.

2. Tryk startknappen STEAM CYCLE START, 4

8

9

Figure 13

32

(DAMPPROGRAM) ind, og slip den. STEAM

(DAMP)---indikatoren (5) tænder, når der

sprøjtes vand ind i ovnen.

Slukning

1. Stil VALGKONTAKT (1) på OVEN OFF (SLUK KET).

2. Luk gashanen (9).

Page 36

Betjening

Model Zephaire Betjeningspanel

BETJENING

1

ON

OFF

ON

OFF

2

3

MAN

AUTO

8

NOTE: Ovne må kun betjenes af kvalificeret per-

sonale.

1. Luk op for gassen på gashanen (på gasmo-

deller).

2. Luk ovnen.

3. TÆND (ON-TÆND) BLOWER (BLÆSERKON-

TAKTEN) (1) på forpanelet. Stil COOL DOWN

(afkøling) (8) på AUTO (automatisk).

Blæseren går i gang, og temperaturkontrollen

starter.

4. Sæt THERMOSTAT (TERMOSTATEN) (3) på

den ønskede temperatur.

På gasovne tændes brænderen, og på el---

ovne starter varmelegemerne. Indikatoren

LIGHT OFF OVEN READY (FORVARMNING)

(2) på betj eningspanelet tænder.

Dersom brænderen ikke tændes på gasmodeller inden for få sekunder, t ænder advarselslampen RESET (GENSTIL) (4). Man skal

så trykke på kontakten RESET (GENSTIL) (5)

for at starte brænderen igen.

Indikatoren LIGHT OFF OVEN READY (FORVARMNING) (2) går ud, når ovnen er kommet

op på temperaturen.

NOTE: Dersom ovnen ikke tænder efter flere

forsøg, bør man sende bud efter en autoriseret installatør.

4

på

gasmodeller

5

Figure 14

På ovne med HUMIDAIRE dampkontrol:

1. Tryk startknappene STEAM CYCLE START

(DAMPPROGRAM) (7) ind, og slip den. Indika-

6

toren for STEAM (DAMP) (6) tænder, når der

sprøjtes vand ind i ovnen.

Afkøling

7

1. Luk ovnlågen op.

2. Tænd (BLOWER) blæseren (1).

3. Stil COOL DOWN (afkøling) (8) på MANUAL

(manuel).

Slukning

1. Stil BLOWER (BLÆSERKONTAKTEN) (1) på

OVEN OFF (SLUKKET).

2. Stil THERMOSTAT (TERMOSTATEN) (3) på

OVEN OFF (SLUKKET).

3. Luk gashanen (på gasmodeller).

33

Page 37

Betjening

CH-Pro3 (Programmérbart digitalbetjeningspanel --- faststof)

NOTE: Ovne må kun betjenes af kvalificeret per-

sonale.

BETJENING

Ovnen tændes:

1. Sæt VALGKONTAKTEN (1) på den ønskede

1

2

funktion; så tænder brænderne på gasovne, og

på el-ovne tændes varmelegemerne. Indikatoren FORVARMNING (7) på panelet tændes.

Hvis brænderen ikke tænder på gasovne inden

for få sekunder, tænder advarselslampen

GENSTIL (15), og man skal trykke på kontakten

GENSTIL (16) for at tænde brænderen igen.

NOTE: Tænder ovnen ikke efter flere forsøg, bør

man sende bud efter en autoriseret installatør.

4

5

7

8

10

12

13

15

16

på

gasmodeller

3

6

9

11

14

Manuel betjening:

NOTE: Man kan lave om på bagetid og -temperatur

ved brug af piltasterne når som helst man

ønsker det ved manuel betjening.

1. Omstil til manuel betjening på MANUEL-tasten

(11); så tænder lyset i MANUEL- og BLÆSERtasten.

2. Indstil bagetiden på PILTASTERNE (3).

Bagning med puls – Tr y k p å B L Æ S E R --- t a s -

ten (9), og indstil pulstiden på PILTASTERNE

(3); lyset i blæsertasten begynder at blinke.

3. Bagetemperaturen indstilles på TEMPERATURPILT ASTERNE (6).

4. Bagning med påfølgende varmeskab –Tryk

HOLD-tasten (8) ned, og holdden nede, mens

varmeskabstemperaturen samtidig indstilles

på TEMPERATURPILTASTERNE (6); så tænder

lyset i HOLD-tasten.

