Blizzard Ski Ski 760LD, Ski 700LD, Ski 800, Ski 760 User Manual

Assembly & Operation Manual

Blizzard Straight Blade Snowplows

Models 700LD, 760LD, 760 & 800

i Table of Contents

Introduction

Congratulations on purchasing the finest

straight blade snowplow available!

Blizzard straight blades are clearing

new trails for innovative design, rugged

durability, quality craftsmanship and

superior performance. Our exclusive

products are manufactured and tested

in Michigan’s Upper Peninsula, the

snow capital of the Midwest. With an

annual snowfall averaging over 250,"

we couldn’t imagine building snow

removal products anywhere else!

Your Blizzard straight blade is equipped

with versatile features designed f or years

of dependable service. The hydraulic

draw latch mounting system positively

aligns the plow for fast installation or

removal. All Blizzard straight blade

snowplows feature an extended moldboard.This unique construction provides

an additional 5" of blade that rolls snow

farther ahead and to the side when

plowing. Now you can move snow

faster, saving fuel and reducing wear

on your truck and plow. Safety features

include full moldboard trip action,

enclosed hydraulics and automatic

cylinder pressure relief.

To ensure years of optimum snowplow

performance, review the contents of this

manual. It contains assembly information, detailed diagrams, complete parts

listings, maintenance guidelines and

troubleshooting tips.

Should you need additional information,

contact your local Blizzard snowplow

dealer.Their knowledgeable staff is well

informed on the latest straight blade

information.They are also your source

for replacement parts, technical assistance and all service repairs.

Comments, suggestions or concerns?

Address all correspondence to:

Blizzard Corporation

Customer Service Department

95 Airpark Boulevard

Calumet, MI 49913

Table of Contents

01 Snowplow Accessories

02 Warning!

03 Snowplow Operation

Assembly Instructions

04 Unpacking & Inspection

05 Moldboard & A-frame Assembly

09 Electrical Assembly - Plow Harness

10 Electrical Assembly - Vehicle Harness

12 Testing The Snowplow

14 Mounting & Dismounting Instructions

Maintenance & Plow Specifications

15 Regular Maintenance

16 Storing Y our Snowplow

17 Plow Specifications

Plow Diagrams & Part Lists

18 Models 700LD, 760LD, 760 & 800 Parts List

22 Models 700LD, 760LD, 760 & 800 Assembly Schematic

24 Manifold Detail with Hydraulic & Electrical Schematics

Electrical Diagrams

25 Molded Plug Pin Locations

26 Plow Harness

27 Plow Harness Wire Schematic

28 Main Lighting Harness - Relay Version

29 Main Lighting Harness - Relay Version Wire Schematic

30 Vehicle Har ness

31 Vehicle Har ness Wire Schematic

32 On/Off Switch Leads & Ground Lead

Torque Specifications

33 Bolts & Hydraulic Adapters

Troubleshooting

34 Troubleshooting Guide

Warranties

36 Limited Consumer Warranty

37 Commercial Warranty

Blizzard Snowplow Airfoil

P/N 81041 (700LD & 760LD)

P/N 52093 (760 & 800)

Help channel air flow to

your truck radiator during

the long haul over the road.Mounted front and center, our custom

airfoil redirects air over the top of the b lade and into the grill of your

vehicle.Don’t get stuckon the side of the road! Keep trucking with

this easy-to-install accessory.The airfoil is shipped with complete

mounting hardware.

Blizzard Snowplow

Touch-Up Paint

P/N 61219 (Gloss White)

P/N 63073 (Gloss Black)

Putting your snowplow away for

the winter? Have a deep scratch

to cover? Clean up your blade and

plow parts with our gloss spray

paints. Made to match your original plow equipment, Blizzard

snowplow touch-up paint provides an excellent finish to help keep

your snowplow looking its best.Paint provided in 12 oz.spray cans.

Blizzard Snowplow Rapid

Action Hydraulic Oil

P/N 63070 (Quart)

P/N 63071 (12 Quarts/Case)

Blizzard hydraulic oil is specially

formulated for use in Blizzard

snowplows.This zinc-free product

can significantly enhance the

operation and performance of the hydraulic system in the most

inclement weather conditions. Blizzard Snowplow Rapid Action

Hydraulic Oil maintains its viscosityto temperatures as low as -60˚F.

Blizzard hydraulic oil is available by the quar t or case.

Straight Blade Joystick

Window Mount Bracket

P/N 61261

This adjustable bracket mounts

easily to your straight blade joy-

stick control and installs quickly

onto any door panel. Ideal for left

hand joystick operation or for

vehicles with center consoles.The window mount bracket is shipped

complete with hardware.Some assembly required.

Snowplow Accessories 01

Snowplow Accessories

All of the accessories pictured below are currently offered for your snowplow. See your local Authorized Blizzard Dealer for pricing and availability.

Visit our web site at www.blizzardplows.com to view new snowplow

accessories and our latest Blizzard snowplow wearables.

Rubber Snow Deflector

P/N 81040 (Model 700LD)

P/N 61243 (Model 760LD)

P/N 61242 (Model 760)

P/N 61260 (Model 800)

Plow safer and easier with

our custom rubber snow deflector.This easy-to-install accessory

keeps snow off of your windshield and in its place—on the ground!

Rugged and durable, the 3/8" thick, 2-ply construction is made to last.

All snow deflectors are shipped with complete mounting hardware.

Blizzard Snowplows

Emergency Parts Kit

P/N 63074

Be prepared for unexpected

plow emergencies! This kit

includes the most common

replacement parts conveniently packaged in a small, durable plastic

case.Custom foam insert holds the following plow parts:Angle cylinder hose, lift cylinder hose, hitch pin w/hair pin cotter, angle cylinder

clevis pin w/cotter, 90˚ angle cylinder fitting, solenoid, Power Hitch™

toggle switch, corrosion prev entive compound (2 oz.) and 10A fuse .

The compact case (13.5"x9" x3.3") allows for easy storage behind

or under your truck seat.

02 Warning!

Warning!

Prior to operating your straight blade, review the WARNING! label at the

passenger’s side rear of the moldboard (shown below).

Note: Read and understand all warnings indicated in this manual prior to

operating the snowplow. Warnings and cautions in the manual are indicated

by the icons shown to the left.

WARNING:

CAUTION:

1. Properly mount the snowplow prior to moving the vehicle.

2. To prevent accidental plow activ ation, turn the Power switch on the snowplow control

to the “OFF” position when not in use.

3. Stand clear of the attachment area when mounting the snowplow to the undercarriage

and operating the Power Hitch Connect/Disconnect switch. Failure to do so may

result in serious injury or death.

4. Securely position all mounting pins prior to operating your snowplow.

5. Do not position your body between the snowplow and the vehicle when servicing

or operating.

6. Position snowplow in such a manner as to not block your vision or plow headlights

while in transit.

7. Do not change the position of the snowplow while in transit.

8. Do not exceed 40 mph when transporting the snowplow.

9. Do not exceed 10 mph when plowing.

10. Always lower the snowplow when the vehicle is parked.

11. Vehicles equipped with air bags are designed to be activated in a frontal collision

equivalent to hitting a solid object or barrier at approximately 14 mph or more.

Careless or high speed driving while plowing snow, which results in vehicle impact

deceleration equivalent to or greater than the airbag deployment threshold described

above, would deploy the airbag.

Blizzard straight blade snowplows are protected by U.S. Patent 6,276,076 B1. Other patents pending.

READ

OWNER’S

MANUAL

THOROUGHLY

PRIOR TO

OPERATING

PLOW.

Calumet, Michigan 49913

BLZ 1024

WARNING

WARNING

Should the WARNING! label or any of the labels

that came with your snowplow become hard to

read or wear off, contact your local Authorized

Blizzard Dealer for replacements.

