Page 1

O

O

P

P

E

E

R

R

A

A

A

A

N

N

T

O

T

D

D

O

R''

R

S

S

P

P

A

A

R

R

T

T

S

S

M

M

A

A

N

N

U

U

A

A

L

L

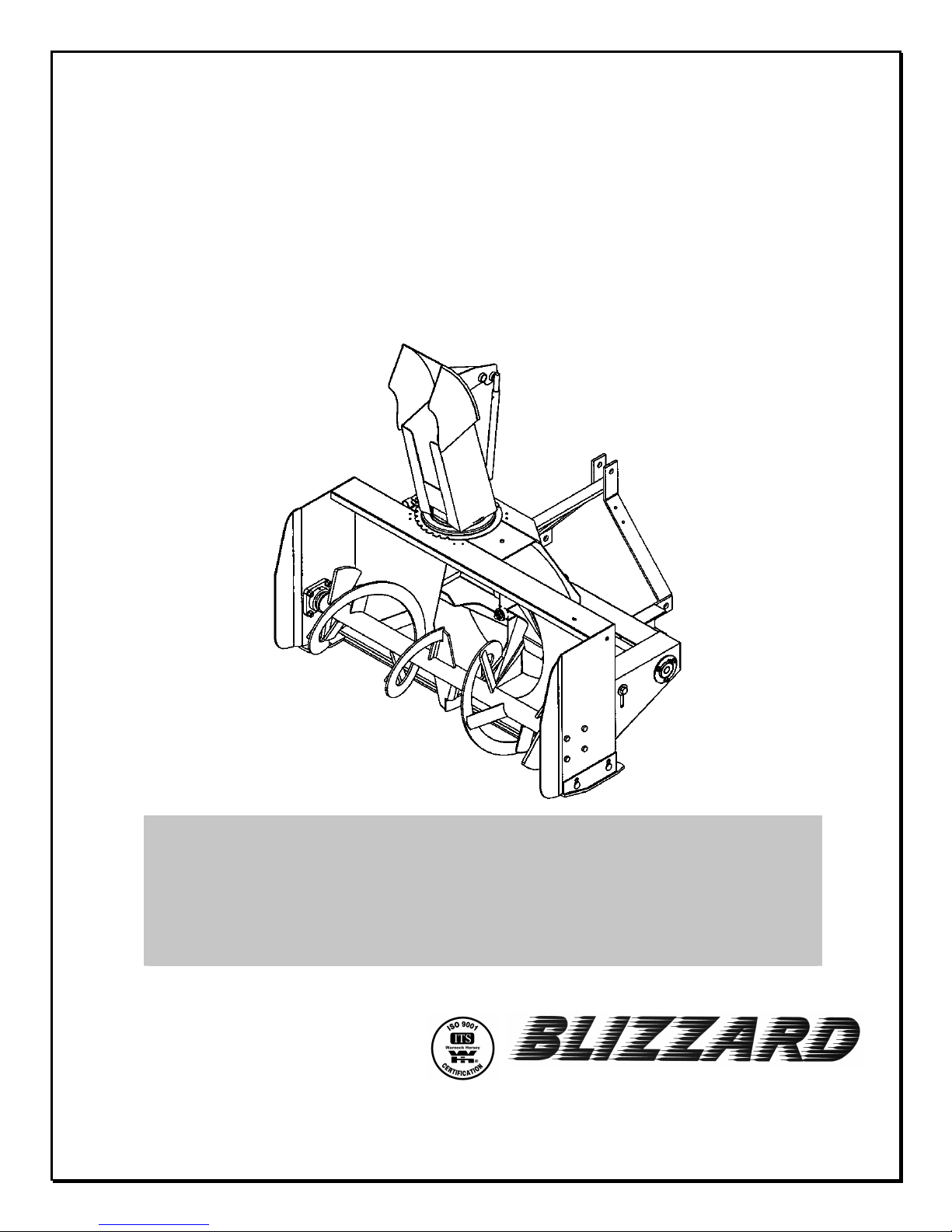

BLIZZARD B54 & B64 MODELS

OM 0277-A

06/02

SNOWBLOWER

SERIAL NO. 2024768 AND UP

by RAD Technologies Inc.

Page 2

Page 3

TABLE OF CONTENT

INTRODUCTION – TO THE PURCHASER.............................................................................................. 3

SAFETY PRE CAUTIONS.......................................................................................................................... 4

Before Operation.............................................................................................................................. 4

Notice................................................................................................................................................ 5

The Snowb l o wer............................................................................................................................... 5

Before Operation............................................................................................................... 5

Snowblower operati o n....................................................................................................... 6

The Tractor.......................................................................................................................................7

General Information........................................................................................................... 7

Operating the Trac to r......................................................................................................... 7

During Operatio n............................................................................................................... 7

Maintenance..................................................................................................................................... 8

Transporting...................................................................................................................................... 8

Storage ......................................................................................................................................... 8

DECALS ................................................................................................................................................... 9

ASSEMBLY.............................................................................................................................................. 10

Snowblo wer Assembly................................................................................................................... 10

Driveline Installation ...................................................................................................... 10

Chute & Manual Ro tati on............................................................................................... 10

Snowblower Installation................................................................................................. 12

Removing the S n owblowe r from th e Tra c to r................................................................. 12

Hydraulic Rotation with Cylinder – 8056 (Optional )....................................................... 13

OPERATION ........................................................................................................................................... 14