5. KLAR-indikatoren (4) tænder, når ovnen har

nået den indstillede bagetemperatur.

6. Tryk så på START-tasten (12); URET (2) begynder nedtælling, og MANUEL-tasten blinker.

Figure 15

34

Page 38

Betjening

CH-Pro3 (Programmérbart digitalbetjeningspanel --- faststof)

7. Når bagetiden er gået, blinker indikatorerne og

displayene, og alarmen lyder. Man kan slukke

for lydalarmen ved tryk på STOP---tasten (14).

NOTE: I bagning med påfølgende varmeskab

slukker alarmen af sig selv, og ovnen

køler ned til varmeskabstemperaturen.

Uret tæller fremad på normal måde.

Man slukker varmeskabsfunktionen ved

tryk på HOLD-tasten (8).

Betjening af produkttypetasterne:

1. Tryk på den ønskede PRODUKT-- -typetast (10),

hvorefter den tilhørende indikator tænder.

2. KLAR-indikatoren (4) tænder, når ovnen er

nået op på bagetemperaturen.

3. Tryk så på START-tasten (12); URET (2) starter

nedtælling, og den pågældende produkttypetast begynder at blinke.

NOTE: Når man benytter pulsbagning, blink-

er blæseindikatoren.

4. Når bage- eller pulsbagetiden er gået, blinker

den pågældende tast-indikator og begge displayer, og lydalarmen går af.

5. Man kan slukke lydalarmen ved at trykke på

STOP-tasten (14).

NOTE: Ved bagning med påfølgende var-

meskab slukker alarmen af sig selv,

og ovnen køler ned til varmeskabstemperaturen. Uret tæller fremad på

normal måde. Man slukker varmeskabsfunktionen ved tryk på HOLD-tasten

(8).

Ovnen slukkes:

1. Ovnen slukkes ved at stille VALGKONTAKTEN

(1) på OVEN OFF.

PROGRAMMÉRING AF PRODUKTTYPETASTERNE

NOTE: Man indprogrammérer standardindstillinger

med samme fremgangsmåde.

1. StilVALGKNAPPEN (1) på den ønskede bagefunktion.

2. Tryk på den ønskede produkttypetast (10); så

tænder lyset i den pågældende produkttypetast og blæsertasten.

3. Tryk på PROG ---tasten programméring (13),

og hold den nede i ca. 5 sekunder til produkttypeindikatoren begynder at blinke.

4. Bagetiden indsættes nu på URPILTASTERNE

(3).

Til bagning med puls – Tr y k p å BL Æ S E R --tasten (9). Indsæt bagetemperaturen på TEMPERATURPILTASTERNE (3).

5. Indtast bagetemperaturen på TEMPERATURPILTASTERNE (6).

6. Bagning med påfølgende varmeskab –Tryk

på HOLD---tasten (8) og hold den nede, mens

varmeskabstemperaturen indtastes på TEMPERATURPILTASTERNE (6) samtidigt.

7. Indstillingerne gemmes ved tryk på PROG--tasten programmering (13).

35

Page 39

Betjening

Digitalbetjeningspanel (elektronisk)

1

2

3

4

65

1. Luk op for gassen på gashanen (på gasmodeller).

2. Luk ovnen.

3. Sæt VALGKONTAKTEN (1) på den ønskede

bagefunktion.

Blæseren går i gang, og temperaturkontrollen

starter.

4. Tryk på tasten TEMP, 4 (TEMPERATUR), og

drej knappen til den ønskede temperatur.

På gasovne tændes brænderen, og på el--ovne starter varmelegemerne. Indikatoren

HEAT, (2) (FORVARMNING) på betjeningspanelet tænder.

Dersom brænderen ikke tændes på gasmodeller inden for få sekunder, t ænder advarselslampen RESET (GENSTIL) (7). Man skal

så trykke på kontakten RESET, (8) (GENSTIL)

for at starte brænderen igen.

Indikatoren HEAT, 2 (FORVARMNING) går ud,

nårovenerkommetoppåtemperaturen.

NOTE: Dersom ovnen ikke tænder efter flere

forsøg, bør man sende bud efter en autoriseret installatør.

Bagning med puls:

7

8

på

gasmodeller

Figure 16

BETJENING

NOTE: Ovne må kun betjenes af kvalificeret per-

sonale.

