Page 1

Since 1848

INSTALLATION INSTRUCTIONS FOR

AB2A VENTILATION SYSTEM

FOR BLODGETT DOUBLE DECK MT3870

COMPUTERIZED CONVEYOR OVEN

LISTED

BLODGETT OVEN COMPANY

A Division of

G. S. BLODGETT CORPORATION

50 Lakeside Avenue, Box 586, Burlington, Vermont 05402 USA Telephone (800) 3315842, (802) 8603700 Fax: (802)8640183

PN M9519 (3/98)

1998 - G.S. Blodgett Corporation

Page 2

TABLE OF CONTENTS

Delivery and Inspection Page 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Page 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning and Maintenance Page 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Servicing Page 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air Flow Measurement Page 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AGENCY APPROVALS

The InVent Hood Systems are Listed by Underwriters Laboratories Inc. (UL) in category YYCW as Exhaust Hoods Without

Exhaust Dampers. They are intended to be installed in accordance with NFPA 96, the Standard for Ventilation Control and

Fire Protection of Commercial Cooking Operations. The basic Standard used by UL to investigate products in this category

is UL 710, the Standard for Exhaust Hoods for Commercial Cooking Equipment.

These hoods are considered to be Type 1 according to the International Mechanical Code (IMC); that is, they are, installed

at or above all commercial food heatprocessing equipment that produces grease vapors or smoke." IMC is published by

the International Code Council, Inc. and is compatible with codes written by the Building Officials and Code Administrators

International, Inc., (BOCA), the International Conference of Building Officials (ICBO), and Southern Building Code Congress

International, Inc. (SBCCI). The Uniform Mechanical Code (UMC) published by ICBO defines a Type I Hood as, a kitchen

hood for collecting and removing grease and smoke." A Type II Hood is a general hood for collecting and removing steam,

vapor, heat or odors." The hood type is determined by the intended use. UL tested and approved the InVents for use in the

Type I environment.

These Hoods are NSF approved to ANSI/NSF21992, Food Equipment

corrosion resistant. Furthermore, that there be no sharp corners or open seams where food, residue or soil collect.

Page 1

. ANSI/NSF21992 requires that all materials used be

Page 3

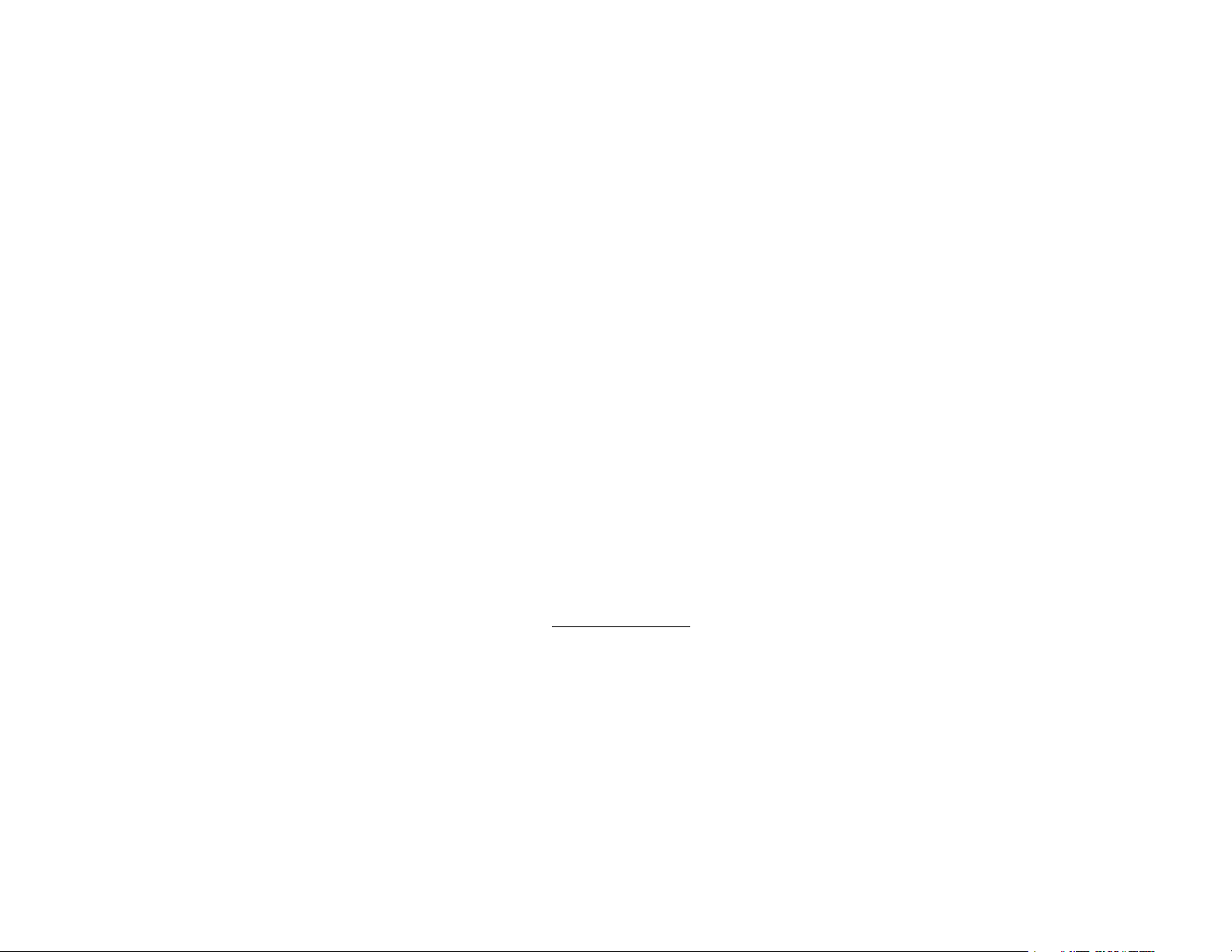

DELIVERY AND INSPECTION

Upon arrival of your AB2A ventilator, inspect the crate for damage and inform the shipper if necessary. Carefully unpack the

unit and match the parts to the list below.

