Page 1

Blizzard, PO Box 245038, Milwaukee, WI 53224-9538 • www.blizzardplows.com

March 15, 2010

Lit. No. 69656, Rev. 03

30269

UNDERCARRIAGE KIT

Ford Super Duty F-250/350/450/550 2008 - 10

Installation Instructions

CAUTION

Read this document before installing the

snowplow.

CAUTION

See your BLIZZARD® outlet/Web site for

specifi c vehicle application recommendations

before installation. The Undercarriage

Selection Guide has specifi c vehicle and

snowplow requirements.

A DIVISION OF DOUGLAS DYNAMICS, L.L.C.

Page 2

SAFETY

SAFETY DEFINITIONS

WARNING

Indicates a potentially hazardous situation

that, if not avoided, could result in death or

serious personal injury.

CAUTION

Indicates a potentially hazardous situation

that, if not avoided, may result in minor or

moderate injury. It may also be used to alert

against unsafe practices.

NOTE: Indicates a situation or action that can lead

to damage to your snowplow and vehicle or other

property. Other useful information can also be

described.

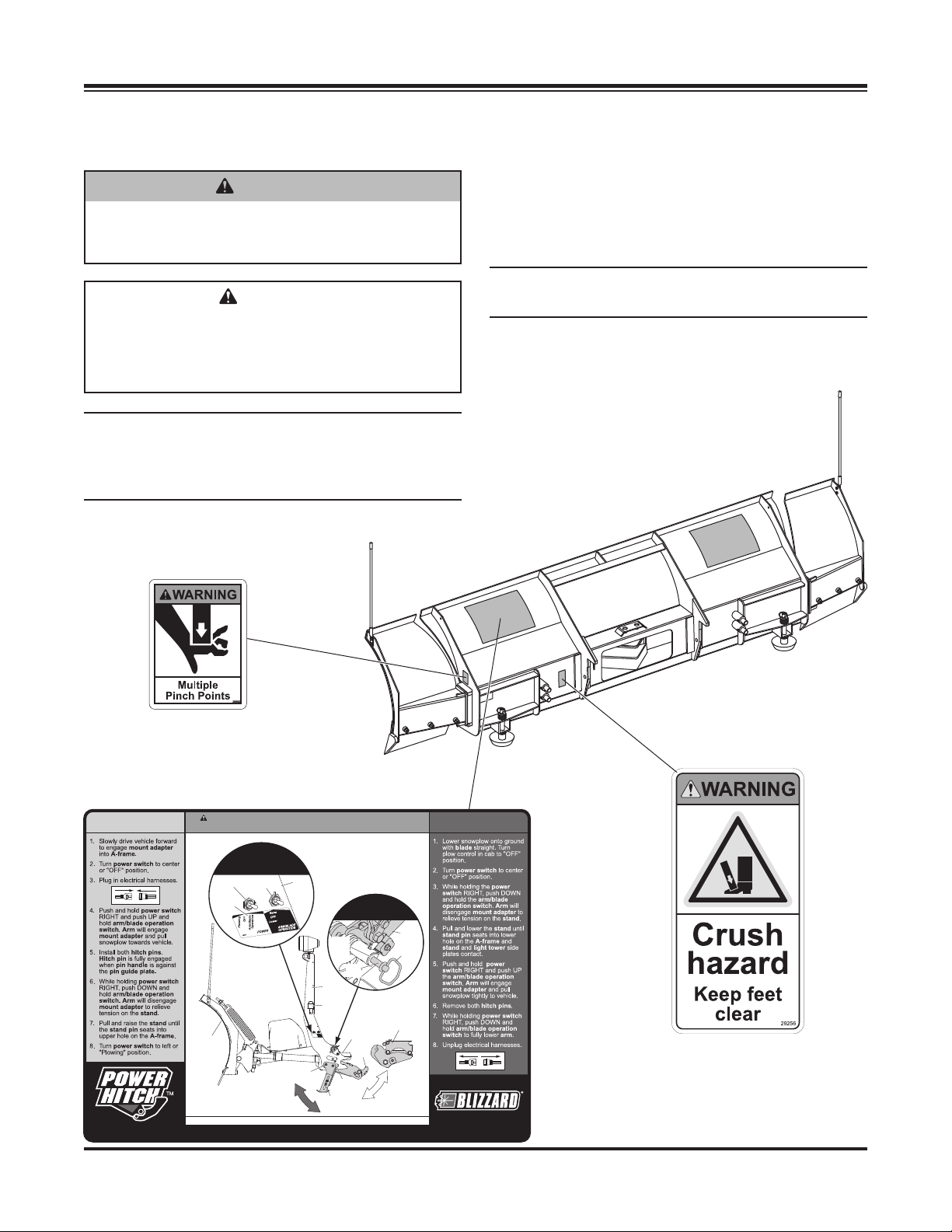

WARNING/CAUTION & INSTRUCTION

LABELS

Become familiar with and inform users about the

warning and instruction labels on the back of the

blade.

NOTE: If labels are missing or cannot be read, see

your sales outlet.

POWER PLOW® and

SPEEDWING™ Blades Only

(both sides)

ATTACH DETACH

U.S. Patents 5,42 0,480; 5,638,618; 5 ,899,007; 6,178,669; 6, 253,470; 6,276,076; 6,393,737; 6,408,549; 6,412,199; 6,442,877; 6,615,513; 7,134,227; RE 35,70 0;

Lit. No. 69656, Rev. 03 2 March 15, 2010

WARNING: Ke ep fingers awa y from snowplow an d truck attac hment

points . POWER HITCH™ arm ra ises behind und ercarriag e pushbeam.

ATTAC H –

Steps 2, 4 , 6 & 8

DETACH –

Steps 2, 3, 5 & 7

Arm / Blade

Power

Operation

Switch

Switch

Label

Blade

Read Owner's Manual for Complete Instructions.

CAN Patents 2,060,425; 2,184,922; 2,229,783; 2,259,508; 2,358,145; 2,358,354; 2,466,195; and other patents pending.

Switch

Light

Towe r

Stand

ATTAC H –

Step 5

DETACH – Step 6

Mount

Pin

Guide

Plate

Hitch

Pin

Light

Towe r

Boot

Raise

OFF

OFF

Lower

Plowing

Operation

Arm/Blade

ARM/BLADE

POWER

48207

OPERATION

A-Frame

Pin

Upper