NOTE: Pulsindstillingenskal indstilles, inden pro-

duktet sættes i ovnen.

1. Tryk på PULS--- tasten. (6).

2. Pulstiden indsættes ved at indstille URET (3).

Pulstiden er en del af bagetiden.

Bagning med påfølgende varmeskab:

NOTE: Varmeskabstiden skal indstilles, inden

produktet sættes i ovnen.

1. Tr y k p å H O L D --- ta s t e n ( 5 ) .

2. Indstil varmetiden på URET (3).

Afkøling

1. Luk ovnlågen op.

2. Stil SELECTOR (valgkontakten) (1) på COOL

DOWN (afkøling).

Slukning

1. Stil VALGKONTAKT (1) på OVEN OFF (SLUK KET).

2. Luk gashanen (på gasmodeller).

36

Page 40

Betjening

Intelliplus Betjeningsmodul

3. Drej TEMPERATURE DIAL, (4) (TEMPERA-

TURKNAPPEN) til den ønskede temperatur.

1

2

3

4

LI G H T O F F OV E N R E A D Y, ( 2 ) --- i n d i k a t o r e n

(FORVARMNING) tænder.

4. Blæserhastigheden reguleres ved tryk på tas-

ten COOK HI/LO FAN, (6) (HØJ/LAV

BLÆSER).

5. Blæserens funktionsmåde indstilles ved tryk

på tasten FAN CON/CYC, (9) (BLÆSER KONTINUERLIG/INTERVAL).

6. Når man trykker på tasten ACTUAL TEMP, (5)

(FAKTISK TEMPERATUR) vises temperaturen

iovnen.

Ovnen er nået op på den indstillede temperat u r, nå r LI G H T OF F O V E N R E A D Y, ( 2 ) --- in d i k a toren (FORVARMNING) går ud.

NOTE: Dersom ovnen ikke tænder efter flere

forsøg, bør man sende bud efter en autoriseret installatør.

Bagning med påfølgende varmeskab:

5

6

7

9

10

Figure 17

BETJENING

NOTE: Ovne må kun betjenes af kvalificeret per-

sonale.

NOTE: Findes kun på el-ovne.

1. Luk ovnen.

2. Stil VALGKONTAKT (1) på OVEN ON

(TÆNDT).

8

11

NOTE: Varmeskabstiden skal indstilles, inden

produktet sættes i ovnen.

1. Tryk på HOLD---tasten (7).

2. Varmetiden indsættes ved at indstille URET

(3).

Kædebagningsprogrammering:

1. Tryk på PGM MODE ON/OFF tasten (10).

2. Tryk på den respektive tast til det PGM---program (8) man ønsker at benytte.

3. Indstil temperatur, blæserhastighed, blæserfunktion og bagetid, jf. ovenfor.

4. Man rykker frem til indstilling af næste del i

kædebagningen ved at trykke på EVENT nr.--tasten (11).

5. Når alle led i kædebagningen er indstillet, skal

mantrykkepåPGMMODEON/OFFtasten

(10).

Programmet drift:

1. Sæt produktet i ovnen.

2. Tryk på tasten med det ønskede opskrift nr.

(8).

Slukning

1. Stil VALGKONTAKTEN (1) på OVEN OFF

(SLUKKET).

37

Page 41

Betjening

Model KCO-25E Digitalbetjening (elektronisk)

1 2 3

4

Figure 18

BETJENING

NOTE: Ovne må kun betjenes af kvalificeret per-

sonale.

1. ON (Tænd) på E L --- K O N TA K T E N ( 1 ) .

2. Vælg en af de programmerede PRODUCT

KEYS, (4) (OPSKRIFT)---taster.

NOTE: Tryk én gang til en plade, to gange til

to plader osv.

Fra fabrikken er disse taster programmeret

som følger:

Opskrift

1 149_C 4 191_C

2 163_C 5 205_C

3 177_C 6 219_C

3. Når PROD og (1 blinker på DISPLAY

(SKÆRMEN) (2), har ovnen nået den indprogrammerede temperatur.

NOTE: Dersom ovnen ikke tænder efter flere

forsøg, bør man sende bud efter en autoriseret installatør.

Tem p. Opskrift Temp

PROGRAMMERING

1. Tryk på PROG ---tasten (3).

2. Når CODE kommer frem på skærmen, indtastes 1111 med opskrifttasterne. Tryk så på

PROG---tasten igen (3).

