Page 1

Installation

manual

ER2

3K

Line voltage:

1 ~ 200 -

240 V

-

Output

: 3~ 0 -

240 V Power

: 0,18-

2,2 kW

Line voltage

3 ~ 380 -

500 V

-

Output:

3~ 0 -

500 V

Power:

0,37- 15,0 kW

Programming manual ER23K

COMPACT-LINE

Inverter

Line voltage: 1(3)~ 200 - 240 V - Output: 3~ 0 - 240 V Power: 0,18- 15,0 kW

Line voltage 3 ~ 525 - 600 V - Output: 3~ 0 - 600 V Power: 0,75- 15,0 kW

EN 61800-3

02/2010

Page 2

Page 3

Contents

Important information __________________________________________________________________________________________ 4

Before you begin______________________________________________________________________________________________ 5

Documentation structure________________________________________________________________________________________ 7

Steps for setting up the drive ____________________________________________________________________________________ 8

Setup - Preliminary Recommendations ____________________________________________________________________________ 9

Factory configuration _________________________________________________________________________________________ 10

Basic functions ______________________________________________________________________________________________ 11

Remote display terminal option, ER22 ____________________________________________________________________________ 13

Remote graphic display terminal option, ER40______________________________________________________________________ 14

Remote display terminal option, ER12 ____________________________________________________________________________ 18

Structure of the parameter tables________________________________________________________________________________ 19

Compatibility of functions ______________________________________________________________________________________ 20

List of functions that can be assigned to inputs/outputs_______________________________________________________________ 22

List of functions that can be assigned to the Network and Modbus control word bits ________________________________________ 24

Checklist ___________________________________________________________________________________________________ 25

Programming _______________________________________________________________________________________________ 26

[SPEED REFERENCE] (rEF-) menu _____________________________________________________________________________ 30

[SETTINGS] (SEt-) menu ______________________________________________________________________________________ 31

[MOTOR CONTROL] (drC-) menu _______________________________________________________________________________ 39

[INPUTS / OUTPUTS CFG] (I-O-) menu __________________________________________________________________________ 45

[COMMAND] (CtL-) menu______________________________________________________________________________________ 48

[COMMAND] (CtL-) menu______________________________________________________________________________________ 59

[APPLICATION FUNCT.] menu (FUn-) ___________________________________________________________________________ 60

[FAULT MANAGEMENT] (FLt-) menu ____________________________________________________________________________ 86

[COMMUNICATION] (COM-) menu ______________________________________________________________________________ 92

[MONITORING] (SUP-) menu __________________________________________________________________________________ 94

Migration ER22K/P - ER23K____________________________________________________________________________________ 99

Diagnostics and troubleshooting________________________________________________________________________________ 100

Index of functions ___________________________________________________________________________________________ 105

Index of parameter codes and customer settings___________________________________________________________________ 106

Wiring / evaluation of PTC ___________________________________________________________________________________ 120

3

Page 4

Important information

The addition of this symbol to a Danger or Warning safety label indicates that an electrical hazard exists, which will result in

personal injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow

this symbol to avoid possible injury or death.

NOTICE

Read these instructions carefully, and look at the equipment to become familiar with the device before trying to install, operate, or maintain

it. The following special messages may appear throughout this documentation or on the equipment to warn of potential hazards or to call

attention to information that clarifies or simplifies a procedure.

DANGER

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death, serious injury or

equipment damage.

WARNING

WARNING indicates a potentially hazardous situation which, if not avoided, can result in death, serious injury or

equipment damage.

CAUTION

CAUTION indicates a potentially hazardous situation which, if not avoided, can result in injury or equipment damage.

CAUTION

CAUTION, used without the safety alert symbol, indicates a potentially hazardous situation which, if not avoided, can

result in equipment damage.

PLEASE NOTE

The word "drive" as used in this manual refers to the "controller portion" of the adjustable speed drive as defined by NEC.

Electrical equipment should be installed, operated, serviced, and maintained only by qualified personnel. No responsibility is assumed by

BLEMO for any consequences arising out of the use of this documentation.

© 2009 BLEMO. All rights reserved.

4

Page 5

Before you begin

Read and understand these instructions before performing any procedure with this drive.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Read and understand this manual before installing or operating the ER23K drive. Installation, adjustment, repair, and maintenance

must be performed by qualified personnel.

• The user is responsible for compliance with all international and national electrical code requirements with respect to grounding of

all equipment.

• Many parts of this drive, including the printed circuit boards, operate at the line voltage. DO NOT TOUCH. Use only electrically

insulated tools.

• DO NOT touch unshielded components or terminal strip screw connections with voltage present.

• DO NOT short across terminals PA/+ and PC/– or across the DC bus capacitors.

• Before repairing the variable speed drive:

- Disconnect all power, including external control power that may be present.

- Place a “DO NOT TURN ON” label on all power disconnects.

- Lock all power disconnects in the open position.

- WAIT 15 MINUTES to allow the DC bus capacitors to discharge.

- Measure the voltage of the DC bus between the PA/+ and PC/– terminals to ensure that the voltage is less than 42 Vdc.

- If the DC bus capacitors do not discharge completely, contact your local BLEMO representative. Do not repair or operate

the drive

• Install and close all covers before applying power or starting and stopping the drive.

Failure to follow these instructions will result in death or serious injury.

DANGER

UNINTENDED EQUIPMENT OPERATION

• Read and understand this manual before installing or operating the ER23K drive.

• Any changes made to the parameter settings must be performed by qualified personnel.

Failure to follow these instructions will result in death or serious injury.

WARNING

DAMAGED EQUIPMENT

Do not install or operate any drive that appears damaged.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

5

Page 6

Before you begin

WARNING

LOSS OF CONTROL

• The designer of any wiring diagram must take account of potential control channel failure modes and, for certain critical control

functions, incorporate a way of achieving a safe state during and after a channel failure. Examples of critical control functions are

emergency stop and overtravel stop.

• Separate or redundant control channels must be provided for critical control functions.

• System control paths may include communication links. Consideration must be given to the implications of unanticipated transmission

delays or failures of the link.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

a) For additional information, refer to NEMA ICS 1.1 (latest edition), "Safety Guidelines for the Application, Installation, and Maintenance of

Solid State Control" and to NEMA ICS 7.1 (latest edition), "Safety Standards for Construction and Guide for Selection, Installation and

Operation of Adjustable-Speed Drive Systems".

a

6

Page 7

Documentation structure

The following ER23K technical documents are available on the BLEMO website (www.blemo.com).

Installation Manual

This manual describes how to install and connect the drive.

User manual

This manual describes the functions and parameters of the drive's terminals and how to use them.

Simplified manual

This manual is a simplified version of the installation and programming manuals. It is supplied with the drive.

Quick Start

This document describes how to connect and configure the drive so that the motor can be started both quickly and easily for basic

applications. This document is supplied with the drive.

Manuals for Modbus, CANopen, etc.

These manuals describe the installation process, the bus or network connections, signaling, diagnostics and the configuration of parameters

specific to communication.

They also describe the communication services of the protocols.

7

Page 8

Steps for setting up the drive

3. Configure:

•

The nominal frequency of the motor

[Standard mot. freq] (bFr) page 39 if this is

not 50 Hz,

•

The motor parameters in the [MOTOR

CONTROL] (drC-) menu, page 39, only if

the factory configuration of the drive is

not suitable,

•

The application functions in the

[INPUTS / OUTPUTS CFG] (I-O-) menu,

page 45, the [COMMAND] (CtL-) menu,

page 48, and the [APPLICATION

FUNCT.] (FUn-) menu, page 60, only if

the factory configuration of the drive

is not suitable.

4. In the [SETTINGS] (SEt-) menu,

adjust the following

parameters:

•

[Acceleration] (ACC), page 31 and

[Deceleration], (dEC) page 31,

•

[Low speed] (LSP), page 32 and [High

speed] (HSP), page 32,

•

[Mot. therm. current] (ItH), page 32.

2. Apply input power to the drive, but do not

give a run command.

Tips:

•

Before beginning programming, complete the customer

setting tables, page

106

.

•

Use the

[Restore config.] (FCS) parameter, page 44

,

to return to the factory settings at any time.

• To locate the description of a function quickly, use the index

of functions on page

105

.

• Before configuring a function, read carefully the "Function

compatibility" section on pages 20 and 21.

• Note:

The following operations must be performed for optimum

drive performance in terms of accuracy and response time:

-

Enter the values indicated on the (motor) rating plate in

the

[MOTOR CONTROL] (drC-)

menu, page 39.

-

Perform auto-tuning with the motor cold and connected

using the

[Auto-tuning] (tun)

parameter, page 41.

-

Adjust the

[FreqLoopGain] (FLG)

parameter, page 32

and the

[Fr.Loop.Stab] (StA)

parameter, page 33.

INSTALLATION

1. Please refer to the Installation Manual.

PROGRAMMING

5. Start the drive.

8

Page 9

Setup - Preliminary Recommendations

Before powering up the drive

DANGER

UNINTENDED EQUIPMENT OPERATION

Make sure that all logic inputs are inactive to avoid any unintended operation.

Failure to follow these instructions will result in death or serious injury.

Before configuring the drive

DANGER

UNINTENDED EQUIPMENT OPERATION

• Read and understand this manual before installing or operating the ER23K drive.

• Any changes made to the parameter settings must be performed by qualified personnel.

• Make sure that all logic inputs are inactive to avoid any unintended operation when parameters are being changed.

Failure to follow these instructions will result in death or serious injury.

