Blizzard 760HD, 760LT, 800HD, 860HD Installation Instructions & Owner's Manual

June 15, 2010

Lit. No. B64090, Rev. 07

Models 760LT, 760HD, 800HD & 860HD

Installation Instructions & Owner's Manual

CAUTION

See your BLIZZARD sales outlet/Web site for

specifi c vehicle application recommendations

before installation. The Undercarriage

Selection Guide has specifi c vehicle and

snowplow requirements.

CAUTION

Read this document before installing the

snowplow.

CAUTION

Read this document before operating or

servicing snowplow.

This manual supersedes all editions with an earlier date.

PREFACE

Congratulations on purchasing the fi nest straight

blade snowplow available! BLIZZARD® straight

blades are clearing new trails for innovative design,

rugged durability, quality craftsmanship and superior

performance. Our innovative products are tested all

over the snowbelt.

This manual provides safety, operation and

maintenance information for your new BLIZZARD

snowplow. To keep your snowplow in good condition,

read and understand this manual and follow its

recommendations. Failure to do so may affect your

warranty coverage.

When service is necessary, your local BLIZZARD

distributor knows your snowplow best. Contact your

BLIZZARD outlet for maintenance, service or any

other assistance you may require.

If you have not already done so, please visit www.

blizzardplows.com to register your new BLIZZARD

snowplow!

Lit. No. B64090, Rev. 07 2 June 15, 2010

TABLE OF CONTENTS

Preface ........................................................................ 2

Safety Information .......................................................4

Vehicle Application Information ................................... 7

Operation .....................................................................8

Unpacking & Inspection .............................................. 9

Torque Sp e c ifi cations ................................................10

Moldboard & A-Frame Assembly .............................. 12

Electrical & Hydraulic Systems.................................. 17

General System Schematics .............................. 17

Hydraulic Guide .................................................. 18

Electrical Installation – Snowplow Side .............. 19

Electrical Schematics – Snowplow Side ............. 20

Electrical Installation – Vehicle Side ................... 23

Electrical Schematics – Vehicle Side .................26

POWER HITCH™ System Instructions ..................... 30

Testing Your Snowplow .............................................31

Headlamp Aiming ......................................................33

Maintenance .............................................................. 34

Technical Specifi cations ............................................35

Troubleshooting ......................................................... 36

Parts Lists .................................................................. 38

Moldboard Parts – All Models .............................38

A-Frame & Pivot Beam Parts – All Models ......... 40

Power Unit Parts – All Models ............................42

Lights, Draw Latch & Control Parts – All Models ..44

Harnesses, Accessories & Kits – All Models ...... 46

Notes ......................................................................... 51

Lit. No. B64090, Rev. 07 3 June 15, 2010

SAFETY

Crush

hazard.

Keep feet

clear.

WARNING

SAFETY DEFINITIONS

WARNING

Indicates a potentially hazardous situation,

that if not avoided, could result in death or

serious personal injury.

CAUTION

Indicates a potentially hazardous situation

that, if not avoided, may result in minor or

moderate injury. It may also be used to alert

against unsafe practices.

NOTE: Indicates a situation or action that can lead

to damage to your snowplow and vehicle or other

property. Other useful information can also be

described.

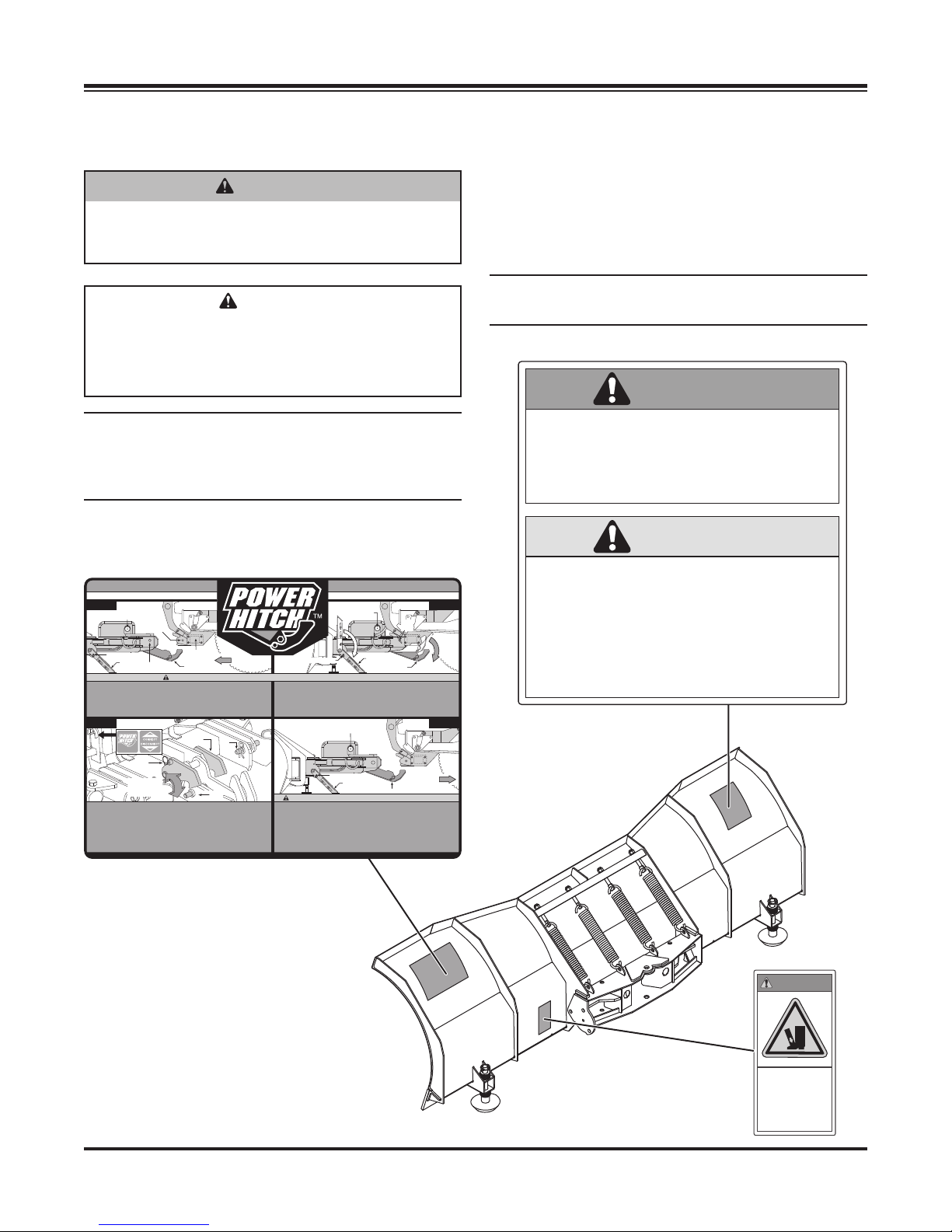

MOUNT INSTRUCTIONS DISMOUNT INSTRUCTIONS

Read Owner's Manual for Complete Instructions. Read Owner's Manual for Complete Instructions.

STEP #1 STEP #1

CONNECT/DISCONNECT

POWER HITCH Switch

•

Kickstand must be lowered, with kickstand pin seated in lower hole on pivot beam.

• Slowly drive vehicle forward until pushbeam receiver mount points contact

A-frame mount bushings.

• Turn POWER HITCH OPERATION switch (on plow control) to "ON" position.

• Connect plow and vehicle electrical harnesses. Connect weather caps together.

STEP #2 STEP #2

• Pull A-frame latch lock pin out and lower A-frame latch over draw pin.