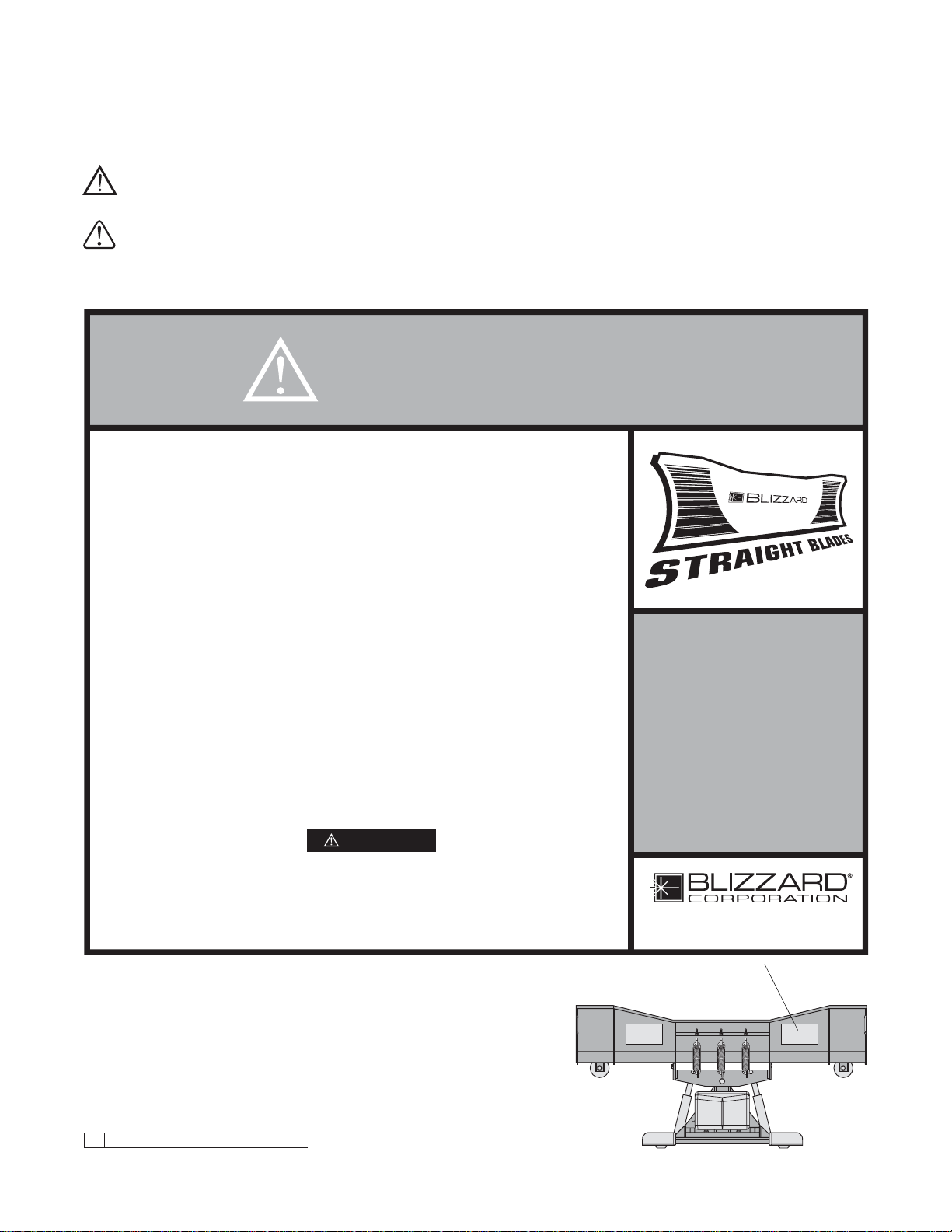

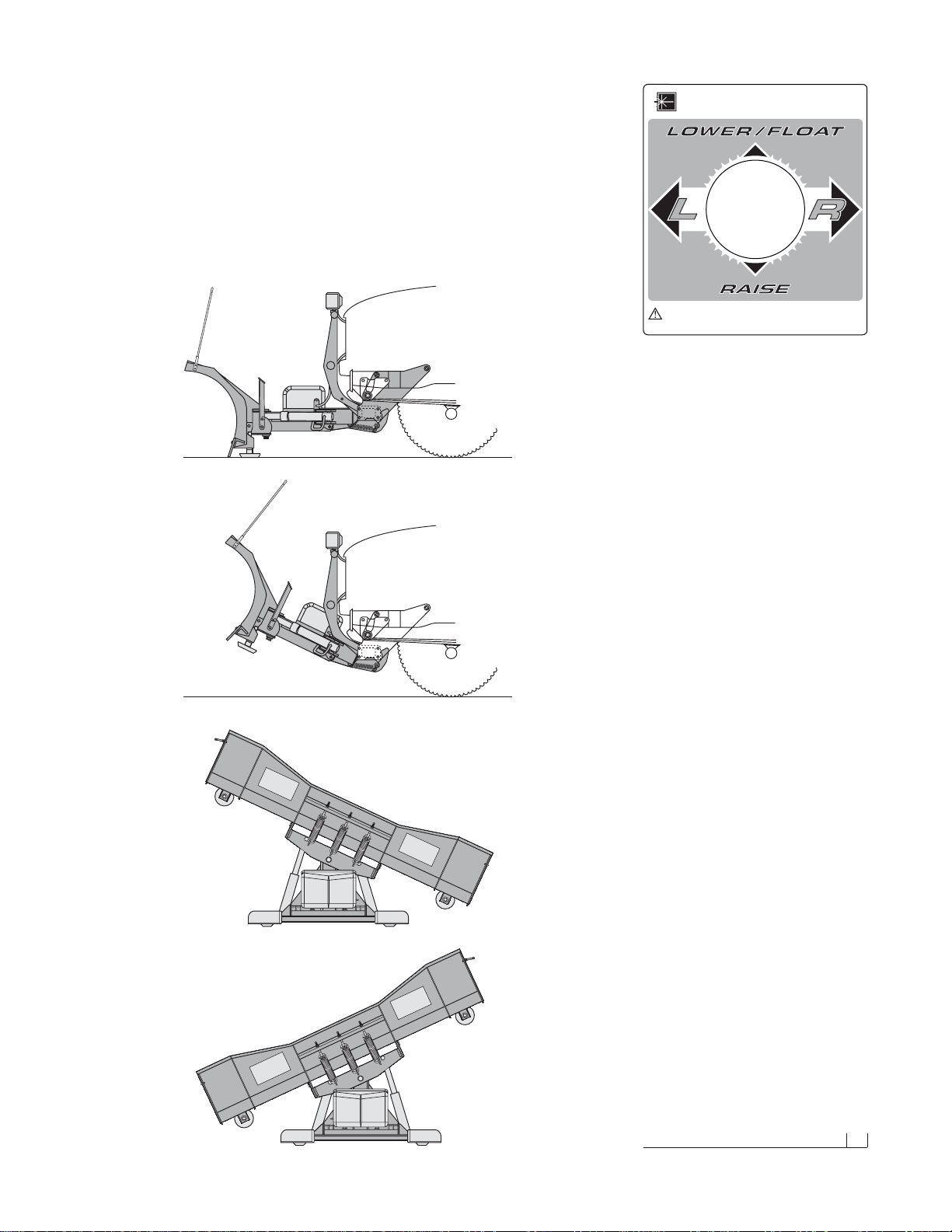

Snowplow Operation 03

Snowplow Operation

Your snowplow is the most advanced and versatile straight blade on the

market.The easy-to-use joystick control allows you to automatically adjust

the plow blade into an infinite number of plowing positions. Review the

illustrations below for instruction on maneuvering your snowplow.