Hole

Stand

Adapter

Pin

Handle

Mount

Adapter

Arm

48208

Page 3

SAFETY

SAFETY PRECAUTIONS

Improper installation and operation could cause

personal injury and/or equipment and property damage.

Read and understand labels and the Owner's Manual

before installing, operating or making adjustments.

WARNING

Lower blade when vehicle is parked.

Temperature changes could change

hydraulic pressure, causing the blade to

drop unexpectedly or damaging hydraulic

components. Failure to do this could result in

serious personal injury.

WARNING

The driver shall keep bystanders clear of the

blade when it is being raised, lowered or angled.

Do not stand between the vehicle and the blade

or within 8 feet of a moving blade. A moving or

falling blade could cause personal injury.

WARNING

Keep hands and feet clear of the blade and

A-frame when mounting or removing the

snowplow. Moving or falling assemblies could

cause personal injury.

WARNING

Do not exceed GVWR or GAWR including the

blade and ballast. The rating label is found on

the driver-side vehicle door cornerpost.

WARNING

To prevent accidental movement of the

blade, always turn the ON/OFF switch to OFF

whenever the snowplow is not in use. The

control indicator light will turn off.

PERSONAL SAFETY

• Remove ignition key and put the vehicle in park or

in gear to prevent others from starting the vehicle

during installation or service.

• Wear only snug-fi tting clothing while working on

your vehicle or snowplow.

• Do not wear jewelry or a necktie, and secure long

hair.

• Wear safety goggles to protect your eyes from

battery acid, gasoline, dirt and dust.

• Avoid touching hot surfaces such as the engine,

radiator, hoses and exhaust pipes.

• Always have a fi re extinguisher rated BC handy,

for fl ammable liquids and electrical fi res.

FIRE AND EXPLOSION

WARNING

Gasoline is highly fl ammable and gasoline

vapor is explosive. Never smoke while

working on vehicle. Keep all open fl ames

away from gasoline tank and lines. Wipe up

any spilled gasoline immediately.

Be careful when using gasoline. Do not use gasoline

to clean parts. Store only in approved containers away

from sources of heat or fl ame.