• Push and hold CONNECT/DISCONNECT switch upward. POWER HITCH arm

will engage back of pushbeam and pull plow into pushbeam receiver mount

points on vehicle.

• Insert both hitch pins and secure each with hair pin cotter.

• Lower POWER HITCH arm to relieve tension on A-frame latch. Raise A-frame

latch and lock into position with lock pin. Raise plow.

• Raise kickstand until kickstand pin seats into upper hole on pivot beam.

Pushbeam

Receiver

Mount Points

Kickstand Pin

Adjustable

Kickstand

A-Frame

Latch

Lock Pin

A-Frame Latch

rotates clockwise

and hooks onto

Draw Pin

U.S. Patents 5,638,618; 5,899,007; 6,178,669; 6,276,076; 6,393,737; 6,408,549; 6,412,199; 6,442,877; 6,615,513; Canadian and other patents pending.

Undercarriage

Pushbeam

POWER

A-Frame

HITCH Arm

Mount Bushing

WARNING: Keep fingers away. POWER HITCH arm raises behind undercarriage pushbeam.

A-Frame

Latch

Slowly Move

Vehicle Forward

•

Raise plow. Lower kickstand until kickstand pin is seated in lower hole on pivot beam.

• Lower plow on flat, level surface. Turn vehicle ignition off.

• Remove hitch pins from A-frame and undercarriage.

• Turn vehicle ignition on.

• Turn POWER HITCH OPERATION switch (on plow control) to "ON" position.

Hitch

Pin

Draw

Pin

• Push and hold CONNECT/DISCONNECT switch downward. POWER HITCH

arm will disengage from behind undercarriage pushbeam and lower.

• Disconnect plow and vehicle electrical harnesses. Install weather caps.

• Turn SYSTEM POWER (on plow control) to "OFF" position.

• Slowly move vehicle backward away from plow.

CONNECT/DISCONNECT

POWER HITCH Switch

Kickstand Pin

CONNECT/DISCONNECT

POWER HITCH Switch

Kickstand Pin

Adjustable

WARNING: Keep fingers away from plow and truck mounting points.

Kickstand

Adjustable

Kickstand

POWER HITCH Arm

POWER

HITCH Arm

Hitch

Pin

Move Vehicle

Backward

Slowly

44812

WARNING/CAUTION & INSTRUCTION

LABELS

Become familiar with and inform users about the

warning and instruction labels on the back of the

blade.

NOTE: If labels are missing or cannot be read, see

your sales outlet.

WARNING

LOWER BLADE WHEN VEHICLE IS PARKED.

DO NOT EXCEED GVWR OR GAWR INCLUDING BLADE

AND BALLAST.

REMOVE BLADE ASSEMBLY BEFORE PLACING

VEHICLE ON HOIST.

CAUTION

READ OWNER'S MANUAL BEFORE OPERATING OR

SERVICING SNOWPLOW.

TRANSPORT SPEED SHOULD NOT EXCEED 45 MPH.

FURTHER REDUCE SPEED UNDER ADVERSE TRAVEL

CONDITIONS.

PLOWING SPEED SHOULD NOT EXCEED 10 MPH.

SEE YOUR SALES OUTLET/WEB SITE FOR SPECIFIC

VEHICLE APPLICATION RECOMMENDATIONS.

59900

Lit. No. B64090, Rev. 07 4 June 15, 2010

WARNING

Crush

hazard.

Keep feet

clear.

SAFETY

SAFETY PRECAUTIONS

Improper installation and operation could cause

personal injury, and/or equipment and property

damage. Read and understand labels and the

Owner's Manual before installing, operating or making

adjustments.

WARNING

Lower blade when vehicle is parked.

Temperature changes could change

hydraulic pressure, causing the blade to

drop unexpectedly or damaging hydraulic

components. Failure to do this could result in

serious personal injury.

WARNING

You can die or be seriously injured. Keep

hands and feet away from hitch mechanism

and snowplow blade when operating the

POWER HITCH™ arm. The action of the arm

moves the snowplow toward the vehicle and

into position for proper attachment.

WARNING

The driver shall keep bystanders clear of

the blade when it is being raised, lowered or

angled. Do not stand between the vehicle and

the blade or within 8 feet of a moving blade. A

moving or falling blade could cause personal

injury.

WARNING

Do not exceed GVWR or GAWR including the

blade and ballast. The rating label is found on

the driver-side vehicle door cornerpost.

WARNING

To prevent accidental movement of the blade,

always turn the control OFF whenever the

snowplow is not in use. The power indicator

light will turn OFF.

CAUTION

Read Owner's Manual before operating or

servicing snowplow.

CAUTION

Transport speed should not exceed 45 mph.

Further reduce speed under adverse travel

conditions.

CAUTION

Plowing speed should not exceed 10 mph.

CAUTION

See your BLIZZARD® outlet for application

recommendations.

HYDRAULIC SAFETY

WARNING

Hydraulic fl uid under pressure can cause skin

injection injury. If you are injured by hydraulic

fl uid, get medical attention immediately.

• Always inspect hydraulic components and hoses

before using. Replace any damaged or worn parts

immediately.

• If you suspect a hose leak, DO NOT use your

hand to locate it. Use a piece of cardboard or

wood.

FUSES

The snowplow electrical and hydraulic systems

contain several blade-style automotive fuses. If

a problem should occur and fuse replacement is

necessary, the replacement fuse must be of the same

type and amperage rating as the original. Installing a

fuse with a higher rating can damage the system and

could start a fi re. Fuse Replacement, including fuse

ratings and locations, is located in the Maintenance

Section of this Owner's Manual.

WARNING

Remove blade assembly before placing

vehicle on hoist.

Lit. No. B64090, Rev. 07 5 June 15, 2010

SAFETY

PERSONAL SAFETY

• Remove ignition key and put the vehicle in park or

in gear to prevent others from starting the vehicle

during installation or service.

• Wear only snug-fi tting clothing while working on

your vehicle or snowplow.

• Do not wear jewelry or a necktie, and secure long

hair.

• Wear safety goggles to protect your eyes from

battery acid, gasoline, dirt and dust.

• Avoid touching hot surfaces such as the engine,

radiator, hoses and exhaust pipes.

• Always have a fi re extinguisher rated BC handy,

for fl ammable liquids and electrical fi res.

FIRE AND EXPLOSION

WARNING

Gasoline is highly fl ammable and gasoline

vapor is explosive. Never smoke while

working on vehicle. Keep all open fl ames

away from gasoline tank and lines. Wipe up

any spilled gasoline immediately.

VENTILATION

WARNING

Vehicle exhaust contains lethal fumes.

Breathing these fumes, even in low

concentrations, can cause death. Never

operate a vehicle in an enclosed area without

venting exhaust to the outside.

BATTERY SAFETY

CAUTION

Batteries normally produce explosive gases

which can cause personal injury. Therefore,

do not allow fl ames, sparks or lit tobacco

to come near the battery. When charging or

working near a battery, always cover your

face and protect your eyes, and also provide

ventilation.

Batteries contain sulfuric acid which burns

skin, eyes and clothing.

Disconnect the battery before removing or

replacing any electrical components.

NOISE

Be careful when using gasoline. Do not use gasoline

to clean parts. Store only in approved containers away

from sources of heat or fl ame.

CELL PHONES

A driver's fi rst responsibility is the safe operation of

the vehicle. The most important thing you can do

to prevent a crash is to avoid distractions and pay

attention to the road. Wait until it is safe to operate

Mobile Communication equipment such as cell phones

or two-way radios.

Airborne noise emission during use is below 70 dB(A)

for the snowplow operator.

