Page 1

BLiNQ Networks Inc.

X-1200 Intelligent Wireless Backhaul System

Installation Guide

Release 1.0

Issue 01 D1

April 2014

Page 2

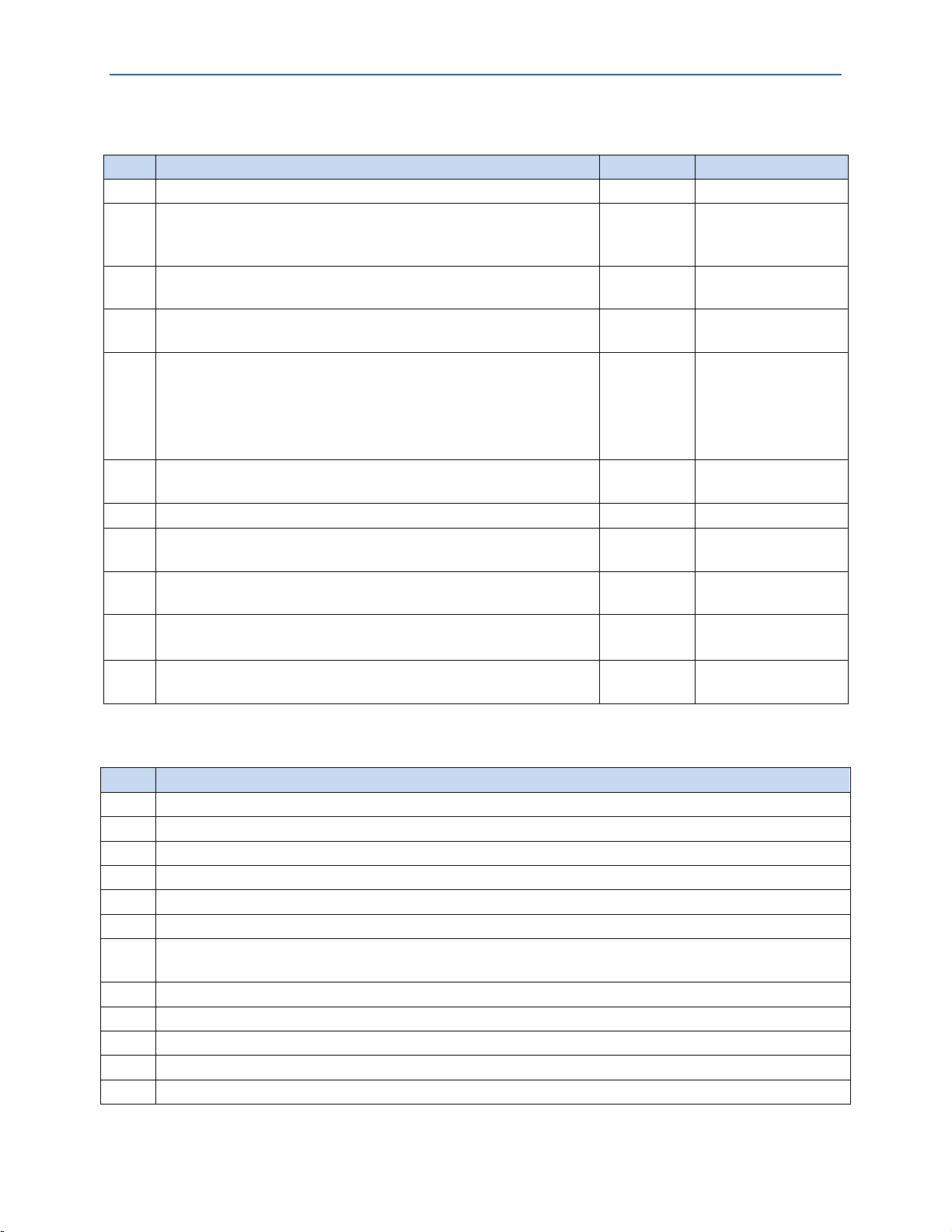

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

Date

Issue

Reason for Issue

August 2013

01

Early Availability

January 2014

1.0

Final Document

April 2014

1.0 D1

Label Update (Approvals); Compliance update including Antenna

Contact Information:

BLiNQ Networks Inc.

400 March Road, Suite 240

Ottawa, ON K2K 3H4

Web Site:

http://www.blinqnetworks.com

Sales Inquiries:

Email: sales@blinqnetworks.com

Telephone: 1-613-599-3388 x280

Customer Support:

Web: http://www.blinqnetworks.com/support

Email: support@blinqnetworks.com

Telephone: 1-613-599-3388 x270

Revision History

Confidential - Restricted Use and Duplication Page ii Issue 01 D1

Page 3

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

Table of Contents

1 Important Safety and Service Notices ..........................................................................................1

1.1 Safety Warnings ............................................................................................................................ 1

1.2 Important Service and Warranty Information .............................................................................. 1

1.3 Overvoltage (Lightning/Surge) Protection .................................................................................... 2

2 System Description .....................................................................................................................4

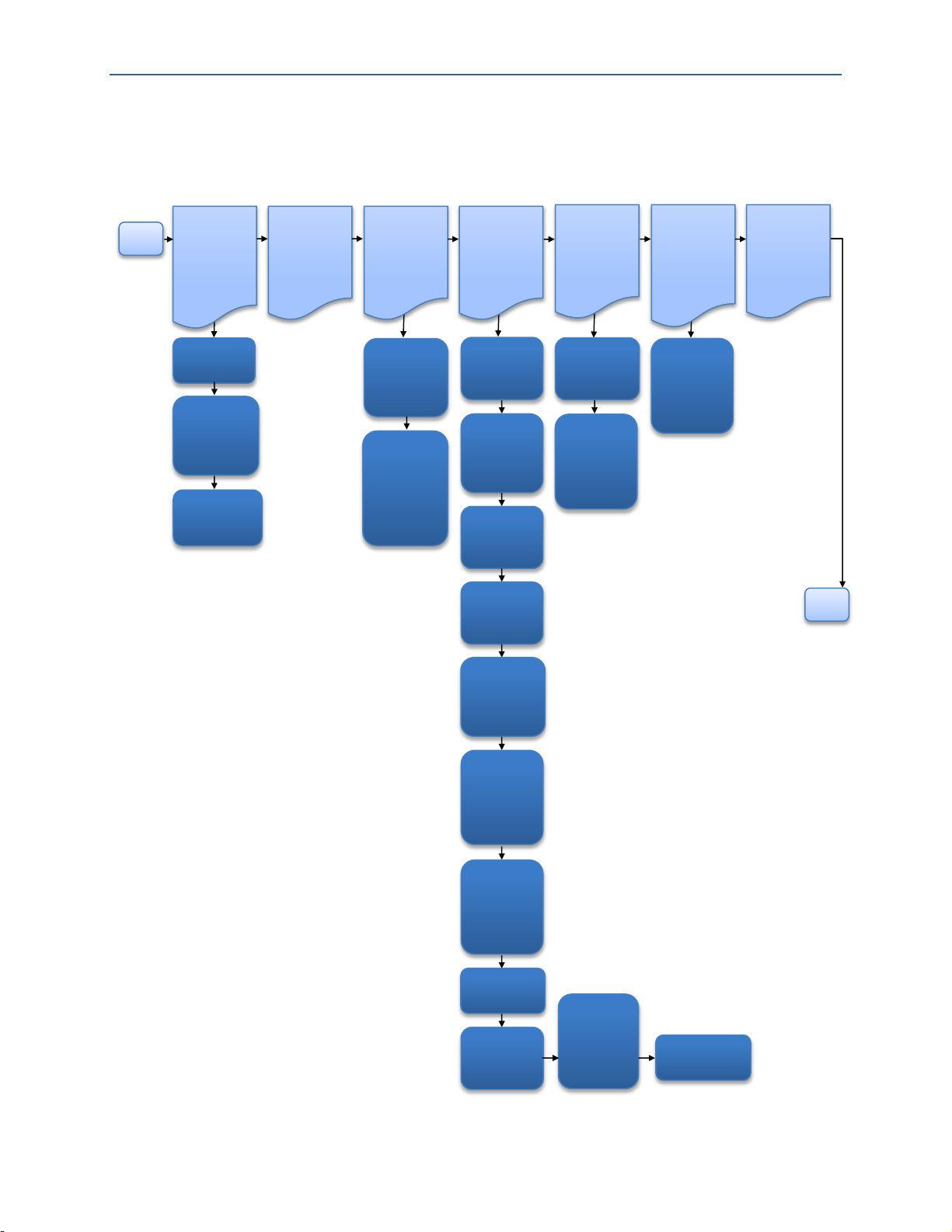

3 Flowchart: Installation Process Overview ....................................................................................7

4 Required Installation Items .........................................................................................................8

5 Site Preparation........................................................................................................................ 11

5.1 Operating Sector Frequency Check ............................................................................................. 11

5.2 HM and RBM Pre-Installation Checks and Service Provisioning ................................................. 11

6 Installing the Modules (General) ............................................................................................... 13

6.1 General Safety Information ........................................................................................................ 13

6.2 Equipment Distance and Orientation ......................................................................................... 14

6.2.1 Hub Modules ....................................................................................................................... 14

6.2.2 Remote Backhaul Modules ................................................................................................. 14

6.3 Mounting to a Pole or Wall ......................................................................................................... 14

6.3.1 Attaching Pole Clamps to Mounting Bracket ...................................................................... 14

6.3.2 Mounting with U- or V-Clamps ........................................................................................... 16

6.3.3 Mounting with Steel Straps................................................................................................. 17

6.3.4 Mounting onto a Wall ......................................................................................................... 18

6.4 Assembling the Module Brackets ............................................................................................... 19

6.4.1 Attach Elevation Bracket ..................................................................................................... 19

6.4.2 Attach Azimuth Bracket ...................................................................................................... 21

6.5 Installing the Power Supply Unit (Optional) ............................................................................... 23

6.5.1 Installing the PSU Bracket ................................................................................................... 23

6.5.2 Installing the Power Supply Unit ......................................................................................... 24

6.6 Installing the Module onto a Mounting Bracket ......................................................................... 26

6.7 Grounding and Overvoltage Protection Instructions .................................................................. 28

6.7.1 Installing the Grounding Cable ............................................................................................ 28

6.7.2 Installing the Lightning/Surge Arrestor ............................................................................... 29

6.8 Connecting to DC Power ............................................................................................................. 31

6.9 Verifying Basic Installation .......................................................................................................... 33

6.10 Connecting to the Ethernet Backhaul Network .......................................................................... 34

6.10.1 Connecting to the RJ45 Ethernet Port ................................................................................ 34

6.10.2 Connecting to the SFP Port ................................................................................................. 36

6.11 Cable Management ..................................................................................................................... 36

Confidential - Restricted Use and Duplication Page iii Issue 01 D1

Page 4

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

7 Installing the Hub Module ......................................................................................................... 38

7.1 Adjusting the Hub Module .......................................................................................................... 38

7.2 Assembling the Beam Steering Antenna (If Required) ............................................................... 41

7.2.1 Installing the Bracket on to the Beam Steering Antenna ................................................... 41

7.2.2 Mounting the Antenna Assembly on to HM ....................................................................... 42

7.2.3 Connections for Antenna and Hub...................................................................................... 44

8 Installing the Remote Backhaul Module .................................................................................... 46

8.1 Using the BSI Feature and Adjusting the Module ....................................................................... 46

9 System and Network Provisioning ............................................................................................. 51

10 Appendix .................................................................................................................................. 52