3. Tryk nu på den pågældende opskrifttast; så

viser skærmen TE# (bogstaverne TE efterfulgt af et ciffer) og den nugældende temperatur. Den nye bagetemperatur indsættes med

opskrifttasterne, og tryk til sidst på PROG--tasten igen (3).

4. Nu viser s kærmen TI# og den nugældende

bagetid for en pande. Man indsætter så den

nye bagetid med opskrifttasterne og trykker til

sidst på PROG---tasten igen (3).

5. Gentag trin 4 for op til tre pander. Skærmen

viser PROG.

6. Man afslutter programmering ved tryk på

PROG---tasten (3).

Slukning

1. OFF (Sluk) p å E L --- K O N TA K TE N (1 ) .

38

Page 42

Betjening

Model KCO-25E med Trinløs Temperaturindstilling

31 2

6

BETJENING

NOTE: Ovne må kun betjenes af kvalificeret per-

sonale.

1. ON (Tænd) på E L --- K O N TA K T E N ( 3 ) .

2. Sæt THERMOSTAT (TERMOSTATEN) (1) på

den ønskede temperatur. Ovnen er nået op

på den indstillede temperatur, når indikatoren

LIGHT OFF OVEN READY, 2 (FORVARMNING) går ud.

NOTE: Dersom ovnen ikke tænder efter flere

forsøg, bør man sende bud efter en autoriseret installatør.

Tidsindstilling (8 programmer)

1. Rul hen på det ønskede program med tasterne PIL OP (UP) og PIL NED (DOWN) (5).

2. Programmetstartes ved at man trykker på tasten START/STOP (6).

Slukning

1. OFF (Sluk) p å E L --- K O N TA K TE N (1 ) .

4 5

Figure 19

PROGRAMMERING AF TIDSINDSTILLING

1. Tryk på tasten TIMER PROGRAM, og hold den

inde (4).

2. Rul til den ønskede bagetid med pil OP og pil

NED--- tasterne (5).

3. Man afslutter programmering ved at trykke på

tasten TIMER PROGRAM (4).

39

Page 43

Vedligeholdelse

Rengøring

ADVARSEL!:

Ovnen MÅ IKKE spules med vand.

DAGLIGT

1. Gennemvæd en klud i let olie. Tør ovnen af

udenpå, mens den er kold, og tør den efter

med en ren k lud.

2. Gørrustfri stålflader rene med et ugiftigt indus trirengøringsmiddel til rustfrit stål. Påfør altid

rengøringsmidlet, når ovnen er kold, og skur

i flugt med granuleringen i metallet.

3. Rengørporcelænsfladerne indeni med et ugiftigt industrirengøringsmiddel til porcelæn.

UGENTLIGT

1. Tag pladerne og pladeholderne ud, og læg

dem i blød i ammoniakvand.

ÅRLIGT

Alle ovne:

1. Efterse alle elektriske forbindelser.

2. Afmontér blæserhjulet (jf. illustration), og læg

det i blød i ammoniakvand.

Gasovne:

1. Gå aftrækssystemet efter for tæring, der kan

forårsages af fugt og forbrændingsprodukter.

2. Kontrollér og justér gastryksindstillingen.

Blæserhjulsdæksel

Blæserhjul

Model DFG-100-3 er afbilledet

Figure 20

40

Page 44

Vedligeholdelse

Udskiftning af Dele

EL-DELE

1. Sluk på hovedafbryderen til ovnen.

2. Tag delene af panelet, og sæt ledningerne til

side.

3. Geninstallér delene.

GASKONTROLVENTILEN

NOTE: Gælder kun gasovne.

1. Luk for gassen, og sluk el--- hovedafbryderen

til ovnen.

2. Tag el-forbindelsen af.

3. Afmontér samlingerne på hver side af gaskontrolventilen.

4. Afmontér røret til vågekonen, forny, geninstallér og justér. Efterse for gaslæk.

AFMONTERING AF BRÆNDER

NOTE: Gælder kun gasovne.

1. Luk for gassen, og sluk el-hovedafbryderen til

ovnen.

2. Tag brænderdækslet af, jf. illustration.

3. Adskil gasledningen osv.

4. Tag skruerne ud af brænderholderbeslaget.

5. Tag brænderen ud af brænderk ammeret.

6. Forny vågekonen, dersom tiltrængt. Installér

brænderen.