General Preparation ....................................................................................................................... 14

Operating Con tro l s ......................................................................................................................... 14

Work and Travel Speed ................................................................................................ 14

Raising and Lowerin g the Snowblower..........................................................................14

Drive Sha ft Oper a ti o n ................................................................................................... 14

Manual Rotation ............................................................................................................ 14

Reduction Chain Tension Adjustment ........................................................................... 14

Skid Shoe Adjustment ................................................................................................... 14

Manual Deflector Adjustment ........................................................................................ 14

Snow Remova l Methods ................................................................................................................ 15

OM 0277 – A 1

Page 4

TABLE OF CONTENT

MAINTENANCE ..................................................................................................................................... 16

Maintenance ..................................................................................................................................16

Storage .......................................................................................................................... 16

Driveline.......................................................................................................................... 16

Lubrication...................................................................................................................... 16

PARTS .................................................................................................................................................... 17

Introduction....................................................................................................................................... 17

Frame and Related Parts - Bli zzard B54 & B64 ............................................................................... 18

Gearbox (663485)............................................................................................................................. 20

Manual Rotation – K i t 9377...............................................................................................................21

Hydraulic Rotati on by Cylinder – Kit 8056.........................................................................................22

Driveline (665341).............................................................................................................................23

WARRANTY ........................................................................................................................................... 24

TORQUE SPECIFICATION TABLE ....................................................................................................... 25

OM 0277-A

2

Page 5

INTRODUCTION

TO THE PURCHASER

All BER-VAC and BLIZZARD products are

designed to give safe, dependable service if they

are operated and maintained according to

instructions. Read and understand this manual

before operation.

This manual has been prepared to assist the

owner and operators in the safe operation and

suitable maintenance of the implements. The

information was applicable to product s at the time

of manufacture and does not include

modifications made afterwards.

Read and understand this operator's manual

before attempting to put an implement into

service. Familiarize yourself with the operating

instructions and all the safety recommendations

contained in this manual and those labeled on the

implements and on the t ractor. Follow the safety

recommendations and make sure that those with

whom you work follow them.

To assist your dealer in handling your needs, please record hereafter the model number and serial

number of your implement and tractor. It is also advisable to supply them to your insurance company. It

will be helpful in the event that an implement or tractor is lost or stolen.

Illustrations

The illustrations may not necessarily reproduce

the full detail and the exact shape of the parts or

depict the actual models, but are intended for

reference only

Direction Reference

Right Hand and Left Hand are determined by

those seen by the conductor looking at the

machine while operating.

MODEL :

SERIAL NUMBER :

DATE OF PURCHASE :

OM 0277-A

3

Page 6

SAFETY PRECAUTIONS

SAFETY FIRST

This symbol, the industry's "Safet y Alert Symbol", is used t hroug hout t his manual and on labels

on the machine itself to warn of the possibility of personal injury. Read these instructions

carefully. It is essent ial that you read the instr uctions and saf et y regulat ions bef ore you attem pt

to assemble or use th i s u n i t.

DANGER : Indicates an immediately hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING : Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

CAU TION : Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

IMPORTANT : Indicates that equipment or property damage could result if instructions

are not followed.

NOTE : Gives helpful information.

All products are designed to give safe, dependable service if they are operated and maintained

according to instructions. Read and understand this manual before operation

responsibility to be certain anyone operating this product reads this manual., and all other applicable

manuals, to become familiar with this eq uipment and all saf ety precautions. Failure to do so could result

in serious personal injury or equipment damage. If you have any questions, consult your dealer.

BEFORE OPERATION

Children

Tragic accidents can occur if t he operator is not

alert to the presence of children. Children are

generally attracted to machines and the work

being done. Never assume children will remain

where you last saw them.

1. Keep children out of the operating area and

under the watchful eye of another

responsible adult.

2. Be alert and turn machine off if children enter

the work area.

4. Never carry children while operating the

machine. They may f all off and be seriously

injured or interf ere with safe operation of the

machine.

5. Never allow children to play on the machine

or attachment even when turned off.

6. Never allow children to operate the machine

even under adult supervision.

7. Use extra care when approaching blind

corners, shrubs, trees, or other obstructions

that might hide children from sight.

. It is the owner's

3. Before and when backing, look behind and

look for small children.

OM 0277-A

4

Page 7

SAFETY PRECAUTIONS- continued

NOTICE

A safe operator is the best insurance against accidents. All oper ators, no mat ter how experienced they

may be, should read this Operator's Manual and all other relat ed manuals before attem pting to operate

an implement. Please read the following section and pay part icular attention to all safety recommendations contained in this manual and those labeled on the implements and on the tractor.

THE SNOWBLOWER

Before Operation

1. Read and understand this operator 's manual

and tractor operator's manual. Know how to

operate all controls and how to stop the unit

and disengage the controls quickly.

2. Never wear loose, torn, or bulky clothing

around the tractor and implement. It may

catch on moving parts or controls, leading to

the risk of accident.

3. Before the snow season, thoroughly inspect

the area where the equipment is t o be used

and remove all doormats, sleds, boards and

other foreign objects.

4. Disengage clut ch and shift into neutral bef or e

starting the engine.

5. Do not operate equipment in wintertime

without wearing adequate winter garments.

9. Replace all missing, illegible, or damaged

safety and warning decals. See list of

decals in the operator's manual.

10. Do not m odify or alter this equipment or any

of its components, or any equipment

function without first consulting your dealer.