10.1 BLiNQ Wireless Devices and RF Safety/Les appareils sans fil BLiNQ et la sécurité RF................ 52

10.2 Equipment Compliance ............................................................................................................... 54

10.2.1 Federal Communications Commission (FCC) Notices ......................................................... 54

10.2.2 Industry Canada Notice ....................................................................................................... 54

10.2.3 Bonded Network ................................................................................................................. 54

10.3 Troubleshooting Guide ............................................................................................................... 55

10.4 List of Acronyms .......................................................................................................................... 57

List of Figures

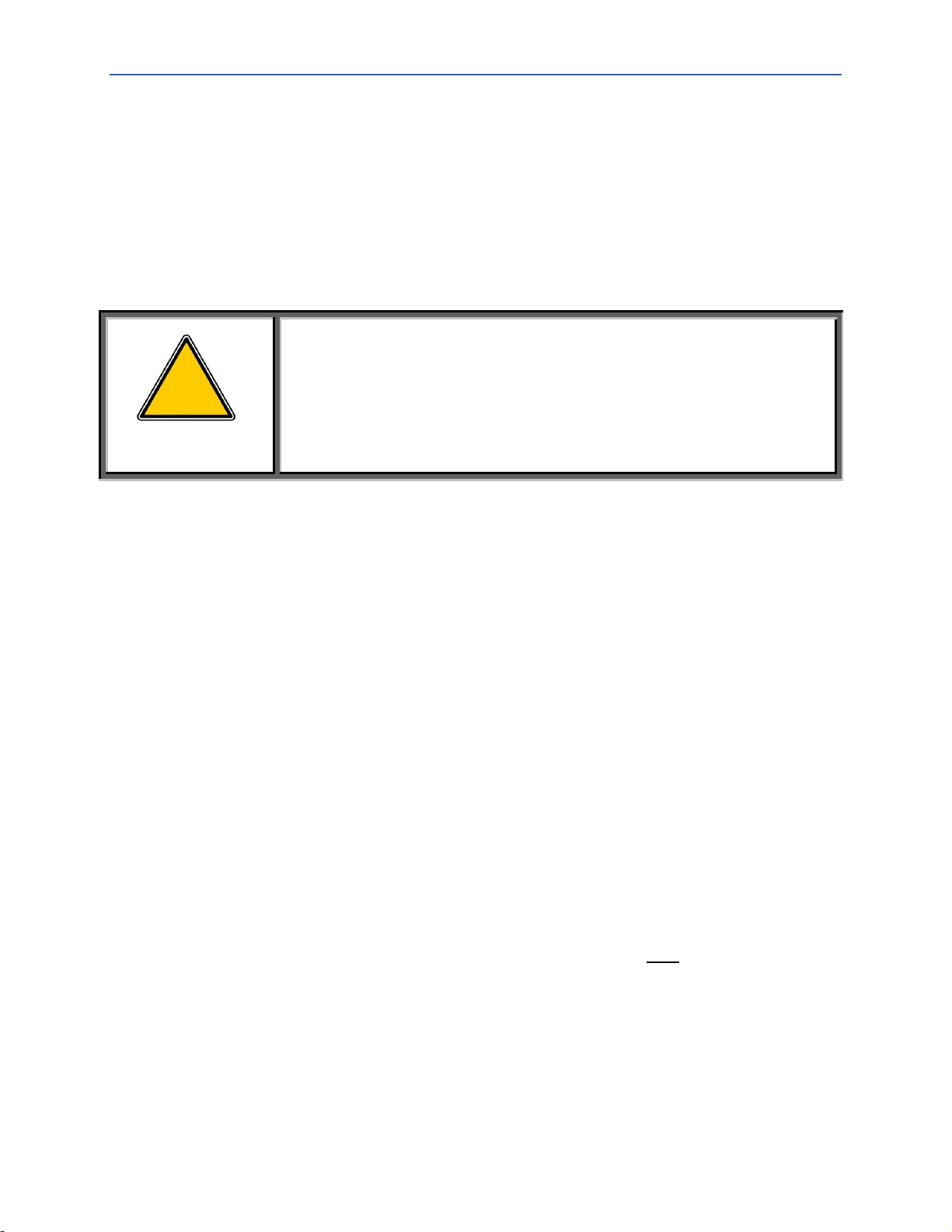

Figure 1 Module Casing Labels .................................................................................................................................... 2

Figure 2 Hub Module ................................................................................................................................................... 6

Figure 3 Remote Backhaul Module .............................................................................................................................. 6

Figure 4 Pole/Wall Mount Bracket............................................................................................................................. 15

Figure 5 Attaching Pole Clamps to Pole/Wall Mount Bracket ................................................................................... 15

Figure 6 Attaching Assembled Pole/Wall Mount Bracket to Pole with U-Clamp or V-Clamp.................................... 17

Figure 7 Attaching Assemble Pole/Wall Mount Bracket to Pole with Straps ............................................................ 18

Figure 8 Attaching Assembled Pole/Wall Mount Bracket to Wall ............................................................................. 19

Figure 9 Elevation Bracket and Associated Hardware ............................................................................................... 20

Figure 10 Elevation Bracket Mounting Position ......................................................................................................... 20

Figure 11 Attaching Elevation Bracket to Back of Module ........................................................................................ 21

Figure 12 Azimuth Bracket and Associated Hardware ............................................................................................... 21

Figure 13 Attaching Azimuth Bracket to Elevation Bracket on Module ..................................................................... 22

Figure 14 PSU Mounting Bracket ............................................................................................................................... 23

Figure 15 Attaching PSU Bracket to Back of Module ................................................................................................. 24

Figure 16 Power Supply Unit (PSU) ............................................................................................................................ 24

Figure 17 PSU Bracket PSU Mounting Studs .............................................................................................................. 25

Figure 18 Power Connection via the PSU................................................................................................................... 26

Figure 19 Module with PSU Installed. ........................................................................................................................ 26

Figure 20 Pole/Wall Mount Bracket Locknut Hardware ............................................................................................ 26

Figure 21 Unit Installed onto the Pole/Wall Mount Bracket ..................................................................................... 27

Confidential - Restricted Use and Duplication Page iv Issue 01 D1

Page 5

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

Figure 22 Module with Grounding Lug ...................................................................................................................... 29

Figure 23 Wiring of Lightning/Surge Arrester (Sold by BLiNQ Networks) .................................................................. 31

Figure 24 HM and RBM LED States ............................................................................................................................ 33

Figure 25 Ethernet Connector Encased in Environmental Housing ........................................................................... 34

Figure 26 Ethernet Connector Assembly - Separated ................................................................................................ 35

Figure 27 Module Cable Management ...................................................................................................................... 37

Figure 28 Hub Module Showing All Connectors ........................................................................................................ 38

Figure 29 HM Horizontal Plane Adjustment via Azimuth Bracket ............................................................................. 39

Figure 30 HM Vertical Plane Adjustment via Elevation Bracket ................................................................................ 39

Figure 31 HM Theta Adjustment Via Elevation Bracket Mounting Holes .................................................................. 40

Figure 32 HM Down-tilt Adjustment with Antenna Mount ....................................................................................... 40

Figure 33 Beam Steering Antenna Mounting Bracket ............................................................................................... 41

Figure 34 Hub Module Antenna Mounting Holes ...................................................................................................... 43

Figure 35 Antenna attached to a Hub Module .......................................................................................................... 43

Figure 36 Beam Steering Antenna RF Connections ................................................................................................... 44

Figure 37 RF Connections on the Hub Module .......................................................................................................... 44

Figure 38 RBM Module Showing All Connectors ....................................................................................................... 46

Figure 39 RBM Horizontal Plane Adjustment via Azimuth Bracket ........................................................................... 48

Figure 40 RBM Vertical Plane Adjustment via Elevation Bracket .............................................................................. 48

Figure 41 RBM Theta Adjustment Via Elevation Bracket Mounting Holes ................................................................ 49

List of Tables

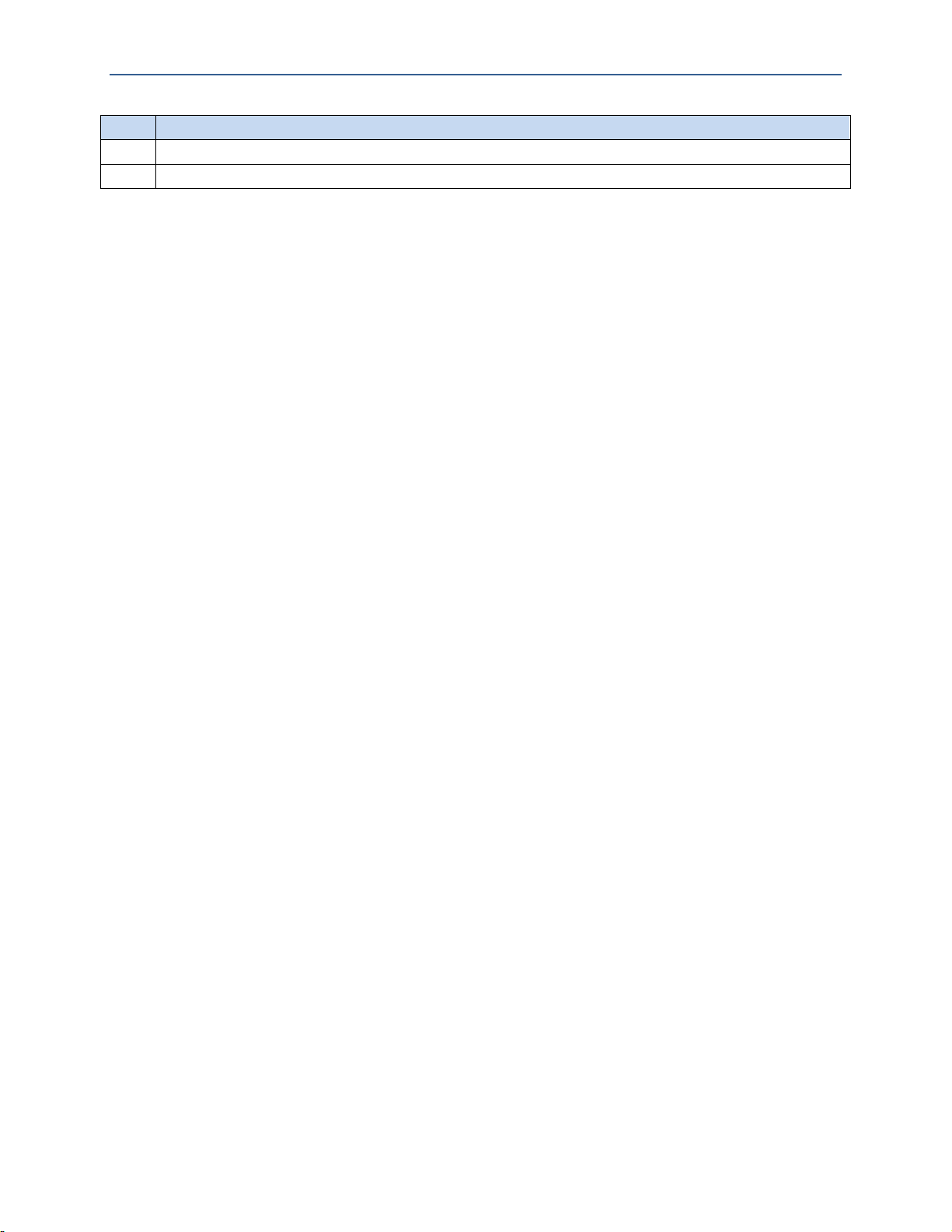

Table 1 X-1200 System Specifications .......................................................................................................................... 4

