Page 1

Project

Item No.

Quantity

Model 6G-SC (6 pan convection steamer on a cabinet base)

CONSTRUCTION

Stainless steel construction

Stainless steel doors with strong continuous hinge and are field

reversible for left or right swing

Insulated doors have a one piece, replaceable seal

Easy open handle and latch provide positive lock and seal when the door

is pushed or slammed shut

Hidden magnetic door switch cuts power to blower and steam flow to that

cavity, when the door is opened

Pan support racks shall be polished stainless steel and removable for

easy cleaning

Wide drip sink with condensate drain is positioned under cavity doors

21-5/8” wide cabinet base shall have stainless steel frame with all stain-

less steel top deck, hinged front access panel and removable side and

rear panels

Front and rear legs shall have adjustable bullet feet

OPERATION

Steamer cavity controls include an ON-OFF power touch pad; 60 minute

mechanical timer, with continuous steam setting; and READY light which

indicates when cavity is ready for steaming.

Auto-Delime button initiates deliming cycle. DELIME indicator light warns

operator of need to delime generator.

atwin gas heated cabinet mounted steam generators to provide atmos-

pheric steam to the chambers at a temperature of approximately 212° F.

Unit will shut off if water level is low or unit builds too much pressure

Each steam generator has an electric water sensor, a 45,000 BTU/hr fir-

ing rate

Each steamer cavity shall have a powerful side mounted blower, which

increases steam velocity and provides efficient steam distribution

throughout cavity and between loaded pans.

Steam generators deliver approximately 15,000 BTUs/hour input per 2

1/2” deep steam pan.

Standing pilot with electronic ignition system

8-10 minutes heat-up time to READY under normal conditions. Cavities

are kept warm and ready for instant steam between loads. No cavity

warm up required, after READY light comes on.

CAPACITY

BLODGETT

44 Lakeside Avenue, Burlington, VT 05401

Toll Free: (800) 331-5842 • Phone: (802) 860-3700 • Fax: (802) 864-0183

OPTIONS AND ACCESSORIES

(AT ADDITIONAL CHARGE)

Flange mounting feet

6G-SC

Gas Convection Steamer on Cabinet Base

6G-SC CONVECTION STEAMER

Pan Size Per Cavity Total

12” x 20” x 1” 6 12

12” x 20” x 2.5” 3 6

12” x 20” x 4” 2 4

STANDARD FEATURES

One year parts and labor warranty*

* For all international markets, contact your local distributor.

Page 2

BLODGETT

44 Lakeside Avenue, Burlington, VT 05401 • Toll Free: (800) 331-5842 • Phone: (802) 860-3700 • Fax: (802) 864-0183

6G-SC CONVECTION STEAMER

Printed in U.S.A. NOTE: FOR COMMERCIAL USE ONLY

NOTE: The company reserves the right to make substitutions of

components without prior notice.

APPROVAL/STAMP

P/N S00135 Rev A (4/11)

WATER SUPPLY:

Water quality is a major factor affecting the performance of your steamer. If you

are unsure of water quality, consult a local water treatment specialist and have

the water analyzed. Your water supply must be within these general guidelines:

Total dissolved solids: Less than 30 PPM Total alkalinity: Less than 20 PPM

Silica: Less than 13 PPM Chlorine: Less than 1.5 PPM

pH Factor: 7.0 - 9.0

Water which fails to meet these standards should be treated by installation of a

water conditioner. Failure or malfunction of this steamer due to poor water quality is not covered under warranty.

WATER & DRAIN CONNECTIONS:

Drain 1-1/2” NPT free venting drain

Cold Water Two 3/4” NPT cold water supply line. Second cold water

connections are provided for spray condenser

Appliance is to be installed with backflow protection in accordance with Federal,

State or Local codes.

MAXIMUM INPUT:

6G-SC 90,000 BTU/hr

GAS SUPPLY:

1/2” NPT pipe or approved equivalent.

Minimum Inlet Pressure:

Natural 3.7" W.C. static to unit

Propane 10.5" W.C. static to unit

POWER SUPPLY:

115 volt, single phase, 60 cycle 15 AMP electric service, 4

AMP maximum load

SHIPPING INFORMATION:

Approx. Weight:

6G-SC 530 lbs. (240 kg)

SHORT FORM SPECIFICATIONS

Provide Blodgett model 6G-SC (6 pan) pressureless steamer with twin, independent electric heated steam generators mounted in 21-5/8” wide cabinet base. All stainless steel construction with two steam cavities, each powered by its own independent atmospheric steam generator with powerful blower to circulate steam within cavity and separate operating controls,

including: 60 minute electromechanical timer with constant steam setting, ready light and DELIME cycle button to initiate deliming. Doors are field reversible, with easy open latch and hidden magnetic door switch, and wide condensate sink with drain is provided under cavity doors. The unit shall have twin atmospheric 45,000 BTU/hr gas steam generators. Unit shall come

up to steam in 8-10 minutes or less from a cold start, and provide warm cavity instant steam capability. Provide options and accessories as indicated.

