Blickman Equipment Corporation AT8003 Service Manual

AT SERIES MANUAL

INSTRUCTIONS

INSTALLATION

OPERATION

MAINTENANCE

REPAIR

BLICKMAN SUPPLY CO. 280

MIDLAND AVE BLDG M1

SADDLE BROOK NJ 07663

INSTALLATION

SETTING UP THE URN - Place the urn carefully in position on urn stand or counter. Faucets should be located over a drip trough or similar

receptacle. Then connect water supply, electric and gas or steam, in accordance with the following suggestions:

WARNING: Gas Urn - Do not install gas urn near a wall without proper insulation (asbestos or other) behind urn. We do install an insulated baffle

for your protection.

WATER CONNECTIONS - Connect urn water inlet connection with matching size water supply pipe. Valve inlet is 3/8" i.p.s. pipe. Somewhere in the

water supply line before the urn, there should be a union and shut-off valve for easy connection or later change. MAKE CERTAIN STRAINER

(PACKED LOOSE WITH URN) IS CONNECTED TO COLD WATER LINE. If local plumbing code requires a check valve and vacuum breaker

before urn inlet, be sure plumber has this part installed. A reducing valve should be provided if water pressure is over 45 P.S.I..

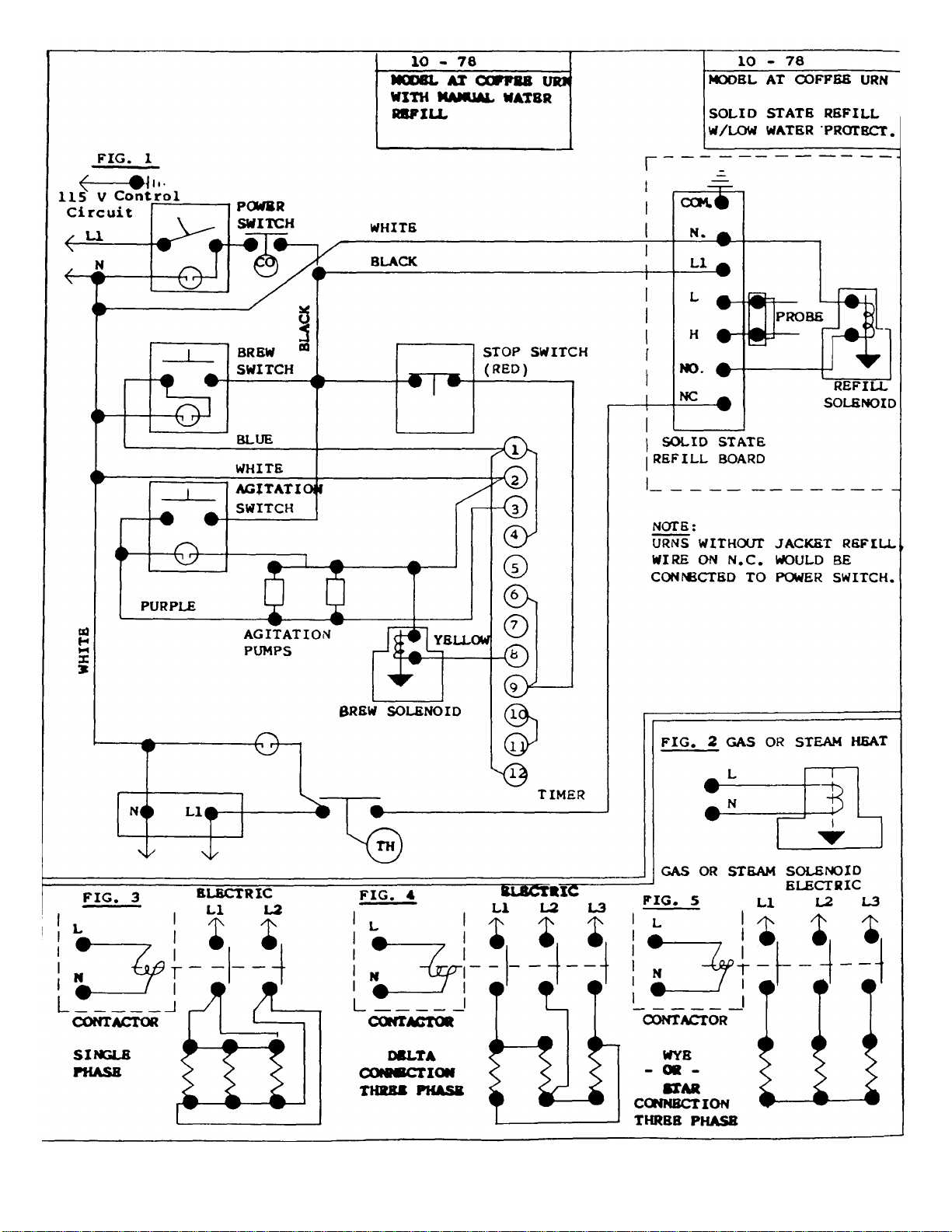

ELECTRIC CONNECTIONS - Be sure that your current characteristics (voltage, etc.) agree with data specified on metal plate attached to urn. An

experienced electrician should make the installation and he should check that the proper size power cable leads to your urn and that the circuit is

fused adequately. (Do not apply power to a dry urn.) A separate 115V electrical connection is required for the control circuit.

Gas Connections - Connect 1/2" gas supply to inlet side of safety pilot. Burner is rated for 44,000 BTU. (Do not apply heat to a dry urn). A separate

115V electrical connection is required for the control circuit.

STEAM CONNECTIONS - On steam heated urns, it is also recommended that a valve be placed in the steam line before the steam line is

connected to the urn. Steam pressure at urn location (not at your steam boiler) should match the pressure for which the urn was built, as indicated

on tag attached to the urn. Excessive pressure can be reduced by installing a reducing valve. Too Iowa pressure may result in insufficient heating

and improper functioning of the thermostat. Steam lines must be blown out before installation to eliminate any accumulation of chips, dirt or white

lead that may clog solenoid. MAKE CERTAIN "Y" STRAINER (PACKED LOOSE WITH URN) IS CONNECTED TO INCOMING STEAM SUPPLY. A

separate 115V electrical connection is required for the control Circuit. Steam pressure of 15-50 P.S.I, should be provided.