Lit. No. B64090, Rev. 07 6 June 15, 2010

VEHICLE APPLICATION INFORMATION

CAUTION

See your BLIZZARD® outlet for specifi c

vehicle application recommendations before

installation. The Undercarriage Selection

Guide has specifi c vehicle and snowplow

requirements.

Vehicle application recommendations are based on

the following:

• The vehicle with the snowplow installed must

comply with applicable Federal Motor Vehicle

Safety Standards (FMVSS).

• The vehicle with the snowplow installed must

comply with the vehicle manufacturer's stated

gross vehicle and axle weight ratings (found on

the driver-side door cornerpost of the vehicle) and

the front and rear weight distribution ratio. In some

cases, rear ballast may be required to comply with

these requirements.

• BLIZZARD Undercarriage Selection Guide is

based on available vehicle capacity for snowplow

equipment on a representative vehicle equipped

with options commonly used for snowplowing and

with 300 lb of front seat occupant weight.

• Weights of front seat occupants can be adjusted

above 300 lb but vehicle with snowplow must not

exceed vehicle GVWR or GAWR.

• In some cases there may be additional limitations

and requirements.

• Installation, modifi cation and addition of

accessories must comply with published

BLIZZARD recommendations and instructions.

Available capacity decreases as the vehicle is

loaded with cargo or other truck equipment or

snowplow accessories are installed.

BALLAST REQUIREMENTS

Position

and secure ballast

as close to the tailgate

as possible.

Ballast (additional weight) is an important part of

qualifying vehicles for snowplow eligibility. Rear

ballast must be used when necessary to remain in

compliance with axle ratings and ratios as specifi ed by

the vehicle manufacturer.

If ballast is required, it is important that it be secured

properly behind the rear axle. A ballast retainer kit is

available from your BLIZZARD outlet, PN 62849.

NOTE: The ballast retainer kit is for snowplow

vehicles requiring ballast. See your BLIZZARD

outlet for the correct amount of ballast required.

Include the weight of the retainer as part of the

ballast requirement. Sand bags are recommended

for use as ballast.

NOTE: Ballast recommended and its weight

calculations assume the entire width of the bed is

fi lled as close to tailgate as possible.

• If there is uncertainty as to whether available

capacity exists, the actual vehicle as confi gured

must be weighed.

Lit. No. B64090, Rev. 07 7 June 15, 2010

OPERATION

Your snowplow is the most advanced and versatile

straight blade on the market. The easy-to-use controls

allow you to automatically adjust the snowplow blade

into an infi nite number of plowing positions. Review

the illustrations below for instruction on maneuvering

your snowplow.

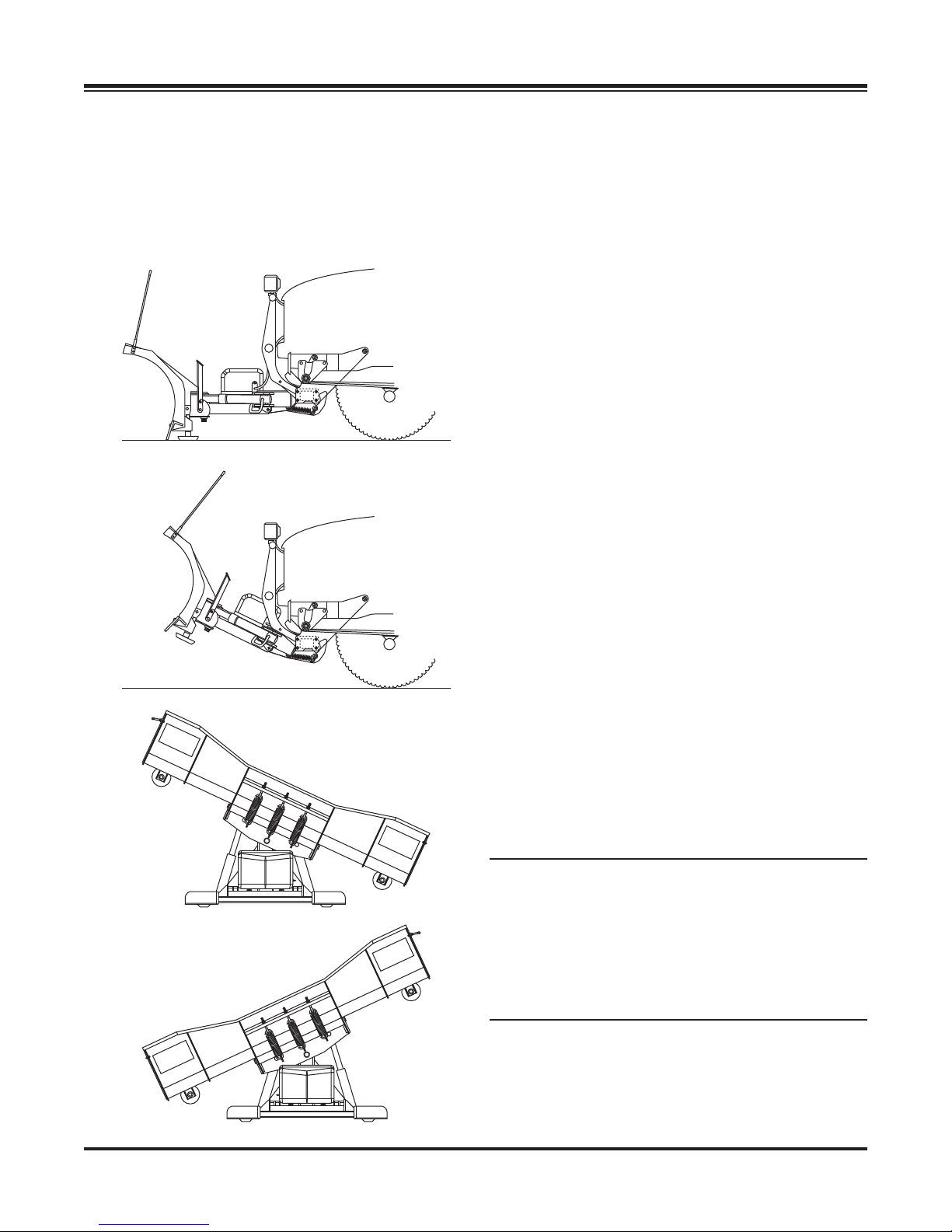

A.

B.

A. Lowered or Float Position

Pushing the joystick forward, toward the

"Lower/Float" designation on the label, or

pushing the D button on the touchpad will lower

your straight blade to the ground. Pushing and

momentarily holding the control in this position will

allow the snowplow to "fl oat," or follow the contour

of the ground when moving forward or backward.

B. Raised Position

Pulling the joystick back, toward the "Raise"

designation on the label, or pushing the U button

on the touchpad will lift your straight blade off of

the ground. To stop raising the snowplow, simply

return the joystick to its "neutral" or center position

or release the touchpad button. The snowplow has

reached its maximum raised position when the

blade stops lifting.

C. Angled Right Position

To angle your straight blade to the right, position

the joystick toward the "R" on the label or push

the R button on the touchpad. To stop angling the

snowplow, return the joystick to its "neutral" or

center position or release the touchpad button.

The snowplow has reached its maximum angled

position when the blade stops moving to the right

side.

C.

D.

D. Angled Left Position

To angle your straight blade to the left, position

the joystick toward the "L" on the label or push

the L button on the touchpad. To stop angling the

snowplow, return the joystick to its "neutral" or

center position or release the touchpad button.

The snowplow has reached its maximum angled

position when the blade stops moving to the left

side.