Item Blodgett P/N Qty Description

A AB2AA 1 AMU/Exhaust Manifold

A1 AB2AA1 1 AMU Duct Extension

A2 AB2AA2 1 Exhaust Duct Extension

A3 AB2AA3 1 Top Exhaust Enclosure Bracket, Left

A4 AB2AA4 2 Exhaust Duct Ceiling Trim

A5 AB2AA5 2 AMU Duct Ceiling Trim

B AB2AB 1 AMU Support Bracket, Right

C AB2AC 1 AMU Support Bracket, Left

D AB2AD 1 Lower Front AMU Plenum

E AB2AE 1 Middle Front AMU Plenum

F AB2AF 1 Upper Front AMU Plenum

G AB2AG 2 Filter Trough/Receptacle

H1 M9500 2 Filter,10x16"

H2 M9501 2 Filter, 10 x 20"

J AB2AJ 1 Vertical Exhaust Manifold, Left

K AB2AK 1 Cooling Fan Exhaust Enclosure

L AB2AL 1 Upper Top End Enclosure, Right

L1 AB2AL1 1 Lower Top End Enclosure, Right

L2 AB2AL2 1 Upper Heat Sheild, Right

M AB2AM 1 Lower End Enlosure, Right

M1 AB2AM1 1 Lower Heat Shield, Right

N AB2AN 1 Upper Top End Enclosure, Left

N1 AB2AN1 1 Lower Top End Enclosure, Left

N2 AB2AN2 1 Upper Heat Shield, Left

P AB2AP 1 Lower End Enclosure, Left

P1 AB2AP1 1 Lower Heat Shield, Left

Q AB2AQ 1 Hardware Bag (includes the following)

Q1 M9519 1 Installation Instructions

Q2 M0652 4 1/4"20 Lock Nut

Q3 M0222 8 1/4"20 x 1/2" Hex Head Screw

Q4 R1417 1 1/4"20 Shoulder Bolt

Page 2

Page 4

Item Blodgett P/N Qty Description

Q5 M9509 1 1/4"20 x 1/2" Thumb Screw with Shoulder Washer

Q6 M3828 2 Stacking Pins

Q7 653 12 1/4" Flat Washer

Q8 M6315 3 #1024 x 1/2" Slotted Hex Head Screw

R AB2AR 3 Oven Securing Clip

S AB2AS 1 Mounting Bracket (Rev. A)

S1 AB2AS1 1 Mounting Bracket (Rev. B)

T AB2AT 1 Vertical Exhaust Manifold, Right

[G]

[P1]

[A4]

[A5]

[A3]

[N1]

[N2]

[A2]

[P]

[A]

[N]

[J]

[A1]

[C]

[S1]

[S]

[K]

[M]

[F]

[D]

[L2]

[L]

[L1]

[M1]

[E]

[T]

[H1]

[B]

[H2]