11. Keep safety decals clean of dirt and grime.

6. Never attempt to make any adjustments

while engine is running. Read this manual

carefully to acquaint yourself with the

equipment as well as the tractor operator's

manual. Working with unfamiliar equipment

can lead to accidents. Be thoroug hly familiar

with the controls and proper use of the

equipment. Know how to stop the unit and

disengage the controls quickly.

7. Keep all shields in place and properly tighten

all mounting hardware.

8. Periodically, inspect all moving parts for

wear and replace with authorized service

parts if an excessive amount of wear is

present.

OM 0279-A

5

Page 8

SAFETY PRECAUTIONS- continued

Snowblower Operation

1. Before leaving the tractor unattended, take

all possible precautions. Disengage the

PTO, stop the engine and remove the

ignition key. Lower the implement to the

ground.

2. Before starting the snowblower, remove any

ice that has accumulated in the

auger/impeller.

3. Watch car efully for foreign objects that could

enter the blower while operating.

4. Be sure the clutch switch/lever is in OFF

position before starting engine.

5. Do not put hands or feet near rotation part s.

Keep clear of discharge opening at all times.

6. Exercise extreme caution when operating on

or crossing a gravel drive, walks, or roads.

Stay alert for hidden hazards or traffic. Do

not carry passengers.

14. Never operate machine at high transport

speeds on a slippery surface.

15. Use extra caution when backing up.

16. Do not direct discharge at bystanders or

animals. Ejected objects may cause injury.

17. Disengage power to auger/impeller when

transporting or when not in use.

18. Never operate the snowblower without good

visibility and lighting.

19. Prolonged exposure to loud noise can

cause impairment or loss of hear ing. Wear

a suitable hearing protective device such

as earmuffs or earplugs to protect against

objectionable or uncomfortable noises

7. Adjust collector housing height to clear

gravel or crushed rock surface.

8. Stop the engine, remove the k ey, and allow

the rotating parts t o stop before unclogging

the collector/impeller housing or chute, and

making any repairs, adjustments or

inspections. Use only a 36" long piece of

wood to unclog blower.

9. If the snowblower starts to vibrate

abnormally, stop the engine immediately

and check for cause. Excessive vibration is

generally a sign of trouble.

10. Do not run the engine indoors except when

starting engine and transport ing attachment

in or out of building. Carbon monoxide gas is

colorless, odorless and deadly.

11. Exercise extreme caution when changing

direction on slopes. Do not attempt to

operate on steep slopes.

12. Never operate snowblower without guards,

and other safety protective devices in place.

13. Never operate snowblower near glass

enclosures, automobiles, window wells,

embankments, etc., without proper

adjustment of snow discharge angle.

OM 0279-A

6

Page 9

SAFETY PRECAUTIONS- continued

THE TRACTOR

General Information

1. Read the operator's manual carefully before

using tractor. Lack of operating knowledge

can lead to accidents.

2. Do not perm it anyone but the oper ator t o ride

on the tractor. There is no safe place for

extra riders.

Operating the Tractor

1. Never run the tractor engine in a closed

building without adequate ventilation, as the

exhaust fumes are very dangerous.

2. Never allow an open flame near the fuel

tank or battery.

3. Make sure the shield is installed when

using a PTO-dr iven equipment and always

replace the shield if damaged.

4. Always bring the tractor to a complete stop,

shut off the engine, lower the implement to

the ground and remove the ignition key

before leaving the tractor.

5. Never park the tractor on a steep slope.

6. Do not attempt to operate on steep slopes.

7. Use of tire chains for better traction and

stability is recommended.

8. Always drive the tractor at speeds

compatible with safety, especially when

operating over rough ground, crossing

ditches, or when turning.

13. Never allow anyone to operate the

snowblower until they are thoroughly familiar

with basic tractor and snowblower operation.

14. Make sure the tractor is counterweight ed as

recommended by your dealer. Weights

provide the necessary balance to prevent

tip-over or loss of traction or steering.

15. Always make sure all snowblower

components are properly installed and

securely fastened BEFORE operation.

During Operation

1. Do not allow anyone to ride on the

tractor/snowblower at any time. There is no

safe place for passeng ers on this equipm ent.

The operator MUST sit in the tractor seat.

2. Eye and hearing prot ection is recommended

when operating the snowblower.

3. Operate only during daylight hours, or when

the area is well lit with bright artificial light.

4. Disengage the PTO (turn to “OFF”), place

the transmission in neutral, set the parking

brake, shut off the engine and remove the

key, and make sure rotating components

have stopped BEFORE leaving the

operator’s seat.

5. Inspect the snowblower after striking any

foreign object to assure that all snowblower

parts are safe and secure and not damaged.

9. Handle fuel with care, as it is highly

flammable.

10. Use approved fuel container.

11. Never add fuel to a running eng ine or a hot

engine.

12. Fill fuel tank outdoors with extreme care.

Never fill fuel tank indoor s. Replace fuel cap

securely and wipe up spilled fuel.

OM 0279-A

7

Page 10

SAFETY PRECAUTIONS- continued

MAINTENANCE

Park the tr act or /snowblower on level ground, set

the parking brak e, disengage the PTO, shut of f

the engine, remove the key, and lower the

implement to the ground BEFORE making any

snowblower adjustments.