NOTE: To prevent premature failure of the power

contactor (solenoid), return the joystick to its

neutral (center) position or release the touchpad

button immediately after the blade reaches the

limit of any position. Continuing to hold the

control after the blade has reached the limit of

movement in any position will reduce the life of

the solenoid.

Lit. No. B64090, Rev. 07 8 June 15, 2010

UNPACKING & INSPECTION

Your BLIZZARD® straight blade has been packaged

to withstand transit and weather related damage.

Fully inspect all components upon receipt of your

snowplow. In the event of shipping damage or missing

parts, immediately contact our Customer Service

Department at 1-888-680-8600.

Begin unpacking and inspection in the following order:

1. Remove the shipping document from the end

panel of the pallet wrap. Retain all documentation

for your records.

2. All wood framing and polyethylene material should

be removed from the pallet for easy access to the

snowplow.

3. Due to the odd shaped components and size

of several assembly parts, various cable ties

and corrugated material are used for scratch

resistance and package orientation. Please

remove these items prior to assembly.

4. Place the main blade assembly on a fl at, level

surface.

Once you have inspected all parts and removed all

packaging materials, your snowplow is ready to be

fully assembled.

Retain this information for your records.

Date of Purchase: ___________________________

Dealer/Distributor: __________________________

Dealer Phone Number: _______________________

Snowplow Serial Number: ____________________

Hydraulic Pump Serial Number: _______________

Lit. No. B64090, Rev. 07 9 June 15, 2010

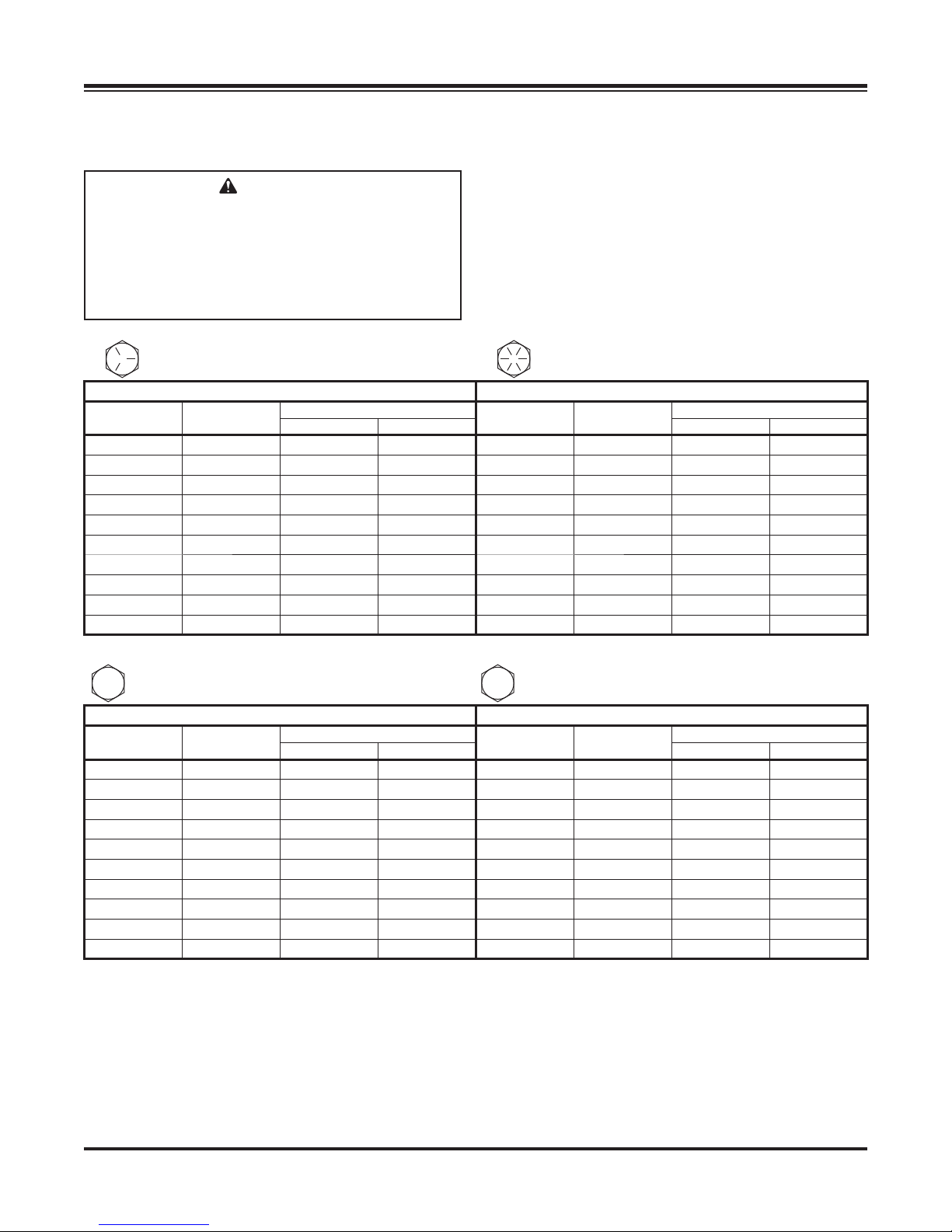

TORQUE SPECIFICATIONS

TORQUE CHART

CAUTION

Read instructions before assembling.

Fasteners should be fi nger tight until

instructed to tighten according to the torque

chart. Use standard methods and practices

when attaching snowplow including proper

personal protective safety equipment.

Grade Identifi cation for J429–Grade 5 Bolt Grade Identifi cation for J429–Grade 8 Bolt

SAE J429 Grade 5 Torque Values SAE J429 Grade 8 Torque Values

Nominal

Thread Size

1/4-20 2,000 6 ft-lb 8 ft-lb 1/4-20 2,850 9 ft-lb 12 ft-lb

5/16-18 3,350 13 ft-lb 18 ft-lb 5/16-18 4,700 18 ft-lb 25 ft-lb

3/8-16 4,950 23 ft-lb 31 ft-lb 3/8-16 6,950 32 ft-lb 44 ft-lb

7/16-14 6,800 37 ft-lb 50 ft-lb 7/16-14 9,600 53 ft-lb 70 ft-lb

1/2-13 9,050 57 ft-lb 75 ft-lb 1/2-13 12,800 80 ft-lb 107 ft-lb

9/16-12 11,600 82 ft-lb 109 ft-lb 9/16-12 16,400 115 ft-lb 154 ft-lb

5/8-11 14,500 113 ft-lb 151 ft-lb 5/8-11 20,300 159 ft-lb 211 ft-lb

3/4-10 21,300 200 ft-lb 266 ft-lb 3/4-10 30,100 282 ft-lb 376 ft-lb

7/8-9 29,435 321 ft-lb 430 ft-lb 7/8-9 41,550 454 ft-lb 606 ft-lb

1-8 38,600 482 ft-lb 640 ft-lb 1-8 54,540 680 ft-lb 900 ft-lb

Clamp Loads

(lb)

Tightening Torque

"Lubricated" "Dry" "Lubricated" "Dry"

Nominal

Thread Size

Clamp Loads

(lb)

Tightening Torque

8.8

Grade Identifi cation for Metric–Grade 8.8 Bolt

Metric Class 8.8 Torque Values Metric Class 10.9 Torque Values

Diameter

(mm)

