Page 1

Project

Item No.

Quantity

Model (2)3G-SBC ( two 3 pan gas boiler free steamer with plumbing con-

nections on a stand)

Model (2)5G-SBC (two 5 pan gas boiler free steamer with plumbing con-

nections on a stand)

CONSTRUCTION

Stainless steel construction

Stainless steel doors with strong continuous hinge and are field

reversible for left or right swing

Insulated doors have a one piece, replaceable seal

Easy open handle and latch provide positive lock and seal when the door

is pushed or slammed shut

Hidden magnetic door switch cuts power to blower and steam flow to that

cavity, when the door is opened

Pan support racks shall be polished stainless steel and removable for

easy cleaning

Gas connectionless steam reservoir is easy to clean through the cavity

door.

OPERATION

ON-OFF rocker switch

Electronic timer with continuous steam setting

Timed steam and stop buttons

Ready light indicates when cavity is ready for steaming

Unit shall come ready to steam in 15 minutes from a cold start, and pro-

vide warm cavity-instant steam capacity. Cavity is kept warm and ready

for instant steam between loads.

Each steamer cavity shall have a powerful side mounted blower, which

increases steam velocity and provides efficient steam distribution

throughout cavity and between loaded pans and no side vents for

increased water/spray resistance.

Steam generating reservoir provides atmospheric steam to the cavity at a

temperature of approximately 212° F.

Gas heater with infrared burners

Steamer shall have a steam lid positioned over the steam generating

reservoir to ensure that adding/removing food does not lower the cavity

or water temperature.

Automatic drain in steam reservoir

CAPACITY

BLODGETT

44 Lakeside Avenue, Burlington, VT 05401 • Phone: (802) 658-6600 • Fax: (802) 864-0183

OPTIONS AND ACCESSORIES

(AT ADDITIONAL CHARGE)

Pan racks for support stand

Flanged foot kit for support stand

Caster kit for support stand

Heat shield kit

4” adjustable legs

(2)G-SBC

Gas Boiler Free

Stacked Convection Steamers

(2)G-SBC BOILER FREE CONVECTION STEAMERS

Pan Size (2)3G-SBC (2)5G-SBC

12” x 20” x 1” 12 pans 20 pans

12” x 20” x 2.5” 6 pans 10 pans

12” x 20” x 4” 4 pans 6 pans

STANDARD FEATURES

Stainless steel stand

One year parts and labor warranty*

* For all international markets, contact your local distributor.

(2)5G-SBC

Page 2

BLODGETT

44 Lakeside Avenue, Burlington, VT 05401 • Phone: (802) 658-6600 • Fax: (802) 864-0183

(2)G-SBC BOILER FREE STEAMERS

SHORT FORM SPECIFICATIONS

Provide Blodgett model (2)3G-SBC (6 pan) or (2)G-SBC (10 pan) boilerfree steamer with with self-contained, atmospheric, gas

heated steam generating reservoir on a stand. Construction shall be all stainless steel. Cavity shall have a powerful side-mounted blower to circulate steam. Standard operating controls shall include: an on-off rocker switch; electronic timer, with continuous

steam, timed steam and stop buttons; READY light. Door shall be field-reversible and shall be equipped with an easy-open latch

and hidden magnetic door switch. The atmospheric steam generating reservoir shall not require a pressure gauge or switches;

shall have an automatic drain and shall have an infrared burner with heating capacity of 108,000 BTU/hr for (2)3G-SBC and

124,000 BTU/hr for (2)5G-SBC. Steamer shall come up to READY in 15 minutes from a cold start and shall provide warm cavity, instant steam capability. Provide options and accessories as indicated.

Printed in U.S.A. NOTE: FOR COMMERCIAL USE ONLY

NOTE: The company reserves the right to

make substitutions of components without

prior notice.