Start-up

Note: When factory settings apply and during power-up/manual reset or after a stop command, the motor can only be powered once the

"forward", "reverse" and "DC injection stop" commands have been reset. If they have not been reset, the drive will display [Freewheel stop]

(nSt) but will not start. If the automatic restart function has been configured ([Automatic restart] (Atr) parameter in the [FAULT

MANAGEMENT] (FLt-) menu, page 86), these commands are taken into account without a reset (to zero) being necessary.

Line contactor

CAUTION

RISK OF DAMAGE TO DRIVE

• Frequent use of the contactor will cause premature ageing of the filter capacitors.

• Do not have cycle times less than 60 seconds.

Failure to follow these instructions can result in equipment damage.

Using a motor with a lower rating or dispensing with a motor altogether

• With the factory settings, motor output phase loss detection is active ([Output Phase Loss] (OPL) = [YES] (YES), page 89). To avoid

having to use a motor with the same rating as the drive when testing the drive or during a maintenance phase, deactivate motor output

phase loss detection ([Output Phase Loss] (OPL) = [No] (nO)). This can prove particularly useful if very powerful drives are being

used.

• Set the [U/F mot 1 selected] (UFt) parameter, page 42, on [Cst. torque] (L) in the [MOTOR CONTROL] (drC-) menu.

CAUTION

RISK OF DAMAGE TO MOTOR

Motor thermal protection will not be provided by the drive if the motor 's nominal current is 20% lower than that of the drive. Find an

alternative source of thermal protection.

Failure to follow these instructions can result in equipment damage.

9

Page 10

Factory configuration

Factory settings

The ER23K is factory-set for the most common operating conditions:

• Display: drive ready [Ready] (rdY) with motor stopped, and motor frequency with motor running.

• The LI5 and LI6 and logic inputs, AI3 analog input, AOC analog output, and R2 relay are unaffected.

• Stop mode when fault detected: freewheel

Code Description Value Page

bFr [Standard mot. freq] [50Hz IEC] 39

tCC [2/3 wire control] [2 wire] (2C): 2-wire control 29

UFt [U/F mot 1 selected] [SVC] (n): Sensorless flux vector control for constant torque applications 42

ACC

DEC

LSP [Low speed] 0 Hz 32

HSP [High speed] 50 Hz 32

ItH [Mot. therm. current] Nominal motor current (value depending on drive rating) 32

SdC1 [Auto DC inj. level 1] 0.7 x nominal drive current, for 0.5 seconds 33

SFr [Switching freq.] 4 kHz 38

rrS [Reverse assign.] [LI2] (LI2): Logic input LI2 46

PS2 [2 preset speeds] [LI3] (LI3): Logic input LI3 69

PS4 [4 preset speeds] [LI4] (LI4): Logic input LI4 69

Fr1 [Ref.1 channel] [AI1] (AI1) - Analog input AI1 28

SA2 [Summing ref. 2] [AI2] (AI2) - Analog input AI2 67

r1 [R1 Assignment]

brA [Dec ramp adapt.] [Yes] (YES): Function active (automatic adaptation of deceleration ramp) 62

Atr [Automatic restart] [No] (nO): Function inactive 86

Stt [Type of stop] [Ramp stop] (rMP): On ramp 63

CFG [Macro configuration] [Factory set.] (Std) (1) 43

[Acceleration]

[Deceleration]

3.00 seconds 61

[No drive flt] (FLt): The contact opens when a fault is detected or when the drive has

been switched off

47

Check whether the values above are compatible with the application. If necessary, the drive can be used without changing the settings.

(1)If you want to keep the drive's presettings to a minimum, select the macro configuration [Macro configuration] (CFG) = [Start/stop] (StS)

followed by [Restore config.] (FCS) = [Config. CFG] (InI) (page 44).

The [Start/stop] (StS) macro configuration is the same as the factory configuration, apart from the I/O assignment:

• Logic inputs:

- LI1, LI2 (reversing): 2-wire transition detection control, LI1 = run forward, LI2 = run reverse.

- LI3 to LI6: Inactive (not assigned).

• Analog inputs:

- AI1: Speed reference 0-10 V.

- AI2, AI3: Inactive (not assigned).

• Relay R1: The contact opens in the event of a detected fault (or drive off).

• Relay R2: Inactive (not assigned).

• Analog output AOC: 0-20 mA, inactive (not assigned).

10

Page 11

Basic functions

Time

(seconds)

Motor current/In drive

Drive thermal protection

Functions:

Thermal protection by PTC probe fitted on the heatsink or integrated in the power module.

Indirect protection of the drive against overloads by tripping in the event of an overcurrent. Typical tripping values:

- Motor current = 185% of nominal drive current: 2 seconds

- Motor current = 150% of nominal drive current: 60 seconds

Drive ventilation

The fan starts up when the drive is powered up then shuts down after 10 seconds if a run command has not been received.

The fan is powered automatically when the drive is unlocked (direction of operation + reference). It is powered down a few seconds after

the drive is locked (motor speed < 0.2 Hz and injection braking completed).

11

Page 12

Basic functions

Tripping time t

in seconds

Motor current/

[Mot. therm. current] (ItH)

Motor thermal protection

Function:

Thermal protection by calculating the I2t.

The protection takes account of self-cooled motors.

CAUTION

RISK OF DAMAGE TO MOTOR

External protection against overloads is required under the following circumstances:

• When the product is being switched on again, as there is no memory to record the motor thermal state

• When supplying more than one motor

• When supplying motors with ratings less than 0.2 times the nominal drive current

• When using motor switching

Failure to follow these instructions can result in equipment damage.

12

Page 13

Remote display terminal option, ER23K

4-character

display

Connector

Access locking switch:

• Position:

[MONITORING] (SUP-) and [SPEED

REFERENCE] (rEF-) menus can be

accessed.

[SETTINGS] (SEt-), [MONITORING]

(SUP-) and [SPEED REFERENCE]

(rEF-) can be accessed.

• Position:

• Position: All menus can be accessed

This terminal is a local control unit which can be mounted on the door of the wall-mounted or floor-standing enclosure. It has a cable with

connectors, which is connected to the drive serial link (see the manual supplied with the terminal). Its display capabilities are practically

identical to those of the ER23K. With this terminal, however, up and down arrows are used for navigation rather than a jog dial. There is

also an access locking switch for the menus. There are three buttons for controlling the drive (1):

• FWD/REV: Reversal of the direction of rotation

• RUN: Motor run command

• STOP/RESET: Motor stop command or reset

Pressing the button a first time stops the motor, and if DC injection standstill braking is configured, pressing it a second time stops this

braking.

View of the front panel:: View of the rear panel :

Note: Protection via customer confidential code has priority over the switch.

Note:

• The remote terminal access locking switch also locks access by the drive keys.

• When the remote display terminal is disconnected, any locking remains active for the drive keys.

• The remote display terminal will only be active if the [Modbus baud rate] (tbr) parameter in the [COMMUNICATION] (COM-) menu,

page 92, still has its factory setting: [19.2 Kbps] (19.2).

(1)To activate the buttons on the remote display terminal, you first have to configure [HMI command] (LCC) = [Yes] (YES), page 58.

Saving and loading configurations

Up to four complete configurations for ER23K drives without an option card can be stored on the remote display terminal. These

configurations can be saved, transported and transferred from one drive to another of the same rating. 4 different operations for the same

device can also be stored on the terminal.

See the [Saving config.] (SCS) and [Restore config.] (FCS) parameters in the [MOTOR CONTROL] (drC-) menu, pages 43 and 44, the

[INPUTS / OUTPUTS CFG] (I-O-) menu, pages 47 and 47, the [COMMAND] (CtL-) menu, pages 59 and 59, and the [APPLICATION

FUNCT.] (FUn-) menu, pages 85 and 85.

To transfer a configuration between an ER23K and an ER22, follow the procedure on page

85.

13

Page 14

Remote graphic display terminal option, ER40

1 Graphic display

2 Function keys:

F1: CODE

F2, F3: not used

F4: MODE

3 Button to stop/reset

4 Run button

5 Navigation button:

• Press (ENT): - To save the current value

- To enter the selected menu or parameter

• Turn CW/CCW: - To increase or decrease a value

- To go to the next or previous line

- To increase or decrease the reference if control via

the display terminal is activated

7

ESC button:cancels a value, a

parameter or a menu to return

to the previous selection

6

Button for reversing the direction

of rotation of the motor

Description of the terminal

Thanks to the screen size of this graphic display terminal, which works with FLASH V1.1IE19 or higher and is part of the ER40, it is possible

to display more detailed information than can be shown on an on-board display. It is connected in the same way as the ER23K remote

display terminal.

Note: Keys 3, 4, 5 and 6 can be used to control the drive directly, if control via the terminal is activated.

To activate the buttons on the remote display terminal, you first have to configure [HMI command] (LCC) = [Yes] (YES), page 58.

14

Page 15

Remote graphic display terminal option, ER40 (continued)

LANGUAGE

English

Français

Deutsch

Espanol

Italiano

Chinese

Russian

Turkish

ER23K

1.5kW/2HP 200/240V

MAIN MENU

DRIVE MENU

LANGUAGE

DRIVE MENU

SPEED REFERENCE

SETTINGS

MOTOR CONTROL

INPUTS / OUTPUTS CFG

COMMAND

Code Mode

APPLICATION FUNCT.

FAULT MANAGEMENT

COMMUNICATION

Powering up the graphic display terminal for the first time

When powering up the graphic display terminal for the first time, the user has to select the required language.

Display after the graphic display terminal has been

powered up for the first time.

Select the language and press ENT.

The drive's rating details will now appear.

3 seconds

or ENT

The [MAIN MENU]

follows automatically.

Automatically switches to the [DRIVE MENU]

menu after 3 seconds.

Select the menu and press ENT.