A.

B.

C.

D.

A. Lowered or Float Position

Pushing the joystick forward, toward the “Lower/

Float” designation on the label, will lower your

straight blade to the ground.Pushing the joystick

ahead until the detent “locks”the control will allow

the snowplow to “float”, or follow the contour of

the ground when moving forward or backward.

B. Raised Position

Pulling the joystick back, toward the “Raise”

designation on the label, will lift your straight

blade off of the ground. To stop raising the plow,

simply return the joystick to its “neutral”or center

position.The snowplow has reached its maximum

raised position when the blade stops lifting –

return the joystick to its neutral position.

C. Angled Right Position

To angle your straight blade to the right, position

the joystick toward the “R” on the label. To stop

angling the plow, return the joystick to its “neutral”

or center position.The snowplow has reached its

maximum angled position when the blade stops

moving to the right side.

D. Angled Left Position

To angle your straight blade to the left, position

the joystick toward the “L” on the label. To stop

angling the plow, return the joystick to its “neutral”

or center position.The snowplow has reached its

maximum angled position when the blade stops

moving to the left side.

***** IMPORTANT *****

To prevent premature failure of the power

contactor (solenoid),initiate the plow function

and return the joystick to its neutral or center

position — except float. DO NOT hold the joystick in any position that allows the pump to

continuously run after the plow has reached

its maximum degree of movement. This will

reduce the useful life of the solenoid.

BLIZZARD

To prevent accidental plow activation, turn

POWER switch to the “OFF” position when

not in use.

BLZ 1017

WARNING

®

04 Unpacking & Inspection

Assembly Instructions

Unpacking & Inspection

Your Blizzard straight blade has been packaged to withstand transit and

weather related damage.Fully inspect all components upon receipt of your

plow. In the event of shipping damage or missing parts, immediately contact

our Customer Service Depar tment toll free at 1-888-680-8600.

Begin unpacking and inspection in the following order:

1. Remove the shipping document from the end panel of the pallet wrap.

Retain all documentation for your records.

2. All wood framing and polyethylene material should be removed from

the pallet for easy access to the snowplow.

3. Due to the odd shaped components and size of several assembly

parts, various cable ties and corrugated material are used for scratch

resistance and package orientation. Please remove these items prior

to assembly.

4. Place the main blade assembly on a flat, level surface.

Once you have inspected all parts and removed all packaging materials,

your snowplow is ready to be fully assembled.

Pallet Wrap End Panel

The tear resistant woven polyethylene pallet wrap

contains a moisture barrier to help protect all

packaged components and keep out the most

inclement weather during shipping and storage.

The end panel of the pallet cover contains important information regarding the snowplow model

and the plow’s serial number.Both of these numbers are given together. The first three digits

and/or two letters in the the number indicated is

always the plow model 700LD , 760LD, 760 or 800

– and the entire seven (nine) digit number make

up the entire serial number.The shipping document is also attached to the end panel.Be sure to

retain this list for your records.