Table 2 Required Items for Hub Module Installation .................................................................................................. 8

Table 3 Required Items for Remote Backhaul Module Installation ............................................................................. 9

Table 4 Summary of Required Installation Tools (Not Provided by BLiNQ Networks) ................................................ 9

Table 5 Recommended Torque Values for Self-Tapping Bolts ................................................................................... 15

Table 6 Recommended Torque Values for U-Bolt or V-Clamp Bolts ......................................................................... 16

Table 7 Recommended Torque Values for Elevation Bracket Bolts ........................................................................... 20

Table 8 Recommended Torque Values for Azimuth Bracket Bolts ............................................................................ 22

Table 9 Recommended Torque Values for PSU Bracket Bolts ................................................................................... 23

Table 10 Recommended Torque Values for PSU Bolts .............................................................................................. 25

Table 11 Recommended Torque Values for Pole/Wall Mount Bracket Locknuts ...................................................... 27

Table 12 Recommended Torque Value for the RJ45 Ethernet Connection ............................................................... 34

Table 13 Recommended Torque Values for HM Bracket Bolts .................................................................................. 39

Table 14 Recommended Torque Values for Antenna Bracket Nuts .......................................................................... 42

Table 15 Recommended Torque Values for Antenna Bracket Bolts .......................................................................... 42

Table 16 Recommended Torque Values for Antenna Cable Connections ................................................................. 44

Table 17 Recommended Torque Values for RBM Bracket Bolts ................................................................................ 47

Table 18 X-1200 System Troubleshooting Guide ....................................................................................................... 55

Table 19 List of Acronyms .......................................................................................................................................... 57

Confidential - Restricted Use and Duplication Page v Issue 01 D1

Page 6

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

This Page Intentionally Left Blank.

Confidential - Restricted Use and Duplication Page vi Issue 01 D1

Page 7

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

WARNING!

Follow all health and safety procedures and recommendations made by

BLiNQ Networks within this X-1200 System Installation Guide. Failure

to do so could result in injury, death, or damage to the equipment.

!

1 Important Safety and Service Notices

Read this X-1200 System Installation Guide and follow all operating and safety instructions.

Installation of the X-1200 system must be done by a qualified professional installer who is experienced

with installing telecommunications equipment and networks. Installations must adhere to the

information and specifications within this X-1200 System Installation Guide.

1.1 Safety Warnings

The product-marketing label indicates the power requirements. Do not exceed the described

limits.

Each module’s power supply must have a resettable circuit breaker rated to a maximum of 20

Amps.

The antenna must be permanently grounded before making any of the connections to the

antenna used with the Hub.

Use only a damp cloth for cleaning. Do not use liquid or aerosol cleaners. Disconnect the power

before cleaning.

Disconnect the power when the unit is stored for long periods.

Do not locate the outdoor unit near power lines or other electrical power circuits.

The system must be properly grounded to protect against power surges and accumulated static

electricity. It is the user’s responsibility to install this device in accordance with the local electrical

codes.

1.2 Important Service and Warranty Information

Keep all product information for future reference.

Refer all repairs to qualified service personnel. Do not remove the covers or modify any part of the

X-1200 system, as this action will void the warranty.

Be sure to do the following upon unpacking the X-1200 system modules. For each Hub Module (HM) and

Remote Backhaul Module (RBM) in your system:

Locate the label on the module casing that lists the Serial Number (SN) and Media Access Control

(MAC) address for the module (Figure 1, “Module Casing Labels”)

Record the SN on your registration card for future reference

Record the MAC address for future reference when provisioning the system

Confidential - Restricted Use and Duplication Page 1 Issue 01 D1

Page 8

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

WARNING!

A qualified professional installer should install the wireless equipment.

The installer must follow local and national codes for electrical

grounding and safety. Failure to meet safety requirements and/or use

of non-standard practices and procedures could result in personal

injury and damage to equipment. A direct lightning strike may cause

serious damage even if these guidelines are followed.

!

Figure 1 Module Casing Labels

1.3 Overvoltage (Lightning/Surge) Protection

All outdoor wireless equipment is susceptible to lightning damage from a direct hit or induced current

from a near strike. Lightning protection and grounding practices in local and national electrical codes

serve to minimize equipment damage, service outages and serious injury. Reasons for lightning damage

can be summarized as follows:

Poorly grounded antenna sites that can conduct high lightning strike energy into equipment.

Lack of properly installed lightning protection equipment that can cause equipment failures from

lightning induced currents.

An overvoltage protection system provides a means by which the energy may enter earth without

passing through and damaging parts of a structure. An overvoltage protection system does not prevent

lightning from striking; it provides a means for controlling it and preventing damage by providing a low

resistance path for the discharge of energy to travel safely to ground. Improperly grounded connections

are also a source of noise that can cause sensitive equipment to malfunction.

A good grounding system disperses most of the surge energy from a lightning strike away from the

building and equipment. The remaining energy on the cable can be directed safely to ground through a

lightning/surge arrestor in series with the cable.

Confidential - Restricted Use and Duplication Page 2 Issue 01 D1

Page 9

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

The X-1200 system is designed with consideration for resistance to the effects of lightning on the access

point electronics. When installing a lightning/surge arrestor for your system installation, observe the

following general industry practices:

Install lightning/surge arrestors in series with the Ethernet and power cables at the point of entry

to the building. If the power cable does not enter the building, the location is at the installer’s

discretion.

In each case the grounding wire should be connected to the same termination point used for the

tower or mast.

Provide direct grounding from the unit, the mounting bracket, the antenna, and the Ethernet

cable surge protection to the same ground bus on the building. Use the grounding screws

provided for terminating the ground wires.

Confidential - Restricted Use and Duplication Page 3 Issue 01 D1

Page 10

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

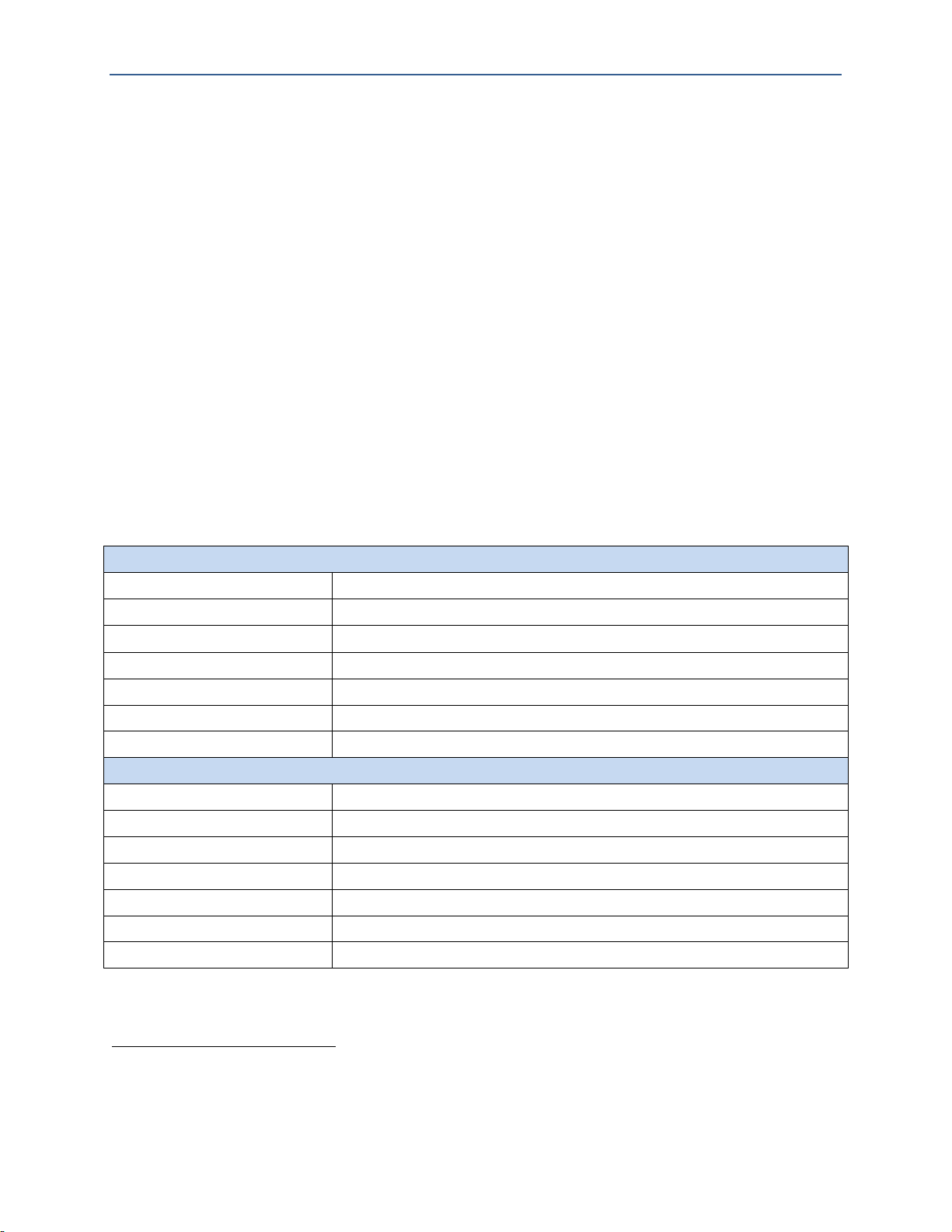

RADIO SPECIFICATIONS

Frequency Band

3.65-3.70 GHz, 3.40-3.60 GHz, 2.50-2.69 GHz, and 5.47-5.875 GHz

Tuning Resolution

50 kHz, minimum

Transmit Power, 3.65 GHz

-15 dBm to +27 dBm per port, 0.25 dB resolution

Transmit Power, 5.8 GHz

-15 dBm to +23 dBm per port, 0.25 dB resolution

Channel Bandwidth

20 MHz (5/10 MHz1)

Receiver Sensitivity

-92 dBm with QPSK @ 1e-03 PER (typ.)

Modulation & Coding

QPSK/16QAM/64QAM/256QAM, bi-directional, fully adaptive

PERFORMANCE

Throughput

Up to 400 Mbps, L2 aggregate uplink and downlink

Spectral Efficiency

11 bps/Hz

Physical Layer

Cyclic Single Carrier Frequency Domain Equalized

Operating Mode

TDD

Latency

3.5 msec for 4 RBM’s assigned to Hub, dual carrier mode

Traffic ratios

50:50, 65:35, 75:25, 35:65, 25:75; user configurable

Frame Size

Up to 2016 bytes

1

2 System Description

The X-1200 is a dual carrier, Point-to-Multipoint (PMP) intelligent wireless transport system

distinguished for its high performance and advanced traffic management capabilities. The X-1200

platform consists of a Hub Module (HM) and up to four (eight1) Remote Backhaul Modules (RBM).

BLiNQ Networks X-1200 system operates in the sub 6 GHz licensed frequency bands. It offers

deployment flexibility for both Line-of-Sight (LOS) and Non Line-of-Sight (TrueNLOS™) operation by

incorporating advanced Physical Layer (PHY) and Media Access Control (MAC) layer algorithms and

techniques. BLiNQ Networks has developed proprietary interference mitigation algorithms and

incorporated self-organizing network techniques into its solutions to increase capacity and reliability

beyond that of ordinary backhaul solutions. This is because in a NLOS environment, interference and

shadowing are the two main reasons that limit capacity and link reliability. Mitigating interference and

enhancing signal reliability maximizes system performance.