1. To avoid injury, do not adjust, unclog or

service the snowblower with the tractor

engine running. Making sure rotating

components have completely stopped before

leaving the operator’s seat

2. Keep the tractor/snowblower clean. Snow

and ice build-up can lead to malfunction or

personal injury from thawing and refreezing

in garage.

3. Always wear eye protection when cleaning or

servicing the snowblower.

4. Do not work under any part of the tractor or

snowblower, unless it is securely supported

by safety stands.

5. Make sure all shields and guards are

securely in place following all service,

cleaning, or repair work.

6. Do not modify or alt er this equipment or any

of its components or operating functions. If

you have questions concerning

modifications, consult with your dealer.

TRANSPORTING

1. If the tractor/snowblower is to be driven on

public roads, it must be equipped with an

SMV (Slow Moving Vehicle) sign. Check

local traffic codes that may apply to unit

usage on public roads and highways in your

area.

2. Be alert for all other traffic when driving the

tractor/snowblower on public roads or

highways.

STORAGE

Before storing the snowblower, certain precautions should be taken to protect it from

deterioration.

1. Clean the snowblower thoroughly.

2. Make all the necessary repairs.

3. Replace all Safety Signs that are damaged,

lost, or otherwise become illegible. If a part

to be replaced has a sign on it, obtain a new

safety sign from your dealer and install it in

the same place as on the removed part.

4. Repaint all parts from which paint has worn

or peeled.

5. Lubricate the snowblower as instructed

under "Lubrication" section.

OM 0279-A

6. When t he snowblower is dry, oil all moving

parts. Apply oil liberally to all surfaces to

protect against rust.

7. Store in a dry place.

8

Page 11

DECALS

Replace immediately if damaged.

660988

660989

656779

664459

664458

664467

655834

Located on

driveline

Included with Option 8056

656780

OM 0279-A

664548

656781

9

Page 12

ASSEMBLY

2

SNOWBLOWER ASSEMBLY

The snowblower is assembled at the factory,

however, snowblower kit must be assembled.

Use the present manual and lay out all par ts for

assembly. Separate bolts and nuts into various

sizes. After assembly, torque all the bolts

according to the Torque Specification Table

enclosed at the end of the manual.

Driveline Installation

1. Remove paint from snowblower gearbox drive

shaft and grease driveline sliding surfaces

and yoke.

2. Remove the bolt of the yoke and slide

driveline yoke over drive shaft using sliding

action of the driveline. Make sure the driveline

is well secured to the drive shaft by replacing

the bolt and tightening it according to the

torque specification table.

Chute & Manual Rotation

1. Place the anti-friction ring (fig.2, item 4) over

the chute base, placing the raised part upside

and toward the center of the frame.

Figure

Figure 1

2. Insert the 1 11/16’’lg. plastic bushing (fig.4,

item 11) in the worm rotation bracket (fig.4,

item 6). G rease the two ends of the rotation

worm (fig.4, item 5) and insert the rotation

worm in the bushing (fig.4, item 11).

3. Insert the 1 5/16’’ plastic bushing (fig.4, item

10) in the tube welded behind blower (fig.3,

item 1)

4. Install the assembly by placing the worm

rotation bracket (f ig.4, item 6) under the right

upper plate of the snowblower (fig .3, item 2).

1

2

OM 0279-A

10

Figure 3

Page 13

ASSEMBLY

5. Install the adjustment tube (fig. 2, item 3) in

the lower hole on the backside of the chute

and the adjustment rod (fig. 2, item 2) in the

upper hole. Lock in place using the 1/4" x 2"

(fig. 2, item 7) cotter pins then insert the

∅5mm x 100mm hair pin (fig. 2, item 6) in the

adjustment tube hole (fig. 2, item 3)

6. Install the chute ( fig.2, item 1) over the plastic

insert (fig.2, item 4), applying grease in

between, and place the four retaining plates

(fig.2, item 5). Secure using eight 1/4’’ x 3/4’’

bolts, lockwashers and nuts (fig.2, items 8-9-

10). Tighten all bolts securely.

7. Install t he support ang le (fig 4, item 21) on the

3 point left attaching plat e using two 3/8’’NC x

1 1/4’’ bolts, lockwashers and nuts (fig. 4,

items 16-17-18). Tighten securely.

8. Install anchor tube (fig.4, item 15) on the

support angle (f ig .4 , item 21) using a 3/4’’NC x

1 1/2’’ bolt, lockwasher and nut (fig. 4, items

22-23-24) making sure the tube leans toward

the tractor.

9. Insert handle bracket (fig.4, item 14) inside

anchor tube (fig.4, item 15). Adjust the height

of the handle bracket according to your needs

and shorten it if necessar y. Fast en loosely with

a 3/8’’ x 5/16’’ set screw (fig 4, item 19).

10. Insert assembled rotation tube (fig.4, item 2)

inside the rotation worm. Align holes and

insert a 10-24 x 1’’ capscrew (fig.4, item 12)

making sure the capscrew sinks in the worm.

Secure with a nylon lock nut (fig. 4, item 13).

11. Install the plastic grommet (fig.4, item 20) in

the handle support.

12. Insert the handle (fig.4, item 1) inside the

grommet and inside the rotation tube (fig.4,

item 2) . Select desired length, align nearest

holes and secure with a 5mm x 100mm

hairpin (fig. 4, item 8).

13. Adjust handle position and height to a

comfortable and safe oper ating position after

the snowblower has been mounted to the

tractor. Tighten set screw (fig 4, item 19) on

anchor tube and the 3/4’’ x 1 1/2’’ bolt

securely (fig. 4, item 22).