Snowplow Serial Number

Hydraulic Pump Serial Number

Telephone Number

Dealer/Distributor

Date of Purchase

Moldboard & A-frame Assembly 05

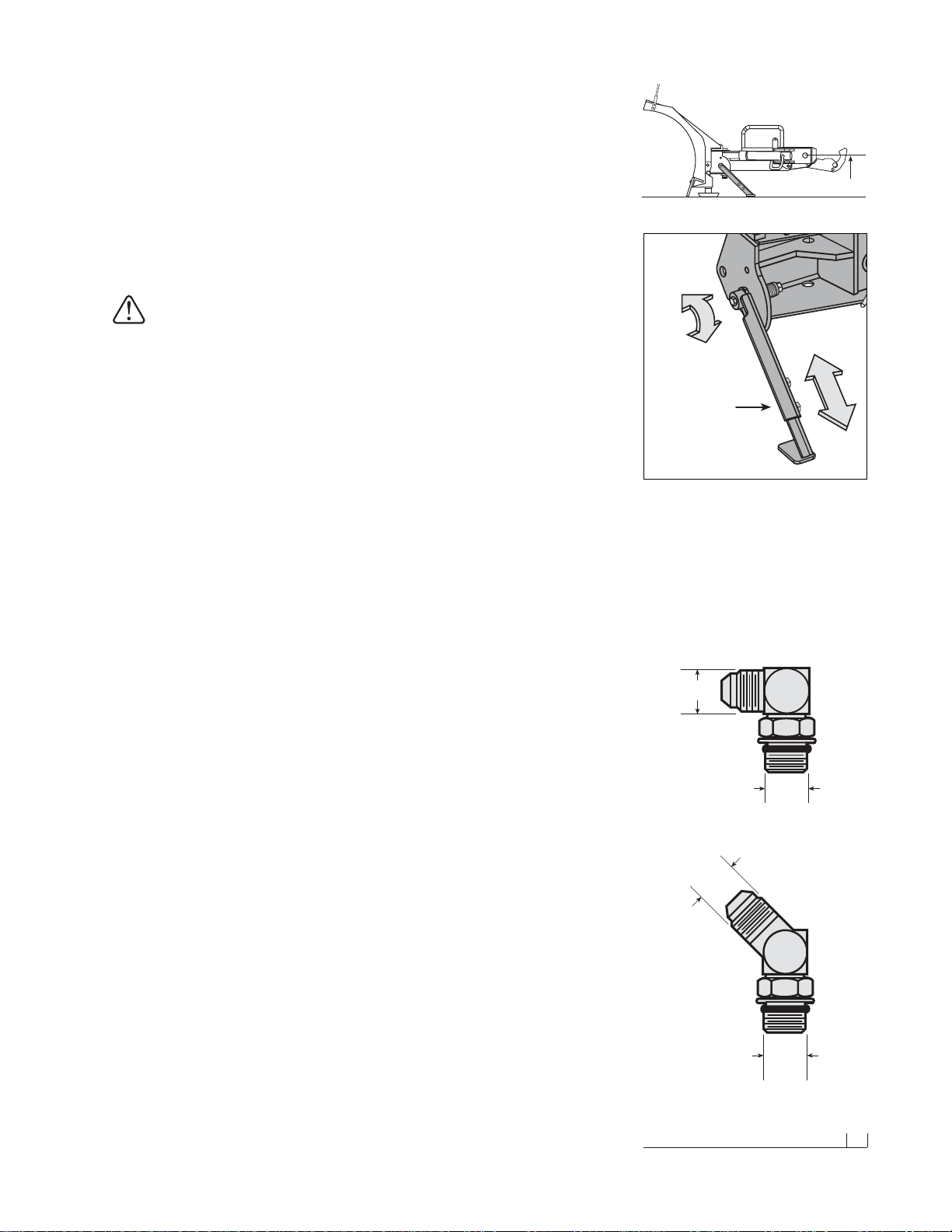

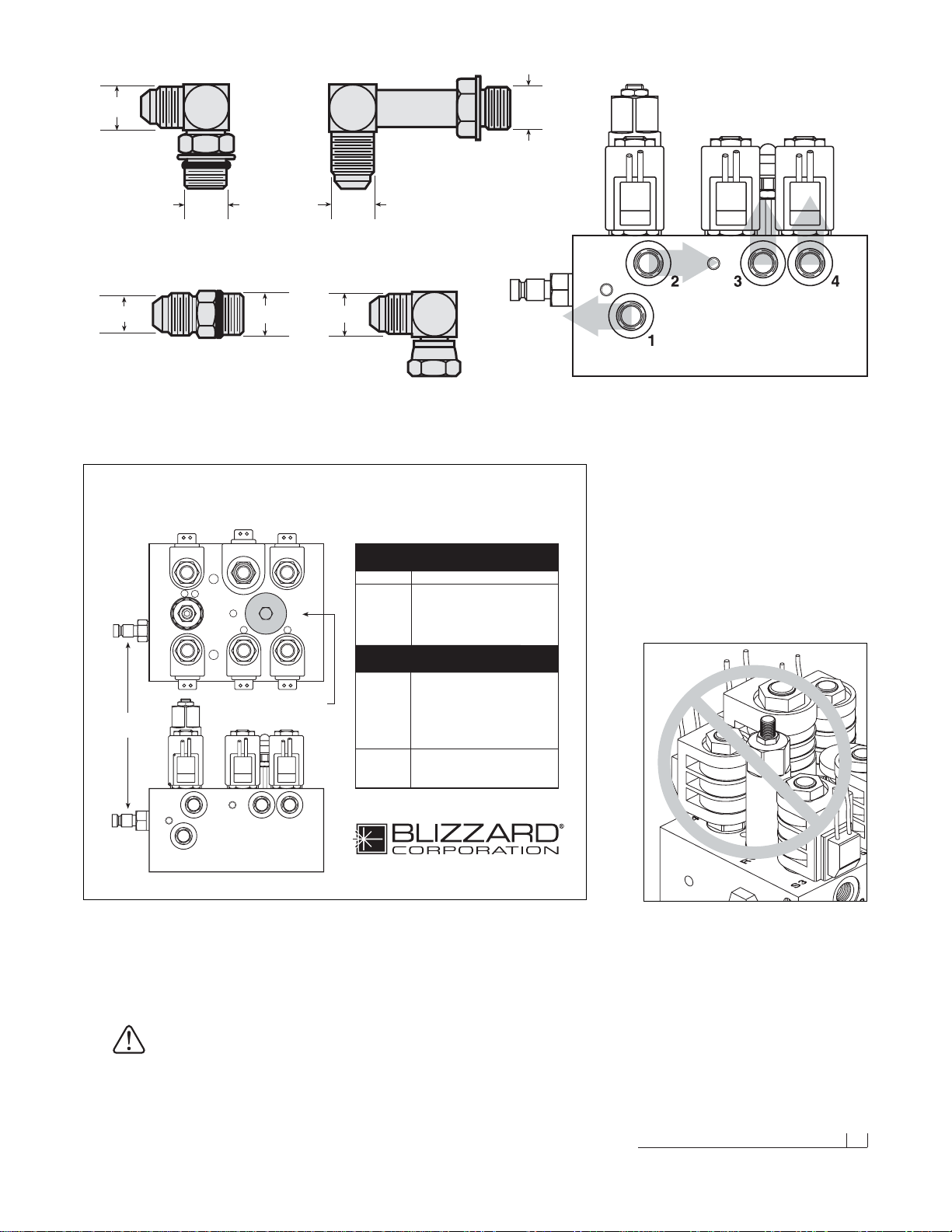

7/16"

7/16"

45˚ Adjustable Elbow O.R.B.Adapter

9/16"

9/16"

90˚ Adjustable Elbow O.R.B.Adapter

Moldboard & A-Frame Assembly

1. Begin the moldboard assembly by positioning the PIVOT BEAM and

A-FRAME near the connecting points at the rear of the blade between

the two center support ribs. Position the pivot beam between the two

support ribs until the connecting points on the beam align with those

on the plow. Inser t one 3/4"-10 x 3" (2" shank) hex head cap screw

through each mounting hole and secure with a 3/4"-10 top lock nut.

Tighten each nut until it is snug with the pivot beam.

CAUTION:Do not over tighten hex head n uts! Binding may

prohibit the pivot beam from moving properly on the plow.

Note:T o aid in the remaining installation, rotate the spring loaded kickstand clockwise until it locks into place.Adjust the foot on the stand

arm so the height of the A-frame, at its mount points, is 12-1/2" to

level ground (See the diagram to the right). Tighten both of the 1/2"-13

top lock nuts on the kickstand.

2. Position each ANGLE CYLINDER with the rod end of the cylinder

in the pivot beam and the hydraulic hose port facing away from the

A-frame.Secure the cylinder to the pivot beam with one 3/4" x 4-1/2"

CLEVIS PIN and one 1/4" x 1-1/2" HAMMERLOCK COTTER PIN.

Note:The hammerlock cotter pin will “lock” itself into place once the

head of the pin is struck. It is not necessary to bend the pin further

upon installation. Extend each cylinder rod until the cylinder base

mounting hole aligns with the hole on the A-frame angle cylinder

bracket. At this point, insert another clevis pin and secure it with a

cotter pin.Repeat the same installation for the opposite angle cylinder.

3. Remove each dust cap from both of the hydraulic angle cylinder ports

and attach one 9/16"-18 x 9/16"-18 90˚ ADJUSTABLE ELBOW O.R.B.

ADAPTER to each port. Note: All of the hydraulic adapters can be

found packaged with the manif old assembly.Reference the table on

page 33 for proper torque specifications. Each adapter should be

angled toward the top of the moldboard.Connect the 3/8" x 24" hydraulic

hose, labeled #1, to the driver’ s side angle cylinder adapter. Attach the

3/8" x 24" hydraulic hose, identified by a #2, to the passenger’s side

angle cylinder adapter.Be careful not to overtighten the hose connections. Route both hoses over the top of each angle cylinder.

4. Next, remove both of the plastic dust caps from the HYDRAULIC

LIFT CYLINDER ports. Attach one 7/16"-20 x 7/16"-20 45˚ ADJUSTABLE ELBOW O.R.B. ADAPTER to the driver’s side port and one

7/16"-20 x 7/16"-20 MALE O.R.B.CONNECTOR ADAPTER to the

passenger’s side port. Once the adapters have been installed on the

cylinder, connect the HYDRAULIC HOSES.Note: Position the fittings

in the cylinder port such that the hoses install directly in the center of

the A-frame access holes.A hose installed too close to the edge of the

opening may work itself free with the operation of the lift cylinder and/

or movement of the plow. The 45˚ adapter on the driver’s side of the

cylinder receives a 1/4" x 17" hose identified by a label containing the

number 3.Connect the 45˚ angle on the hose to the hydr aulic adapter

on the cylinder.The male connector adapter on the passenger’s side

of the cylinder receives a 1/4" x 15" hose identified by a label containing the number 4.Tighten the 45˚ end of the hose to the hydraulic

The kickstand is mounted to the side of the pivot

beam with one 1/2"-13 x 4-1/2" hex cap screw

and top lock nut. To pivot the kickstand, simply

pull the spring loaded leg out and rotate it until

the pin locks into place.The kickstand also has

an adjustable foot that can be moved to accommodate varying vehicle heights. The proper

height of your snowplow mounting points to level

ground should be set at 12-1/2".