The X-1200 system delivers 11 bps/Hz spectral efficiency. The system is designed for use in multiple

applications that include small cell mobile backhaul, optical fiber cable extension and enterprise data

backhaul services by providing up to 400 Mbps of throughput in dual 2x20 MHz channels.

Table 1 lists the system specifications.

Table 1 X-1200 System Specifications

Future Software Release

Licensed:+26dBm for MCS 7 and +25dBm for MCS 8; Unlicensed: +22dBm for MCS 6, +21 for MCS 7 and +20 for MCS 8

Confidential - Restricted Use and Duplication Page 4 Issue 01 D1

Page 11

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

PERFORMANCE (Cont)

Antenna System

2x2 MIMO, Spatial Multiplexing / Tx & Rx Diversity

Remote Backhaul Module: Integral antenna, 14 dBi

Hub Module: Beam Steering Antenna, 17 dBi

Configuration

PTP or PMP up to 42 Remotes

Power Consumption

< 72 W

Power

-48 Vdc nominal, -36 to -60 Vdc range

Connectivity

Copper 1000BaseT

Optional Fiber Gig-E (Hub only)

Synchronization

Integral GPS antenna and receiver, 1588v2, SyncE

QoS

8 queues per service flow, 4 SF’s per RBM per direction

Security

AES-256

NETWORKING

Configuration

Ethernet bridge

Attributes

802.1Q, 802.1ad, DSCP/ToS/802.1p (IPv4/IPv6)

Features

Per RBM service flows, Dynamic Bandwidth Sharing

OPERATIONS, ADMINISTRATION AND MANAGEMENT (OAM)

Configuration

WebUI / CLI, radio and Ethernet performance monitoring

EMS Integration

SNMP v2c/v3

OAM Protocols

HTTP(S), TCP/IP, UDP, (S)FTP, SSH

MECHANICAL/ENVIRONMENTAL/COMPLIANCE

RBM Dimensions

12.6” x 8.3” x 5.1” (32 x 21 x 13 cm)

Hub Dimensions

15.0” x 18.0” x 5.1” (38 x 46 x 13 cm)

Weight (Hub & RBM)

RBM < 8.8 lbs. (4.0 kg); Hub < 15.5 lbs. (7.0 kg)

Temperature Range

-45°C to +55°C (-49 °F to 131 °F)

Enclosure Protection

IP67

Compliance

EMC: FCC Part 15 Subpart B, C, E; ICES-003 Class B

Radio: FCC Part 90z, RSS 197

Safety: UL/CSA 60950-1,-22

2

The X-1200 system operates in licensed Time Division Duplexing (TDD) bands including 3.65-3.70 GHz,

3.40-3.60 GHz, 2.50-2.69 GHz bands in both Point-to-Point (PTP) and Point-to-Multipoint (PMP)

configurations. Additionally, the X-1200, when configured for dual-carrier mode, operates in unlicensed

frequency bands including 5.47-5.875 GHz bands. It incorporates Multiple Input Multiple Output

(MIMO) technology and operates at high Modulation and Coding Scheme (MCS) rates to provide high

capacity. In addition, the product incorporates BLiNQ Networks interference management techniques

which include multiple power control algorithms to maximize performance in dense networks.

8 in future release

Confidential - Restricted Use and Duplication Page 5 Issue 01 D1

Page 12

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

Front

Back

Front without Antenna

Back

Side

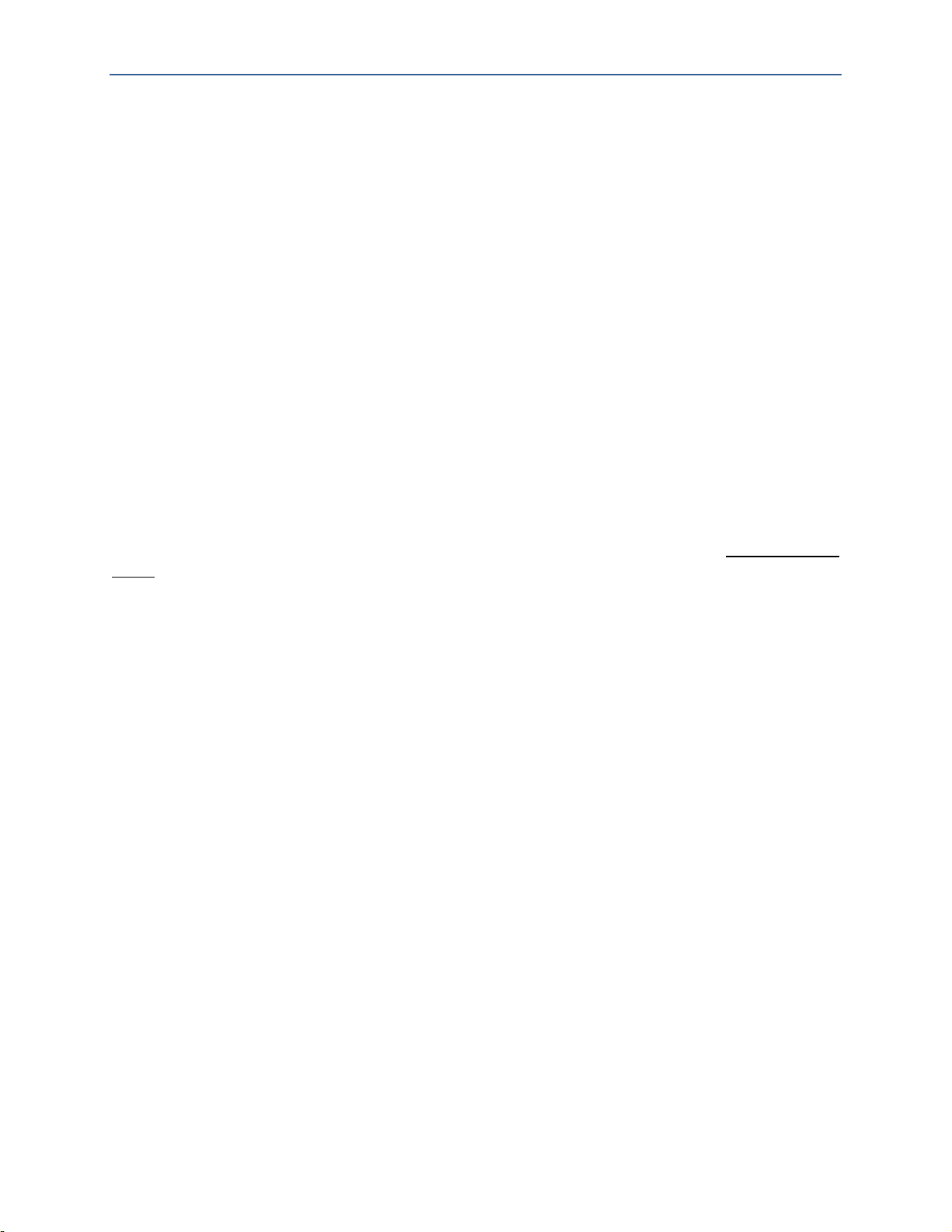

The X-1200 system has a small, all-outdoor, zero-footprint form factor that can be easily deployed

unobtrusively on towers, poles, building sidewalls or rooftops. It consists of the following modules:

Hub Module (HM): A sector controller which serves as the aggregation point controlling up to 4

Remote Backhaul Modules (RBMs), featuring an integral Beam Steering Antenna.

Figure 2 Hub Module

Remote Backhaul Module (RBM): A subscriber unit that is installed outdoors on customer

premises, including public infrastructure assets such as light and utility poles in mobile backhaul

applications. RBMs feature an integrated antenna.

8 in future software release.

Confidential - Restricted Use and Duplication Page 6 Issue 01 D1

Figure 3 Remote Backhaul Module

Page 13

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

Start

Important

Safety and

PAGE 1

Installation

Preparation

the Modules

13

Installing the

PAGE 46

System and

Provisioning

Warnings

Service and

Information

(Lightning/Surge)

Protection

Check

Installation

Checks and

Provisioning

Information

Module

BSI Feature

the Module

Equipment

Orientation

Mounting to

Wall

Assembling

the Module

Brackets

Supply Unit

(Optional)

the Module

Bracket

Grounding

Overvoltage

Protection

Instructions

to DC Power

Installation

Connecting

Network

END

Assembling

Antenna (If

Required)

Management

3 Flowchart: Installation Process Overview

To get started quickly, follow the process below. For more details, click on the chapter/section title.

Service

Notices

Safety

Important

Warranty

Overvoltage

Required

Items

PAGE 8

Site

PAGE 11

Operating

Sector

Frequency

HM and

RBM Pre-

Service

Installing

(General)

PAGE

General

Safety

Distance

and

a Pole or

Installing

the Hub

Module

PAGE 38

Adjusting

the Hub

the Beam

Steering

Remote

Backhaul

Module

Using the

and

Adjusting

Network

PAGE 51

Installing

the Power

Installing

onto a

Mounting

and

Connecting

Verifying

Basic

to the

Ethernet

Backhaul

Cable

Confidential - Restricted Use and Duplication Page 7 Issue 01 D1

Page 14

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

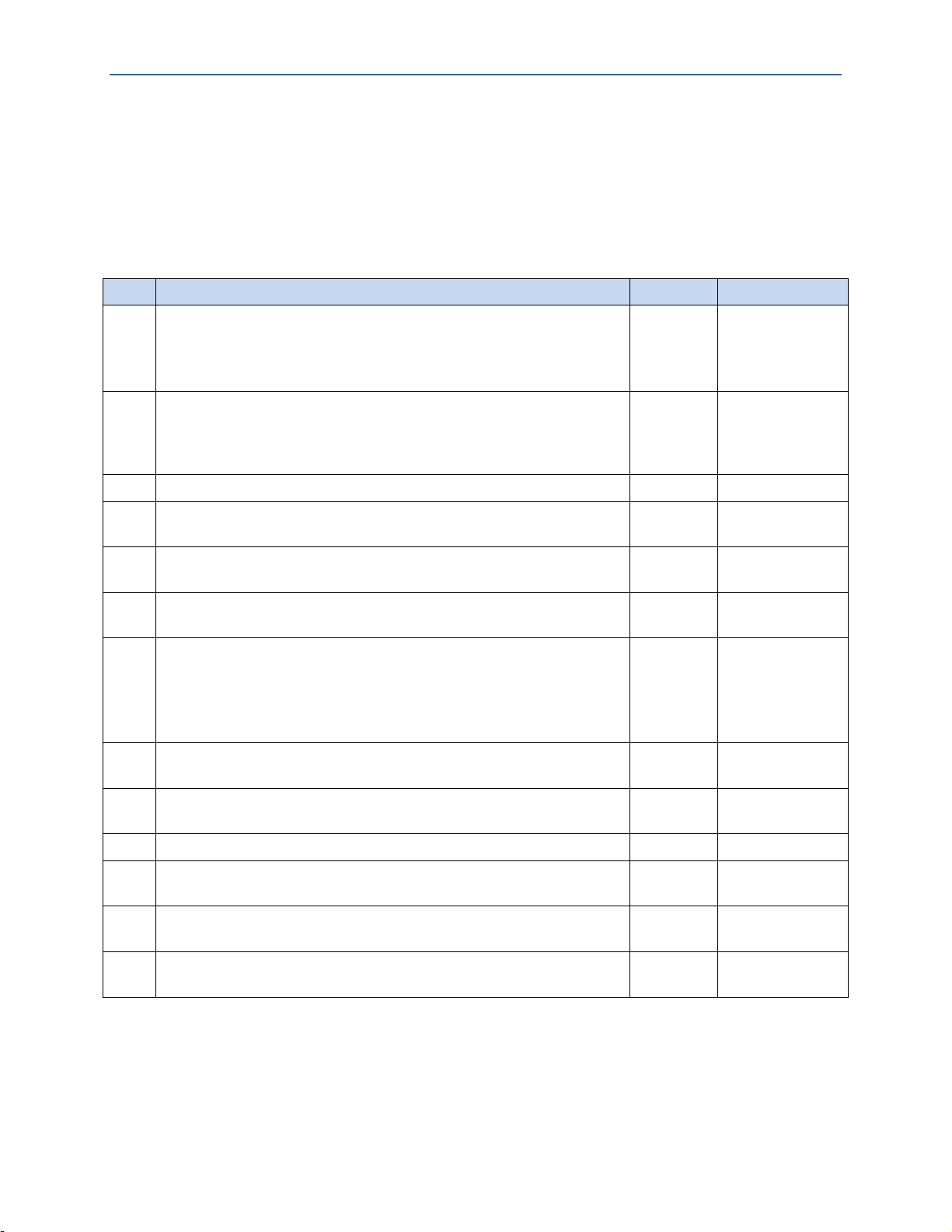

No.