Figure 1

Page 3

Page 5

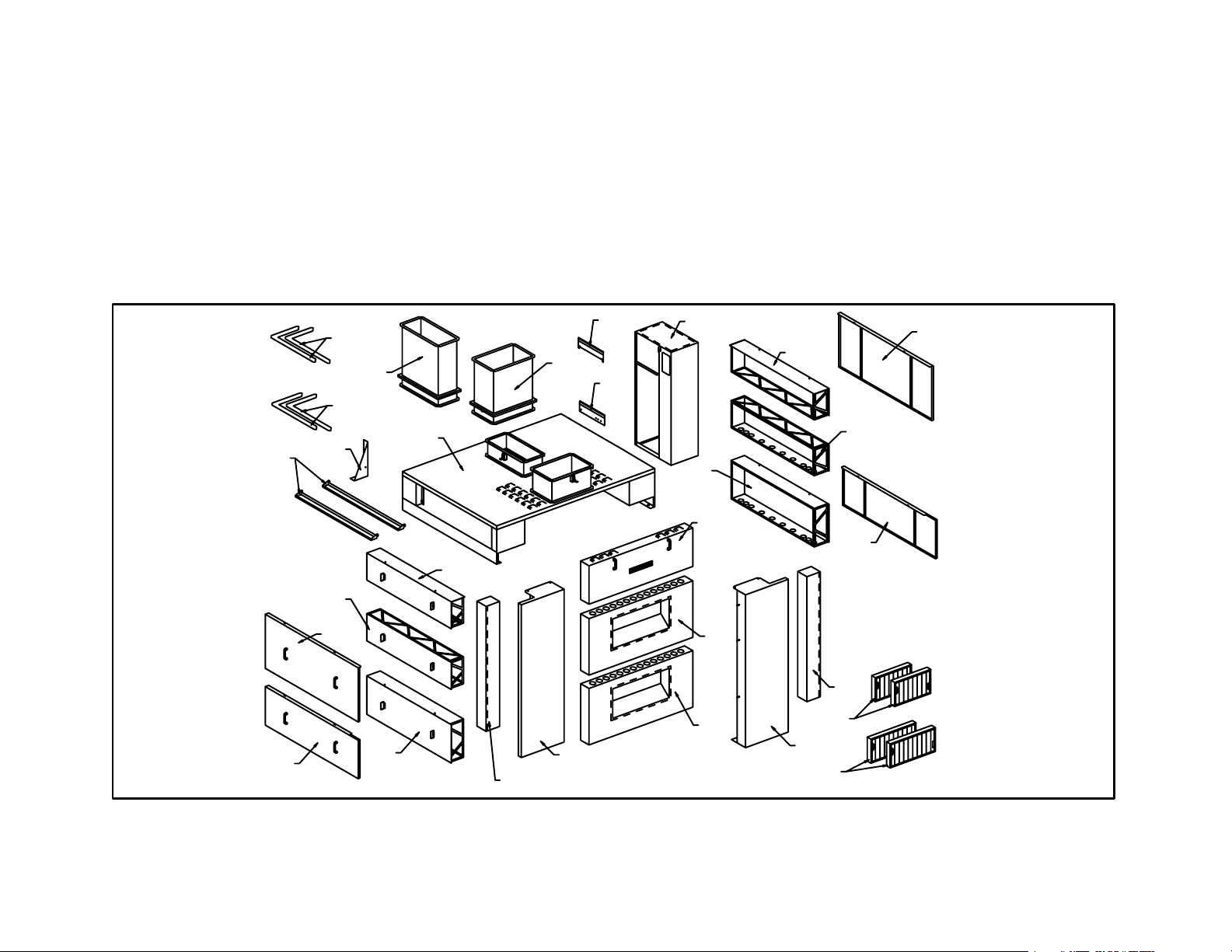

INSTALLATION

Step 1 - Oven Preparation

Assemble both ovens as described in

the Blodgett MT3870 OwnerOperator

Manual.

Use the three (3) Oven Securing Clips

[R] to secure the two decks together

and prevent shifting. (See Figure 2)

[R]

[R]

[R]

Page 4

Figure 2

Page 6

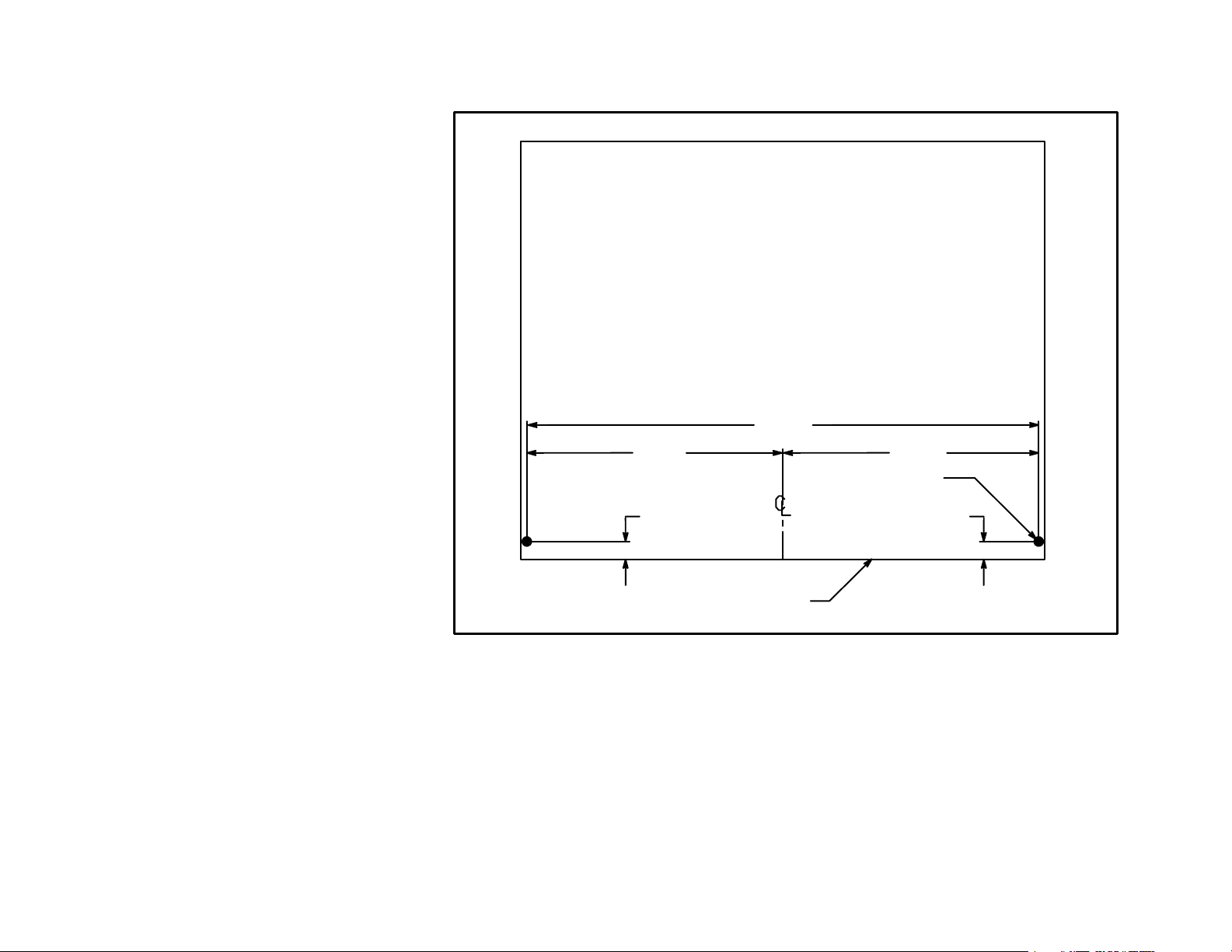

If the ovens are equipped with align

ment knockouts, remove the two (2)

front indents. Those holes should

match the two (2) shown in Figure 3.

If the ovens are not equipped with align

ment indents, locate the center, front,

top edge of the upper oven. Drill two (2)

7/16" diameter holes in the top of the

oven as indicated in Figure 3. The holes

should penetrate both the top skin" of

the oven as well as the angle frame

members. There is no need to penetrate

the top of the oven by more than 7/8".