Spring Loaded

Adjustable

Pivot Beam

Kickstand

12-1/2"

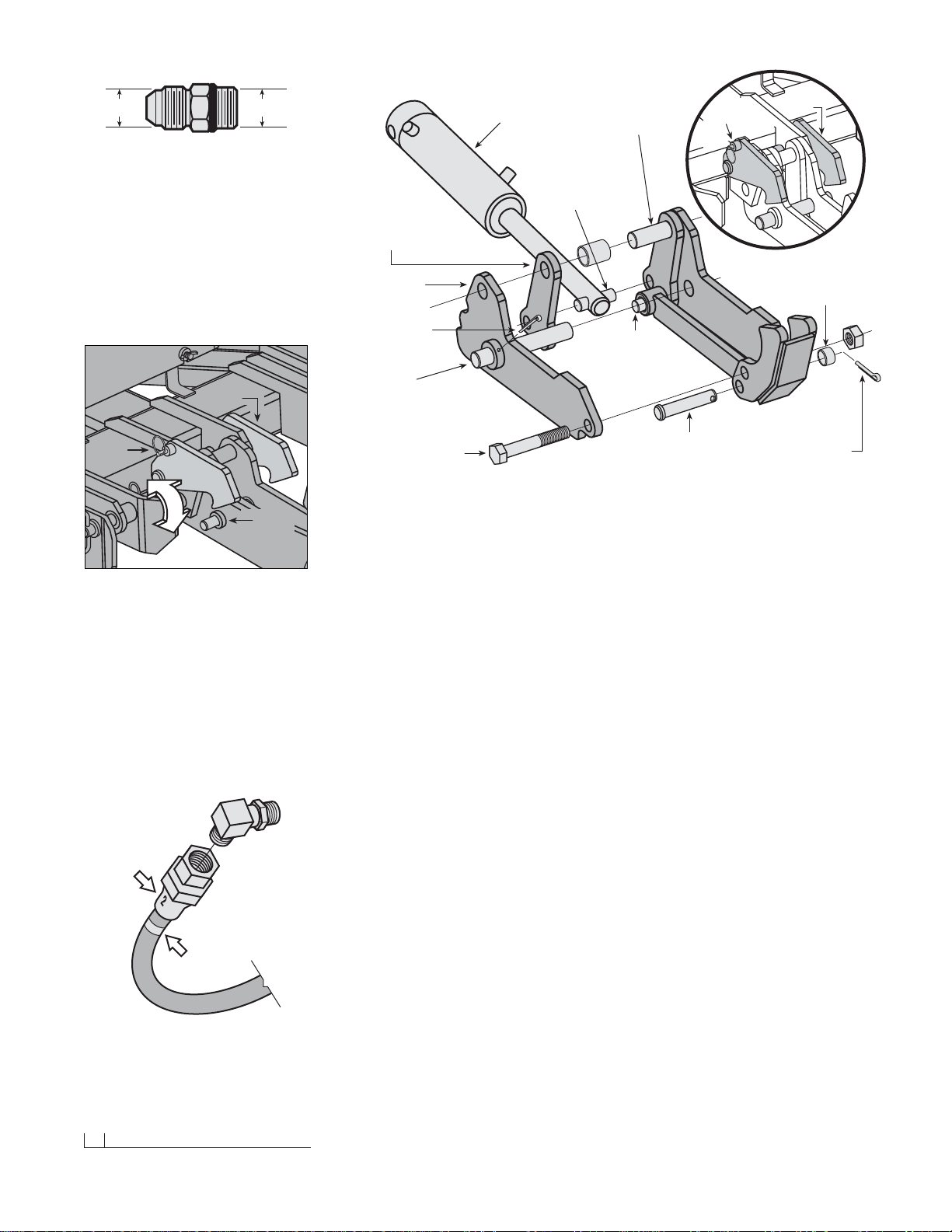

06 Moldboard & A-frame Assembly (cont.)

adapter on the cylinder.Both hoses should be routed through the triangular openings in the A-frame.

5. Begin the draw latch installation by first removing the DRAW LATCH

MOUNT PIN & SPACER from the assembly. By removing this pin, the

INNER DRAW LATCH PLATES can swing free.Proceed to remove

the INNER DRAW LATCH PLATE LIFT CYLINDER MOUNT PIN.

Position the plates on either side of the lift/lo w er cylinder rod and insert

the pin through the plates and cylinder rod.With the cylinder connected

to the inner draw latch plates, rotate the draw latch assembly toward

the draw latch mount holes on the A-frame.Align the holes in the outer

draw latch plate with those of the inner draw latch plates and the

A-frame. Note: The A-FRAME LATCH, located at the rear center of

the A-frame, should be raised up to insert the draw latch mount pin.

Pull the A-FRAME LATCH PULL PIN out and rotate the latch counterclockwise if it is locked into position.Secure the assembly to the A-frame

by replacing the draw latch mount pin and spacer.Reset the A-frame

latch so the A-frame latch pull pin locks into place.

Once you have completed the draw latch installation, we will shift our

attention to assembly of the manifold.The manifold, pump and coil harness

have been joined together at the factory; however, the manifold contains

several components that you will need to install prior to securing the

assembly to the A-frame.

6. Each of the 4 HOSE PORTS on the HYDRAULIC MANIFOLD are

covered with stretch wrap .Remove the wrap and install the appropriate

fitting (illustrated on page7) in its respective port.

Note: All por ts are identified by a stamped number on the manifold.

The numbers also identify the hydraulic functions, which can be referenced on the label under the hydraulic pump and manifold cover

(see illustration on page 7).

7/16" 7/16"

Male O.R.B.Connector Adapter

A-Frame

Latch Pull Pin

A-Frame

Latch

Outer Draw

Latch Plate

Inner Draw

Latch Plate

Draw Latch Mount Pin

(1" DIA. x 4-21/32") or

(1" DIA. x 3-7/8") for

700LD & 760LD only

Inner Draw Latch

Plate Lift Cylinder

Mount Pin

(3/4" DIA. x 2-1/2") or

(5/8" DIA. x 2-3/8") for

700LD & 760LD only

Draw Latch Arm

Pivot Pin

(3/4" DIA. x 2-1/2") or

(3/4" DIA. x 2-3/8") for

700LD & 760LD only

Hydraulic

Lift / Lower

Cylinder

Draw Pin

(1" DIA. x 6-1/2") or

(1" DIA. x 5-5/8") for

700LD & 760LD only

3/16" x 2-1/2"

Cotter Pin

Hex Head Cap Screw

(3/4"-10 x 4-1/2") or

(3/4"-10 x 4") for

700LD & 760LD only

1" O.D., 25/32" I.D. x 5/8"

Spacer

Clevis Pin

(3/4" x 3-41/64") or

(3/4" x 3-7/16") for

700LD & 760LD only

1/4" x 1-1/2"

Hammerlock

Cotter Pin

Draw Latch Assembly

The draw latch consists of a series of interconnected plates and pins that attach to the A-frame

and the hydraulic lift cylinder.

Draw

Pin

A-Frame

Latch

Lock Pin

A-Frame

Latch

To mount the straight blade, the A-frame latch

should be lowered over the draw pin– this allows

the draw latch to pull the plow into the undercarriage. Once the plow is safely attached to the

undercarriage, rotate the A-frame latch counterclockwise until the lock pin snaps into place.The

A-frame latch is only used to mount the plow.

Do not allow the lock pin to set behind the pin

catch hole in the raised position.The A-frame

latch should always be locked in place when

not in use.

Stamped

Number

Printed

Label

All of the hoses shipped with the snowplows

contain either a stamped number on the sleeve or

a printed label applied to the hose. All numbers,

stamped or printed, correspond with the stamping

of the ports on the manifold.

Moldboard & A-frame Assembly (cont.) 07

Installing The Manifold Adapters

There are a total of 6 hydraulic adapters to install.

All of the adapters can be found packaged with

the manifold assembly. Remove the protective

stretch wrap from the manifold in a clean area.

DO NOT let any foreign objects enter into the

open ports.The valves can become contaminated

and greatly hinder the plow’s performance.

Review the table on page 33 for proper torque

specifications.