Figure 4

OM 0279-A

11

Page 14

ASSEMBLY

CAUTION: To avoid personal injury,

check the full lifting range of the snow blow er,

to ensure that the chute rotation handle is

clear of the operator’s area when the

snowblower is in raised position.

14. Install plastic handle (fig.4 item 9) over

rotation handle.

15. Tighten all bolts according to the Torque

Specification Table at the end of the manual.

NOTE

DEFLECTOR, replace the adjustment rod and

tube with a 2" x 6" cylinder.

: To convert to a HYDRAULIC

Snowblower Installation

1. Attach tractor lower hitch arms (fig.5, items 1)

to snowblower attaching plates using the hitch

pins and secure with linchpins (fig.5, items 2).

2. Inst all the tractor upper hitch (f ig.5 item 3) on

the upper hole of snowblower (fig.5, item 5)

attaching plates using tractors pins and

linchpins (fig.5, items 4).

3. Adjust snowblower using the tractor upper

hitch so that it runs level.

CA UTION: Before connecting

snowblower driveline to tractor drive shaft,

make sure driveline is not too l ong in raised,

lowered and middle position. If the driveline

is too long it must be shortened, to avoid

damaged to tractor.

5. Connect driveline to tractor drive P.T.O.,

make sure that the driveline yoke pin is

properly engaged.

Removing Snowblower from Tractor:

1. Set snowblower completely on the ground to

release all pressure from the three- point. Set

parking brake and turn engine off.

2. Detach upper link by removing linchpin and

pin (fig.5, items 4).

3. Disconnect driveline from tractor P.T.O. shaft

and set driveline on support chain.

4. Carefully detach lower links (fig. 5, items 1)

by removing linchpins (fig.5, items 2) and

loosen anti-sway turnbuckles.

IMPORTANT

snowblower, retorque all bolts after the first

10 hours of operation.

: To avoid damage to the

4. Set the tractor anti-sway turnbuckles so the

snowblower does not sway.

Figure 5

OM 0279-A

12

Page 15

ASSEMBLY

6

Hydraulic Rotation with Cylinder 8056 (Optional) Figure 6

1. Place the plastic anti-fr iction insert (f ig.2, it em

4) over the chute base, placing the raised part

upside and toward the center of the frame.

2. Install the adjustment tube (fig. 2, item 3) in

the lower hole on the backside of the chute

and the adjustment rod (f ig. 2, item 2) in the

upper hole. Lock in place using the 1/4" x 2"

(fig. 2, item 7) cotter pins then insert the

∅5mm x 100mm hair pin (fig. 2, item 6) in the

adjustment tube hole (fig. 2, item 3)

3. Install the chute (fig .2, item 1) over the plastic

insert (fig.2, item 4), applying grease in

between, and place the four retaining plates

(fig.2, item 5). Secure using eight 1/4’’ x 3/4’’

bolts, lockwashers and nuts (fig.2, items 8-9-

10). Tighten all bolts securely.

4. Install the cylinder bracket (Fig. 6, item 1)

through the ∅13/32" hole on the frame by

inserting a 3/ 8" NC x 1" bolt (item 13), then

tighten with a flat washer (∅7/16" hole), a

lockwasher and a nut (items 6-7-8).

5. Install the bell crank (item 2) on the f rame by

sliding a spacer (item 4) under the cylinder

bracket, opposite the ∅11/16"hole. Insert a

bushing (item 5) in the ∅1 1/8" hole of the bell

crank and slide the bell crank between the f lat

bars of the cylinder bracket. Fasten

everything by inserting a 5/8" NC x 3 3/4" bolt

(item 12), a lockwasher and a nut (items 16-

17).

6. Install the push arm (item 3) by sliding it

between the bell crank plates, greasing

generously.

7. Insert a 3/8’’ x 3/4’’NC shoulder screw (item

14) under the part and tighten with a ∅3/8"

hole flat washer (item 10) and a 5/16’’NC

stover.nut (item 9), leaving some movement

to the push arm.

8. Slide the other push arm end between the flat

bars welded on the chute base. Inserting a

∅7/16" hole nylon flat washer (item 15) under

the push arm. Fasten everything with a 3/8" x

1" shoulder screw (item 11), a ∅3/8" hole

flatwasher (item 10) and a 5/16’’NC stover.nut

(item 9), leaving some movement to the

mechanism.

Figure

9. This system works with a 8’’ hydraulic cylinder

extension and a 20 1/4’’ centre-to-centre pin

retracted.

OM 0279-A

13

Page 16

OPERATION

GENERAL PREPARATION

1. Read the operator’s manual carefully before

using the tractor and snowblower. Be

thoroughly familiar with the controls and

proper use of the equipment. Know how to

stop the unit and disengage the controls

quickly.

2. Make sure the snowblower is clear of snow

before engaging the driveline.

3. Make sure the auger and fan operate freely.

4. Check the oil level in the worm gear box and

if necessary, add 80W90 SAE gear oil,

AGMA 5EP oil or equivalent.

5. Check the two shear bolts, one on the driving

shaft, and the one on the PTO, for proper

tightness.

6. Adjust so that the snowblower skid shoes run

level.

7. Wear adequate winter outer garments while

operating equipment.