68 1/2

34 1/4 34 1/4

7/16 (2 PLS)

2 7/162 7/16

Page 5

FRONT OF OVEN

Figure 3

Page 7

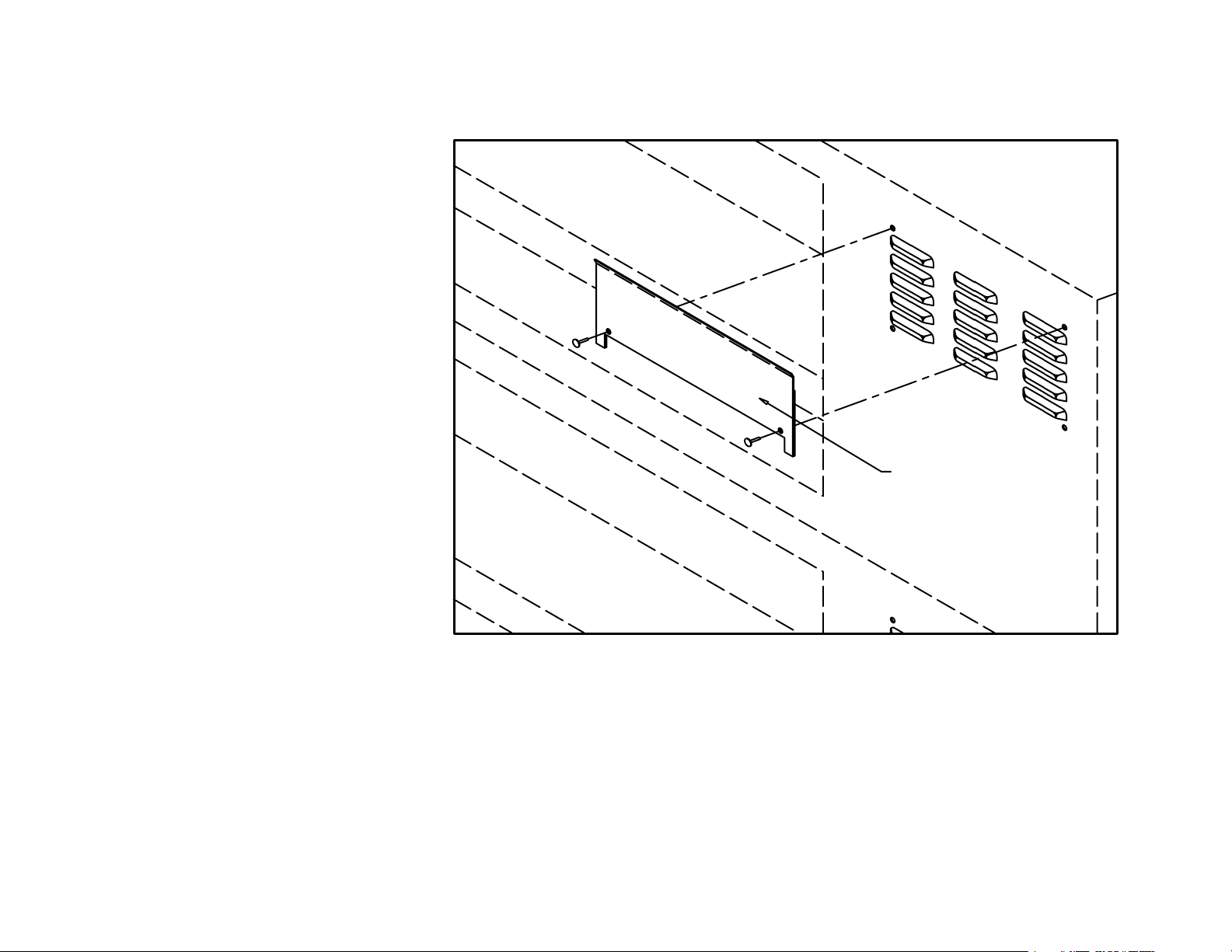

If the ovens are equipped with louvered

cooling fan exhaust outlets, attach the

Cooling Fan Exhaust Enclosure Mount

ing Plate [S1] to the top oven using two

#1024x1/2" screws [Q8] provided. See

Figure 4. For older oven models use the

alternate Cooling Fan Exhaust Enclo

sure Mounting Plate [S].

[S1]

Page 6

Figure 4

Page 8

Step 2 - AMU Installation:

Thread two (2) Stacking Pins [Q6] into

the fittings on the bottom of the AMU/Ex

haust Manifold/Duct Connection as

sembly [A]. Carefully lift the AMU/Ex

haust Manifold/Duct Connection as

sembly [A] and place it on top of the

ovens. The alignment pins will fit into the

alignment holes in the top of the oven

and prevent the AMU/Exhaust Manifold/

Duct Connection assembly [A] from

shifting on top of the oven. (See

Figure 5)

If the AMU/Exhaust Manifold/Duct Con

nection assembly [A] does seat tightly

against the top of the oven, apply a bead

of high temperature silicone sealant in

the seam between the AMU/Exhaust

Manifold/Duct Connection assembly

[A] and the sides of the oven.

[A]

[Q6]

Silicone

Sealant

Alignment Hole

Page 7

Figure 5

Page 9

Attach the AMU Support Bracket, Right

[B] to the AMU/Exhaust Manifold/Duct

Connection assembly [A] using two (2)

1/4"20 x 1/2" Hex Head Cap Screws

[Q3] and 1/4" Flat Washers [Q7]. (See

Figure 6)

Attach the AMU Support Bracket, Left

[C] to the AMU/Exhaust Manifold/Duct

Connection [A] assembly using two (2)

1/4"20 x 1/2" Hex Head Cap Screws

[Q3] and 1/4" Flat Washers [Q7]. (See

Figure 6)

[Q3] (4)

[Q7] (4)

[B]

[C]

Page 8

Figure 6

Page 10

Secure the AMU Support Bracket, Right

[B] below the right front support leg

mounting flange. (See Figure 7) Use the

same inner, front bolt and washer that

secures the leg in place to hold the AMU

Support Bracket, Right [B].