15

Page 16

Remote graphic display terminal option, ER40 (continued)

ER23K

1.5kW/2HP 200/240V

MAIN MENU

DRIVE MENU

LANGUAGE

DRIVE MENU

Standard mot. freq

2/3 wire control

Ref.1 channel

SPEED REFERENCE

SETTINGS

MOTOR CONTROL

INPUTS / OUTPUTS CFG

COMMAND

APPLICATION FUNCT.

FAULT MANAGEMENT

COMMUNICATION

DRIVE MENU

Ready

Code Mode

Powering up the drive for the first time

When powering up the drive for the first time, the user immediately accesses the 3 parameters below: [Standard mot. freq] (bFr), [Ref.1

channel] (Fr1), and [2/3 wire control] (tCC), page 29. .

Display after the drive has been powered up for the

first time.

The [MAIN MENU]

follows automatically.

3 seconds

ESC

Automatically switches to the [DRIVE MENU]

menu after 3 seconds.

Select the menu and press ENT.

The word "Ready" appears on the graphic display

terminal if you press the ESC key when in the

[DRIVE MENU].

16

Page 17

Remote graphic display terminal option, ER40 (continued)

ER23K

1.5kW/2HP 200/240V

MAIN MENU

DRIVE MENU

LANGUAGE

DRIVE MENU

SPEED REFERENCE

SETTINGS

MOTOR CONTROL

INPUTS / OUTPUTS CFG

COMMAND

Code Mode

APPLICATION FUNCT.

FAULT MANAGEMENT

COMMUNICATION

DRIVE MENU

Ready

Code Mode

Subsequent power-ups

Display after powering up.

The [MAIN MENU]

follows automatically.

3 seconds

ESC

Automatically switches to the [DRIVE MENU]

menu after 3 seconds.

Select the menu and press ENT.

The word "Ready" appears on the graphic display

terminal if you press the ESC key when in the

[DRIVE MENU].

17

Page 18

Remote display terminal option, ER12

1 Graphic display

2 MODE button (1): If [SPEED

REFERENCE] (rEF-) is displayed,

this will take you to the

[SETTINGS] (SEt-) menu. If not, it

will take you to the [SPEED

REFERENCE] (rEF-) menu.

3 ESC button

Used to quit a menu/parameter or

remove the currently displayed

value in order to revert

to the previous value

retained in the memory

4 RUN button

Executes the function

assuming it has been

configured

5 Navigation keys

6 ENT button

Used to save the current value or

access the selected menu/parameter

8 Button for reversing the direction

of rotation of the motor

7 STOP button

Used to stop the motor and

perform a reset

Description of the terminal

This terminal is a local control unit which can be mounted on the door of the wall-mounted or floor-standing enclosure. It has a cable with

connectors, which is connected to the drive serial link (see the manual supplied with the terminal). Its display capabilities are practically

identical to those of the ER23. With this terminal, up and down arrows are used for navigation rather than a jog dial.

(1) If the drive is locked by a code ([PIN code 1] (COd), page 97), pressing the Mode key enables you to switch from the [MONITORING]

(SUP-) menu to the [SPEED REFERENCE] (rEF-) menu and vice versa.

To activate the buttons on the remote display terminal, you first have to configure [HMI command] (LCC) = [Yes] (YES), page 58.

18

Page 19

Structure of the parameter tables

APPLICATION FUNCT.] menu (Fun-)

Code Name/Description Adjustment

range

Factory

setting

PI-

•

[PI regulator]

Note: The "PI regulator" function is incompatible with several functions (see page 20). It can only

be configured if these functions are unassigned, in particular the summing inputs (set [Summing

ref. 2] (SA2) to [No] (nO), page 67) and the preset speeds (set [2 preset speeds] (PS2) and

[4 preset speeds] (PS4) to [No] (nO), page 69) which will have been assigned as part of the

factory settings.

PIF

• [PID feedback ass.]

[Non] (nO)

no

AI1

A12

A13

-

[Non] (nO): not assigned

-

[AI1] (AI1): analog input AI1

-

[AI2] (AI2): analog input AI2

-

[AI3] (AI3): analog input AI3

5

2

3

1

4

6

8

7

1. Name of menu on 4-digit 7-segment display

2. Submenu code on 4-digit 7-segment display

3. Parameter code on 4-digit 7-segment display

4. Parameter value on 4-digit 7-segment display

5. Name of menu on ER40 graphic display terminal

6. Name of submenu on ER40 graphic display terminal

7. Name of parameter on ER40 graphic display terminal

8. Value of parameter on ER40 graphic display terminal

The parameter tables contained in the descriptions of the various menus are organized as follows.

Example :

19

Page 20

Compatibility of functions

Incompatible functions

The following functions will be inaccessible or deactivated in the cases described below:

Automatic restart

This is only possible for the 2-wire level control type ([2/3 wire control] (tCC) = [2 wire] (2C) and [2 wire type] (tCt) = [Level] (LEL) or

[Fwd priority] (PFO)).

Catch on the fly

This is only possible for the 2-wire level control type ([2/3 wire control] (tCC) = [2 wire] (2C) and [2 wire type] (tCt) = [Level] (LEL) or

[Fwd priority] (PFO)).

This function is locked if automatic standstill injection has been configured as DC ([Auto DC injection] (AdC) = [Continuous] (Ct)).

Function compatibility table

The choice of application functions may be limited by the number of I/O and by the fact that some functions are incompatible with one

another. Functions which are not listed in this table are compatible.

If there is an incompatibility between functions, the first function configured will prevent the others being configured.

To configure a function, first check that functions which are incompatible with it are unassigned, especially those which are

assigned in the factory settings.

Summing inputs (factory setting)

+/- speed (1)

Management of limit switches

Preset speeds (factory setting)

PI regulator

Jog operation

Brake control

DC injection stop

Fast stop

Freewheel stop

Summing inputs (factory setting)

+/- speed (1)

Management of limit switches

Preset speeds (factory setting)

PI regulator

Jog operation

Brake control

DC injection stop

Fast stop

Freewheel stop

(1)Excluding special application with reference channel [Ref.2 channel] (Fr2) (see diagrams 51 and 53)

Incompatible functions Compatible functions Not applicable

Priority functions (functions which cannot be active at the same time):

f

Stop functions take priority over run commands.

Speed references via logic command take priority over analog references.

The function marked with the arrow takes priority over the other.

f

f f

f f

20

Page 21

Compatibility of functions

Logic and analog input application functions

Each of the functions on the following pages can be assigned to one of the inputs.

A single input can activate several functions at the same time (reverse and 2nd ramp for example). The user must therefore ensure that

these functions can be used at the same time.

The [MONITORING] (SUP-) menu ([[LOGIC INPUT CONF.]] (LIA-) parameter, page 98, and [[ANALOG INPUTS IMAGE]] (AIA-) parameter,

page 98) can be used to display the functions assigned to each input in order to check their compatibility.

Before assigning a reference, command or function to a logic or analog input, the user must check that this input has not already been

assigned in the factory settings and that no other input has been assigned to an incompatible or unwanted function.

• Example of incompatible function to be unassigned:

In order to use the "+speed/-speed" function, the preset speeds and summing input 2 must first be unassigned.

The table below lists the factory-set input assignments and the procedure for unassigning them.

Assigned input Function Code To unassign, set to: Page

LI2 Run reverse rrS nO 46

LI3 2 preset speeds PS2 nO 69

LI4 4 preset speeds PS4 nO 69

AI1 Reference 1 Fr1 Anything but AI1 56

LI1 Run forward tCC 2C or 3C 45

AI2 Summing input 2 SA2 nO 67

21

Page 22

List of functions that can be assigned to inputs/outputs

Logic inputs Page Code Factory setting

Not assigned - - LI5 - LI6

Run forward - - LI1

2 preset speeds 69 PS2 LI3

4 preset speeds 69 PS4 LI4

8 preset speeds 69 PS8

16 preset speeds 70 PS16

2 preset PI references 77 Pr2

4 preset PI references 78 Pr4

+ speed 74 USP

- speed 74 dSP

Jog operation 72 JOG

Ramp switching 62 rPS

2nd current limit switching 81 LC2

Fast stop via logic input 63 FSt

DC injection via logic input 63 dCI

Freewheel stop via logic input 64 nSt

Run reverse 46 rrS LI2

External fault 88 EtF

RESET 87 rSF

Forced local mode 93 FLO

Reference switching 57 rFC

Control channel switching 58 CCS

Motor switching 82 CHP

Forward limit switch 84 LAF

Reverse limit switch 84 LAr

Fault inhibition 91 InH

Analog inputs Page Code Factory setting

Not assigned - - AI3

Reference 1 56 Fr1 AI1

Reference 2 56 Fr2

Summing input 2 67 SA2 AI2

Summing input 3 67 SA3

PI regulator feedback 77 PIF

22

Page 23

List of functions that can be assigned to inputs/outputs

Analog/logic output Page Code Factory setting

Not assigned - - AOC/AOV

Motor current 46 OCr

Motor frequency 46 OFr

Motor torque 46 Otr

Power supplied by the drive 46 OPr

Drive detected fault (logic data) 46 FLt

Drive running (logic data) 46 rUn

Frequency threshold reached (logic data) 46 FtA

High speed (HSP) reached (logic data) 46 FLA

Current threshold reached (logic data) 46 CtA

Frequency reference reached (logic data) 46 SrA

Motor thermal threshold reached (logic data) 46 tSA

Brake sequence (logic data) 46 bLC

Relay Page Code Factory setting

Not assigned - - R2

Detected fault 47 FLt R1

Drive running 47 rUn

Frequency threshold reached 47 FtA

High speed (HSP) reached 47 FLA

Current threshold reached 47 CtA

Frequency reference reached 47 SrA

Motor thermal threshold reached 47 tSA

Brake sequence 47 bLC

LI1

to

Copy of the logic input 47

LI6

23

Page 24

List of functions that can be assigned to the Network and

Modbus control word bits

Bits 11 to 15 of the control word Page Code

2 preset speeds 69 PS2

4 preset speeds 69 PS4

8 preset speeds 69 PS8

16 preset speeds 70 PS16

2 preset PI references 77 Pr2

4 preset PI references 78 Pr4

Ramp switching 62 rPS

2nd current limit switching 81 LC2

Fast stop via logic input 63 FSt

DC injection 63 dCI

External fault 88 EtF

Reference switching 57 rFC

Control channel switching 58 CCS

Motor switching 82 CHP

24

Page 25

Checklist

Carefully read the information contained in the programming, installation and simplified manuals, as well as the information in the catalog.