OPERATING CONTROLS

Work and Travel Speed

Work ing ground speed will depend on the depth

and density of the snow to be cleared. Normally,

ground speed will range from 4 to 7 MPH for light,

dry snowfalls 3 to 6 inches, and 1 to 3 MPH for

heavy, wet or drifted snow. To transport,

disengage the drive shaft and raise the

snowblower to full transport height.

Reduction Chain Tension Adjustment

The premature wear of the chain may be caused

by tension being too tight. It is therefore important

not to tighten chain to its maximum.

• To adjust the tension on the drive chain,

loosen the bolt (item 1), securing the idler

sprocket to the snowblower housing.

• To tighten the chain, lower the bolt. Leave

approximately 1/8" deflection in one span of

the chain. Retighten securely the bolt holding

the idler sprocket.

Skid Shoe Adjustment

Adjust the skid shoes so that the snowblower

runs level and according to the surface conditions

so that stones are not thrown with the snow.

Adjust both skid shoes to the same height to

keep the cutting edge level and adjust upwards

for smooth surfaces.

Loosen skid shoe bolts (item 2) and adjust

according to instructions below, and securely

tighten bolts:

Clearance between cutting edge and surface:

Level paved surface : Adjust to 1/16" to 1/8"

•

Uneven or gravel surface: Adjust to 1/2" to 5/8"

•

Raising and Lowering the Snowblower

Move the three point lever on right hand side of

seat down or forward to lower, and up or

rearward to raise.

Drive Shaft Operation

The mid drive shaf t is activated by pulling up the

drive shaft lever on left side of seat. Push down

to disengage.

Ma n ua l R o t at i on (if so equipped)

Turning the handle clockwise turns the chute in

a clockwise direction.

WARNING: To avoid personal injury,

be sure the tractor engine is off, the drive

shaft disengaged, and all movement has

stopped before making any adjustments.

OM 0279-A

Manual Deflector Adjustment

Set the angle of deflection according to the

distance the snow must be thrown. To set the

deflector angle, remove the adjusting pipe hair

pin and adjust the adjusting rod to the desired

deflector angle. Secure with the adjusting pipe

hairpin.

14

Page 17

OPERATION

SNOW REMOVAL METHODS

When removing snow, do not use t he snowblower as a dozer blade to push snow. Let the snowblower

work its way through deep drifts. If the speed of your tractor is too f ast, the snowblower may become

overloaded and clog. For best r esults, r aise the snowblower and remove a top layer of snow. A second

pass with the snowblower will remove the remaining snow.

IMPORTANT

WARNING: Do not use hands or feet to unclog chute. Do not attempt to clear clogg ed chute of

snow while tractor engine is running. If t he chute clogs, disengage the drive shaft, shut off the tractor

engine, remove the ignition key, wait for all movement to stop, and then clear the snow from the chute.

A definite pattern of operation is required to thoroughly clean the snow area. These patterns will avoid

throwing snow in unwanted places as well as eliminating a second removal of snow

: Use full RPM power when removing wet, sticky snow. Low RPM power will tend to clog

the chute.

Where it is possible to throw the snow to the left

and right (above), as on a long driveway, it is

advantageous to start in the middle. Plow from

one end to the other, throwing snow to both sides

without changing the direction of the discharge

guide

OM 0279-A

If the snow can only be thrown to one side of the

driveway or sidewalk (above), start on the

opposite side. At the end of t he first pass, rot ate

the discharge guide 180 degrees for the return

pass. At the end of each succeeding pass, rot ate

the discharge guide 180 degrees to maintain

direction of throw in the same area.

15

Page 18

MAINTENANCE

MAINTENANCE

Storage

1. Check the shear bolts at f req uent intervals f or

proper tightness to be sure the blower is in

safe working condition.

2. Never store the tractor with fuel in the fuel

tank inside a building where open flame or

sparks are present. Allow the engine to cool

before storing in any enclosure.

3. Run the snowblower a few minutes after

blowing snow to prevent freeze up of the

auger and the impeller.

WARNING: Provide adequate blocking

before working under the snowblower when in the

raised position.

Driveline

Lubrication

1. GEAR : Check the oil level in the worm gear

drive every month. If necessary add SAE

80W90 gear oil, AGMA 5EP or equivalent.

2. REDUCTION CHAIN : Lubricate with chain

saw lubricant every 4 hours of operation and

after each use.

3. DRIVELINE (S) : Grease each u-joint fitting

every 8 hours of operation. Slide drive shaft

apart and coat sliding surfaces with grease

every 8 hours of operation.

4. ROTATION SHAFT : Grease the shaft each 8

hours of operation.

IMPORTANT: When the snowblower is not

used for more than two weeks, perform

driveline maintenance and alw ays store it in a

dry place, away from bad weather conditions.

OM 0279-A

16

Page 19

PARTS

I

NTRODUCTION

All parts are illust rated in "exploded views" which show the individual parts in their norma l relationship

to each other. Reference numbers are used in t he illustrations. These numbers correspond to those in

the "Reference Number" (REF) colum n, and are followed by the description and quantity required.

O/L - "Obt ain Locally" in the par t number colum n indicates common hardware that is available at your

local hardware supply.

All reference to right and lef t, forward or rearward, are from the operator's seat, facing the steering

wheel.

Orders must give the complete description, correct part number, the t otal amount required, t he serial

number, the method of shipment and the shipping address.

The manufacturer reserves the rights to change, modify, or elim inate from time to time, for technical

or other reasons, cer tain or all data, specifications, or the product or pr oducts themselves, without any

liability or obligation.