Secure the AMU Support Bracket, Left

[C] below the left front support leg

mounting flange. (See Figure 7) Use the

same inner, front bolt and washer that

secures the leg in place to hold the AMU

Support Bracket, Left [C].

The AMU Support Bracket, Right [B]

and AMU Support Bracket, Left [C]

should be parallel and square and held

firmly against the front of the ovens.

[B]

Page 9

Figure 7

Page 11

Place the Lower Front AMU Panel [D] on

the lower pins of the AMU Support

Bracket, Right [B] and AMU Support

Bracket, Left [C]. (See Figure 8)

Place the Middle Front AMU Panel [E] in

the middle pins of the AMU Support

Bracket, Right [C] and AMU Support

Bracket, Left [D].

[B]

Place the Upper Front AMU Panel [F] in

the upper pins of the AMU Support

Bracket, Right [C] and AMU Support

Bracket, Left [D].

[E]

[F]

[D]

[C]

Figure 8

Page 10

Page 12

Step 3 - Exhaust Installation:

Attach the Vertical Exhaust Manifold,

Right [T] to the AMU Support Bracket,

Right [B] with two (2) 1/4"20 x 1/2"

Thumb Screws [Q5]. (See Figure 9)

Attach the Vertical Exhaust Manifold,

Left [J] to the AMU Support Bracket, Left

[C] with two (2) 1/4"20 x 1/2" Thumb

Screws [Q5]. (See Figure 9)

[A]

[Q5]

[J]

[Q5]

[T]

[K]

Page 11

Figure 9

Page 13

Attach the Cooling Fan Exhaust Enclo

sure [K] to the AMU/Exhaust Manifold/

Duct Connection [A].

Flange

Ta b

[K]

On ovens with louvered exhaust ports,

remove the tab from the Cooling Fan Ex

haust Enclosure [K] and replace the fas

teners into the holes. The Cooling Fan

Exhaust Enclosure [K] will be held in

place by the Cooling Fan Exhaust En

closure Mounting Plate [S or S1].

For ovens that have separate cooling

fans and grills on the right side (oppo

site the control cabinets), a tab on the

Cooling Fan Exhaust Enclosure [K] will

fit over the rivet in the AMU/Exhaust Man

ifold/Duct Connection [A]. (See

Figure 10) The flange on the Cooling

Fan Exhaust Enclosure [K] should rest

on top of the oven before the rivet bot

toms out in the slot of the flange.

[S or S1]

Oven

[A]

Rivet

Page 12

Figure 10

Page 14

Caution: The hole location described below should not interfere with any oven control center components. Care must

be taken when locating and drilling this hole to avoid damage to internal components.

Drill one (1) 1/4" diameter hole into the

upper control cabinet as shown in

Figure 11. The distance from the top of

the upper oven to the center line of the

hole should be the same as the distance

from the top of the upper oven to the

center line of the pin welded in the sur

face of the Vertical Exhaust Manifold,

Left [J].

Insert one (1) 1/4"-20 Shoulder Bolt

[Q4] through the hole and secure it in

place with one (1) 1/4" Flat Washer [Q7]

and one (1) 1/4"-20 Lock Nut [Q2].

1

15 9/16

Shoulder Bolt [Q5]

Page 13

FRONT VIEW

Figure 11

Page 15

Locate the Bracket, Top Exhaust Enclo

sure, Left Hand [A3] at the junction of

the AMU/Exhaust Manifold, Duct As

sembly [A] and the forward, inboard

edge of the upper oven control cabinet.

(See Figure 12). The forward edge of

the Bracket, Top Exhaust Enclosure,

Left Hand [A3] should be vertical. There

should be a minimum of 343/16" be

tween the front face of the control cabi

net and the rear face of the Vertical Ex

haust Manifold, Left [J]. If necessary,

loosen the bolts that hold the control

cabinet to the oven and shift the control

cabinet rearward.

Using the Bracket, Top Exhaust Enclo

sure, Left Hand [A3] as a template, draw

marks on the top of the control cabinet.

Drill one (1) 1/4" diameter hole in the

spot marked. Secure the Bracket, Top

Exhaust Enclosure, Left Hand [A3] in

place using 1/4"20 x 1/2" Hex Head

Cap Screws [Q3], 1/4" Flat Washers

[Q7], and 1/4"20 Lock Nuts [Q2] as

shown in Figure 12.

[Q2]

[Q7]

[Q3]

[A3]