Before starting to use the drive, please check the following points relating to mechanical and electrical installations.

For the full range of documentation, please visit www.blemo.com.

1. Mechanical installation (see the simplified and installation manuals)

• For details of the different installation types and recommendations concerning ambient temperature, please refer to the installation

instructions in the simplified or installation manuals.

• Install the drive vertically in accordance with the specifications. Please refer to the installation instructions in the simplified or

installation manuals.

• When using the drive, both the environmental conditions defined under standard 60721-3-3 and the levels defined in the catalog must

be respected.

• Install the required options for your application. Refer to the catalog for details.

2. Electrical installation (see the simplified and installation manuals)

• Ground the drive. See the sections on how to ground equipment in the simplified and installation manuals.

• Make sure the input supply voltage matches the nominal drive voltage and connect the line supply in accordance with the simplified

and installation manuals.

• Make sure you use appropriate input line fuses and circuit breakers. See the simplified and installation manuals.

• Arrange the cables for the control terminals as required (see the simplified and installation manuals). Separate the supply and control

cables in accordance with EMC compatibility rules.

• The ER23-...K and ER23-.../4K ranges include an EMC filter Using an IT jumper helps reduce leakage current. This is explained in

the paragraph about the internal EMC filter on the ER23-...K and the ER23-.../4K in the installation manual.

• Make sure the motor connections are right for the voltage (star, delta).

3. Using and starting up the drive

• Start the drive. [Standard mot. freq] (bFr), page 28, is displayed the first time the drive is powered up. Make sure the frequency defined

by frequency bFr (the factory setting is 50 Hz) matches the motor's frequency.

• When the drive is powered up for the first time, the [Ref.1 channel] (Fr1) parameter, page 28, and the [2/3 wire control] (tCC)

parameter, page 29, are displayed after [Standard mot. freq] (bFr). These parameters will need to be adjusted if you wish to control

the drive locally.

• When the drive is powered up subsequently, [Ready] (rdY) is displayed on the HMI.

• The [Restore config.] (FCS) function, page 44, is used to reinitialize the drive with the factory settings.

25

Page 26

Programming

• 4 x 7 segment display

• RUN button: Controls powering up

of the motor for forward running if

the [2/3 wire control] (tCC)

parameter in the [INPUTS /

OUTPUTS CFG] (I-O-) menu is set

to [Local] (LOC), page 45

• Jog dial - can be used for

navigation by turning it clockwise

or counter-clockwise - pressing

the jog dial enables the user to

make a selection or confirm

information.

• Used to quit a menu or parameter

or to clear the value displayed in

order to revert to the value in the

memory

STOP/RESET button

• Enables detected fault to be reset

• Can be used to control motor stopping

- If [2/3 wire control] (tCC) is not set to

[Local] (LOC), freewheel stop

- If [2/3 wire control] (tCC) is set to [Local]

(LOC), stop on ramp or freewheel stop

during DC injection braking

• 2 CANopen status LEDs

• MON LED, illuminated if

[MONITORING] (SUP-)

menu is active

• CONF LED, illuminated if the

[SETTINGS] (SEt-),

[MOTOR CONTROL]

(drC-),[INPUTS / OUTPUTS

CFG] (I-O-), [COMMAND]

(CtL-), [APPLICATION

FUNCT] (FUn-), [FAULT

MANAGEMENT] (FLt-)

or [COMMUNICATION]

(COM-) menus are active

Functions as a potentiometer if [Ref.1

channel] (Fr1-) in the [COMMAND]

(CtL-) menu is set to [Image input

AIV1] (AIV1)

• MODE button (1): If

[SPEED REFERENCE]

(rEF-) is displayed, this will

take you to the

[SETTINGS] (SEt-) menu.

If not, it will take you to the

[SPEED REFERENCE]

(rEF-) menu.

• Load LED

• REF LED, illuminated if

[SPEED REFERENCE]

(rEF-) menu is active

Description of the HMI

Functions of the display and the keys

Normal display, with no fault code displayed and no startup:

- : Displays the parameter selected in the [MONITORING] (SUP-) menu (default: motor frequency).

If the current is limited, the display flashes. In such cases, CLI will appear at the top left if an ER40 graphic display terminal is

connected to the drive.

- InIt: Initialization sequence

- rdY: Drive ready

- dCb: DC injection braking in progress

- nSt: Freewheel stop

- FSt: Fast stop

- tUn : Auto-tuning in progress

In the event of a detected fault, the display will flash to notify the user accordingly. If an ER40 graphic display terminal is

connected, the name of the detected fault will be displayed.

(1) If the drive is locked by a code ([PIN code 1] (COd), page 97), pressing the Mode key enables you to switch from the [MONITORING]

(SUP-) menu to the [SPEED REFERENCE] (rEF-) menu and vice versa.

26

Page 27

Programming

These three parameters are

only visible when the drive is

powered up for the first time.

The settings can be amended

subsequently in the menus:

[MOTOR CONTROL] (drC-)

for [Standard mot. freq] (bFr),

[COMMAND] (CtL-) for [Ref.1

channel] (Fr1)

[INPUTS / OUTPUTS CFG]

(I-O-) for [2/3 wire control]

(tCC)

[MOTOR CONTROL] (drC-)

[FAULT MANAGEMENT] (FLt)

[COMMUNICATION] (COM-)

[MONITORING] (SUP-)

[SETTINGS] (SEt-)

[INPUTS / OUTPUTS CFG]

(I-O-)

[COMMAND] (CtL-)

[APPLICATION FUNCT.] (FUn-)

[SPEED REFERENCE] (rEF-)

Structure of the menus

Powering up Parameter selection

On the 7-segment display, a dash after menu and submenu codes is used to differentiate them from parameter codes.

Examples: [APPLICATION FUNCT.] (FUn-) menu, [Acceleration] (ACC) parameter

27

Page 28

Programming

Configuring the [Standard mot. freq] (bFr), [2/3 wire control] (tCC), and

[Ref.1 channel] (Fr1) parameters

These parameters can only be modified when the drive is stopped and no run command is present.

Code Description Adjustment

range

bFr

50

60

Fr1

AI1

AI2

AI3

AIU1

UPdt

UPdH

LCC

Mdb

nEt

• [Standard mot. freq]

This parameter is only visible the first time the drive is powered up.

It can be modified at any time in the [MOTOR CONTROL] (drC-) menu.

[50Hz IEC] (50): 50 Hz

[60Hz NEMA] (60): 60 Hz

This parameter modifies the presets of the following parameters: [High speed] (HSP), page 32, [Freq.

threshold] (Ftd), page 37, [Rated motor freq.] (FrS), page 39, and [Max frequency] (tFr), page 42

• [Ref.1 channel]

-

[AI1] (AI1) - Analog input AI1

-

[AI2] (AI2) - Analog input AI2

-

[AI3] (AI3) - Analog input AI3

-

[Network AI] (AIV1) - In terminal control mode, the jog dial functions as a potentiometer.

If [ACCESS LEVEL] (LAC) = [Level 2] (L2) or [Level 3] (L3), the following additional assignments are possible:

-

[+/- SPEED] (UPdt): +/- speed reference via LI. See configuration page 74.

-

[+/-spd HMI] (UPdH): +/- speed reference by turning the jog dial on the ER23K keypad.

To use, display the frequency [Output frequency] (rFr), page 95. The +/- speed function via the keypad or the

terminal is controlled from the [MONITORING] (SUP-) menu by selecting the [Output frequency] (rFr)

parameter.

If [ACCESS LEVEL] (LAC) = [Level 3] (L3), the following additional assignments are possible:

-

[HMI] (LCC) reference via the remote display terminal, [HMI Frequency ref.] (LFr) parameter in the

[SETTINGS] (SEt-) menu, page 31

-

[Modbus] (Mdb): Reference via Modbus

-

[Network] (nEt): Reference via network communication protocol

Factory

setting

[50Hz IEC] (50)

[AI1] (AI1)

28

Page 29

Programming

2 s

2 s

Code Description Adjustment

range

tCC

• [2/3 wire control]

DANGER

UNINTENDED EQUIPMENT OPERATION

When the [2/3 wire control] (tCC) parameter is changed, the [Reverse assign.] (rrS) parameter, page 46, and the

[2 wire type] (tCt) parameter, page 45, and all the assignments involving the logic inputs will revert to their default

values.

Check that this change is compatible with the wiring diagram used.

Failure to follow these instructions will result in death or serious injury.

Control configuration:

2C

3C

LOC

-

[2 wire] (2C): 2-wire control

-

[3 wire] (3C): 3-wire control

-

[Local] (LOC): Local control (RUN/STOP/RESET drive) (invisible if [ACCESS LEVEL] (LAC) = [Level 3] (L3),

page 56)

2-wire control: The open or closed state of the input controls running or stopping.