KONTROLDÅSEKOMPONENTER

1. Sluk for strømmen.

2. Tag brænderdækslet af.

3. Tag kontroldåsedækslet af.

4. Skyd kontroldåsepanelet ud.

5. Forny eller reparér komponenterne, som

tiltrængt.

6. Genmontér panelet, kontroldåsedækslet og

brænderdækslet.

Brænderdæksel

Kontroldåsedæksel

Model DFG -100-3 afbildet

Figure 21

41

Page 45

Installatie-en Gebruikshandleiding

voor Gas en Elektrische Convectieovens

Exportserie

42

Page 46

Installatie

Aflevering en Plaatsing

AFLEVERING EN INSPECTIE

Alle Blodgett ovens worden in containers verzondenomschadetevoorkomen.Bijafleveringvan

uw nieuwe oven gaat u als volgt te werk:

D

Inspecteer de verzendingscontainer op externe

schade. Vermeld eventuele schade op het

afleveringsbewijs dat door de chauffeur ondertekend moet worden.

D

Haal de oven uit de verpakking. Inspecteer de

oven op schade binnenin. Expediteurs aanvaarden s chadeclaims voor verborgen schade

indien ze binnen vijftien dagen na aflevering op

de hoogte worden gesteld en de verzendingscontainer voor inspectie wordt bewaard.

Blodgett is niet aansprakelijk voor verlies of

schade die tijdens het vervoer is ontstaan.

Wanneer de expediteur de verzending accepteert, aanvaardt hij de volle verantwoordelijkheid voor het af leveren van het product in

goede staat. Wij zijn echter wel bereid u te helpen als hetnoodzakelijkblijkt een schadeclaim

in te dienen.

PLAATSING VAN OVEN

Door de plaatsing van de oven vooraf te plannen

en goed uit te voeren, zal de oven lang meegaan

en veel voldoening schenken.

D

Plaats de oven tenminste 15,2 cm bij de achterwand en de zijwand vandaan.

D

Plaats de oven in een goed geventileerde

ruimte.

D

Plaats de oven onder een afzuigkap volgens de

plaatselijk en landelijk geldende installatienormen.

D

Plaats de oven zodanig dat u bij de stekker

kunt.

D

Installeer de oven op een plaats waar geen

tocht is.

D

Houd de omgeving van de oven vrij van brandbare stoffen zoals papier, karton en ontvlambarevloeistoffenenoplosmiddelen.

D

Plaats de oven niet op een gewelfde vloerlijsten

bevestig hem niet permanent aan de wa nd.

Hierdoor wordt de luchtstroom beperkt en de

vereiste ventilatie belemmerd.

D

Bij de plaatsing van gasmodellen moet voldoende ruimte worden gelaten voor de luchtopening naar de verbrandingskamer.

Voordat de oven op de nutsleidingen worden aangesloten moet het plaatje met de nominale w aarden worden geraadpleegd om zeker te stellen dat

deze waarden overeenstemmen met de gas--- (in dien van toepassing) en stroomvoorzieningen die

voor de oven beschikbaar zijn.

43

Page 47

Installatie

Assemblage van Oven

NOTE: Het toestel moet worden geïnstalleerd

conform de plaatselijke voorschriften en

mag alleen worden gebruikt in een goed

geventileerde ruimte.

NOTE: De installatie mag alleen door een be-

voegde installateur worden uitgevoerd.

BEVESTIGING VAN POTEN

Poten van 10 cm

1. Legdeovenopzijnachterkant.

2. Schroef de poten in de gaten in de hoeken van

de oven. Draai de zeskantmoeraan de bovenkant van elke poot vast.

3. Kantel de oven op zijn poten.

4. Stel de afstelbare voetdoppen op het juiste niveau voor de oven in.

Potenvan15cm,18cmen64cm

1. Legdeovenopzijnachterkant.

2. Leg de bout met schroefdraad van elke poot

op één lijn met de moer die in elke hoek aan

de onderkant zit. Draai de poten naar rechts

om ze vast te zetten.

3. Leg de gaten in elke pootplaat op één lijn met

de gaten in het ovenframe. Bevestig elke poot

met twee 1/2” bouten.

NOTE: Raadpleeg de installatie van de

zwenkwielen, indien van toepassing.