CELL PHONES

A driver's fi rst responsibility is the safe operation of

the vehicle. The most important thing you can do

to prevent a crash is to avoid distractions and pay

attention to the road. Wait until it is safe to operate

Mobile Communication Equipment such as cell

phones or two-way radios.

VENTILATION

WARNING

Remove blade assembly before placing

vehicle on hoist.

CAUTION

Refer to the Undercarriage Selection Guide

for minimum vehicle recommendations and

ballast requirements.

Lit. No. 69656, Rev. 03 3 March 15, 2010

Vehicle exhaust contains lethal fumes.

Breathing these fumes, even in low

concentrations, can cause death. Never

operate a vehicle in an enclosed area without

venting exhaust to the outside.

WARNING

Page 4

TORQUE SPECIFICATIONS

TORQUE CHART

CAUTION

Read instructions before assembling.

Fasteners should be fi nger tight until

instructed to tighten according to the torque

chart. Use standard methods and practices

when attaching snowplow including proper

personal protective safety equipment.

Grade Identifi cation for J429–Grade 5 Bolt Grade Identifi cation for J429–Grade 8 Bolt

SAE J429 Grade 5 Torque Values SAE J429 Grade 8 Torque Values

Nominal

Thread Size

1/4-20 2,000 6 ft-lb 8 ft-lb 1/4-20 2,850 9 ft-lb 12 ft-lb

5/16-18 3,350 13 ft-lb 18 ft-lb 5/16-18 4,700 18 ft-lb 25 ft-lb

3/8-16 4,950 23 ft-lb 31 ft-lb 3/8-16 6,950 32 ft-lb 44 ft-lb

7/16-14 6,800 37 ft-lb 50 ft-lb 7/16-14 9,600 53 ft-lb 70 ft-lb

1/2-13 9,050 57 ft-lb 75 ft-lb 1/2-13 12,800 80 ft-lb 107 ft-lb

9/16-12 11,600 82 ft-lb 109 ft-lb 9/16-12 16,400 115 ft-lb 154 ft-lb

5/8-11 14,500 113 ft-lb 151 ft-lb 5/8-11 20,300 159 ft-lb 211 ft-lb

3/4-10 21,300 200 ft-lb 266 ft-lb 3/4-10 30,100 282 ft-lb 376 ft-lb

7/8-9 29,435 321 ft-lb 430 ft-lb 7/8-9 41,550 454 ft-lb 606 ft-lb

1-8 38,600 482 ft-lb 640 ft-lb 1-8 54,540 680 ft-lb 900 ft-lb

Clamp Loads

(lb)

Tightening Torque

"Lubricated" "Dry" "Lubricated" "Dry"

Nominal

Thread Size

Clamp Loads

(lb)

Tightening Torque

8.8

Grade Identifi cation for Metric–Grade 8.8 Bolt

Metric Class 8.8 Torque Values Metric Class 10.9 Torque Values

Diameter

(mm)

5 1,389 3 ft-lb 5 ft-lb 5 1,987 5 ft-lb 7 ft-lb

6 1,965 6 ft-lb 8 ft-lb 6 2,812 8 ft-lb 11 ft-lb

7 2,826 10 ft-lb 13 ft-lb 7 4,044 14 ft-lb 19 ft-lb

8 3,579 14 ft-lb 19 ft-lb 8 5,121 20 ft-lb 27 ft-lb

10 5,672 28 ft-lb 37 ft-lb 10 8,116 40 ft-lb 53 ft-lb

12 8,243 49 ft-lb 65 ft-lb 12 11,796 70 ft-lb 92 ft-lb

14 11,246 77 ft-lb 103 ft-lb 14 16,092 111 ft-lb 148 ft-lb

16 15,882 125 ft-lb 167 ft-lb 16 21,970 173 ft-lb 231 ft-lb

18 19,423 172 ft-lb 229 ft-lb 18 26,868 238 ft-lb 317 ft-lb

20 24,784 244 ft-lb 325 ft-lb 20 34,284 338 ft-lb 450 ft-lb

Clamp Loads

(lb)

Tightening Torque

"Lubricated" "Dry" "Lubricated" "Dry"

10.9

Grade Identifi cation for Metric–Grade 10.9 Bolt

Diameter

(mm)

Clamp Loads

(lb)

Tightening Torque

Lit. No. 69656, Rev. 03 4 March 15, 2010

Page 5

UNDERCARRIAGE INSTALLATION

INSTALLATION INSTRUCTIONS

NOTE: For easier assembly and installation, vehicle

and all snowplow components should be on a

smooth, level, hard surface, such as concrete.