Description

Quantity

Note

1

X-1200 Hub Module (HM)

Beam Steering Antenna Kit includes Antenna unit, Down-tilt antenna

bracket, screws, nuts and washers for mounting to X-1200 unit, SPI

control cable (x1), and RF cables NType to NType (x4)

1

2

X-1200 Module Mount Kit with Self-Tapping Screw Bolts—Includes

module elevation bracket, module azimuth bracket, two pole clamps,

and pole/wall mount bracket

1*

Screws not

provided for

wall/mast side

(1/4 in. holes)

3

Coaxial RF Cables: N-type male termination at both ends, outdoor rated

2 or 4*

Nominal 1 m long

4

Outdoor-rated Shielded Ethernet cable, CAT5e or better

< 100

meters

Not provided by

BLiNQ Networks

5

Ethernet cable connector and environmental housing with shielded

RJ45 connectors

1

Provided by

BLiNQ Networks

6

SFP, fiber and connectors (if optional fiber optic Ethernet possibility is

to be used)

Not provided by

BLiNQ Networks

7

Power Cable:

Shielded 18 AWG 2 conductors 90C water resistant, black and white

conductor jackets, outdoor rated cable, 5-8 mm thick

Power Connector:

Weatherized DC connector to fit on power cable

1*

Option of 10m,

20m, 40m

terminated

cables

8

6-gauge grounding cable

1

Not provided by

BLiNQ Networks

9

Power Supply Unit (PSU) Kit includes PSU, PSU bracket and associated

hardware for installation.

1*

Optional

10

Lightning/Surge Arrester

1*

Optional

11

Access to NOC Server, Providing FTP, SysLog, SNMP Browser, and DNS

Services

1

12

Basic Portable Personal Computer (PC); with NIC (Ethernet) port

required

1

Not Provided by

BLiNQ Networks

13

Miscellaneous hardware and software as required: for example,

compass, sniffer application, FTP client

as

required

Not Provided by

BLiNQ Networks

*Sold as a separate line item by BLiNQ Networks.

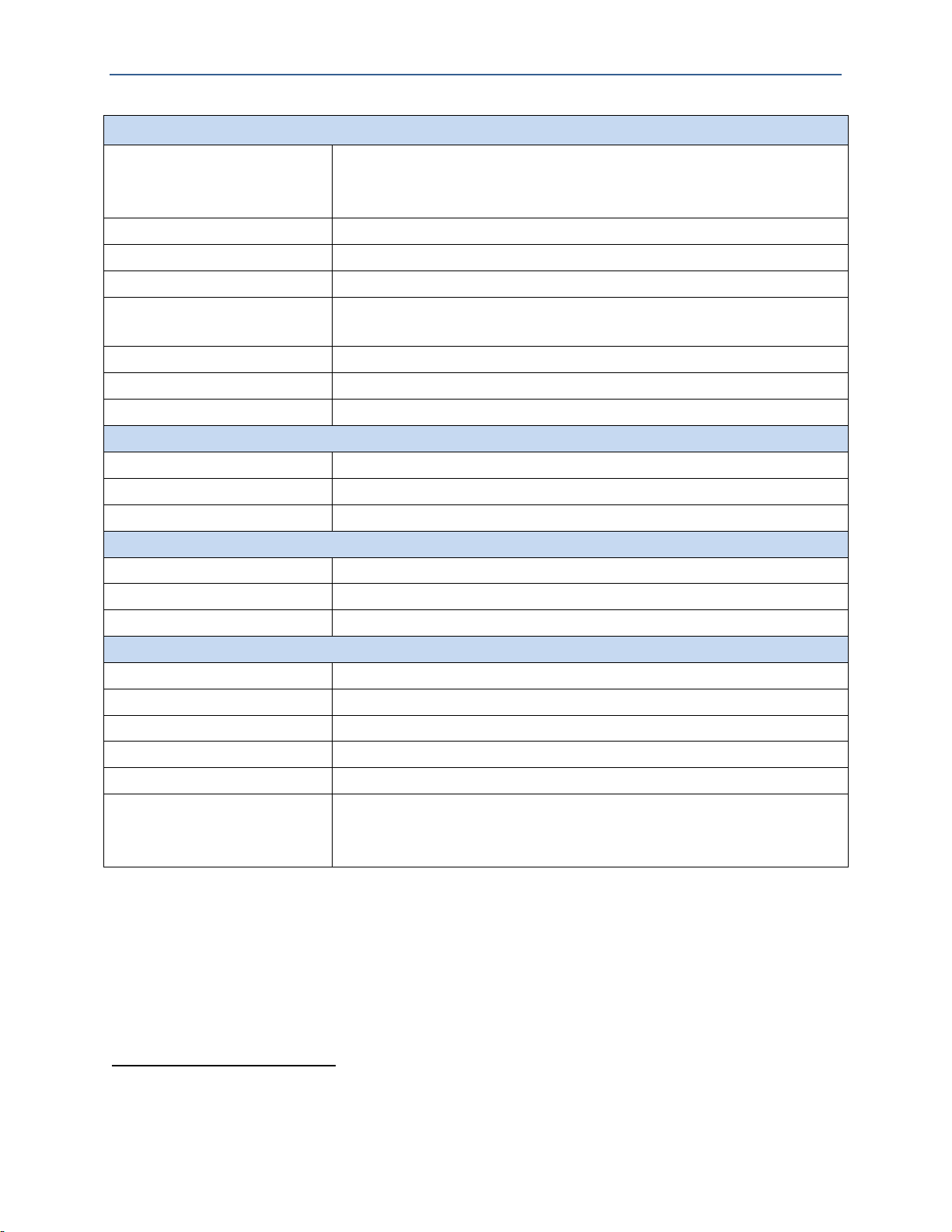

4 Required Installation Items

Table 2 lists the items required to install the X-1200 Hub Module (HM).

Table 3 lists the items required to install the X-1200 Remote Backhaul Module (RBM).

Table 4 lists the tools required to install the X-1200 system modules.

Table 2 Required Items for Hub Module Installation

Confidential - Restricted Use and Duplication Page 8 Issue 01 D1

Page 15

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

No.

Description

Quantity

Note

1

X-1200 Remote Backhaul Module (RBM)

1

Per site

2

X-1200 Module Mount Kit with Self-Tapping Screw Bolts—Includes

module elevation bracket, module azimuth bracket, two pole

clamps, and pole/wall mount bracket

1*

Screws not provided

for wall/mast side

(1/4 in. holes)

3

Outdoor-rated Shielded Ethernet cable, CAT5e or better

< 100

meters

Not provided by

BLiNQ Networks

4

Ethernet cable connector and environmental housing with shielded

RJ45 connectors

1

Provided by BLiNQ

Networks

5

Power Cable:

Shielded 18 AWG 2 conductors 90C water resistant, black and

white conductor jackets, outdoor rated cable, 5-8 mm thick

Power Connector:

Weatherized DC connector to fit on power cable

1*

Option of 10m, 20m,

40m connectorized

cables

6

6-gauge grounding cable

1

Not provided by

BLiNQ Networks

7

Lightning/Surge Arrester

1*

Optional

8

Access to NOC Server, Providing FTP, SysLog, SNMP Browser, and

DNS Services

1

9

Basic Portable Personal Computer (PC); with NIC (Ethernet) port

required

1

Not provided by

BLiNQ Networks

10

Miscellaneous hardware and software as required:

for example, wrench, compass

as required

Not provided by

BLiNQ Networks

11

Power Supply Unit (PSU) Kit includes PSU, PSU bracket and

associated hardware

1 each*/

RBM

Optional

*Sold as a separate line item by BLiNQ Networks.

No.

Description

1

Socket wrench with 3/8 in. driver head, with long and short ½ in. and 7/16 in. sockets

2

Slot head screwdrivers, small and medium size

3

Phillips #2 screwdriver

4

Torque wrench, 3/8 in. head with range for 4-60Nm or 3-45lbf-ft

5

Ratchet wrenches, ½ in. and 7/16 in.

6

Steel straps (for installation on pole diameters 3.5 in./9 cm or larger)

7

Four 5/16 in. or M8 wall mounting bolts, or equivalent, for wall installation (and bolt reinforcement

hardware if wall material requires it)

8

Black marker

9

Crimp tool

10

Cable ties

11

Torque screwdriver ¼ head with 5-40inlb range

12

Allen drivers metric 3mm and SAE 3/16” for GND lug and Beam Steering Antenna bracket

Table 3 Required Items for Remote Backhaul Module Installation

Table 4 Summary of Required Installation Tools (Not Provided by BLiNQ Networks)

Confidential - Restricted Use and Duplication Page 9 Issue 01 D1

Page 16

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

No.

Description

13

Metric 7mm nut driver (socket) for the power supply mounting nuts

14

Metric 8mm nut driver (socket) for Beam Steering Antenna studs mounting to bracket

Confidential - Restricted Use and Duplication Page 10 Issue 01 D1

Page 17

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

5 Site Preparation

To prepare the installation site, perform the following checks prior to installation of an X-1200 Hub

Module (HM) or Remote Backhaul Module (RBM).

Section 5.1, “Operating Sector Frequency Check”, page 11

Section 5.2, “HM and RBM Pre-Installation Checks and Service Provisioning”, page 11

5.1 Operating Sector Frequency Check

The operating frequency must be determined prior to the installation and be based on a cell site

frequency plan. BLiNQ Networks strongly advises that a comprehensive site survey be performed before

installation to determine the optimum antenna orientation and identify any potential source of

interference.

5.2 HM and RBM Pre-Installation Checks and Service

Provisioning

This section requires use of the BLiNQ X-1200 WebUI. The X-1200 WebUI is the configuration tool for

use with X-1200 HMs and RBMs. It is a standard web application that runs directly on the X-1200

equipment through the default port for HTTP (that is, port 80), and is accessible at URL http://<IP of the

node>.

For instructions on how to use the X-1200 WebUI, refer to the X-1200 System User Guide. The default

username and password for access is: admin.