4. Kantel de oven op zijn poten.

5. Stel de afstelbare pootdoppen (of zwenkwielen) bij om de oven waterpas te maken.

Figure 1

Afstelbare poten van 15 cm

Figure 2

44

Page 48

Installatie

Assemblage van Oven

BEVESTIGING AAN VOETSTUK

1. Zet de oven op het voetstuk. Centreer het

t.o.v. het frame.

2. Verwijderhetrechterzijpaneelvandeoven.

3. Legde gaten in de onderkant van oven op één

lijnmetdegateninhetvoetstuk.

4. Bevestig de oven aan het voetstuk met bouten, sluitringen en moeren, zoals afgebeeld.

5. Breng het zijpaneel weer aan.

AANBRENGEN VAN ZWENKWIELEN

NOTE: Installeer de blokkeerbare zwenkwielen

aan de voorkant. Installeer de andere

zwenkwielen aan de achterkant.

Zwenkwielen voor enkele en dubbele stapelovens

1. Bevestig de poten.

2. Maak de borgmoer los op elke afstelbare

pootdop. Verwijder de doppen.

3. Steek een zwenkwiel in elke poot zoals afge beeld. Draai de borgmoeren vast om de

zwenkwielen vast te zetten.

Afstelbare

pootdop

Zwenkwiel

Afgebeeld zijn poten van 64 cm

Figure 3

Figure 4

Zwenkwielen met laag profiel voor dubbele stapelovens

1. Leg de drie gaten in elke zwenkwielplaat op

één lijn met de gaten in de onderkant van de

oven. Maak elk wiel vast met drie 1/2” bouten.

Figure 5

45

Page 49

Installatie

Assemblage van Oven

ASSEMBLAGE DUBBELE UITVOERING

NOTE: Vergeet niet de afvoerkasten van de en-

kele oven te verwijderen voordat u het afvoerkoppelstuk bevestigd.

AC-500, DFG-100/200, CTB, Mark V en

Zephaire E&G

1. Bevestig de korte poten aan de onderste gedeelten.

2. Stapel de ovens op elkaar.

3. Plaats de klemmen over de rand van de ovenframes.

4. Bout de klemmen aan elkaar vast met de bijgeleverde3/8”boutenenmoeren.

5. Bevestig het afvoerkoppelstuk.

Stapelklemmen

3. Leg de gaten in de voor--- en achterhoeken

van de ovens op één lijn.

4. Bevestig de ovens met bouten, sluitringen en

moeren zoals afgebeeld.

5. Breng het deksel van de verbrandingskamer

en het zijpaneel weer aan.

Figure 7

KCO-25E

1. Bevestig de korte poten aan de onderste gedeelten.

2. Stapel de ovens op elkaar.

3. Verwijder de onderste linker en rechter

schroeven uit het bovenste gedeelte. Verwijder de bovenste linker en rechter schroeven

uit het onderste gedeelte.

4. Bevestig de twee stapelhoekstukken gebruik

de verwijderde s chroeven.

5. Bevestig het afvoerkoppelstuk.

Afvoerkoppelstuk

Figure 6

DFG-50

1. Stapel de ovens op elkaar.

2. Verwijder het deksel van de verbrandingskamer en het zijpaneel.

Stapelhoekstuk

Figure 8

46

Page 50

Installatie

Assemblage van Oven

VEILIGHEIDSKABEL VAN GASSLANG

(gasmodellen)

Als de oven op zwenkwielen is gemonteerd moet

naast een snelkoppeling een commerciële, flexibele veiligheidsverbinding met een minimum binnendiameter van 1,9 cm worden gebruikt.

1. Monteer de bijgeleverde beugel op de poot-

bout net onder de gasinlaat.

2. Bevestig de klem op de veiligheidskabel aan

de montagebeugel.

Achterkant van oven

Beugel voor

veiligheidskabel

Afgebeeld is een dubbele stapeloven

Figure 9

VENTILATIE (gasmodellen)

Een mechanisch aangedreven afzuigkap van het

luifel type is vereist. De kap moet de oven volledig

bedekken en aan alle zijden die niet aan een wand

grenzen minstens 15 cm overhangen. De afstand

van de vloer tot de onderste rand van de kap mag

niet meer zijn dan 2,1 m.

WAARSCHUWING:

Een slecht geventileerde oven kan ge-

vaarlijk zijn voor de gezondheid van de

gebruiker en kan ook leiden tot problemen met de werking van de oven, slechte

bakresultaten en mogelijk schade aan de

uitrusting.