5 1,389 3 ft-lb 5 ft-lb 5 1,987 5 ft-lb 7 ft-lb

6 1,965 6 ft-lb 8 ft-lb 6 2,812 8 ft-lb 11 ft-lb

7 2,826 10 ft-lb 13 ft-lb 7 4,044 14 ft-lb 19 ft-lb

8 3,579 14 ft-lb 19 ft-lb 8 5,121 20 ft-lb 27 ft-lb

10 5,672 28 ft-lb 37 ft-lb 10 8,116 40 ft-lb 53 ft-lb

12 8,243 49 ft-lb 65 ft-lb 12 11,796 70 ft-lb 92 ft-lb

14 11,246 77 ft-lb 103 ft-lb 14 16,092 111 ft-lb 148 ft-lb

16 15,882 125 ft-lb 167 ft-lb 16 21,970 173 ft-lb 231 ft-lb

18 19,423 172 ft-lb 229 ft-lb 18 26,868 238 ft-lb 317 ft-lb

20 24,784 244 ft-lb 325 ft-lb 20 34,284 338 ft-lb 450 ft-lb

Clamp Loads

(lb)

Tightening Torque

"Lubricated" "Dry" "Lubricated" "Dry"

10.9

Grade Identifi cation for Metric–Grade 10.9 Bolt

Diameter

(mm)

Clamp Loads

(lb)

Tightening Torque

Lit. No. B64090, Rev. 07 10 June 15, 2010

Turns Size

N/A -02 6–7

N/A -03 8–9

2-0411–12

2-0514–15

1-1/2 -06 18–20

1-1/2 -08 36–39

1-1/2 -10 57–63

1-1/4 -12 79–88

1-1494–103

1-16108–113

1-20127–133

1-24158–167

1-32245–258

Size

-02 6–7

-03 8–10

-04 13–15

-05 17–21

-06 22–25

-08 40–43

-10 43 –57

-12 68–75

-14 90 –99

-16 112–123

-20 146–200

-24 154 –215

-32 218–290

ft-lb

min–max

ft-lb

min–max

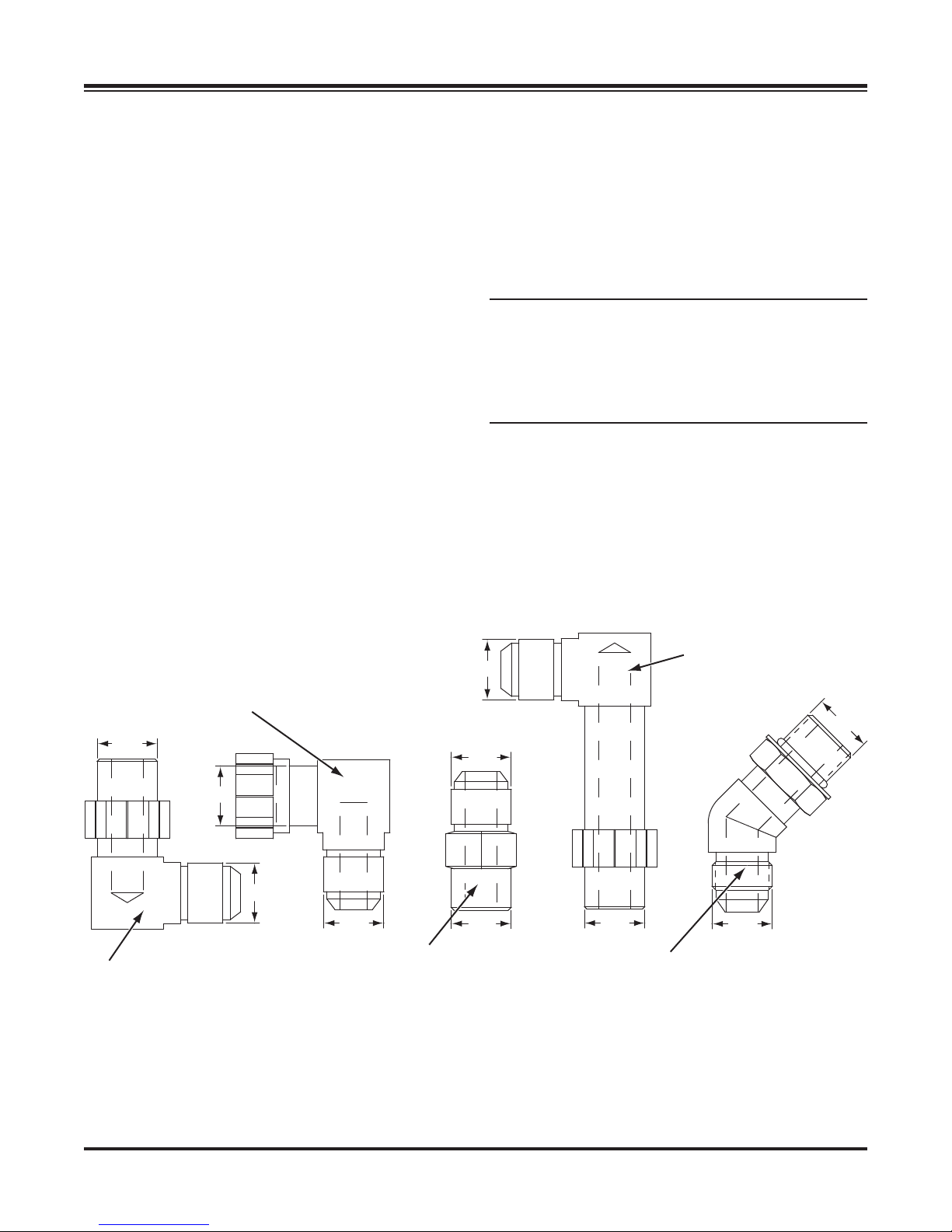

Assembly Steps

1. Verify the port, O-ring, sealing surfaces and threads are clean and free of damage.

2. Lubricate the threads and the O-ring with 10W hydraulic fl uid.

3. For an adjustable ORB, completely back off the locknut and washer.

4. Hand tighten the fi tting until it contacts the port spotface. Point the elbow or tee in the desired

direction and hold.

5. Torque to specifi cation.

NOTE: Torque values specifi ed are for threads lubricated with 10W hydraulic fl uid.

TORQUE SPECIFICATIONS

37° JIC Flare Torque Values

Assembly Steps

1. Make sure the tubing and threads are clean.

2. Lubricate the threads with 10W hydraulic fl uid.

3. Hand tighten the nut/sleeve to approximately 30 in-lb.

4. Make alignment marks on the nut and fi tting.

5. Tighten to turn or torque specifi cation.

6. When fully tightened, make a second set of alignment marks at the fully tightened position.

NOTE: Torque values specifi ed are for threads lubricated with 10W hydraulic fl uid.

Overtightening will reduce the clamping force resulting in loss of seal and reduction of fl ow.