Wiring example:

LI1: Forward

LIx: Reverse

3-wire control (pulse control): A "forward" or "reverse" pulse is sufficient to control startup, a "stop" pulse is

sufficient to control stopping.

Wiring example:

LI1: Stop

LI2: Forward

LIx: Reverse

Factory

setting

[2 wire] (2C)

The jog dial (ENT) needs to be pressed and held down (for 2 s) to change the assignment for this parameter.

29

Page 30

[SPEED REFERENCE] (rEF-) menu

rEF-

SEt-

drC-

I-0-

CtL-

FUn-

FLt-

COM-

SUP-

The [SPEED REFERENCE] (rEF-) menu displays [HMI Frequency ref.] (LFr), [Image input AIU1] (AIU1) or [Frequency ref.] (FrH) depending

on which control channel is active.

During local control, the HMI's jog dial functions as a potentiometer, making it possible to increase or reduce the reference value within

limits defined by the [Low speed] (LSP) and [High speed] (HSP) parameters.

When local control is deactivated, by the [Ref.1 channel] (Fr1) parameter, only the reference values are displayed. The value will be readonly and can only be changed via the jog dial (the speed reference is supplied by an AI or another source).

The reference displayed will depend on how the drive has been configured.

Code Description Factory setting

LFr

AIU1

FrH

• [HMI Frequency ref.]

This parameter only appears if the function has been enabled.

It is used to change the speed reference from the remote control.

ENT does not have to be pressed to enable a change of reference.

• [Image input AIU1]

Used to amend the speed reference via the jog dial

• [Frequency ref.]

This parameter is read-only. It enables you to display the speed reference applied to the motor, regardless of

which reference channel has been selected.

0 to 500 Hz

0 to 100%

LSP to HSP Hz

30

Page 31

[SETTINGS] (SEt-) menu

Speed reference via the display terminal

Scaling factor for the [Cust. output value] (SPd1) parameter

rEF-

SEt-

drC-

I-0-

CtL-

FUn-

FLt-

COM-

SUP-

The adjustment parameters can be modified with the drive running or stopped.

Note: Changes should preferably be made with the drive stopped.

Code Description Adjustment range Factory setting

LFr

*

rPI

*

ACC

AC2

*

dE2

*

dEC

• [HMI Frequency ref.]

This parameter is displayed if [HMI command] (LCC) = [Yes] (YES), page 58 or if [Ref.1 channel] (Fr1)/[Ref.2

channel] (Fr2) = [HMI] (LCC) page 56, and if a remote display terminal is connected. In such cases, [HMI

Frequency ref.] (LFr) can also be accessed via the drive's keypad.

[HMI Frequency ref.] (LFr) is reinitialized to 0 when power is switched off.

• [Internal PID ref.]

Parameter is only visible if [PID feedback ass.] (PIF) is not set to [No] (nO), page 77.

• [Acceleration]

Defined to accelerate from 0 to the nominal frequency [Rated motor freq.] (FrS) in the [MOTOR CONTROL]

(drC-) menu.

• [Acceleration 2]

Parameter can be accessed if [Ramp 2 threshold] (Frt) > 0, page 62, or if [Ramp switch ass.] (rPS) is assigned,

page 62.

• [Deceleration 2]

Parameter can be accessed if [Ramp 2 threshold] (Frt) > 0, page 62, or if [Ramp switch ass.] (rPS) is assigned,

page 62.

• [Deceleration]

Defined to decelerate from the nominal frequency [Rated motor freq.] (FrS) (parameter in the [MOTOR CONTROL]

(drC-)) menu to 0.

Check that the value for [Deceleration] (dEC) is not too low in relation to the load to be stopped.

0 to HSP -

0.0 to 100% 0%

In accordance with

Inr, page 61

In accordance with

Inr, page 61

In accordance with

Inr, page 61

In accordance with

Inr, page 61

3 s

5 s

5 s

3 s

These parameters only appear if the corresponding function has been selected in another menu. When the parameters can

also be accessed and set from within the configuration menu for the corresponding function, their description is detailed in

*

these menus, on the pages indicated, to aid programming.

31

Page 32

[SETTINGS] (SEt-) menu

rEF-

SEt-

drC-

I-0-

CtL-

FUn-

FLt-

COM-

SUP-

FLG low

FLG correct

FLG high

In this case,

reduce FLG.

Code Description Adjustment

range

tA1

*

tA2

*

tA3

*

tA4

*

LSP

HSP

ItH

• [Begin Acc round]

Parameter can be accessed if the [Ramp type] (rPt) = [Customized] (CUS), page 60.

• [End Acc round]

Parameter can be accessed if the [Ramp type] (rPt) = [Customized] (CUS), page 60.

• [Begin Dec round]

Parameter can be accessed if the [Ramp type] (rPt) = [Customized] (CUS), page 60.

• [End Dec round]

Parameter can be accessed if the [Ramp type] (rPt) = [Customized] (CUS), page 60.

• [Low speed]

Motor frequency at min. reference

• [High speed]

Motor frequency at max. reference: Ensure that this setting is appropriate for the motor and the application.

• [Mot. therm. current]

Set [Mot. therm. current] (ItH) to the nominal current indicated on the motor's rating plate.

If you wish to suppress thermal protection, see [Overload fault mgt] (OLL), page 89.

0 to 100 10

0 to (100-tA1) 10

0 to 100 10

0 to (100-tA3) 10

0 to HSP 0

LSP to tFr bFr

0.2 to 1.5 In (1) In accordance

Factory

setting

with the drive

rating

UFr

FLG

*

(1)In corresponds to the nominal drive current indicated in the Installation Manual and on the drive nameplate.

*

32

• [IR compensation]

- For [U/F mot 1 selected] (UFt) = [SVC] (n) or [Energy sav.] (nLd), page 42: IR compensation

- For [U/F mot 1 selected] (UFt) = [Cst. torque] (L) or [Var. torque] (P), page 42: Voltage boost

Used to optimize the torque at very low speed (increase [IR compensation] (UFr) if the torque is insufficient).

Check that the value for [IR compensation] (UFr) is not too high when the motor is in a hot state otherwise some

instabilities can occur.

Note: Changing [U/F mot 1 selected] (UFt), page 42, will cause [IR compensation] (UFr) to return to its factory

setting (20%).

• [FreqLoopGain]

Parameter can only be accessed if [U/F mot 1 selected] (UFt) = [SVC] (n) or [Energy sav.] (nLd), page 42.

The FLG parameter adjusts the drive's ability to follow the speed ramp on the basis of the inertia of the machine

being driven.

Too high a gain may result in operating instability.

These parameters only appear if the corresponding function has been selected in another menu. When the parameters can

also be accessed and set from within the configuration menu for the corresponding function, their description is detailed in

these menus, on the pages indicated, to aid programming.

0 to 100% 20%

1 to 100% 20%

Page 33

[SETTINGS] (SEt-) menu

rEF-

SEt-

drC-

I-0-

CtL-

FUn-

FLt-

COM-

SUP-

StA low

StA correct

StA high

In this case,

reduce StA.

Code Description Adjustment range Factory setting

StA

*

SLP

*

IdC

*

• [Fr.Loop.Stab]

Parameter can only be accessed if [U/F mot 1 selected] (UFt) = [SVC] (n) or [Energy sav.] (nLd), page 42.

Used to adapt the return to steady state after a speed transient (acceleration or deceleration), according to the

dynamics of the machine.

Gradually increase the stability to avoid any overspeed.

• [Slip compensation]

Parameter can only be accessed if [U/F mot 1 selected] (UFt) = [SVC] (n) or [Energy sav.] (nLd), page 42.

Adjusts the slip compensation around the value set by the nominal motor speed.

The speeds given on motor rating plates are not necessarily exact.

• If slip setting < actual slip: the motor is not rotating at the correct speed in steady state.

• If slip setting > actual slip: the motor is overcompensated and the speed is unstable.

• [DC inject. level 1]

Parameter can be accessed if [Type of stop] (Stt) = [DC injection] (dCI), page 63, or if [DC injection assign.] (dCI)

is not set to [No] (nO), page 63.

After 5 seconds, the injection current is limited to 0.5 [Mot. therm. current] (ItH) if set to a higher value.

1 to 100% 20%

0 to 150% 100%

(2) 0 to In (1) 0.7 In (1)

tdC

*

tdC1

*

SdC1

*

tdC2

*

SdC2

*

(1)In corresponds to the nominal drive current indicated in the Installation Manual and on the drive nameplate.

(2)Note: These settings are not related to the "automatic standstill DC injection" function.

*

• [DC injection time 2]

Parameter can be accessed if [Type of stop] (Stt) = [DC injection] (dCI) , page 63.

• [Auto DC inj. time 1]

Parameter can be accessed if [Auto DC injection] (AdC) is not set to [No] (nO), page 65.

• [Auto DC inj. level 1]

Parameter can be accessed if [Auto DC injection] (AdC) is not set to [No] (nO), page 65.

Note: Check that the motor will withstand this current without overheating.

• [Auto DC inj. time 2]

Parameter can be accessed if [Auto DC injection] (AdC) is not set to [No] (nO), page 65.

• [Auto DC inj. level 2]

Parameter can be accessed if [Auto DC injection] (AdC) is not set to [No] (nO), page 65.

Note: Check that the motor will withstand this current without overheating.

These parameters only appear if the corresponding function has been selected in another menu. When the parameters can

also be accessed and set from within the configuration menu for the corresponding function, their description is detailed in

these menus, on the pages indicated, to aid programming.