OM 0277-A

17

Page 20

PARTS

FRAME AND RELATED PARTS – BLIZZARD B54 & B64

OM 0277-A 18

Page 21

PARTS

Cotter p

airp

∅

5

g

FRAME AND RELATED PARTS – BLIZZARD B54 & B64

REF. DESCRIPTION QTY. PART #

B54 B64

1 Housing 1 --- --2 Chute ass'y 1 664793 664793

3 Nylon ring 1 659151 659151

4 Bolt hex. 1/4" NC x 3/4" 8 O/L O/L

5 Retaining plate 4 659146 659146

6 Lockwasher 1/4" dia. hole 8 O/L O/L

7 Nut hex. 1/4 " NC 8 O/L O/L

8

9 Bearing 1 1/4" hole 2 4300001 4300001

10 Bolt hex. 1/2"NC x 1 1/2" 8 O/L O/L

11 Lockwasher 1/2" 12 O/L O/L

12 Nut hex. 1/2" NC 12 O/L O/L

13 Auger 1 666259 666269

14 Fan 1 664400 664400

15 Key 3/8" x 3/8" x 2 3/4" lg 1 654174 654174

16 Bolt hex. 3/8"NC x 1 1/2" 5 O/L O/L

17 Lockwasher 3/8" dia. hole 5 O/L O/L

18 Flatwasher 7/16" dia. hole 1 O/L O/L

19 Idler bushing 1 666264 666264

20 Idler 1 654010 654010

21 Flatwasher 11/16" dia. hole 2 O/L O/L

22 Bolt hex. 5/8"NC x 4 1/2" 1 O/L O/L

23 Idler 1 666263 666263

24 Chain #60 x 72 links, incl. connect. link 1 659143 659143

25 Fan washer 1 661554 661554

26 Adjustment tube 1 654076 654076

27 Adjustment rod 1 654074 654074

28

H

29 Driveline series 40 1 665341 665341

30 Hitch pin Cat.1 2 654196 654196

31 Bearing 1 1/8" hole with locking collar 1 4300016 4300016

32 Lockwasher 5/8" 1 O/L O/L

33 Nut hex. 5/8"NC 1 O/L O/L

34 Connecting link #60 1 654839 654839

35 Driving shaft 1 666256 666268

36 Shear plate 1 666257 666257

37 Bolt hex. 5/16"NC x 1 3/4" gr.5, incl. nut 1 665547 665547

38 Gearbox 1 663485 663485

39 Nut hex. 3/8"NC 8 O/L O/L

40 Bolt hex. 3/8"NC x 5" 4 O/L O/L

41 Linchpin 7/16" PTD 2 O/L O/L

42 Left adjustable skid shoe 1 666254 666254

43 Right adjustable skid shoe 1 666255 666255

44 Carriage bolt 1/2" NC x 1" lg 4 O/L O/L

45 Carriage bolt 3/8" x 3/4" lg 3 O/L O/L

46 Serrated flange nut 3/8" NC 3 O/L O/L

47 Sprocket #60A32 1 654167 654167

48 Self-lubricating bushing 1 659834 659834

49 Flange with grease slot 1 4300014 4300014

50 Flange with tip and grease fittin

in ∅1/4" x 2"

in

mm x 100mm lg.

2 O/L O/L

1 O/L O/L

1 4300015 4300015

OM 0277-A 19

Page 22

PARTS

G

EARBOX (663485)