Browser support for X-1200 WebUI:

Mozilla Firefox

Internet Explorer 9 (IE9)

WebKit-based browsers, for example:

Apple Safari

Google Chrome

Operating System (OS) support for X-1200 WebUI:

Windows

Mac OS X

Linux

Note: With the exception of IE9, both web browser and OS support for the X-1200 WebUI always refer

to the most recent versions.

The default configuration settings on the HM and RBM include:

Fixed, non-routable local craft IP address: 169.254.1.1

Management IP address: 192.168.26.2

Operating Frequency (e.g. 3.65 GHz)

Channel bandwidth (20 MHz)

Confidential - Restricted Use and Duplication Page 11 Issue 01 D1

Page 18

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

Uplink/downlink TDD ratio on the Hub

Preamble series index value

RF transmitter disabled on the HM (not transmitting)

Perform the following pre-installation checks and service provisioning on the HM and RBMs:

1. Verify the modules can be powered up and Ethernet connectivity can be established.

2. Verify and record the Media Access Control (MAC) address of each RBM unit (located on the label

on the outside of the unit).

3. Using the X-1200 WebUI for HMs:

a. Verify the configuration settings on the HM and update if necessary.

b. Verify the active software version on the HM and upgrade if necessary.

c. To allow the HM to go into service after installation, provision these HM radio operation

parameters through the ‘Setup > Radio Interface Page’ either before or after installation:

Radio Administrative State (set to ‘Enabled’)

RF Frequency

Max. Transmit Power

Preamble Phase Index (Optional)

Rate Adaption (Optional)

d. (Optional) Provision these HM system parameters as needed through the ‘Setup > System Page’

either before or after installation:

System Identification (including Name, Location, Contact, Description)

Ethernet Port Configuration

Management Interface IP Address

For more information, refer to the X-1200 System User Guide.

4. Using the X-1200 WebUI for RBMs:

a. Verify the configuration settings on each RBM and update if necessary.

b. Verify the active software version on each RBM and upgrade if necessary.

c. To allow the RBM to go into service after installation, provision these RBM radio operation

parameters through the ‘Setup > Radio Interface Page’ either before or after installation:

Radio Administrative State (set to ‘Enabled’)

d. (Optional) Provision these RBM system parameters as needed through the ‘Setup > System Page’

either before or after installation:

System Identification (including Name, Location, Contact, Description)

Ethernet Port Configuration

Management Interface IP Address

For more information, refer to the X-1200 System User Guide.

Confidential - Restricted Use and Duplication Page 12 Issue 01 D1

Page 19

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

WARNING!

Installation of the equipment must comply with local and national

electrical codes.

Personnel mounting the equipment must understand grounding

methods.

!

6 Installing the Modules (General)

As needed, refer to these sections and follow these steps to properly install either the Hub Module (HM)

or Remote Backhaul module (RBM):

Section 6.1, “General Safety Information”, page 13

Section 6.2, “Equipment Distance and Orientation”, page 14

Section 6.3, “Mounting to a Pole or Wall”, page 14

Section 6.3.1, “Attaching Pole Clamps to Mounting Bracket”, page 16

Section 6.3.2, “Mounting with U- or V-Clamps”, page 17

Section 6.3.3, “Mounting with Steel Straps”, page 17

Section 6.3.4, “Mounting onto a Wall”, page 18

Section 6.4, “Assembling the Module Brackets”, page 19

Section 6.4.1, “Attach Elevation Bracket”, page 19

Section 6.4.2, “Attach Azimuth Bracket”, page 21

Section 6.5, “Installing the Power Supply Unit (Optional)”, page 23

Section 6.6, “Installing the Module onto a Mounting Bracket”, page 26

Section 6.7, “Grounding and Overvoltage Protection Instructions”, page 28

Section 6.8, “Connecting to DC Power”, page 31

Section 6.9, “Verifying Basic Installation”, page 33

Section 6.10, “Connecting to the Ethernet Backhaul Network”, page 34

Section 6.11, “Cable Management”, Page 36

6.1 General Safety Information

Before performing any of the tasks in this chapter, read the safety warnings and service notices in

Chapter 1, “Important Safety and Service Notices”.

The system requires one person to properly and safely install the X-1200 system modules.

Confidential - Restricted Use and Duplication Page 13 Issue 01 D1

Page 20

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

6.2 Equipment Distance and Orientation

6.2.1 Hub Modules

Locate the Hub Module (HM) with as much distance as possible from other transmitting equipment.

The installer must mount the Beam Steering Antenna on the HM, as it can not be remotely mounted.

The HM must also have clear view of the sky for its Global Positioning System (GPS) antenna (located on

top of the unit) to work and to synchronize transmissions with other HMs.

When mounting the HM, ensure it is oriented so that the cable connectors/connections point downward

and the GPS antenna points upward.

6.2.2 Remote Backhaul Modules

When installing multiple Remote Backhaul Modules (RBMs), the distance required between the RBMs

depends on the average transmit power in use by the RBMs. Contact your supplier for the

recommended distance between RBMs for your particular installation.

When mounting the RBMs, ensure they are oriented so that the power cable connectors point

downward.

6.3 Mounting to a Pole or Wall

The following sections describe how to attach a mounting bracket to either a pole or wall:

Section 6.3.1, “Attaching Pole Clamps to Mounting Bracket”; recommended for pole diameters

up to 4 in./10 cm.

Section 6.3.2, “Mounting with U- or V-Clamps”; recommended for pole diameters up to

4 in./10 cm

Section 6.3.3, “Mounting with Steel Straps”; recommended for pole diameters up to 3.5 in./9 cm

or larger

Section 6.3.4, “Mounting onto a Wall”

6.3.1 Attaching Pole Clamps to Mounting Bracket

Use the pole clamps with pole/wall mounting brackets for pole diameters up to 4 in./10 cm. If the pole is

larger, see Section 6.3.3, “Mounting with Steel Straps”.

Required parts and tools:

Two pole clamps, pole/wall mount bracket (Figure 4, “Pole/Wall Mount Bracket”)

Socket wrench with 3/8 in. driver head, with long and short ½ in. and 7/16 in. sockets

Torque wrench, 3/8 in. head with range for 4-60Nm or 3-45lbf-ft

Confidential - Restricted Use and Duplication Page 14 Issue 01 D1

Page 21

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

Item

Description

Torque

Note

1

Self-tapping bolts (x2)

27.1Nm or 20lbf-ft

—

Front View

Back View

Self-Tapping

Bolts

Orientation

Cut-out (Up)

Figure 4 Pole/Wall Mount Bracket

Table 5 Recommended Torque Values for Self-Tapping Bolts

To attach the two pole clamps to the pole/wall mount bracket, refer to Figure 5 and follow these steps:

1. Place the pole clamps within the top and bottom of the pole/wall mounting bracket, aligning the

bolt holes of the clamps with those of the bracket.

2. Use the socket wrench to lightly tighten the self-tapping bolts through the clamp holes into the

holes on the back of the bracket (do not over tighten).

3. Use the torque wrench to tighten down the self-tapping bolts and finish the installation of the pole

clamps to the pole/wall mount bracket (do not over tighten). See Table 5 for torque values.

Note: Pole clamps are not required for pole diameters greater than 4 in./10 cm.

Figure 5 Attaching Pole Clamps to Pole/Wall Mount Bracket

Confidential - Restricted Use and Duplication Page 15 Issue 01 D1

Page 22

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

Item

Description

Torque

Note

1

U- or V-Clamp bolts (x4)

16.3Nm or 12lbf-ft

—

6.3.2 Mounting with U- or V-Clamps

Use the U- or V-clamps for pole diameters up to 4 in./10 cm. If the pole is larger, see Section 6.3.3,

“Mounting with Steel Straps”.

Required parts and tools:

Pole/wall mount bracket with attached pole clamps; see Section 6.3.1, “Attaching Pole Clamps to

Mounting Bracket”

Two U- or V-clamps (use one type or the other; do not mix) and associated hardware, both sized

either 1.5 in./4 cm, 2 in./5 cm, 2.5 in./6 cm, 3 in./8 cm, 3.5 in./9 cm, or 4 in./10 cm to match pole

diameter at installation site

Socket wrench with ½ in. socket

Torque wrench, 3/8 in. head with range for 4-60Nm or 3-45lbf-ft

Table 6 Recommended Torque Values for U-Bolt or V-Clamp Bolts

To install the pole/wall mount bracket onto a vertical pole up to 4 in. (10 cm) in diameter using U-clamps

or V-clamps, refer to Figure 6, “Attaching Assembled Pole/Wall Mount Bracket to Pole with U-Clamp or

V-Clamp” and follow these steps:

1. Select a mounting location on the pole and place the pole clamp notches from the assembled

pole/wall mounting bracket against the pole. Ensure the orientation cut-out is pointing up (see

Figure 4, “Pole/Wall Mount Bracket”).

2. Insert one U-bolt or V-bolt through the top of the pole/wall mount bracket. Install the washers and

then hand-tighten the nuts.

3. Insert a second U-bolt or V-bolt through the bottom of the pole/wall mount bracket. Install the

washers and then hand-tighten the nuts.

4. Position the pole/wall mount bracket on the pole as needed before further tightening the bolts.

5. Use the socket wrench to evenly tighten all four bolts of the pole/wall mount bracket to the pole (do

not over tighten).

6. Use the torque wrench to tighten down all four bolts and finish the installation of the pole/wall

mount bracket to the pole (do not over tighten). See Table 6, “Recommended Torque Values for UBolt or V-Clamp Bolts” for torque values for more information.

7. Install the HM or RBM onto the mounted pole/wall mount bracket. See Chapter 7, “Installing the

Hub Module” or Chapter 8, “Installing the Remote Backhaul Module” as applicable.

Confidential - Restricted Use and Duplication Page 16 Issue 01 D1

Page 23

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

Top View

Figure 6 Attaching Assembled Pole/Wall Mount Bracket to Pole with U-Clamp or V-Clamp

6.3.3 Mounting with Steel Straps

Use steel straps to mount the modules onto poles with diameters 3.5in./9 cm or larger. If the pole has a

smaller diameter, see previous mounting methods.

Required parts and tools:

Pole/wall mount bracket with attached pole clamps; see Section 6.3.1, “Attaching Pole Clamps to

Mounting Bracket”

Note: When using straps on poles greater than 4 in./10 cm in diameter, pole clamps are not

required for the pole/wall mounting bracket.

Customer-provided steel straps and associated hardware

Slot head screwdriver or Phillips #2 screwdriver

To install the pole/wall mount bracket onto a vertical pole that is 3.5 in./9 cm in diameter or larger using

metal straps, refer to Figure 7, “Attaching Assemble Pole/Wall Mount Bracket to Pole with Straps” and

follow these steps:

1. Assemble the two steel straps and the assembled pole/wall mounting bracket together by threading

the straps through the top and bottom strap slots of the bracket, respectively.

2. Select a mounting location on the pole and place the steel straps with the assembled pole/wall

mounting bracket around the pole. Ensure the orientation cut-out is pointing up (see Figure 4,

“Pole/Wall Mount Bracket”).

3. Position the pole/wall mounting bracket on the pole as needed and tighten the straps around the

pole with a slot head or Philips #2 screwdriver, as applicable. Ensure the steel straps are as tight as

possible.

Note: Once the steel straps are tightened to full tension, the pole/wall mounting bracket cannot be

adjusted unless the straps are disassembled or cut.

4. Install the HM or RBM onto the mounted pole/wall mount bracket. See Chapter 7, “Installing the

Hub Module” or Chapter 8, “Installing the Remote Backhaul Module”, as applicable.