1. Remove the air dam and bumper. Retain the

fasteners for later installation.

2. Remove compatibility structures, if equipped.

Retain them for reinstallation if the snowplow

mount is removed.

Remove compatibility structures.

5. Place a spacer inside the passenger's side of the

truck frame with the slots closest to the center

of the vehicle. Insert a 7/16" x 2-1/2" cap screw

down through a 7/16" fl at washer, the spacer,

the truck frame (and a washer on F-450 and

F-550 installations only).

6. Position the passenger-side rear bracket so the

cap screw goes through the appropriate hole.

Then place the sway bar in position and align the

sway bar bracket so the fastener is in the correct

hole. Attach a 7/16" locknut and hand tighten.

7. Insert a second 7/16" x 2-1/2" cap screw through

a washer, the spacer, truck frame, (a washer on

F-450 and F-550 installations only), rear bracket

and sway bar bracket. Attach a 7/16" locknut and

hand tighten.

8. Insert a 1/2" x 1-1/2" cap screw and 1/2" washer into

the truck frame and out through the front hole in the

rear bracket. Attach a 1/2" locknut and hand tighten.

9. Position the passenger-side mount so that the rear

hole is aligned with the rear hole in the bracket.

Insert a 1/2" x 1-1/2" cap screw through the hole in

the mount and rear bracket, attach a 1/2" locknut

and hand tighten.

3. Remove the metal sway bar brackets and retain

for reinstallation later in this procedure.

4. Completely remove the sway bar fasteners and bolt

clips from the keyholes in the truck frame. Retain

the fasteners and clips for future reinstallation if the

mount kit is removed from the vehicle.

10. Rotate the mount up against the truck frame.

Insert a 1/2" x 1-1/2" cap screw into the inner rear

hole at the front of the mount and through the

truck frame. Attach a 1/2" washer and locknut on

the inside of the truck frame and hand tighten.

11. Insert a 1/2" x 1-1/2" cap screw into the inner

front hole in the passenger-side mount. Attach a

1/2" locknut on the inside of the truck frame and

hand tighten.

12. Insert a 1/2" x 1-1/2" cap screw and 1/2" washer

into the truck frame and out through the outer

rear hole in the mount. Attach a 1/2" washer and

locknut and hand tighten.

13. Insert a 1/2" x 1-1/2" cap screw into the truck

frame and out through the outer front hole in the

mount. Attach a 1/2" locknut and hand tighten.

14. Install two more cap screws through the holes in

the mount and rear bracket. Attach locknuts to

fully secure the rear bracket to the mount. Hand

tighten fasteners.

Lit. No. 69656, Rev. 03 5 March 15, 2010

Page 6

UNDERCARRIAGE INSTALLATION

CAUTION

Diesel equipped vehicles must use supplied

1/2" x 1-1/4" cap screws between frame and

intercooler to prevent intercooler damage

during assembly and use.

15. Repeat steps 5–9 on the driver's side.

16. Rotate the mount up against the truck frame.

Insert a 1/2" x 1-1/4" cap screw and 1/2" washer

into the truck frame and out through the inner

rear hole at the front of the mount. Attach a

1/2" locknut and hand tighten.

1/2" x 1-1/2" Cap Screw

1/2" x 1-1/4" Cap Screw

(Insert from inside of

frame, driver's side only)

1/2" x 1-1/2" Cap Screw

(Insert from

inside of frame)

22. Fully tighten rear bracket fasteners according to

the torque chart.

23. Make sure the mounts are tight up against the

truck frame. Fully tighten the fasteners securing

the mount to the truck frame and rear bracket

according to the torque chart.

24. Remove the plastic bracket holding the metallic

cooling lines from the passenger side of the truck

frame. Stack three 1/2" washers over the bracket

fastener.

Remove bracket and

add three washers

17. Insert a 1/2" x 1-1/4" cap screw into the truck frame

and out through the inner front hole in the driver-side

mount. Attach a 1/2" locknut and hand tighten.

18. Insert a 1/2" x 1-1/2" cap screw and 1/2" washer

into the truck frame and out through the outer

rear hole in the mount. Attach a 1/2" washer and

locknut and hand tighten.