REF. DESCRIPTION QTY. PART #

1 Casing 2 659848

2 Gear 2 662236

3 Shim 1 656649

4 Bearing 4 656653

5 Parallel Key 2 659850

6 Input Shaft 1 664663

7 Oil Seal 3 659852

8 Output Shaft 1 659853

9 Shim 1 659854

10 Snap Ring 2 656652

11 Shim 2 659855

12 O-Ring 1 661144

13 Plug 1 659847

14 Bolt hex. M8 x 55mm – 8.8 8 O/L

15 Nut hex. M8, -8 8 O/L

OM 0277-A

20

Page 23

PARTS

MANUAL ROTATION – KIT 9377

REF. DESCRIPTION QTY PART #

1 Handle 1 658252

2 Rotation tube 1 660188

3 Rotation yoke 1 659595

4 Universal block 1 658193

5 Rotation worm 1 659161

6 Worm r otation bracket 1 659145

7 Roll pin 1/4" x 1 1/4" 1 O/L

8 Hairpin 5mm x 100mm 1 659073

9 Plastic handle 1 656797

10 Plastic bushing 1 5/16" 1 657335

11 Plastic bushing 1 11/16" 1 657336

12 Capscrew 10-24 x 1" 1 O/L

13 Nylon insert locknut 10-24 1 O/L

14 Handle support bracket 1 660187

15 Anchor tube 1 660269

16 Bolt hex. 3/8"NC x 1 1/4" 2 O/L

17 Nut hex. 3/8" 2 O/L

18 Lockwasher 2 O/L

19 Square head setscrew 3/8" x 5/16" 1 O/L

20 Plastic grommet 1 657390

21 Support angle 1 660388

22 Bolt hex. 3/4"NC x 1 1/2" 1 O/L

23 Lockwasher 1 O/L

24 Nut hex. 3/4" 1 O/L

OM 0277-A 21

Page 24

PARTS

HYDRAULIC ROTATION BY CYLINDER – KIT 8056

EF. DESCRIPTION QTY PART NUMBER

R

1 Cylinder Bracket 1 664450

2 Bell Crank 1 664451

3 Push Arm 1 664452

4 Spacer 1 664429

5 Bushing 1 664428

6 Flatwasher (7/16") 1 O/L

7 Hex. Nut (3/8" NC) 1 O/L

8 Lockwasher (3/8") 1 O/L

9 Stover Nut (5/16" NC) 2 O/L

10 Flat washer (3/8") 2 O/L

11 Shoulder Screw (3/8" x 1", 5/16" NC) 1 664583

12 Hex. Bolt (5/8" NC x 3 3/4") 1 O/L

13 Hex. Bol t (3 /8 " NC x 1") 1 O/L

14 Shoulder screw (3/8" NC x 3/4", 5/16"NC) 1 664576

15 Nylon Flat washer (7/16") 1 O/L

16 Lockwasher (5/8") 1 O/L

17 Hex. nut (5/8" NC) 1 O/L

OM 0277-A 22

Page 25

PARTS

DRIVELINE (665341)

REF. DESCRIPTION QTY. PART NUMBER

1 Quick disconnect Yoke - Q.L. type 1 664543

2 Universal Joint Kit 2 658094

3 Outer Yoke 1 664544

4 Outer Tube 1 659107

5 Inner Tube 1 659105

6 Inner Yoke 1 664545

7 Yoke with Key 1 665350

8 Shield 1 664547

9 Bolt 8mm x 1.25mm x 45mm long gr.8.8 1 O/L

10 Nut 8mm x 1.0mm 1 O/L

OM 0277-A 23

Page 26

WARRANTY

RAD TECHNOLOGIES INC.

RAD TECHNOLOGIES INC. warrants to the original buyer that the equipment is f ree from defects in

material and workmanship. RAD TECHNOLOGIES INC.'s obligation, under this warranty, will be

limited to the repair or replacement of any non-wear part or component, which RAD TECHNOLOGIES

INC. finds to be defective within one year from the date of original purchase (unless otherwise-

specified). The applicable warranty period for comm ercial or rental use shall be ninety (90) days from

the date of purchase

In no event shall RAD TECHNOLOGIES INC. be liable f or consequential, special, direct or indirect

damages incurred by the buyer/user.

All components not manufactured by RAD TECHNOLOGIES INC. (such as motors, actuators,

hydraulic components, tires, ...etc.) are covered by the original manufacturer's warranty in conjunction

with RAD TECHNOLOGIES INC.

RAD's obligation under t his warranty shall be limited to repairing or replacing, free of charge to t he

original purchaser, any part that , in RAD' s judg ment , shall show evidence of such def ect, provided the

distributor returns the part prepaid within thirty (30) days from date of failure.

This warranty shall not be interpreted to render RAD TECHNOLOGIES INC. liable for injuries or

damages of any kind or nature to person or property. This warranty does not extend to losses

because of delays, or to any expenses or losses incurred for labor, subst itute machinery, rental or for

any other reason.

Except as set forth above, RAD TECHNOLOGIES INC. shall have no obligation or liability of any kind

on account of any of its equipment and shall not be liable f or special or consequential damages. RAD

TECHNOLOGIES INC. makes no other warranty, expressed or implied, and specifically, RAD

TECHNOLOGIES INC. disclaims any implied warranty or merchantability or fitness for a particular

purpose. Some states or provinces do not permit limitations or exclusions of implied

warranties or incidental or consequential damages, so the limitations or exclusions in this

warranty may not apply.

This warranty is subject to any existing conditions of supply, which may directly affect our ability to

obtain materials or manufacture replacement parts. RAD TECHNOLOGIES INC. reserves the right to

make improvements in design or changes in specifications at any time, without incurring any

obligation to owners of units previously sold.

No one is authorized to alter, modify or enlarge this warranty nor the exclusions, limitations and

reservations.

2835 Chemin de l'Aéroport, Thetford Mines (Québec) G6G 5R7

Tél.: (418) 338-4499 Fax: (418) 388-6090

Internet: www.radinte r.c o m EM AIL: radtech@radinter.com

OM 0277-A

24

Page 27

TORQUE SPECIFICATION TABLE

GENERAL SPECIFICATION TABLE

Use the following torques when special torques are not given Note: These values apply to

fasteners as received from supplier, when dry. These values do not apply if lubricants are used.

BOLT SIZES (SAE)

INCHES Pounds-Foot Newtons-Meter

1/4 5 7

5/16 10 14

3/8 20 27

7/16 25 41

1/2 88 119

9/16 121 164

5/8 165 224

3/4 297 403

7/8 440 597

1 638 865

1 1/8 840 1139

1 1/4 1180 1600

1 3/8 1570 2129

TORQUE

1 1/2 2070 2807

BOLT SIZES (METRIC)

MILLIMETERS

M6 10 13

M8 22 30

M10 40 54

M12 59 80

M14 93 126

M16 130 176

M18 168 228

M20 205 278

TORQUE

Pounds-Foot Newtons-Meter

OM 0277-A

25

Page 28

Manufactured by:

RAD Technologies Inc.

2835, Chemin de l’Aéroport

Thetford Mines, Québec, Canada, G6G 5R7

Tel.: (418) 338-4499 - Fax.: (418) 338-6090

E-mail : radtech@radinter.com

Internet : www.radinter.com

Printed in Canada

Loading...

Loading...