Figure 12

Page 14

Page 16

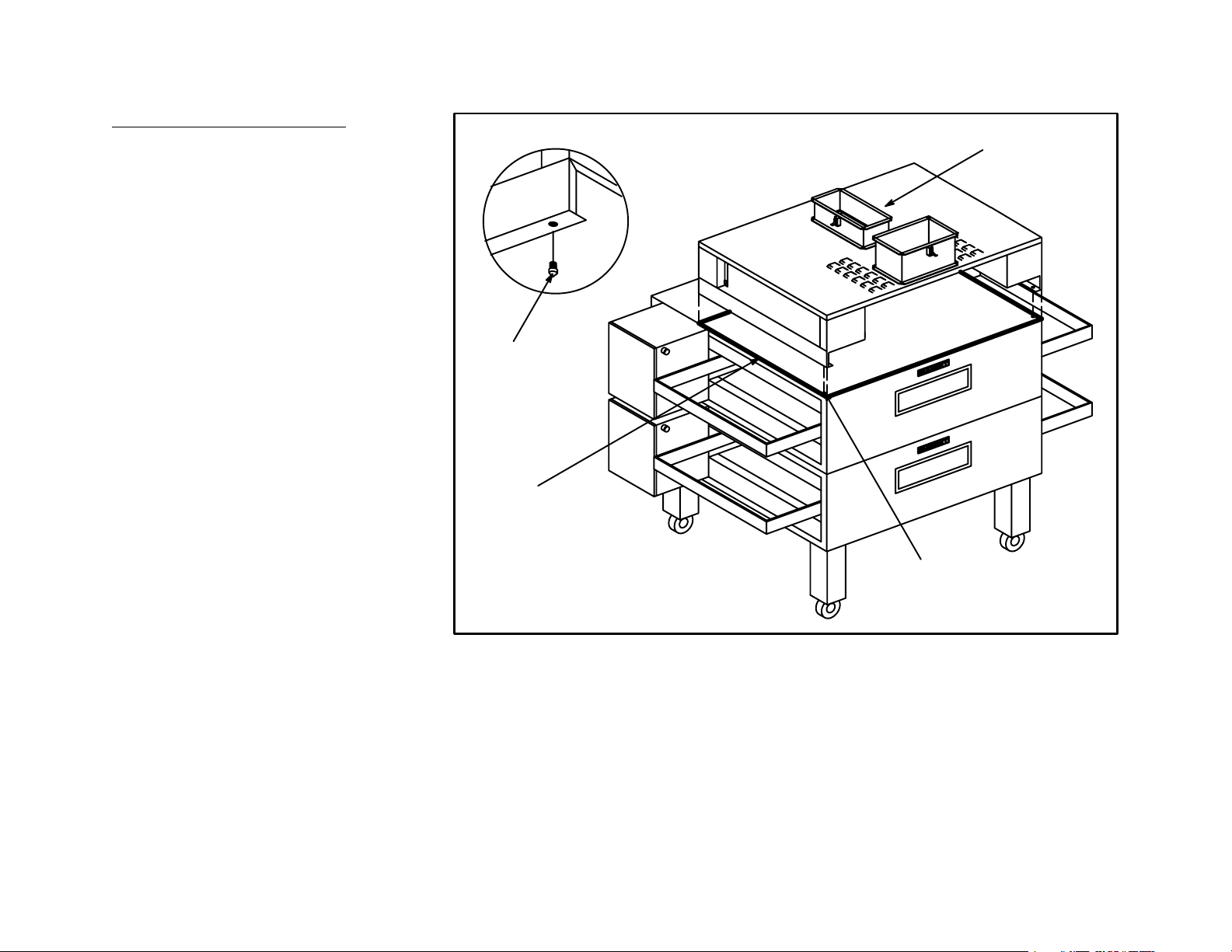

Install one (1) Filter Trough/Receptacle

[G] into the opening in each end of the

AMU/Exhaust Manifold/Duct Connec

tion [A] assembly. The tabs in the Filter

Trough/Receptacle [G] fit into the slots

on the sides of the openings in the AMU/

Exhaust Manifold/Duct Connection [A]

assembly. (See Figure 13)

Insert one (1) 10 x 16" Filter [H1] and

one (1) 10 x 20" Filter [H2] into each end

of the AMU/Exhaust Manifold/Duct Con

nection [A] assembly. Install the top of

the Filter [H1 and H2] into the channel

in the top of the AMU/Exhaust Manifold/

Duct Connection [A] assembly first.

Then allow the bottom of the Filter [H1

and H2] to drop into the Filter Trough/

Receptacle [G].

Repeat the above procedure on the oth

er end of the oven for the remaining Fil

ter Trough/Receptacle [G], one (1) 10 x

16" Filter [H1] and one (1) 10 x 20" Filter

[H2].

[G]