19. Insert a 1/2" x 1-1/2" cap screw into the truck

frame and out through the outer front hole in the

mount. Attach a 1/2" locknut and hand tighten.

20. Install two more 1/2" x 1-1/2" cap screws through

the holes in the mount and rear bracket. Attach

locknuts to fully secure the rear bracket to the

mount. Hand tighten fasteners.

21. Install the cross bar using four 1/2" x 1-1/2" cap

screws and 1/2" locknuts. Hand tighten fasteners.

25. Reinsert the fastener into the original hole to hold

its position. Wrap the cable tie around the entire

frame and tubing behind the bracket. Do not wrap

cable tie over any other wires or tubes, or go

inside the truck frame.

Place cable tie around entire

frame and under all cables

Lit. No. 69656, Rev. 03 6 March 15, 2010

Page 7

UNDERCARRIAGE INSTALLATION

26. Tighten the cable tie until it is snug, taking care

not to crimp tubing. Trim excess length.

Tubin g should

clear cap screws

27. Check for a U-bracket distance of 30-7/16" ± 1/8".

Take a second measurement farther back on

the mounts to ensure that they are parallel. If the

U -bracket distance is not within 30-7/16" ± 1/8",

then 1/2" fl at washers may be used to shim one

or both mounts in the appropriate direction to

obtain the desired dimension. Tighten all fasteners

according to the torque chart after achieving the

appropriate dimensions.

28. Reattach the bumper with original fasteners.

29. If the air dam does not clear the U-brackets, notch

as needed.

30. With the vehicle on level ground, measure from

the ground to the center of the hole on the

U-bracket side plate on the mount.

The height of the mount should be 14-1/4" or less

from the center of the U-bracket hole to level

ground. If the measured height is 14-1/4" or less,

no height adjustment adapter plates are needed.

If the mount is higher than 14-1/4", the appropriate

adapter plates need to be attached to the mount

adapter. (The mount adapter comes packaged with

the blade crate assembly.)

If the measured height is 14-1/4"–16", install the

short height adjustment adapter plates as described.

Short

Adapter

Plate

Center

of Hole

Mount

30-7/16" ± 1/8"

Center to Center

Mount

Adapter

If the measured height is 16"–17-1/4", install the

tall height adjustment adapter plates as described.

Center

Tall

Adapter

Plate

Mount

Adapter

of Hole

14-1/4" – 16"

Mount

16" – 17-1/4"

Lit. No. 69656, Rev. 03 7 March 15, 2010

Page 8

MOUNT ADAPTER INSTALLATION

MOUNT ADAPTER INSTALLATION

Install adapter plates as follows:

1. Position the adapter plate against the driver's side

portion of the mount adapter as shown. Insert a

3/4" x 2-3/4" cap screw through the lower front

adapter plate hole and through the appropriate

hole on the mount adapter. Secure with a locknut.

Mount Adapter

3/4" Washer

Adapter Plate

3/4" Locknut

3/4" x 2-3/4" Cap Screw

2. Insert a cap screw through the rear adapter plate

hole, through the slot on the mount adapter and

through a washer. Secure with a locknut.

3. Repeat for the passenger's side. Tighten all

fasteners according to the torque chart.

NOTE: After fi ve to ten hours of snowplow usage,

retorque all undercarriage assembly fasteners.

Lit. No. 69656, Rev. 03 8 March 15, 2010

Page 9

Lit. No. 69656, Rev. 03 9 March 15, 2010

Page 10

Blizzard

PO Box 245038

Milwaukee, WI 53224-9538

www.blizzardplows.com

A DIVISION OF DOUGLAS DYNAMICS, L.L.C.

Blizzard reserves the right under its product improvement policy to change construction or design details and furnish equipment when so

altered without reference to illustrations or specifi cations used. Blizzard or the vehicle manufacturer may require or recommend optional

equipment for snow removal. Do not exceed vehicle ratings with a snowplow. Blizzard offers a limited warranty for all snowplows and

accessories. See separately printed page for this important information. The following are registered (®) or unregistered (™) trademarks of

Douglas Dynamics, L.L.C.: BLIZZARD®, POWER HITCH™, POWER HITCH™ 2, POWER PLOW®, SPEEDWING™.

Printed in U.S.A.

Lit. No. 69656, Rev. 03 10 March 15, 2010

Loading...

Loading...