Confidential - Restricted Use and Duplication Page 17 Issue 01 D1

Page 24

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

Top View

Figure 7 Attaching Assemble Pole/Wall Mount Bracket to Pole with Straps

6.3.4 Mounting onto a Wall

The pole/wall mounting bracket has four wall-mounting holes that you use to mount the HM or RBM

directly onto a wall.

Required parts and tools:

Pole/wall mount bracket with attached pole clamps; see Section 6.3.1, “Attaching Pole Clamps to

Mounting Bracket”

Four customer-provided 5/16-in. or M8 wall mounting bolts or equivalent

If the wall material requires it, customer-provided bolt reinforcement hardware (for example,

four wall shoe anchor bolts)

Socket wrench with 3/8 in. driver head, with long and short ½ in. and 7/16 in. sockets

Torque wrench, 3/8 in. head with range for 4-60Nm or 3-45lbf-ft

Black marker

To install the pole/wall mount bracket onto a wall, refer to Figure 8, “Attaching Assembled Pole/Wall

Mount Bracket to Wall” and follow these steps:

1. Identify an area on the wall that meets the safety, space, and environmental requirements for the

HM or RBM.

2. Place the pole/wall mounting bracket onto the location on the wall. Mark the locations of the four

wall-mounting holes using a black marker.

3. If required, install the bolt reinforcement hardware onto the wall at the four mounting hole

locations.

Note: The installer should mount the bolt reinforcement hardware to the wall with the correct

distance apart so that when the bolts are installed through the mounting bracket wall mount holes

they align with the holes in the wall.

4. Install and hand-tighten the four mounting bolts through the pole/wall mounting bracket and into

the wall. Ensure the orientation cut-out is pointing up (see Figure 4, “Pole/Wall Mount Bracket”).

5. Use the socket wrench to evenly tighten all four bolts of the pole/wall mount bracket to the wall.

Confidential - Restricted Use and Duplication Page 18 Issue 01 D1

Page 25

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

Clamping brackets are

during bolting.

4X Wall Mounting

within slots

Orientation Cut-out

6. Use the torque wrench to tighten down all four bolts to finish the installation of the pole/wall

mount bracket to the wall. Base the torque on the third-party hardware bolt specifications and wall

material (do not over tighten).

7. Install the HM or RBM onto the mounted pole/wall mount bracket. See Chapter 7, “Installing the

Hub Module” or Chapter 8, “Installing the Remote Backhaul Module” as applicable.

left in place to prevent

the Pole Mount

bracket from crushing

Bolts anywhere

Figure 8 Attaching Assembled Pole/Wall Mount Bracket to Wall

6.4 Assembling the Module Brackets

Assemble the HM or RBM brackets BEFORE installing the HM or RBM onto an installed pole/wall mount

bracket. The mounting brackets offer three degrees of adjustment: elevation up-tilt up to 30 degrees,

azimuth up to +/- 25 degrees and theta of up to +/-10%.

6.4.1 Attach Elevation Bracket

Required parts and tools:

Elevation bracket and associated hardware from X-1200 Module Installation Kit (Figure 9,

“Elevation Bracket and Associated Hardware”)

Socket wrench with 3/8 in. driver head, with long and short ½ in. and 7/16 in. sockets

Torque wrench, 3/8 in. head with range for 4-60Nm or 3-45lbf-ft

Confidential - Restricted Use and Duplication Page 19 Issue 01 D1

Page 26

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

Item

Description

Torque

Note

1

Elevation bracket bolts (x4)

10.8Nm or 8lbf-ft

Mount the elevation bracket in the top

center on the HM or RBM.

Elevation Bracket Bolts

and Washers

Orientation Cut-out (Up)

Elevation Bracket

Central slot where you have a

0-30 degree up-tilt adjustment

Orientation Cut-out

Figure 9 Elevation Bracket and Associated Hardware

Figure 10 Elevation Bracket Mounting Position

Table 7 Recommended Torque Values for Elevation Bracket Bolts

The Elevation bracket allows for an adjustment range of 0-30 degrees up-tilt only. You achieve this by

moving the module assembly within two central slots on the bracket and releasing/tightening four side

bolts (two at the top and two within the central slots).

Confidential - Restricted Use and Duplication Page 20 Issue 01 D1

Page 27

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

6 Mounting Holes

(total)

Use top 4 mounting

holes to attach

elevation bracket

Azimuth Bracket

Bolts and Washers

Orientation

Cut-out (Up)

To attach the elevation bracket onto the HM or RBM, refer to Figure 11, “Attaching Elevation Bracket to

Back of Module” and follow these steps:

1. Place the elevation bracket on the back of the unit, in the top center position, with the orientation

cut-out (triangle) pointing up. Align the four bolt holes so that they are centered with the holes on

the back of the module enclosure.

2. Place a lock washer and then a washer on the back of each of the four bolts.

3. Use the socket wrench to lightly tighten all four bolts of the elevation bracket to the unit (do not

over tighten).

4. Use the torque wrench to evenly tighten down all four bolts and finish the installation of the

elevation bracket to the module (do not over tighten). Follow the Torque setting from Table 7,

“Recommended Torque Values for Elevation Bracket Bolts”.

Figure 11 Attaching Elevation Bracket to Back of Module

6.4.2 Attach Azimuth Bracket

Required parts and tools:

Azimuth bracket and associated hardware from X-1200 Module Installation Kit (See Figure 12,

“Azimuth Bracket and Associated Hardware”)

Socket wrench with 3/8 in. driver head, with long and short ½ in. and 7/16 in. sockets

Torque wrench, 3/8 in. head with range for 4-60Nm or 3-45lbf-ft

Figure 12 Azimuth Bracket and Associated Hardware

Confidential - Restricted Use and Duplication Page 21 Issue 01 D1

Page 28

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

Item

Description

Torque

Note

1

Azimuth bracket bolts (x4)

16.3Nm or 12lbf-ft

—

4 bolts attach azimuth

bracket and at final

installation, adjust the

module

Table 8 Recommended Torque Values for Azimuth Bracket Bolts

The Azimuth bracket allows for an adjustment range of +/- 15 degrees from the pole axis. The module is

pivoting on a set of two vertical bolts and locked in place by another two.

To attach the azimuth bracket onto the HM or RBM, refer to Figure 13, “Attaching Azimuth Bracket to

Elevation Bracket on Module” and follow these steps:

1. Place the azimuth bracket within the installed elevation bracket, aligning the two bolt holes on

either side with the bolt holes on the sides of the elevation bracket. Ensure that the azimuth bracket

orientation cut-out is pointing up.

2. First, place a lock washer and then a flat washer on to each of the four bolts.

3. Thread, by hand, the four bolts through the bolt holes on both sides of the elevation bracket into

the bolt holes of the azimuth bracket. Make sure the azimuth bracket sits flat within the elevation

bracket while doing this step.

4. Use the socket wrench to lightly tighten all four bolts (do not over tighten).

NOTE: During the final installation stages, you loosen these bolts to adjust the elevation of the

module. See Section 8.1, “Using the BSI Feature and Adjusting the Module” for the steps on

adjusting the module.

5. As a final step in the module installation (after all adjustments to module on the pole), use the

torque wrench to tighten down all four bolts and finish the installation of the azimuth bracket to the

unit (do not over tighten). See Table 8, “Recommended Torque Values for Azimuth Bracket Bolts”

for torque values.

Confidential - Restricted Use and Duplication Page 22 Issue 01 D1

Figure 13 Attaching Azimuth Bracket to Elevation Bracket on Module

Page 29

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

Item

Description

Torque

Note

1

Power supply bracket bolts (x2)

10.8Nm or 8lbf-ft

Mount the bracket in the lower two (2)

mounting holes on the HM or RBM.

Mounting Holes (x2)

Dedicated Cable Tie-down

Management Slots (x4)

Mounting Posts (x4)

6.5 Installing the Power Supply Unit (Optional)

The installation of the power supply unit (PSU) and the PSU bracket are optional. You only need to install

the PSU and PSU bracket, if you do NOT have a direct -48 Vdc power supply. The PSU allows you to

convert from another power source (i.e., North America: 120 Volts, European: 220 Volts) to -48 Vdc.

If desired, you can install the PSU onto the PSU bracket before installing the complete PSU assembly

onto the module. If you choose this method: always ensure that the AC cable is accessible from the top

of the PSU and the DC output cable is at the bottom.

6.5.1 Installing the PSU Bracket

To install the PSU, the PSU bracket needs to be installed onto the module.

Note: The PSU bracket is symmetrical, and there is no specific mounting orientation.

Figure 14 PSU Mounting Bracket

Required parts and tools:

Power Supply Unit (PSU) bracket and associated hardware from X-1200 Power Supply Unit (PSU)

Installation Kit

Socket wrench with 3/8 in. driver head, with long and short ½ in. and 7/16 in. sockets

Torque wrench, 3/8 in. head with range for 4-60Nm or 3-45lbf-ft

Cable ties, as needed

Table 9 Recommended Torque Values for PSU Bracket Bolts

To attach the power supply bracket onto the HM or RBM, refer to Figure 15, “Attaching PSU Bracket to

Back of Module” and follow these steps:

1. Place the power supply bracket on the back of the unit, in the lower center position. Align the two

bolt holes so that they are centered with the holes on the back of the module enclosure.

2. Place a lock washer on each of the two bolts.

3. Thread, by hand, each of the bolts into the mounting holes. Ensure that the PSU mounting bracket

holes and the holes on the module are aligned.

4. Use the socket wrench to lightly tighten the two bolts of the power supply bracket to the unit (do

not over tighten).

Confidential - Restricted Use and Duplication Page 23 Issue 01 D1

Page 30

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

6 Mounting Holes

(total)

Use 2 mounting

holes to attach

PSU bracket

5. Use the torque wrench to evenly tighten down the two bolts and finish the installation of the power

supply bracket to the module (do not over tighten). Follow the Torque setting from Table 9,

“Recommended Torque Values for PSU Bracket Bolts”.

Figure 15 Attaching PSU Bracket to Back of Module

6.5.2 Installing the Power Supply Unit

If you do not have a direct -48 Vdc power supply, you must install the -48 Vdc power supply unit (PSU).

The PSU allows you to convert from another power source (i.e., North America: 120 Volts) to -48 Vdc. To

install the PSU bracket onto the module, see Section 6.5.1, “Installing the PSU Bracket”.

Figure 16 Power Supply Unit (PSU)

Required parts and tools:

Installed Power Supply Unit (PSU) bracket on module

Confidential - Restricted Use and Duplication Page 24 Issue 01 D1

Socket wrench ¼ in. driver head with long and short ½ in. and 7/16 in. sockets

Torque wrench, ¼ in. head with range for 4-60Nm or 3-45lbf-ft

Cable ties, as needed

If needed, outdoor weatherproof AC cabling and connectors, as required for your installation (for

instance: shielded 18 AWG 2 conductors 90°C water resistant, black and white conductor jackets,

outdoor rated cable, 5-8 mm thick with weatherized DC connector to fit on power cable)

Page 31

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

Item

Description

Torque

Note

1

Power supply nuts (M4x4)

2.7Nm or 2lbf-ft

Mount the PSU to the four (4) mounting

holes on the PSU bracket.

WARNING!

Always ensure that the power is OFF before installing this device.

Installation of the equipment must comply with local and national

electrical codes.

4 Mounting Studs

!