Page 15

Figure 13

Page 17

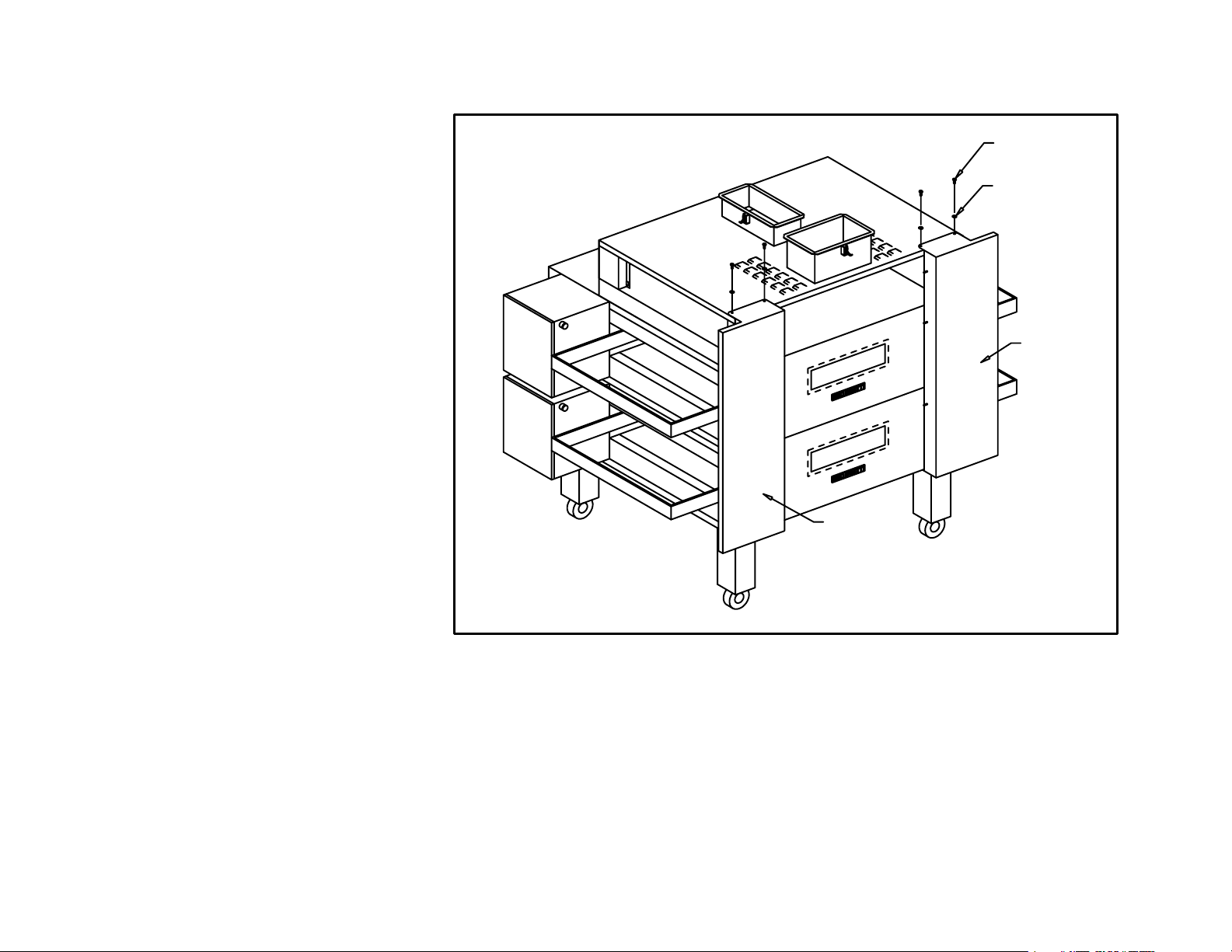

Mount the Lower Top End Enclosure,

Right Hand [L1] in place. The slots on

the sides toward the rear of the Lower

Top End Enclosure, Right Hand [L1] will

fit over the pins in the Cooling Fan Ex

haust Enclosure [K] and the Vertical Ex

haust Manifold, Right Hand [T].

Mount the Upper Top End Enclosure,

Right Hand [L] in place. The angle to the

rear of the Upper Top End Enclosure,

Right Hand [L] will fit into the angle in the

AMU/Exhaust Manifold/Duct Connec

tion [A].

Mount the Lower End Enclosure, Right

Hand [M] in place. The slots on the sides

towards the rear of the Lower End Enclo

sure, Right Hand [M] will fit over the pins

in the Cooling Fan Exhaust Enclosure [K]

and the Vertical Exhaust Manifold, Right

Hand [T]. (See Figure 14)

[A]

[T]

[L1]

[L]

[M]

[K]

Page 16

Figure 14

Page 18

Mount the Upper Right Hand Heat

Shield [L2] in place by locating the slots

over the pins in the Upper Top End En

closure, Right Hand [L].

[L]

Mount the Lower Right Hand Heat Shield

[M1] in place by locating the slots over the

pins in the Lower End Enclosure, Right

Hand [M]. (See Figure 15)

[L1]

[L2]

[M1]

[M]

Figure 15

Page 17

Page 19

Mount the Lower Top End Enclosure,

Left Hand [N1] in place. The slots on the

sides towards the rear of the Lower Top

End Enclosure, Left Hand [N1] will fit

over the pins in the Bracket, Top Ex

haust Enclosure, Left Hand [A3] and the

Vertical Exhaust Manifold, Left Hand [J].

Mount the Upper Top End Enclosure,

Left Hand [N] in place. The angle to the

rear of the Lower End Enclosure, Left

Hand [N] will fit into the angle in the

AMU/Exhaust Manifold/Duct Connection

[A].

[A]

[A3]

[N1]

Mount the Lower End Enclosure, Left

Hand [P] in place. The slots on the sides

towards the rear of the Lower End En

closure, Left Hand [P] will fit over the

Shoulder Bolt [Q5] in the control cabi

net and the pin on the Vertical Exhaust

Manifold, Left Hand [J]. (See Figure 16).

[N]

[P]

[J]

Figure 16

Page 18

Page 20

Mount the Upper Left Hand Heat Shield

[N2] in place by locating the slots over

the pins in the Upper Top End Enclo

sure, Left Hand [N].

Mount the Lower Left Hand Heat Shield

[P1] in place by locating the slots over

the pins in the Lower End Enclosure,

Left Hand [P]. (See Figure 17).

[N]

[N2]

[P1]

Page 19

[P]

Figure 17

Page 21

Step 4 - Duct Connection:

Note: The Duct Collar Extensions [A1 and A2] are designed to remain in place when the oven is rolled away for maintenance

or cleaning. Therefore, they should be rigidly fastened to the ceiling structure as they are not intended to support the

weight of the duct work and/or fans.

Roll the oven into its operating location.

Locate the Exhaust Duct Extension [A2]

on top of the exhaust duct collar (part of

the AMU/Exhaust Manifold/Duct Con

AMU Duct

Exhaust

Duct

nection [A]) and secure it in place with

the two (2) overcenter latches. The ex

haust duct extension is designed to

penetrate an eight foot (8'0") tall ceiling

by approximately two inches (2"). Con

nect the duct from the exhaust fan to the

Finished Ceiling

[A1]

[A]

[A2]

[A]

Exhaust Duct Extension [A2]. (See

Figure 18)

Locate the AMU Duct Extension [A1] on

top of the Air Make Up duct collar (part

Wall

of the AMU/Exhaust Manifold/Duct Con

nection [A]) and secure it in place with

the two (2) overcenter latches. The

AMU duct extension is also designed to

penetrate an eight foot tall ceiling by

approximately two inches (2"). Connect

the duct from the Air Make Up fan to the

AMU Duct Extension [A1].