(2) 0.1 to 30 s 0.5 s

0.1 to 30 s 0.5 s

0 to 1.2 In (1) 0.7 In (1)

0 to 30 s 0 s

0 to 1.2 In (1) 0.5 In (1)

33

Page 34

[SETTINGS] (SEt-) menu

rEF-

SEt-

drC-

I-0-

CtL-

FUn-

FLt-

COM-

SUP-

Code Description Adjustment range Factory setting

JPF

JF2

JGF

*

rPG

*

rIG

*

FbS

*

PIC

YES

*

nO

• [Skip Frequency]

Helps to prevent prolonged operation at a frequency range of ± 1 Hz around [Skip Frequency] (JPF). This function

helps to prevent a critical speed which leads to resonance. Setting the function to 0 renders it inactive.

• [Skip Frequency 2]

Helps to prevent prolonged operation at a frequency range of ± 1 Hz around [Skip Frequency 2] (JF2). This

function helps to prevent a critical speed which leads to resonance. Setting the function to 0 renders it inactive.

• [Jog frequency]

Parameter can be accessed if [JOG] (JOG) is not set to [No] (nO), page 72.

• [PID prop. gain]

Parameter is only visible if [PID feedback ass.] (PIF) is not set to [No] (nO), page 77.

It provides dynamic performance when PI feedback is changing quickly.

• [PID integral gain]

Parameter is only visible if [PID feedback ass.] (PIF) is not set to [No] (nO), page 77.

It provides static precision when PI feedback is changing slowly.

• [PID fbk scale factor]

Parameter is only visible if [PID feedback ass.] (PIF) is not set to [No] (nO), page 77.

For adapting the process.

• [PID correct. reverse]

Parameter is only visible if [PID feedback ass.] (PIF) is not set to [No] (nO), page 77.

-

[No] (nO): Normal

-

[Yes] (YES): Reverse

0 to 500 Hz 0 Hz

1 to 500 Hz 0 Hz

0 to 10 Hz 10 Hz

0.01 to 100 1

0.01 to 100/s 1

0.1 to 100 1

[No] (nO)

rP2

*

rP3

*

rP4

*

SP2

*

*

• [Preset ref. PID 2]

Parameter is only visible if [PID feedback ass.] (PIF) is not set to [No] (nO), page 77, and if [2 preset PID ref.]

(Pr2), page 77, has been enabled by the input selection.

• [Preset ref. PID 3]

Parameter is only visible if [PID feedback ass.] (PIF) is not set to [No] (nO), page 77, and if [4 preset PID ref.]

(Pr4), page 78, has been enabled by the input selection.

• [Preset ref. PID 4]

Parameter is only visible if [PID feedback ass.] (PIF) is not set to [No] (nO), page 77, and if [4 preset PID ref.]

(Pr4), page 78, has been enabled by the input selection.

• [Preset speed 2]

See page 70.

These parameters only appear if the corresponding function has been selected in another menu. When the parameters can

also be accessed and set from within the configuration menu for the corresponding function, their description is detailed in

these menus, on the pages indicated, to aid programming.

0 to 100% 30%

0 to 100% 60%

0 to 100% 90%

0 to 500 Hz 10 Hz

34

Page 35

[SETTINGS] (SEt-) menu

rEF-

SEt-

drC-

I-0-

CtL-

FUn-

FLt-

COM-

SUP-

Code Description Adjustment

range

SP3

*

SP4

*

SP5

*

SP6

*

SP7

*

SP8

*

SP9

*

• [Preset speed 3]

See page 70.

• [Preset speed 4]

See page 70.

• [Preset speed 5]

See page 70.

• [Preset speed 6]

See page 70.

• [Preset speed 7]

See page 70.

• [Preset speed 8]

See page 70.

• [Preset speed 9]

See page 70.

0 to 500 Hz 15 Hz

0 to 500 Hz 20 Hz

0 to 500 Hz 25 Hz

0 to 500 Hz 30 Hz

0 to 500 Hz 35 Hz

0 to 500 Hz 40 Hz

0 to 500 Hz 45 Hz

Factory setting

SP10

*

SP11

*

SP12

*

SP13

*

SP14

*

SP15

*

SP16

*

• [Preset speed 10]

See page 70.

• [Preset speed 11]

See page 71.

• [Preset speed 12]

See page 71.

• [Preset speed 13]

See page 71.

• [Preset speed 14]

See page 71.

• [Preset speed 15]

See page 71.

• [Preset speed 16]

See page 71.

0 to 500 Hz 50 Hz

0 to 500 Hz 55 Hz

0 to 500 Hz 60 Hz

0 to 500 Hz 70 Hz

0 to 500 Hz 80 Hz

0 to 500 Hz 90 Hz

0 to 500 Hz 100 Hz

These parameters only appear if the corresponding function has been selected in another menu. When the parameters can

also be accessed and set from within the configuration menu for the corresponding function, their description is detailed in

*

these menus, on the pages indicated, to aid programming.

35

Page 36

[SETTINGS] (SEt-) menu

rEF-

SEt-

drC-

I-0-

CtL-

FUn-

FLt-

COM-

SUP-

Code Description Adjustment

range

CLI

CL2

*

tLS

rSL

*

UFr2

*

• [Current Limitation]

Used to limit the torque and the temperature rise of the motor.

• [I Limit. 2 value]

Parameter is only visible if [Current limit 2] (LC2) is not set to [No] (nO), page 81.

• [Low speed time out]

After operating at [Low speed] (LSP) for a given time, the motor is stopped automatically. The motor restarts if

the frequency reference is greater than the [Low speed] (LSP) and if a run command is still present.

Note: Value 0 corresponds to an unlimited period.

• [PID wake up thresh.]

Parameter is only visible if [PID feedback ass.] (PIF) is not set to [No] (nO), page 77.

If the "PI" and "Low speed operating time" [Low speed time out] (tLS) functions, page 36, are configured at the

same time, the PI regulator may attempt to set a speed lower than [Low speed] (LSP).

This results in unsatisfactory operation, which consists of starting, operating at [Low speed] (LSP), then

stopping, and so on.

The [PID wake up thresh.] (rSL) parameter (restart error threshold) is used to set a minimum PID error threshold

for restarting after a stop at prolonged [Low speed] (LSP).

The function is inactive if [Low speed time out] (tLS) = 0.

• [IR compensation 2]

For [U/F mot.2 selected] (UFt2) = [SVC] (n) or [Energy sav.] (nLd): IR compensation.

For [U/F mot.2 selected] (UFt2) = [Cst. torque] (L) or [Var. torque] (P): voltage boost.

Used to optimize the torque at very low speed (increase [IR compensation 2] (UFr2) if the torque is insufficient).

Check that the value for [IR compensation 2] (UFr2) is not too high when the motor is in a hot state otherwise

some instabilities can occur. Changing [U/F mot.2 selected] (UFt2) will cause [IR compensation 2] (UFr2) to

return to its factory setting (20%).

0.25 to 1.5 In (1) 1.5 In (1)

0.25 to 1.5 In (1) 1.5 In (1)

0 to 999.9 s 0 (no time limit)

0 to 100% 0%

0 to 100% 20%

Factory setting

(1) In corresponds to the nominal drive current indicated in the Installation Manual and on the drive nameplate.

These parameters only appear if the corresponding function has been selected in another menu. When the parameters can

also be accessed and set from within the configuration menu for the corresponding function, their description is detailed in

*

these menus, on the pages indicated, to aid programming.

36

Page 37

[SETTINGS] (SEt-) menu

rEF-

SEt-

drC-

I-0-

CtL-

FUn-

FLt-

COM-

SUP-

FLG2 low FLG2 correct

FLG2 high

In this case,

reduce FLG2.

StA2 low StA2 correct StA2 high

In this case,

reduce StA2

Code Description Adjustment

range

FLG2

• [FreqLoopGain 2]

Parameter can only be accessed if [U/F mot.2 selected] (UFT2) = [SVC] (n) or [Energy sav.] (nLd), page 83.

The [FreqLoopGain 2] (FLG2) parameter adjusts the drive's ability to follow the speed ramp on the basis of the

inertia of the machine being driven.

Too high a gain may result in operating instability.

0 to 100% 20%

*

StA2

• [Freq. loop stability 2]

Parameter can only be accessed if [U/F mot.2 selected] (UFT2) = [SVC] (n) or [Energy sav.] (nLd) , page 83.

Used to adapt the return to steady state after a speed transient (acceleration or deceleration), according to the dynamics

of the machine.

Gradually increase the stability to avoid any overspeed.

0 to 100% 20%

*

Factory setting

SLP2

*

Ftd

ttd

Ctd

(1)In corresponds to the nominal drive current indicated in the Installation Manual and on the drive nameplate.

*

• [Slip compensation 2]

Parameter can only be accessed if [U/F mot.2 selected] (UFT2) = [SVC] (n) or [Energy sav.] (nLd), page 83.

Adjusts the slip compensation around the value set by the nominal motor speed.

The speeds given on motor rating plates are not necessarily exact.

• If slip setting < actual slip: The motor is not rotating at the correct speed in steady state.

• If slip setting > actual slip: The motor is overcompensated and the speed is unstable.

• [Freq. threshold]

Threshold beyond which the contact on the relay ([R1 Assignment] (r1) or [R2 Assignment] (r2) = [Freq.Th.att.]

(FtA)) closes or output AOV = 10 V ([Analog./logic output] (dO) = [Freq. limit] (FtA)).

• [Motor therm. level]

Threshold beyond which the contact on the relay ([R1 Assignment] (r1) or [R2 Assignment] (r2) = [Th.mot. att.]

(tSA)) closes or output AOV = 10 V ([Analog./logic output] (dO) = [Drv thermal] (tSA)).