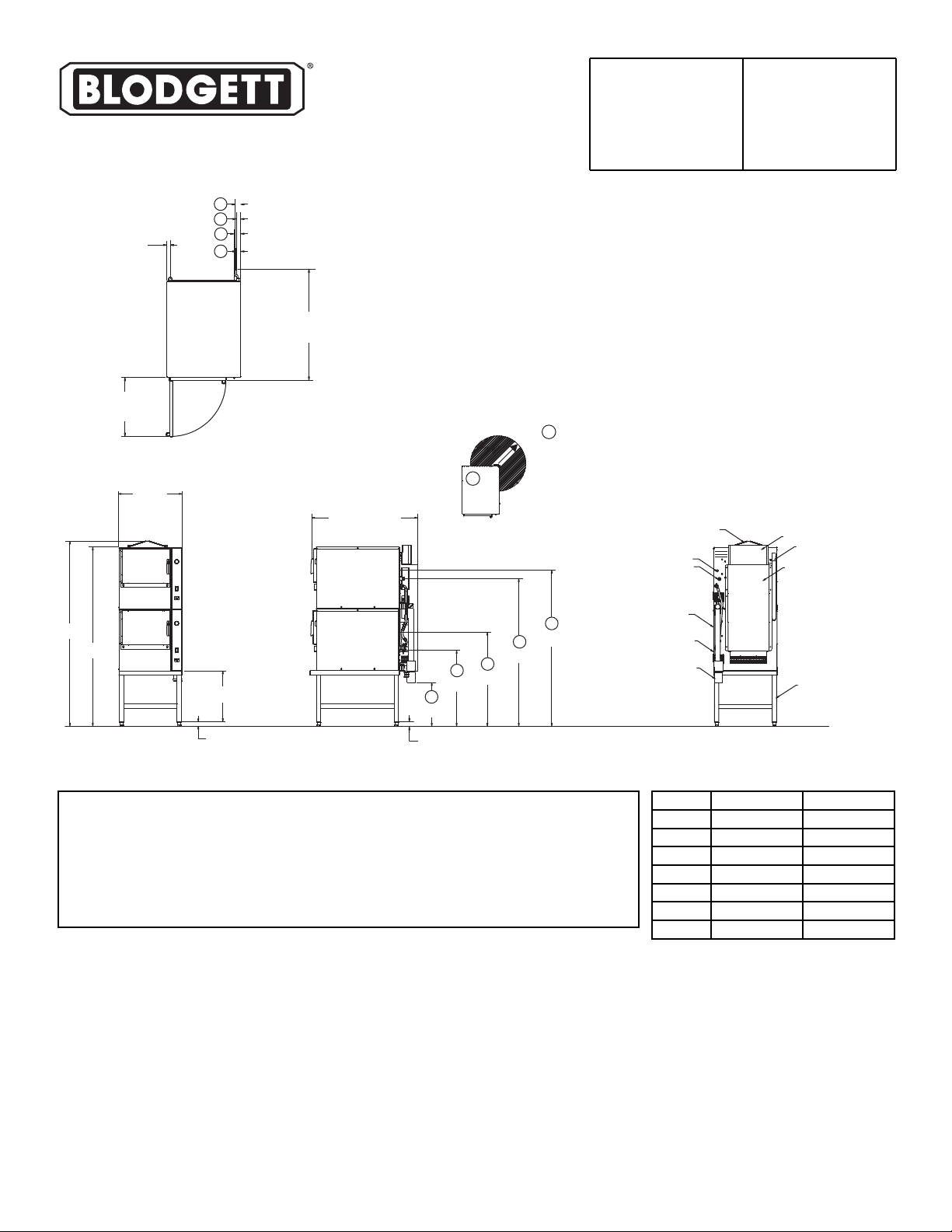

DRAIN

Unit

6

18 (457)

5

STEAM FREE

ZONE

NOTES:

Drain connection:

Gas connection:

Water supply:

Electrical connection:

1. 2.5 (64) hose type (drain free venting). DO NOT connect directly

to drain, allow 2” air gap.

2. ½” FPT

3. 3/4” male hose connection. 30 to 60 PSIG with a flow rate of 1.5-3.0

GPM. Pressure regulation is required for water pressure over 60 PSI. DO NOT use

treated water.

4. conduit hose size = 13/16” hole.

5. If the floor drain only services this steamer, then the drain may be located within the

steam free zone. Steam free zone must be observed if other appliances cause steam

at the floor drain.

6. Do not install steamer directly above steam venting floor drains.

7. Dimensions are in inches (mm).

1

1 (25)

32.75

(832)

17.38

(441)

1.03 (26)

Steam exhaust

3

4

1.38 (35)

1.25 (32)

TOP VIEW

2 (51)

2

Exhaust flue not

shown in this view

21.75

(552)

A

B

FRONT VIEW

1.5 (38) min.

2.63 (87) max.

Exhaust Flue

Steam Exhaust

Exhaust

Flue Cover

Double stack

stand shown

with bullet feet

Electrical Supply

Electrical Supply

Gas Supply

Water Supply

Drain Connection

Flue Guard

REAR VIEW

SIDE VIEW

1

36.13 (918)

C

3

D

4

E

2

F

4

G

5 (127) with casters

(not shown)

8 (203)

APPROVAL/STAMP

P/N S00152 Rev A (6/11)

MAXIMUM INPUT:

(2)3G-SBC 108,000 BTU

(2)5G-SBC 124,000 BTU

MININUM REQUIRED CLEARANCES:

Left and right side 2” (51mm)

Rear 6” (152mm)

SHIPPING INFORMATION:

(2)3G-SBC 486 lbs. (220 kg)

(2)5G-SBC 555 lbs. (252 kg)

(2)3G-SBC (2)5G-SBC

A

63.06 (1601) 66.63 (1693)

B

61.06 (1551) 64.69 (1642)

C

14.81 (377) 6.31 (160)

D

25.75 (655) 17.44 (443)

E

32 (812) 24.50 (622)

F

50.25 (1276) 48.13 (1223)

G

53.13 (1349) 52.13 (1324)

GAS SUPPLY:

Minimum Inlet Pressure:

Natural 4.3" W.C. static to unit

Propane 10.5" W.C. static to unit

POWER SUPPLY (per cavity):

115 volt, single phase, 60 cycle 15 AMP electric

service, 4 AMP maximum load

Loading...

Loading...