Page 20

Figure 18

Page 22

CLEANING AND MAINTENANCE

Caution: The oven and the ventilation system get hot during operation. Allow the oven/ventilation system assembly

to cool so as to avoid possible injury.

Note: NFPA 96, Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations, requires that "hoods,

grease removal devices, exhaust fans, and ducts shall have a clearance of at least 18" (457.2 mm) to combustible mate

rial, 3" (76.2 mm) to limited combustible material, and 0" (0 mm) to noncombustible material." The AB2A InVent is

equipped with louvers on the top of the hood which supply makeup air to the general vicinity of the oven and help to

cool the area around the oven. DO NOT store or place items on top of the hood.

Every month:

Remove the Heat Shields [L2, M1, N2 and P1] and End Enclosures [L, L1, M, N, N1 and P] by lifting them up and pulling

them away from the oven. Remove the Filters [H1 and H2] by lifting them up and then swinging the bottom out and down.

Remove the Filter Trough Receptacles [G]. Clean the parts by running them through a dishwasher or wash them by hand

with hot, soapy water. Do not use scouring pads (plastic or metal) on the exterior surfaces as they will scratch and

mar the exterior finish. Rinse the panels in warm water and dry them. Install the Filter Trough/Receptacles, Filters, End

Enclosures and Heat Shields as described on pages 15 through 19.

Every three (3) months:

Remove the Heat Shields [L2, M1, N2 and P1] and End Enclosures [L, L1, M, N, N1 and P] by lifting them up and pulling

them away from the oven. Remove the Filters [H1 and H2] by lifting them up and then swinging the bottom out and down.

Remove the Filter Trough Receptacles [G]. Lift off the Cooling Fan Exhaust Enclosure [K]. Remove the Vertical Exhaust

Manifolds, [T and J], by removing the thumb screws [Q5]. Clean the parts by running them through a dishwasher or wash

them by hand with hot, soapy water. Do not use scouring pads (plastic or metal) on the exterior surfaces as they will

scratch and mar the exterior finish. Wipe out the exhaust channel portion of the AMU/Exhaust Manifold/Duct Connection

[A] assembly. Brush and clean the louvers or guards of the oven cooling fans. Dry the parts and return them to their posi

tions as described in the Exhaust Installation portion of this manual (pages 11 through 18).

Note: This regular maintenance is in addition to the daily, quarterly, semiannual and annual cleaning schedule included in

the oven operating manual.

Page 21

Page 23

SERVICING

For servicing the oven, disconnect the

gas and electric services from the oven

as described in the MT3870 Owner Op

erator Manual. To move the oven/ven

tilation system assembly for mainte

nance, release the overcenter latches

on the exhaust and Air MakeUp duct

collars. Slide the clamping collars up

and secure them out of the way. Release

the brakes on the front locking casters

of the oven assembly. Roll the oven out

away from the wall. (See Figure 19).

[A2]

Clamping

Collars

OverCenter

Latches

Exhaust Duct

AMU Duct

[A1]

Clamping

Collar

A

Page 22

B

Figure 19

Page 24

AIR FLOW MEASUREMENT

Ports are provided on both the exhaust

and makeup air duct collars of the

AMU/Exhaust Manifold/Duct Connec

tion [A] assembly. (See Figure 20). The

ports are sealed with 1/4"20 threaded

fasteners. After removing the threaded

fasteners, a manometer can be con

nected to the ports using 1/4" soft vinyl

tubing. After adjusting the air flow using

the manometer and the graphs on the

following pages, the tubing is to be re

moved and the threaded fasteners rein

stalled into the ports. High temperature

sealant should be applied to the threads

of the fastener inserted into the exhaust

duct port to ensure a greasetight seal.

Pressure

Ports

Figure 20

Page 23

Page 25

The recommended minimum exhaust air flow is onethousand, sixhundred cubic feet per minute (1600 CFM). The recom

mended maximum makeup air flow is onethousand twohundred cubic feet per minute (1200 CFM). The recommended

net amount of air exhausted from the kitchen is fourhundred cubic feet per minute (400 CFM). The ventilator will perform

satisfactorily with onehundred percent (100%) makeup air. However, it is generally recommended that the kitchen area be

slightly negative in pressure relative to the rest of the building.

Exhaust air static pressure should be taken at the port provided on the Exhaust Duct on the AMU/Exhaust Manifold/Duct

Connection [A] with a manometer. See Figure 20 for port location. Refer to the chart below to reference static pressure to

air flow. A static pressure of one inch of water column (1.0" w.c.) is recommended to achieve an air flow of sixteenhundred

cubic feet per minute (1600 CFM).

AB2A Exhaust Air Flow

2500

2000

1500

1000

Cubic Feet per Minute

500

0

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8

Static Pressure (inches w.c.)

Page 24

Page 26

Makeup air should be tempered to prevent temperatures from dropping below 40F (4.4C) or exceeding 90F (32.2C).

The ventilator will operate satisfactorily at temperatures outside of these limits, however, operator comfort may be affected.

Additional loading of the building's Heating Ventilation and Air Conditioning (HVAC) system may also result.

Makeup air static pressure should be taken at the port provided on the Supply Duct on the AMU/Exhaust Manifold/Duct Con

nection [A] with a manometer. See Figure 20 for port location. Refer to the chart below to reference static pressure to air flow.

A static pressure of ninehundredths of an inch of water column (0.09" w.c.) is recommended to achieve an air flow of twelve

hundred cubic feet per minute (1200 CFM).

AB2A MakeUp Air Flow

2500

2000

1500

1000

Cubic Feet per Minute

500

0

0.00 0.05 0.10 0.15 0.20 0.25

Static Pressure (inches w.c.)

Page 25

Page 27

Figure 21

Page 26

Loading...

Loading...