7/16" 9/16"

7/16"

9/16"

9/16"

9/16"

9/16"

Male O.R.B.Connector Adapter & 90˚ Swivel Elbow Adapter

(Ports #3 & #4)

90˚ Adjustable Elbow O.R.B.Adapter

(Port #1)

Male Extra Long Elbow Adapter

(Port #2)

S6 S8S4

RV FC

S3 S5 S7

Hydraulic Hose Identification Guide

Straight Blade Snowplows

Calumet, Michigan 49913

HYDRAULIC HOSES

1

23 4

Port Function

S3 Left Angle - Right Cylinder

S4 Right Angle - Left Cylinder

S6 & S7 Raise - Lift Cylinder (Base)

S5 & S8 Lower - Lift Cylinder (Rod)

S5 & S7 Float

RV Angle Relief Valve

FC Variable Flow Control Valve

BLZ 1035

NOTE: Energize the following

solenoids for the functions:

1Right Angle - Left Cylinder

2 Left Angle - Right Cylinder

3Raise - Lift Cylinder (Base)

4Lower - Lift Cylinder (Rod)

Pressure Gauge

Quick Connect

Clockwise - Decreases Plow Drop Speed

Counterclockwise - Increases Plow Drop Speed

Note: The gray arrows shown on the manifold illustration above indicate

the direction the 90˚ adapters should face to receive the hydraulic hoses.

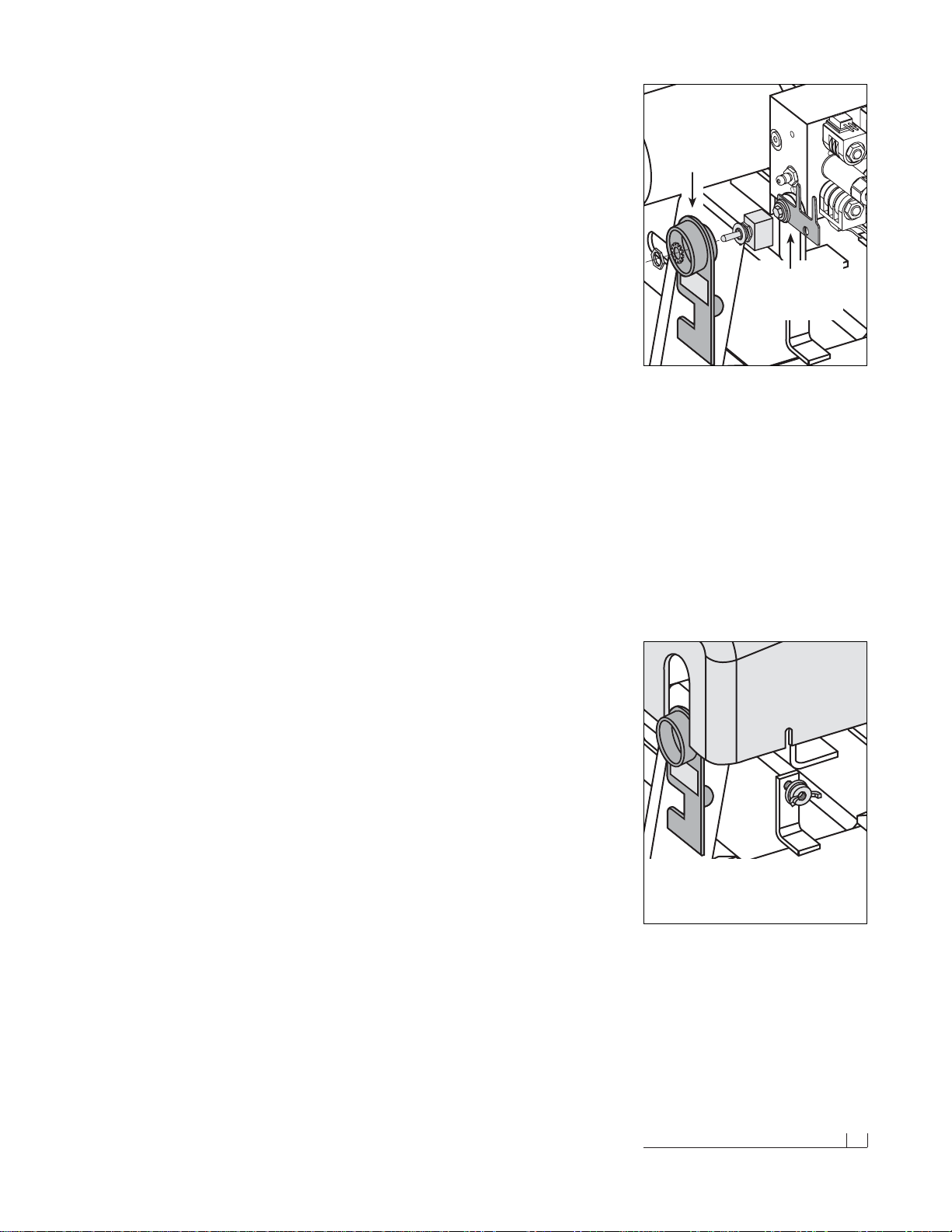

7. Next, align the mount holes in the pump with the holes in the hinged

bracket, located on the A-frame .Note:To help facilitate the pump mount,

first angle the hinged bracket as needed and tighten the bracket

hardware, locking it in place.

CAUTION:When installing the manifold between the mount

brackets on the A-frame, hold the manifold at the sides of

the block.Never handle the manifold b y the wire lead coils.

Doing so can cause a solenoid cartridge to bend, causing

the cartridge to stick when activated.

When installing the manifold between the mount

brackets on the A-frame, DONOT handle the

manifold by the wire lead coils.The solenoid

cartridges can bend, causing them to stick when

activated.Always carry the manifold by the sides

of the aluminum block.

08 Moldboard & A-frame Assembly (cont.)

Secure one 3/8"-16 x 3/4" hex head cap screw and 3/8" flat washer

through the top mount hole in the bracket and into the pump. Insert

one 3/8"-16 x 1-3/4" threaded stud and 3/8"-16 jam nylon insert lock

nut through the bottom mount hole in the bracket and into the pump.

The threaded stud should bottom out in the pump.Note:A medium

strength threadlocker , such as Loctite®242® should be used on both

of the pump mount fasteners.This will help prev ent the fasteners from

working free.

8. Once the pump and manifold assembly is in place, connect the

hydraulic hoses to their respectiv e adapters on the manifold. Remember,

the labeling on the hydraulic hoses correspond with the stamped

numbers on the manifold.

Begin installing the hoses with the driver’s side r aise cylinder hose (#3).

Attach the straight end of the hose to the 7/16"-20 x 9/16"-18 90˚

swivel elbow adapter on the manifold. Connect the passenger’s side

lower cylinder hose to Port #4. Loop the hose through the opening in

the A-frame and connect the straight end of the hose to the 7/16"-20

90˚ swivel elbow adapter. Run both angle cylinder hoses (#1 and #2)

over the A-frame angle and to their respective manifold por ts. Note:

The lift cylinder hoses should be routed through the triangular openings

in the A-frame.