• [Current threshold]

Threshold beyond which the contact on the relay ([R1 Assignment] (r1) or [R2 Assignment] (r2) = [I attained] (CtA))

closes or output AOV = 10 V ([Analog./logic output] (dO) = [Current limit] (CtA)).

These parameters only appear if the corresponding function has been selected in another menu. When the parameters can

also be accessed and set from within the configuration menu for the corresponding function, their description is detailed in

these menus, on the pages indicated, to aid programming.

0 to 150% 100%

0 to 500 Hz bFr

1 to 118% 100%

0 to 1.5 In (1) In (1)

37

Page 38

[SETTINGS] (SEt-) menu

rEF-

SEt-

drC-

I-0-

CtL-

FUn-

FLt-

COM-

SUP-

[Scale factor display] (SdS) x [Output frequency] (rFr)

1000

Code Description Adjustment

range

SdS

• [Scale factor display]

0.1 to 200 30

Used to display a value in proportion to the output frequency [Output frequency] (rFr): the machine speed, the motor

speed, etc.

• If [Scale factor display] (SdS) y 1, [Cust. output value] (SPd1) is displayed (possible definition = 0.01)

• If 1 < [Scale factor display] (SdS) y 10, [Cust. output value] (SPd2) is displayed (possible definition = 0.1)

• If [Scale factor display] (SdS) > 10, [Cust. output value] (SPd3) is displayed (possible definition = 1)

• If [Scale factor display] (SdS) > 10 and [Scale factor display] (SdS) x [Output frequency] (rFr) > 9,999:

the display will show

[Cust. output value] (SPd3) = to 2 decimal places

example: for 24,223, display will show 24.22

- If [Scale factor display] (SdS) > 10 and [Scale factor display] (SdS) x [Output frequency] (rFr) > 65,535, display

locked at 65.54

Example: Display motor speed for

4-pole motor, 1,500 rpm at 50 Hz (synchronous speed):

[Scale factor display] (SdS) = 30

[Cust. output value] (SPd3) = 1,500 at [Output frequency] (rFr) = 50 Hz

SFr

• [Switching freq.]

(1)

2.0 to 16 kHz 4 kHz

Parameter can also be accessed in the [MOTOR CONTROL] (drC-) menu. The frequency can be adjusted to

reduce the noise generated by the motor.

If the frequency has been set to a value higher than 4 kHz, in the event of excessive temperature rise, the drive

will automatically reduce the switching frequency and increase it again once the temperature has returned to

normal.

Factory setting

(1)Parameter can also be accessed in the [MOTOR CONTROL] (drC-) menu.

38

Page 39

[MOTOR CONTROL] (drC-) menu

Standard motor frequency

Return to factory settings/Restore configuration

rEF-

SEt-

drC-

I-0-

CtL-

FUn-

FLt-

COM-

SUP-

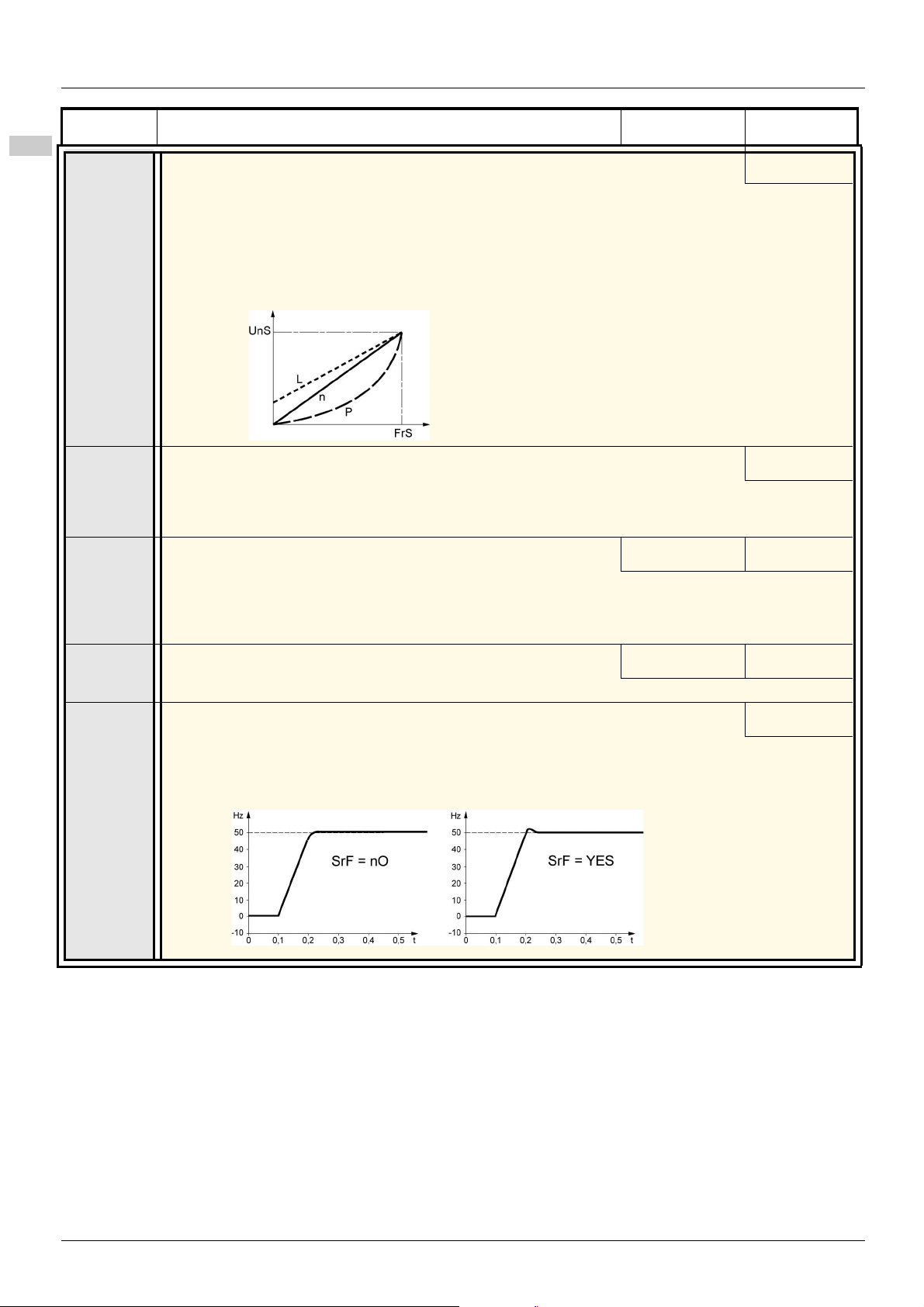

[Rated motor volt.] (UnS) (in volts)

[Rated motor freq.] (FrS) (in Hz)

With the exception of [Auto tuning] (tUn), which can power up the motor, parameters can only be changed in stop mode, with no run

command present.

On the optional ER23K remote display terminal, this menu can be accessed with the switch in the position.

Drive performance can be optimized by:

- Entering the values given on the motor rating plate in the Drive menu

- Performing an auto-tune operation (on a standard asynchronous motor)

Code Description Adjustment

range

bFr

50

60

UnS

FrS

nCr

(1)In corresponds to the nominal drive current indicated in the Installation Manual and on the drive nameplate.

• [Standard mot. freq]

[50Hz IEC] (50): 50 Hz: IEC

[60Hz NEMA] (60): 60 Hz: NEMA

This parameter modifies the presets of the following parameters: [High speed] (HSP), page 32, [Freq.

threshold] (Ftd), page 37, [Rated motor freq.] (FrS), page 39, and [Max frequency] (tFr), page 42.

• [Rated motor volt.]

Nominal motor voltage given on the rating plate. When the line voltage is lower than the nominal motor voltage,

set [Rated motor volt.] (UnS) to the same value as the line voltage for the drive terminals.

ER23-...K: 100 to 240 V

ER23-.../3K: 100 to 240 V

ER23-.../4K: 100 to 500 V

ER23-.../6K: 100 to 600 V

• [Rated motor volt.]

Nominal motor frequency marked on the rating plate. The factory setting is 50 Hz, or 60 Hz if [Standard mot.

freq] (bFr) is set to 60 Hz.

Note: The ratio must not exceed the following values:

ER23-...K: 7 max.

ER23-.../3K: 7 max.

ER23-.../4K: 14 max.

ER23-.../6K: 17 max.

The factory setting is 50 Hz, or preset to 60 Hz if [Standard mot. freq] (bFr) is set to 60 Hz.

• [Rated mot. current]

Nominal motor current given on the rating plate.

In accordance

with the drive

rating

10 to 500 Hz 50 Hz

0.25 to 1.5 In (1) In accordance

Factory

setting

[50Hz IEC] (50)

In accordance

with the drive

rating

with the drive

rating

39

Page 40

[MOTOR CONTROL] (drC-) menu

rEF-

SEt-

drC-

I-0-

CtL-

FUn-

FLt-

COM-

SUP-

100 - slip as a %

100

50 - slip in Hz

50

60 - slip in Hz

60

Code Description Adjustment range Factory setting

nSP

COS

rSC

nO

InIt

8888

• [Rated motor speed]

0 to 9,999 rpm then 10.00 to 32.76 krpm

If, rather than the nominal speed, the nameplate indicates the synchronous speed and the slip in Hz or as a

%, calculate the nominal speed as follows:

• Nominal speed = synchronous speed x

or

• Nominal speed = synchronous speed x (50 Hz motors)

or

• Nominal speed = synchronous speed x (60 Hz motors)

• [Motor 1 Cosinus Phi]

Motor Cos Phi given on the motor rating plate

• [Cold stator resist.]

-

[No] (nO): function inactive. For applications which do not require high performance or do not tolerate

automatic auto-tuning (passing a current through the motor) each time the drive is powered up.