ADJUSTMENT OF THERMOSTATS - Normally the thermostats should not have to be adjusted after installation. However, if any adjustment is

required, see page 19.

3 AT

some basic rules to follow:

GENERAL CAUTIONS - Before any heat is allowed

As with any piece of equipment of this type to enter the urn, it is most important that the unit be

filled with water. Open the water inlet valve located

at the lower right-hand corner and allow the water

jacket to fill to a minimum of 3/4 as shown on th e

center gauge glass, preferably filling to 2" from top

of gauge glass.

The urn should never be operated without water as

this may result in damage to the heating elements

improper operation may be hazardous. Here are

Make certain unit is connected to proper voltage,

water and ste am pressure, and gas.

Do not open control panel while power is on. Any

electrical repairs should be made by a licensed

electrician.

Remember, you are working with water at over

and/or the thermostat control.

200°F. Before spraying water, make certain

spray arm is properly seated in nozzle.

START-UP

PREPARATION OF URN - Be sure that all packing material is brushed from inside. Remove tape covering at bottom of urn liner. Wash

out urn thoroughly.

CHECKING FLOW RATE - It is advisable to check the flow rate through your timing mechanism by using the following procedure:

Remove the cover from one of the liners and place the spray arm assembly directly over the liner. Set your timer for approximately 4

minutes and push the START button.

When the START button is depressed, the red light in the timer will glow, indicating that the urn is in a brewing cycle. THE VERY FIRST

TIME THAT YOU PRESS THIS BUTTON YOU WILL NOT GET ANY WATER OUT OF THE SPRAY ASSEMBLY UNTIL THE HEAT

EXCHANGE COIL INSIDE YOUR URN HAS FILLED TO A POINT WHERE IT WILL COME OUT OF THE SPRAYER. When water

starts to come out of the sprayer, push the STOP button, drain off any water that has accumulated in the liner and start the cycle over

again (the reason for doing this is to give you a full measure of water from the time your brewing cycle starts. IT IS NOT NECESSARY

TO DO THIS EVERY TIME - ONLY THE VERY FIRST TIME YOU SET UP THE URN.)

Your Touch 'n Brew coffee urn is equipped with an automatic flow control valve which allows fresh incoming water to pass through a

heat exchange coil/built into the urn, at the rate of 3/4 gallon per minute. Since you have set your time for 4 minutes - at the end of a 4

minute cycle you should have approximately 3 gallons of water in the liner. It is important that you measure this first cycle to determine

any change in time that may be required.