O-Ring Boss Torque Values

Lit. No. B64090, Rev. 07 11 June 15, 2010

MOLDBOARD & A-FRAME ASSEMBLY

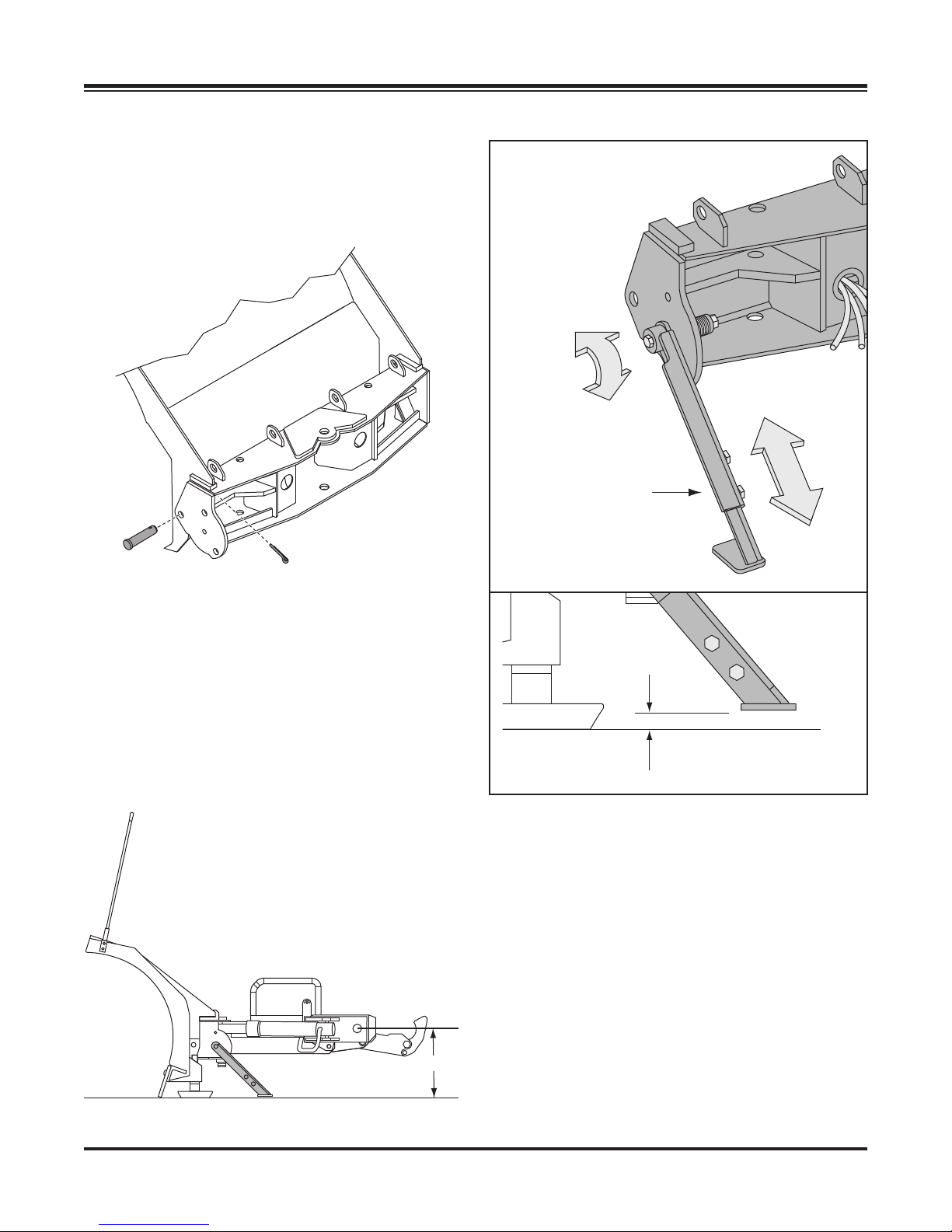

1. Position the pivot beam and A-frame near

the connecting points at the rear of the blade

between the two center support ribs. Insert one

3/4" x 3" clevis pin through each mounting hole

and secure with 1/4" x 1-1/2" cotter pin.

Spring Loaded

Adjustable

Pivot Beam

Kickstand

2. Mount the kickstand to the end of the pivot beam

(driver-side) using the 1/2" x 4-1/2" cap screw

provided. The spring, bushing and locknut are

located on the inside of the pivot beam. Review

the diagrams below and to the right. To pivot the

kickstand, pull the spring loaded leg out and rotate

it until the pin locks into place. Adjust the foot on

the stand arm so that the foot is 1/8" from the

ground when the A-frame is level and the A-frame

mount points are 12-1/2" from the ground. Tighten

both of the locknuts on the kickstand.

1/8" Ground

Clearance

Lit. No. B64090, Rev. 07 12 June 15, 2010

12-1/2"

MOLDBOARD & A-FRAME ASSEMBLY

3. Position each angle cylinder with the rod

end of the cylinder in the pivot beam and

the hydraulic hose port facing away from

the A-frame. Secure the cylinder to the pivot

beam with a 3/4" x 5" clevis pin (95739) and a

1/4" x 1-1/2" cotter pin (B61357). Extend each

cylinder rod until the cylinder base mounting hole

aligns with the hole on the A-frame angle cylinder

bracket. Insert another clevis pin and secure it

with a cotter pin.

4. Remove the dust cap from both of the hydraulic

angle cylinder ports and attach one 9/16" 90°

adjustable elbow ORB adapter to each port. Each

adapter should be angled toward the top of the

moldboard. Connect one 3/8" x 24" hydraulic

hose (B60091) to each angle cylinder adapter. Be

careful not to overtighten the hose connections.

Route both hoses over the TOP of each cylinder.

This will prevent them from hanging or being

pinched. Tighten fi ttings and hoses per torque

chart.

5. Remove the plastic dust caps from the hydraulic

lift cylinder ports. Attach one 9/16" 45° adjustable

elbow ORB adapter (B60272) to the driver-side

port (base end) and one 9/16" x 9/16" male ORB

connector adapter (B60007) to the passengerside port (rod end). Once the adapters have been

installed on the cylinder, connect the hydraulic

hoses. Tighten fi ttings and hoses per torque chart.

NOTE: Position the 45° fi tting in the cylinder port

so that the hoses install directly in the center of

the A-frame access holes. A hose installed too

close to the edge of the opening may work itself

free with the operation of the lift cylinder and/or

movement of the snowplow.

The 45° adapter receives a 3/8" x 17" hydraulic

hose (B60273). Connect the 45° angle on the

hose to the hydraulic adapter on the cylinder.

The male connector adapter receives a

3/8" x 15" hydraulic hose (B60274). Connect the

45° end of the hose to the hydraulic adapter on the

cylinder. Both hoses should be routed through the

triangular openings in the A-frame. Tighten fi ttings

and hoses per torque chart.