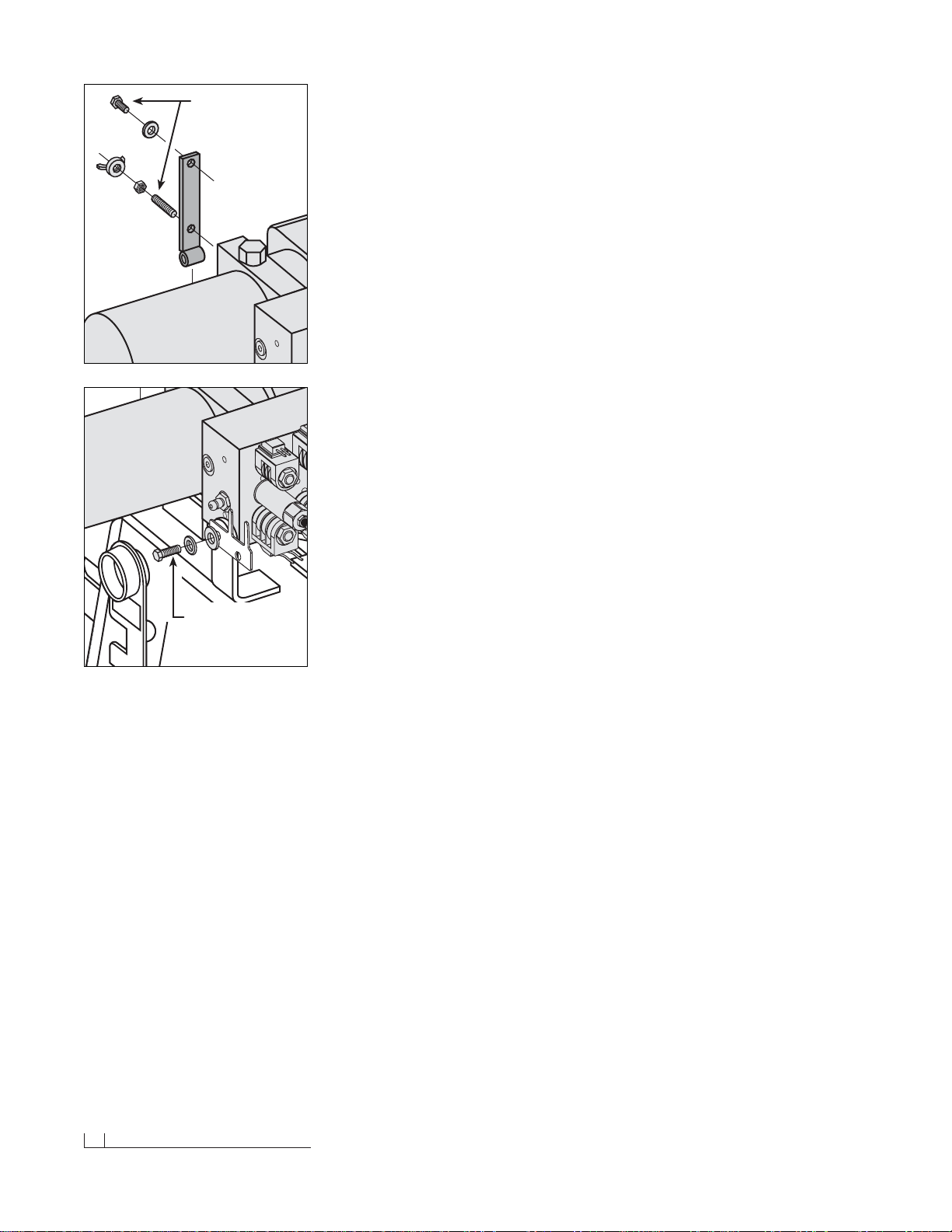

9. Next, secure the manifold to the A-fr ame.Remove both 3/8" flat washers,

3/8" split lock washers and 3/8"-16 x 1" hex head cap scre ws from the

manifold and align the mount holes with the A-frame brac kets .Position

the DIODE PACK MOUNT BRACKET against the outside of the Aframe bracket on the driv er’s side. Note: Both of the prongs should be

facing up.Align the outside hole on the diode bracket with the holes

on the A-frame and manifold.Properly replace and tighten all hardware.

Note:A medium strength threadlocker, such as Loctite®242® should

be used to secure the manifold mount fasteners.

10. Hook each EXTENSION SPRING to the receiving holes located on

the pivot beam and connect the opposite end of the spring to their

respective SPADE BOLTS.Install the 5/8"-11 x 5" spade bolts through

the EXTENSION SPRING MOUNTING ANGLE on the top rear of the

blade.Secure each spade bolt by placing one 5/8" flat washer on the

bolt and thread one 5/8"-11 nylon insert lock nut.Tighten each lock nut

until a piece of paper can pass between the 3th & 4th coils on the spring.

11. Install the flexible BLADE GUIDES at each end of the moldboard.

Insert the 5/16"-18 x 1" hex head cap screw through the holes provided

at the top of the outside reinforcement rib.Tighten all screws using the

nylon insert lock nuts provided.

Congratulations! You have successfully completed half of the installation.

Don’t quit now, you’re nearly out of the garage!

A medium strength threadlocker, such as Loctite®

242®, should be used to properly secure the

mount hardware for the pump and manifold. This

will help prevent the hardware from working free

from vibration and plow use. Apply a liberal

amount of threadlocker to both threaded fasteners and the threads in the pump (top diagram).

The manifold receives two 3/8"-16 x 1" hex cap

screws—one on each side of the A-frame. Likewise, use threadlocker on these fasteners and

the tapped holes in the manifold (bottom diagram).

Use Loctite® on

Manifold Mount

Hardware

Apply Loctite®

To Pump Mount

Hardware Upon

Installation

Electrical Assembly - Plow Harness 09

Electrical Assembly - Plow Harness

1. Begin the electrical assembly by connecting the RED POWER WIRE

from the PLOW ELECTRICAL HARNESS to the PUMP motor terminal

stud using the hardware provided on the pump.

2. Place one 3/8" INTERNAL/EXTERNAL TOOTH LOCK WASHER, the

BLACK GROUND WIRE (from the harness) and the RED GROUND

WIRE on the COIL WIRE HARNESS (from the manifold) over the

tapped hole on the pump and secure the ground using one 3/8"-16 x

3/4" hex head cap screw.

3. Remove the hex jam nut and external tooth lock washer from the

POWER HITCH CONNECT/DISCONNECT TOGGLE SWITCH and

insert it through the back of the mounting bracket on the A-frame.Align

the notch in the key washer on the switch to the notch on the bracket.

Replace the lock washer and jam nut and tighten until the switch is

firmly in place. Next, attach the connector on the plow harness to the

switch. Note: Use caution when making the connection.Switches can

break if done forcefully.

4. Continue the harness installation by connecting the PLASTIC FEMALE

ELECTRICAL CONNECTOR on the harness to the PLASTIC MALE

ELECTRICAL CONNECTOR found on the coil wire har ness.

5. Finalize the harness installation by sliding the DIODE PACK over the

diode pack mount brack et located behind the connect/disconnect toggle

switch. Position the wire har ness braid in the notch on the switch

bracket and secure it with a cable tie.The diode pack mount bracket

contains an extra hole f or a cable tie. Use it to secure the diode pack.

6. To install the PUMP & MANIFOLD COVER, align the notches in the

cover with the welded bolts on the A-frame br ack ets.Secure the cover

with two 3/8" FLANGED WING NUTS. Verify the cover is positioned

over the protective toggle switch hood.Pop the front of the cover on

the threaded stud and secure it with the remaining wing nut.

Congratulations! You have just completed building the finest snowplow

available! However, the vehicle wire harness still needs to be installed.

That is the focus of the second half of the electrical assembly instruction.

Diode Pack

Mount Bracket

Draw Latch

Toggle Switch

Mount Bracket

The diode pack (on the plow harness) clips onto

the diode pack mount bracket.Place a cable tie

through the hole at the end of the bracket and

over the pack to secure it in place.

The draw latch toggle switch installs through the

rear of the bracket with the protective hood.Align

the key washer with the slot cut in the bracket to

prevent the switch from turning. Secure the

switch with the hardware provided.Note: Use the

square notch in the bracket (below the protective

hood) to position the braided harness.Use another

cable tie to hold the harness against the bracket.

The Pump Cover Installs Over

The Top Of The Draw Latch

Switch Bracket

To properly secure the pump and manifold cover

on the A-frame, position the cover over the top of

the protective hood on the draw latch switch

mount bracket. Align the slots in the cover with

the welded bolts on the A-frame brackets—

secure the cover using three flanged wing nuts.