TIMER SETTING - The following chart will give you approximate flow rates for your urn. If any compensation time is

necessary, this should be figured into brewing cycles.

GALLONS 1-1/2 3 4-1/2 6 7-1/2 9 10

MINUTES 2 4 6 8 10 12 13-1/2

FLAVORING-IN - When putting a new urn into operation, the breaking-in process (generally known as "seasoning" or "burning-in") is

accomplished by making the first batch of coffee very strong and allowing it to remain in the urn at least three to four hours. If possible,

keep this first batch of coffee in over night - under low heat. Dispose of this first batch. Then clean out urn before making coffee for

serving.

4 AT

BETWEEN BREWS - A quick rinse between brews is desirable. 1. Start daily with well cleaned coffee urn.

3.

Push POWER SWITCH.

OPERATION

CLEANING

er all brewed coffee has been drawn from the urn spray over

2.

Drain the water off, again spray over

2

gallons of fresh hot

water, brush it out and drain again. Wipe down liner with clean

D. Set filter into liner

- put cover on

- and posi

tion spray arm

If urn is not going to be used again immediately, put a gallon or

When thermostat is in Brewing range the urn is ready to brew

6.

Push START button. Urn will spray over the proper amount

of

7.

Allow

10

minutes for fresh coffee to ripen. Coffee is now

urn before each preparation. (See Step 4B above.) Don't leave

5.

Drain urn cleaning solution off and rinse

3

or

4

times with fresh

7.

Leave a gallon or so of fresh water in urn until just before

2. Keep water in jacket at a height of 2" from the top of the

water gauge glass. Fill by opening water inlet valve.

IMPORTANT: Do not fill above this mark.

4. Set thermostat to #10 position.

A. Check timer setting . . . 3/4 gallon of water for every minute. DAILY - Daily cleaning after the last batch of coffee is used

B. Rinse liner by putting spray arm over empty liner - push

START button - after 30 seconds push STOP button - and

drain liner.

C. Fill filter* with proper amount of fresh coffee. Be exact . . .

don't guess. The quantity of ground coffee depends on the

desired strength-from 2 to 3 gallons per pound. Increased

amounts are required for iced coffee or demi-tasse.

nozzle through hole in cover.

5.

coffee.

1. Rinse liner by spraying water over empty liner for about 30

seconds.

2. Drain the water off. The urn is ready for the next brew.

should be regular routine.

1. Aft

two gallons of fresh hot water and thoroughly brush it out with

long handled brush.

towel.

3.

so of fresh water in the liner. Do not drain this water off until

just before making next coffee brew.

TWICE A WEEK - Coffee urns must have a special scouring

twice a week. To scour the urn thoroughly:

water and cut off. The urn is provided with an automatic

agitation system which operates for the last 30 seconds of

the brewing cycle. This eliminates the necessity for

repouring. (The MANUAL AGITATION button is for use

between brews and operates only while button is

ready to serve. 3. Scrub inside of liner and inside of cover with long handled

NOTE: Never serve coffee that has been held over 1-1/2

hours. Don't make fresh coffee on top of old. Always wash out

coffee in urns overnight. Wash out thoroughly before closing.

Leave a gallon or so of fresh water in liner.

THE BLICKMAN FILTERING SYSTEMS - SEE PAGE 10.

1. Be sure water jacket is 3/4 full of water and turn on heat.

2. Fill liner with several gallons of water and add at least 1-1/2

ozs. of coffee urn cleaning compound. Allow this solution to

remain in the liner approximately 30 minutes, during which

time heat should be on full.

brush.

4. Use long thin brush to clean coffee gauge glass. Use same

brush to clean fitting at bottom of liner and pipe connecting to

coffee faucet.

hot water, repeating steps 3 and 4 again. Drain rinse water.

6. Occasionally take faucet valves apart and clean thoroughly. *FOR COMPLETE DETAILS ON USE AND CLEANING OF

brewing next batch of coffee.