Schade die rechtstreeks voo rtvloeit uit

slechte ventilatie wordt niet door de garantie van de fabrikant gedekt.

Ovens die besteld zijn met ontluchting via een afzuigkap worden met een tochtomleider geleverd.

Installeer de tochtomleider als volgt:

1. Plaats de omleider over het afvoerkoppelstuk

met de open kant naar de voorkant van de

oven gericht.

2. Bevestig de omleider met de bijgeleverde

plaatschroeven.

47

Tocht o m l eid e r

Voorkant

van oven

Oven op volle grootte afgebeeld

Figure 10

Page 51

Installatie

Het aansluiten van de voor zieningen

GASAANSLUITING (indien van toepassing)

Sluit de oven op een gasleiding met de juiste soort

gas aan overeenkomstig de plaatselijke en landelijke installatienormen (zie typeplaat).

Het instellen van de apparatuur op andere

soorten gas

1. Sluitde gasklep af en draai de bedieningschakelaar uit.

2. Demonteer het gasblok door middel van de

koppelingen.

3. Demonteer de brander en vervang de inspuiters.

4. Installeer de brander en het gasblok.

5. Controleer op lekkage en mogelijke losse

elektrische verbindingen.

6. Stel de branderdruk zonodig af, zie afbeelding.

Afstelling Drukmeetnippel

HET INSTALLER EN VAN DE INLAATDRUKAFSLUITER

NOTE: Uitsluitend Zephaire-G/DFG-50 units.

Raadpleeg de afbeelding voor de plaats

van de drukafsluiter.

1. Verwijderde blauwe pijpdop van de gasinlaatpijp.

2. Breng draadafdichting aan op de mannelijke

pijpdraad.

3. Draai de inlaatdrukafsluiter op de gaspijp en

maak hem goed vast.

4. Controleer op lekkage.

Gasaansluiting

Drukmeetnippel

DFG-50 DFG-100/Zephaire-G AC-500

Verdeelstuk

Drukmeetnippel

Figure 11

48

Achterkant van oven - alle eenheden

Drukmeetnippel

Verdeelstuk

Page 52

Installatie

G20/G2520/25Volledigingesch

2,10182x0,3816Aardgas

G20/G2520/25Volledigingesch

2,1092x0.388Aardgas

G20/G2520/25Volledigingesch

2,10182x0.3817,6Aardgas

G20/G2520/25Volledigingesch

1,751620,5Aardgas

Het aansluiten van de voor zieningen

Soort

Gas

DFG-100-3

G25 25 12 2,60 18 2 x 0,38 16 Aardgas

G20 20 8 2,60 18 2 x 0,38 16 Aardgas

G20/G25 20/25 Volledig ingesch- 2,10 18 2 x 0,38 16 Aardgas

G30 30/50 17 1,60 10 2 x 0,20 16 Butaan

G31 30/37/50 24 1,60 10 2 x 0,20 16 Propaan

DFG-50

G25 25 12 2,50 9 2 x 0.38 8 Aardgas

G20 20 8 2,50 9 2 x 0.38 8 Aardgas

G20/G25 20/25 Volledig ingesch- 2,10 9 2 x 0.38 8 Aardgas

G30 30/50 17 1,60 9 2 x 0,20 8 Butaan

G31 30/37/50 24 1,60 9 2 x 0,20 8 Propaan

Zephaire-G-L

G25 25 12 2,70 18 2 x 0.38 17,6 Aardgas

G20 20 8 2,70 18 2 x 0.38 17,6 Aardgas

G20/G25 20/25 Volledig ingesch- 2,10 18 2 x 0.38 17,6 Aardgas

Inlaatdruk

mbar

Branderdruk

mbar

roefde drukregelaar

roefde drukregelaar

roefde drukregelaar

Diameter

inspuiter

mm

Luchto-

pening

mm

Waakvla-

minspuiter

mm

Standaard

Toevoerwaarde

kW (H

)

i

G30 30/50 17 1,60 10 2 x 0,20 17,6 Butaan

G31 30/37/50 24 1,60 10 2 x 0,20 17,6 Propaan

AC-500

G25 25 12 2,10 16 --- 20,5 Aardgas

G20 20 8 2,10 16 --- 20,5 Aardgas

G20/G25 20/25 Volledig ingesch- 1,75 16 --- 20,5 Aardgas

roefde drukregelaar

G30 30/50 17 1,32 16 --- 20,5 Butaa n

G31 30/37/50 24 1,32 16 --- 20,5 Propaan

49

Page 53

Installatie

k

q

Het aansluiten van de voor zieningen

ELEKTRISCHE AANSLUITING

NOTE: De elektrische aansluiting mag alleen

door een bevoegde installateur worden

uitgevoerd.