Table 10 Recommended Torque Values for PSU Bolts

Figure 17 PSU Bracket PSU Mounting Studs

To install the power supply unit:

1. Place the PSU on top of the four (4) raised studs on the PSU bracket. Position the PSU so that the AC

cable access is at the top and the DC output cable access is at the bottom.

2. Place a lock washer on each of the PSU studs, then position and tighten the PSU nuts to the

specified torque. Follow the Torque setting from Table 9, “Recommended Torque Values for PSU

Bracket Bolts”.

3. Route the AC cable to allow for adjustments when the unit swings up to fine-tune the alignment

angle, ensure that the cable provides sufficient movement so that the cable is not tight. Connect the

AC cable from the AC power source to the PSU AC cable using the desired connectors/method for

your installation.

On PSU:

Connect ACL (Brown) to AC Line (i.e., in USA - Black)

Connect ACN (Blue) to AC Neutral (i.e., in USA - White)

Connect Ground (Green/Yellow) to AC Ground

Confidential - Restricted Use and Duplication Page 25 Issue 01 D1

Page 32

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

DC Power Port

PSU DC Power Connector

On PSU, Dedicated Cable

Tie-down Management

Slots (x4)

Locknut

Washer

4. Using the DC connector on the end of the PSU DC power cable, connect the -48 Vdc power supply

cable to the X-1200 module DC power port. Provide a small loop in the DC power cable at the

bottom of the X-1200 to allow for movement.

Figure 18 Power Connection via the PSU

5. With cable ties, use the dedicated cable tie slots on the side of the PSU mounting bracket to neatly

collect and contain (dress) the cables from the PSU. If needed, see section 6.11, “Cable

Management” for more information.

Figure 19 Module with PSU Installed.

6.6 Installing the Module onto a Mounting Bracket

Prerequisites:

Attached elevation and azimuth brackets on back of HM or RBM

Mounted pole/wall mounting bracket

Required parts and tools:

Pole/wall mount bracket locknut hardware from X-1200 Module Installation Kit (See Figure 20,

“Pole/Wall Mount Bracket Locknut Hardware”)

Socket wrench with 3/8 in. driver head, with long and short ½ in. and 7/16 in. sockets

Torque wrench, 3/8 in. head with range for 4-60Nm or 3-45lbf-ft

Figure 20 Pole/Wall Mount Bracket Locknut Hardware

Confidential - Restricted Use and Duplication Page 26 Issue 01 D1

Page 33

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

Item

Description

Torque

Note

1

Pole/wall mount bracket locknuts (x3)

16.3Nm or 12lbf-ft

—

Optional

Power

Supply

Washer and

Lock Nut

Washer and

Lock Nut

Table 11 Recommended Torque Values for Pole/Wall Mount Bracket Locknuts

To install the HM or RBM onto the mounted pole/wall mount bracket, refer to Figure 21, “Unit Installed

onto the Pole/Wall Mount Bracket” and follow these steps:

Note: When installing the HM or RBM, orient it with the chassis cabling openings pointing downward.

Never mount the HM or RBM with the bottom facing up or to the side.

1. Carefully fit the azimuth bracket into the pole/wall mount bracket.

2. Place a washer on each bolt protruding through the top of the azimuth bracket from the pole/wall

mount bracket. Thread a locknut, by hand, onto the two bolts.

3. Place a washer and then thread a locknut, by hand, onto the one bolt protruding through the

bottom of the pole/wall mount bracket from the azimuth bracket.

4. Use the socket wrench to evenly tighten all three locknuts (do not over tighten).

NOTE: During final installation, you loosen these bolts to adjust the azimuth of the module. See

Section, 8.1 “Using the BSI Feature and Adjusting the Module” for steps on adjusting the module.

5. As a final step in module installation, use the torque wrench to evenly tighten down all three

locknuts to finish the installation of the HM or RBM to the pole or wall (do not over tighten). See

Table 11, “Recommended Torque Values for Pole/Wall Mount Bracket Locknuts” for torque values.

Figure 21 Unit Installed onto the Pole/Wall Mount Bracket

Confidential - Restricted Use and Duplication Page 27 Issue 01 D1

Page 34

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

WARNING!

The X-1200 system modules MUST be externally grounded using a

customer-supplied ground cable before power is applied. Contact

the appropriate electrical inspection authority or a qualified

electrician if you are uncertain whether suitable grounding (or

shielding from electrical surge) is available.

Lightning/surge arresters may only be connected and installed by a

qualified electrician (If used)

Always ensure that the power is OFF before performing any

grounding or overvoltage protection tasks.

All country-specific safety regulations, rules, and laws must be

observed to provide a properly grounded and overvoltage

protected equipment site.

!

6.7 Grounding and Overvoltage Protection Instructions

Ensure that you externally ground the X-1200 system modules. Two (2) grounding screws with a twohole lug are provided on the side of the module enclosure for this purpose. Connect the ground lug to

the main ground to safeguard against possible lightning strikes.

Further, to ensure the survivability of the indoor or outdoor connecting equipment from a lightning

strike, BLiNQ Networks recommends either installing the lightning/surge arrester that is sold separately

by BLiNQ Networks, or another suitable third-party arrester unit. This helps to provide an equipment

site that is properly grounded and protected from electrical surges.

In all X-1200 equipment installations, after the equipment is mounted, you must provide a properly

grounded and shielded environment for the installation site before connecting power or network cables.

If used, install the lightning/surge arrester in series with the Ethernet and power cables.

6.7.1 Installing the Grounding Cable

Required parts and tools:

6-gauge grounding cable

Phillips #2 screwdriver

Two (2) PH SEMS screws – ¼-20 x 3/8 in.

Crimp tool

Wire stripper

Confidential - Restricted Use and Duplication Page 28 Issue 01 D1

Page 35

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

Grounding Lug

Figure 22 Module with Grounding Lug

To ground the unit, follow these general steps:

1. If needed, strip and attach (crimp) the two-hole ground lug of the unit to the grounding cable.

2. Use the Phillips #2 screwdriver to connect the two-hole grounding lug to the unit’s grounding screws

shown in Figure 22, “Module with Grounding Lug” (do not over tighten).

3. Ensure the other end of the ground wire is connected to a reliable earth ground, such as a grounding

rod or an appropriate grounding point on a pole that is grounded.

4. Ensure there is enough slack in the ground cable to allow for unit adjustments later on the

pole/wall. Or preferably, wait until adjustments to the module are complete and then attach

grounding lug to the unit as a final step in the module installation.

6.7.2 Installing the Lightning/Surge Arrestor

To install a lightning/surge arrester (sold separately by BLiNQ Networks), follow these general steps:

1. Mount the arrester close to the entry of the building if the signals are entering a building. Mount the

unit with the strain reliefs facing the ground, as shown in Figure 23, “Wiring of Lightning/Surge

Arrester (Sold by BLiNQ Networks)”.

2. Remove the cover screws using a medium slot head screwdriver and lift off the cover.

3. Thread the incoming Ethernet cable from the data source through one of the strain reliefs on the

bottom of the unit. Strip back the cable jacket as needed using wire strippers. Run the Ethernet

cable through the copper ground lug on the inside of the Arrester and clamp the Ethernet cable,

ensuring there is a good electrical connection of the Ethernet cable shield to the lug.

4. Gently pull the terminal blocks off of the Ethernet pin strip terminals (where present—two are

typically provided).

5. Install the Ethernet conductor wires into the top Ethernet pin strip terminals (the bottom terminals

are not used), in this order:

Blue

Blue/White

Orange

Orange/White

Confidential - Restricted Use and Duplication Page 29 Issue 01 D1

Page 36

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

Green

Green/White

Brown

Brown/White

6. Secure and seat the conductors to the pin strip terminals by gently but firmly pressing them into

place with the terminal blocks removed in step 4. Gently pull the terminal blocks off again when

done.

7. Once all the conductors are seated to the pin strip terminals, gently press the terminal blocks into

the pin strip terminals of your choice for storage.

8. Repeat steps 3 through 7 through the other strain relief for the outgoing Ethernet cable running to

the X-1200 equipment.

Note: Ensure the left-side and right-side Ethernet conductor wire colors match.

9. Thread the incoming DC power cable from the power source through one of the strain reliefs on the

bottom of the unit.

10. Using wire strippers, strip back the DC cable jacket about 1 in./25.4 mm to expose the two wires,

then strip the insulation about 3/8 in./9.5 mm from each wire.

11. Insert the Ground Return (RTN) wire into DC+ of the four-position power terminal strip (the top

position), and the -48 Vdc wire into DC- of the power terminal strip (the bottom position), and

tighten each wire down to the terminal using a small slot head screwdriver.

12. Repeat steps 9 through 11 through the other strain relief for the outgoing DC power cable running

to the X-1200 equipment.

13. Confirm the left-side and right-side Ethernet conductor wire colors match between the left and right

Ethernet pin strip terminals.

14. Confirm the DC power cable polarity is correct: RTN goes to DC+; -48 Vdc goes to DC-

15. Tighten the strain reliefs onto the cables (do not over tighten).

16. Reinstall the cover.

17. Connect the external ground lug on the unit to a solid Earth ground. The unit must be grounded for

the arrester to work properly.

Confidential - Restricted Use and Duplication Page 30 Issue 01 D1

Page 37

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

Ground Lug

Blocks

Reliefs

Terminals

Ethernet

Pin Strip

Terminal

Four-Position Power

Terminal Strips

External

Cable Strain

Figure 23 Wiring of Lightning/Surge Arrester (Sold by BLiNQ Networks)

6.8 Connecting to DC Power

Before proceeding, if you do not have a direct -48 Vdc power supply, you must install the module power

supply unit (PSU). The PSU allows you to convert from another power source (i.e., North America: 120V)

to -48 Vdc. See Section 6.5, “Installing the Power Supply Unit (Optional)” for more information.

BLiNQ Networks provides a 10 m (32.9 ft), 20 m (65.7 ft), or 40 m (131.2 ft) DC power cable (as

applicable for the installation site) with both the HM and RBM. One end of the cable comes equipped

with a DC power connector, while the other end comes terminated with no stripping of either the

external sheathing or any of the internal wires. When connecting the HM or RBM to DC power:

Ensure the input is -48 Vdc and powered from an approved AC/DC power supply or from a DC

source separated from AC mains by double or reinforced insulation.

Ensure that the power can be conveniently removed, if necessary, by disconnecting the DC

power connector plug from the back of the unit. This plug should be accessible for servicing the

unit.

The HM or RBM is protected against an inadvertent reverse polarity connection. Ensure that the DC

power supply is not under-rated and that it is capable of meeting the power requirement of Table 1,

“X-1200 System Specifications” under various temperature and solar loading conditions.

Note: You may have to cut the cable to the specific cable length needed for your installation.

Confidential - Restricted Use and Duplication Page 31 Issue 01 D1

Page 38

BLiNQ Networks Inc. X-1200 System Installation Guide Release 1.0

WARNING!

The X-1200 equipment must be externally grounded using a

customer-supplied ground wire before power is applied. Contact

the appropriate electrical inspection authority or an electrician if

you are uncertain whether suitable grounding is available.

Always ensure that the power is OFF before connecting or

disconnecting power to the unit.

!

To connect the HM or RBM to a DC power source, follow these steps:

1. Verify that the equipment is properly grounded as described in the Section 6.7, “Grounding and

Overvoltage Protection Instructions”.

2. Turn off power to the DC power source at the designated circuits.

3. Align the DC power cable connector with the two-prong key inside of the DC power connector

receptacle on the module, then push the cable connector into the connector receptacle and hand

tighten the connector screw until fully seated.