-

[Init] (InIt): activates the function. To improve low-speed performance whatever the thermal state of the motor.

-

Value of cold state stator resistance used, in m

Note:

• It is strongly recommended that this function is activated for mechanical handling applications.

• The function should only be activated [Init] (InIt) when the motor is cold.

• When [Cold stator resist.] (rSC) = [Init] (InIt), the [Auto-tuning] (tUn) parameter is forced to [Power on] (POn).

At the next run command the stator resistance is measured with an auto-tune. The [Cold stator resist.] (rSC)

then changes to a value of (8888) and maintains it, [Auto-tuning] (tUn) is still forced to [Power on] (POn). The

[Cold stator resist.] (rSC) parameter remains at [Init] (InIt) as long as the measurement has not been

performed.

• Value 8888 can be forced or changed using the jog dial (1).

0 to 32,760 rpm In accordance

with the drive

rating

0.5 to 1 In accordance

with the drive

rating

[No] (nO)

Ω.

(1)Procedure:

- Check that the motor is cold.

- Disconnect the cables from the motor terminals.

- Measure the resistance between 2 of the motor terminals (U. V. W.) without modifying its connection.

- Use the jog dial to enter half the measured value.

- Increase the factory setting of [IR compensation] (UFr), page 32, to 100% rather than 20%.

Note: Do not use [Cold stator resist.] (rSC) if it is not set to [No] (nO) or = [Power on] (POn) with catch on the fly ([CATCH ON THE FLY]

(FLr-), page 88).

40

Page 41

[MOTOR CONTROL] (drC-) menu

rEF-

SEt-

drC-

I-0-

CtL-

FUn-

FLt-

COM-

SUP-

Code Description Adjustment

range

tUn

• [Auto tuning]

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• During auto-tuning the motor operates at nominal current.

• Do not work on the motor during auto-tuning.

Failure to follow these instructions will result in death or serious injury.

DANGER

UNINTENDED EQUIPMENT OPERATION

• It is essential that the [Rated motor volt.] (UnS), [Rated motor freq.] (FrS), [Rated motor freq.] (nCr), [Rated motor

speed] (nSP) , and [Rated motor power] (nPr) or [Motor 1 Cosinus Phi.] (COS) parameters are configured

correctly before starting auto-tuning.

• When one or more parameters have been changed after auto-tuning has been performed, [Auto-tuning] (tUn)

will return [No] (nO) and the procedure will have to be repeated.

Failure to follow these instructions will result in death or serious injury.

nO

YES

dOnE

rUn

POn

LI1

to

LI6

-

[No] (nO): Auto-tuning not performed

-

[Yes] (YES): Auto-tuning is performed as soon as possible, then the parameter automatically changes to

[Done] (dOnE) or [No] (nO) in the event that Auto-tuning is not successful [AUTO TUNING FAULT] (tnF)

is displayed if [Autotune fault mgt] (tnL) = [Yes] (YES), page 90).

-

[Done] (dOnE): Use of the values given the last time auto-tuning was performed

-

[Drv running] (rUn): Auto-tuning is performed every time a run command is sent.

-

[Power on] (POn): Auto-tuning is performed on every power-up.

-

[LI1] to [LI16] (LI1) to (LI6): Auto-tuning is performed on the transition from 0 V 1 of a logic input assigned

to this function.

Note:

[Auto-tuning] (tUn) is forced to [Power on] (POn) if [Cold stator resist.] (rSC) = [Init] (InIt).

Auto-tuning is only performed if no command has been activated. If a "freewheel stop" or "fast stop"

function is assigned to a logic input, this input must be set to 1 (active at 0).

Auto-tuning may take 1 to 2 seconds. Do not interrupt the process. Wait for the display to change to [Done]

(dOnE) or [No] (nO).

Factory setting

[No] (nO)

tUS

tAb

PEnd

PrOG

FAIL

dOnE

Strd

• [Auto tuning state]

(For information only, cannot be modified)

-

[Not done] (tAb): The default stator resistance value is used to control the motor.

-

[Pending] (PEnd): Auto-tuning has been requested but not yet performed.

-

[In Progress] (PrOG): Auto-tuning in progress.

-

[Failed] (FAIL): Auto-tuning was unsuccessful.

-

[Done] (dOnE): The stator resistance measured by the auto-tuning function is used to control the motor.

-

[Entered R1] (Strd): The cold state stator resistance ([Cold stator resist.] (rSC) which is not set to [No]

(nO)) is used to control the motor.

[Not done] (tAb)

41

Page 42

[MOTOR CONTROL] (drC-) menu

rEF-

SEt-

drC-

I-0-

CtL-

FUn-

FLt-

COM-

SUP-

Voltage

Frequency

Code Description Adjustment

range

UFt

L

P

n

nLd

nrd

YES

nO

SFr

• [U/F mot 1 selected]

-

[Cst. torque] (L): Constant torque for motors connected in parallel or special motors.

-

[Var. torque] (P): Variable torque for pump and fan applications.

-

[SVC] (n): Sensorless flux vector control for constant torque applications.

-

[Energy sav.] (nLd): Energy saving, for variable torque applications not requiring high dynamics (behaves

in a similar way to the [Var. torque] (P) ratio with no load and the [SVC] (n) ratio on load).

• [Noise reduction]

-

[Yes] (YES): Frequency with random modulation.

-

[No] (nO): Fixed frequency.

Random frequency modulation helps to prevent any resonance which may occur at a fixed frequency.

• [Switching freq.]

The frequency can be adjusted to reduce the noise generated by the motor.

If the frequency has been set to a value higher than 4 kHz, in the event of excessive temperature rise, the

drive will automatically reduce the switching frequency and increase it again once the temperature has

returned to normal.

(1) 2.0 to 16 kHz 4 kHz

Factory setting

[SVC] (n)

[Yes] (YES)

tFr

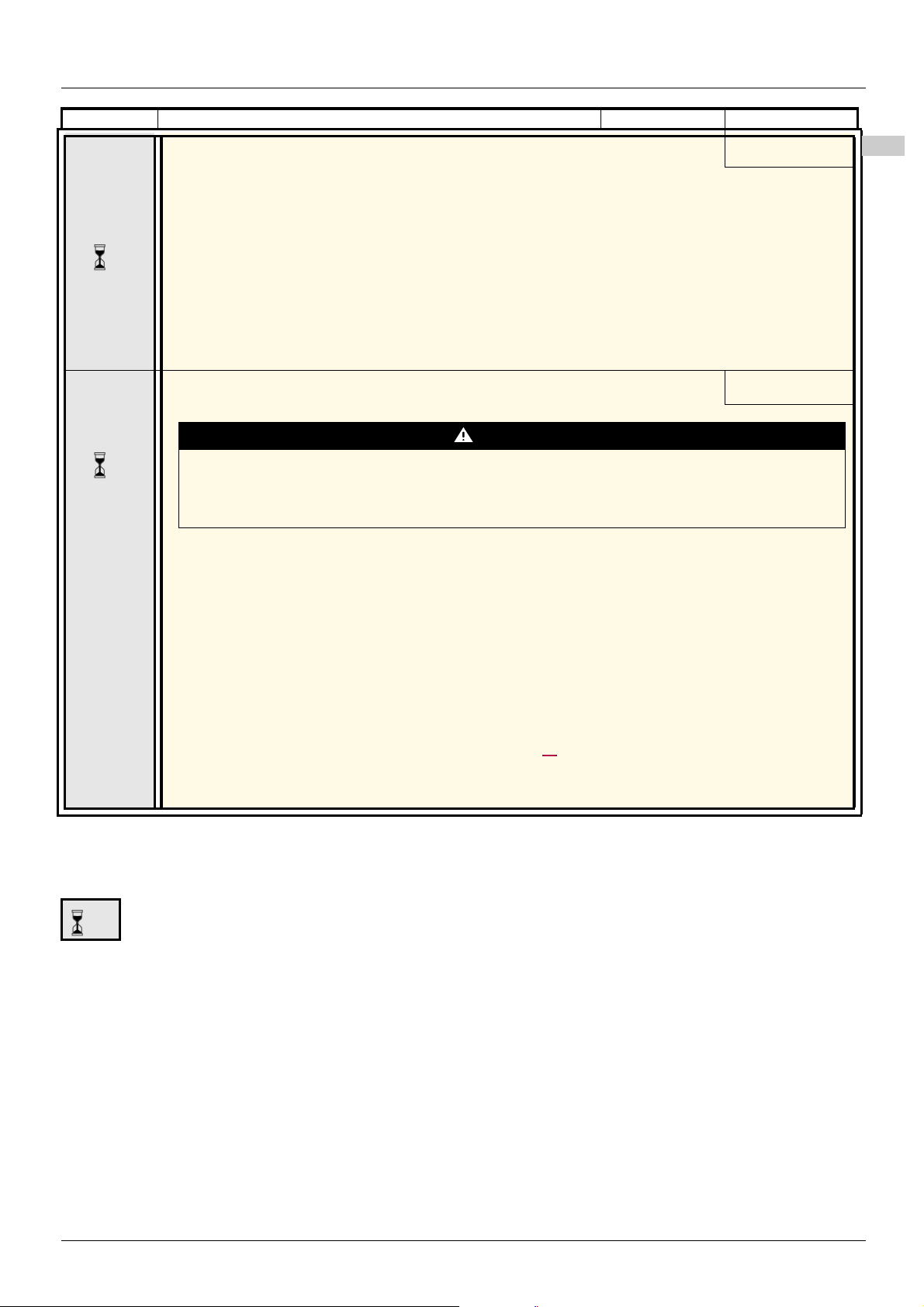

SrF