B60006

- Manifold Ports #3 & 4

9/16

56590

- Manifold Port #1

- Angle Cylinders

9/16

9/16

9/16

B60007

- Manifold Ports #3 & 4

- Lift Cylinder Rod End

9/16

9/16

9/16

B60072

- Manifold Port #2

9/16

9/16

B60272

- Lift Cylinder Base End

9/16

Lit. No. B64090, Rev. 07 13 June 15, 2010

MOLDBOARD & A-FRAME ASSEMBLY

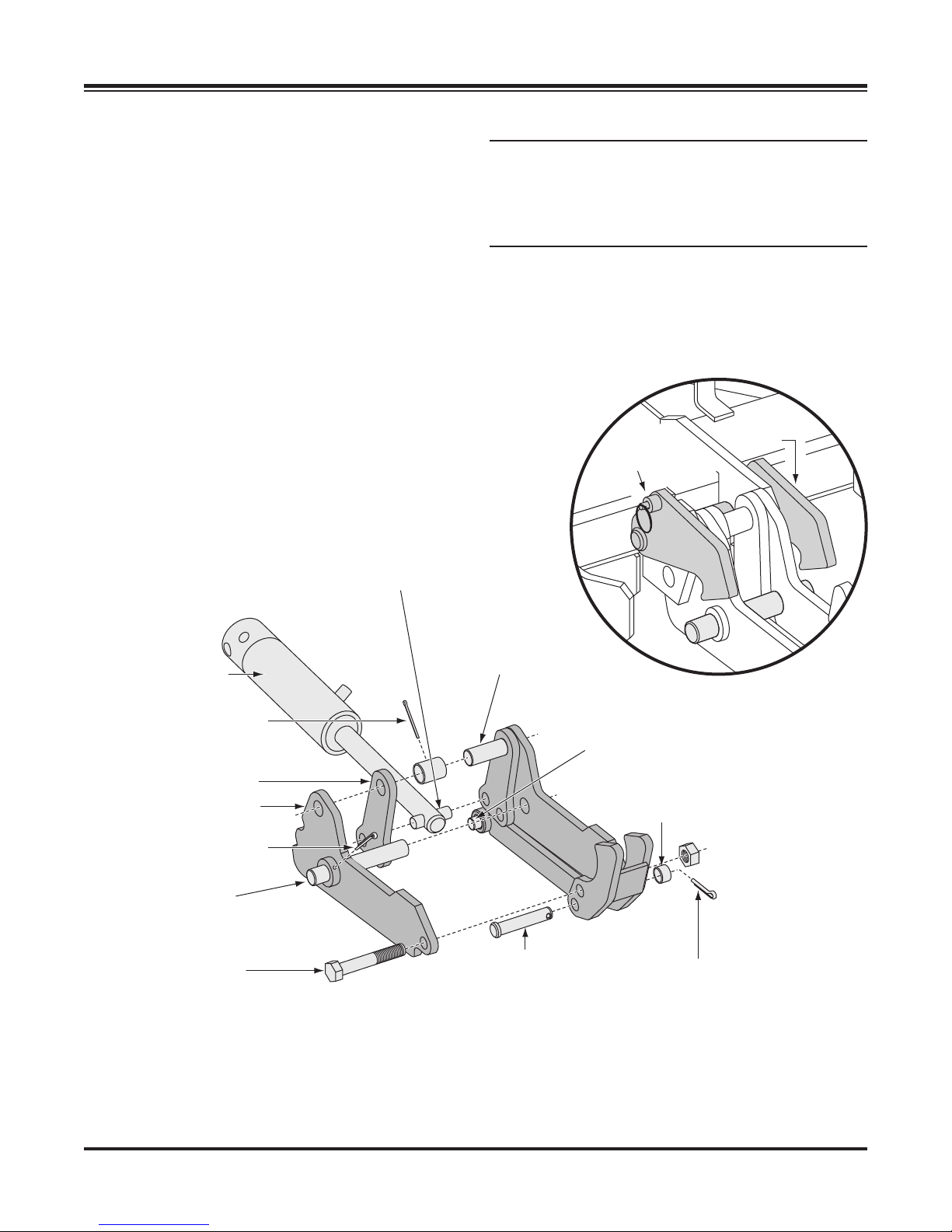

6. Remove the draw latch mount pin, spacer and

cotter pin from the draw latch assembly. By

removing this pin, the inner draw latch plates can

swing free. Remove the inner draw latch plate lift

cylinder mount pin. Position the plates on either

side of the lift/lower cylinder rod and insert the

pin through the plates and cylinder rod. With the

cylinder connected to the inner draw latch plates,

rotate the draw latch assembly toward the draw

latch mount holes on the A-frame. Align the holes

in the outer draw latch plate with those of the inner

draw latch plates and the A-frame.

Inner Draw Latch Plate

Lift Cylinder Mount Pin

3/4" x 2-1/2" or

5/8" x 2-3/8" (760LT only)

NOTE: The A-frame latch, located at the rear/

center of the A-frame, should be raised up

to insert the draw latch mount pin. Pull the

A-frame latch pull pin out and rotate the latch

counterclockwise if it is locked into position.

Secure the assembly to the A-frame by replacing

the draw latch mount pin, spacer and cotter pin.

Reset the A-frame latch so the A-frame latch pull

pin locks into place.

A-Frame

A-Frame

Latch Pin

Latch

Hydraulic

Lift/Lower Cylinder

3/16" x 2-1/2"

Cotter Pin

Inner Draw Latch Plate

Outer Draw Latch Plate

3/16" x 2-1/2"

Cotter Pin

Draw Pin

1" x 6-1/2" or

1" x 5-5/8" for 760LT only

Cap Screw

3/4"-10 x 4-1/2" or

3/4"-10 x 4" for 760LT only

Draw Latch Mount Pin

1" x 4-21/32" or

1" x 3-7/8" (760LT only)

Draw Latch Arm Pivot Pin

3/4" x 2-1/2" or

3/4" x 2-3/8" for 760LT only

1" OD x 25/32" ID x 5/8"

Clevis Pin

3/4" x 3-41/64" or

3/4" x 3-7/16" for 760LT only

Spacer

1/4" x 1-1/2"

Cotter Pin

Lit. No. B64090, Rev. 07 14 June 15, 2010

MOLDBOARD & A-FRAME ASSEMBLY

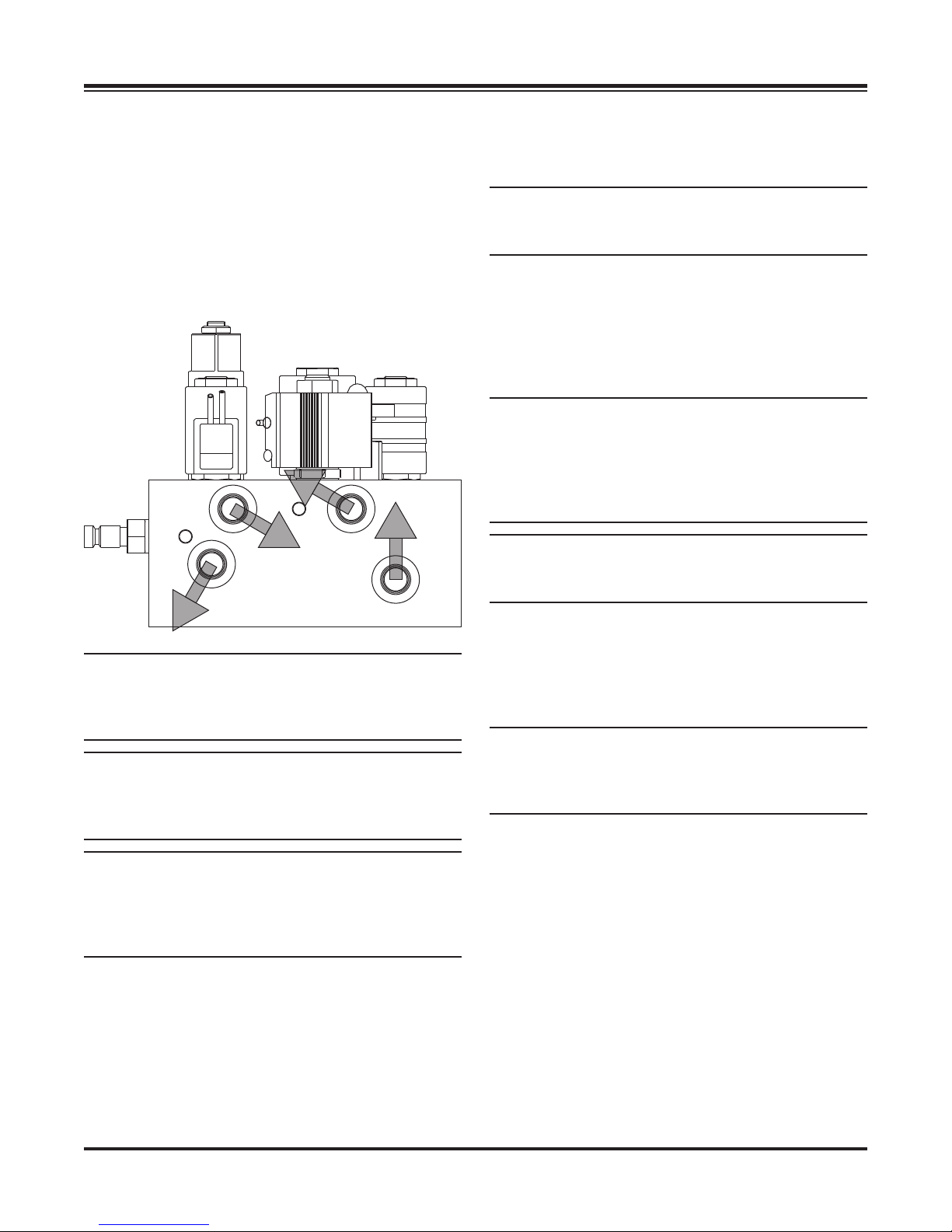

7. Assemble the manifold. The manifold, pump

and coil harness have been connected at the

factory; however, the manifold contains several

components that you will need to install prior to

securing the assembly to the A-frame. Each of the

hose ports on the manifold is covered with stretch

wrap. Remove the wrap and install the appropriate

fi tting in its respective port. Tighten fi ttings and

hoses per torque chart.