NOTE: De elektrische aansluiting dient te geschie-

den volgens NEN 1010 en de plaatselijk geldende voorschriften.

Er is een snoerontlasting vereist voor het netsnoer.

De installateur moet een netsnoerdoorvoer leveren die voldoet aan alle plaatselijke en landelijke

installatienormen.

Voor gasovens:

NOTE: Gasmodellen hebben een fasegevoelige

regeleenheid voor de brander. Als de fase

en de nulleider worden verwisseld, blokkeert de regeleenheid.

Sluit fase + neutraal + aarde aan.

Frequentie

W/sectie Spanning Fase

CTB/CTBR

5,6 400 3N 50 9 8 8 1

8,0 400 3N 50 13 11 11 2

(Hz)

Voor elektrische modellen:

Sluit de oven aan op een afzonderlijke groep met

een vaste aansluiting en stroomonderbreker. De

stroomonderbreker moet alle polen, inclusief de

nulleider, met tenminste 3 mm tussen de contacten onderbreken.

Voor 1---fase --- sluit fase + neutraal + aarde aan.

Vo o r 3 --- f a s e --- s lu it L1 + L 2 + L3 + neu t r a a l +

aarde aan.

HET EERSTE OPSTARTEN

1. Stelde THERMOSTAT(THERMOSTAAT) in op

260_C en laat de oven 2 uur werken alvorens

het produkt erin te zetten. Deze procedure

produceert rook.

2. Reinig de oven na het eerste inbrandproces.

Raadpleeg pagina 60 voor de juiste reinigingsaanwijzingen.

Maximale Belasting

L1 L2 L3 N

KCO-25E

3,0 230 1N 50 13 --- --- 13

Mark V-III

11,0 400 3N 50 18 15 15 3

Zephaire-E

11,0 400 3N 50 18 15 15 3

DFG-100-3

0,7 230 1N 50 3 --- --- 3

DFG-50

0,7 230 1N 50 3 --- --- 3

Zephaire-G-L

0,7 230 1N 50 3 --- --- 3

AC-500

1,3 230 1N 50 6 --- --- 6

50

Page 54

2

3

Alleen bij

gasovens

4

5

Bediening

Elektromagnetische Bedieningen

BEDRIJF

NOTE: Bediening mag alleen geschieden door

1

1. Draai de gasklep open. (Alleen bij gasovens.)

2. Doedeovendeurdicht.

3. Draai de KEUZE---schakelaar (1) naar de ge-

4. Stel de THERMOSTAT (THERMOSTAAT) (5)

NOTE: Als de oven na een paar keer proberen

bevoegd personeel.

wenste bakstand.

De ventilator begint te draaien en de tempera-

tuurregelaar gaat aan.

op de gewenste temperatuur in.

De brander ontsteekt of de elementen gaan

aan. Het lampje LIGHT OFF OVEN READY

(LICHT UIT OVEN KLAAR) (4) op het bedieningspaneel wordt verlicht.

Als bij het starten van een gasoven, de brander niet binnen een paar seconden ontsteekt,

gaat het waarschuwingslampje RESET (2)

aan. Druk op de RESET---schakelaar (3) om

de brander opnieuw te starten.

Het lampje LIGHT OFF OVEN READY (LICHT

UIT OVEN KLAAR) (4) gaat uit wanneer de

oven op temperatuur is gekomen.

nog niet start, moet u contact opnemen

met een bevoegde installateur.

Voor de HUMIDAIRE--bedieningsoptie:

1. Wanneer er stoom gewenst wordt, stelt u de

6

7

8

Figure 12

51

STEAM CYCLE TIMER (STOOMCYCLUSTIJDKLOK) (8) in op de vereiste inspuittijd.

2. Druk kortstondig op de STEAM CYCLE

START (STOOMCYCLUSSTART)---knop (7)

en laat deze los. De STEAM (STOOM)---indicator (6) gaat aan terwijl er water in het bakcompartiment wordt gespoten.

Afkoelen

1. De ovendeur openen.