5AT

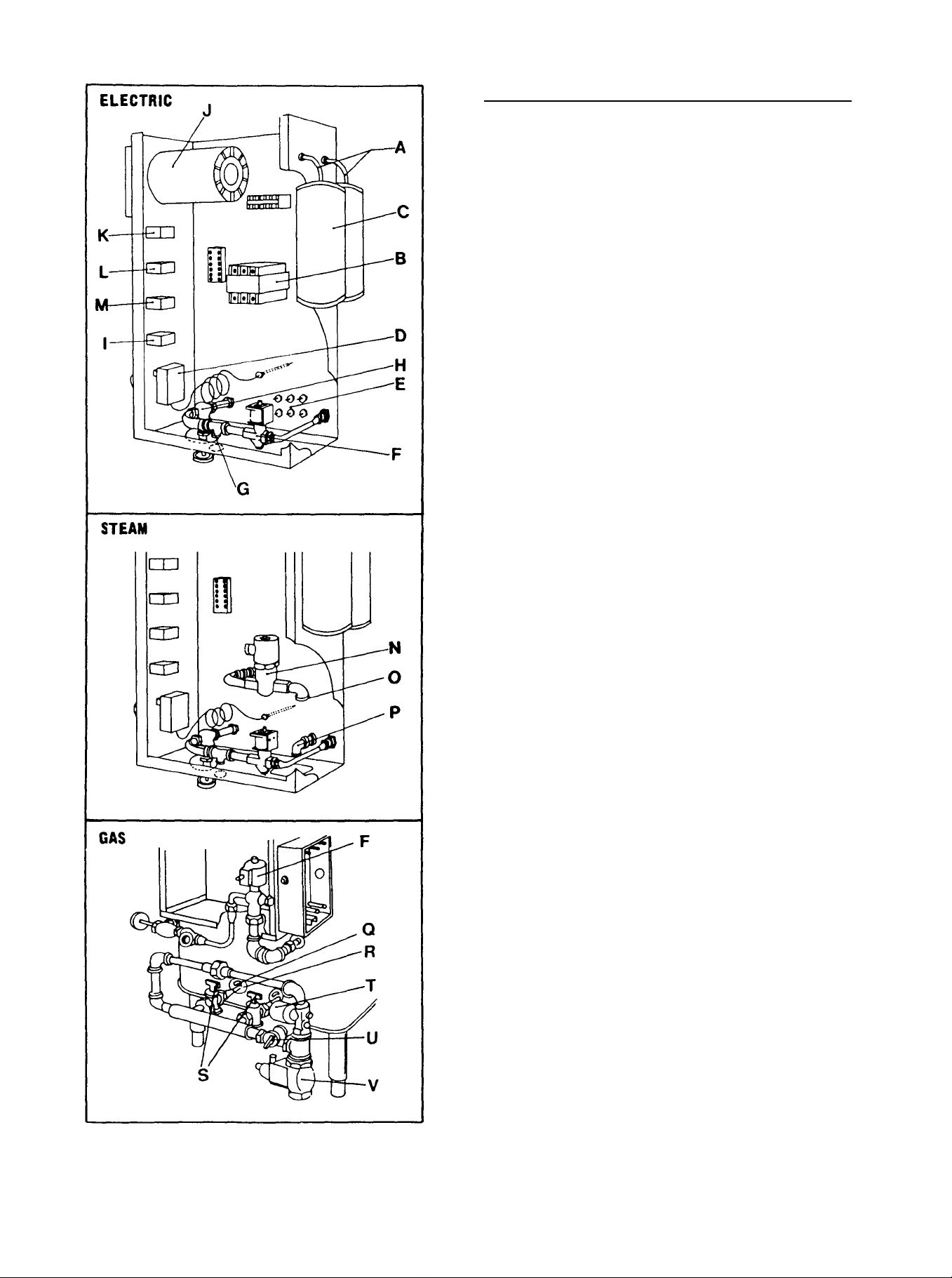

CONTROL BOX ASSEMBLY

U.

A.

Agitator Pump Hose

B. Contactor

C.

Agitator Pumps

D. Thermostat (How to Adjust Thermostat" See Page 19)

E.

Electric Heating Elements

F. Combination Solenoid - Flow Control

G

Water Inlet

H.

Water Inlet Valve

|.

Power Switch

J.

Timer

K.

START Button

L.

Manual Agitation Button

M

STOP Button

N.

Steam Solenoid Valve

0.

3/8" Steam Inlet

P.

3/8" Steam Return

Q

Adjustable Air Mixer Plate

R. Adjustable Gas Orifice

S.

Gas Cocks (Normally Open)

T. Gas Solenoid

Manual By -Pass Gas Cock

(Normally Closed)

V.

Safety Pilot

6AT

7 AT

Loading...

Loading...