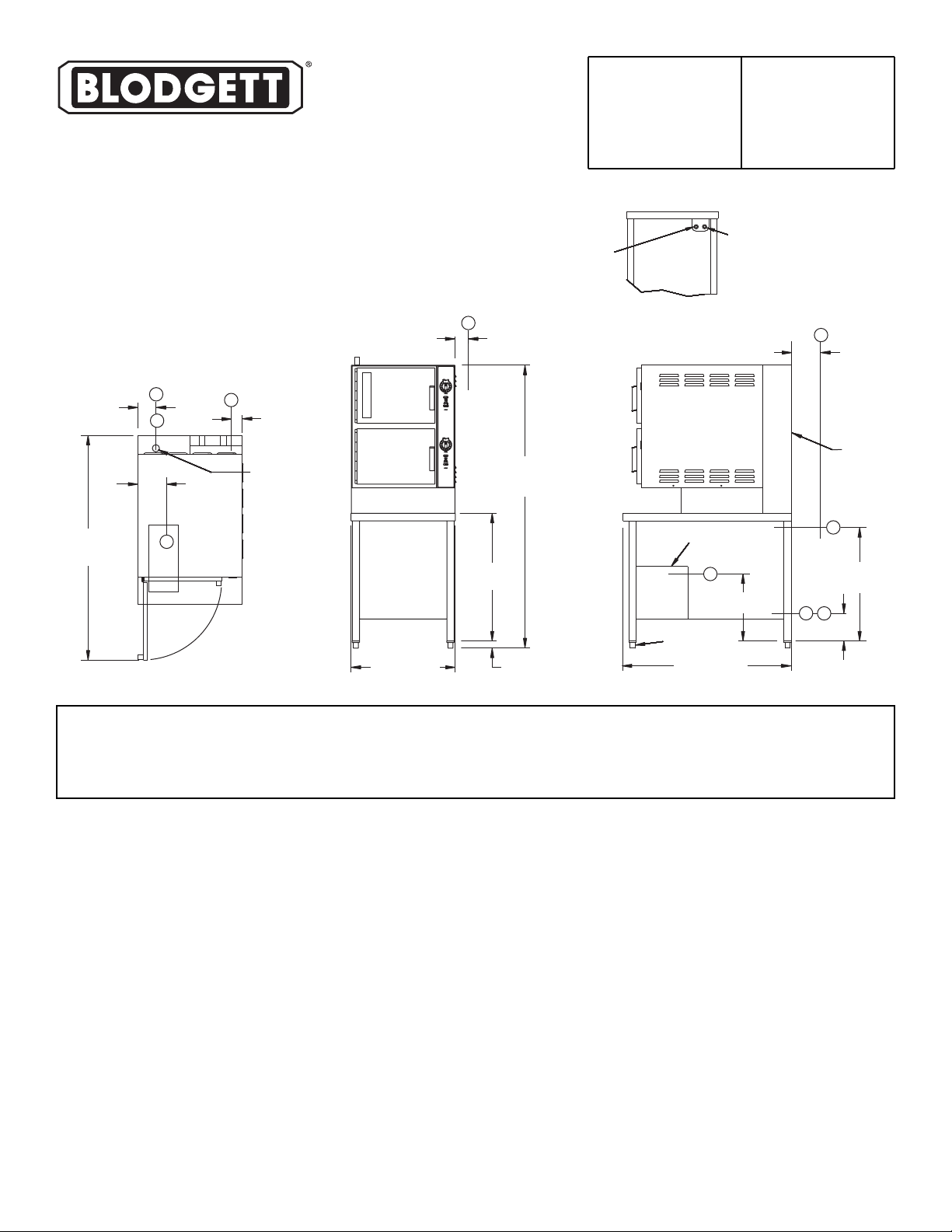

Treated

water supply

connection

Un-treated

water supply

connection

(optional)

DETAIL VIEW

of water connection

(if second connection ordered)

(REAR VIEW)

NOTES:

1. Drain connection 1-1/2” tube (drain free venting)

2. Cold water supply at 30 to 60 PSIG with a flow rate of 1/5-3/0 GPM and

with a 3/4” NH connection.

3. Electrical connection 1” conduit.

4. Minimum clearance required

5. Dimensions are in inches (mm).

6. Gas connection: ½” NPT

TOP VIEW

1

2

3.75 (95)

Condensate

drain vent

6

(152)

3

49

(1245)

6

2 (51)

FRONT VIEW

21.63 (549)

26.56

(686)

59.13

(1502)

2 (51)

4

1.5 (38) min

2.63 (67) max

SIDE VIEW

2

3

1

Adjustable

bullet feet

Electrical box

5.75

(146)

23.63

(600)

14 (356)

35.19 (894)

4

6 (152)

Flue

stack

6

Loading...

Loading...