10 Electrical Assembly - Vehicle Harness

Electrical Assembly - Vehicle Harness

CAUTION:Alwa ys perf orm the vehic le wire harness assembly with the vehicle off and the keys out of the ignition. Use

caution when testing the electrical wires for the vehicle’s

headlight functions.

1. Begin the installation of the electrical har ness under the hood. Insert

the WHITE POWER CONNECTOR & RED POWER WIRE (with FUSE)

end of the harness through the driver’s side fire wall access panel into

the vehicle cab.Note:You may need to widen an opening or cut access

to the cab interior to facilitate the assembly. Loosely position the

remaining portion of the harness over the driver’s side fender w ell and

place the MOLDED RUBBER POWER CONNECTOR near the bumper .

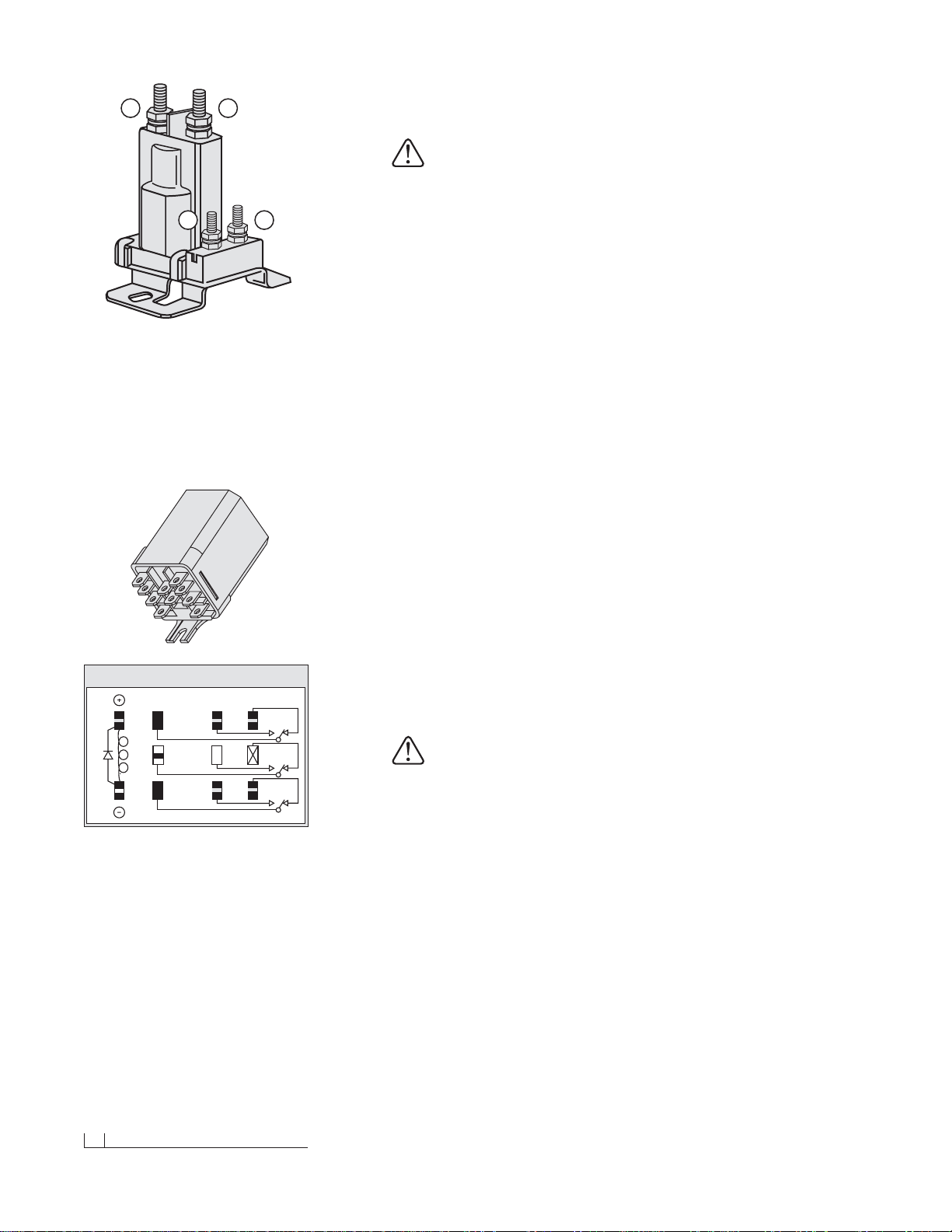

2. Next, attach the POWER CONTACTOR (SOLENOID) to the driver’s

side wheel well or engine fan guard using two 12-14 x 3/4" hex washer

self-drilling screws.Note: Some model vehicles provide mounting

locations for accessory components.Connect the 24" BLACK GROUND

WIRE to either small terminal on the solenoid and attach the opposite

end to the vehicle with one hex washer self-dr illing screw. Locate the

BROWN/WHITE PUMP SOLENOID ACTIVATION WIRE on the wire

harness and position the eyelet over the remaining small terminal on

the contactor.Secure it with the hardware provided on the solenoid.

3. Proceed to connect the BLACK VEHICLE WIRE HARNESS GROUND

WIRE to the negative terminal on the vehicle’ s battery.Cut the wire to

length and crimp a 3/8" DIA. END RING TERMINAL on the wire.It is

also recommended that the ring terminal be soldered. Note: The har-

ness should be secured to the vehicle prior to taking the necessary

measurement. Measure the distance needed for the RED POWER

WIRE to reach the solenoid and properly secure an end ring terminal

to it. Connect the power wire to either large terminal on the solenoid.

CAUTION:Do not fasten the wire harness to areas that come

in contact with moving engine parts or possess extreme

heat.The harness could become tangled and/or melt causing

electrical failure and vehicle damage.

4. Attach and solder an end ring ter minal to both ends of the remaining

length of the red 4 gauge wire. Connect one end of the wire to the

open terminal on the solenoid and the remaining end to the positive

terminal on the battery.

5. With the vehicle harness secured to the truck, position the MAIN

LIGHTING HARNESS such that both of the large, gray VEHICLE

HEADLIGHT CONNECTORS are near the truck headlights and the

smaller, black PLOW HEADLIGHT CONNECTORS are near the grill

of the vehicle.

6. Plug the 9 TERMINALS, from the main lighting har ness, into the

HEADLIGHT RELAY. See the illustration to the left. Connect the

GREEN & YELLOW wire, from the vehicle harness with the molded

power plug, to the remaining spade on the relay. Securely mount the

relay to the vehicle with the terminals facing down. Installing the relay

in this position will allow moisture to drain from the relay.

A B

C D

Heavy-Duty Power Contactor (Solenoid)

There are four wires that need to be attached to

the power contactor:

(A) Red Power Battery Wire

(B) Vehicle Wire Harness Red Power Wire

(C) 24" Black Ground Wire

(D) Brown/White Pump Solenoid Activation Wire

A

B

G/Y

BK/W

Y7

W/R 8

LT. G 9

HIGH

GROUND

LOW

Y/B 4

WHITE 5

Y/R 1

N/A 2

LT. G/B 6

LT. G/R

3

3PDT RELAY (30 AMPS) 12 VOLTS

Connect the color coded wires from the vehicle

harness to the headlight relay shown above.The

wires correspond to the numbers/letters on the

relay or the color abbreviations on the illustration.

(A) BK/W = Black/White Wire

(B) G/Y= Green/Yellow Wire

(1) Y/R = Yellow/Red Wire

(2) N/A = Not Applicable

(3) LT.G/R = Light Green/Red Wire

(4) Y/B = Yellow/Black

(5) W = White

(6) LT.G/B = Light Green/Black

(7) Y = Yellow

(8) W/R = White/Red Wire

(9) LT. G= Light Green

Loading...

Loading...