32

1

8. Align the mount holes in the pump with the holes

in the hinged bracket, located on the A-frame.

NOTE: Before mounting the pump, angle the

hinged bracket as needed and tighten the bracket

hardware to lock it in place.

Secure with 3/8" x 3/4" cap screw and 3/8" fl at

washer through the top mount hole in the bracket

and into the pump. Insert 3/8" x 1-3/4" threaded

stud with 3/8" locknut through the bottom mount

hole in the bracket and into the pump. The

threaded stud should bottom out in the pump.

NOTE: When installing the manifold between the

mount brackets on the A-frame, hold the manifold

at the sides of the block. Never handle the

manifold by coils. Doing so can cause a solenoid

cartridge to bend, causing the cartridge to stick

when activated.

NOTE: A medium strength thread-locking

compound should be used on both of the pump

mount fasteners.

4

NOTE: The arrows shown on the manifold

illustration indicate the direction the 90° adapters

should be positioned to receive the hydraulic

hoses.

NOTE: DO NOT let any foreign objects enter

into the open ports. The valves can become

contaminated and greatly hinder the snowplow's

performance. Torque to proper specifi cations.

NOTE: All ports are identifi ed by a stamped

number on the manifold. The numbers also

identify the hydraulic functions, which can be

referenced on the label under the hydraulic pump

and manifold cover.

9. Connect the hydraulic hoses to their respective

adapters on the manifold. Hose PN B60091

Ports #1 and #2, Hose PN B60273 Port #3 and

Hose PN B60274 Port #4. Tighten hoses per

torque chart.

NOTE: Both lift cylinder hoses should be routed

through the triangular openings in the A-frame.

Position these hoses over the A-frame angle and

to their respective manifold ports.

Lit. No. B64090, Rev. 07 15 June 15, 2010

MOLDBOARD & A-FRAME ASSEMBLY

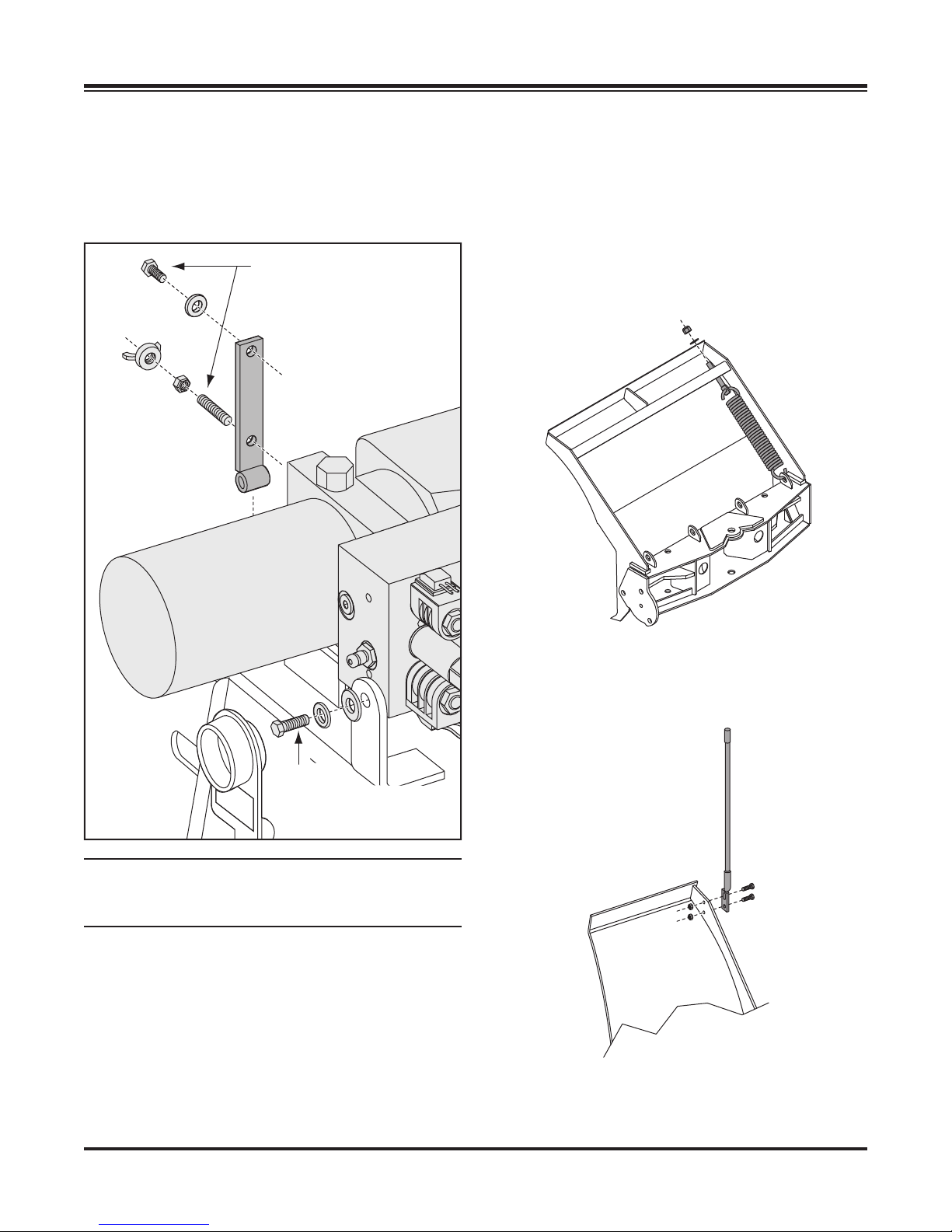

10. Secure the manifold to the A-frame. Remove the

washers, split lock washers and cap screws from

the manifold and align the mount holes with the

A-frame brackets. Properly replace and tighten all

hardware.

Apply

Thread-Locking

Compound

11. Hook each extension spring to the receiving holes

on the pivot beam and attach the opposite end of

the spring to its respective spade bolts. Install the

spade bolts through the extension spring mounting

angle on the top rear of the blade. Secure each

spade bolt by placing one 5/8" fl at washer on the

bolt and thread one 5/8" locknut. Tighten each

locknut until a piece of paper can pass between

the 3rd and 4th coils on the spring.

Apply

Thread-Locking

Compound

NOTE: A medium-strength threadlocking

compound should be used to secure the manifold

mount fasteners.

12. Install the blade guides at each end of the

moldboard. Insert the cap screw through the holes

at the top of the wing reinforcement rib. Tighten all

screws with locknuts.

Lit. No. B64090, Rev. 07 16 June 15, 2010

Loading...

Loading...